Method for restarting twisting device after end breaking of yarn

A technology of restarting and yarn, applied in the direction of piecing device, spinning machine, transportation and packaging, etc., can solve the problems of no twist number, no mutual twist, two separate, no mutual twist, etc. The effect of uniform number of twists

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In particular, each two-for-one twisting spindle and winding device can be run and stopped independently of the remaining two-for-one twisting spindles or the remaining winding devices of the entire machine.

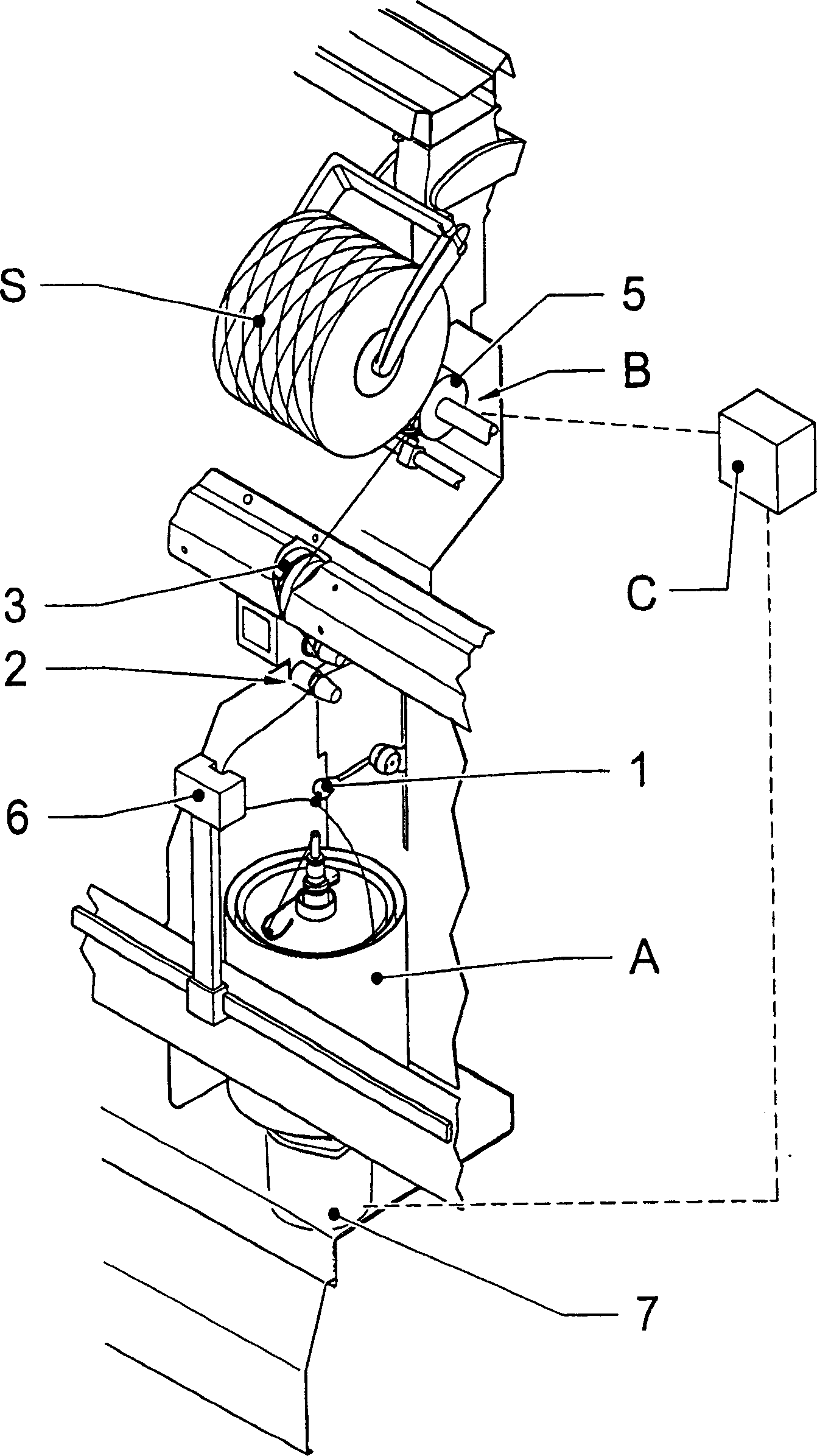

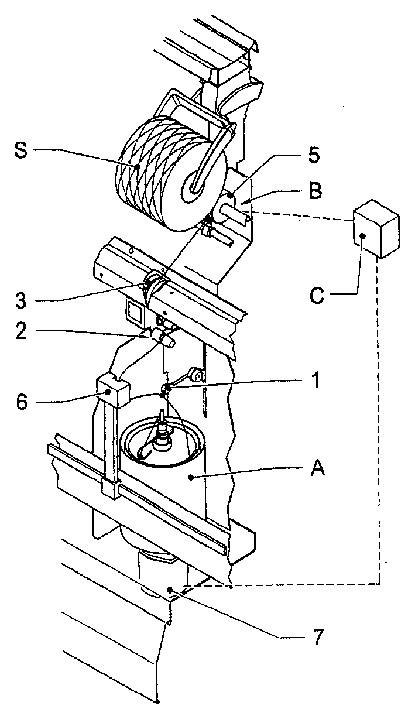

[0020] During the operation of the machine, the twisted yarn 2 produced by the operation of the two-for-one twisting spindle A passes through the pigtail-shaped yarn guide 1 located on the extension of the hollow shaft of the spindle, and then passes through a traditional yarn feeding device 2, and passes through The overfeed yarn mechanism 3 is then wound onto a drum S driven, for example, by a friction drive roller 5 .

[0021] When the twisting device is restarted after a yarn break, the end of the twisted thread unwound from the grooved drum S is inserted into a splicer or knotter 6 and fixed on a fixed point therein, Make the end of the twisted thread between the fixed point and the drum S have a complete number of twists, and after the fixed point, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com