Patents

Literature

41results about How to "Reduce the driving source" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

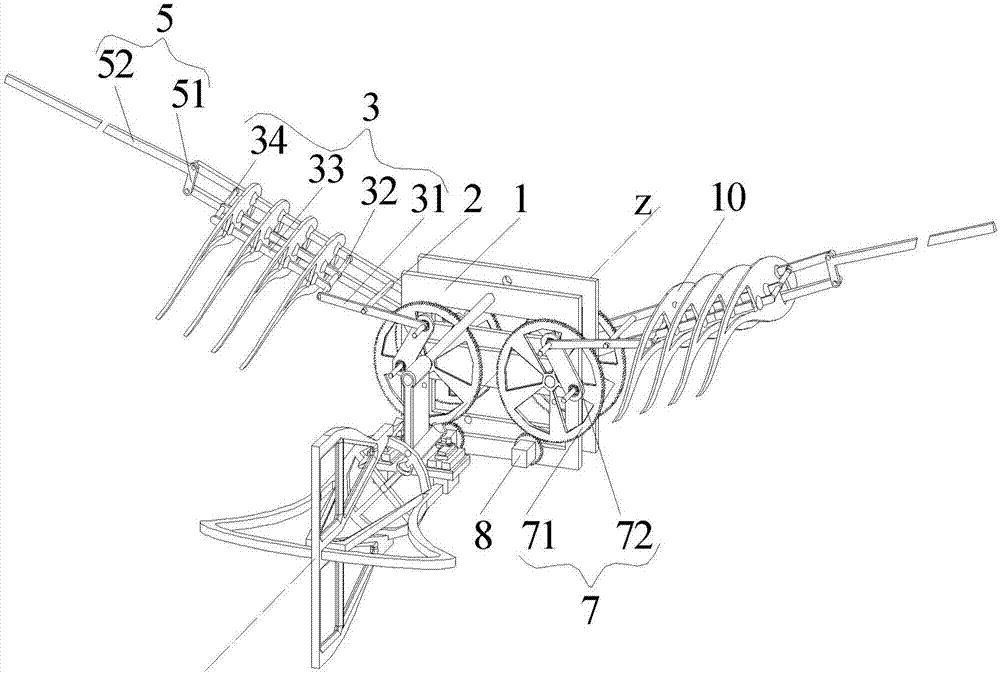

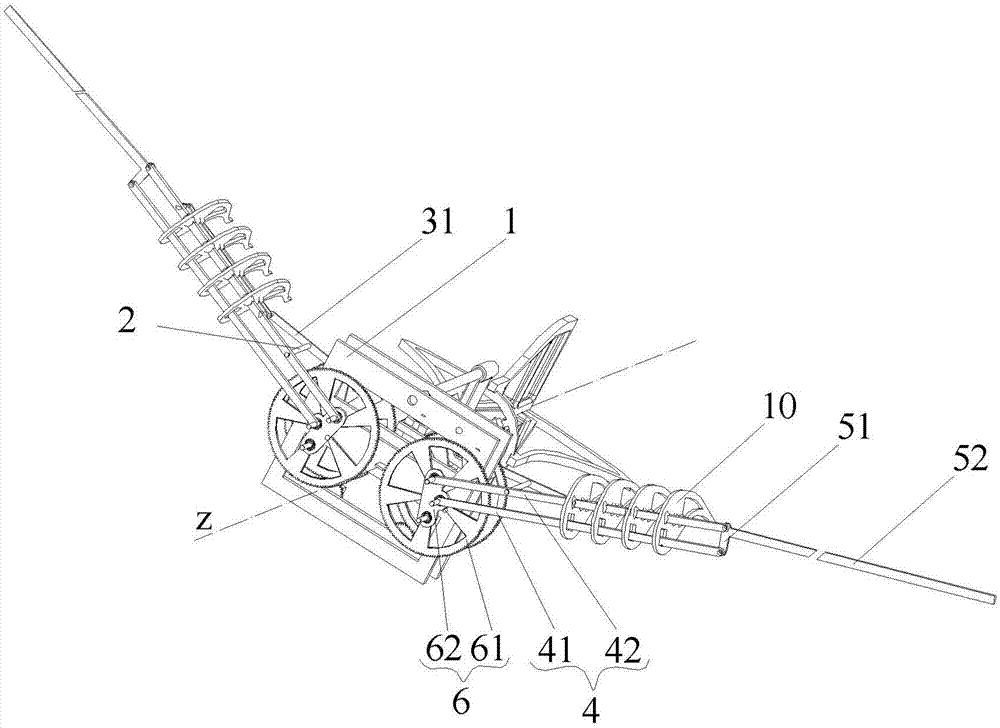

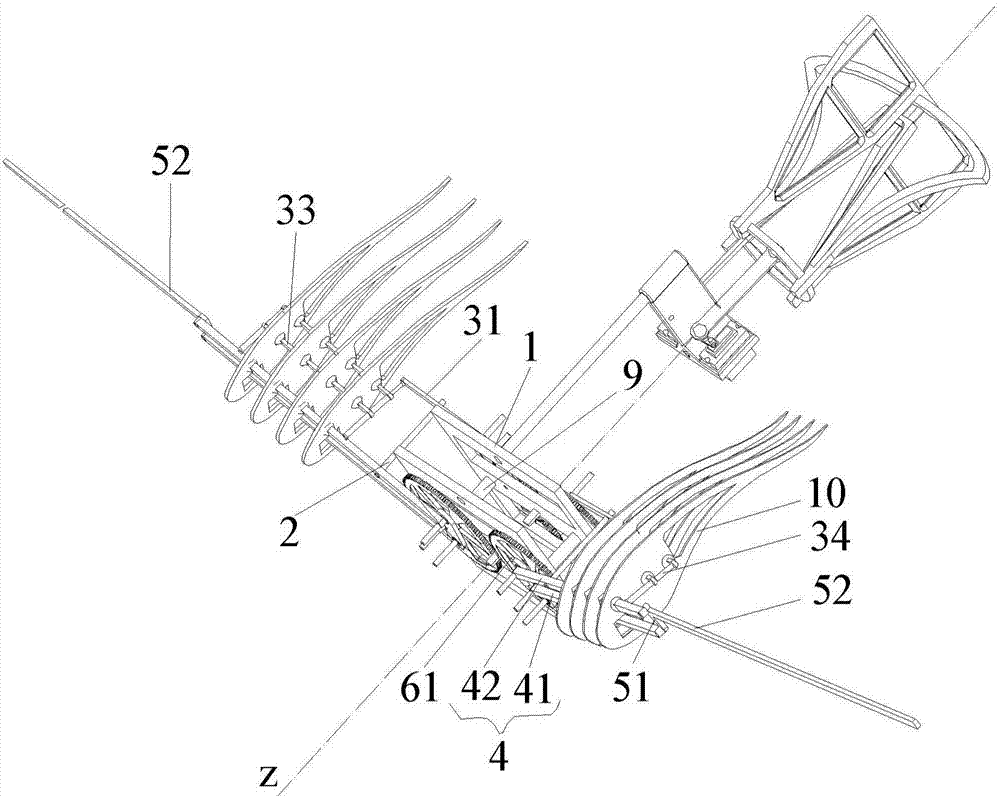

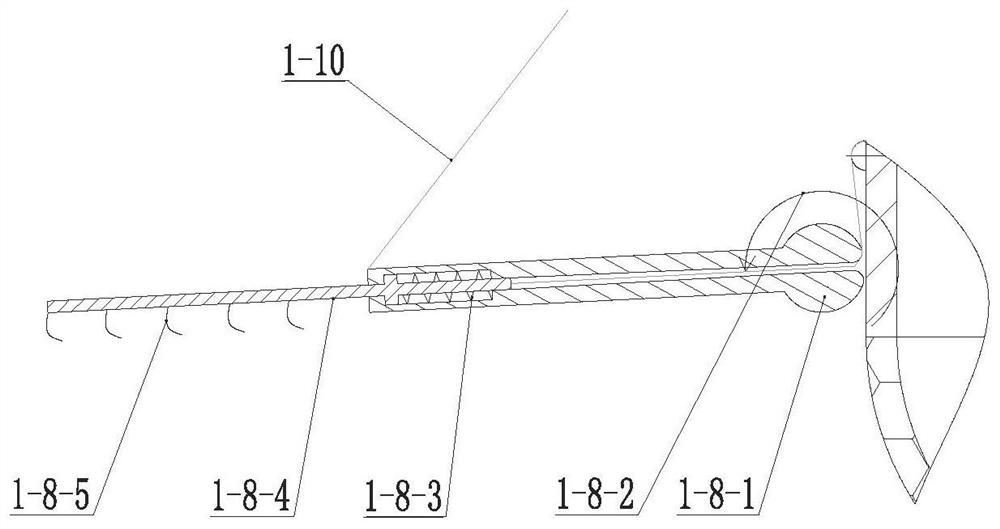

Flapping wing aircraft capable of realizing twisting of inner wings

The invention provides a flapping wing aircraft capable of realizing twisting of inner wings. The flapping wing aircraft comprises a rack, wings, rear drive devices and front drive devices. The rack has mounting positions. The wings are symmetrically arranged on the both sides of the rack. The wing on each side comprises an inner wing main flapping rod and an inner wing auxiliary flapping rod. The inner wing main flapping rods generate lift required during the flapping wing flight process. The inner wing auxiliary flapping rods generate lift and thrust required during the flapping wing flight process. The front drive devices are mounted in the mounting positions of the rack at the front and used for driving the inner wing main flapping rods. The rear drive devices are mounted in the mounting positions of the rack at the rear and used for driving the inner wing auxiliary flapping rods. The inner wing main flapping rods and the inner wing auxiliary flapping rods on the both sides of the rack have phase differences. The flapping wing aircraft has the advantages that the design of front and rear inner wing flapping mechanisms having the phase differences is provided, the flapping wing motions which are in accordance with the flapping wing flight principle are conducted, and the takeoff, direct flight and landing functions can be fulfilled when the left and right wings are synchronized; and when differential motions are conducted, the functions such as pitching, yawing and steering under the asynchronous control of frequencies and amplitudes of the left and right flapping wings can be fulfilled.

