Patents

Literature

80results about How to "Even twist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

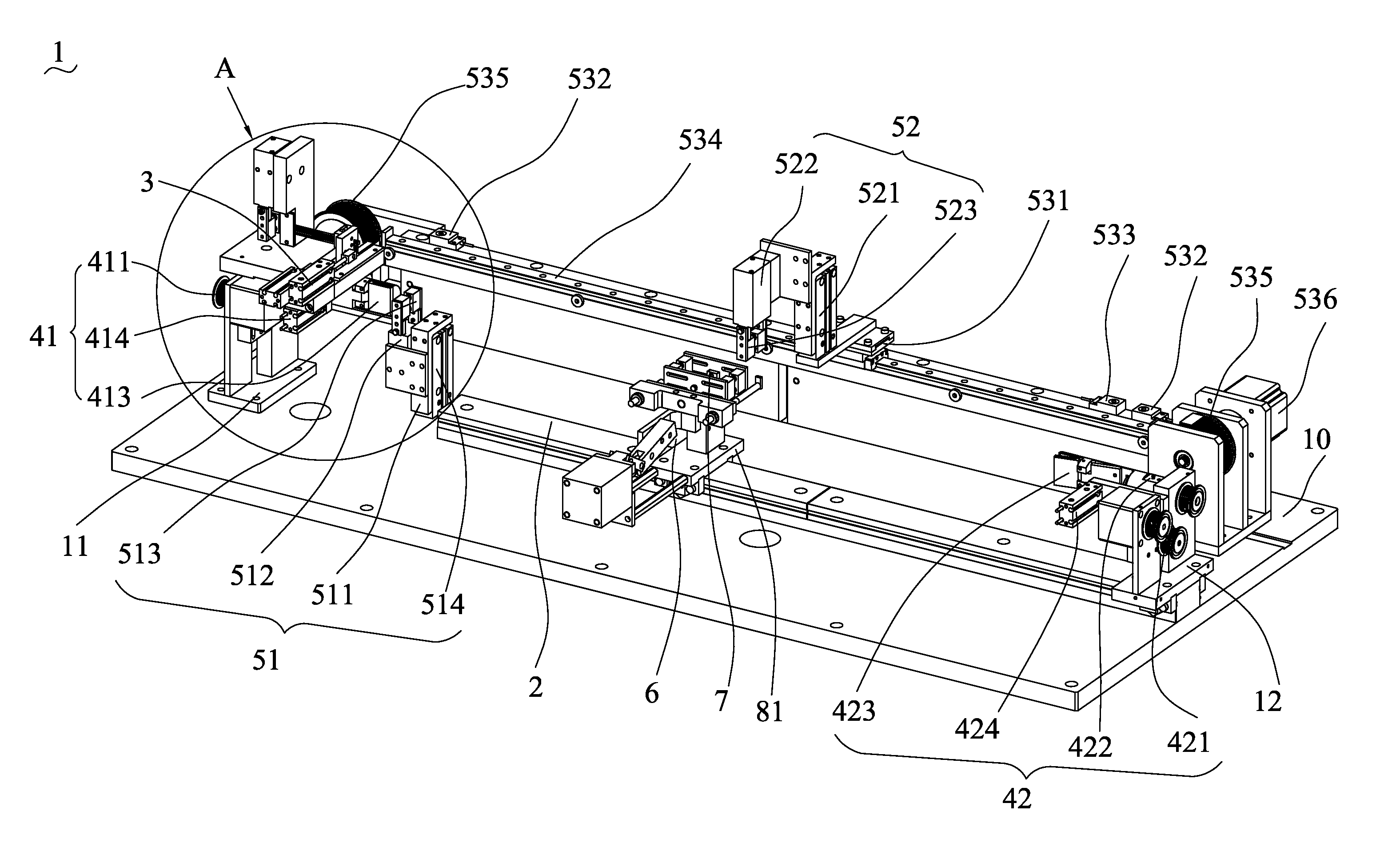

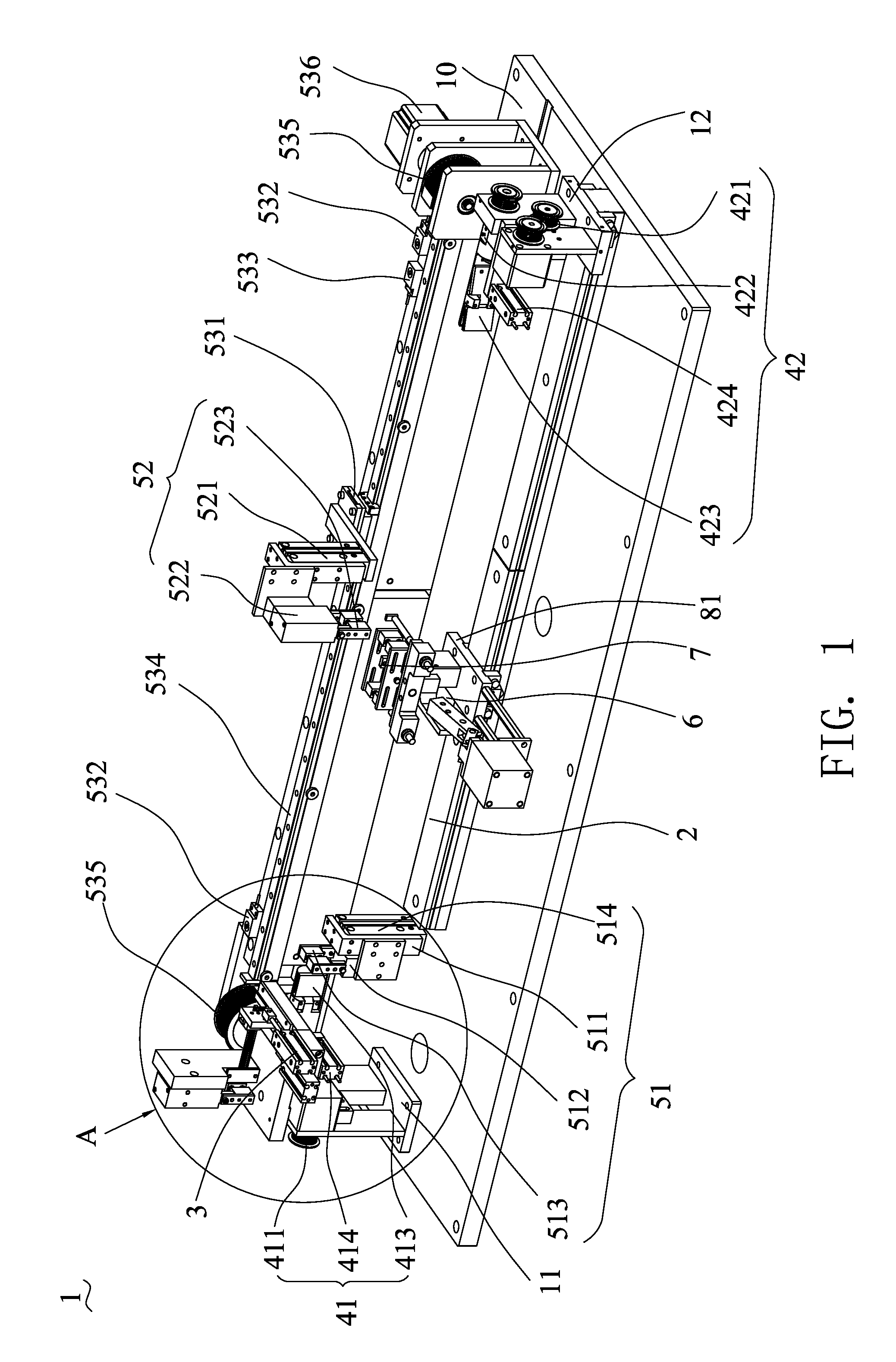

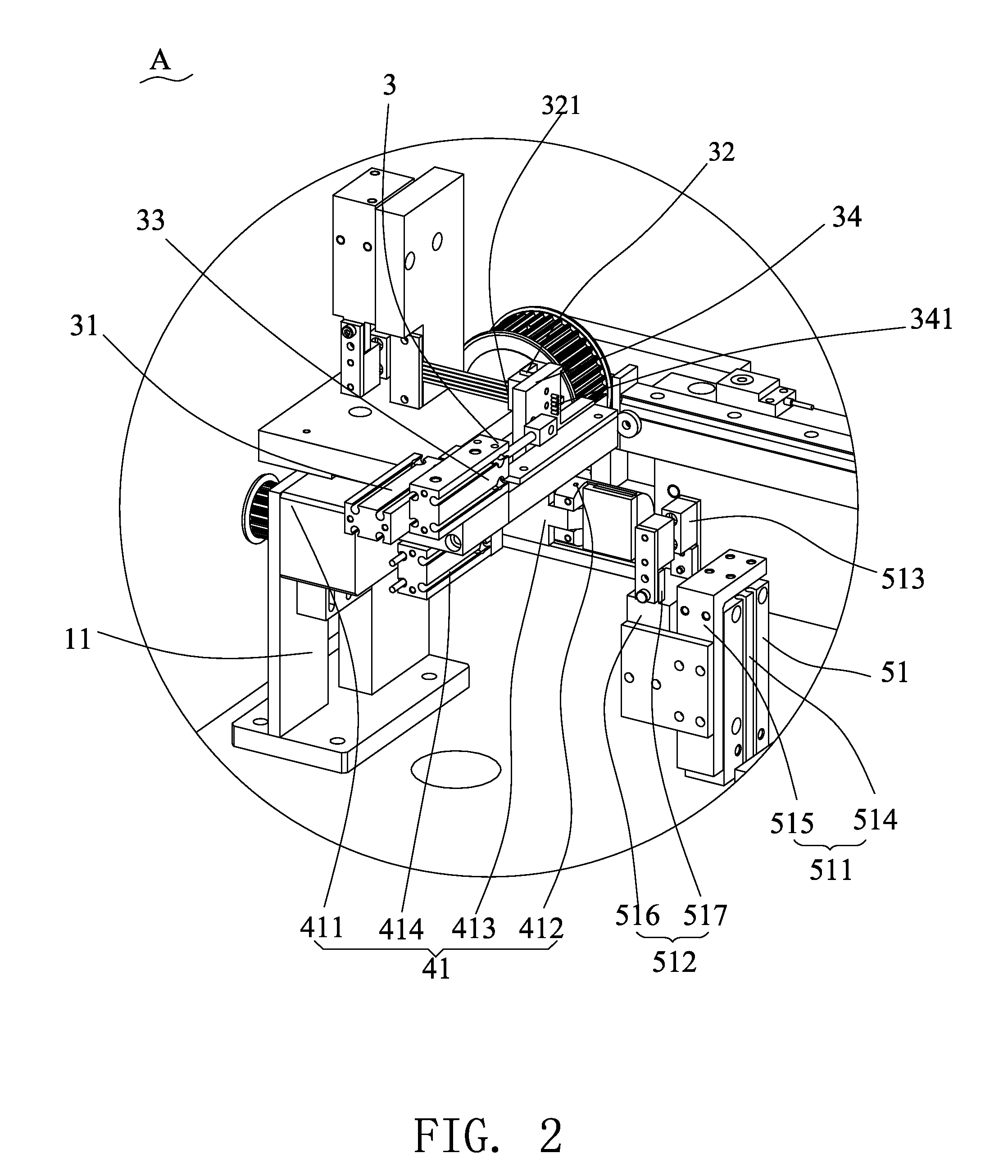

Automatic wire cutting and twisting apparatus

InactiveUS20120042984A1Easy to controlLaborious to useWire articlesRope making machinesWire cuttingEngineering

