Insulated core wire, high-fire-retardant data cable and processing craft thereof

A technology for insulated core wires and data cables, which is applied in the direction of insulated cables, cable/conductor manufacturing, insulators, etc., can solve the problems of low temperature resistance and flame retardant grades of insulated core wires, achieve low dielectric loss coefficient, and improve flame retardant properties , the effect of preventing the spread of flames

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

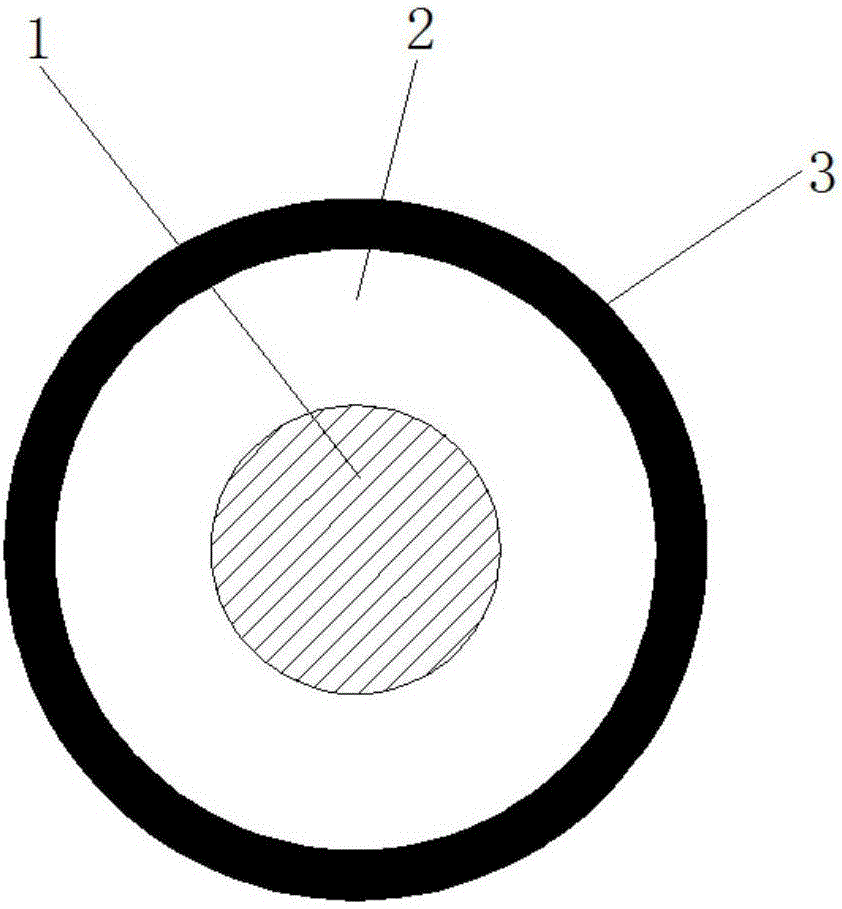

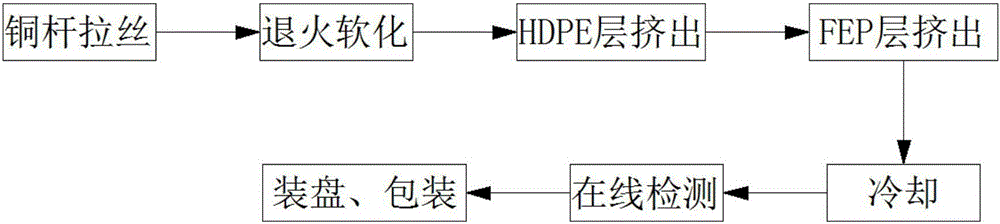

[0046] The first embodiment is an insulated core wire, refer to figure 1As shown, the insulated core wire includes a conductor 1, and the outer peripheral side of the conductor 1 is sequentially covered with an inner insulating layer 2 and an outer insulating layer 3 along its radial direction; the inner insulating layer 2 is an HDPE insulating layer, and the outer insulating layer 3 is FEP insulation.

[0047] Among them, HDPE is a copolymer of tetrafluoroethylene and hexafluoropropylene.

[0048] Wherein, the conductor 1 is a single crystal copper conductor, and the conductor 1 is single or multiple, that is, one or more conductors 1 are arranged in a single inner insulating layer 2 .