Owner:NANTONG UNIVERSITY

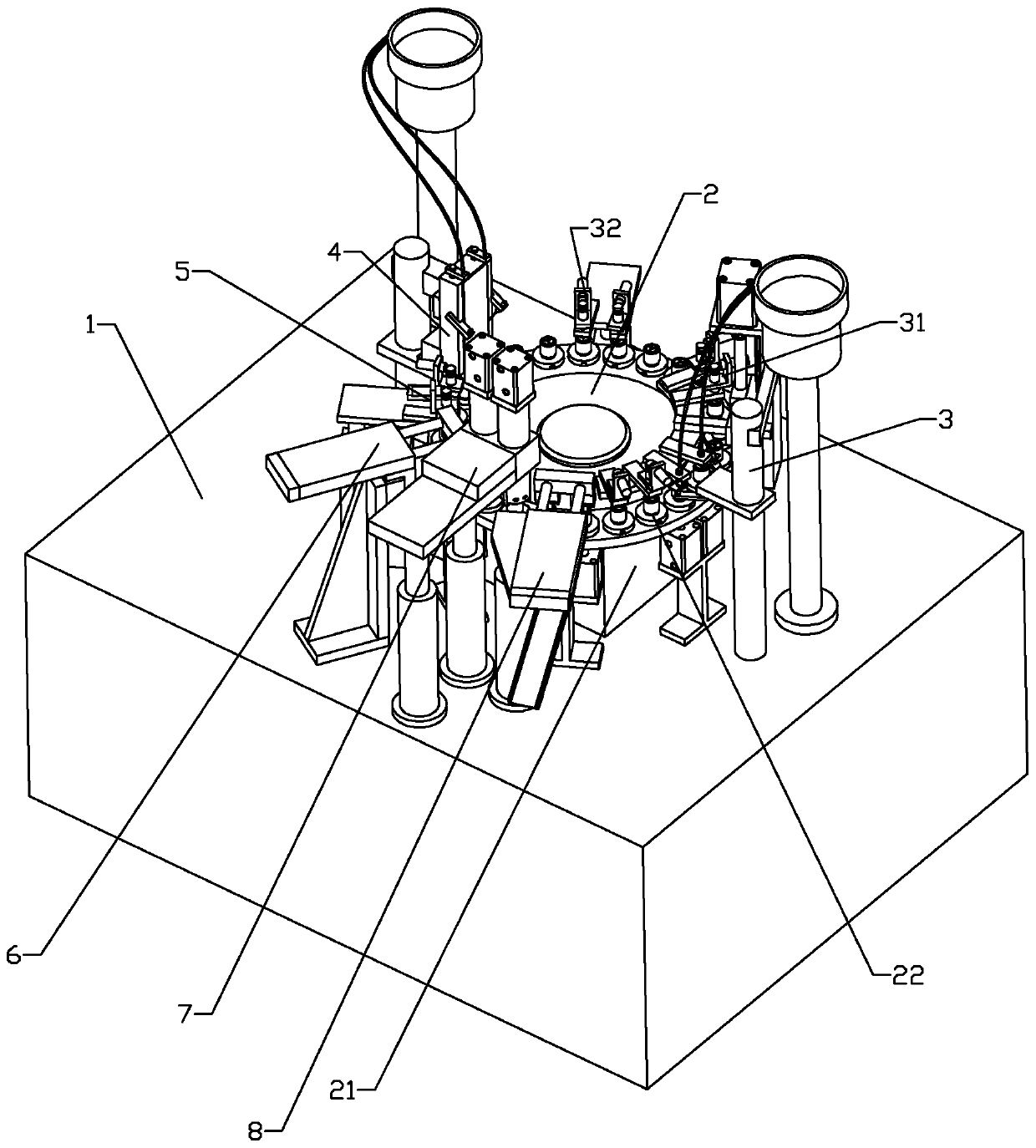

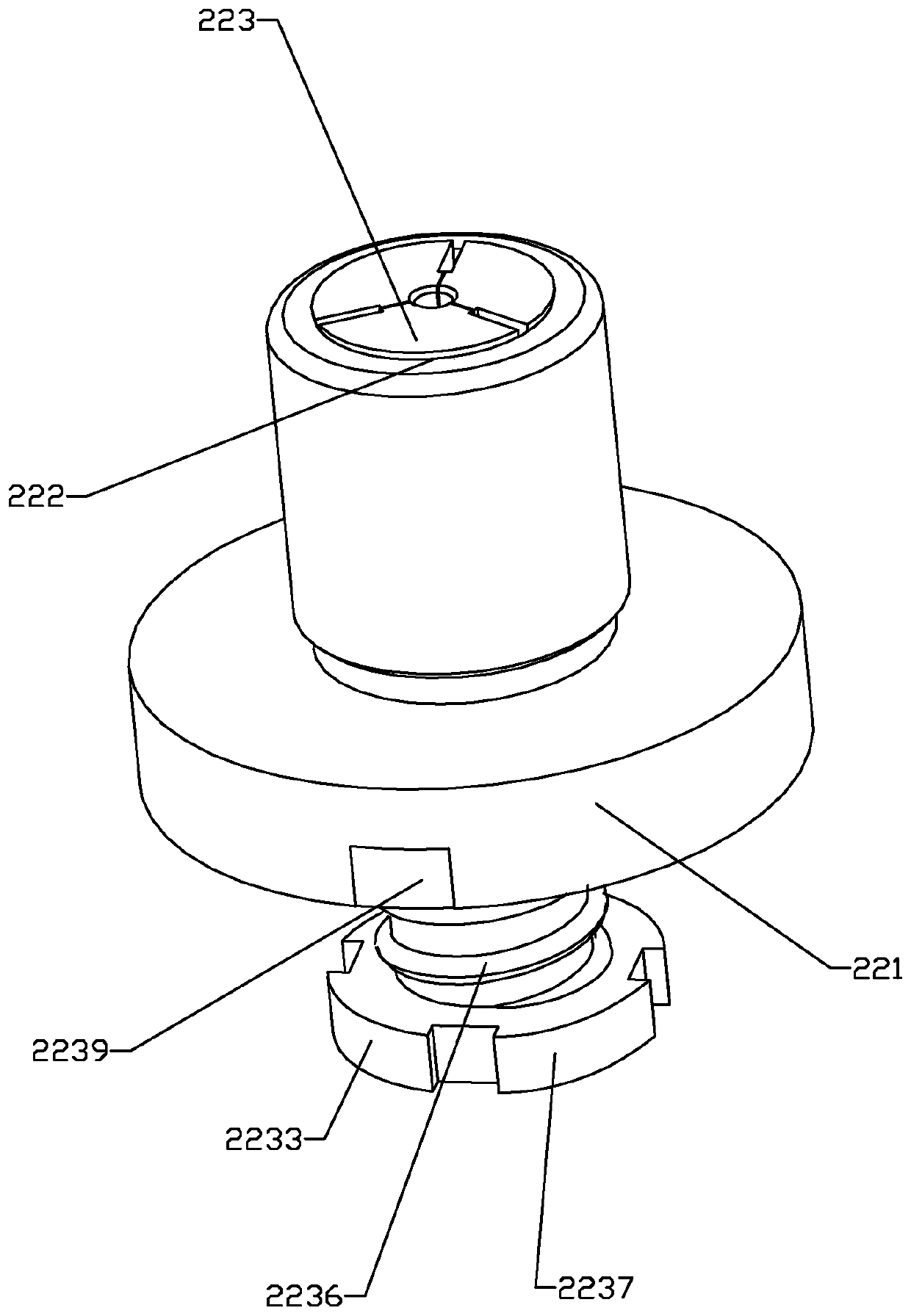

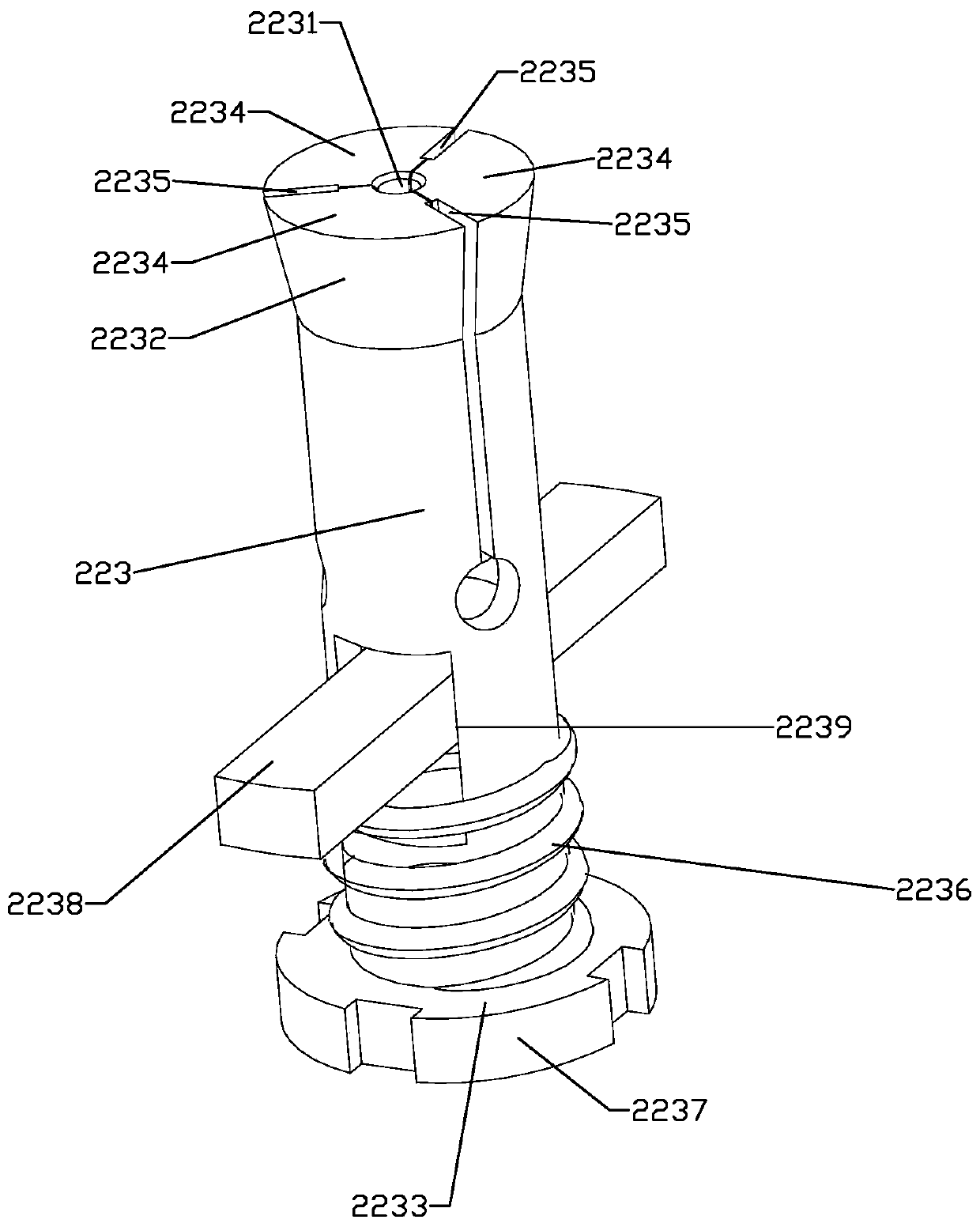

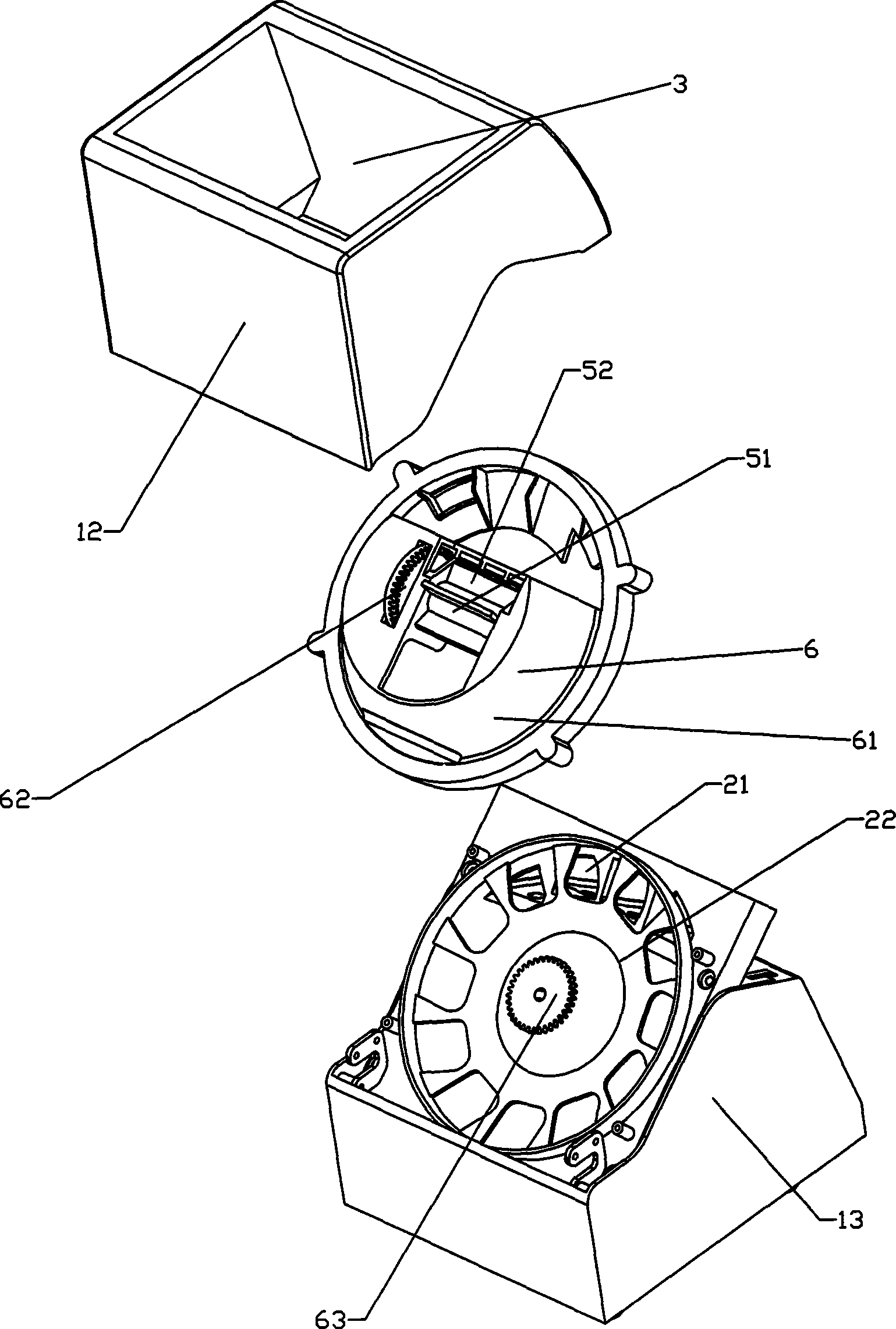

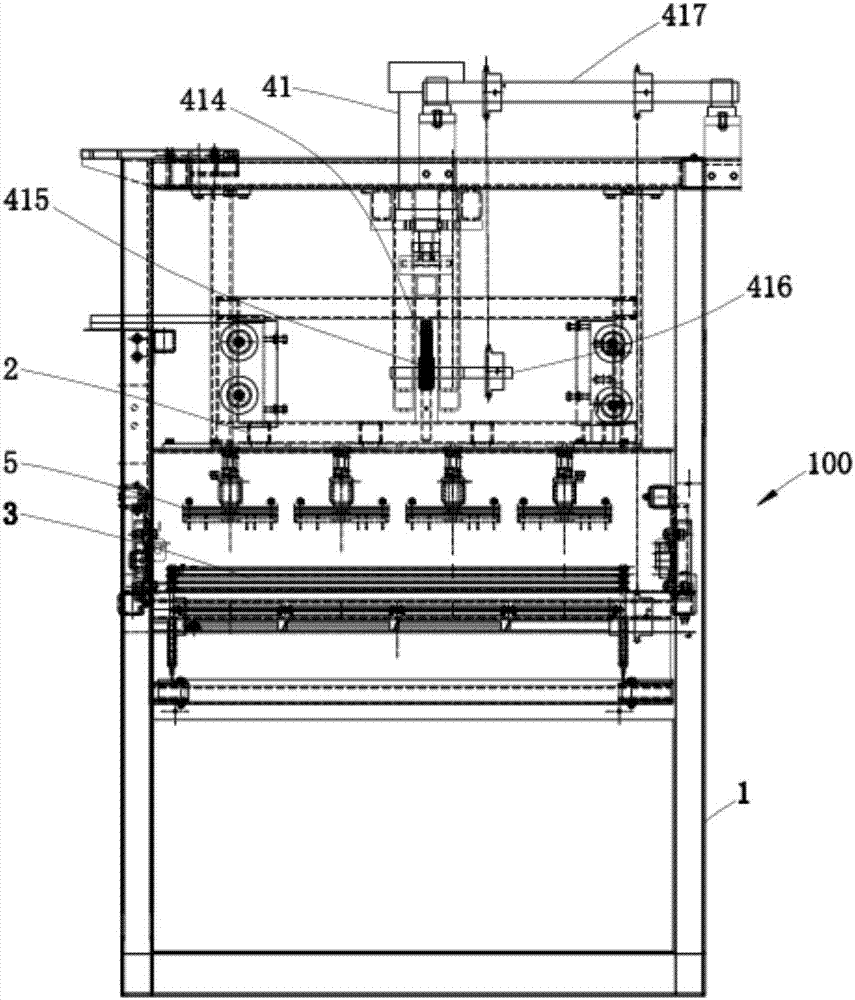

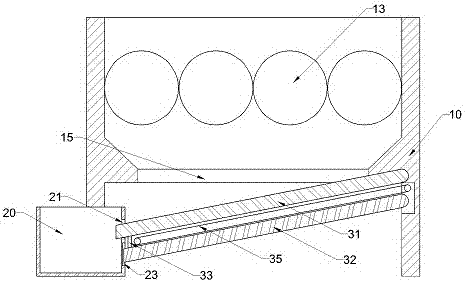

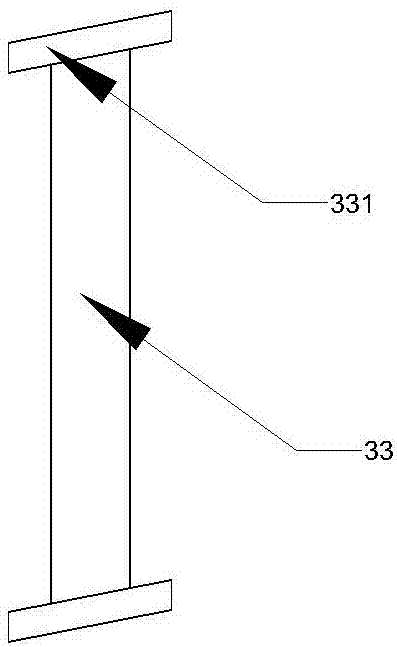

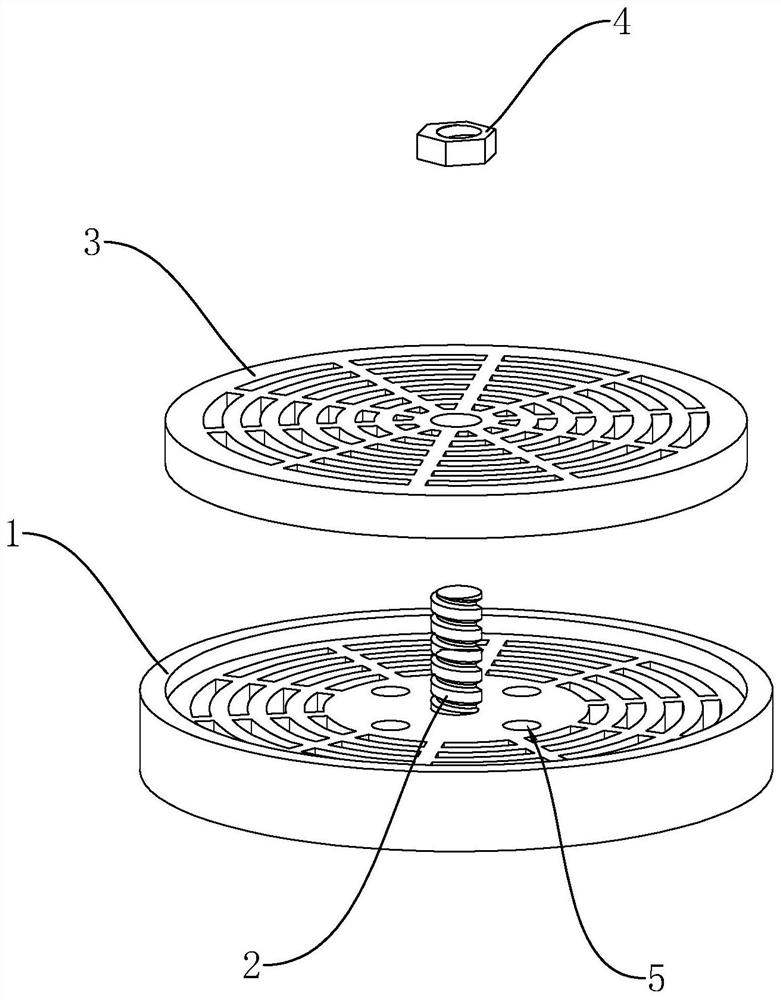

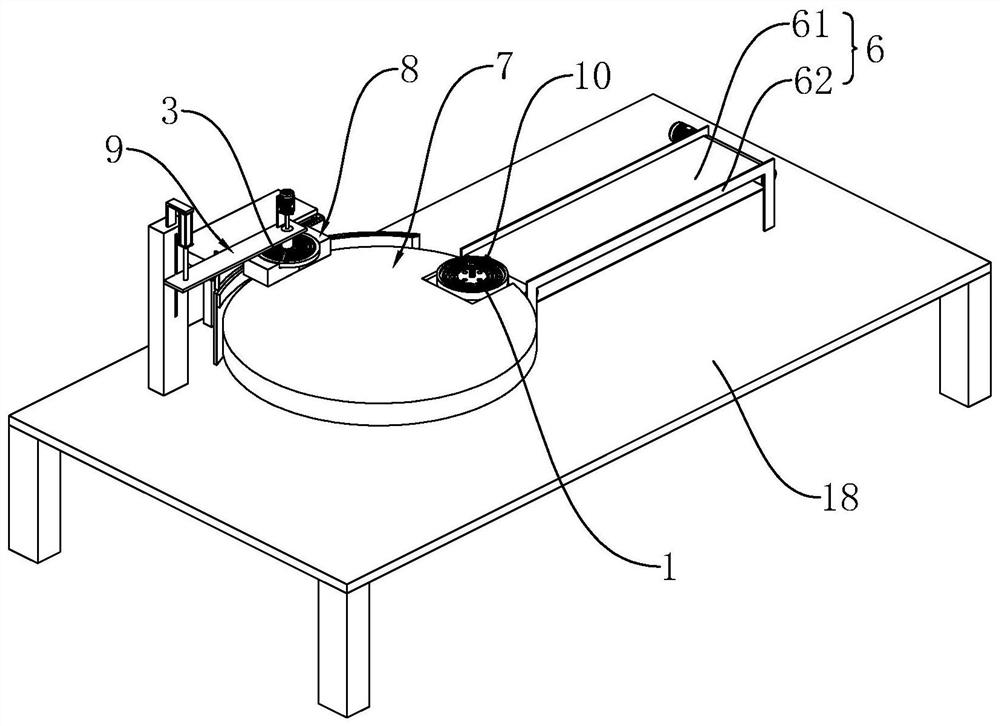

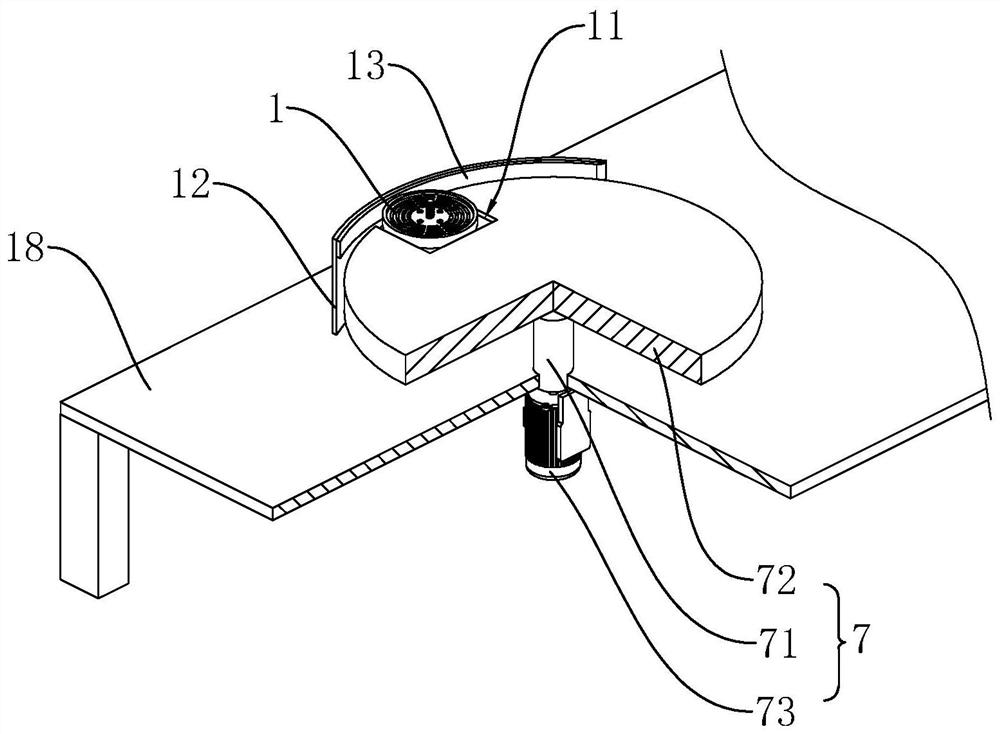

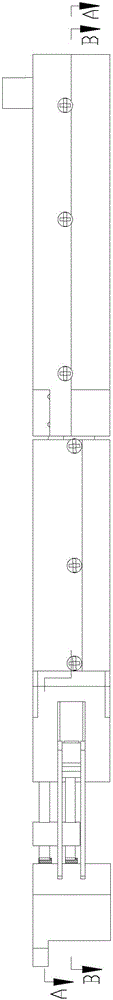

Ballpoint pen spring nib assembling device

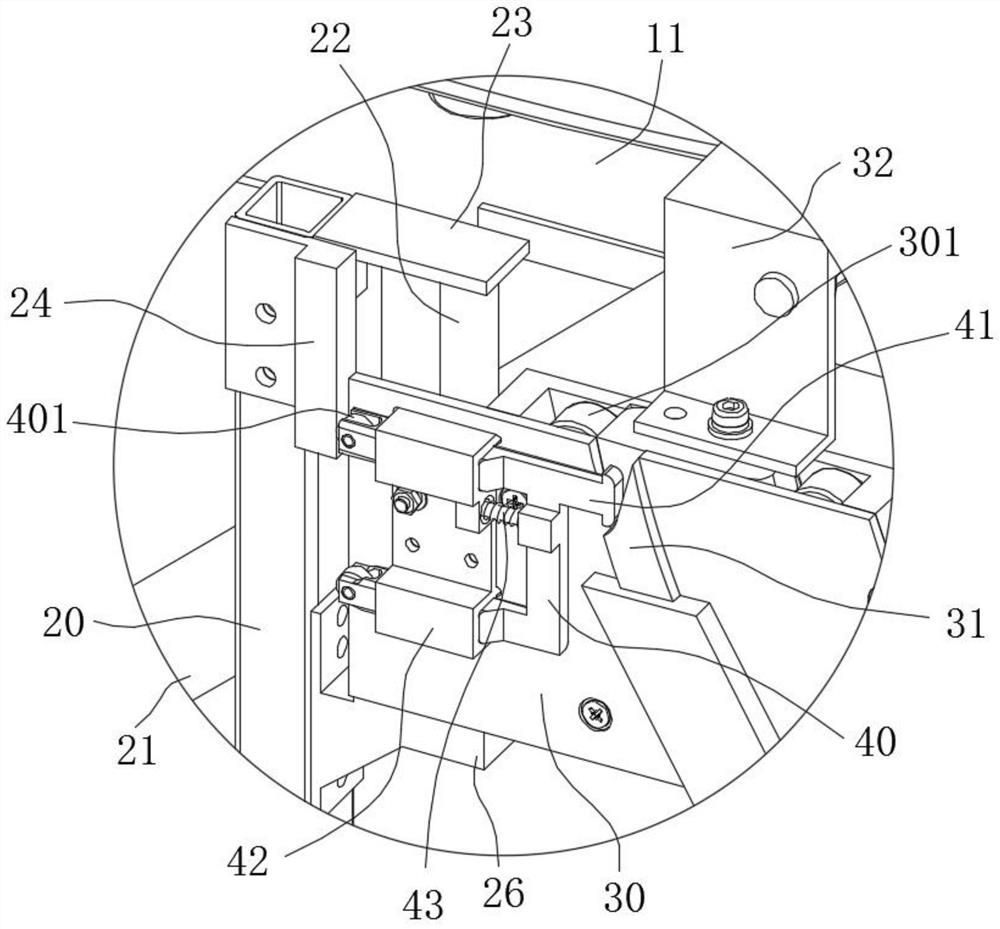

