A kind of yarn dyeing method

A dyeing method and yarn dyeing technology, which are applied in dyeing method, textile material processing, liquid/gas/vapor yarn/filament processing and other directions, can solve the problems of insufficient uniform dyeing of yarn and inconvenient replacement of dyes in dyeing boxes. , to achieve the effect of feeling plump, eliminating tension and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

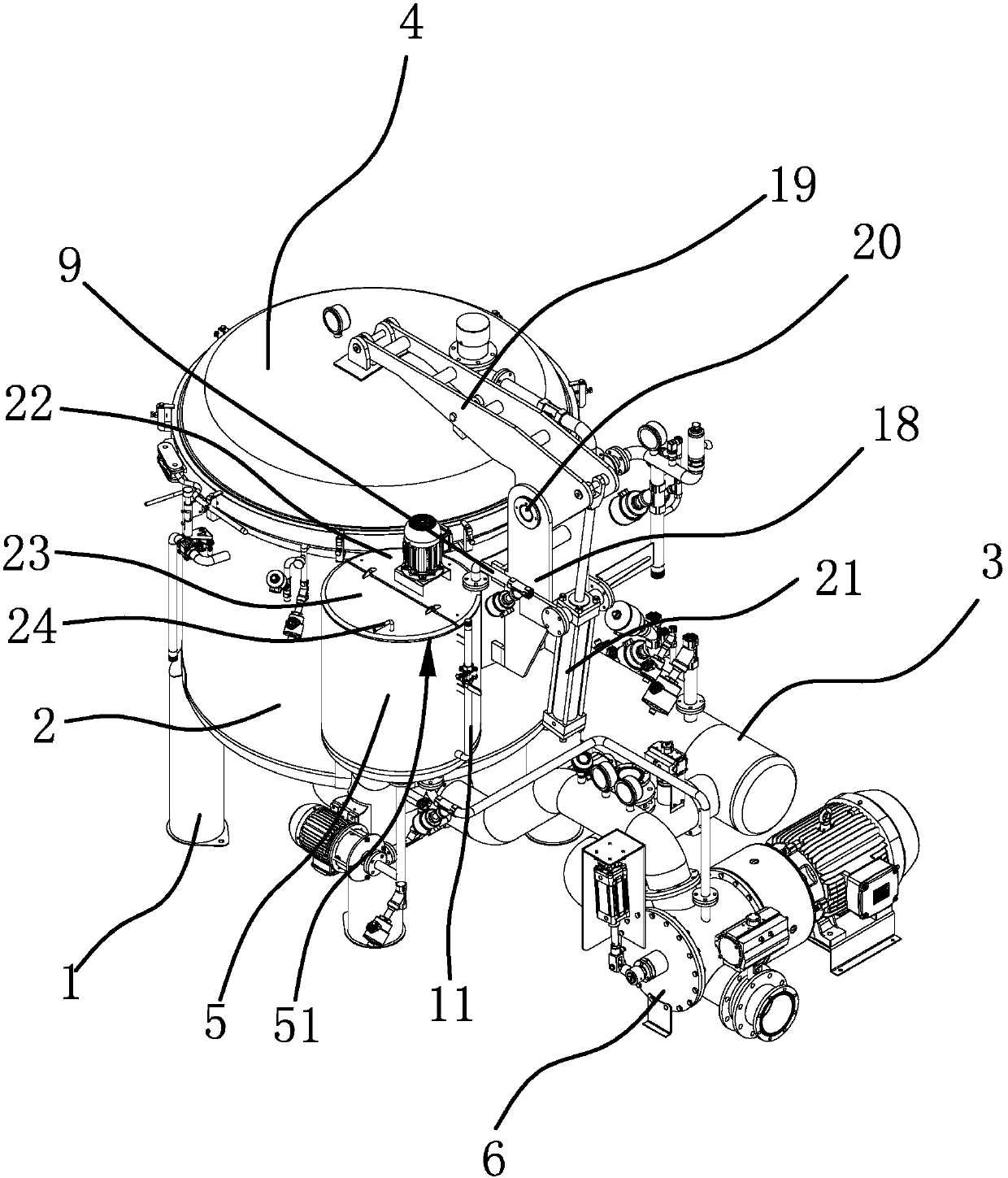

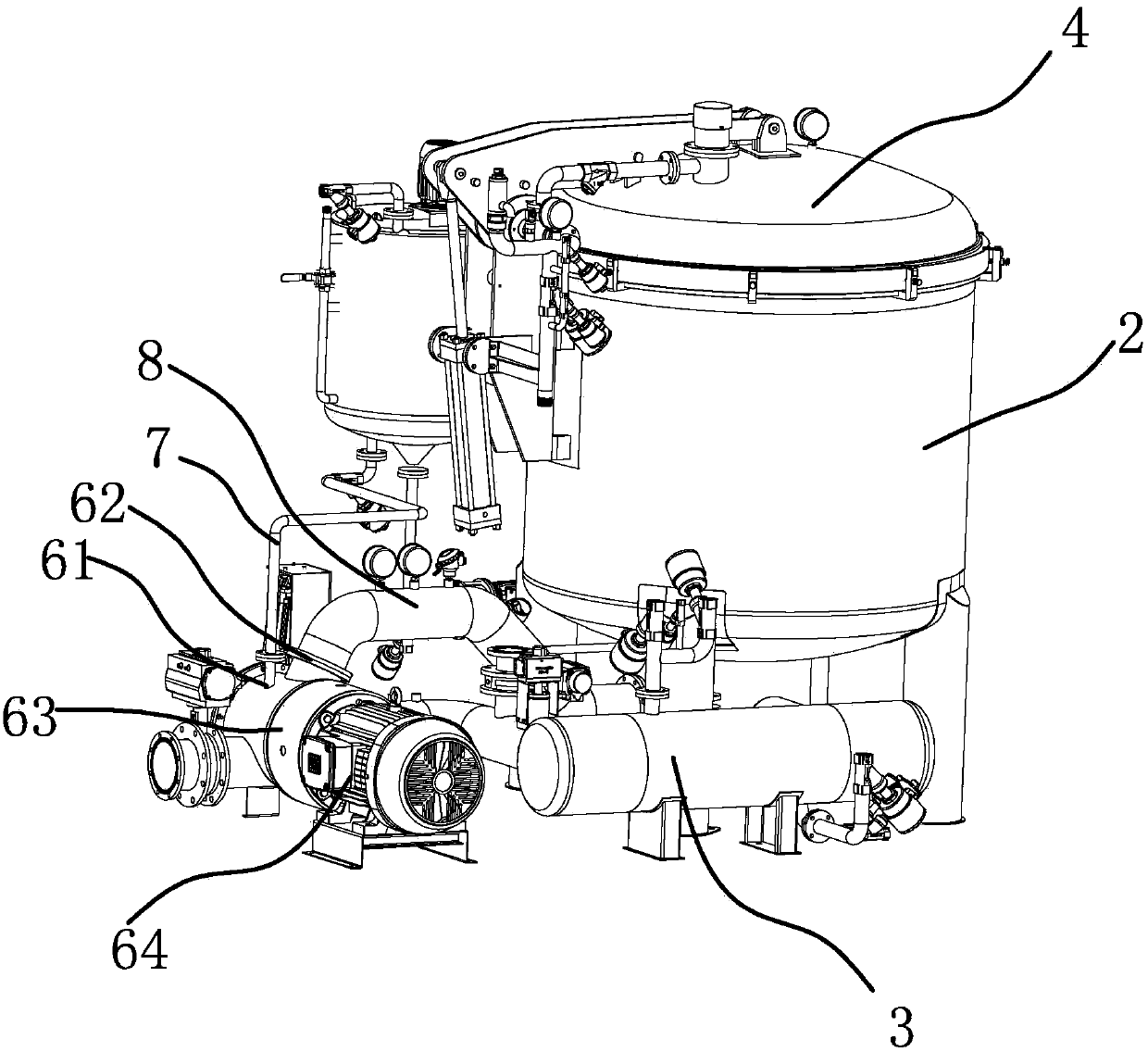

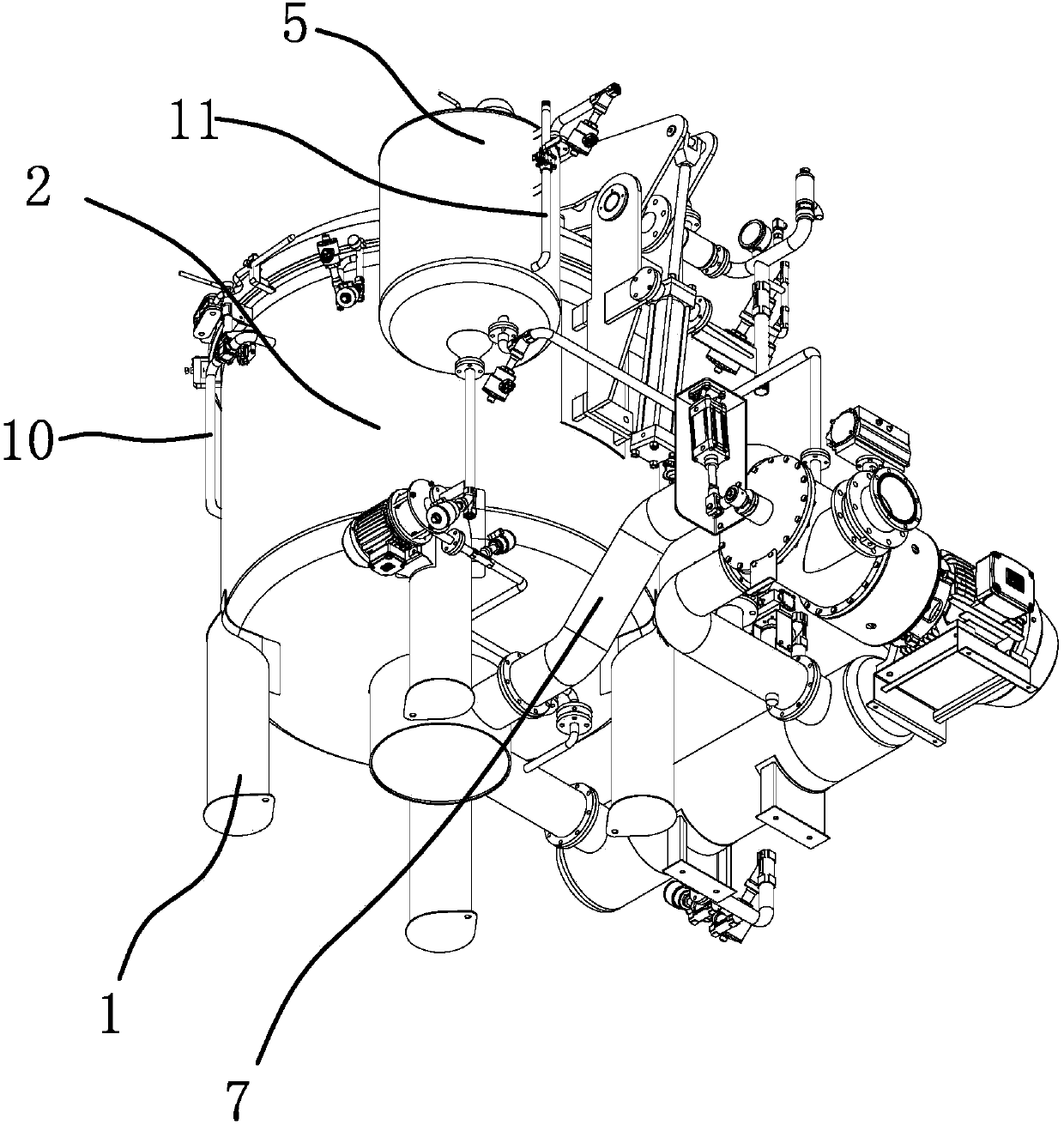

[0040] Such as figure 1 , figure 2 with image 3 As shown, the yarn dyeing device includes a frame 1, a dyeing barrel 2 and an air compressor 3. The dyeing barrel 2 is set on the frame 1, and the air compressor 3 communicates with the cavity in the dyeing barrel 2; 2 The upper end is provided with an openable