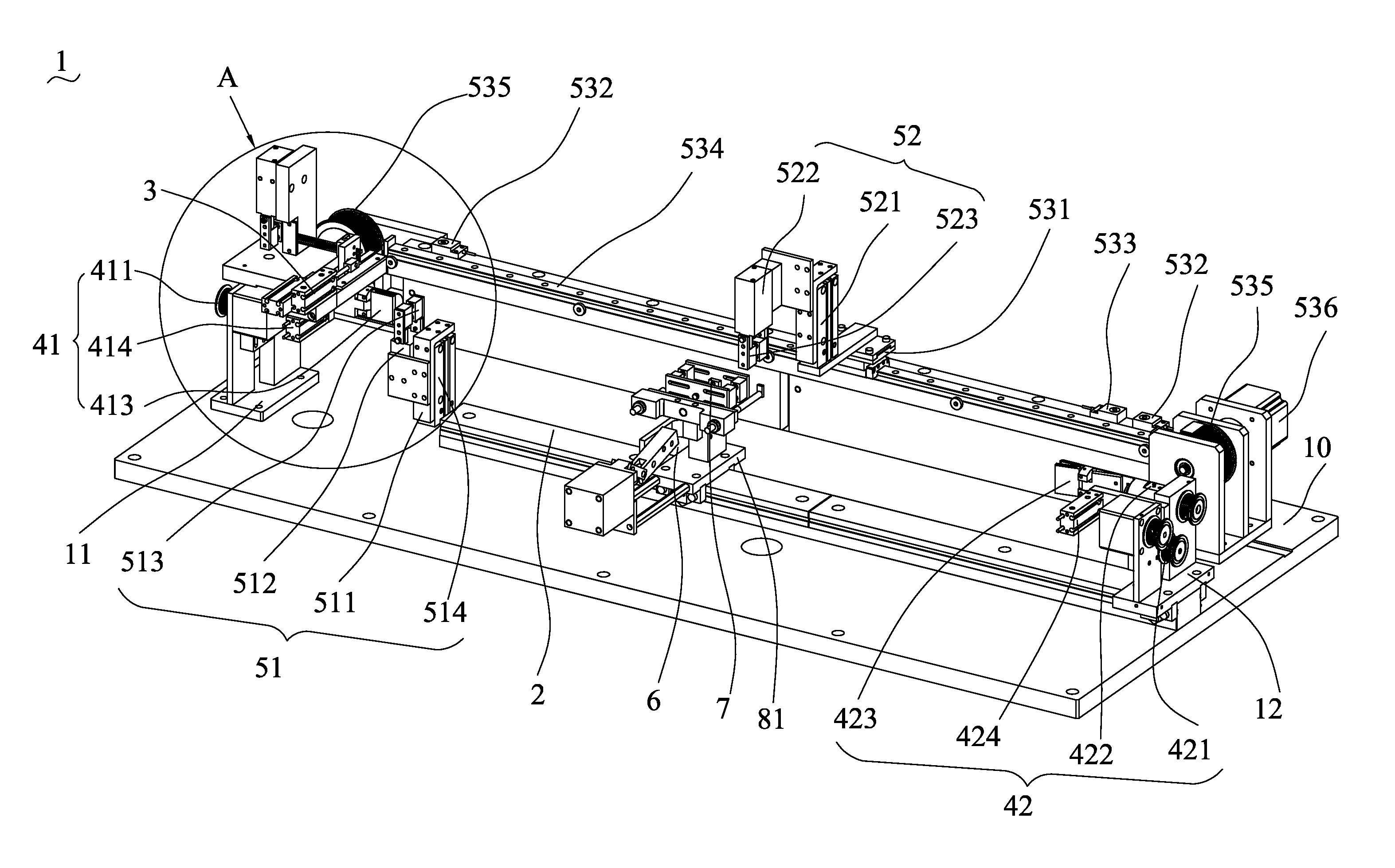

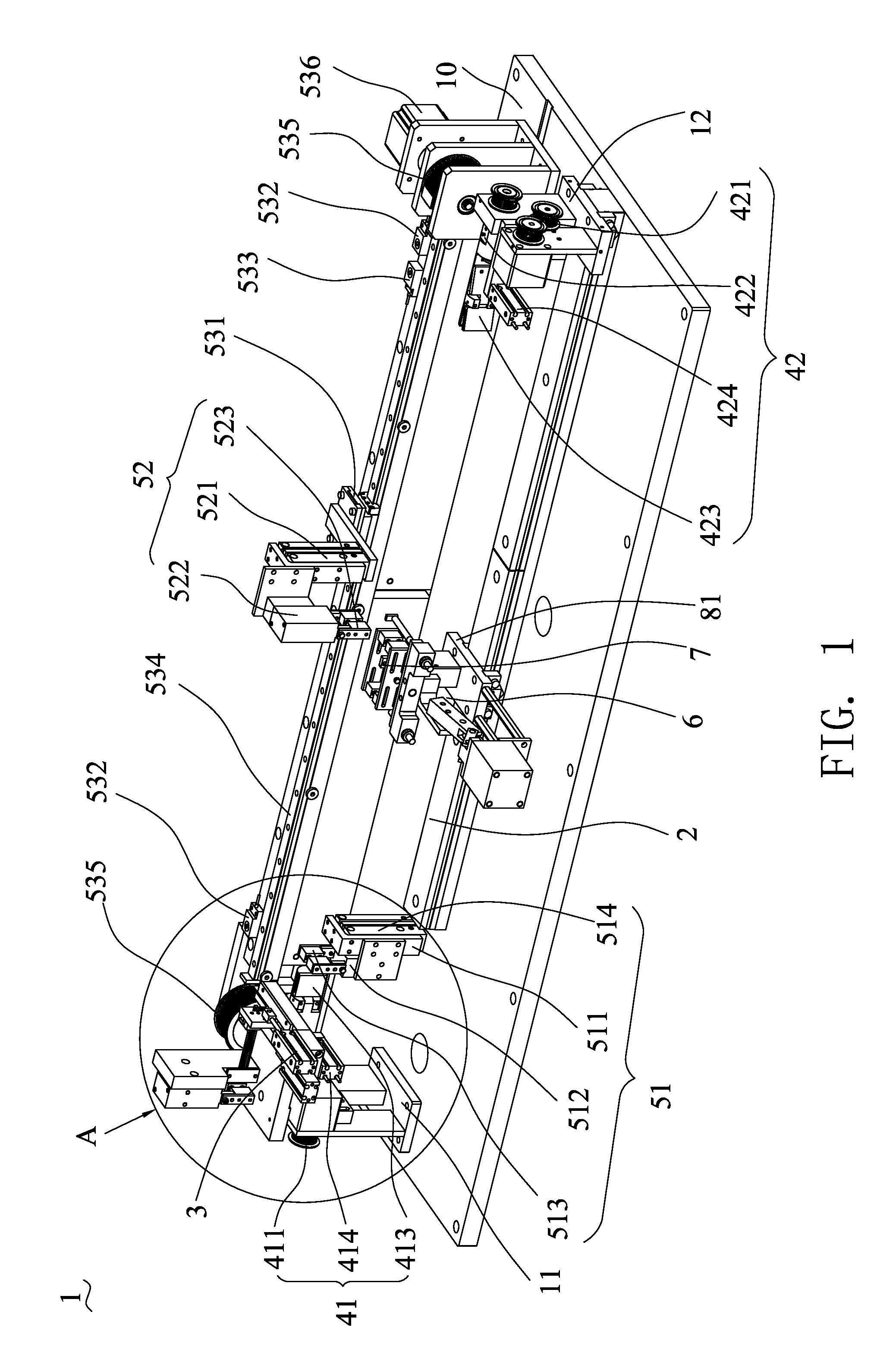

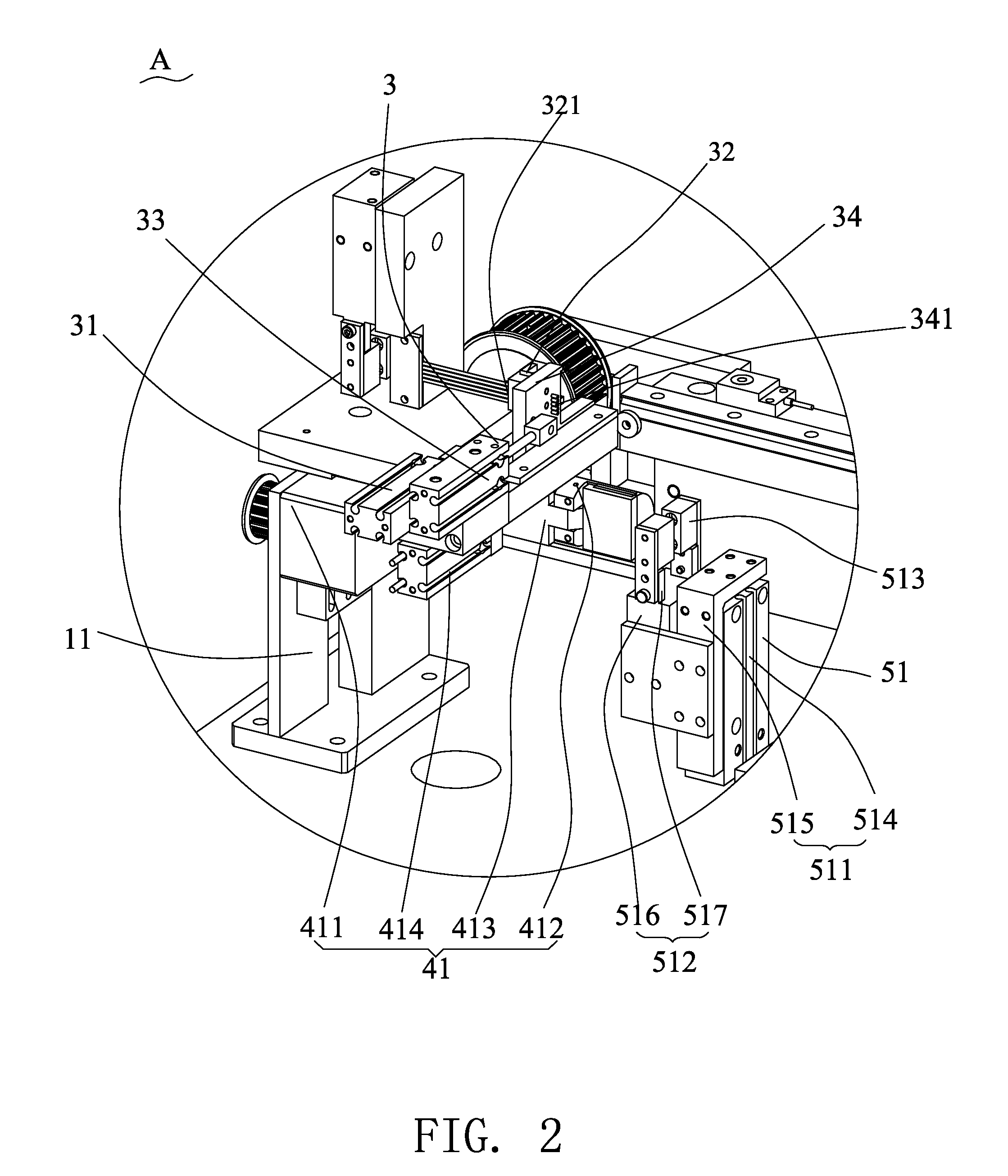

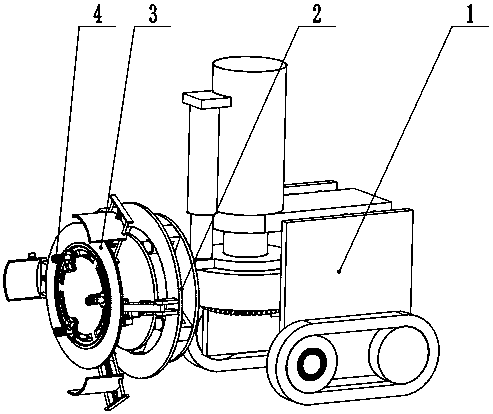

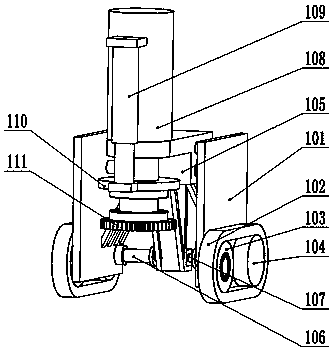

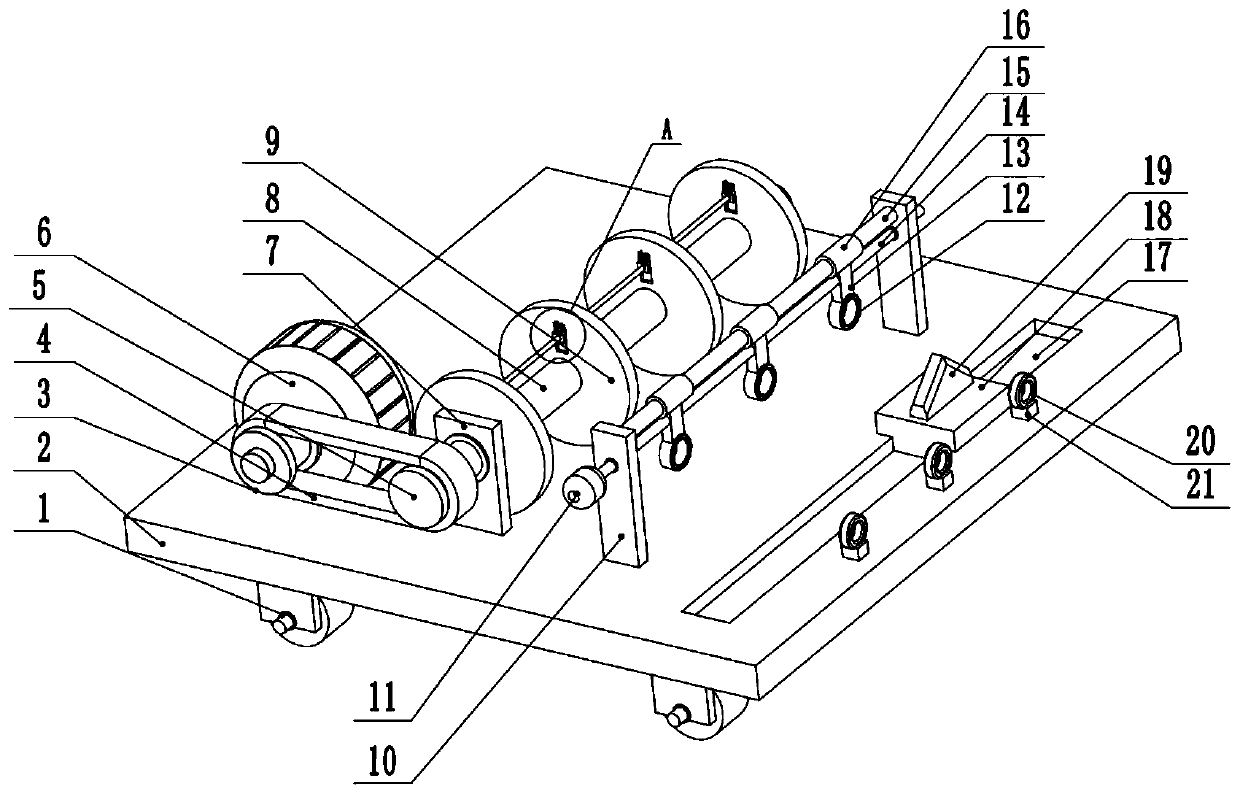

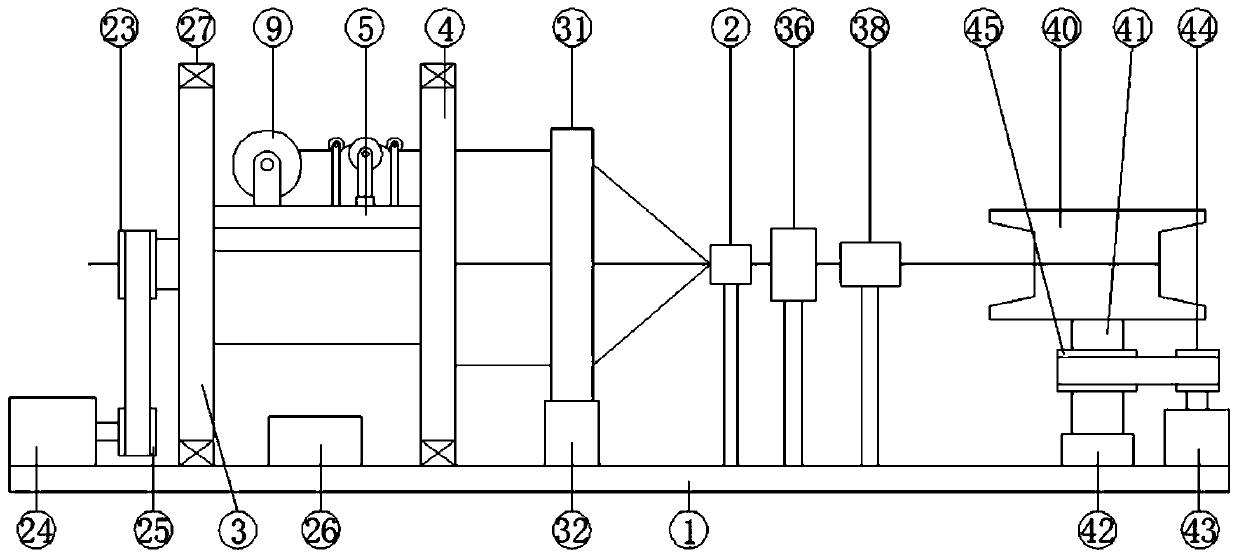

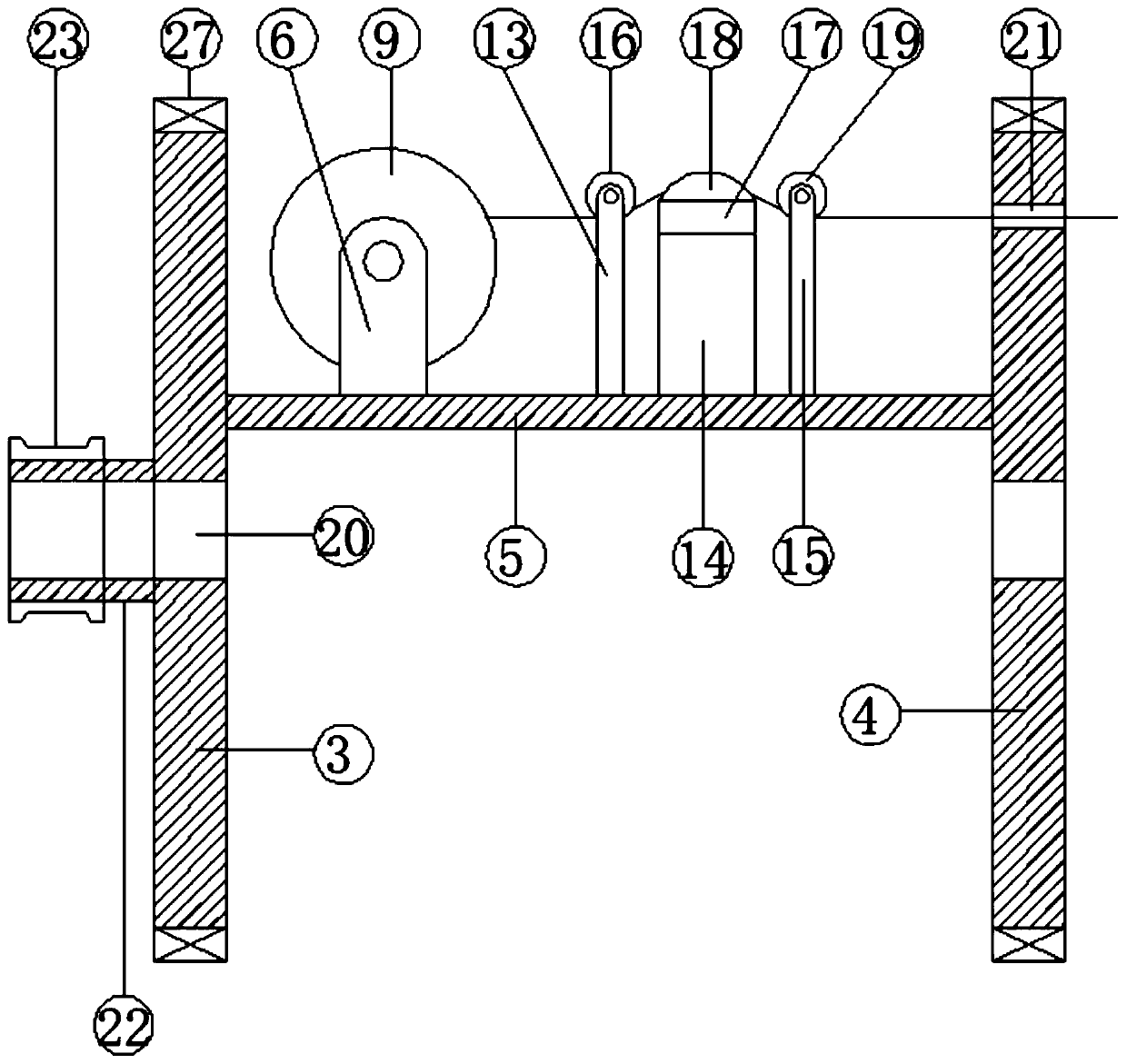

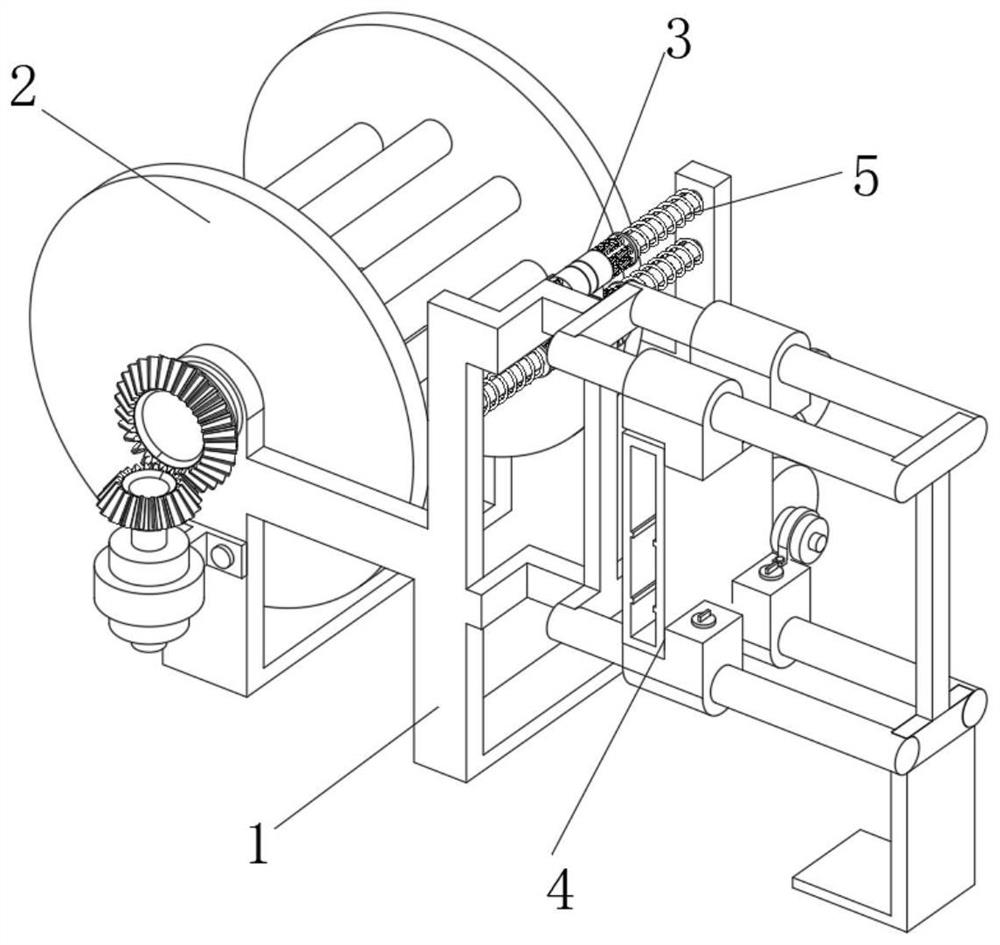

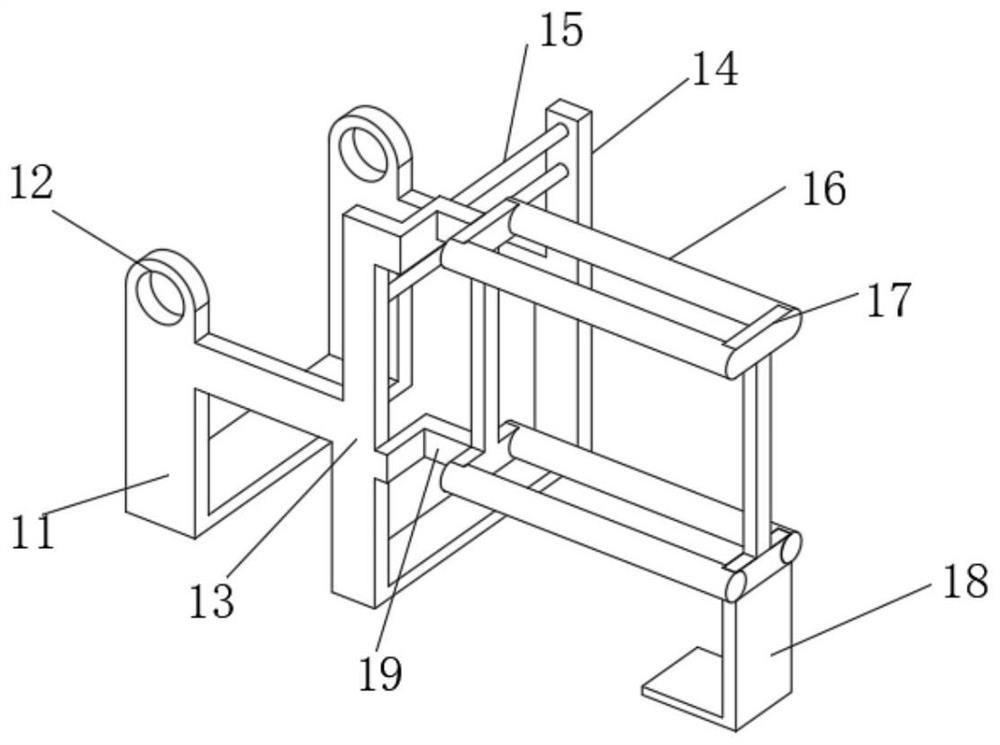

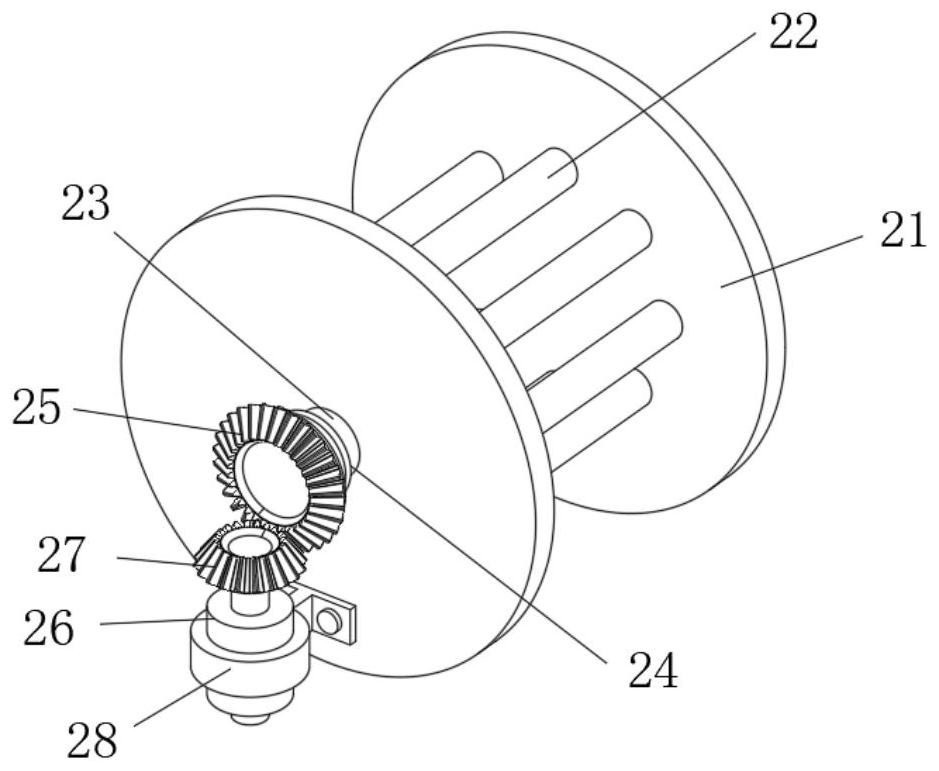

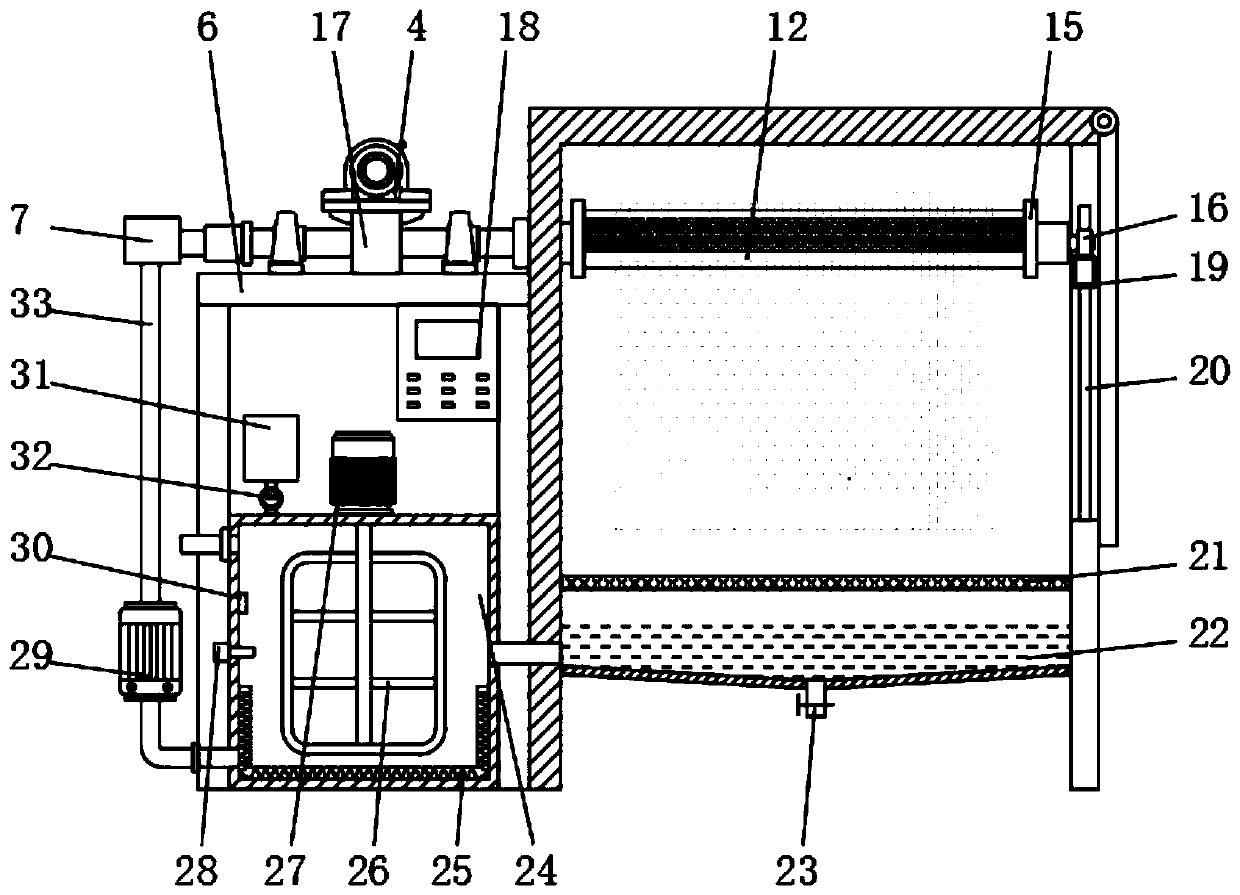

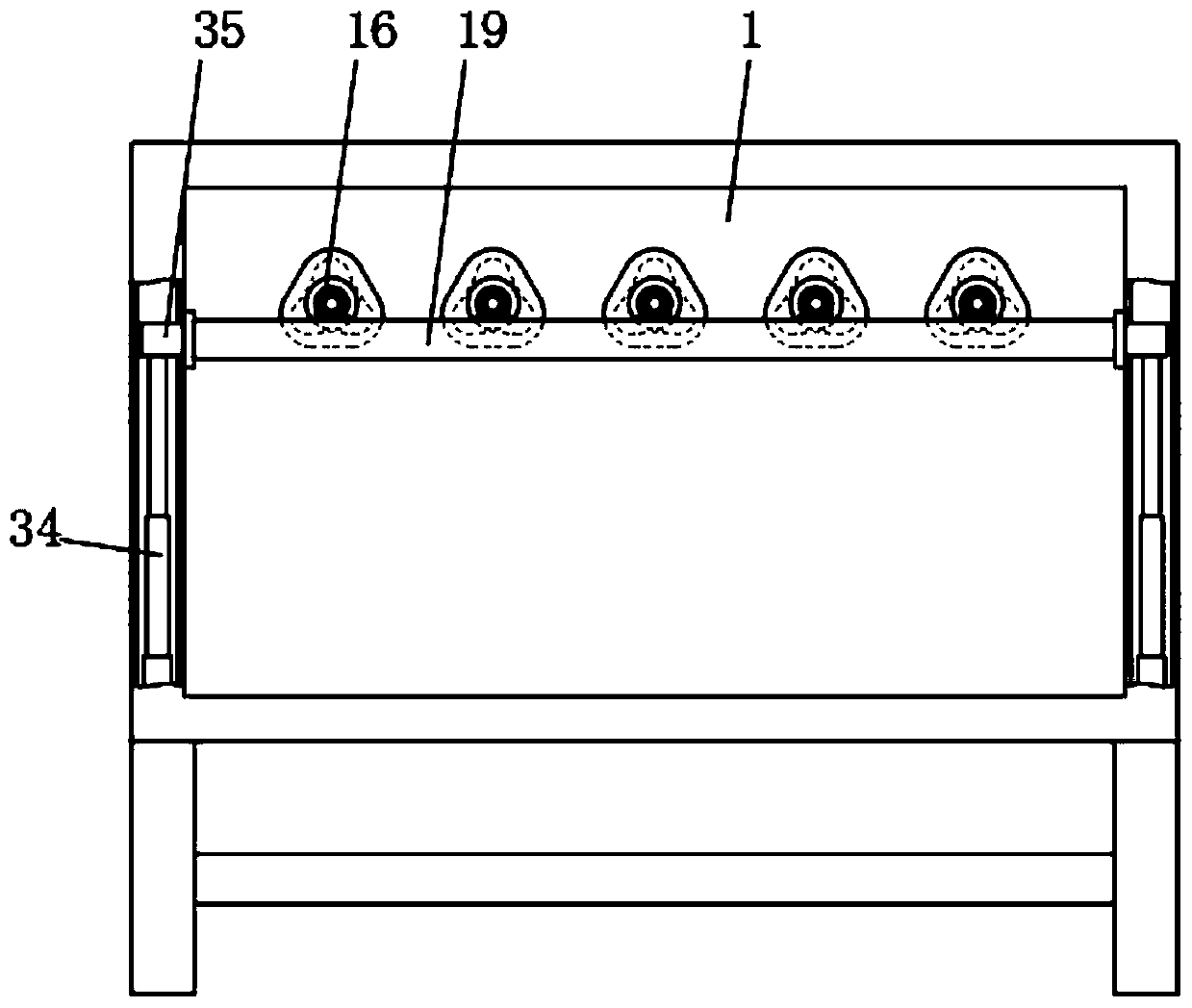

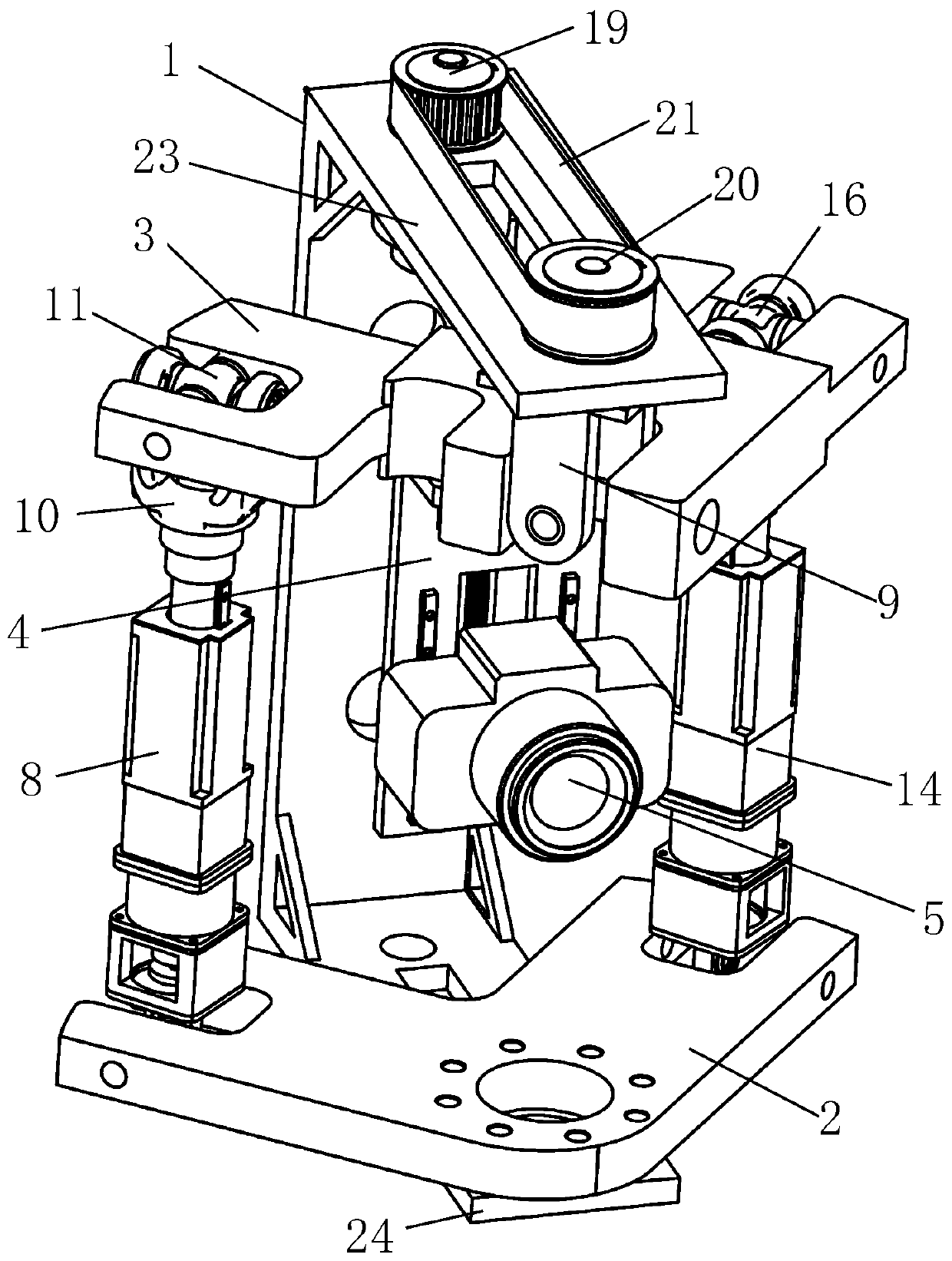

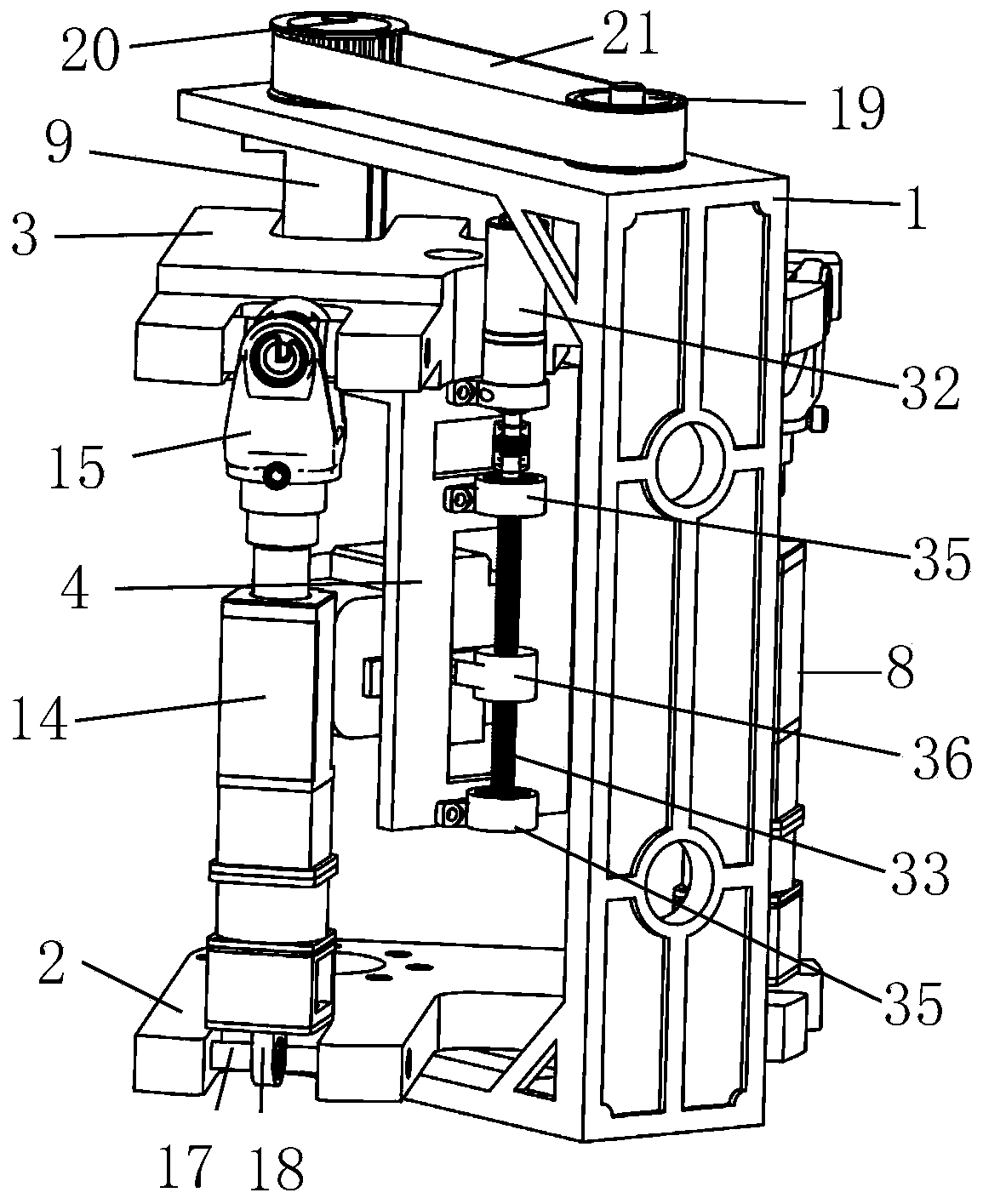

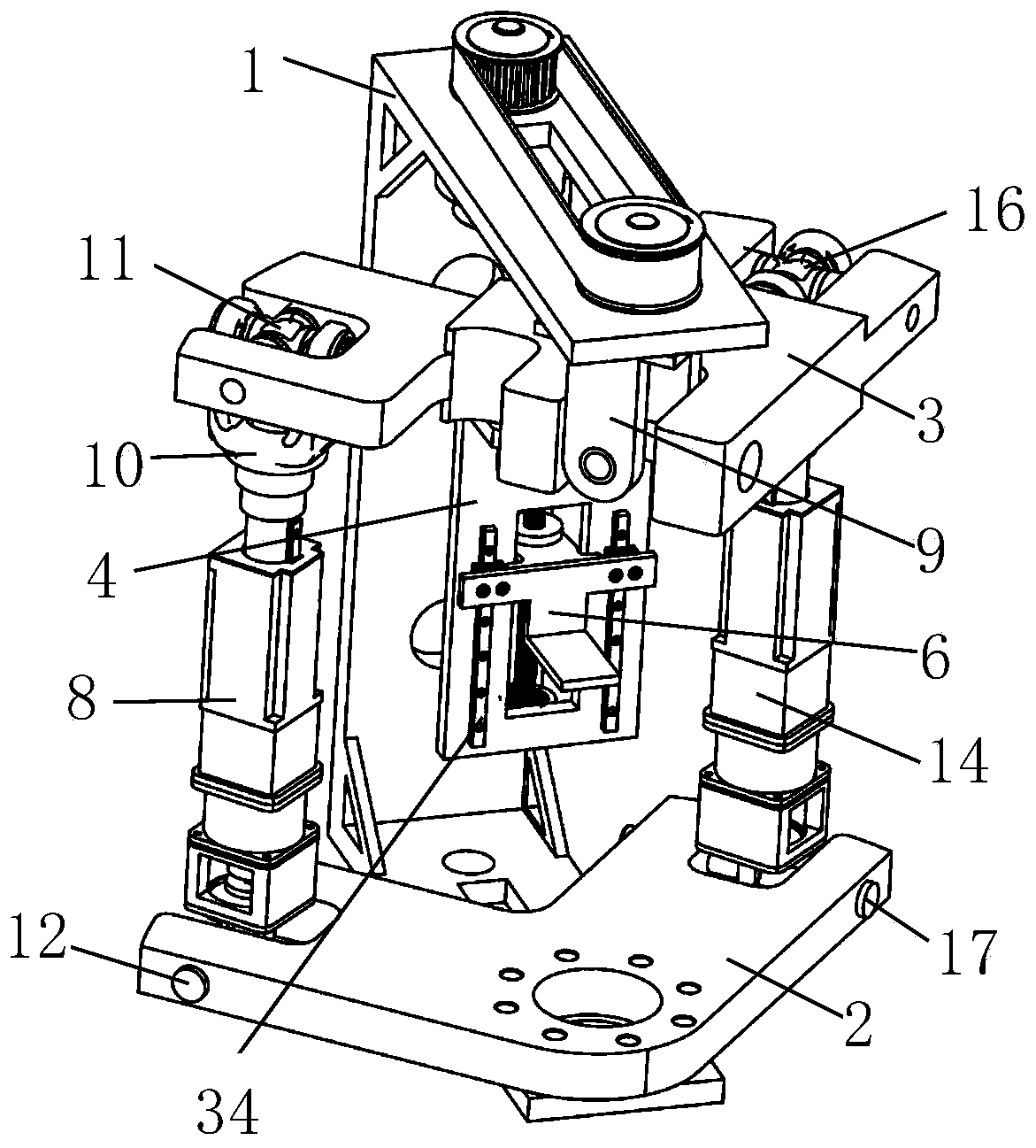

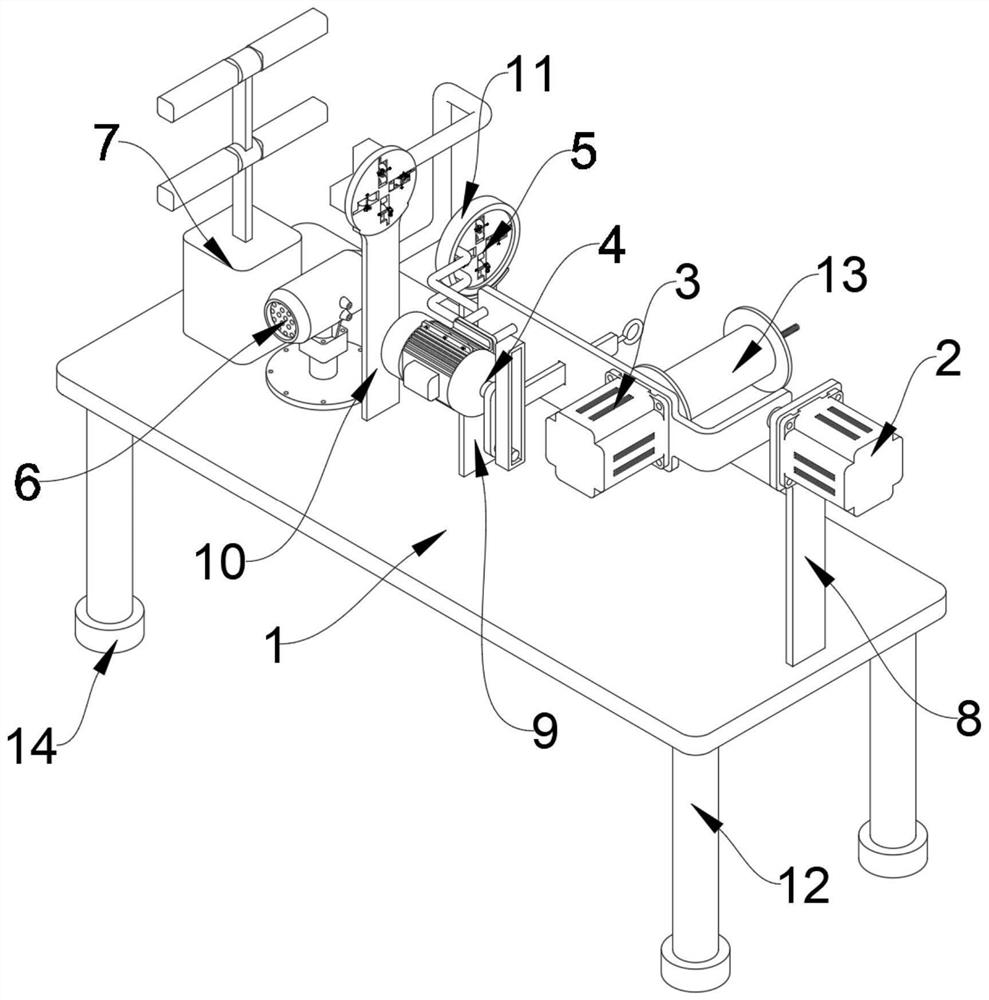

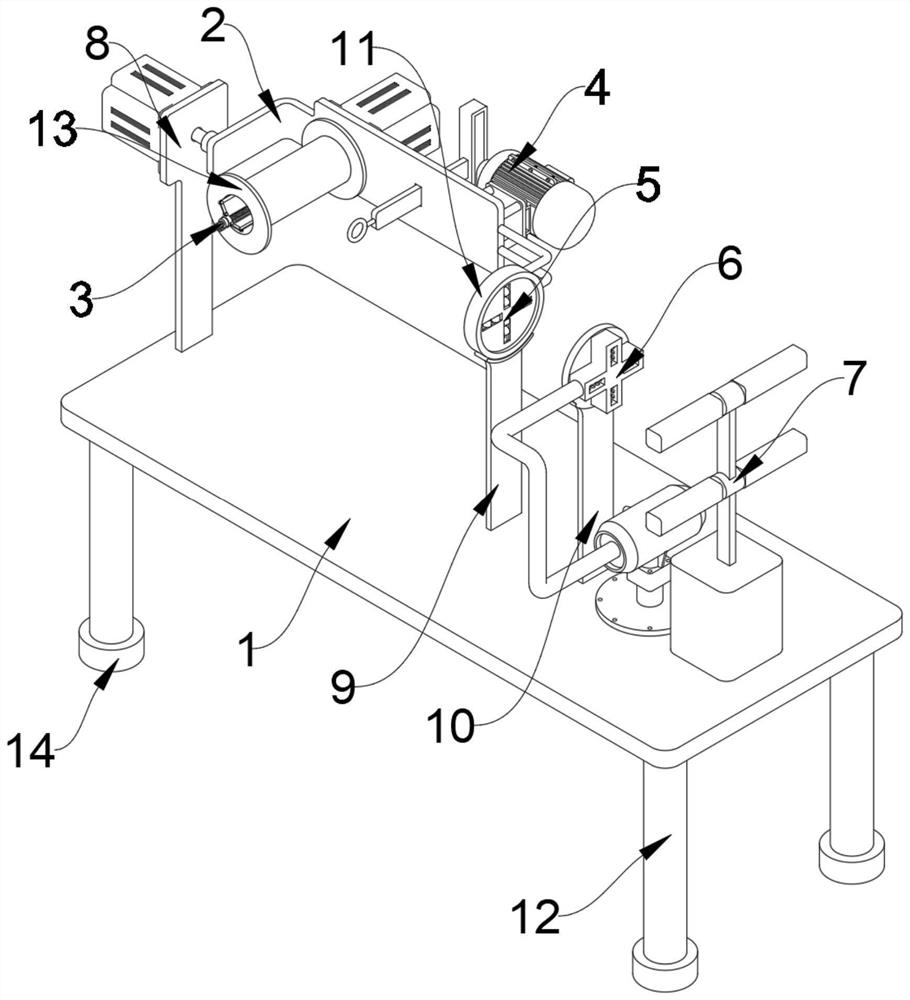

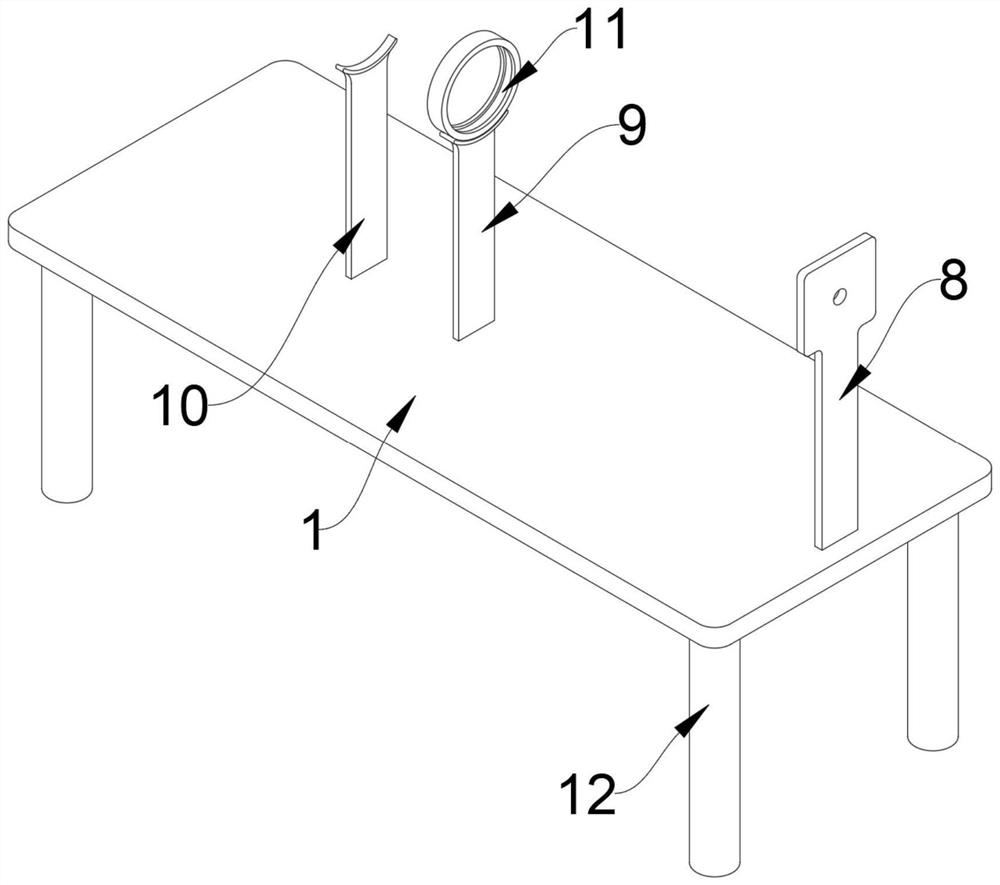

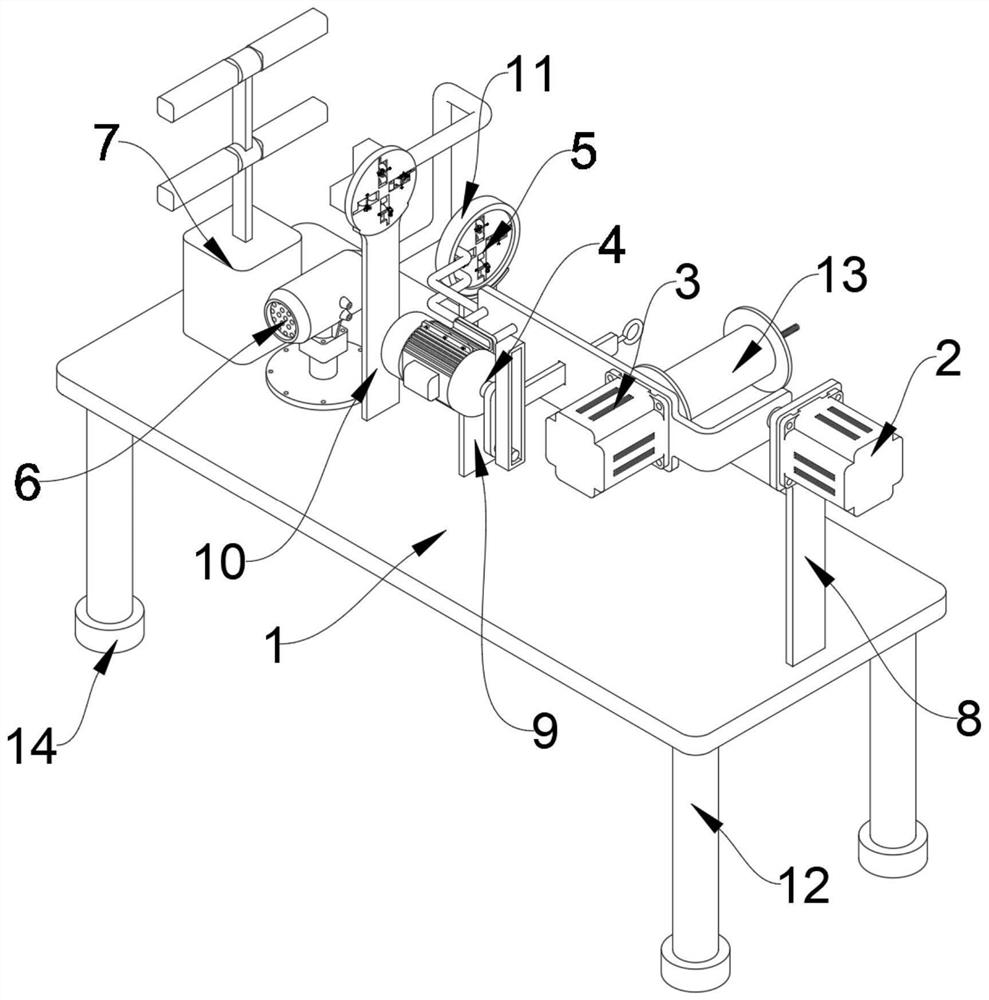

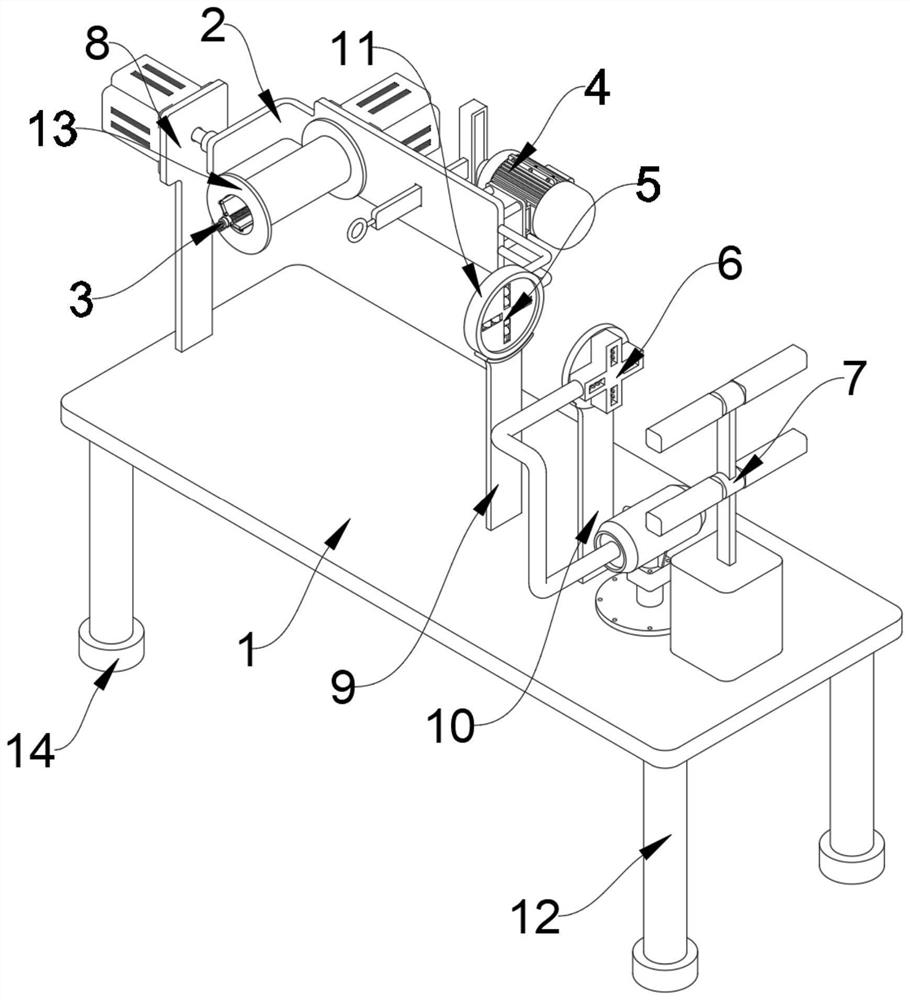

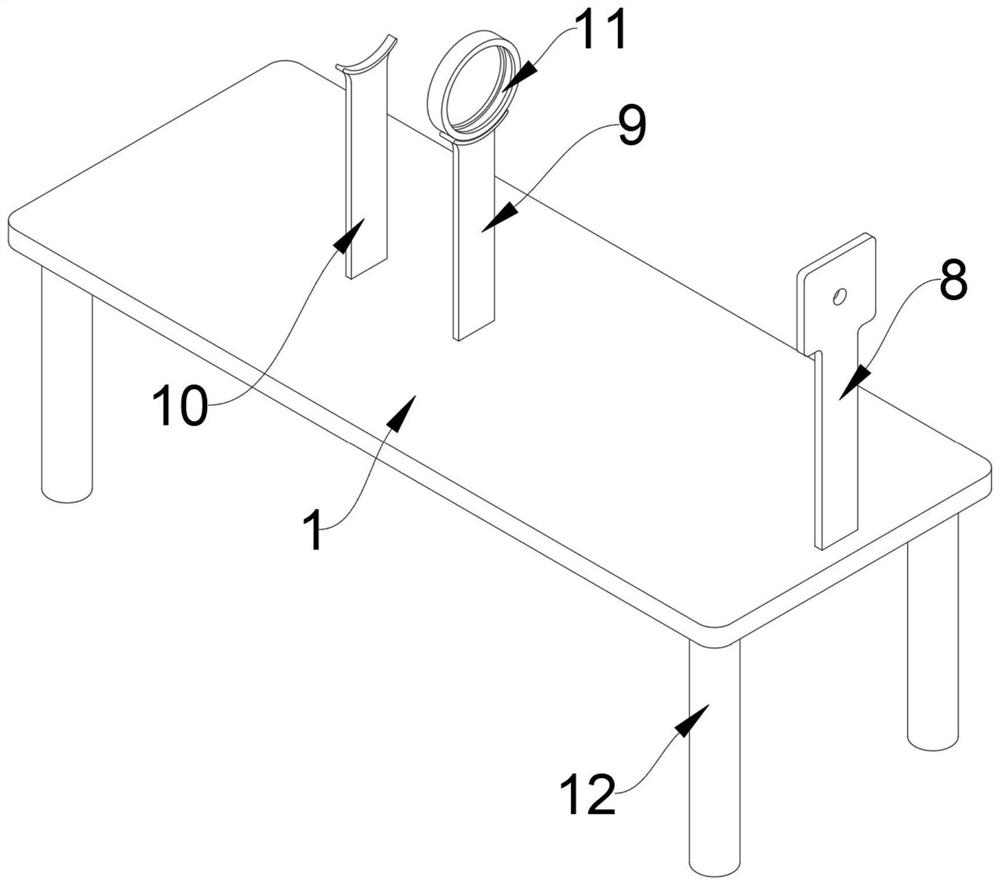

An automatic wire cutting and twisting apparatus includes a chassis board on which a start-terminal mounting rack, an end-terminal mounting rack, and a mounting track are mounted. The start-terminal mounting rack opposes a start terminal of the mounting track. The end-terminal mounting rack is position-adjustably coupled to an end terminal of the mounting track. A wire cutting mechanism is mounted on the start-terminal mounting rack and forms ingress and egress for wires. A wire twisting mechanism includes start-terminal and end-terminal rotation sections respectively mounted on the start-terminal and end-terminal mounting racks. A wire dragging mechanism includes a start-terminal dragging section mounted on the chassis board and a slidable dragging section movable above the mounting track. A wire pick-up mechanism is position-adjustably mounted on the mounting track. A cutting and twisting control mechanism is electrically connected to the wire cutting mechanism, the wire twisting mechanism, and the wire dragging mechanism.