ActiveCN111251749AQuality assuranceUniform deformationPen repairingBall-point pensElectric machineryEngineering

The invention relates to a ballpoint pen spring nib assembling device. The assembling device comprises an assembling platform, an assembling rotary disc and a rotary disc motor, wherein the edge of the assembling rotary disc is provided with conveying clamps for clamping nibs for conveying; and a nib feeding device for placing the nibs on the conveying clamps, a first nib detection device for detecting whether the nibs exist on the conveying clamps or not, a second nib detection device for detecting whether the nibs on the conveying clamps conform to the standard or not, a spring feeding device for placing springs on the nibs of the conveying clamps, a spring detecting device for detecting whether the springs are assembled in place or not, a waste discharging device for taking away unqualified nibs, a deformation device for extruding and deforming the side surfaces of the qualified nibs to limit the springs in the nibs, and a qualified product discharging device for taking away the deformed nibs are sequentially arranged at the position, close to the edge of the assembling rotary disc, of the assembling platform in the rotating direction. According to the technical scheme, the ballpoint pen spring nib assembling device improves the yield, improves the assembling efficiency and reduces the machining cost.

Owner:WENZHOU UNIVERSITY +1

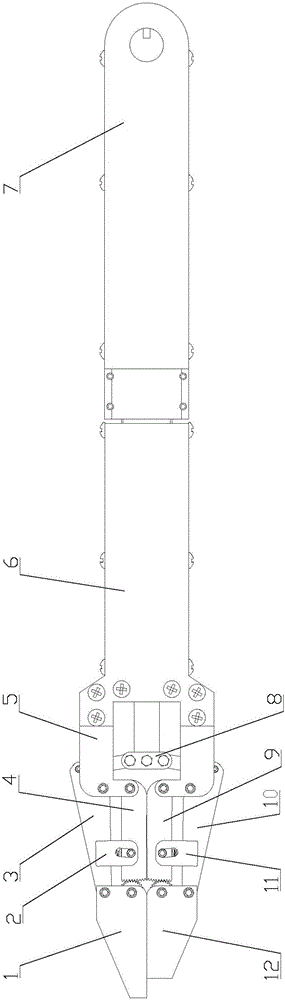

Tail end structure of multipurpose manipulator

InactiveCN103448070ASimple structureFlexible structureGripping headsWheelchairs/patient conveyanceDrive motorEngineering

The invention discloses a tail end structure of a multipurpose manipulator. The tail end structure of the manipulator can be used for finishing delicate action such as picking of paper, operating keys, grabbing of small pills and the like besides the grabbing action of a general clamping manipulator, and can be used for finishing other life operation such as opening and closing of doors in cooperation with the arm of the manipulator. According to the tail end structure, all actions of fingers are finished by using one motor, so that the number of driving motors for the manipulator is reduced, the weight of the manipulator can be effectively reduced, unnecessary energy consumption is reduced, and a plurality of operating functions are completed on the premise of keeping a simple structure.

