Novel dyeing machine

A dyeing machine and barrel technology, applied in spray/jet textile material treatment, textile material carrier treatment, textile material treatment equipment configuration, etc., can solve the problems of accumulation, increase energy consumption, increase liquor ratio, etc., and achieve uniform dyeing, The effect of reducing the liquor ratio and reducing the running weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

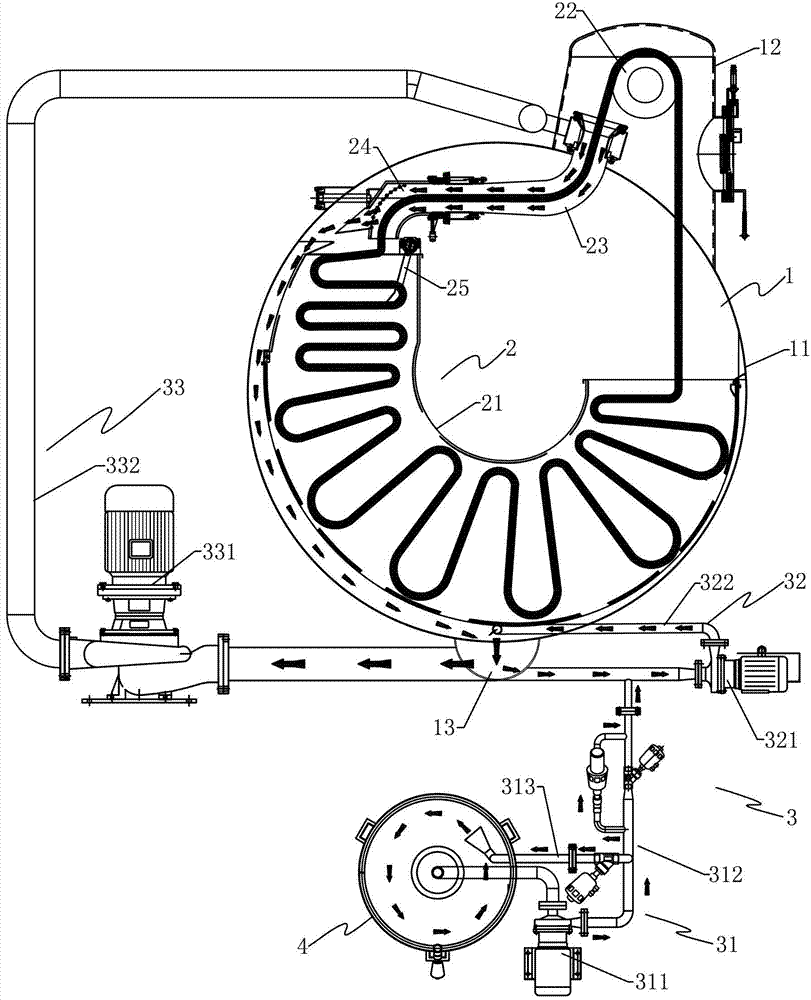

[0025] Such as Figures 1 to 3 As shown, the dyeing machine of the present invention includes an organic barrel 1 , a cloth moving system 2 and a mixing system 3 .

