High-efficiency yarn dyeing device

A yarn dyeing and high-efficiency technology, applied in the field of dyeing equipment, can solve the problems of low economic benefit, large labor and large bath, and achieve the effects of improving dyeing efficiency, uniformity and twist balance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

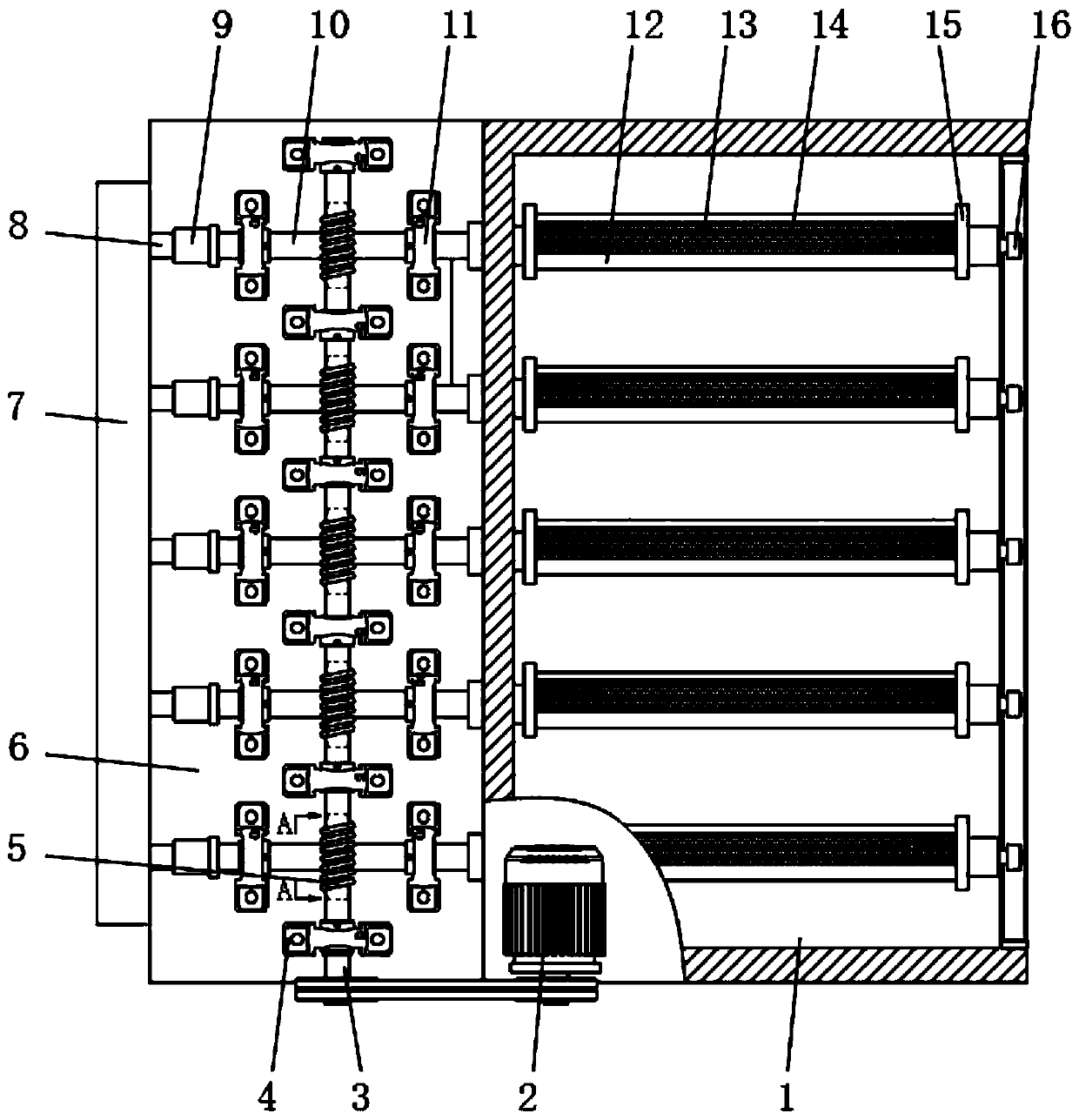

[0034] Embodiment one, with reference to figure 1 and Figure 4 , a high-efficiency yarn dyeing device, including a dyeing bin 1, a dye solution box 24 and a spray pipe 12, a driving motor 2 is installed on the dyeing bin 1, and a drive shaft is connected to one side of the driving motor 2 through a belt and a pulley. 3. The drive shaft 3 is erected on the platform 6 through the first bearing seat 4 and the bracket 17, and the drive shaft 3 is provided with a worm 5, and a worm gear 36 is connected to the bottom of the worm 5, and the worm gear 36 is installed on the hollow shaft 10, and The hollow shaft 10 is erected on the platform 6 through the second bearing seat 11. One end of the hollow shaft 10 is connected to the branch pipe 8 through the rotary joint 9, and the other end runs through the side wall of the dyeing chamber 1 to connect with the injection pipe 12. The platform 6 is located in the dyeing chamber 1. Side, and below the platform 6 is provided with a dye solu...