[0049] The insulated core wire in this embodiment includes a conductor 1, and the outer peripheral side of the conductor 1 is coated with an HDPE insulating layer and a FEP insulating layer in turn; since the FEP insulating layer is arranged on the outside of the HDPE insulating layer, and t...

Embodiment 2

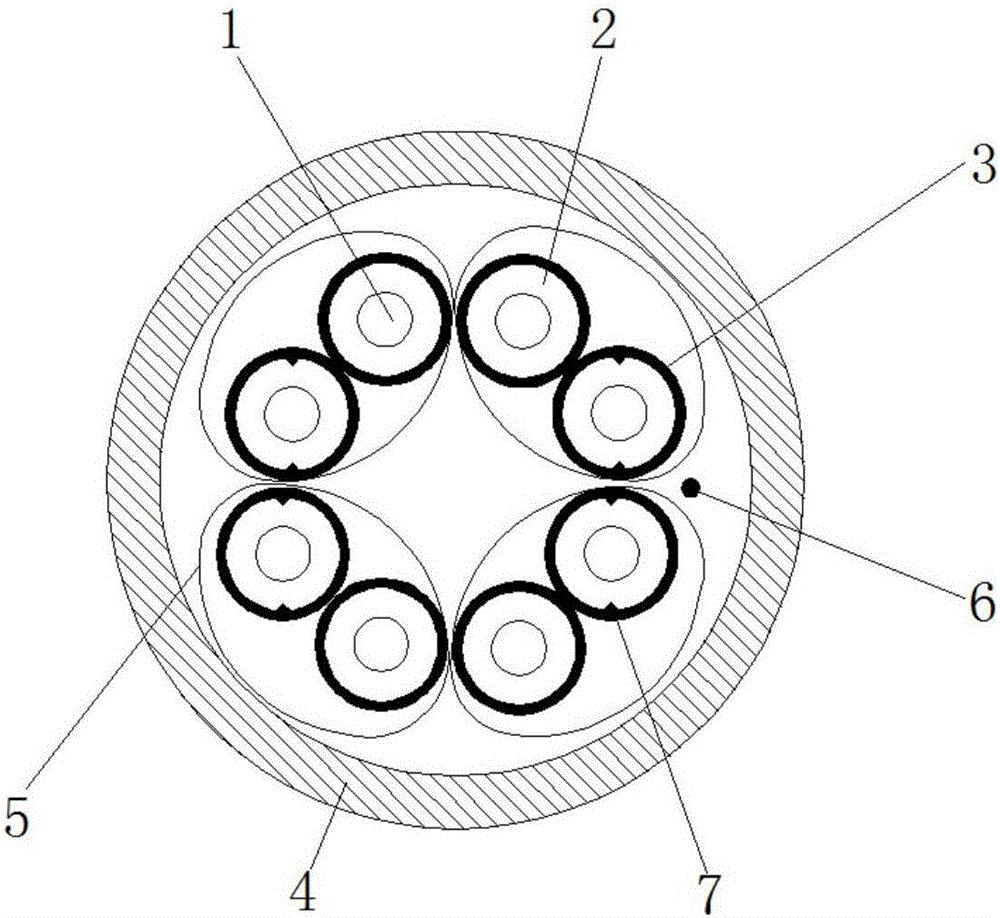

[0067] The second embodiment is a high flame retardant data cable, refer to image 3 As shown, it includes the sheath layer 4 and the insulated core wire in Embodiment 1, and the sheath layer 4 covers the outer peripheral side of the insulated core wire.

[0068] The high flame-retardant data cable in this embodiment can produce the beneficial effect of the insulated core wire in Embodiment 1, and will not be repeated here.

[0069] In this embodiment, there are multiple insulated core wires, and each insulated core wire is paired and twisted respectively. Two pairs of twisted wires 5 are formed, and there are multiple groups of twisted wires 5; The outer peripheral side of line 5.

[0070] Wherein, the twisted wires 5 are arranged in 4 groups.

[0071] In this embodiment, a tear line 6 is provided inside the sheath layer 4 , and the extension direction of the tear line 6 is the same as that of the conductor 1 .

[0072] Among them, adding the tear wire 6 in the data cable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com