Twisting device capable of uniformly twisting

A twisting device and uniform technology, applied in textiles and papermaking, etc., can solve the problems of insufficiently uniform twisting and inability to limit the position, and achieve the effect of avoiding entanglement and reducing wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

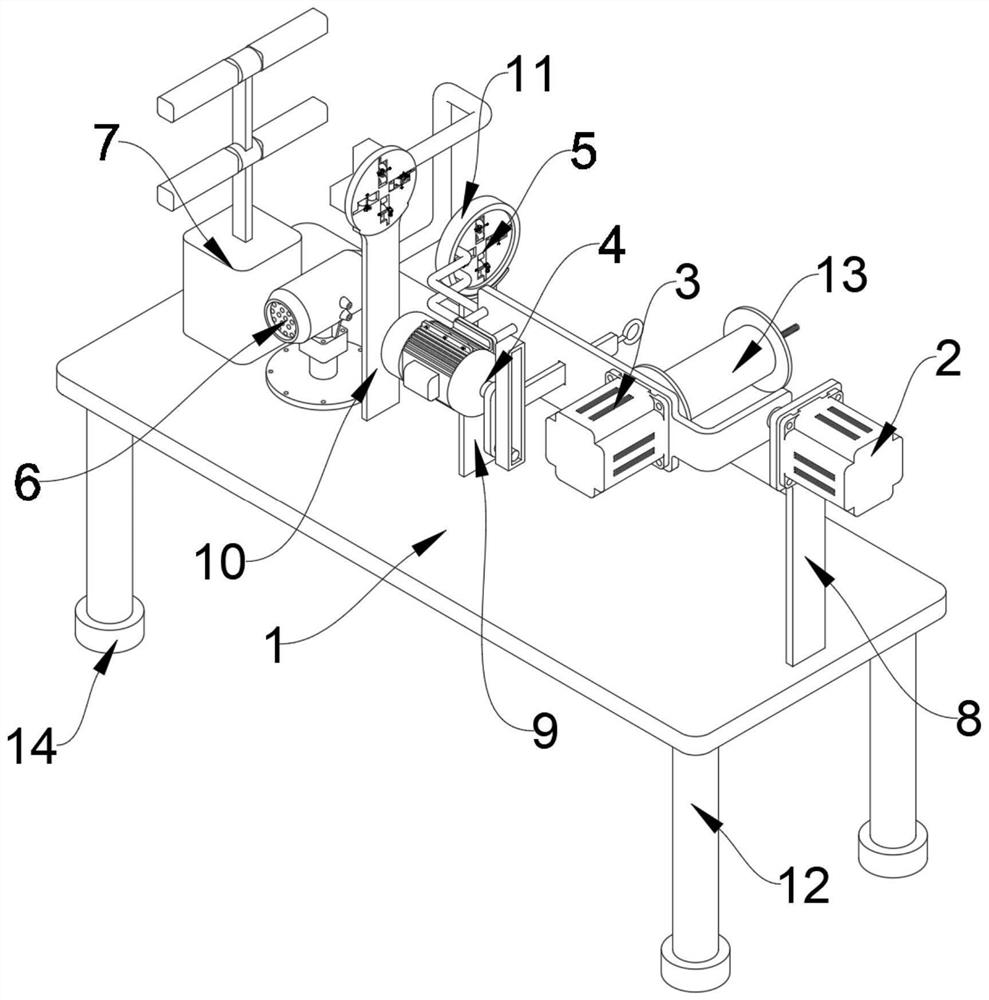

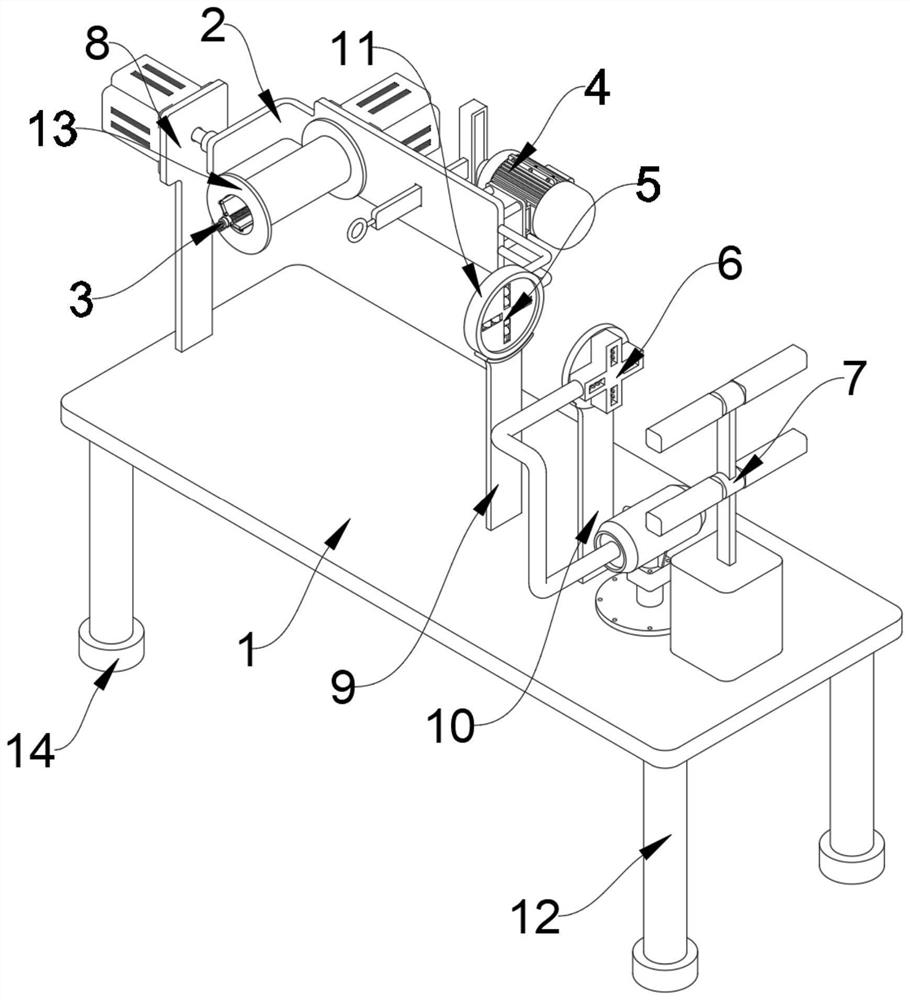

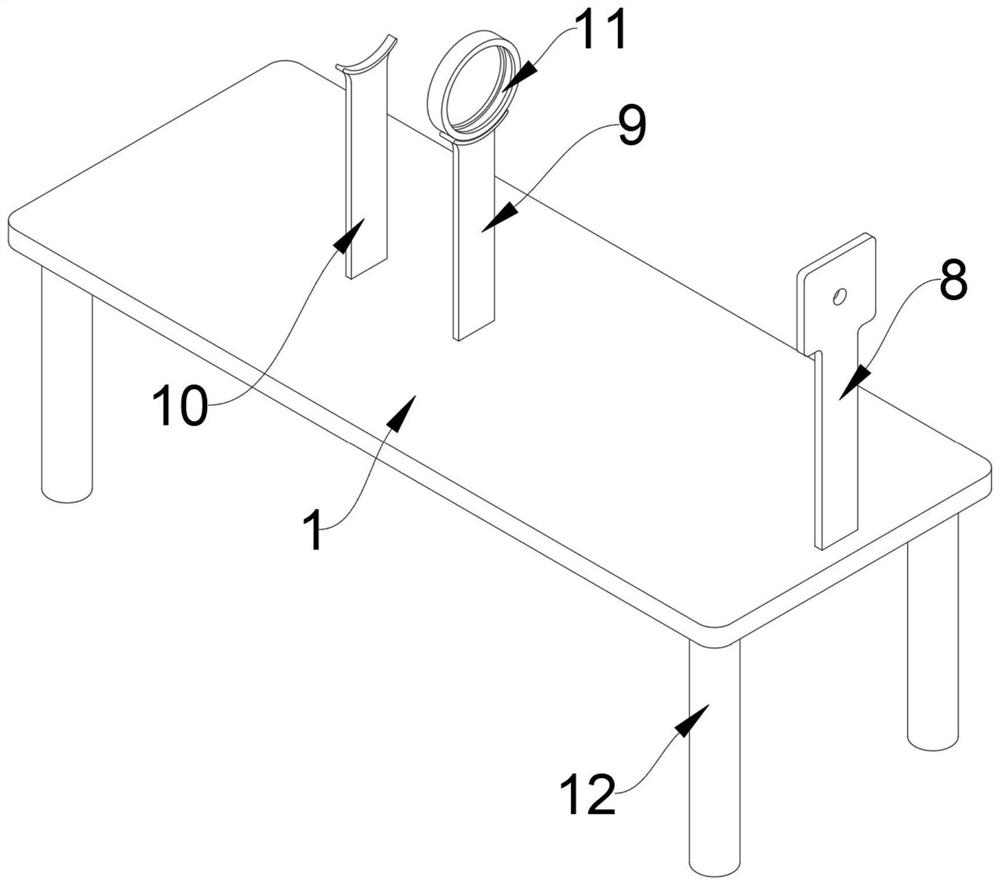

[0045] refer to Figure 1-9 , a twisting device with uniform twisting, comprising a device main body 1, one end of the upper end of the device main body 1 is welded with a storage rack 7, the storage rack 7 includes a fixed frame 701, a circular positioning ring 702 and a rotating rod 703, fixed The middle position of the frame 701 is welded to be connected with two circular positioning rings 702, and both sides of the circular positioning rings 702 are rotatably connected with a rotating rod 703, and the lower end of the device main body 1 is connected with four load-bearing rods 12 by welding, so that the device main body 1 is fixed more firmly, and the lower ends of the four load-bearing rods 12 are all socketed and connected with feet 14, so that the feet 14 can protect the load-bearing rods 12, and one end of the upper end of the device main body 1 is welded and connected with the first support plate 8, and the device body 1 The middle position of the upper end is welded ...

Embodiment 2

[0052] On the basis of the first embodiment, a method for using a twisting device with uniform twisting is disclosed, the steps are:

[0053] Step 1: Fix the four spindles for winding the yarn on the outer sides of the four rotating rods 703 respectively;

[0054] Step 2: pass one end of the yarn wound on the outer side of the spindle through the working chamber 502 and the heating chamber 603, and then pass through the threading coil 405 and wind it around the winding coil 13;

[0055] Step 3: Rotate the worm 508, drive the carriage 503 to slide inside the working chamber 502 through the worm gear 507, so that the second roller 506 contacts the yarn, and the yarn is limited by the second roller 506 and the first roller 505 ;

[0056] Step 4: start the first motor 201, and drive the storage plate 202 to rotate through the first motor 201, thereby driving the twisting disc 5 to rotate, and twisting the yarn;

[0057] Step 5: Start the second motor 301. After the second motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com