Owner:CHENG UEI PRECISION IND CO LTD

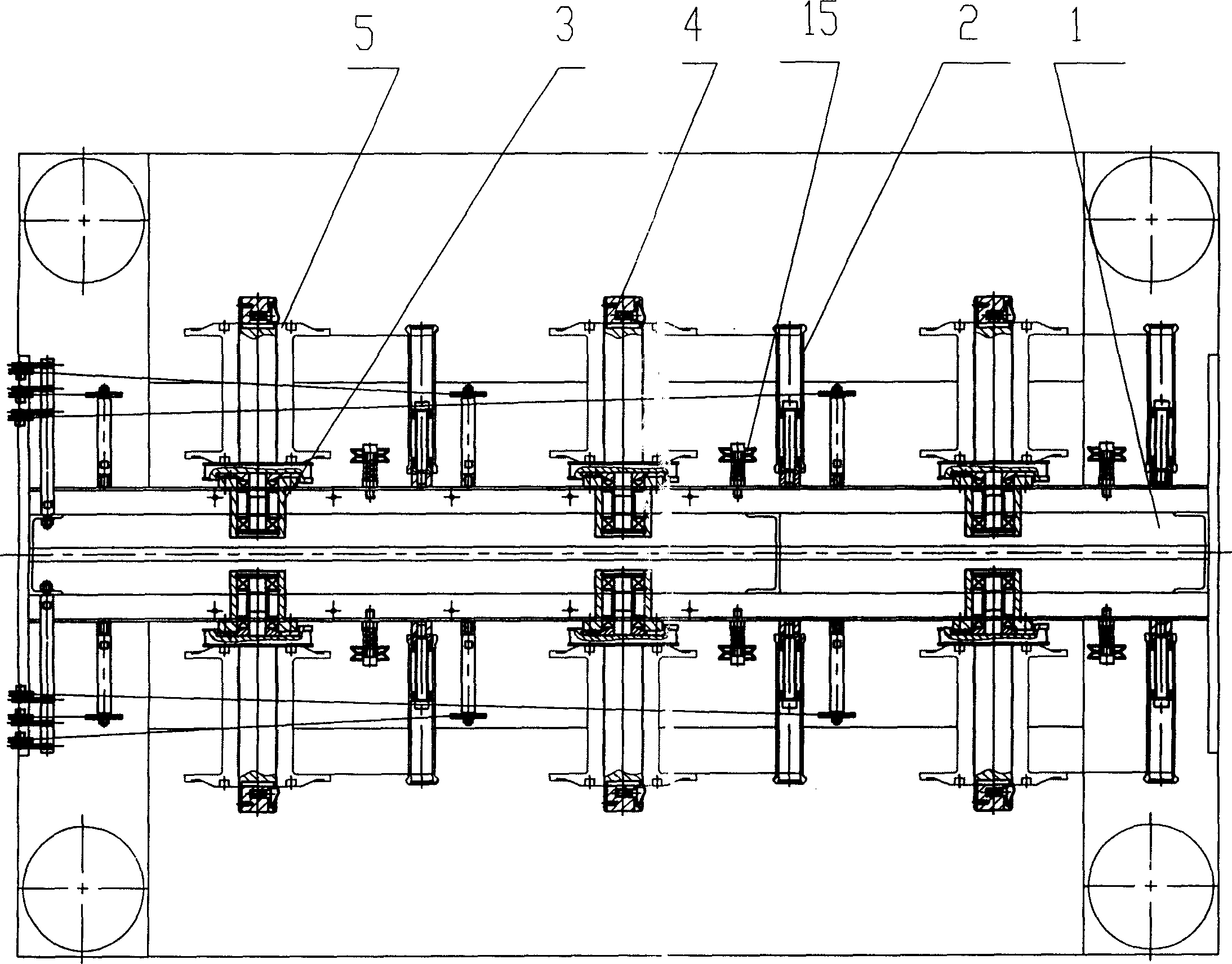

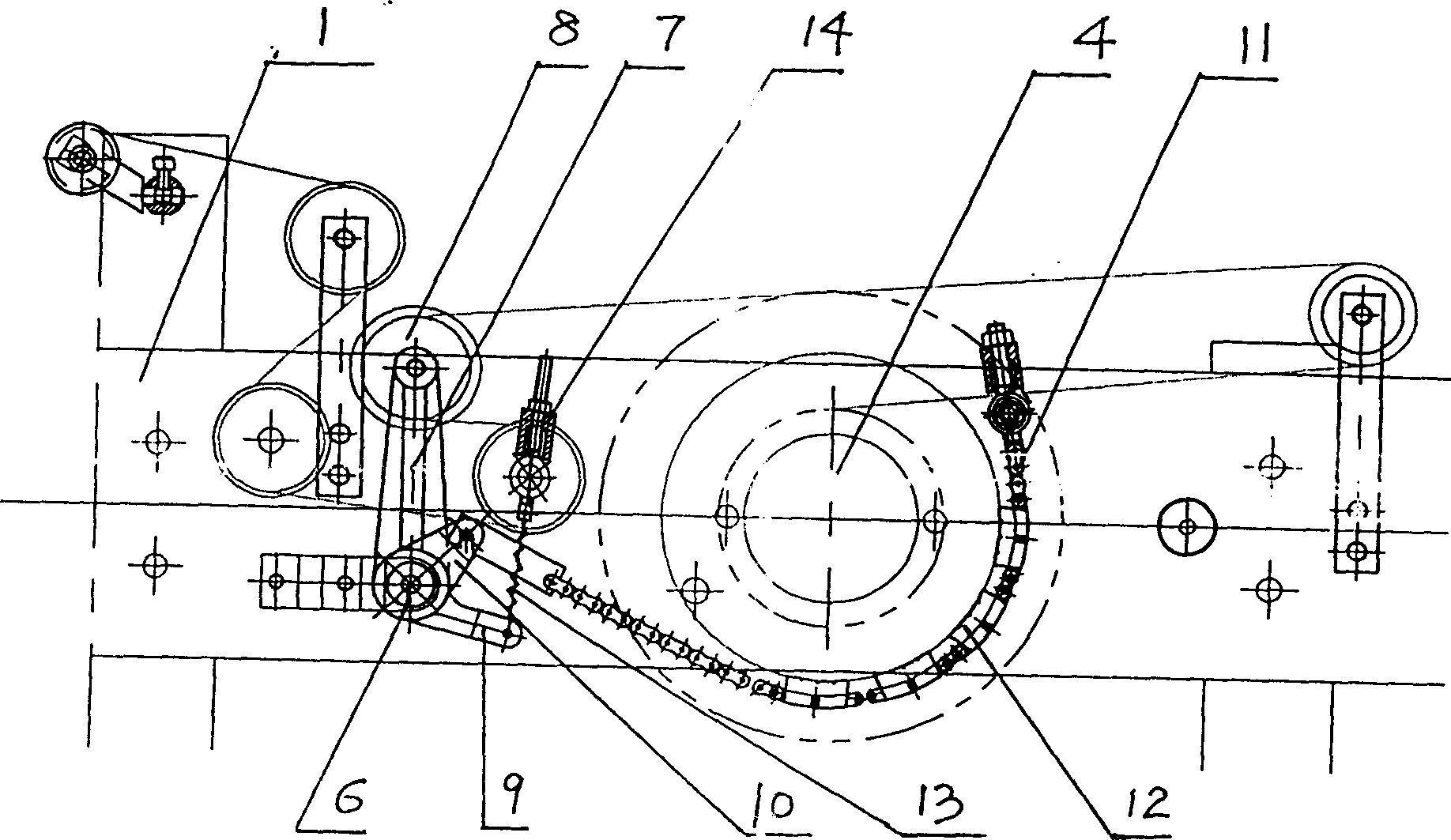

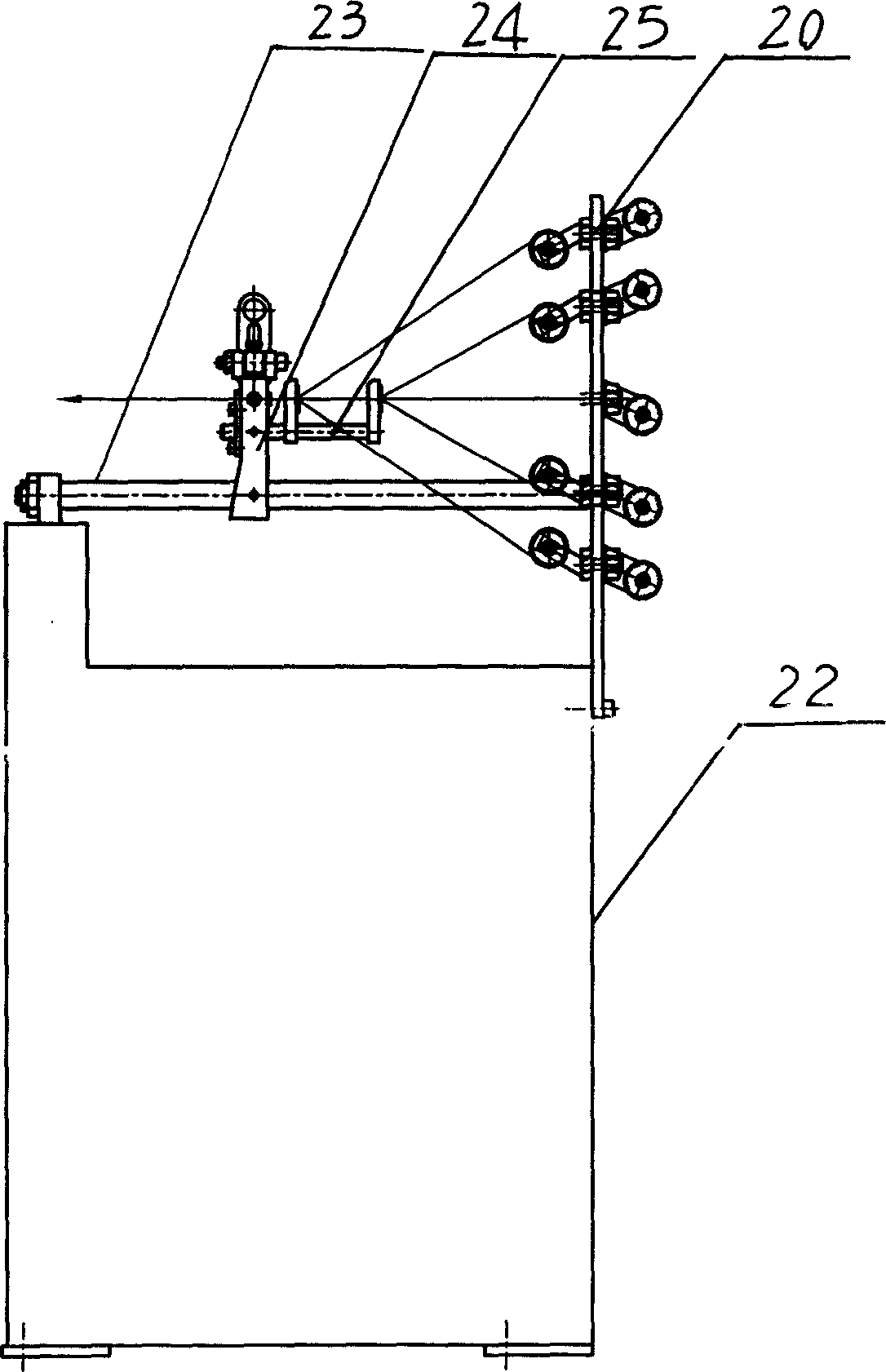

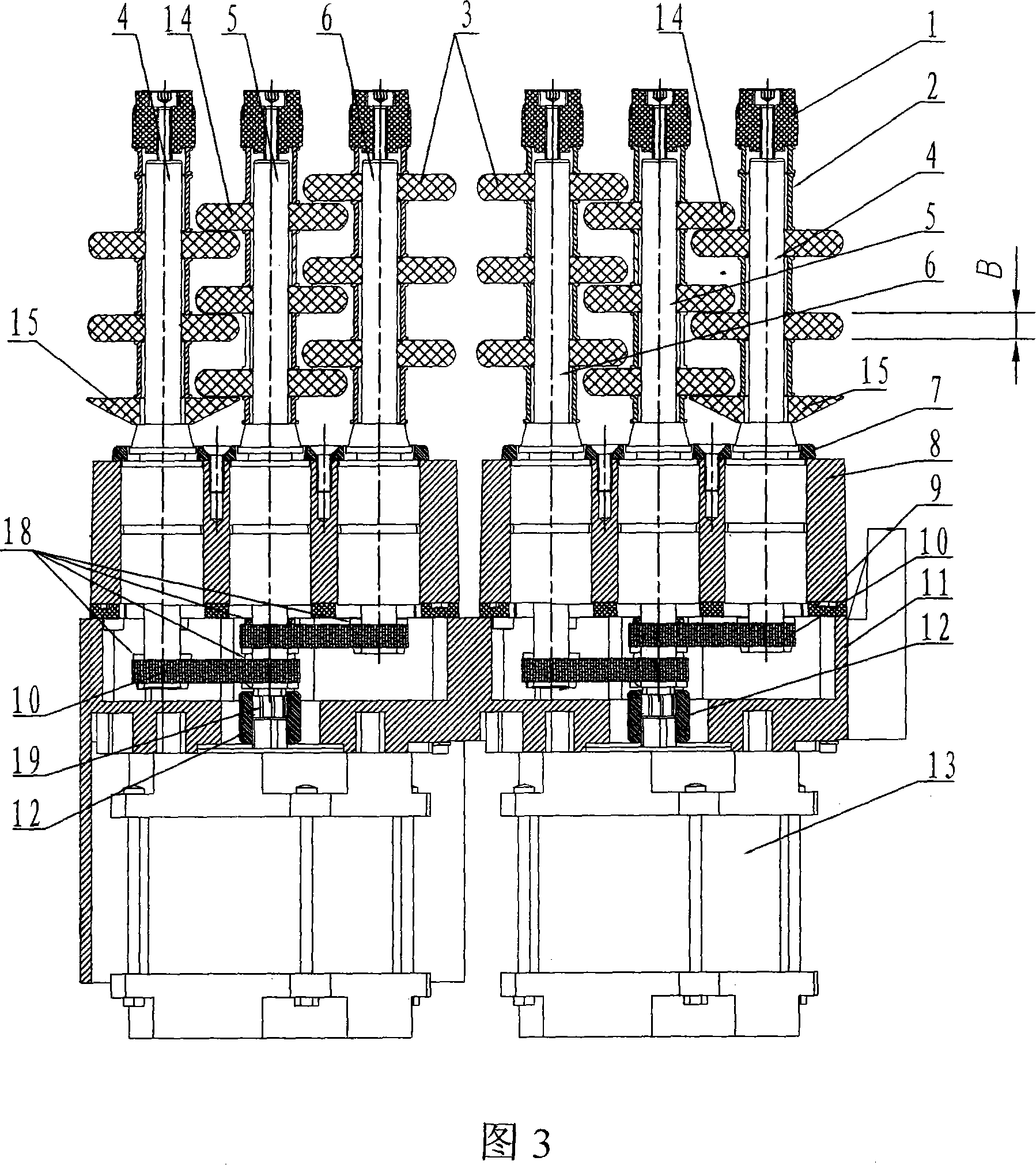

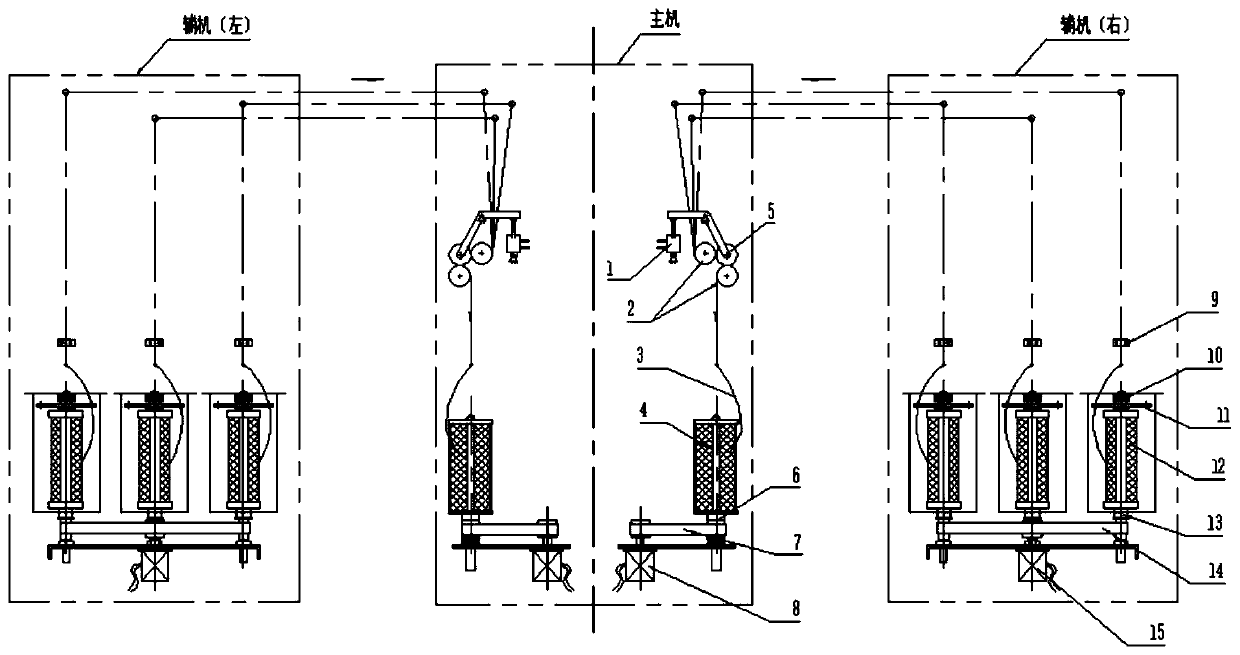

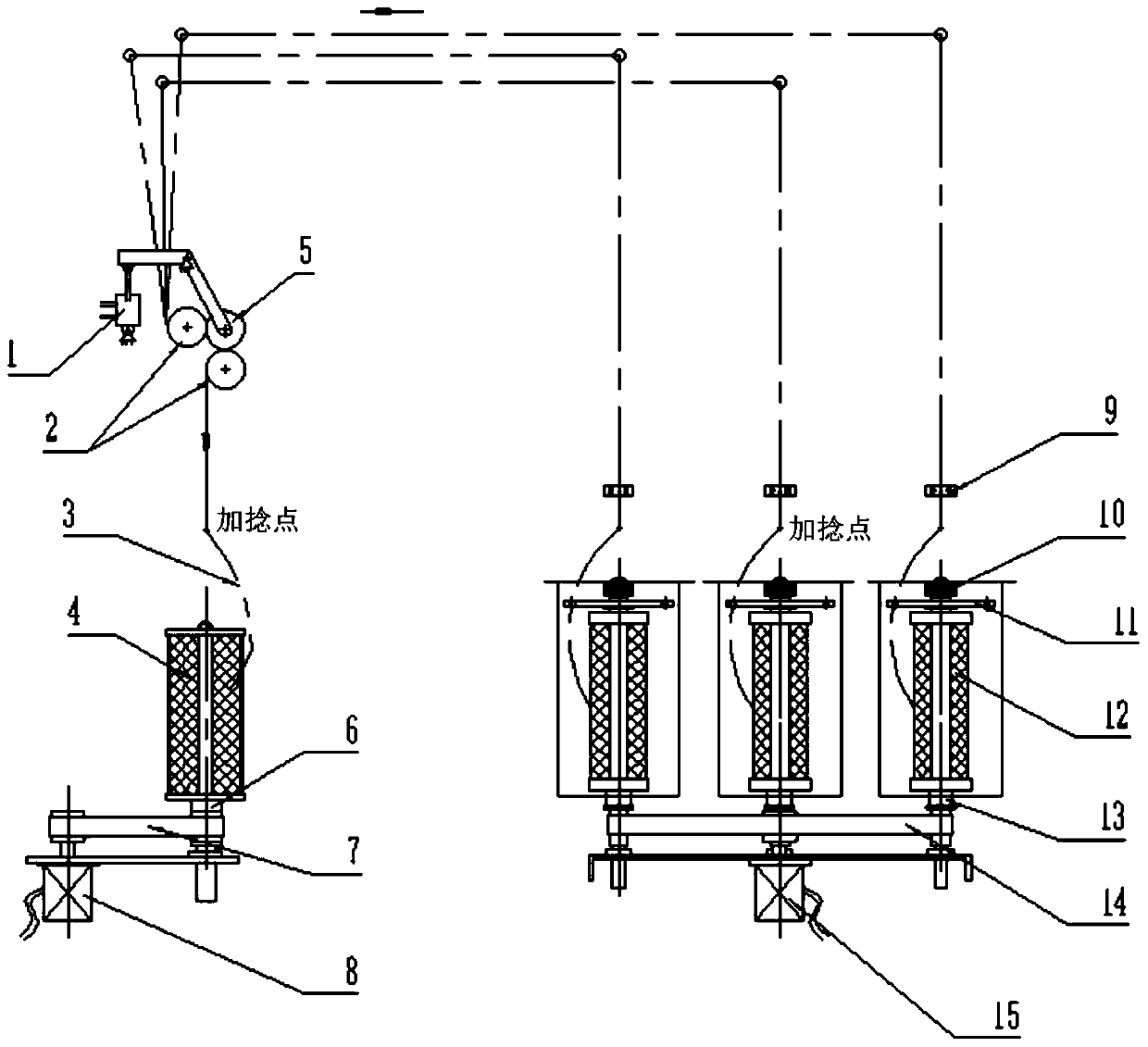

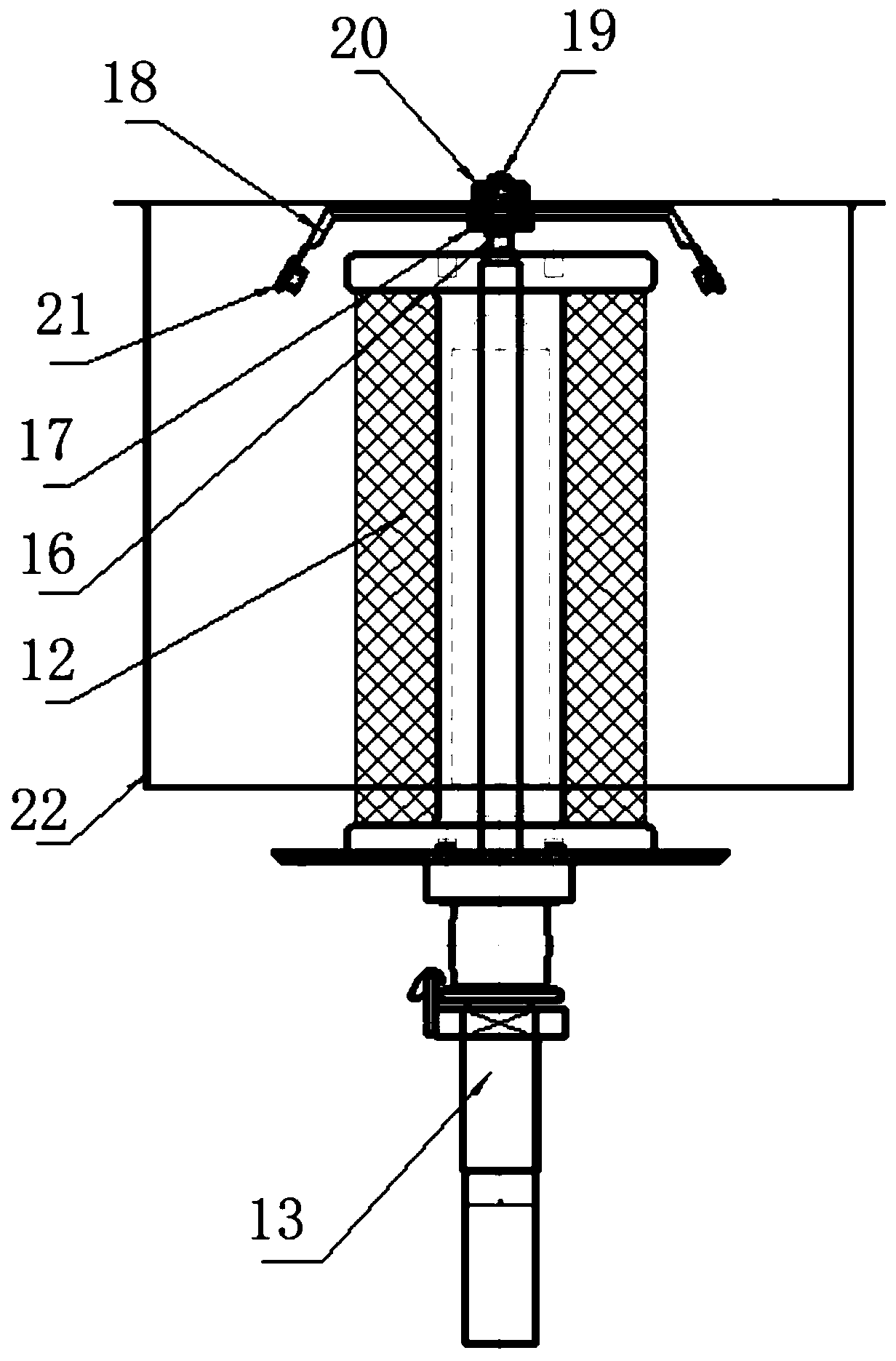

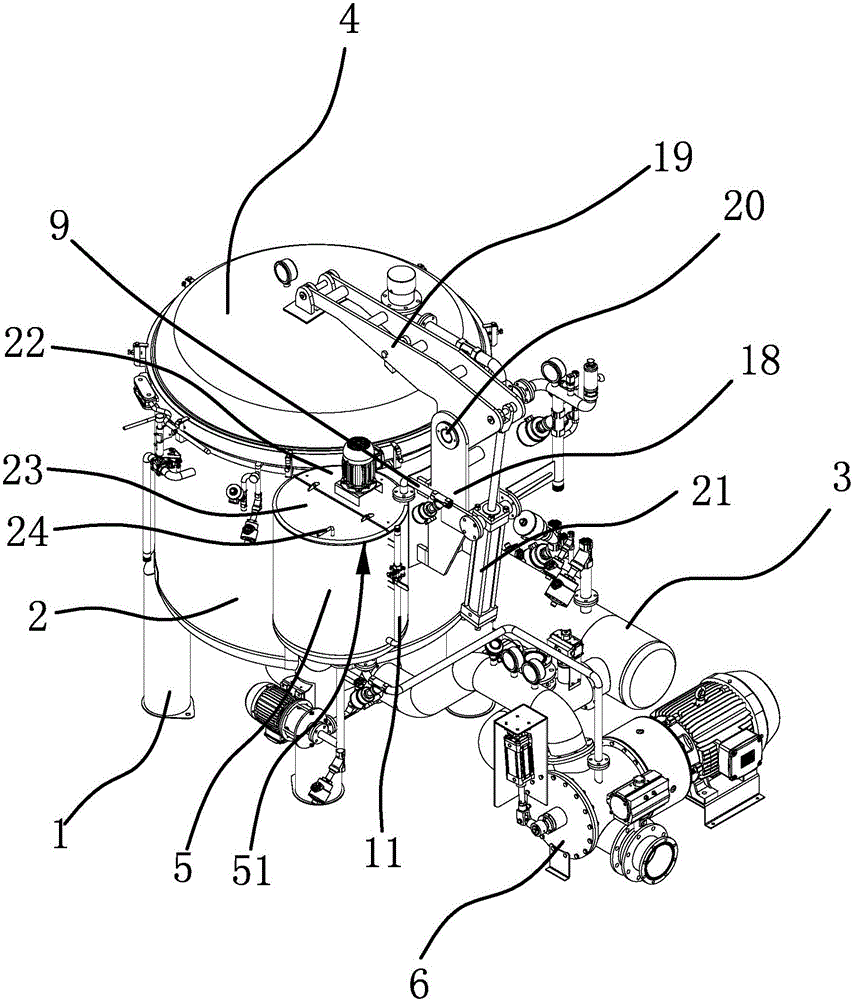

General purpose type wire stranding machine

This invention discloses an all-purpose strander, which comprises a setting-out part, a branching matched part and a main frame strander contractor part, wherein the setting-out part comprises the setting-out frame (1) and setting-out seat, and the setting-out frame (1) is installed erectly with several setting-out seats in it; the main shafts of each setting-out seat are arranged horizontal in parallel, and around each setting-out seat it sets guide wheel (15) and guide pipe (2); the tension automatic adjust device are set on each setting-out seat. The strander is modularized and is fit for stranding steel cord of several formats.

Owner:JIANGSU XINGDA STEEL TYPE CORD

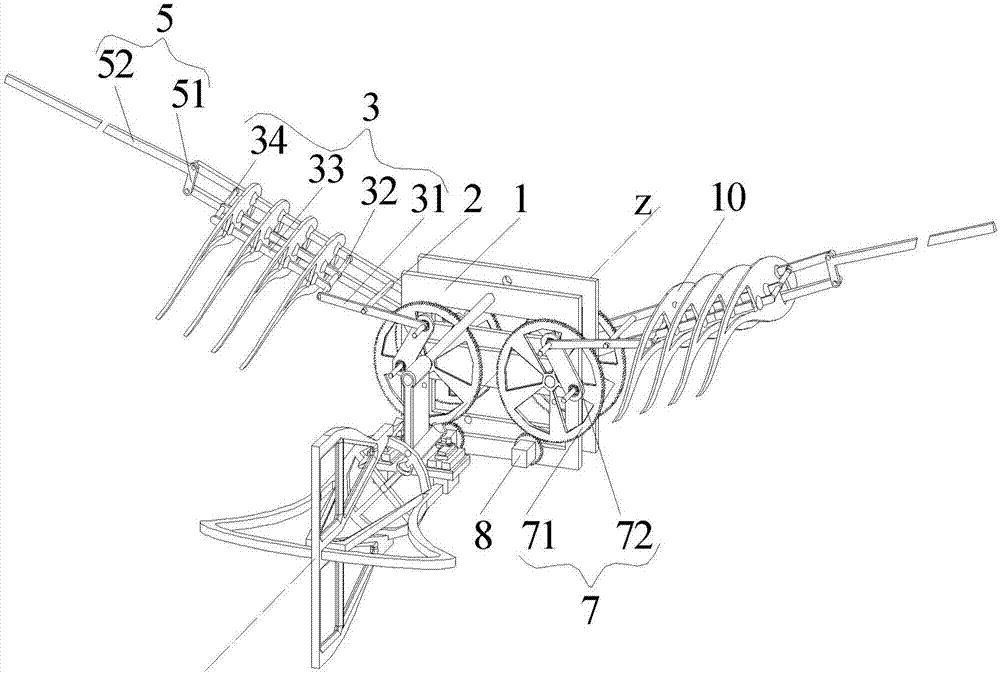

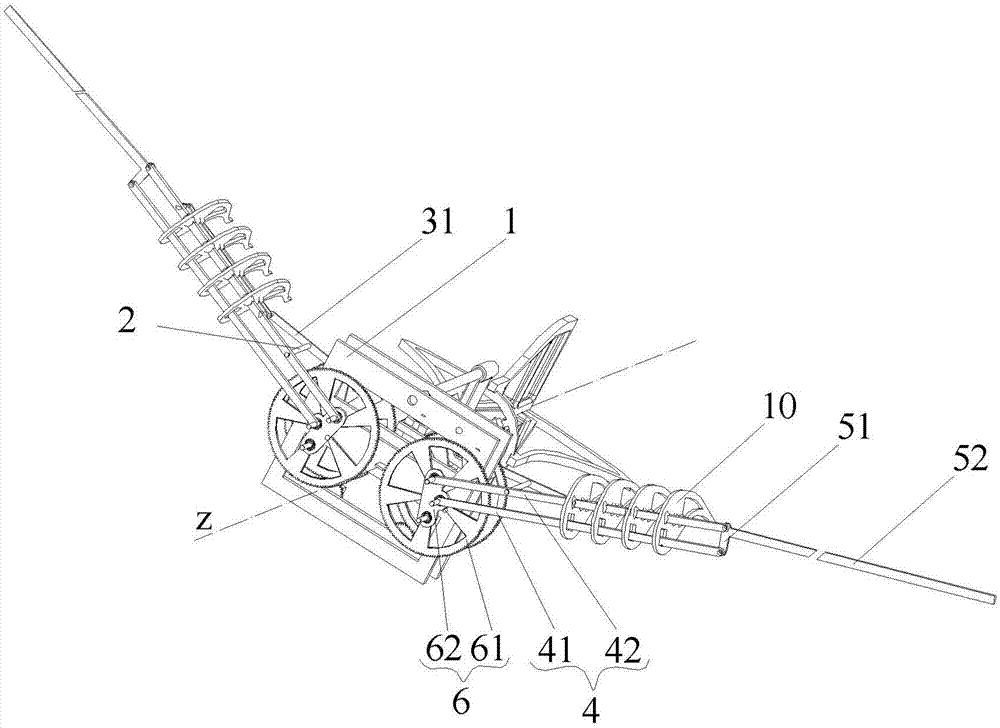

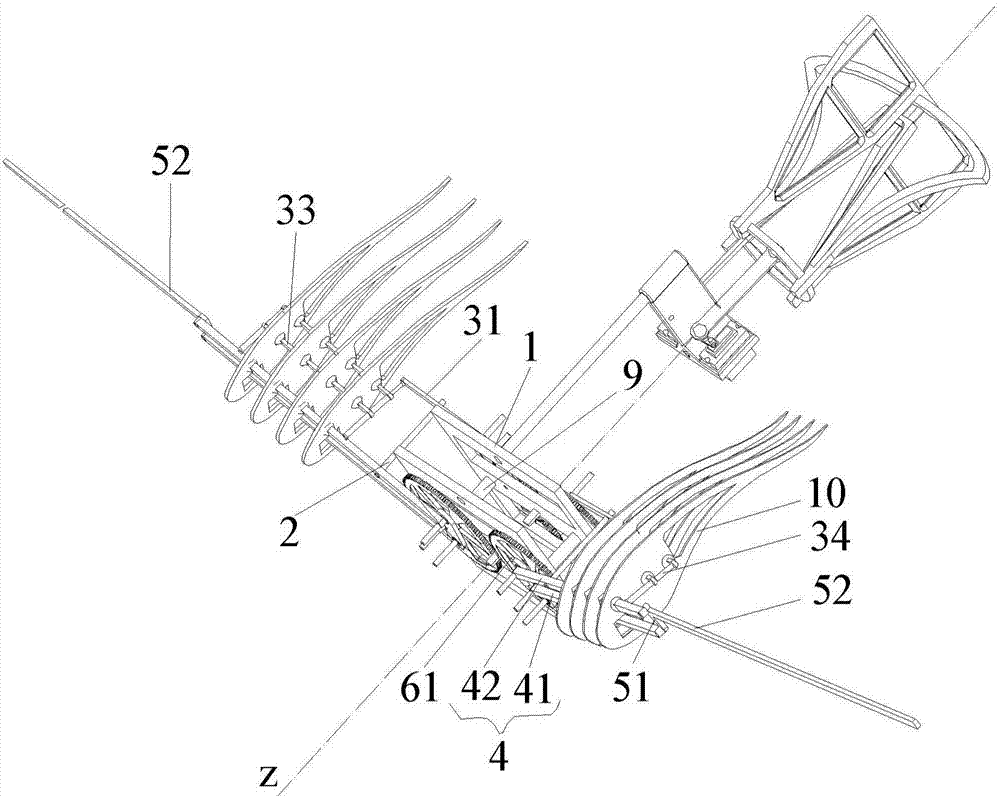

Flapping wing aircraft capable of realizing twisting of inner wings

The invention provides a flapping wing aircraft capable of realizing twisting of inner wings. The flapping wing aircraft comprises a rack, wings, rear drive devices and front drive devices. The rack has mounting positions. The wings are symmetrically arranged on the both sides of the rack. The wing on each side comprises an inner wing main flapping rod and an inner wing auxiliary flapping rod. The inner wing main flapping rods generate lift required during the flapping wing flight process. The inner wing auxiliary flapping rods generate lift and thrust required during the flapping wing flight process. The front drive devices are mounted in the mounting positions of the rack at the front and used for driving the inner wing main flapping rods. The rear drive devices are mounted in the mounting positions of the rack at the rear and used for driving the inner wing auxiliary flapping rods. The inner wing main flapping rods and the inner wing auxiliary flapping rods on the both sides of the rack have phase differences. The flapping wing aircraft has the advantages that the design of front and rear inner wing flapping mechanisms having the phase differences is provided, the flapping wing motions which are in accordance with the flapping wing flight principle are conducted, and the takeoff, direct flight and landing functions can be fulfilled when the left and right wings are synchronized; and when differential motions are conducted, the functions such as pitching, yawing and steering under the asynchronous control of frequencies and amplitudes of the left and right flapping wings can be fulfilled.

Owner:NANTONG UNIVERSITY

Twisting device of polyester composite fiber

ActiveCN109576852AEffective one-way twistingHigh strengthContinuous wound-up machinesYarnPolyester compositeTextile industry

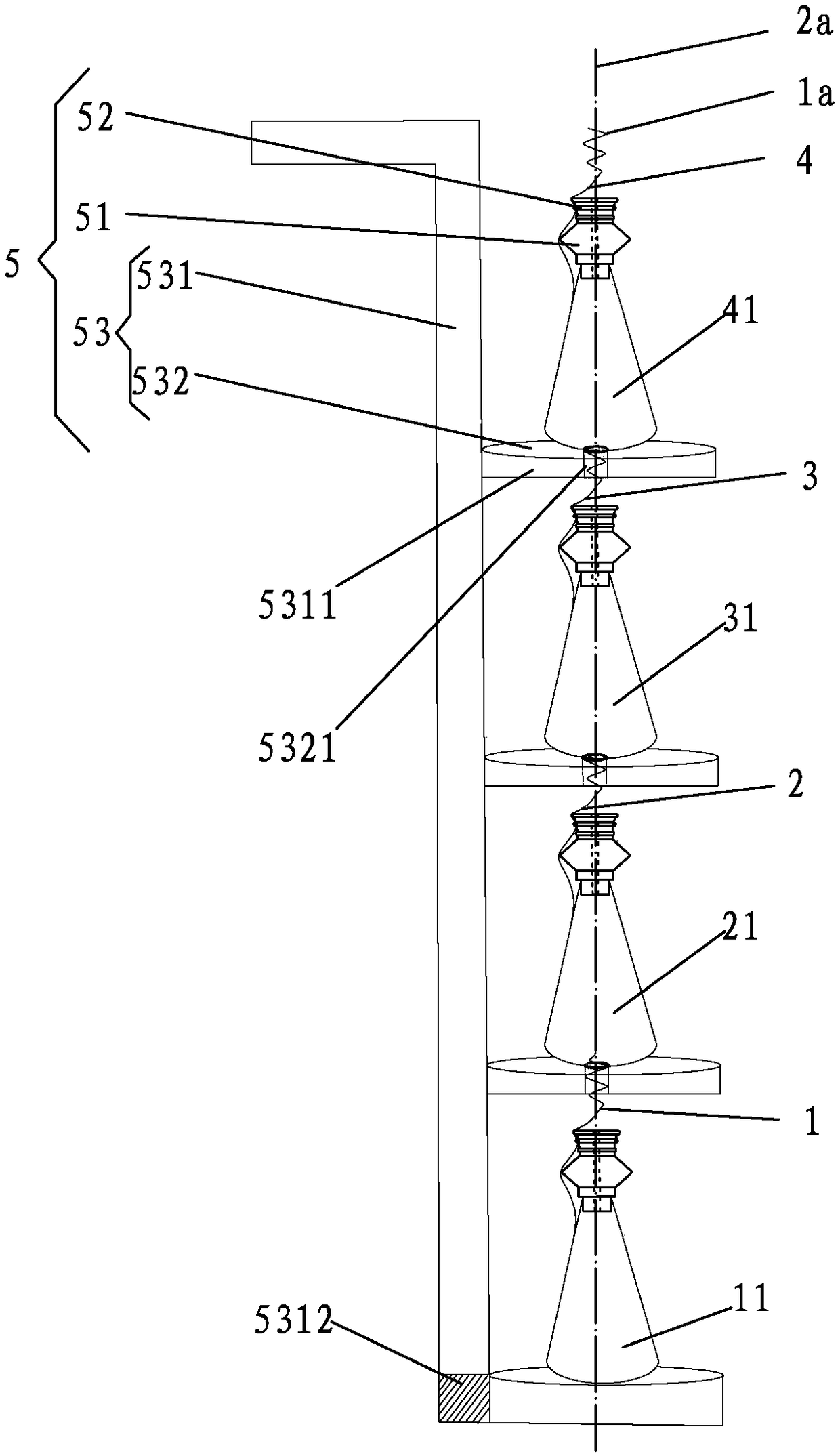

The invention discloses a twisting device for polyester composite fiber, and belongs to the field of textile industry equipment. The device includes a silk reel turntable, a self-twisting mechanism and a thread combination cylinder. The silk reel is used for supplying threads, the self-twisting mechanism includes a silk thread limit turntable, a silk thread self-twisting turntable and a fixed trough plate, wherein the middles of the silk thread limit turntable and the silk thread self-twisting turntable are fixed together, and the fixed trough plate sleeves the silk thread self-twisting turntable. The silk thread self-twisting turntable is provided with first through holes corresponding location cylinders one to one, and an annular silk thread self-twisting gap is formed between the innerside face of the fixed trough plate and the silk thread self-twisting turntable. The thread combination cylinder is shaped like an inverted funnel, and the thread combination cylinder is internally provided with second through holes or threading troughs for locating silk threads. First connection rods and second connection rods are used for connecting the thread combination cylinder, the silk thread self-twisting turntable and the silk reel turntable into a whole to make the thread combination cylinder, the silk thread self-twisting turntable and the silk reel turntable rotate synchronously. The device has self-twisting and combination functions of the silk threads, unnecessary entanglement between the silk threads can be efficiently avoided, and the twisted polyester composite silk threads have uniform texture and high strength.

Owner:JIANGSU ZHENYANG NEW SYNTHETIC FIBER

Automatic tire dismounting robot

ActiveCN111300027AControl small angle deflectionStable clampingWheel mounting apparatusMetal working apparatusCircular discElectric machinery

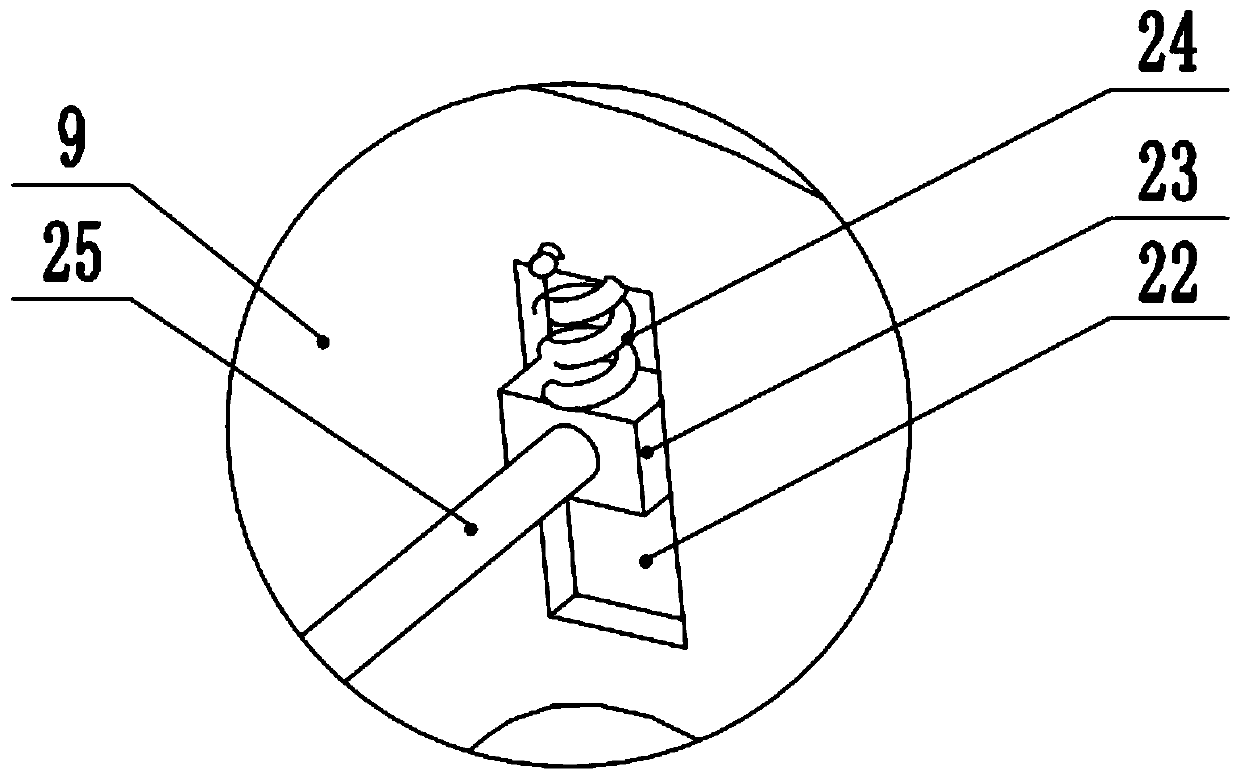

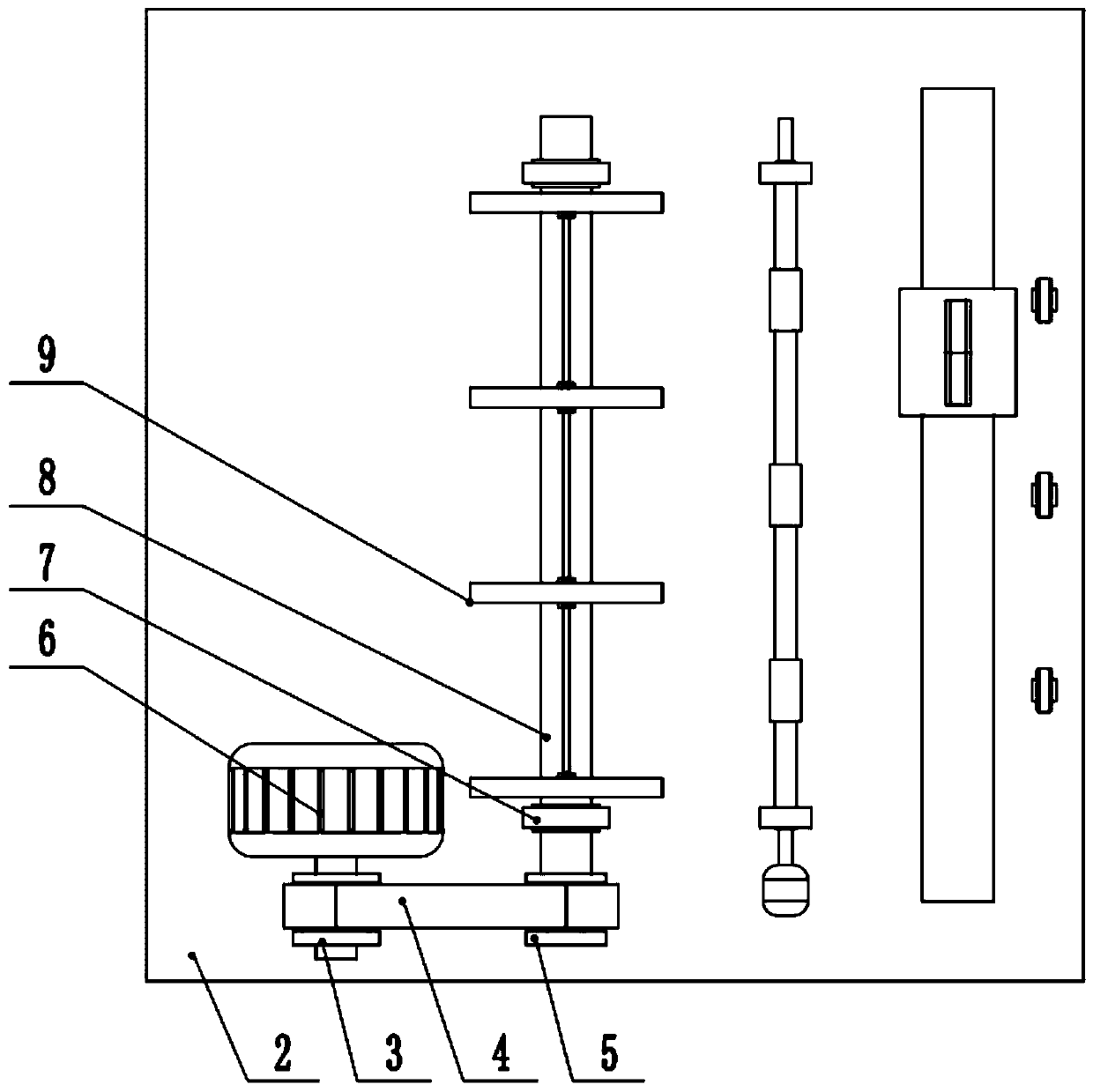

The invention provides an automatic tire dismounting robot. A main body of the automatic tire dismounting robot consists of a moving part, a middle part, a clamping part, a screwing part and the like,the moving part comprises a traveling plate, a walking crawler belt, an outer telescopic sleeve, an inner telescopic shaft and the like; the middle part comprises a rotating ring, a chassis, an outerframe, a supporting rod and the like; the clamping part comprises a disc frame, a lead screw, a clamping frame, an inner ring rack and the like; and the screwing part comprises a motor end cover, a turbine cover, a screwing bolt tail end, a telescopic spring and the like. During use, the moving part controls the robot to move to the position near a tire, the middle part controls the clamping partto be aligned with a tire and clamp the tire, and then the screwing part is screwed to detach a screw on the tire.

