Dyeing machine for yarns

A dyeing machine and yarn technology, which is applied in the field of dyeing devices, can solve the problems of inconvenient replacement of dyes in a dyeing box, insufficient uniform dyeing of yarns, etc., and achieve the effects of plump hand feeling, elimination of tension and reduction of liquor ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

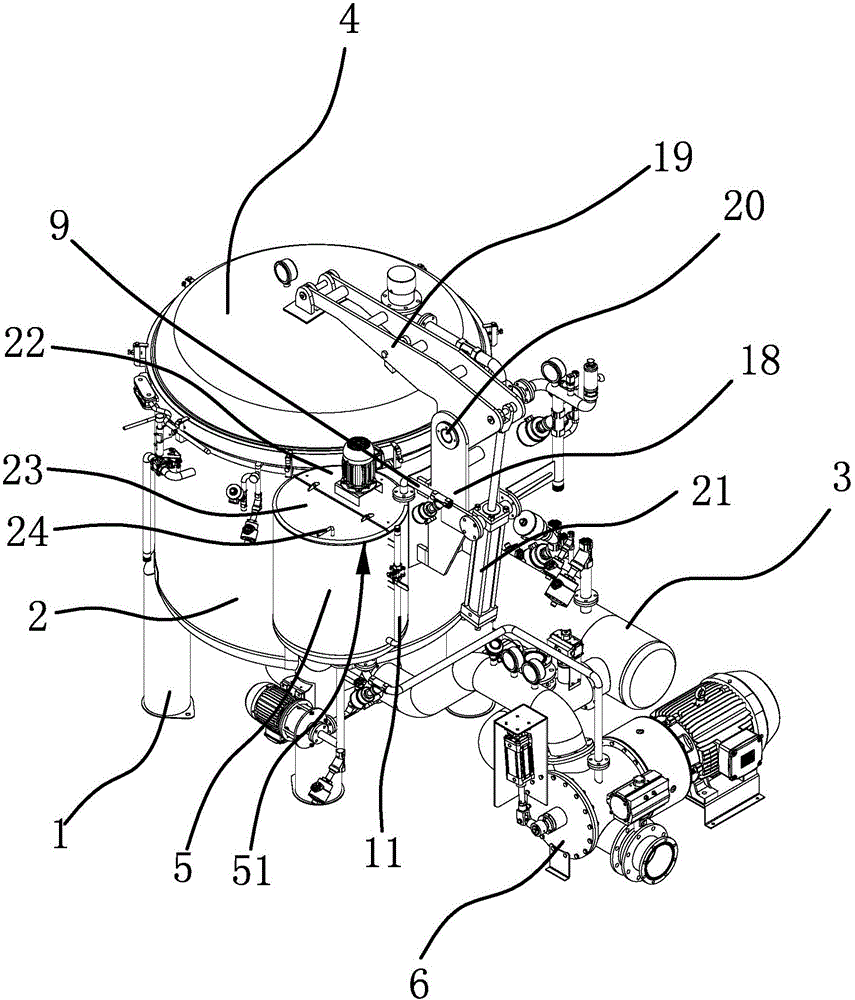

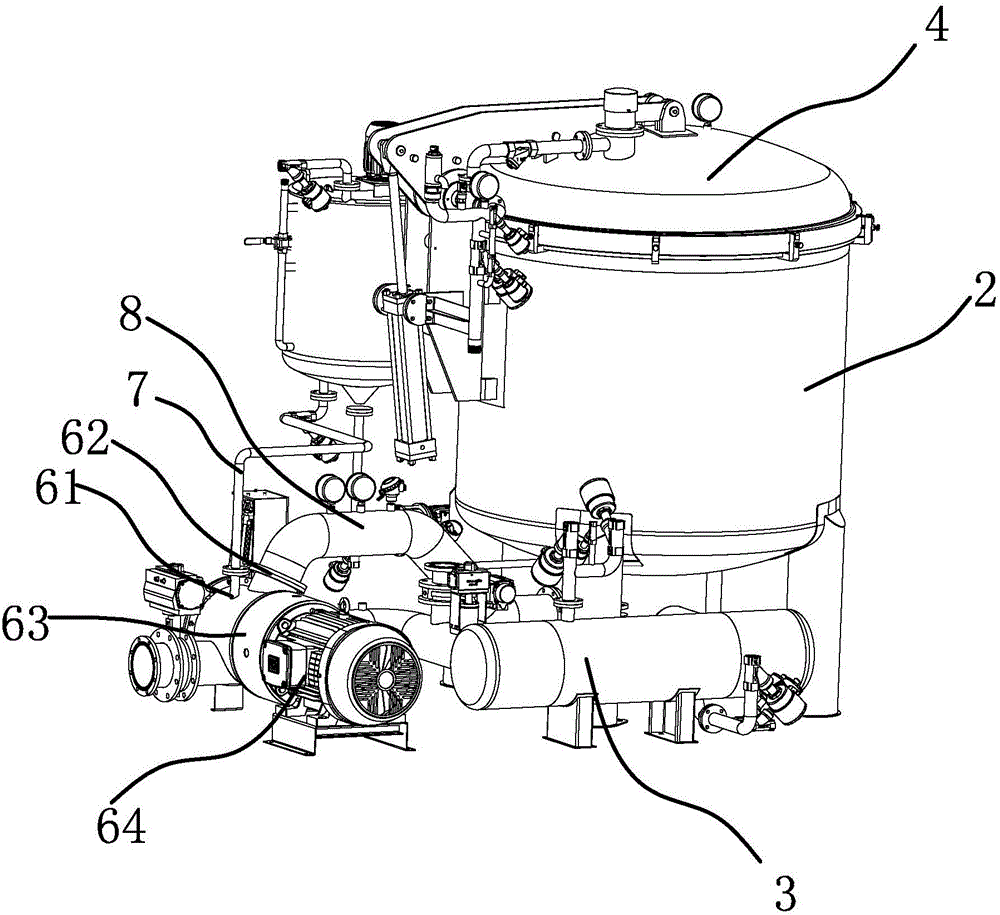

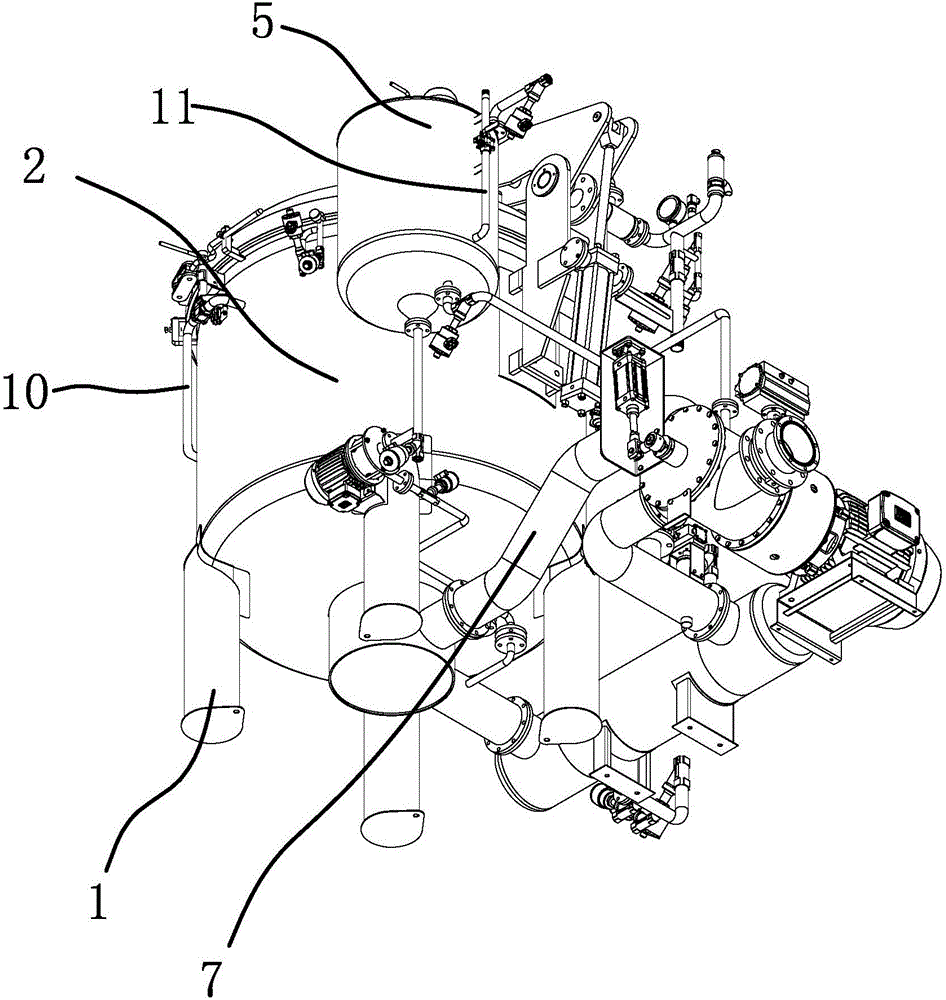

[0040] Such as figure 1 , figure 2 and image 3 Shown, the dyeing machine of this yarn comprises frame 1, dyeing bucket 2 and air compressor 3, and dyeing bucket 2 is arranged on the frame 1, and air compressor 3 is connected with the cavity in the dyeing bucket 2; Dyeing bucket 2. The upper end is provided with a barrel cover 4 that can be opened. The dyeing device also includes a liquid distribution barrel 5 and a filter 6. The upper end of the liquid distribution barrel 5 has an opening 51. The lower end of the liquid distribution barrel 5 is connected with the liquid distribution barrel 5 and the dyeing barrel 2. Liquid flow pipe one 7, filter 6 has inlet 61 and outlet 62 respectively, and the lower end of dyeing bucket 2 is connected with liquid flow pipe two 8 and liquid flow pipe two 8 is connected with the inlet 61 of filter 6, and filter 6 The outlet 62 is connected with the liquid flow pipe 3 9 that communicates with the filter 6 and the liquid distribution barrel...

Embodiment 2

[0045] A kind of dyeing method of yarn is provided in the present embodiment, and this dyeing method comprises the following steps:

[0046] a. Yarn preparation and inspection: Before yarn dyeing, inspect the quality of the yarn. The appearance of the yarn is required to be clean and free of stains, and it is neutral. The stacking time should not exceed 8 hours, and it should be covered with a damp cloth;

[0047] B, feeding: the yarn is put into the dyeing bucket 2, and placed on the dyeing rod 17,

[0048] c. Dye preparation: prepare anthraquinone vat dyes in the dye barrel, add caustic soda and sodium hydrosulfite 5-6g according to the raw material of each mass of anthraquinone structure, preferably 5.5g in the present embodiment; inject water to make into a solution, and add 0.2-0.5 g / L of bone glue retarding agent; preferably 0.35 g / L in this embodiment.

[0049] D. Dye injection and dyeing: inject the prepared dye into the dyeing barrel 2, and dip for 20-30min; preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com