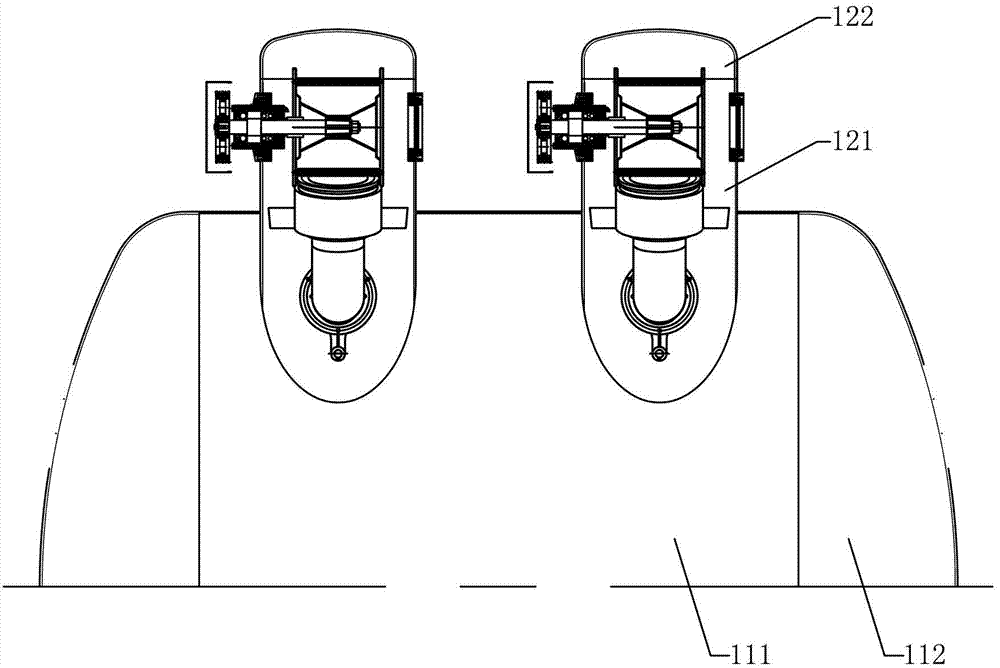

[0026] The above-mentioned machine barrel 1 includes a transverse barrel 11 and a cylinder head 12. The transverse barrel 11 is mainly composed of a middle barrel 111 and THA heads 112 on both sides. The cylinder head 12 is mainly composed of an elliptical connecting pipe 121 and a flat head 122. Wherein, the elliptical connecting pipe 121 of the cylinder head 12 is sealed and connected with the middle cylinder 111 of the transverse cylinder 11 to form an integral machine barrel 1; furthermore, a water collection tank 13 is arranged at the bottom of the machine barrel 1, and a mixing bucket 4 is arranged outside.

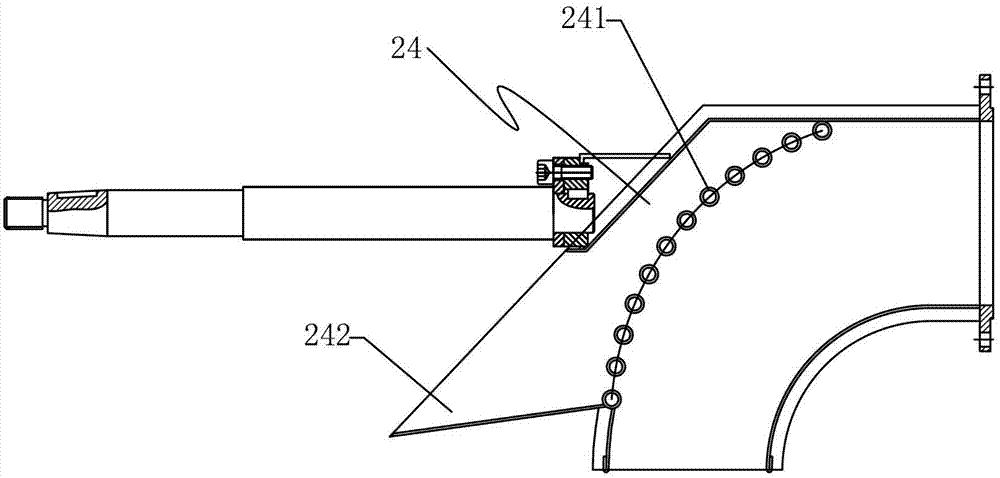

[0027] The above-mentioned cloth running system 2 includes a cloth collecting bin 21, a cloth lifting wheel 22, a cloth guide pipe 23, a horizontal distribution pipe 24, and an upper and lower distribut...

Embodiment 2

[0031] Such as Figure 4 As shown, the embodiment described in this embodiment is basically the same as that of Embodiment 1, the only difference being that the barrel 1 is provided with a wheel shell 5 outside, and the wheel shell 5 is connected to the barrel 1 through a connecting pipe 51, The cloth collecting bin 21, the cloth guide pipe 23, the horizontal distribution pipe 24, the upper and lower distribution plates 25 of the cloth running system 2 are located in the barrel 1, and the cloth lifting wheel 22 is located in the wheel shell 5, that is, the cloth lifting wheel 22 is placed outside the Barrel 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com