Owner:合肥派霸电气科技有限公司

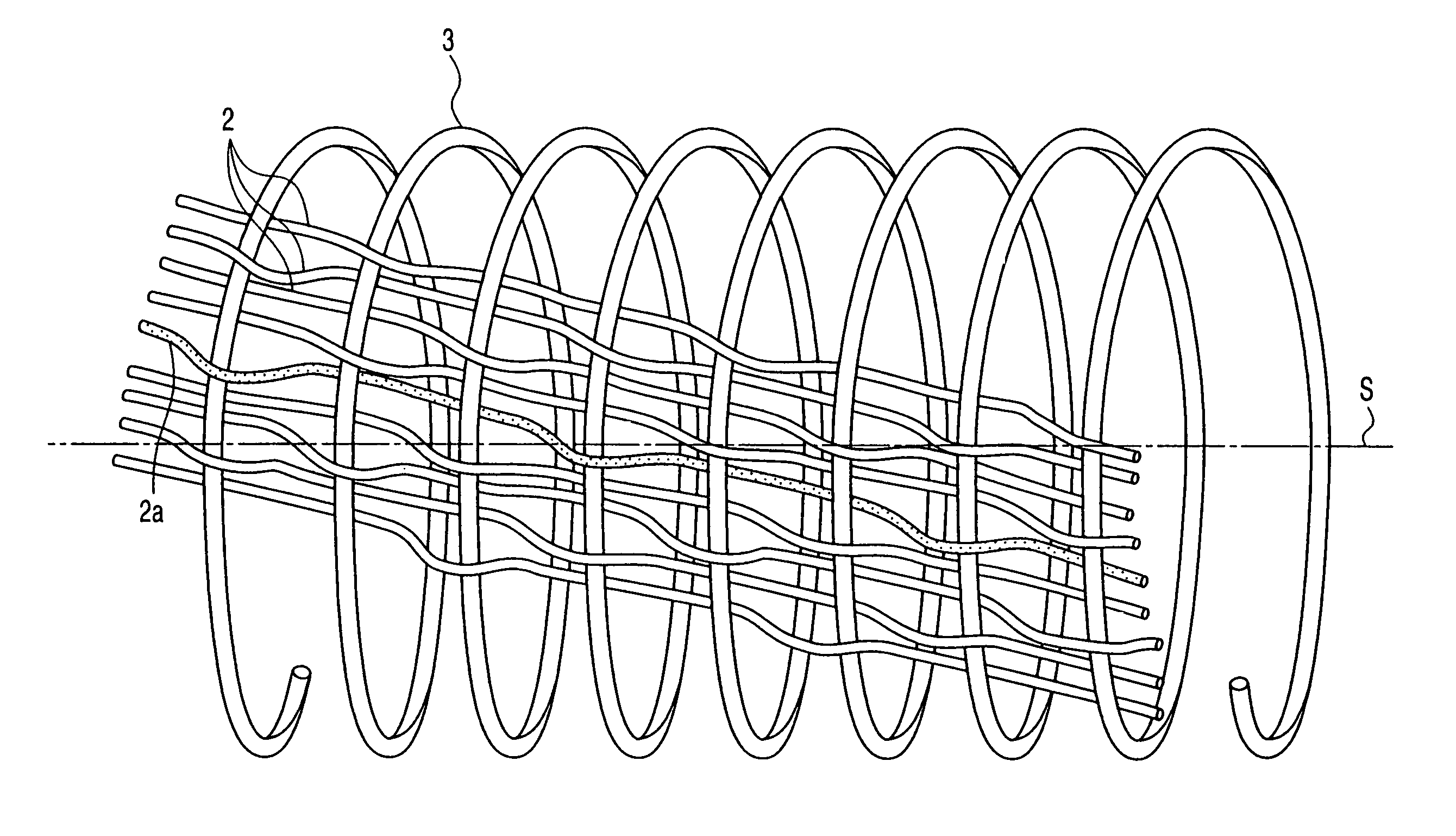

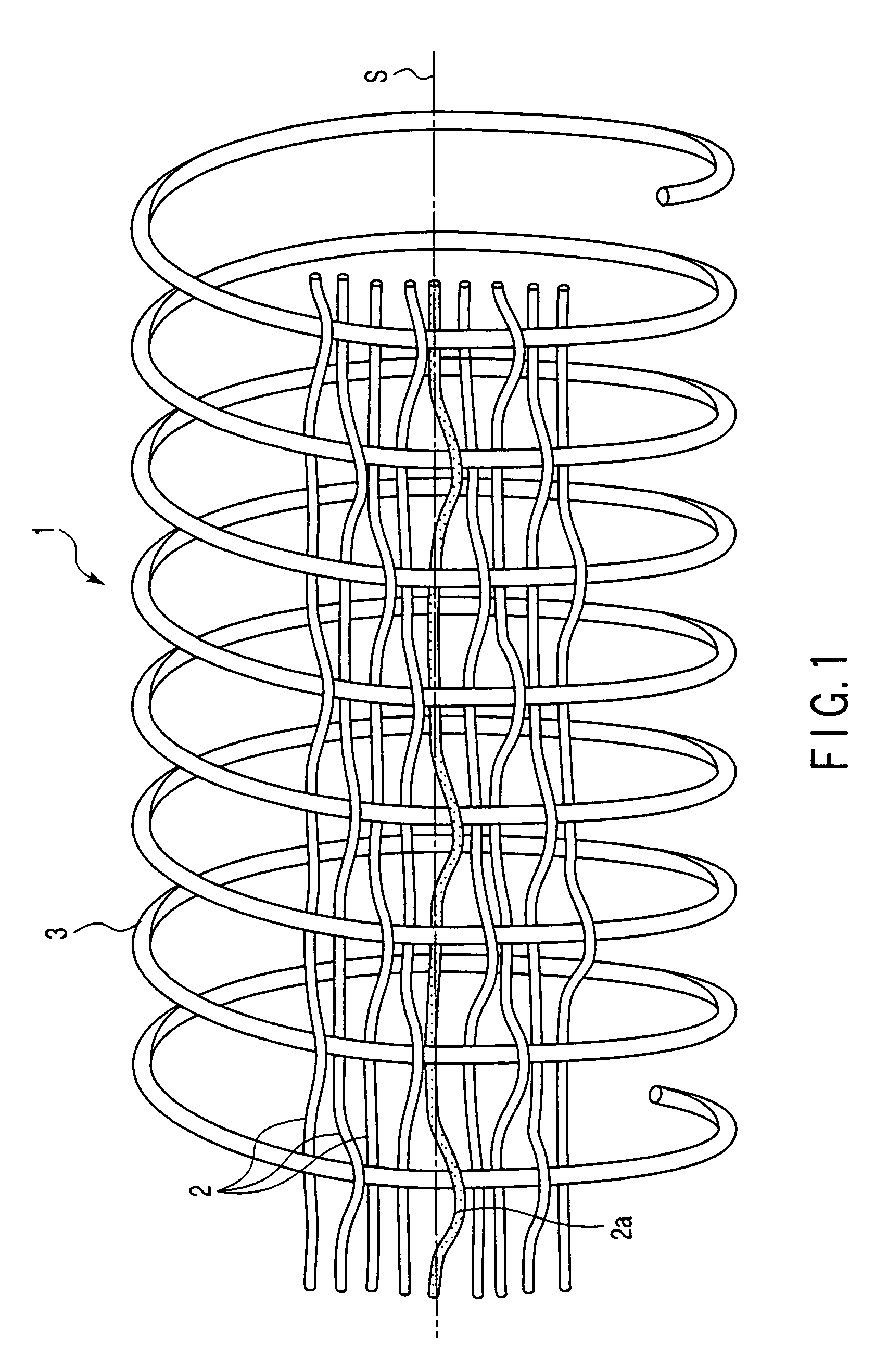

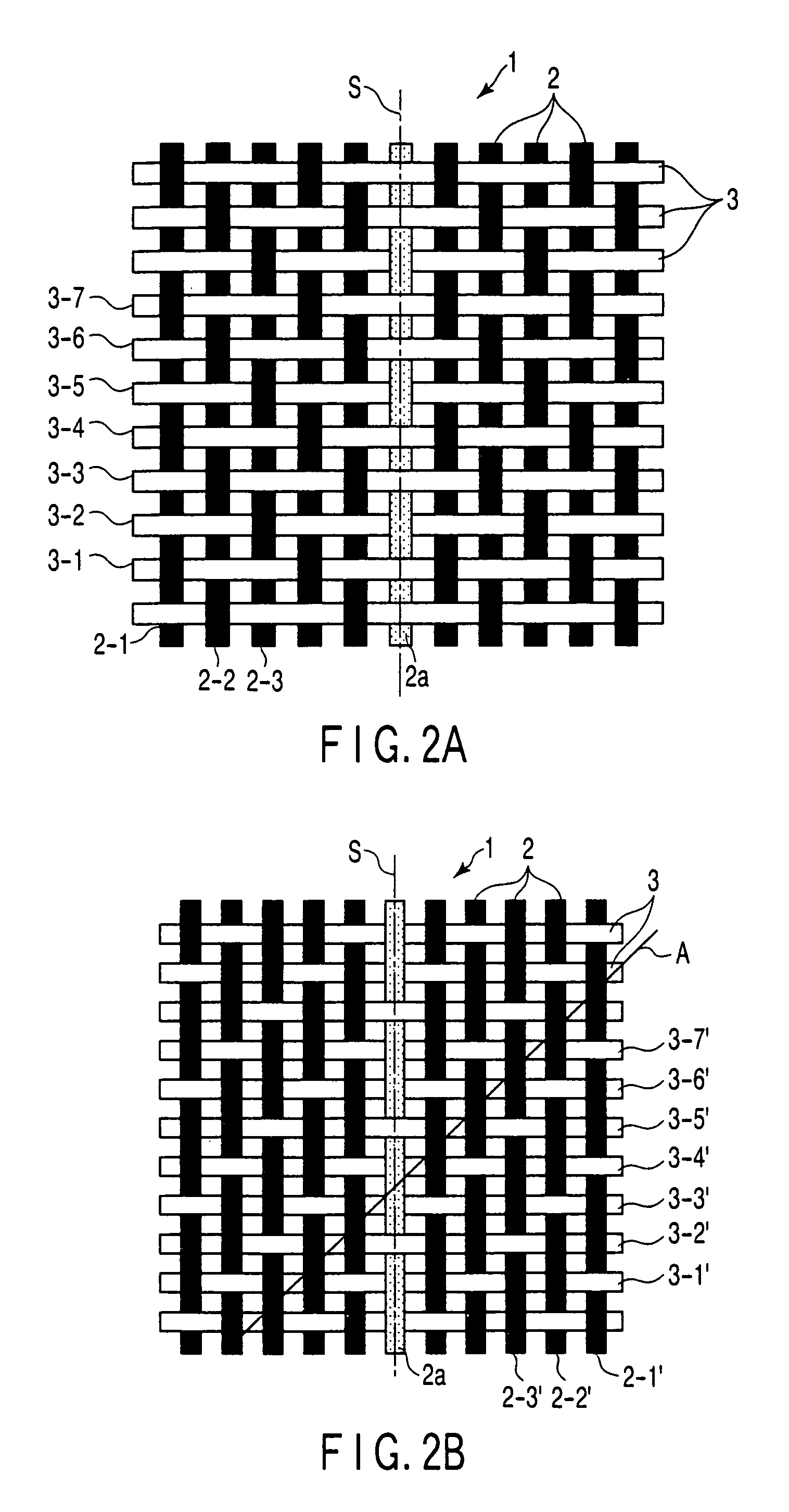

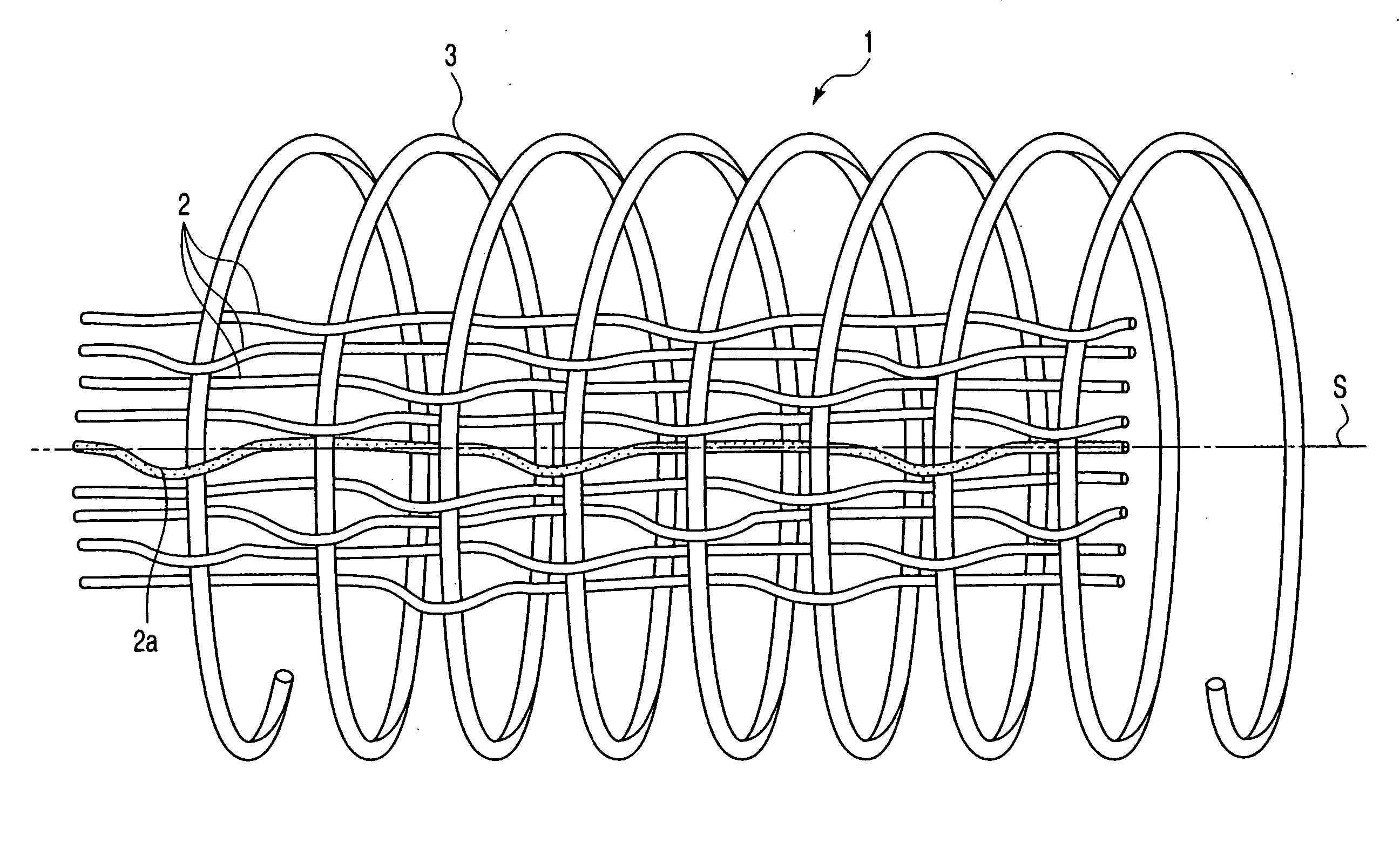

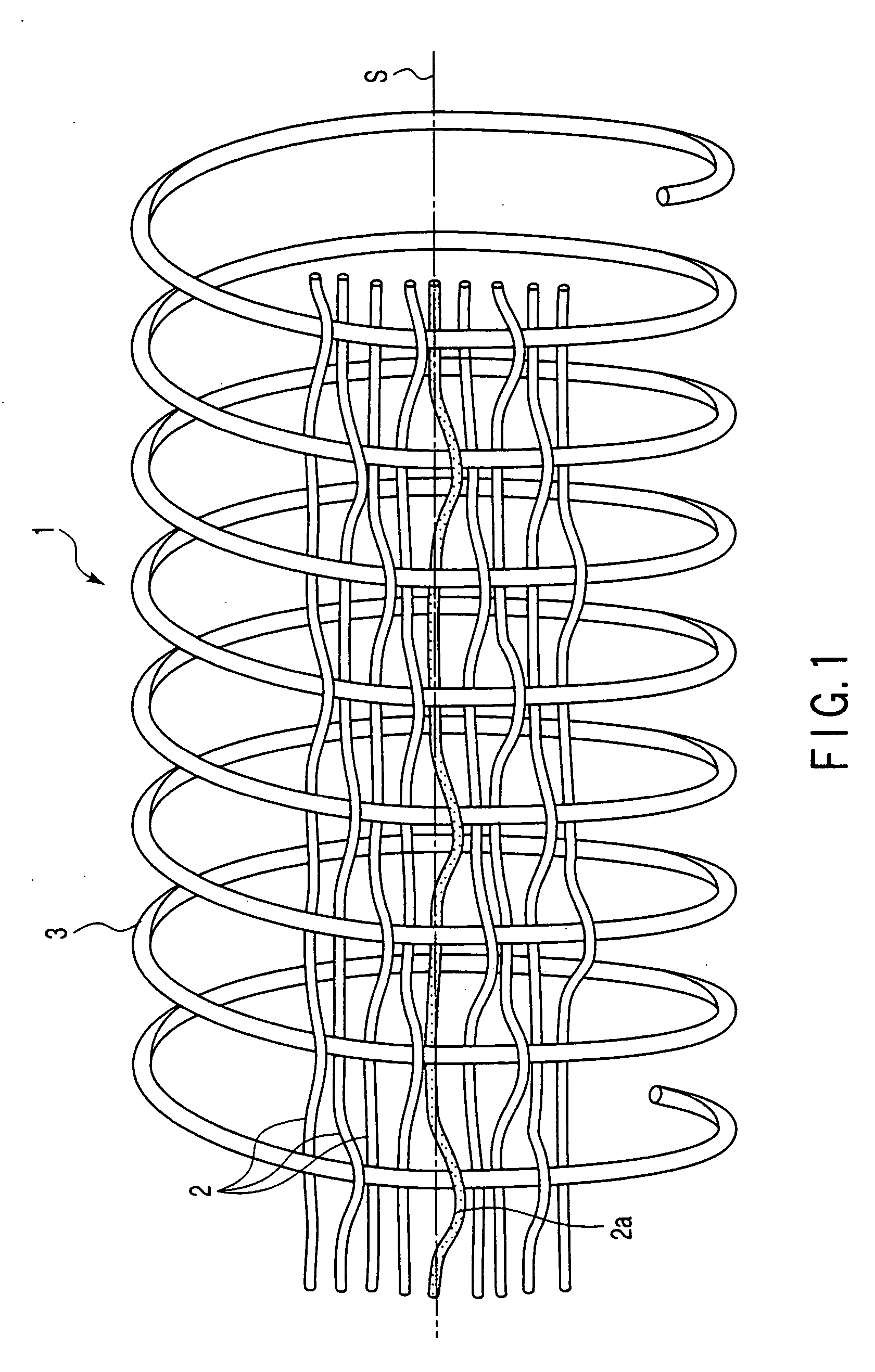

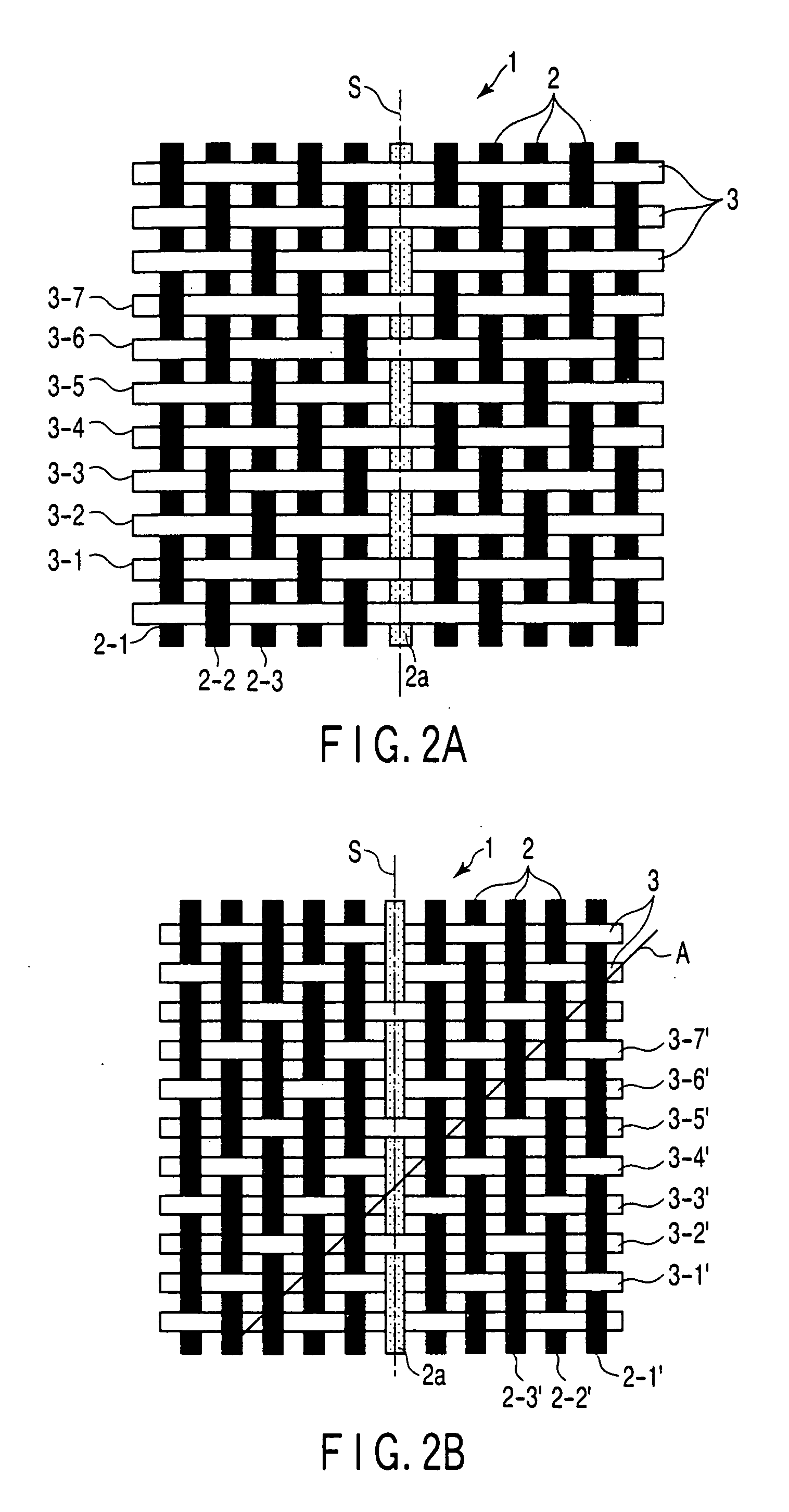

Cylindrical jacket, jacket hose, suction hose, and cylindrical jacket manufacturing apparatus

InactiveUS7926517B2Small pressure lossEven twistCircular loomsFlexible pipesMarine engineeringManufactured apparatus

Owner:SAKURA GOMME KK

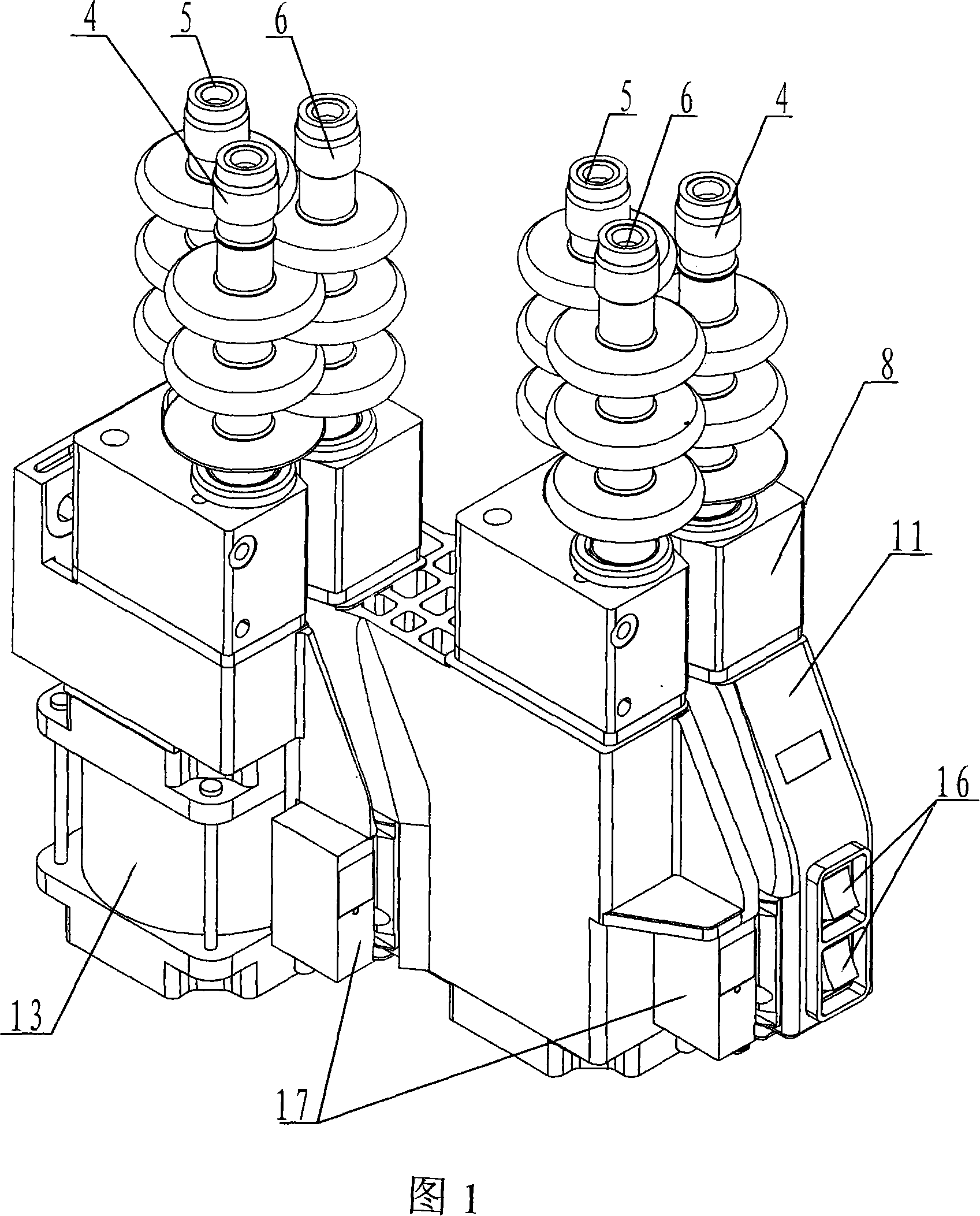

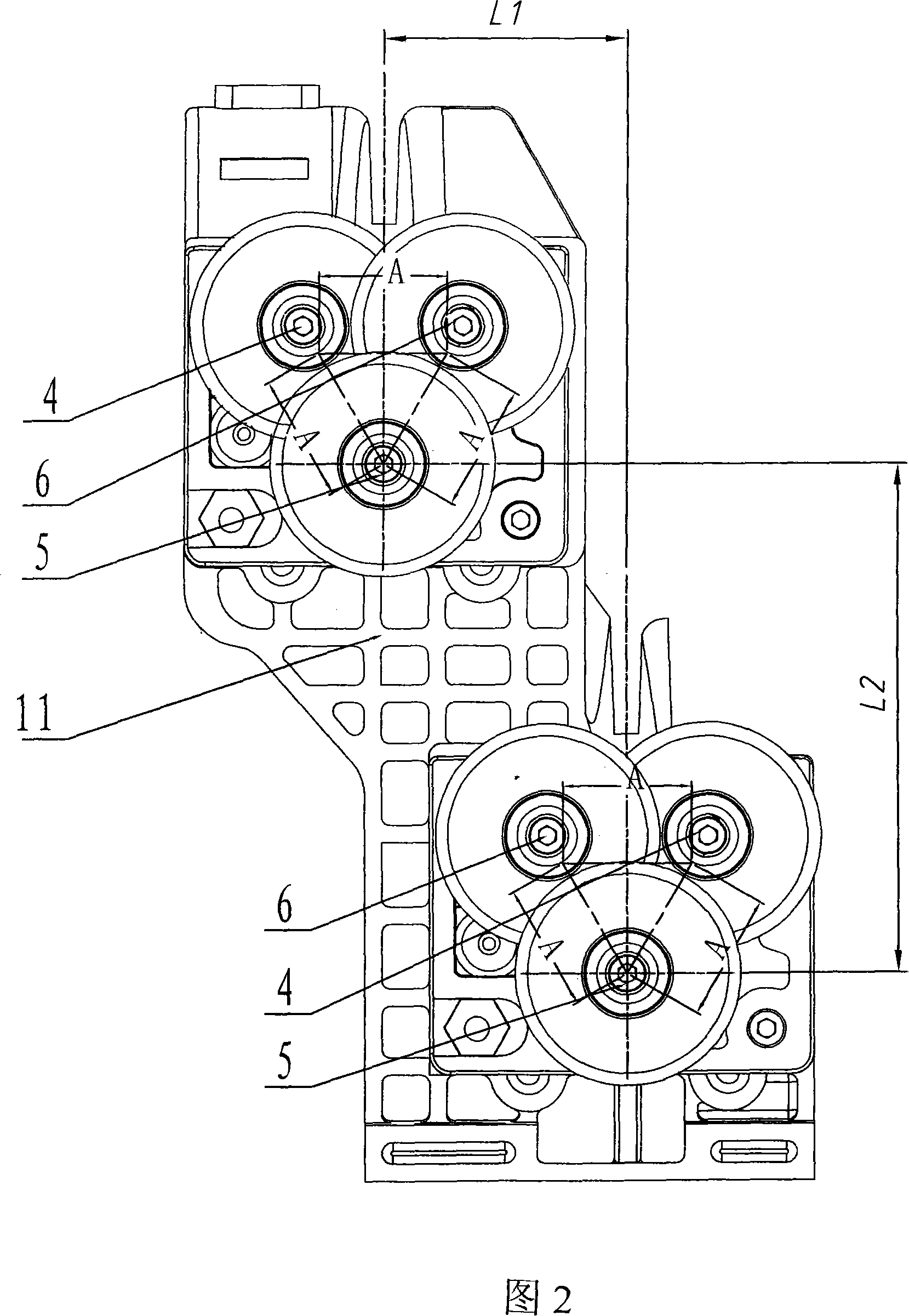

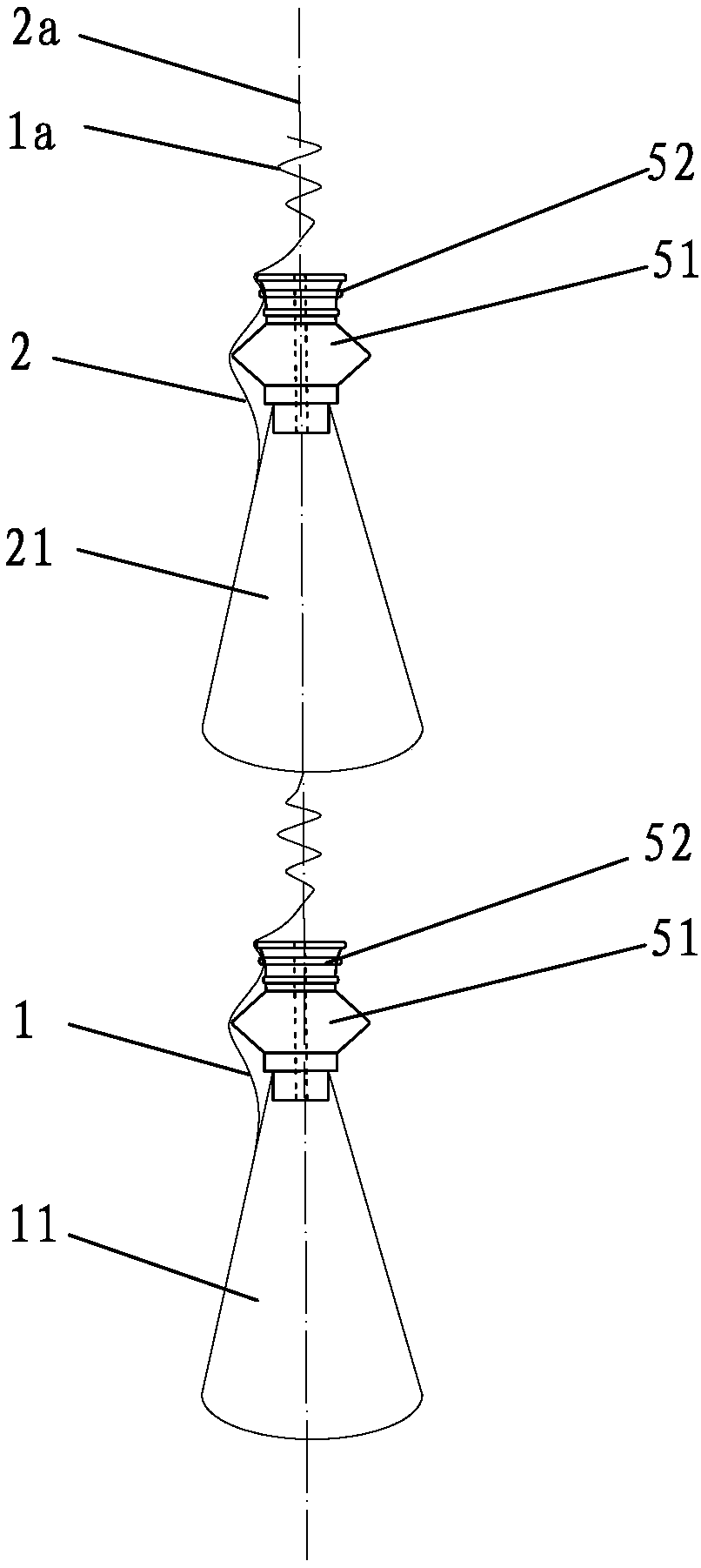

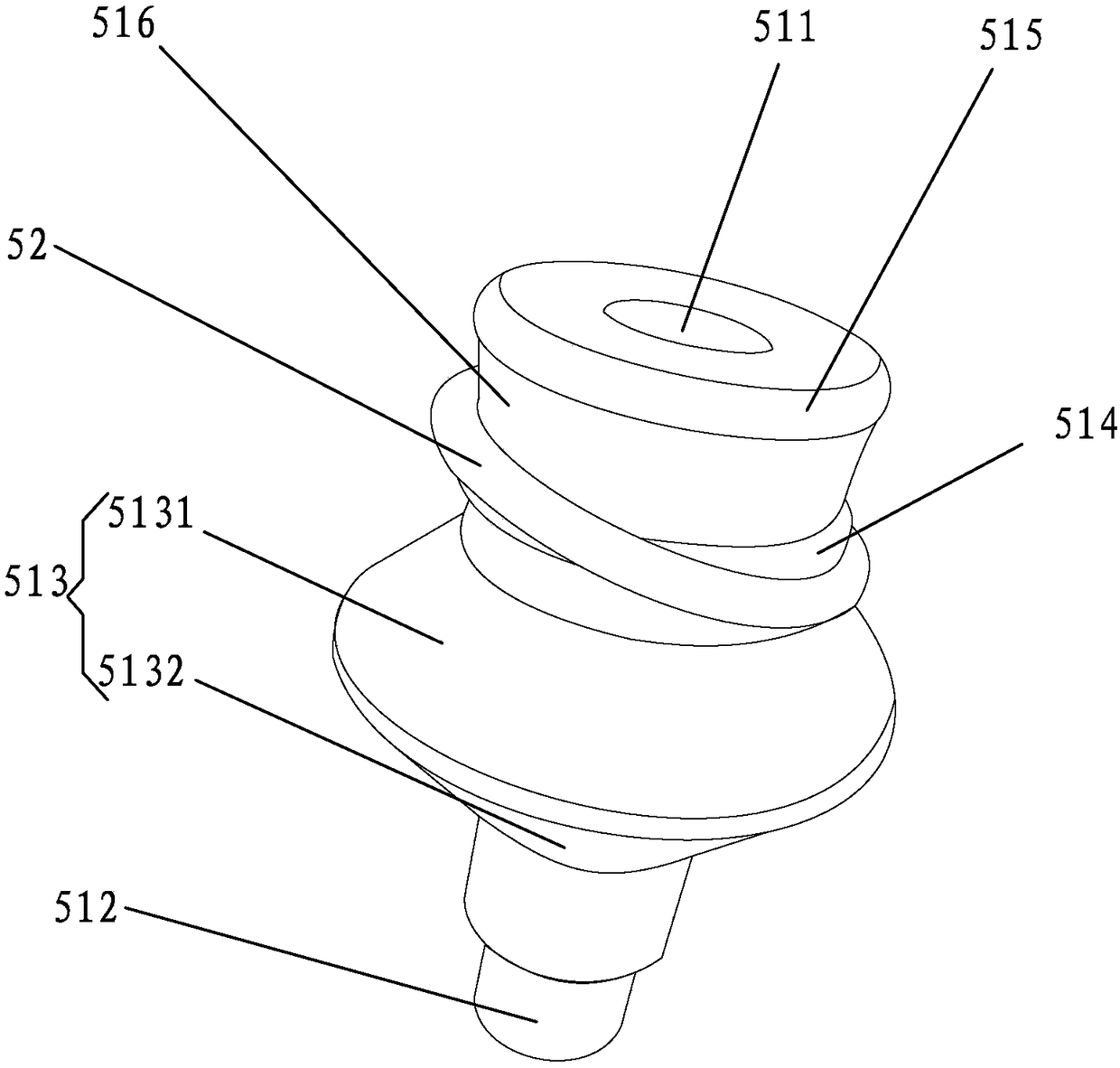

Composite double ingot set false twisting device of false-twist texturing machine

The compound double spindle false twisting device for false twist texturing machine contains two spindle sets comprising one driving spindle and two driven spindles each with spindle centers constituting one equilateral triangle, one motor to drive two driving spindles in these two spindle sets, two spindle seats, one support for the spindle sets, the motor and the spindle seats to be set on, one on-line tensioner, and one motor controlling switch. One such compound double spindle false twisting device can perform S twisting and Z twisting simultaneously. The compound double spindle false twisting device has smart structure, smooth and stable false twisting and easy control.