Embodiment 2

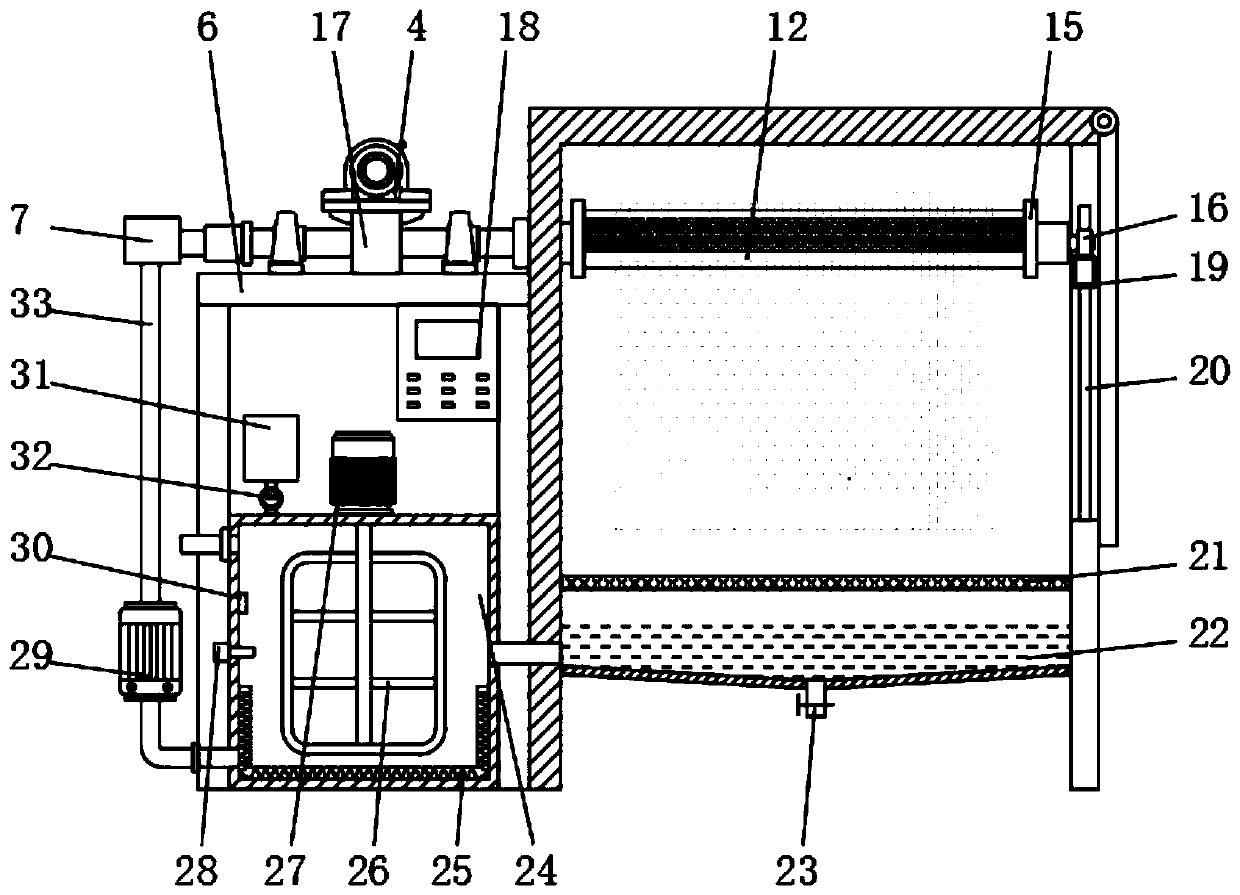

[0035] Embodiment two, refer to figure 2, a stirring motor 27 is installed on the top of the dye liquor box 24, and a stirring rod 26 is connected to the inside of the dye liquor box 24 below the stirring motor 27, and a temperature sensor 30 and a concentration detection device are respectively arranged on one side of the stirring rod 26 and located on the inner surface of the dye liquor box 24. 28, and a heating layer 25 is provided below the stirring rod 26, a stirring motor 27 is provided with a dyeing agent 31 and a flow controller 32 from top to bottom, and is connected to the dye solution tank 24, and a control panel 18 is embedded on the front surface of the platform 6 , and the control panel 18 is electrically connected to the driving motor 2, the stirring motor 27, the concentration detector 28, the circulating pump 29, the temperature sensor 30 and the flow controller 32 through the PLC controller provided inside, and the stirring is started by the control panel 18 ...

