Twisting adjusting device of rope twisting machine

A technology of adjusting device and rope twisting machine, which is applied in auxiliary devices for rope making, textiles and papermaking, and control parts, etc. It can solve problems such as uneven twisting of ropes, reduction of steel wire rope strength, and uneven tension of rope strands, etc., to achieve steel wire rope Compaction, improved quality, even twist effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

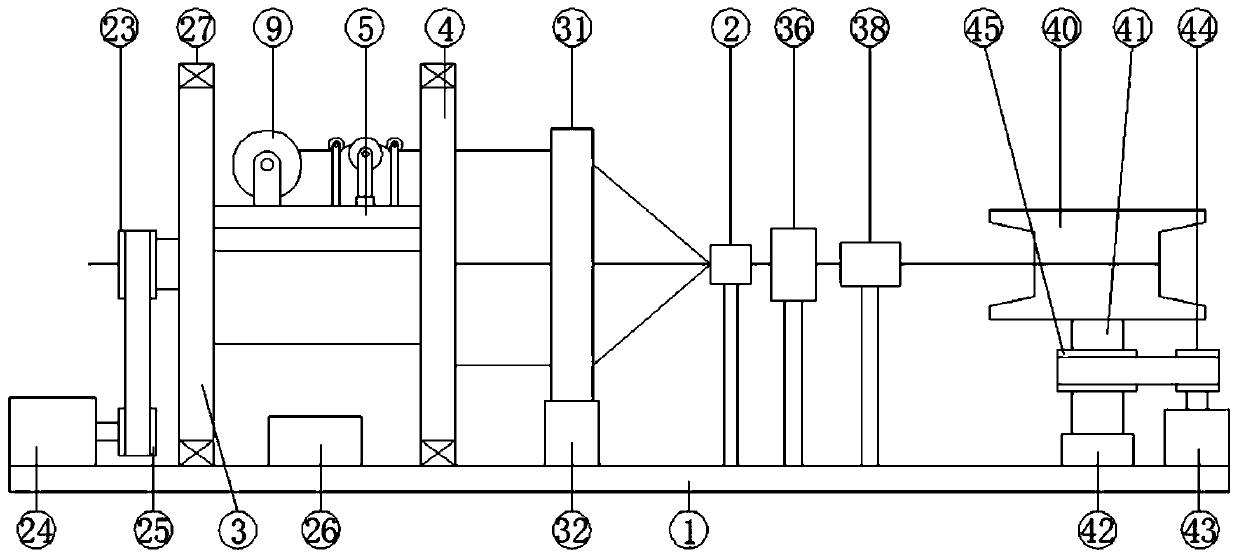

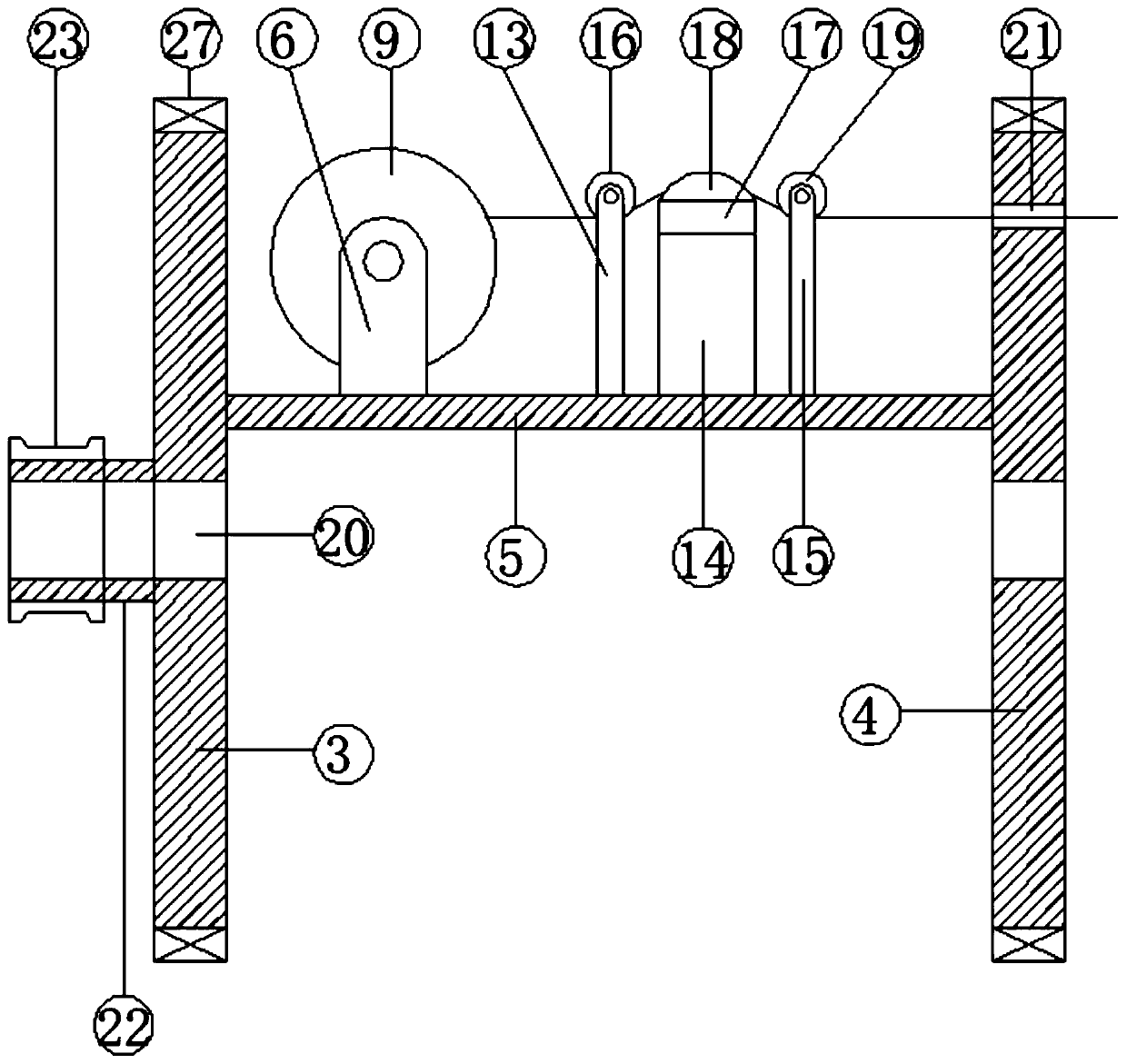

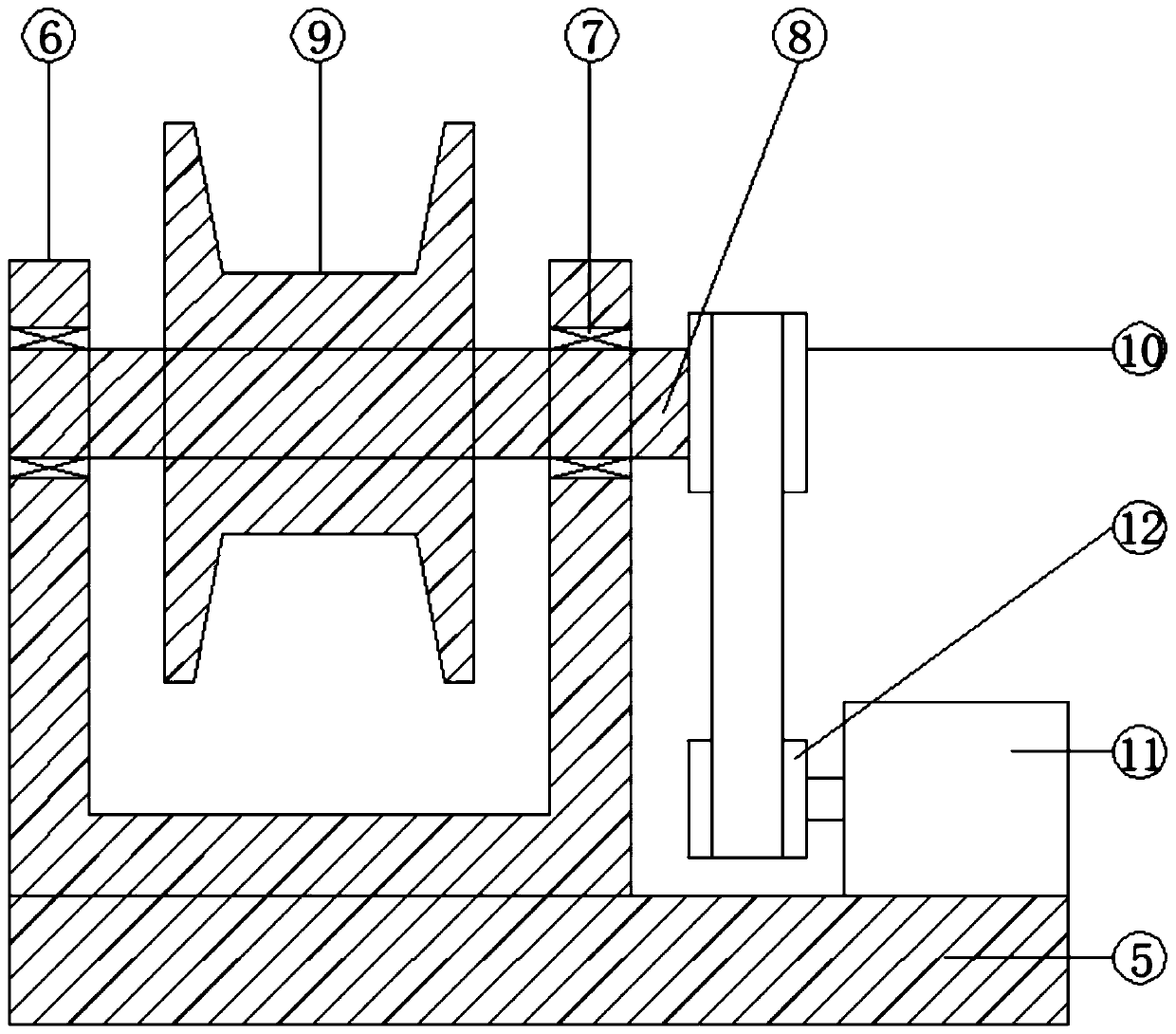

[0032] see Figure 1-9, according to an embodiment of the present invention, a twisting adjustment device for a rope twisting machine includes a base 1, and the base 1 is sequentially provided with a tension adjustment device, an angle adjustment device, a die 2, a longitudinal clamping device, A transverse clamping device and a winding device, the tension adjustment device includes a first turntable 3 and a second turntable 4, and three mounting plates