Loose knitted fabric anti-pleat cloth box

A technology of knitted fabric and loose type, which is applied in the field of loose knitted fabric anti-shrinkage cloth box, can solve the problems of increasing environmental protection costs, waste of treatment agents and clean water, etc., and achieve the goal of reducing sewage discharge, saving water resources, and reasonable equipment design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific structure of the present invention is further described below;

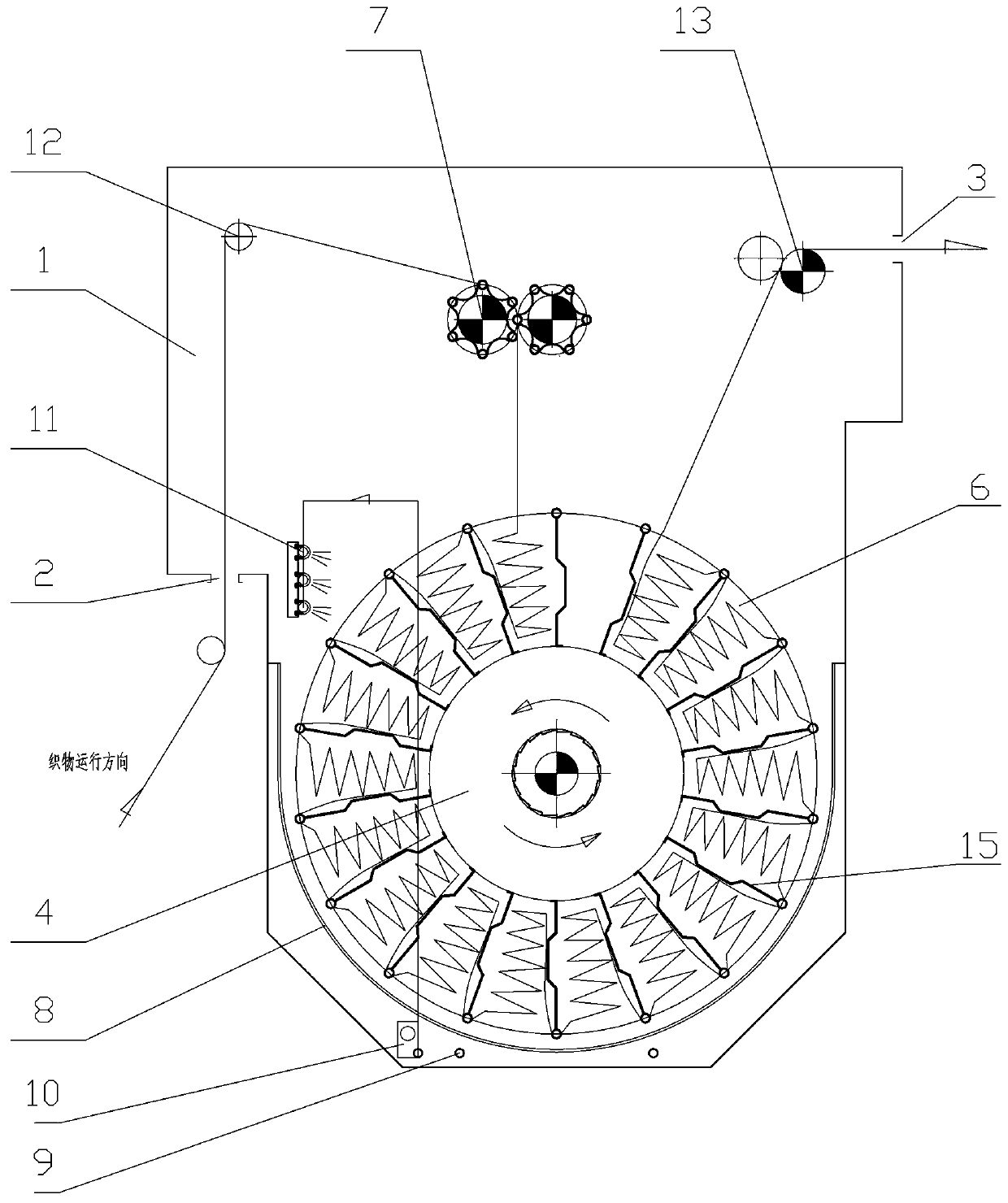

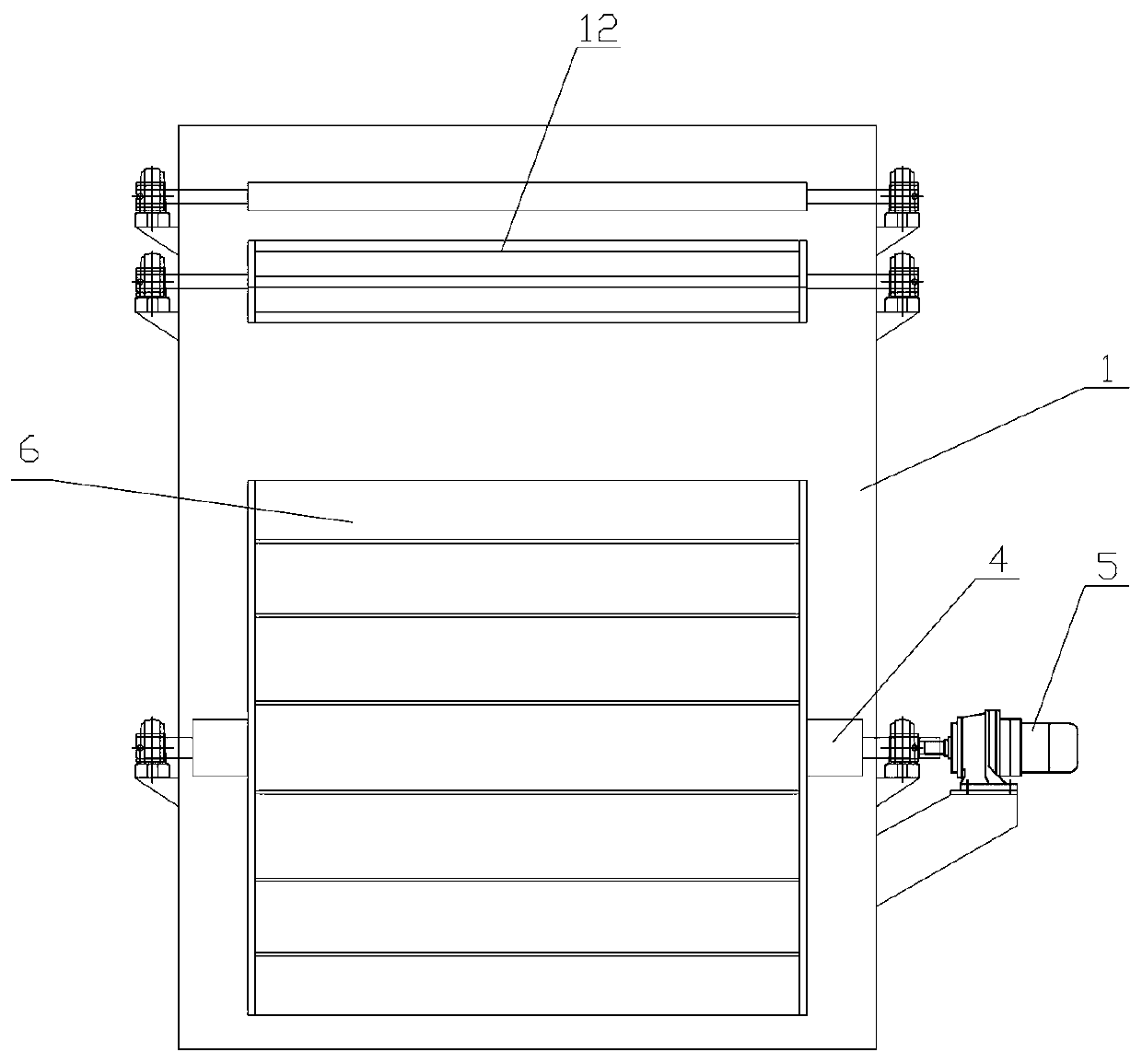

[0020] The loose knitted fabric anti-shrinkage cloth box of the present invention has a structure such as figure 1 with figure 2 As shown, the upper part of the feeding end of the box body 1 protrudes to one side, the lower side of the protruding part is provided with a cloth inlet 2, the feeding transition roller 12 is arranged directly above the cloth inlet 2, and the cloth outlet 3 is arranged on the vertical side of the box body 1 superior.

[0021] The feeding transition roller 12 is arranged in the box body 1 close to the cloth inlet 2. After the loose knitted fabric enters from the cloth inlet 2, the feeding transition roller 12 is guided and then enters between a pair of doffing rollers 7. The doffing rollers 7 are six The corner cloth roller 7 is provided with a pair of cloth outlet rollers 13 near the cloth outlet 3 in the box body 1 .

[0022] The casing 1 is provided with a run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com