Owner:JIANGSU HAIYUAN MACHINERY

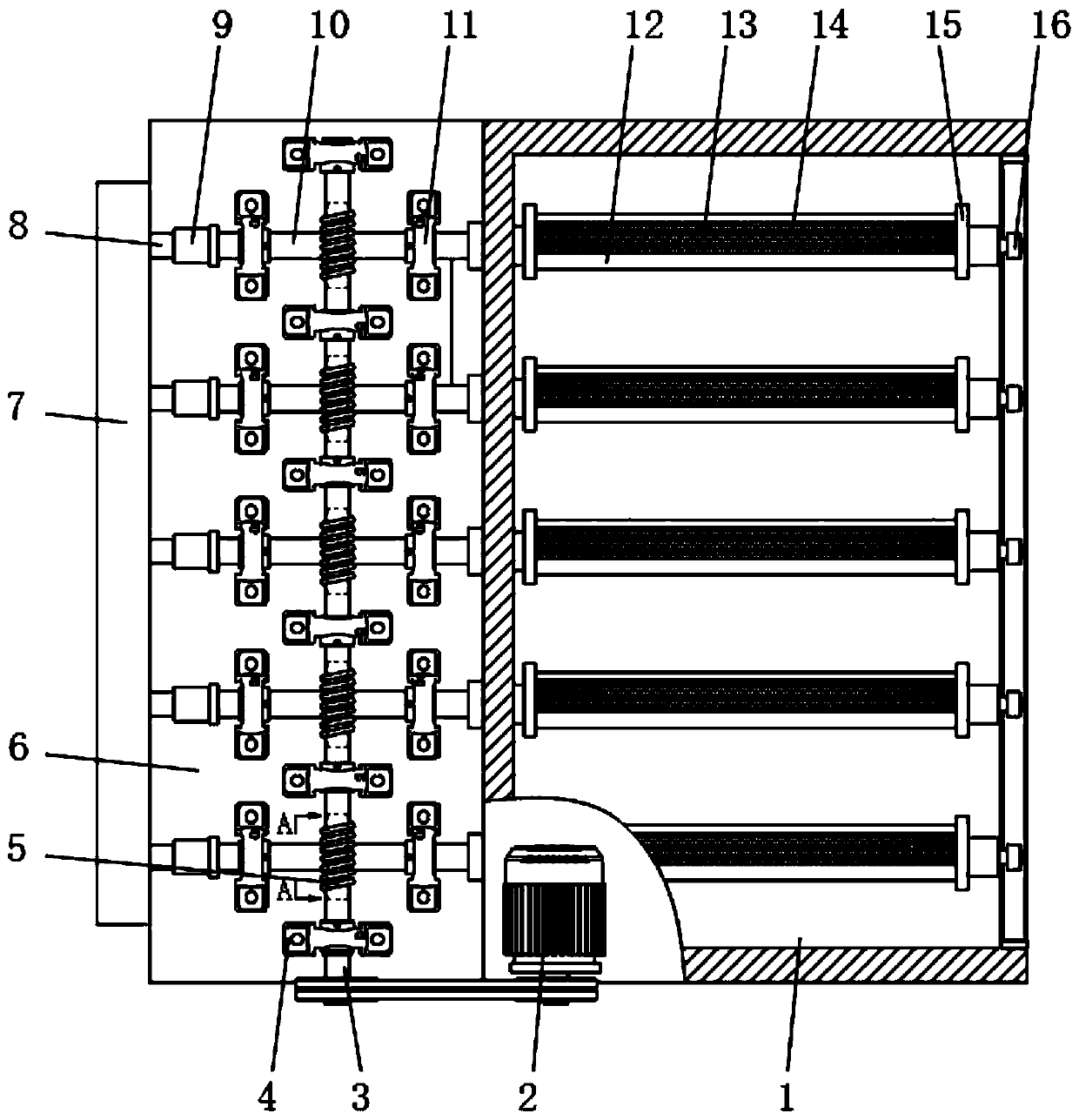

Automatic wire cutting and twisting apparatus

InactiveUS8176946B2Easy to controlLaborious to useRope making machinesManufacturing wire harnessesWire cuttingEngineering

An automatic wire cutting and twisting apparatus includes a chassis board on which a start-terminal mounting rack, an end-terminal mounting rack, and a mounting track are mounted. The start-terminal mounting rack opposes a start terminal of the mounting track. The end-terminal mounting rack is position-adjustably coupled to an end terminal of the mounting track. A wire cutting mechanism is mounted on the start-terminal mounting rack and forms ingress and egress for wires. A wire twisting mechanism includes start-terminal and end-terminal rotation sections respectively mounted on the start-terminal and end-terminal mounting racks. A wire dragging mechanism includes a start-terminal dragging section mounted on the chassis board and a slidable dragging section movable above the mounting track. A wire pick-up mechanism is position-adjustably mounted on the mounting track. A cutting and twisting control mechanism is electrically connected to the wire cutting mechanism, the wire twisting mechanism, and the wire dragging mechanism.

Owner:CHENG UEI PRECISION IND CO LTD

One-step composite twisting frame

The invention provides a one-step composite twisting frame, and belongs to the technical field of textile machinery. By arranging an unwinding device on the top of a first twist spindle, the problemsthat in the yarn twisting process, uneven yarn twist, fuzzing, bubbling and the like are caused by unstable balloon tension can be effectively solved. The one-step composite twisting frame comprises afirst twisting mechanism, a roller transmission structure and the a second twisting mechanism; in the first twisting mechanism, single twisting is conducted through the first twisting spindle, and two or more yarns completing single twisting enter the roller transmission structure for monofilament stranding to form a twisted yarn; the second twisting mechanism is used for second twisting of the twisted yarn; the unwinding device is arranged on the top of the first twist spindle, that is to say, a bracket is additionally arranged in the middle of a twisting zone of the yarns, the size of a balloon formed through high-speed rotation of the yarns in the twisting zone is fixed, the balloon size is basically the same, and the yarn quality problem generated by colliding with other parts cannotbe caused; the problems of yarn fuzzing, bubbling, more white dots, more broken ends and the like of a traditional one-step twisting frame can be effectively solved.

Owner:HANGZHOU CHANGYI TEXTILE MACHINE

Portable type cable twisting device

InactiveCN110790079ASimple structureEasy to useFilament handlingStructural engineeringLever pressing

Owner:湖南新耒传导材料科技有限公司

Adjustable transformation equipment pedestal adapted to non-uniform settlement

InactiveCN108075361AAvoid leaningCorrective tiltSubstation/switching arrangement casingsEngineeringScrew thread

The invention relates to an adjustable transformation equipment pedestal adapted to non-uniform settlement, and belongs to the technical field of transformation equipment fittings. The pedestal is composed of a foot seat, a support and a supporting plate. The foot seat is formed by welding three sleeves to an annular plate, and the included angle between every two sleeves is 120 degree. The support is composed of a screw and a nut thereof, the top of the screw is smoothly spherical, and part under the top of the screw includes threads. The supporting plate is an annular plate, and the lower surface of the supporting plate includes a smoothly spherical groove. The smoothly spherical top in the upper portion of the screw can be placed in the smoothly spherical groove, and is connected to thesupporting plate via an L-shaped connecting piece. When transformation equipment inclines due to non-uniform settlement of a building, the pedestal can be used to rectify the transformation equipment.

Owner:NANJING UNIV OF TECH

Technical yarns, textile fabric and use

InactiveCN101285226AReduced number of jointsFew jointsMonocomponent polyethers artificial filamentContinuous wound-up machinesYarnEngineering

The invention discloses an industrial yarn and an industrial fabric as well as a use thereof. Yarn is the yarn which is made from a raw material of heat resistant fiber, after the yarn is weaved, the joint number of the yarn in a fabric is below 10 / 100m2. Tensile strength of the fabric, of which the longitude direction is above 500 N / 5cm based on JIS L 10968.12.1A law, and the fabric is applied in the filtering material field and a reinforcement fabric of non-woven fabric. The invention has the advantages of reducing the joint number of the yarn, reducing unevenness of yarn twist, improving strength of the fabric and stability of ventilation degree value and improving overall performance of the finished product.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

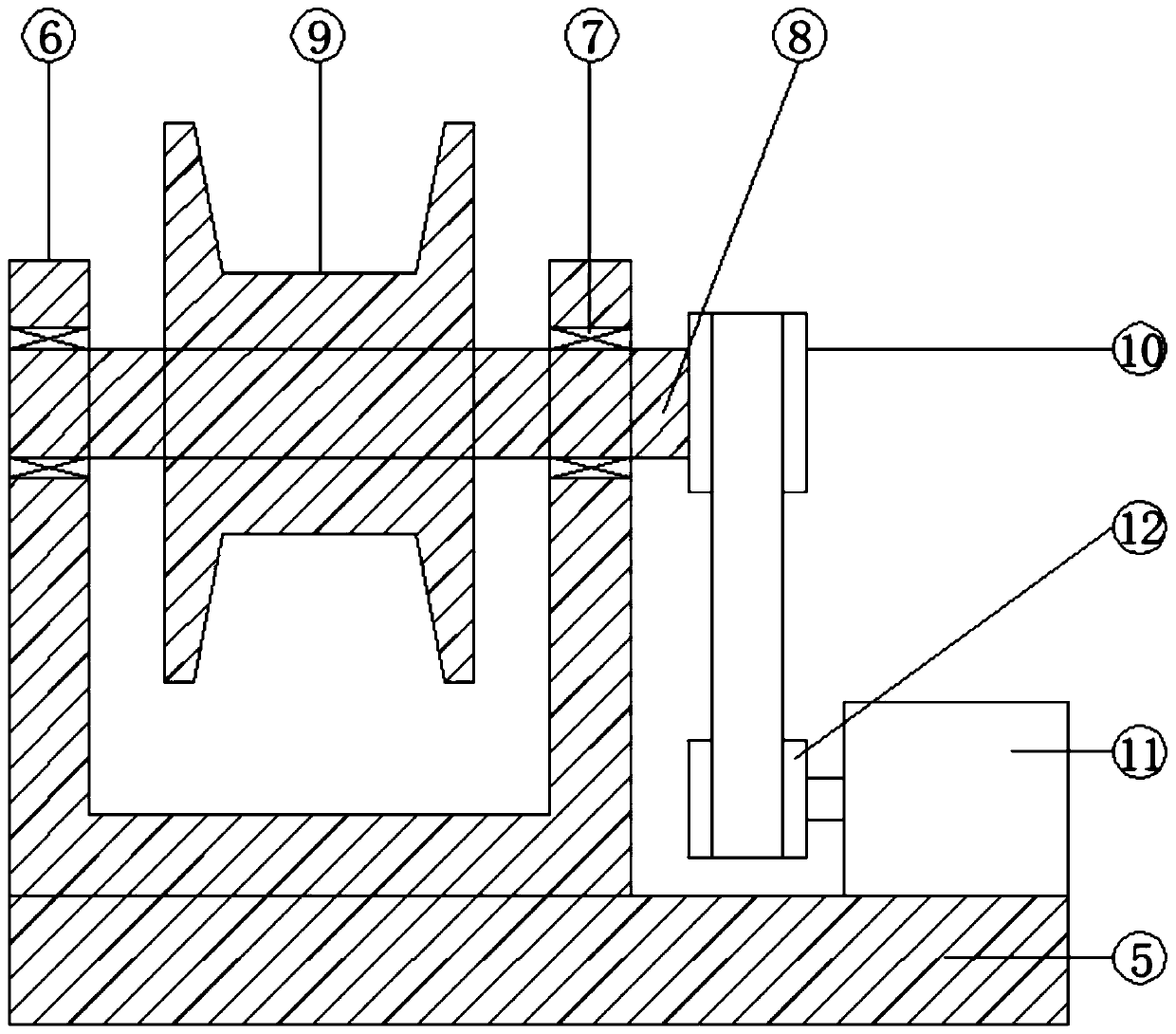

Twisting adjusting device of rope twisting machine

The invention discloses a twisting adjusting device of a rope twisting machine. The twisting adjusting device comprises a base on which a tension adjusting device, an angle adjusting device, a die orifice, a longitudinal clamping device, a transverse clamping device and a rolling device are sequentially arranged from left to right; the tension adjusting device comprises a first rotary table and asecond rotary table, three mounting plates are fixedly arranged between the first rotary table and the second rotary table, and equidistantly arranged along a circumference direction of the first rotary table; and a first mounting bracket is fixedly arranged on one end, close to the first rotary table, of each mounting plate. The twisting and adjusting device disclosed by the invention has the advantages that a pressure sensor can be used for detecting the pressure on an arc limiting slide rail by each strand, the payoff speed can be adjusted according to a pressure value, so that the pressurevalues on the arc limiting slide rail by three strands remain the same, namely, the tensions of three strands are same, a disk can remain the same of included angles between the three stands and a center shaft, so that the twisting in the rope-forming of the strands is uniform, and the strength of a steel wire rope is greatly improved.

Owner:嘉善精田精密机械股份有限公司

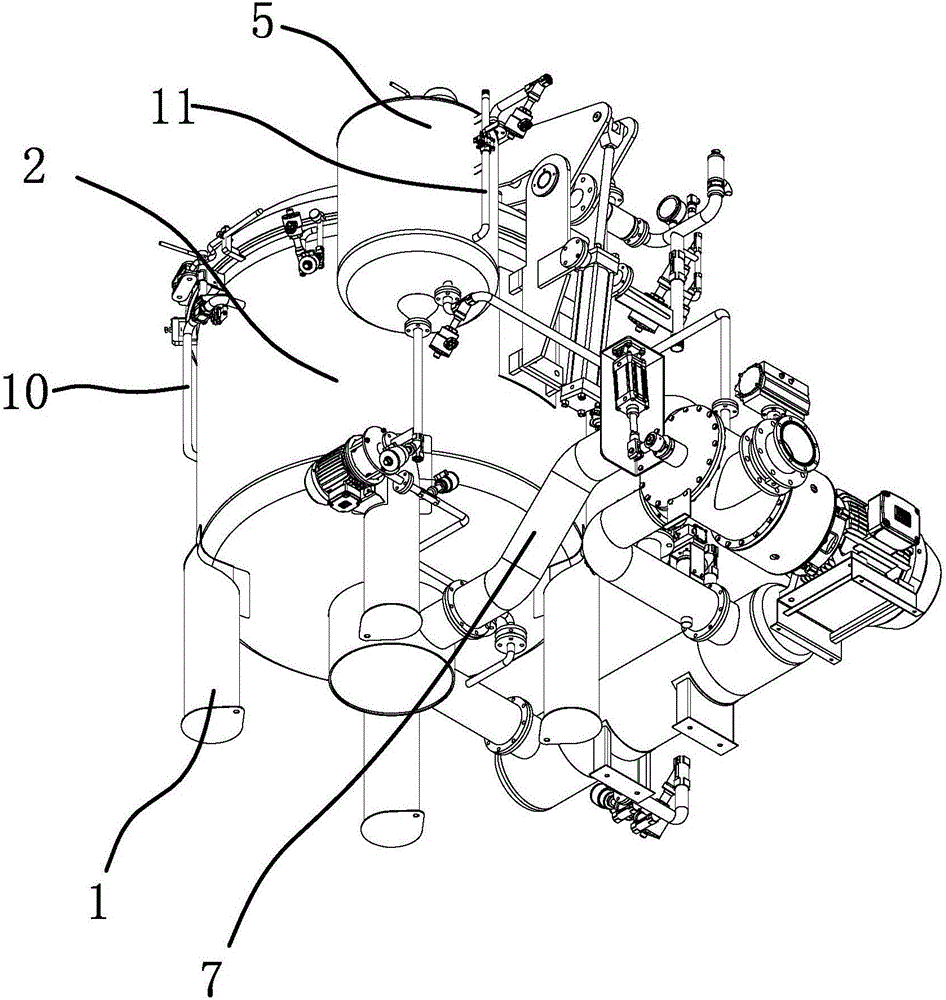

Yarn dyeing method

ActiveCN105821613AImprove efficiencyLower liquor ratioTextile treatment containersTextile treatment machine arrangementsRing dyeingDye injection

The invention provides a yarn dyeing method, and belongs to the technical field of textile related equipment. The technical problems that for an existing dyeing method, the dyeing efficiency is low, and dyeing is inconvenient are solved. The yarn dyeing method comprises the steps of 1, yarn preparation and inspection, wherein the yarn quality is inspected before yarn dyeing is conducted, and it is required that the appearance of yarns is clean and free of stain, the yarns are neutral, the stacking time must not be over 8 h, and the yarns are covered with wet cloth; 2, feeding, wherein yarns are put into a dye vat and arranged on a yarn dyeing rod; 3, dye preparation, wherein anthraquinone vat dye is prepared in a dye barrel, 5 g-6 g of caustic soda and 5-6 g of rongalite are added according to each part by mass of raw material with an anthraquinone type structure, water is injected to obtain a solution, and 0.2 g / L-0.5 g / L of bone glue retarding agent is added; 4, dye injection and dyeing, wherein the prepared dye is injected into the dye vat; 5, yarn taking-out. The yarn dyeing method has the advantages of being high in dyeing efficiency and uniform in dyeing, and the yarns subjected to dyeing is fluffy and full in hand feeling.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

Cylindrical jacket, jacket hose, suction hose, and cylindrical jacket manufacturing apparatus

InactiveUS20060162954A1Small pressure lossEven twistCircular loomsFlexible pipesEngineeringMechanical engineering

Owner:SAKURA GOMME KK

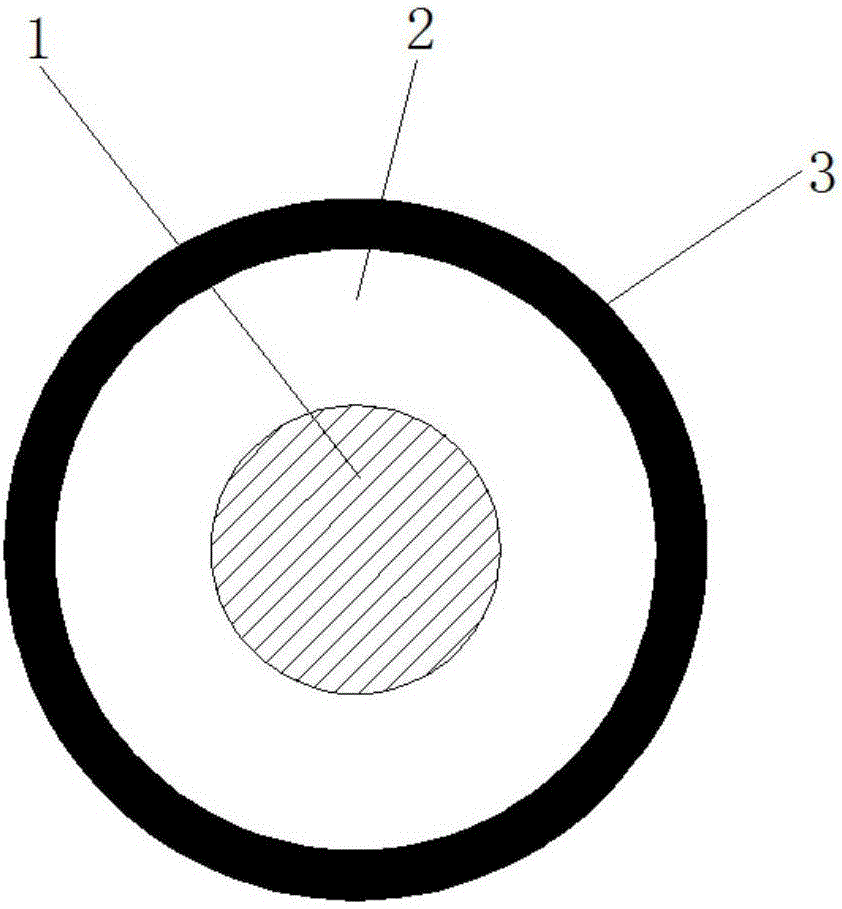

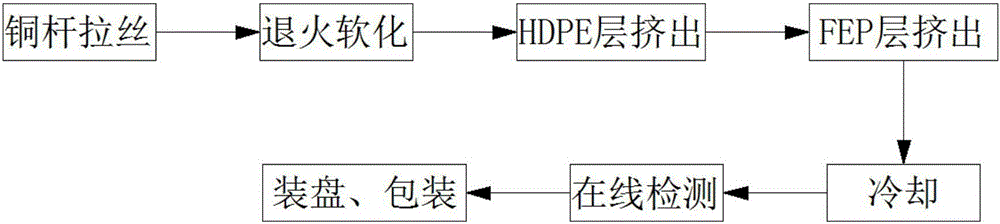

Insulated core wire, high-fire-retardant data cable and processing craft thereof

InactiveCN106782860AHigh temperature resistanceCan stop the spreadPlastic/resin/waxes insulatorsClimate change adaptationElectrical conductorInsulation layer

The invention provides an insulated core wire, a high-fire-retardant data cable and the processing craft thereof, particularly relates to the technical field of the cables and cords. The insulated core wire comprises a conductor wherein the periphery of the conductor covers an inner insulation layer and an outer insulation layer in turn along the radial direction. The inner insulation layer is the HDPE insulation layer and the outer insulation layer is the FEP insulation layer, which solves the technical problem of the low of the insulated core wire temperature grade and flame retardant grade in the prior art and is capable of greatly improving the temperature grade and flame retardant grade of the cables. And the data cable owns the technical effects of higher security transfer property and fireproof performance.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