are fixed between the first turntable 3 and the second turntable 4 5 and the mounting plates 5 are arranged at equal intervals along the circumferential direction of the first turntable 3 , and a first mounting bracket 6 is fixed on one end of the mounting plate 5 close to the first turntable 3 . The upper ends of the two side walls of the bracket 6 are fixedly embedded with a first bearing 7, a first transmission shaft 8 is fixed between the first bearings 7, and a pay-off disc 9 is fixed in the middle of the first transmissio...

Embodiment 2

[0035] see figure 1 , 6 And 7, for the limit device, the limit device includes a fourth bearing 33, a fourth mounting bracket 34 and a third limit wheel 35, the fourth bearing 33 is fixed in the circular hole 30, so The inner walls of the upper and lower ends of the fourth bearing 33 are fixedly provided with fourth installation brackets 34 , and third limit wheels 35 are installed on the fourth installation brackets 34 . Limit hole.

[0036] Through the above solution of the present invention, the rope to be twisted can be limited, and the rope to be twisted can be positioned at the central axis, thereby improving the quality of the steel wire rope.

Embodiment 3

[0038] see figure 1 , 8 And 9, for the longitudinal clamping device, the longitudinal clamping device includes a fifth mounting bracket 36, the fifth mounting bracket 36 is fixed on the base 1 through a connecting rod, and the fifth mounting bracket 36 is fixed on the base 1 Two longitudinal clamping wheels 37 are rotatably installed; for the transverse clamping device, the transverse clamping device includes a sixth mounting bracket 38, and the sixth mounting bracket 38 is fixed on the On the base 1 , the sixth mounting bracket 38 has a rectangular frame structure, and two transverse clamping wheels 39 are rotatably mounted on the inner wall.

[0039] Through the above-mentioned solution of the present invention, the twisted steel wire rope can be clamped laterally and longitudinally, so that the steel wire rope is more compact.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com