Embodiment 3

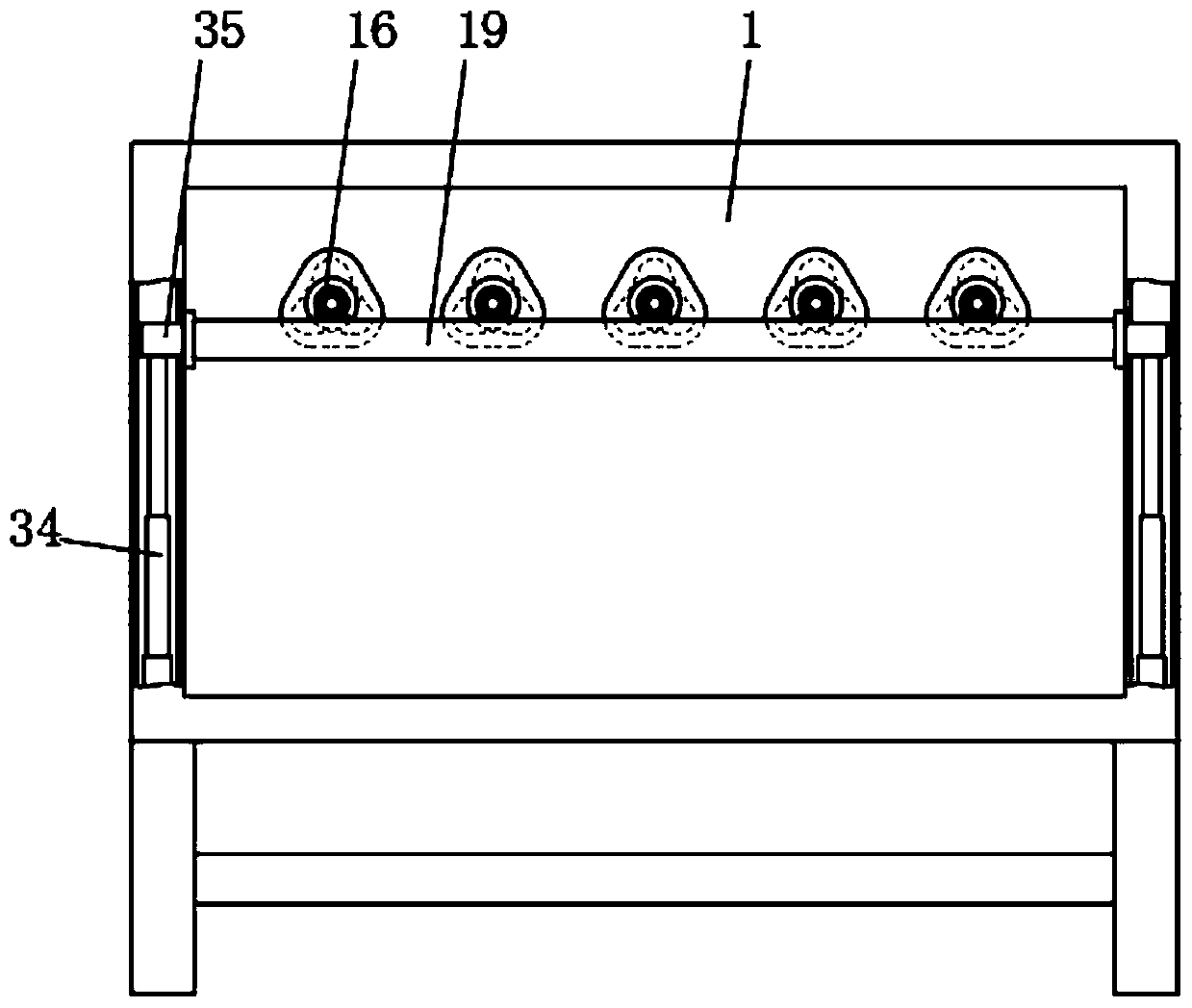

[0036] Embodiment three, refer to figure 2 and Figure 5 , a plurality of injection pipes 12 are provided, and a plurality of injection pipes 12 are evenly arranged inside the dyeing chamber 1. The inside of the injection pipe 12 is a cavity structure, and baffles 15 are welded at both ends, and a support bearing is installed on one end surface 16. The injection pipe 12 has a triangular cross-section and an arc-shaped concave surface 13 on the side. A plurality of nozzles 14 are uniformly arranged on the surface of the arc-shaped concave surface 13. One side of the dye solution tank 24 communicates with the flow divider 7 through the main pipe 33, and the main pipe 33 is installed There is a circulation pump 29, and a plurality of branch pipes 8 are arranged on one side of the flow divider 7, and each branch pipe 8 is connected to the corresponding injection pipe 12 through a rotary joint 9 and a hollow shaft 10, and a filter screen 21 is arranged under the inside of the dyei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com