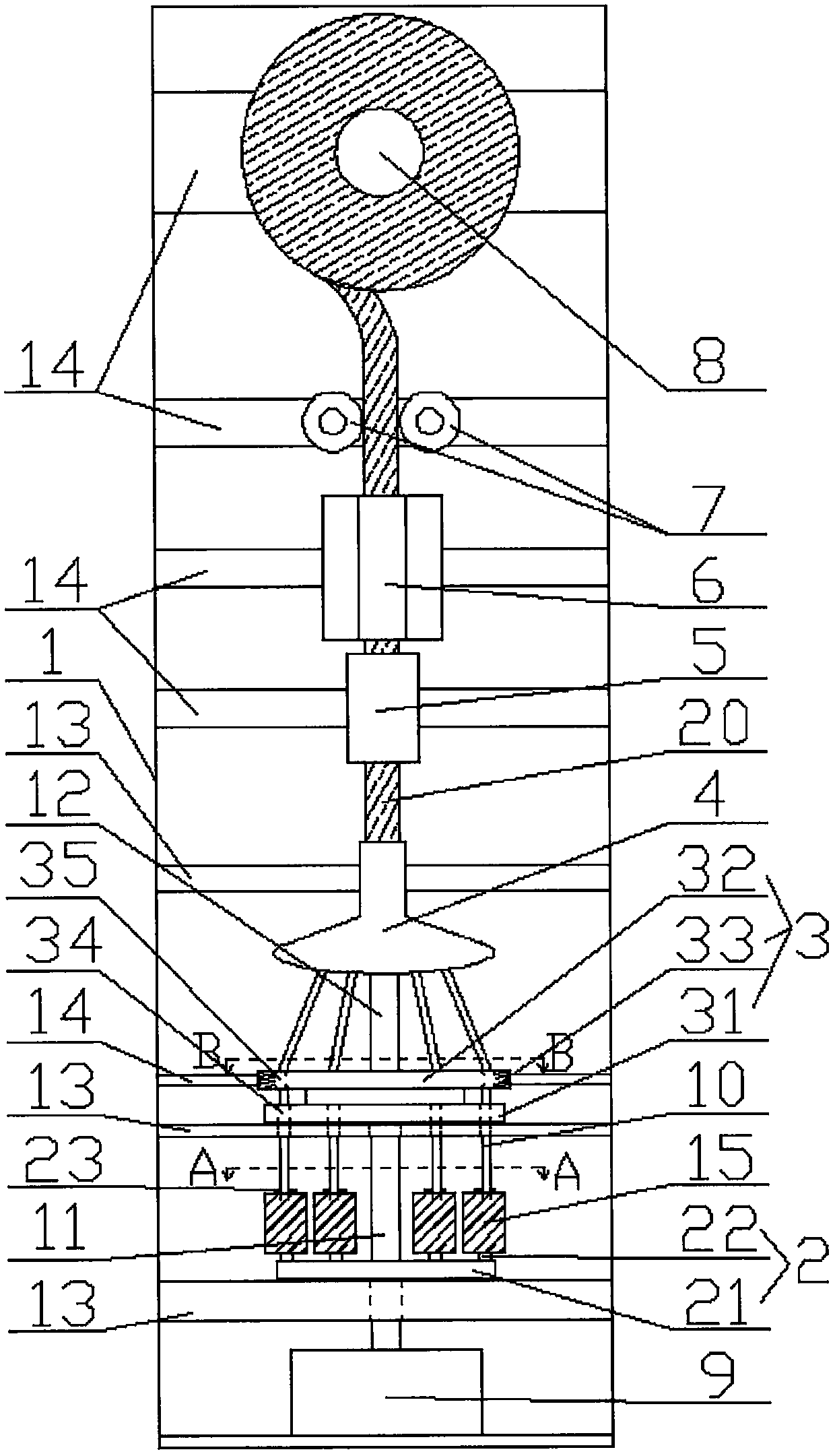

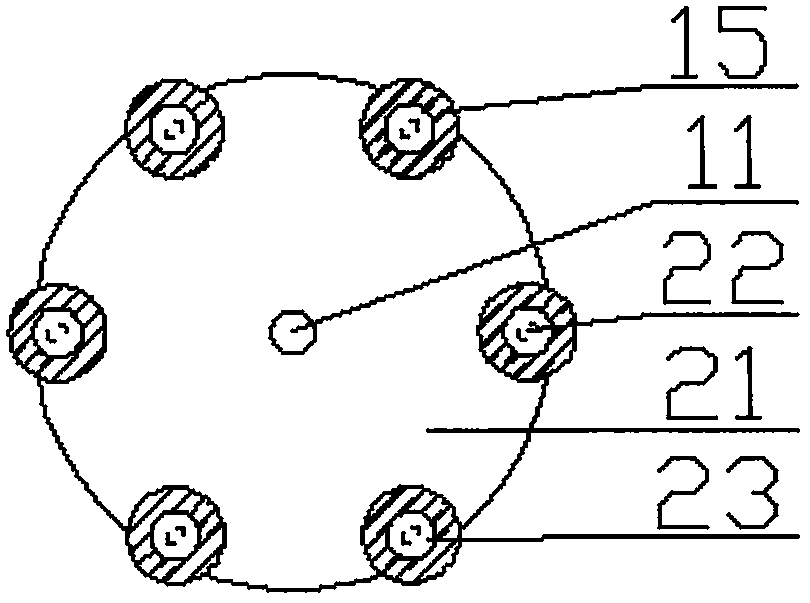

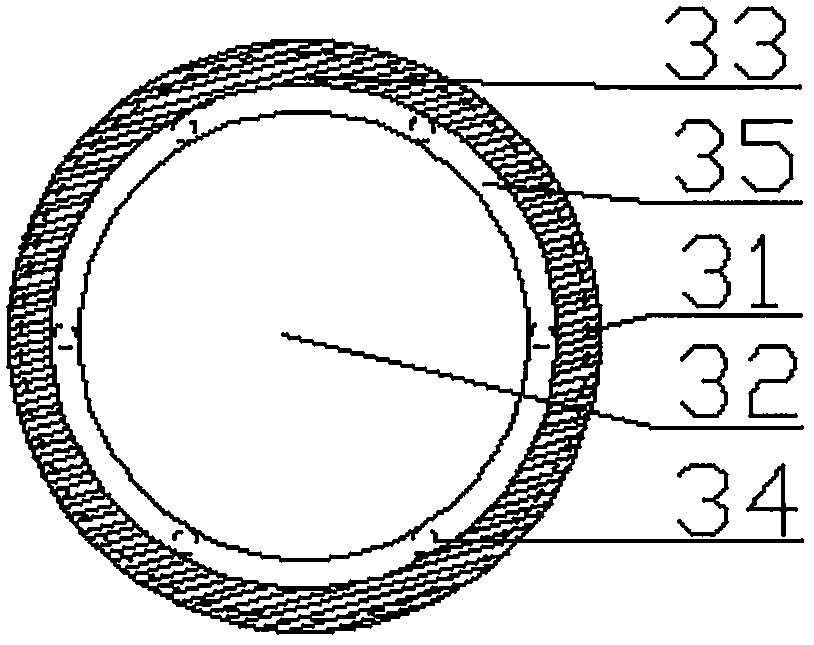

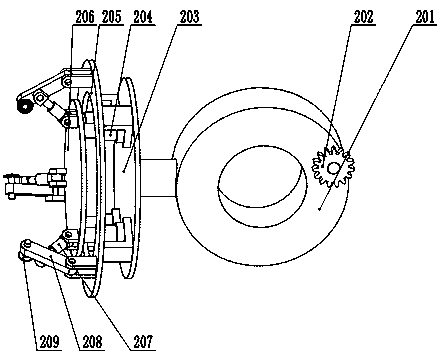

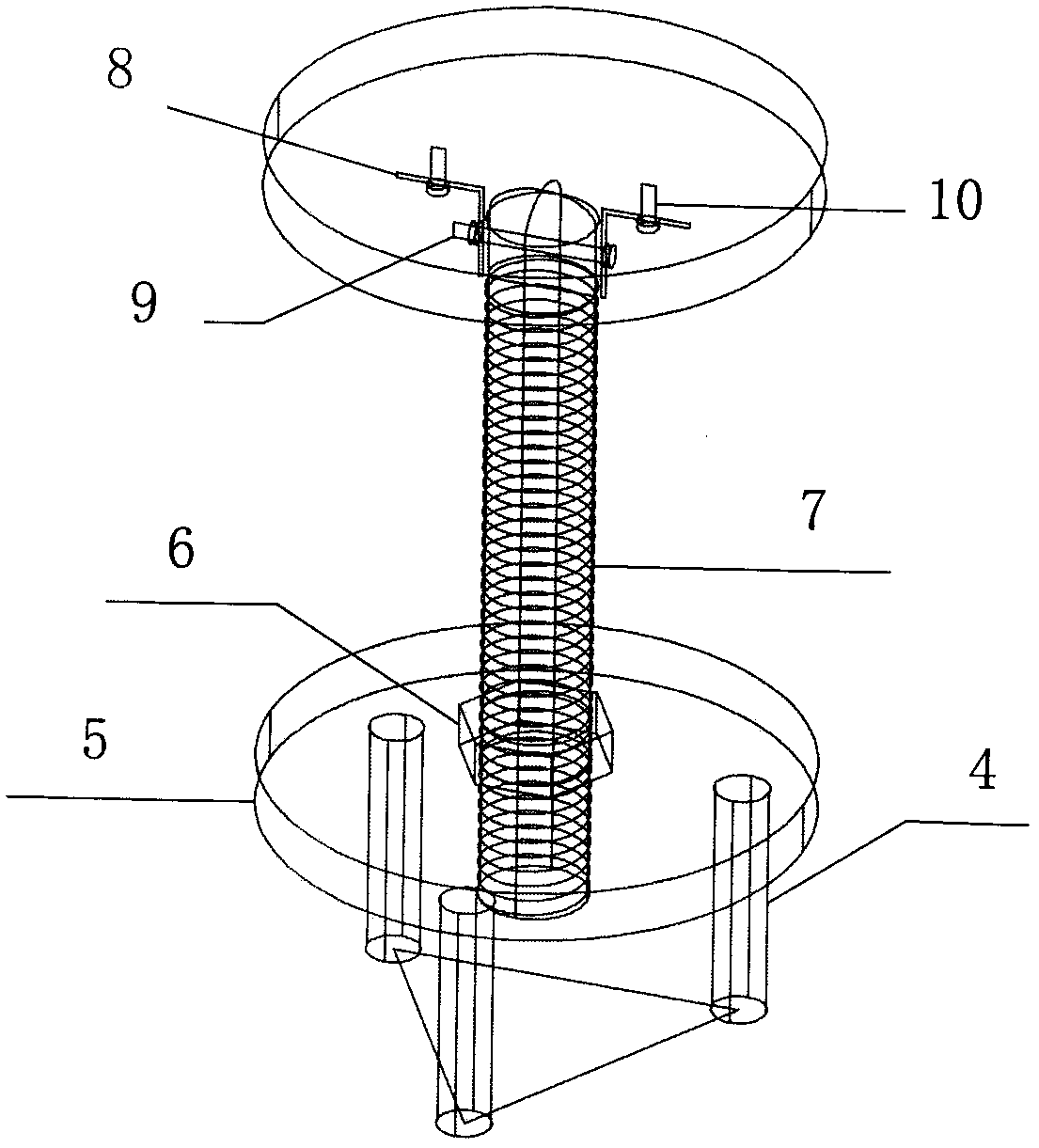

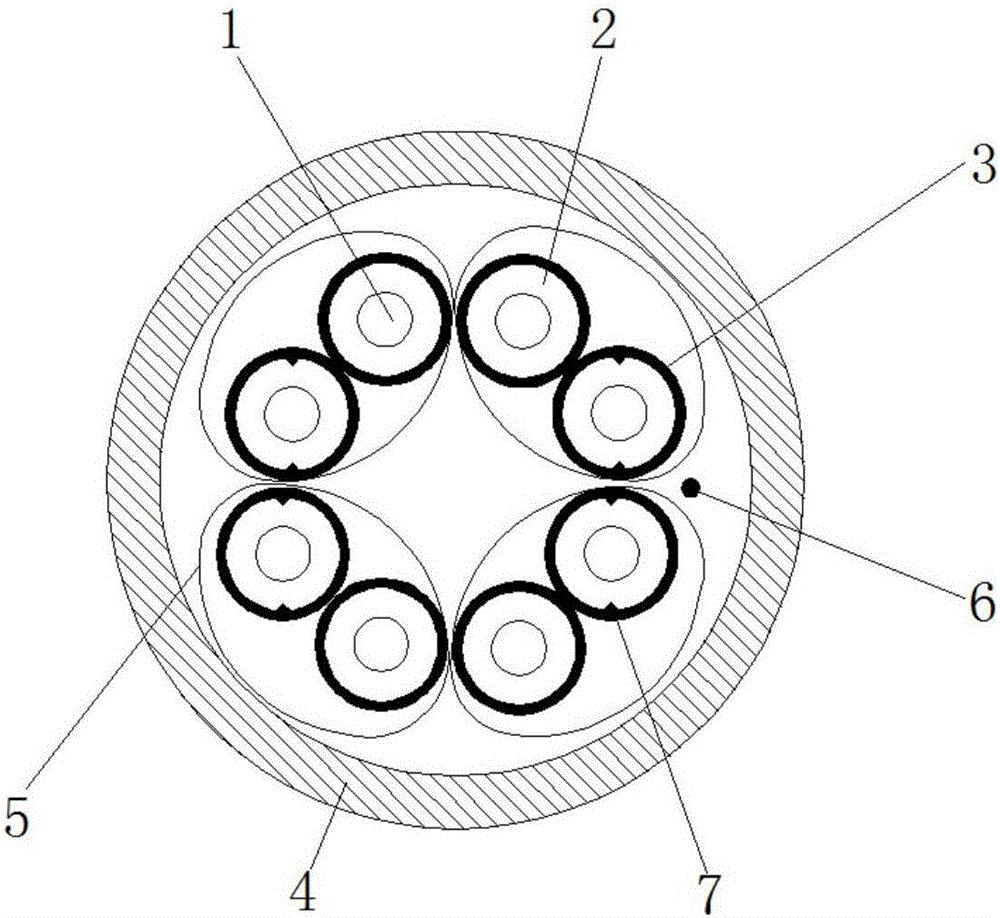

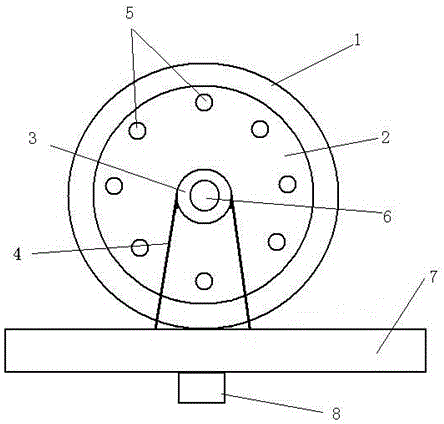

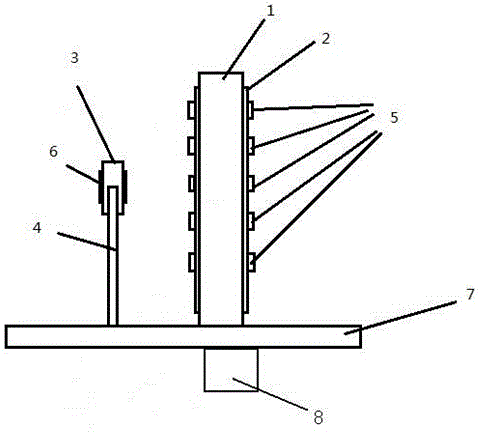

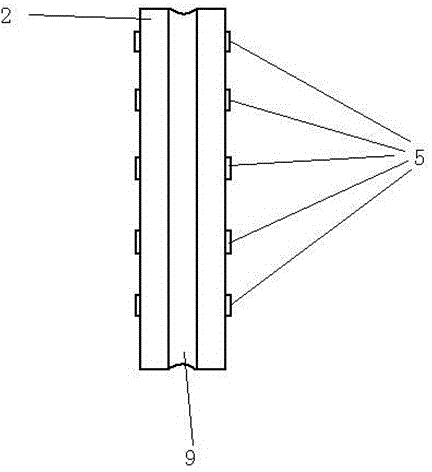

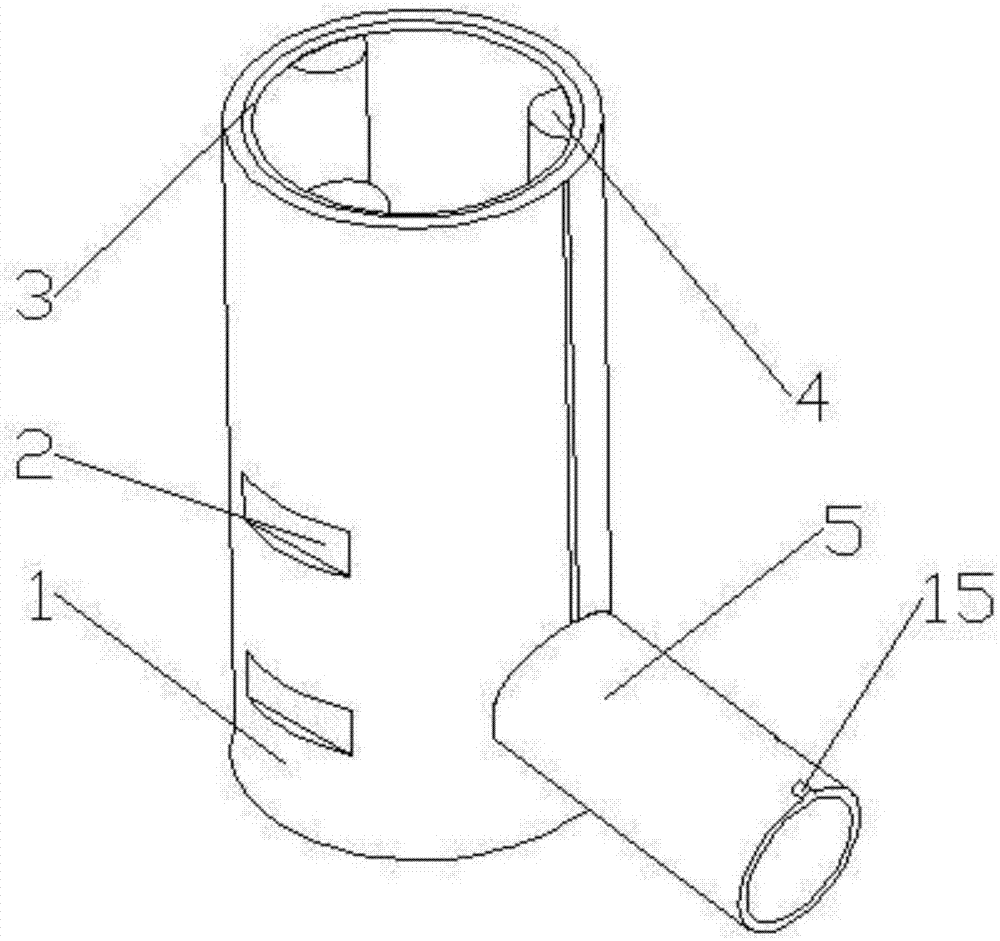

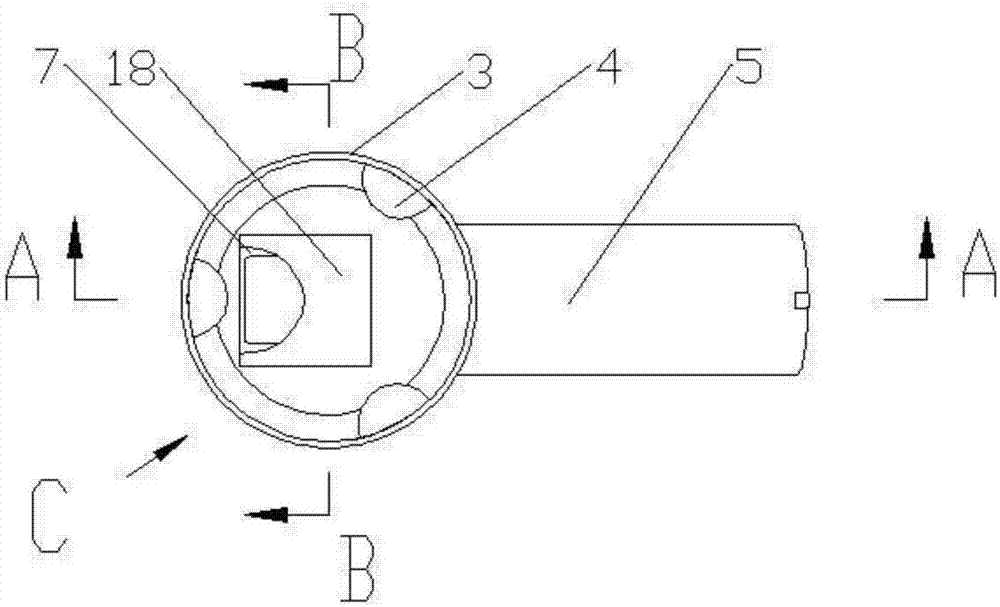

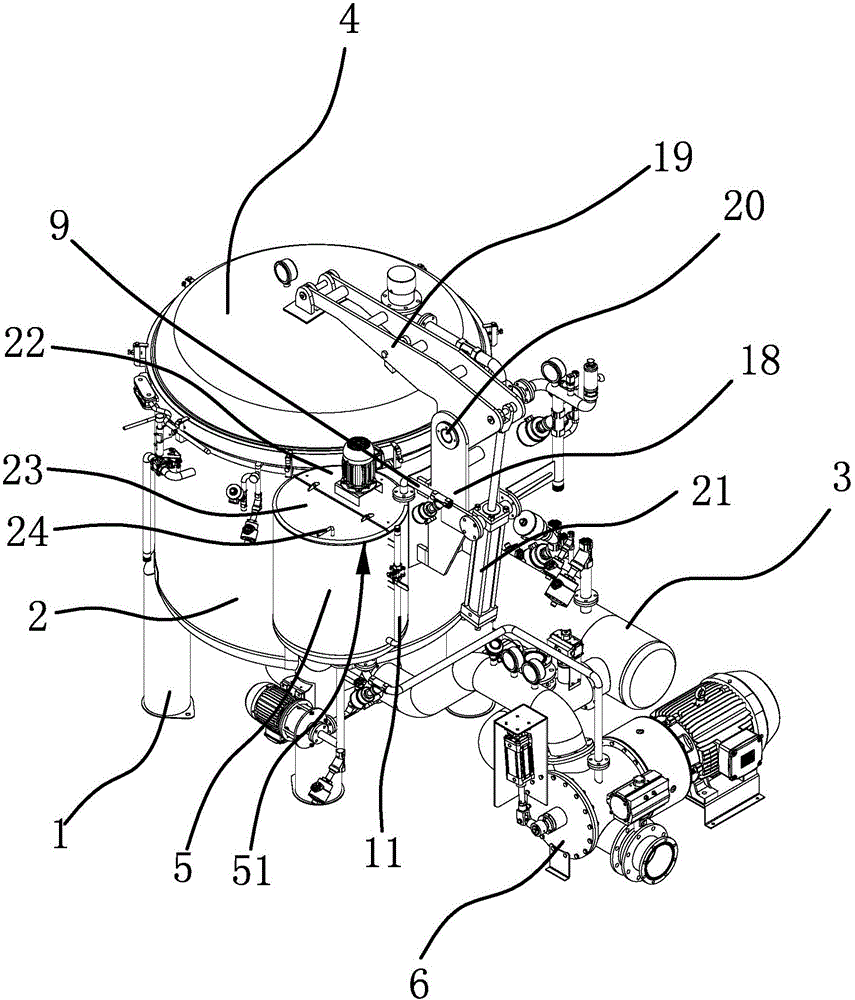

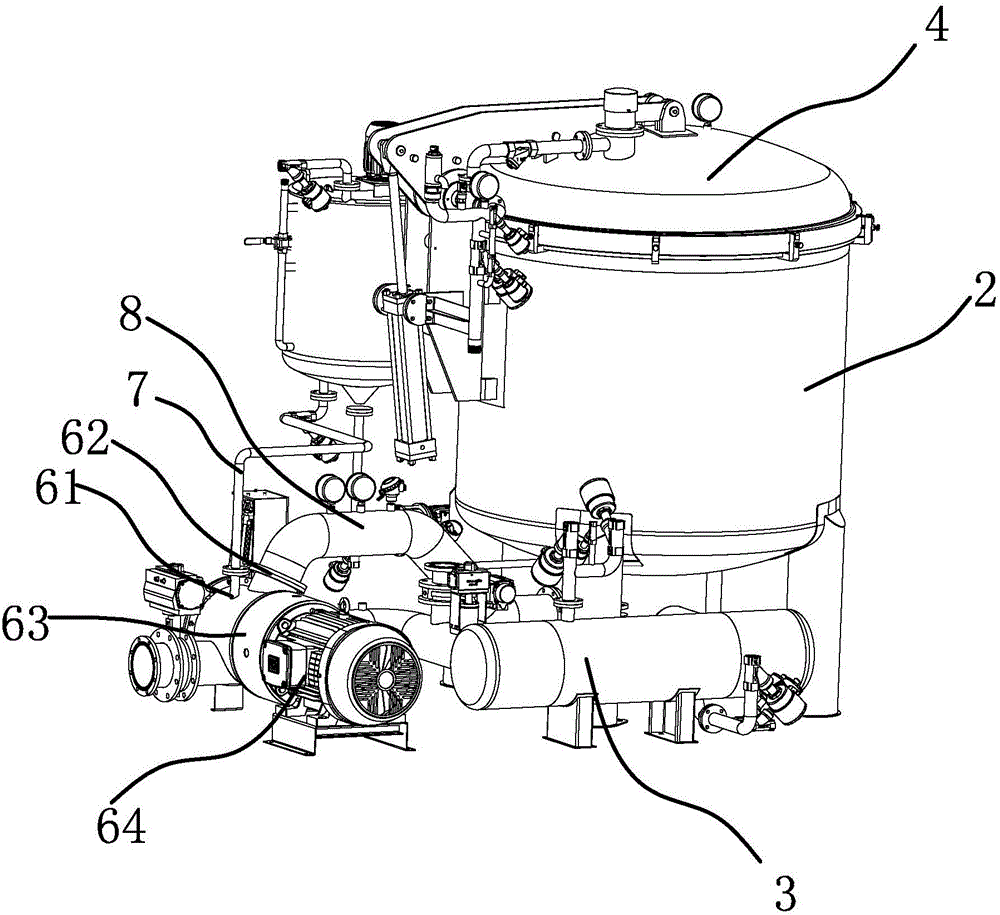

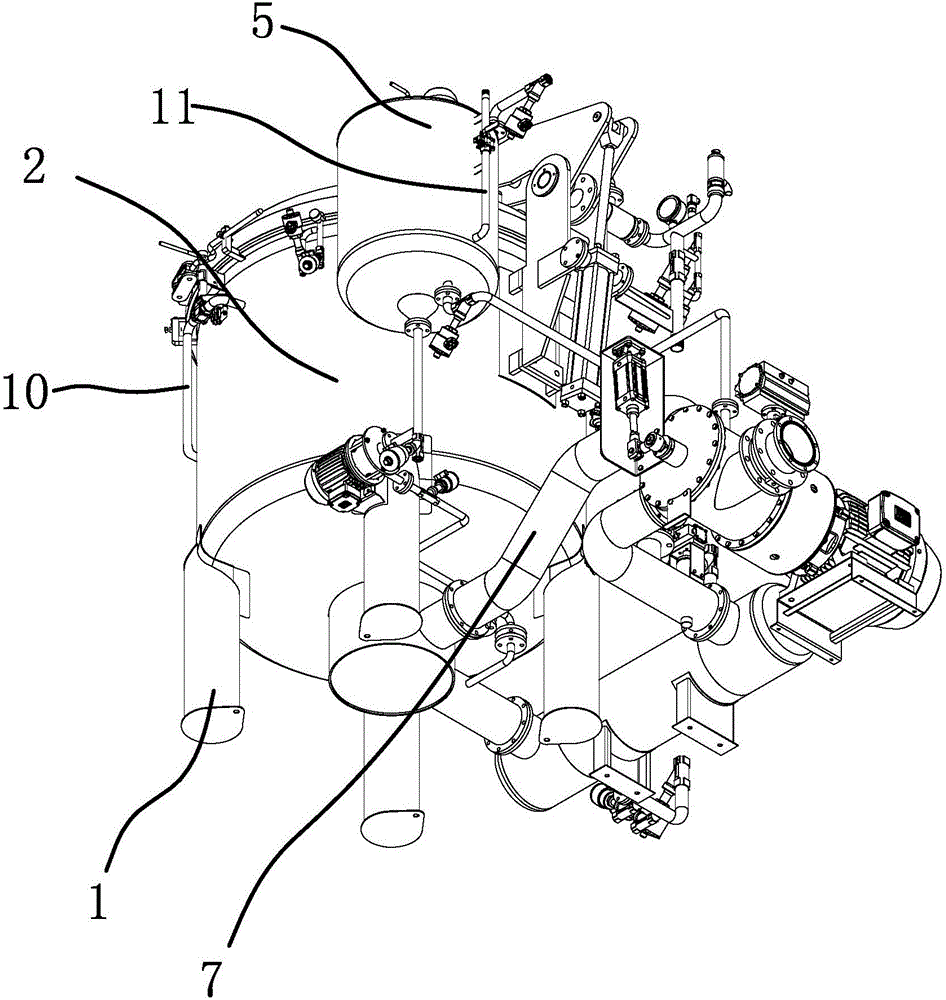

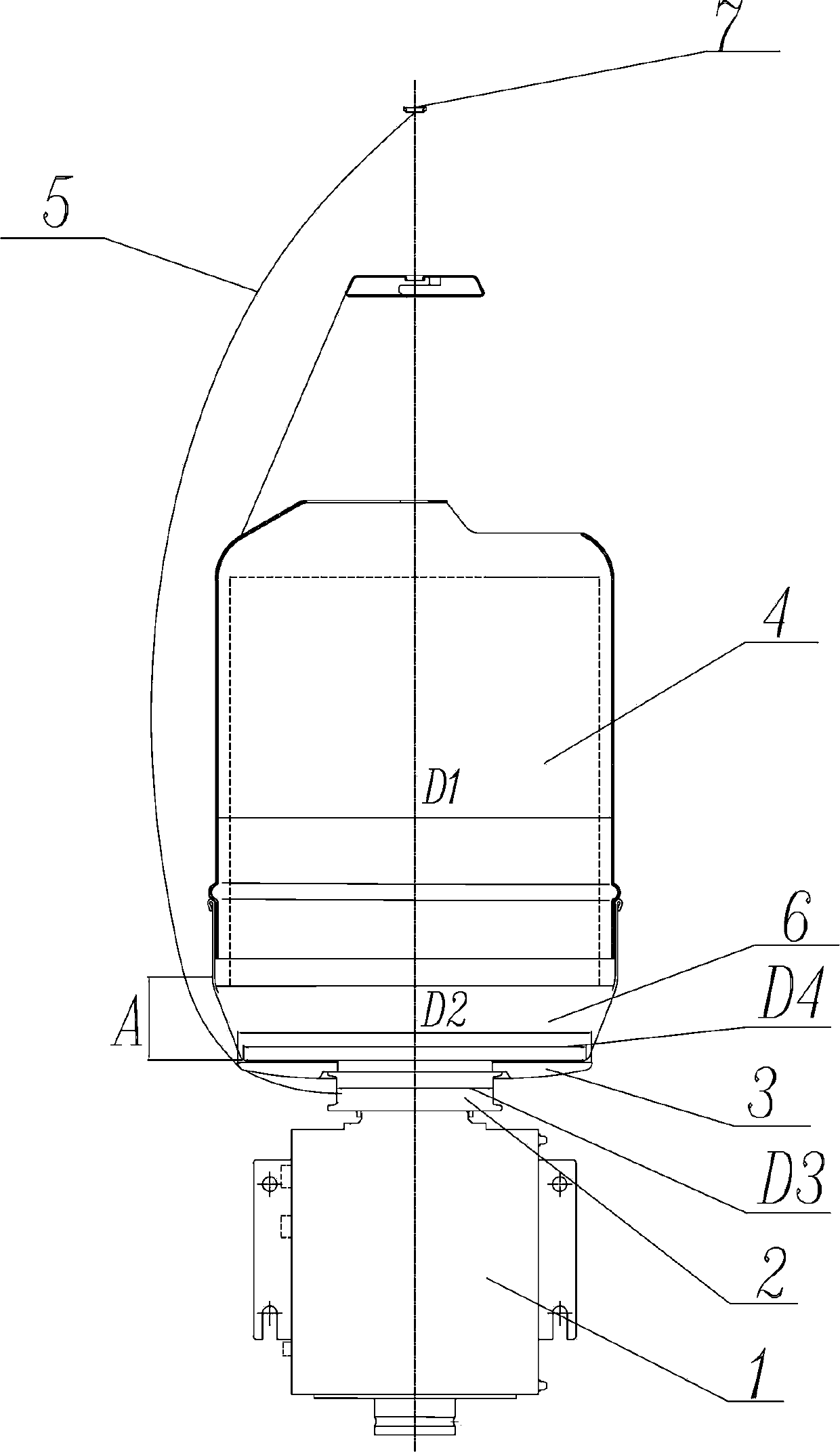

Cable line stranding device

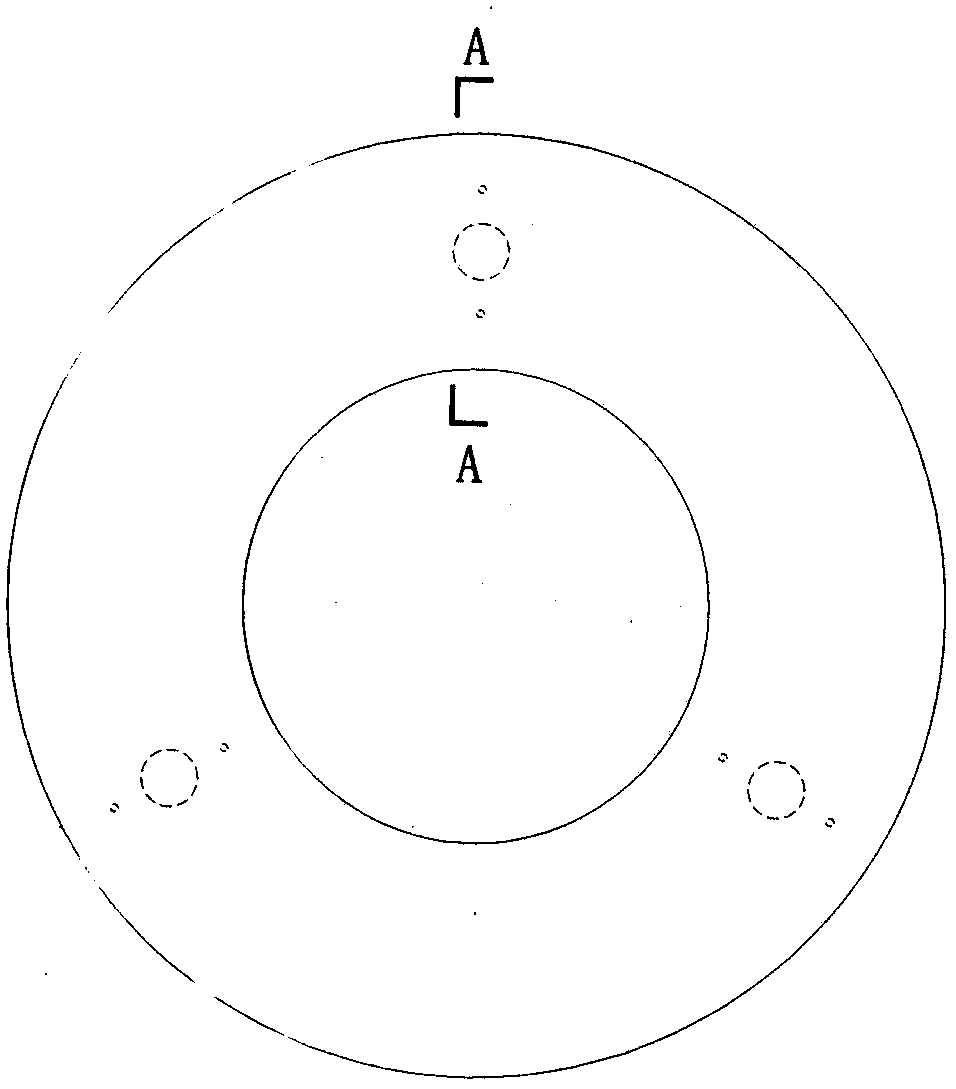

The present invention discloses a cable line stranding device. The cable line stranding device comprises a circular bearing sleeve (1), a disc (2), a line-outgoing coil (3), a line-outgoing coil support (4), a support platform (7) and a motor (8). The motor (8) is located at the lower portion of the support platform (7), and the disc is embedded in the circular bearing sleeve (1); and the circular bearing sleeve (1) is vertically disposed at the upper surface of the support platform (7), and the line-outgoing coil (3) is installed at the top end of the line-outgoing coil support (4) and is in parallel with the disc (2). According to the invention, a motor is configured to drive the rotation of a disc, single lines shunted to each disc hole are stranded, so that the softness and the integrity of cable lines are improved, the wires may be uniformly and rapidly stranded together and the production processing efficiency and the quality of the cable lines are improved.

Owner:程友根

Building construction cable rack based on reciprocating rotation

InactiveCN112456233ANot to be brokenSave yourself the hassleFilament handlingCable installation apparatusArchitectural engineeringElectric cables

The invention relates to the technical field of building construction, in particular to a building construction cable rack based on reciprocating rotation. The building construction cable rack comprises a cable stranding rack, a stranding device is arranged in one end of the cable stranding rack, a cable limiting device is arranged at the position, close to the top, in the cable stranding rack, and a side pulling device is arranged at the end, away from the stranding device, of the cable stranding rack. The twisting device comprises two circular stranding discs, multiple cylindrical winding columns are fixedly connected to the side wall between the two stranding discs in an annular arrangement manner, the cable limiting device comprises two middle limiting devices which are symmetrically arranged up and down, and side limiting devices are arranged on the two sides of the two middle limiting devices. The side pulling device comprises a side pulling fixed shell, sliding fixed devices arearranged at the upper end and the lower end of the side pulling fixed shell in a bilateral symmetry manner, and a side pulling driving device is arranged in the side pulling fixed shell. The buildingconstruction cable rack mainly solves the problem that when a cable is hooked and is not easy to pull, the cable is prone to being damaged when the cable is stranded by the stranding discs.

Owner:成月香

Twisting method of natural yarn blending, twisting weaving method and twisting device

PendingCN108221171AReduced time required for twisting processAvoid delivery delaysYarnBraidYarnBody shape

The invention discloses a twisting method of natural yarn blending. A second yarn which is wound by coils is uncoiled around at least one first yarn to twist, and is twisted into a twisted yarn. The invention also discloses a twisting weaving method of the natural yarn blending using the method, and a twisting device of the natural yarn blending for the method. The twisting device comprises a twisting guide body, wherein the twisting guide body is used for supporting the uncoiled to-be-twisted yarn, and is in a rotary body shape; a twisting guide through hole is formed in the twisting guide body, and the other to-be-twisted yarn passes through the twisting guide through hole; one end, corresponding to the twisting guide through hole, of the twisting guide body is a guide-in end, and the other end is a guide-out end; a movable ring is annularly arranged on the guide-out end, and is used for enabling the uncoiled to-be-twisted yarn to uncoil around the twisting guide body. The twisting method has the advantages that the twisted yarn with uniform twisting degree and ideal tension and elasticity can be obtained; the problems of large color difference and the like in the production process of the yarn blending product are relieved; the natural yarn blending and yarn twisting can be directly performed on a weaving machine, the required yarn twisting treatment time is shortened, the delay of delivery is avoided, and the yarn manufacturing cost is reduced.

Owner:SINCETECH FUJIAN TECH CO LTD

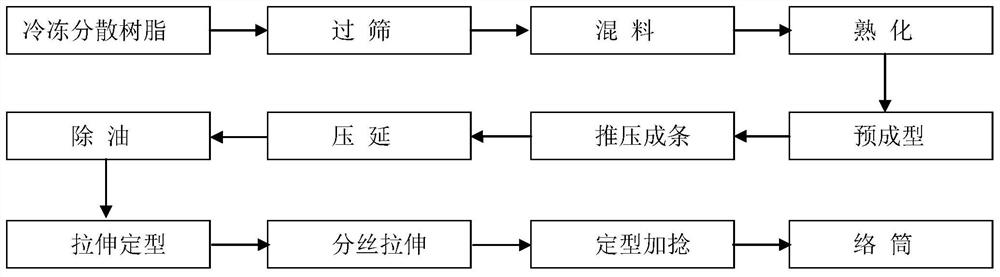

Preparation method of polytetrafluoroethylene ultra-thin filament

ActiveCN113005545AHigh tensile strengthTwist evenlyFilament/thread formingMonocomponent halogenated hydrocarbon artificial filamentCompression moldingPolymer science

The invention belongs to the technical field of polytetrafluoroethylene fiber preparation, and particularly relates to a preparation method of a polytetrafluoroethylene ultra-thin filament. The preparation method comprises the steps of carrying out low-temperature treatment on polytetrafluoroethylene dispersed granules, mixing the treated polytetrafluoroethylene dispersed granules with auxiliary oil, curing, and carrying out compression molding; putting the polytetrafluoroethylene mixture into a pushing and pressing die cavity with the compression ratio of 260, pushing and pressing, and continuously extruding strips to obtain polytetrafluoroethylene material strips; pressing the polytetrafluoroethylene material strips into a film, and performing heat treatment to remove oil; stretching the de-oiled film for multiple times to obtain a polytetrafluoroethylene film; longitudinally cutting the polytetrafluoroethylene film into a plurality of flat filaments, heating and stretching, preparing the obtained filaments into round filaments in a secondary twisting manner, performing twisting and setting while quickly cooling, and finally winding the filaments on a shaft through a winding drum to prepare the polytetrafluoroethylene ultra-thin filament. The polytetrafluoroethylene ultra-thin filament prepared by the preparation method disclosed by the invention is high in strength, uniform in linear density, free of burrs and low in shrinkage rate.