bucket lid 4. The dyeing device also includes a liquid mixing bucket 5 and a filter 6. The liquid mixing bucket 5 has an opening 51 at the upper end, and the lower end of the liquid mixing bucket 5 is connected with the liquid mixing bucket 5 and the dyeing bucket 2 The second liquid flow pipe 7 and the filter 6 respectively have an inlet 61 and an outlet 62. The lower end of the dyeing barrel 2 is connected with a liquid flow pipe 2 8 and the liquid flow pipe 2 8 is connected with the inlet 61 of the filter 6, The outlet 62 is connected to the liquid flow pipe 9 connecting the filter 6 and the liquid mixing barrel 5; the dyeing barrel 2 is provided with a liquid level gau...

Embodiment 2

[0045] The present embodiment provides a yarn dyeing method, which includes the following steps:

[0046] a. Yarn preparation and inspection: Before dyeing the yarn, inspect the quality of the yarn. The yarn must be clean and free from stains and neutral. The stacking time should not exceed 8 hours, and it should be covered with a damp cloth;

[0047] b. Feeding: Put the yarn into the dyeing barrel 2 and place it on the dyeing rod 17,

[0048] c. Dye preparation: prepare anthraquinone vat dyes, add 5-6g of caustic soda and sodium hydroxide for each part of the raw material of anthraquinone type structure, preferably 5.5g in this embodiment; pour water to make a solution, and Add 0.2-0.5g / L of bone glue retarder; in this embodiment, it is preferably 0.35g / L.

[0049] d. Dye injection and dyeing: Inject the prepared dye into the dyeing barrel 2 and dip it for 20-30 minutes; in this embodiment, it is preferably 25 minutes;

[0050] f. Take out the yarn.

[0051] The pre-dyeing treatment of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com