Owner:SHANDONG SENRONG PLASTIC IND TECH

High-efficiency yarn dyeing device

InactiveCN110670279AFree relaxationFully relaxTextile treatment machine arrangementsLiquid/gas/vapor treatment of definite length materialsYarnSpinning

The invention discloses a high-efficiency yarn dyeing device, which comprises a dyeing bin, a dyeing liquid box and spraying pipes; a driving motor is mounted on the dyeing bin, one side of the driving motor is in transmission connection with a driving shaft through a belt and a pulley, and the driving shaft is erected on a platform through a first bearing block and a bracket. In the invention, the plurality of spraying pipes for hanging yarns are arranged inside the dyeing bin; the driving shaft which is in transmission connection via the belt and the belt pulley is driven to rotate by the driving motor; a worm arranged on the driving shaft is in transmission connection with a turbine mounted on hollow shafts; the spraying pipes connected with the hollow shafts in a one-to-one correspondence mode rotate synchronously, and a dyeing liquid is sprayed onto yarns through nozzles to uniformly dye the yarns; the manner of synchronously driving multiple spraying pipes to rotate for dyeing helps improve dyeing efficiency of the device, and allows the yarns suspended on the spraying pipes to be freely untwisted until the twist is balanced, so that the tension in spinning is eliminated.

Owner:傅全辉

Planet vehicle stabilizing platform

PendingCN111532221AHigh control precisionReliable structureExtraterrestrial carsVehicle componentsPhysicsEngineering

The invention discloses a planet vehicle stabilizing platform. A supporting frame is arranged on a planet vehicle; a first adapter piece is rotatably connected to the supporting frame through a firstrotating shaft; a second adapter piece is rotatably connected to the first adapter piece through a second rotating shaft, and the first rotating shaft is perpendicular to the second rotating shaft; amovable platform is rotatably connected to the second adapter piece through a third rotating shaft, and the third rotating shaft is perpendicular to the second rotating shaft; a first driving device drives the movable platform to rotate around the first rotating shaft; the second driving device drives the movable platform to rotate around the second rotating shaft; the third driving device drivesthe movable platform to rotate around the third rotating shaft; and a stable object is arranged on the movable platform, and when the planet vehicle is unstable, the movable platform is driven to rotate around one or more of the first rotating shaft, the second rotating shaft and the third rotating shaft to restore to an initial position so that the stable object is kept stable. According to the stabilizing platform, the three driving devices are connected in parallel to drive the movable platform to rotate around the three shafts to counteract shaking, the stable object is kept stable, control precision is high, and a structure is stable and reliable.

Owner:SHANGHAI AEROSPACE SYST ENG INST

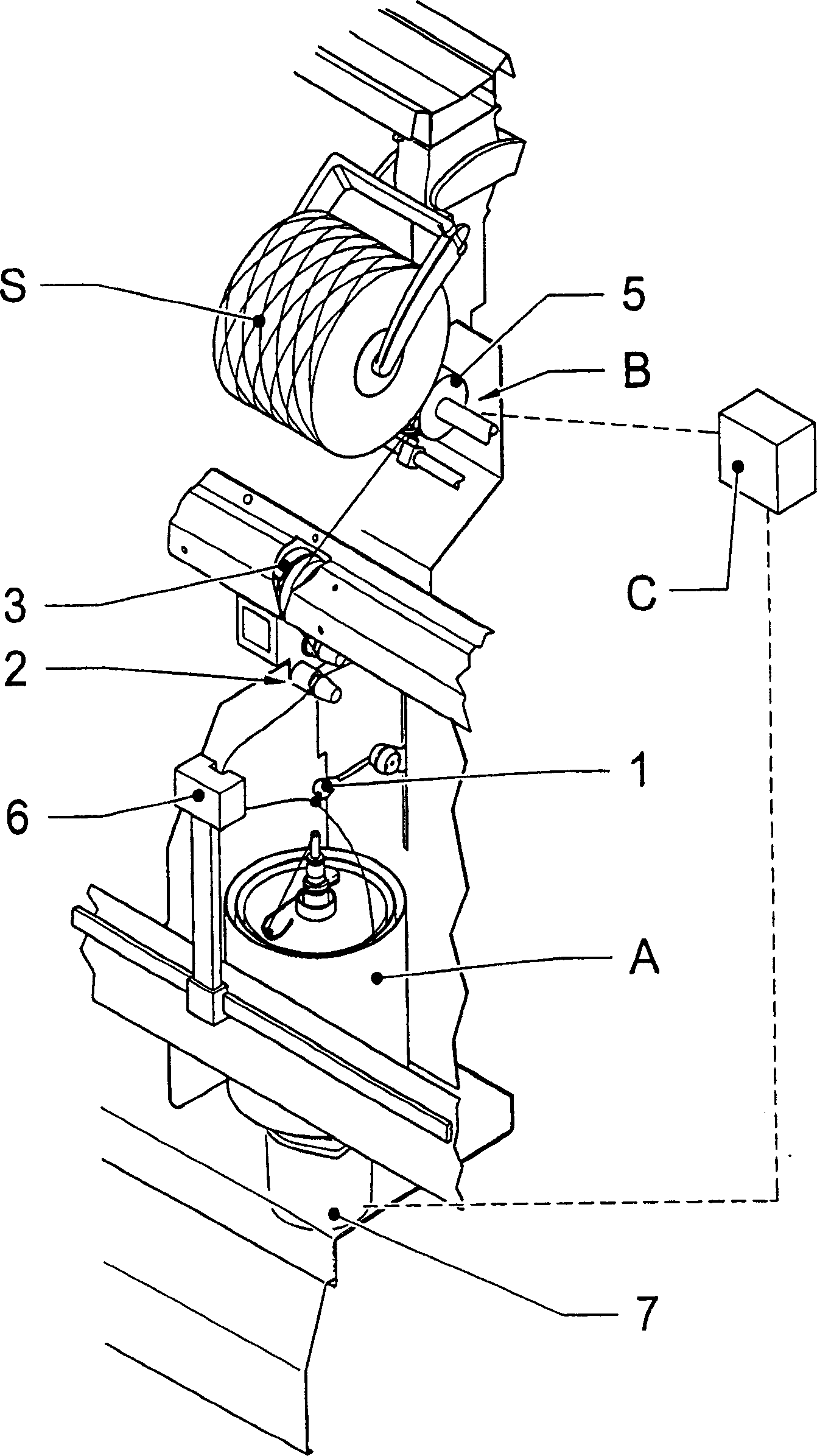

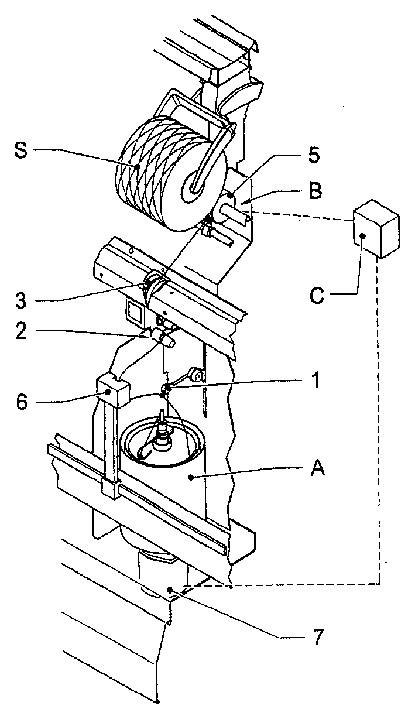

Method for restarting twisting device after end breaking of yarn

A method for restarting a twisting device comprising a twisting spindle (A) and a winding device (B) after a yarn breakage, in which method the twisted yarn is fed from a drum downstream of the twisting spindle ( S) under unwinding, fix it on a fixed point after twisting the yarn to obtain a yarn section with a complete number of twists, and fix it at a position behind the fixed point, that is, in the fixed position viewed from the groove drum It is cut at such a position after the fixed point, and then the single yarn located behind the fixed point is mechanically or manually knotted or spliced with the spinning end from the twisting spindle, and before that, the winding process It is necessary to delay the start after the re-running of the twisting spindle until the predetermined number of twists for the twisted yarn returns to the fixed point through the knotting position or the splicing position.

Owner:VOLKMANN GMBH & CO KG

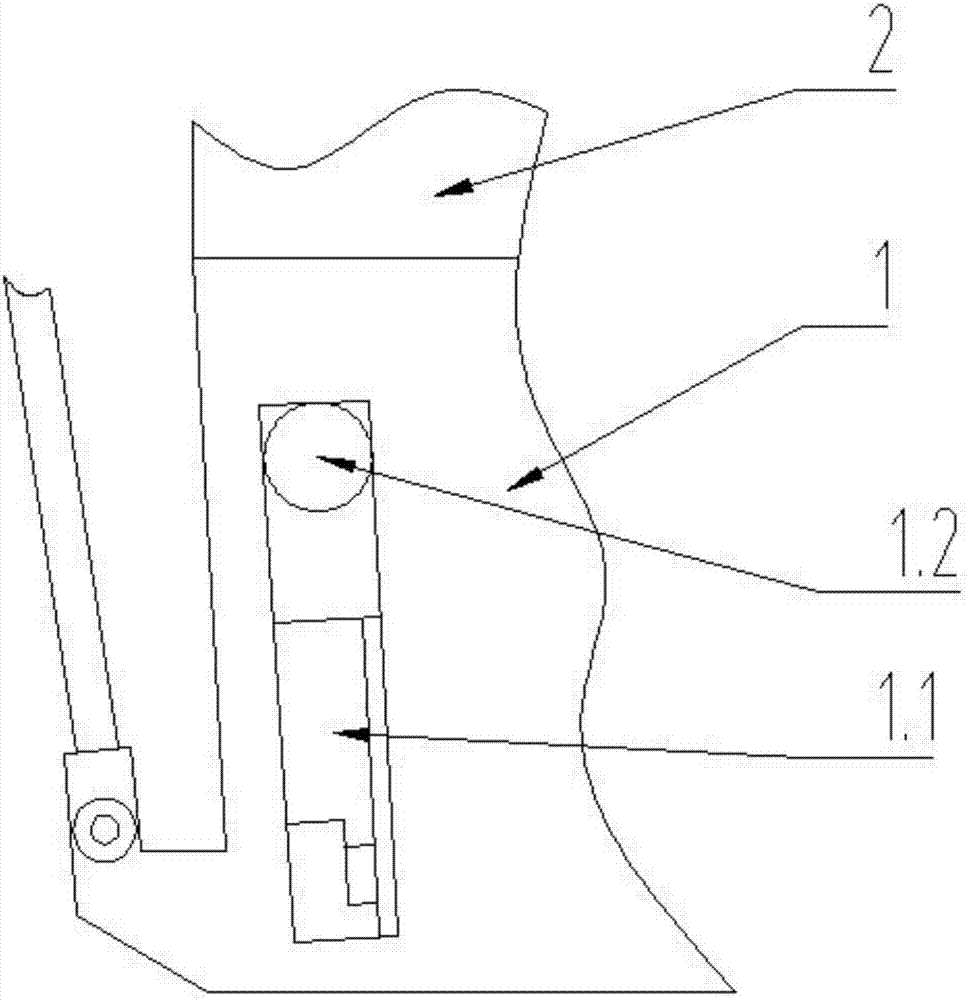

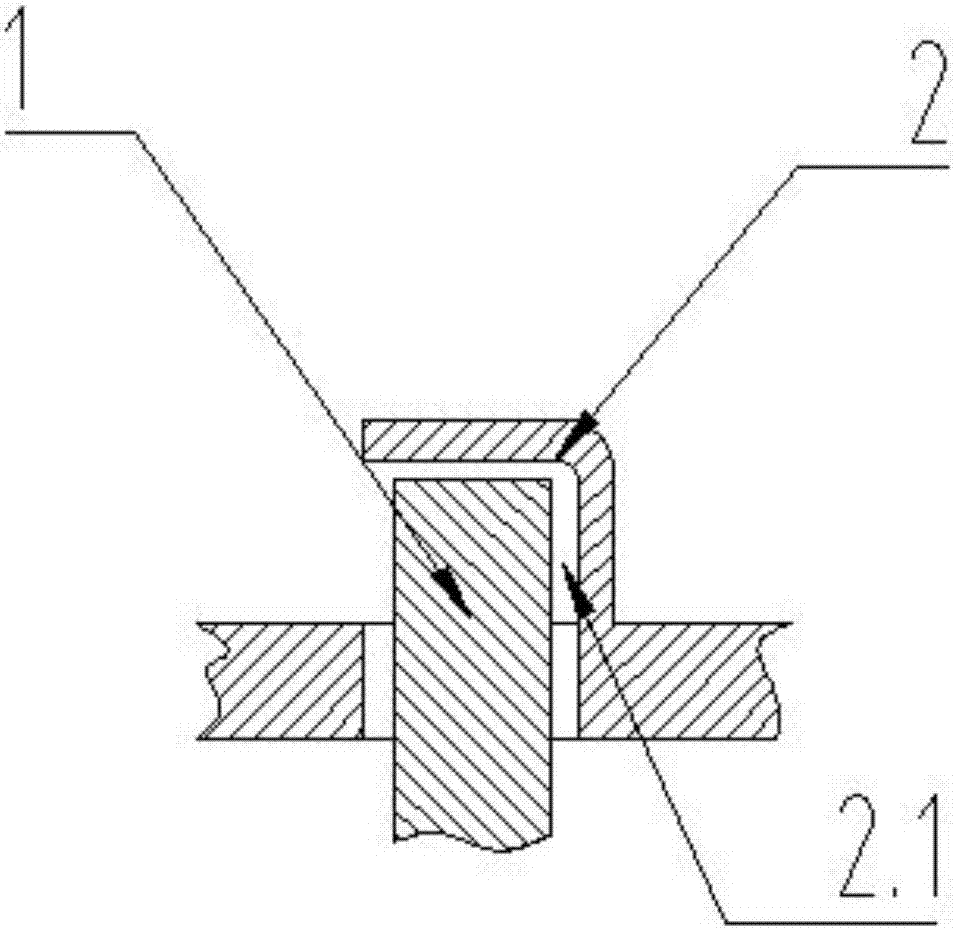

Milling machine floating material receiving device

The invention discloses a milling machine floating material receiving device. The device comprises a floating plate (1) and a hood side plate (2), the two sides of the floating plate (1) are connected with the hood side panel (2) through a hydraulic cylinder, the upper end of the hood side plate (2) is provided with a clamping groove (2.1), the upper end of the floating plate (1) is limited in the clamping groove (2.1), and the device is characterized in that the clamping groove (2.1) is semi-closed, and the width of the clamping groove is larger than the thickness of the floating plate (1); the floating plate (1) is provided with a sliding groove through hole (1.1), the portion where the hood side plate (2) is connected with the sliding groove through hole (1.1) is provided with a guide block (1.2), and the floating plate (1) floats up and down along the guide block (1.2); the inclined angle of the vertical guide surface of the sliding groove through hole (1.1) in the driving direction of a milling machine ranges from 7 degrees to 12 degrees. Accordingly, improvement is conducted on the original basis, the phenomena that materials are stacked in a slideway gap, and the floating plate is jammed are avoided.

Owner:侯忠备

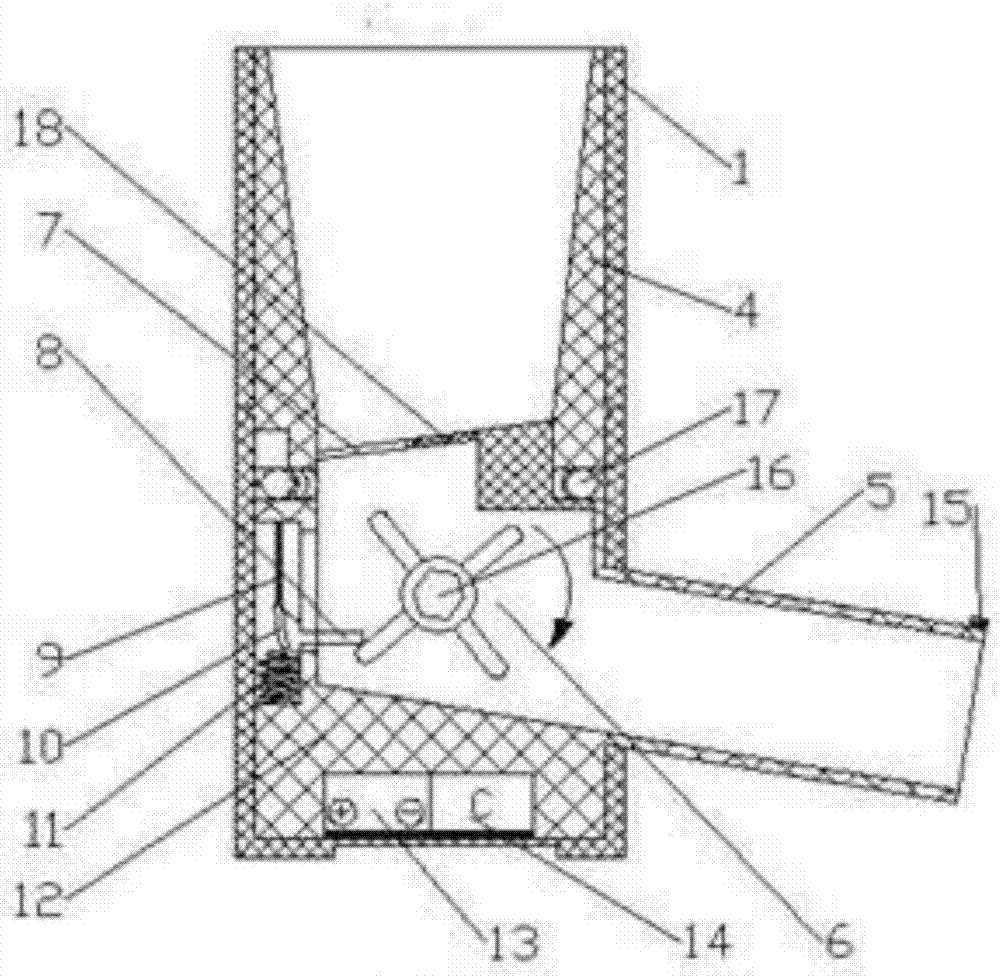

Large granular food feeder for people with impaired upper limbs and working method thereof

ActiveCN107157687AReduce complexityImprove liquidityDwelling equipmentNursing accommodationManipulatorEngineering

The invention discloses a large granular food feeder for people with impaired upper limbs and a using method thereof. The feeder mainly comprises a cylindrical shell, a cup body, a rubber thumbwheel, a driving device and a reciprocating device for twisting the cup back and forth; the thumbwheel is driven to rotate by the driving device; when the thumbwheel rotates, food leaked out from the bottom of the cup body is sent to a housing conveying nozzle; eating is completed by the disabled coming close to the feeder or by the old / the disabled assisting manipulators. According to the invention, by means of the old / the disabled assisting manipulators, the problem of eating large granular food for people with impaired upper limbs can be effectively assisted; the complexity of operation instruction of the old / the disabled assisting manipulators can be reduced; requirement of functions for the old / the disabled assisting manipulators is reduced; inconvenience of picking up food using spoons, chopsticks or forks with the old / the disabled assisting manipulators can be avoided and the awkward situation of leakage of food during feeding process can be avoided. Chances of self-help feeding are provided for people with impaired upper limbs.

Owner:SHANDONG UNIV OF SCI & TECH

A twisting device with uniform twisting

The invention relates to the technical field of spinning equipment and discloses a twisting device with uniform twisting. The present invention comprises a device main body, one end of the upper end of the device main body is welded and connected with a first support plate, the middle position of the upper end of the device main body is welded and connected with a second support plate, the upper end of the second support plate is screwed with a fixing ring, and the upper end of the device main body is A third support plate is welded to the end of the second support plate away from the first support plate. The present invention can limit the position when twisting yarns of different sizes by setting the twisting disk, so that the device can twist and feed the yarn evenly, so that twisting can be performed more uniformly, and can effectively reduce the The wear and tear of the yarn by the device can be heated by setting the heating mechanism to clean the plush on the yarn, and the yarn can be evenly wound around the winding coil by setting the limit mechanism, thus effectively Avoid the phenomenon that the yarn is tangled into a ball.

Owner:宿迁市正益纺织有限公司

Twisting device capable of uniformly twisting

The invention relates to the technical field of spinning equipment, and discloses a twisting device capable of uniformly twisting. The twisting device comprises a device main body, wherein one end ofthe upper end of the device main body is in welding connection to a first support plate; the middle position of the upper end of the device main body is in welding connection to a second support plate; the upper end of the second support plate is in bolt connection to a fixed ring; and the position, at one end away from the first support plate of the second support plate, at the upper end of the device main body is in welding connection to a third support plate. A twisting disc can be arranged for limiting yarns of different dimensions during twisting, and twists and uniformly takes in yarns,so that twisting can be more uniform, wear, on the yarns, of the device can be effectively reduced; a heating mechanism can be arranged for heating the yarns to clear plush on the yarns; and a limiting mechanism can be arranged for winding the yarns at the peripheral side of a winding ring, so that a phenomenon that the yarns are wound into a cluster is effectively avoided.

Owner:宿迁市正益纺织有限公司

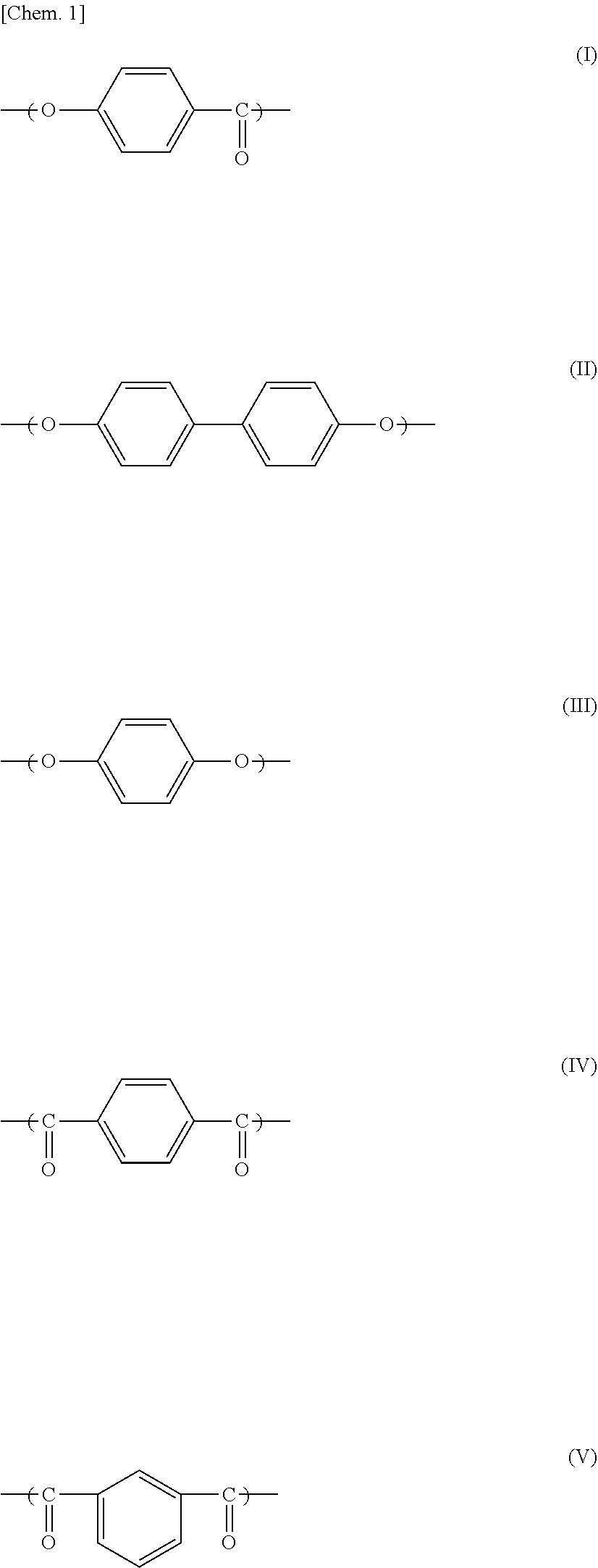

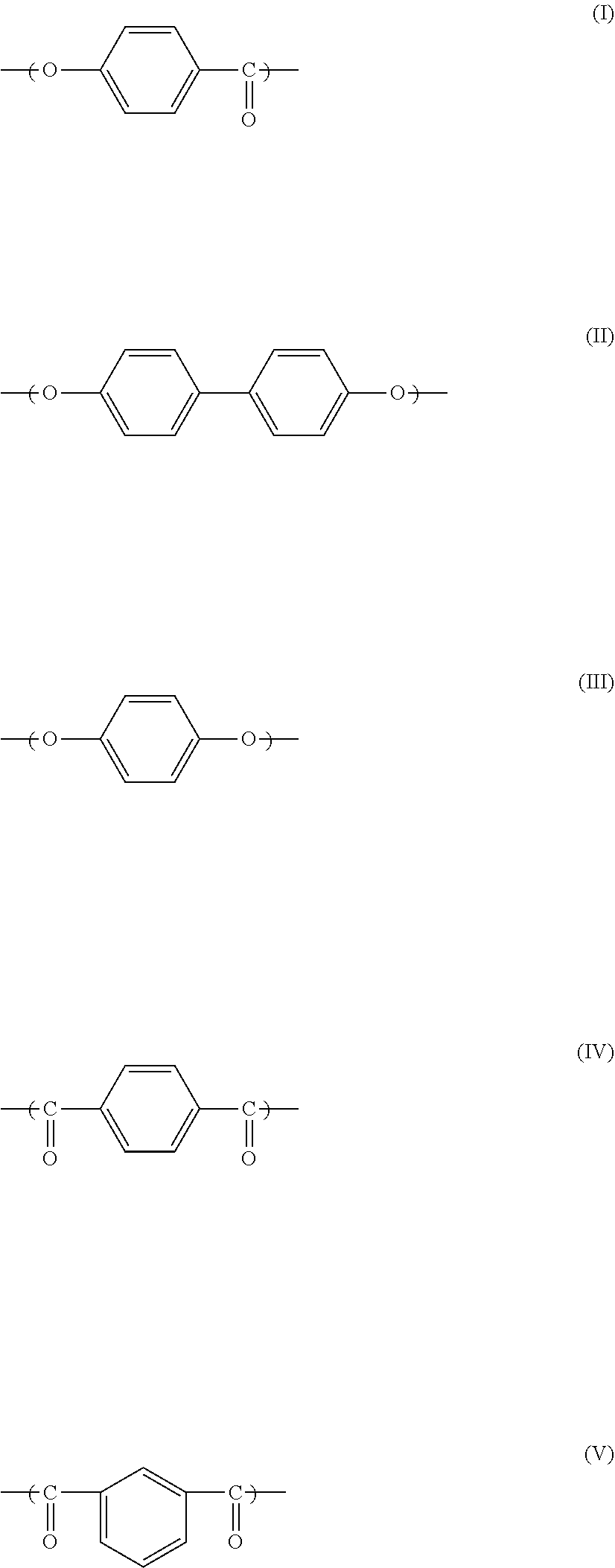

Twisted cord of liquid-crystal polyester multifilaments, production method therefor, and product comprising said twisted cord

PendingUS20210087332A1Raise attentionIncreased torsional strengthWeft knittingMonocomponent copolyesters artificial filamentPolyesterPolymer science

The present invention addresses the problem of providing a twisted cord of liquid-crystal polyester multifilaments which gives various high-order processed products capable of retaining desired product shapes and which is suitable for use in general industrial material applications such as high-strength ropes, slings, and nets. The twisted cord of liquid-crystal polyester multifilaments has a coefficient of variation in longitudinal-direction cord diameter, X, of less than 30%.

Owner:TORAY IND INC

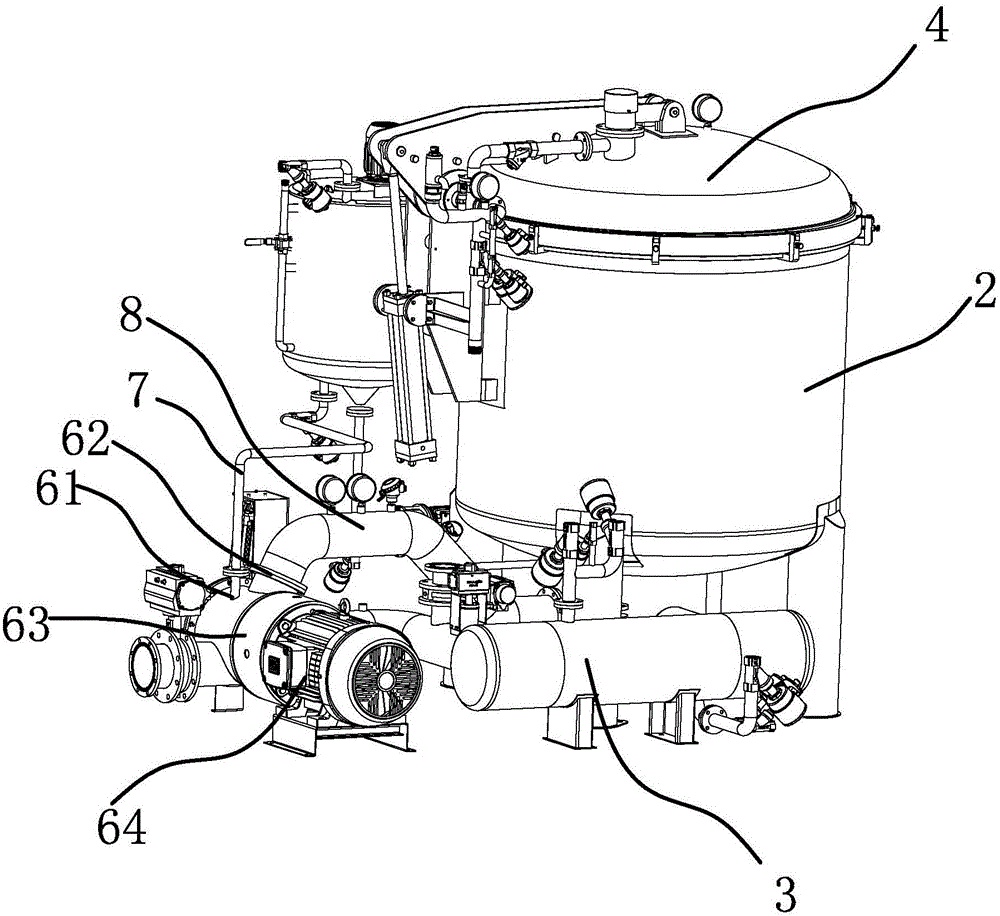

Dyeing machine for yarns

InactiveCN105821604AImprove efficiencyLower liquor ratioTextile treatment machine arrangementsDyeing processYarnEngineering

The invention provides a dyeing machine for yarns. The machine belongs to the technical field of spinning-related equipment and solves the technical problems such as that existing dyeing machines for yarns have low efficiency and cannot be used conveniently. The dyeing machine for the yarns provided by the invention comprises a rack, a dyeing bucket and an air compressor, wherein the dyeing bucket is disposed on the rack, and the air compressor communicates with a cavity in the dyeing bucket; an openable bucket cover is disposed on the upper end of the dyeing bucket, the dyeing device also comprises a liquid preparation bucket and a filter, an opening is formed in the upper end of the liquid preparation bucket, the lower end of the liquid preparation bucket is connected a liquid flow pipe 1 which communicates with the liquid preparation bucket and the dyeing bucket, the filter is equipped with an inlet and an outlet respectively, the lower end of the dyeing bucket is connected to a liquid flow pipe 2, the liquid flow pipe 2 is connected to the inlet of the filter, and the outlet of the filter is connected to a liquid flow pipe 3 which communicates with the filter and the liquid preparation bucket; a liquid level meter 1 which can display the liquid level inside the dyeing bucket is disposed on the dyeing bucket; and a liquid level meter 2 which can display the liquid level inside the liquid preparation bucket is disposed on the liquid preparation bucket. The dyeing device provided by the invention increases the efficiency and is more energy-saving and environment-friendly.

Owner:ZHEJIANG DUOYUAN TEXTILE TECH CO LTD

Energy-saving electric spindle assembly

Disclosed is an energy-saving electric spindle assembly. The energy-saving electric spindle assembly comprises a motor, a rotatable yarn storage tray which is directly connected with a motor output shaft, a rotatable twisting tray which is connected with the yarn storage tray, and a spindle tank which is arranged above the twisting tray and is stationary. The spindle tank is used for containing a feeding package. The minimum diameter of the bottom of the spindle tank is phi 210 mm to phi 215 mm, the maximum outer diameter of the spindle tank is phi 245 mm to phi 250 mm, the diameter of the twisting tray is phi 220 mm to phi 225 mm, and the diameter of the yarn storage tray is phi 80 mm to phi 85 mm. According to the energy-saving electric spindle assembly, the size, the structure and the geometrical shape of the spindle tank, the twisting tray and the yarn storage tray are optimized and designed, the diameter of free ballooning which is generated by the way that yarns rotate along with a spindle is reduced, the quality of twisted yarns is guaranteed, and meanwhile energy needed by a twisting frame for driving the spindle to work is reduced. According to the energy-saving electric spindle assembly, for a feeding yarn conventional variety with the yarn fineness range being 840 dtex-2600 dtex and the package diameter being smaller than or equal to 230 mm, the direct twisting or two-for-one twisting spindle assembly with the above characteristics is compared with the structure in the prior art, and the purpose for saving energy by 10%-13% is achieved.

Owner:YICHANG JINGWEI TEXTILE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com