Owner:SOUTH CHINA UNIV OF TECH

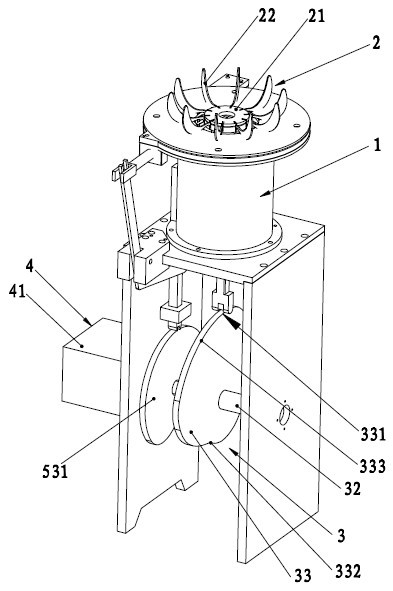

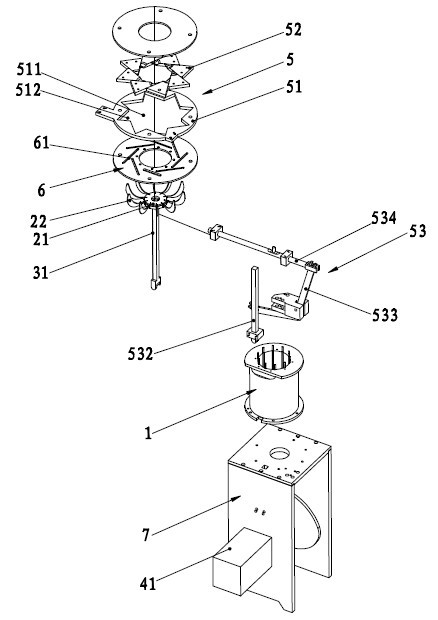

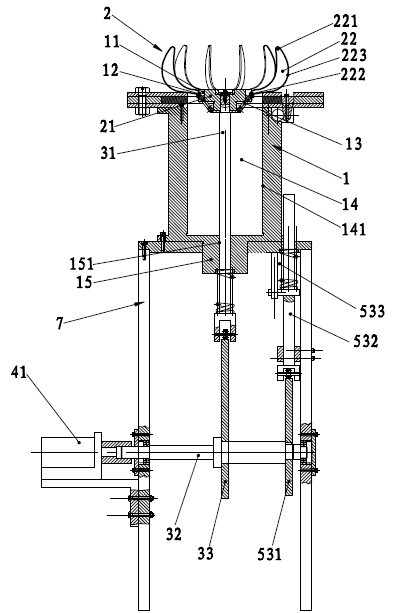

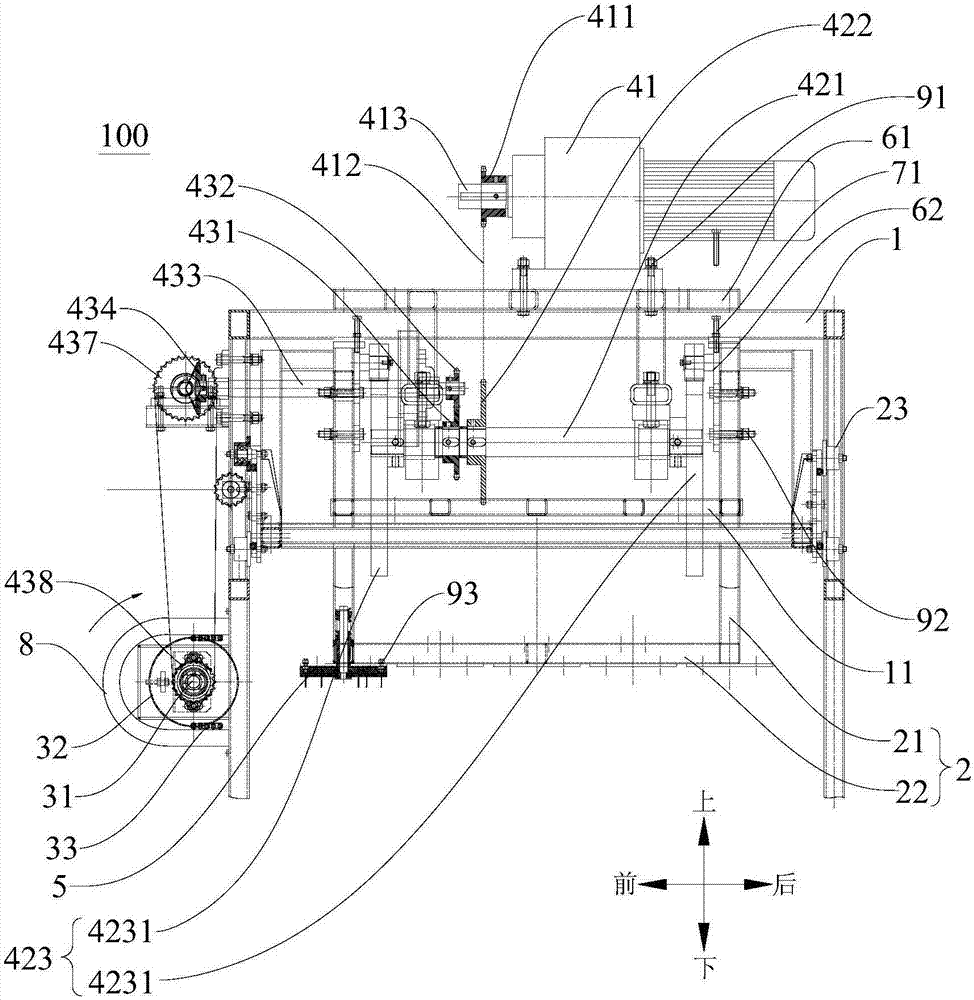

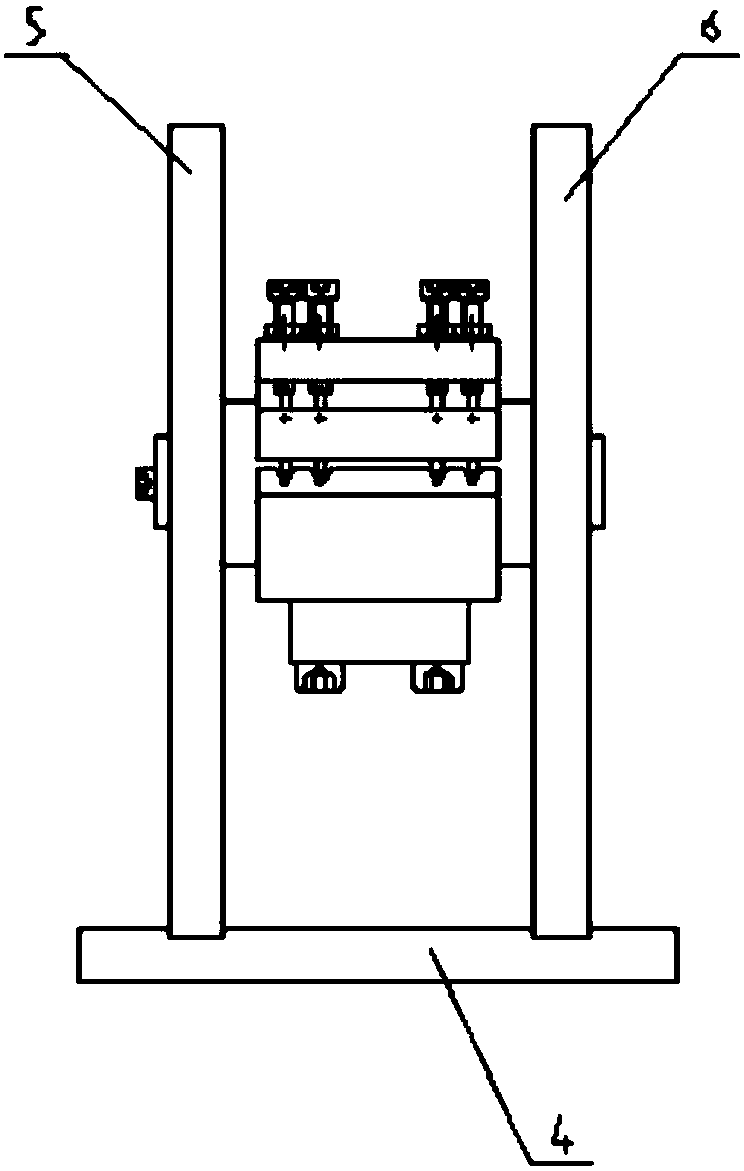

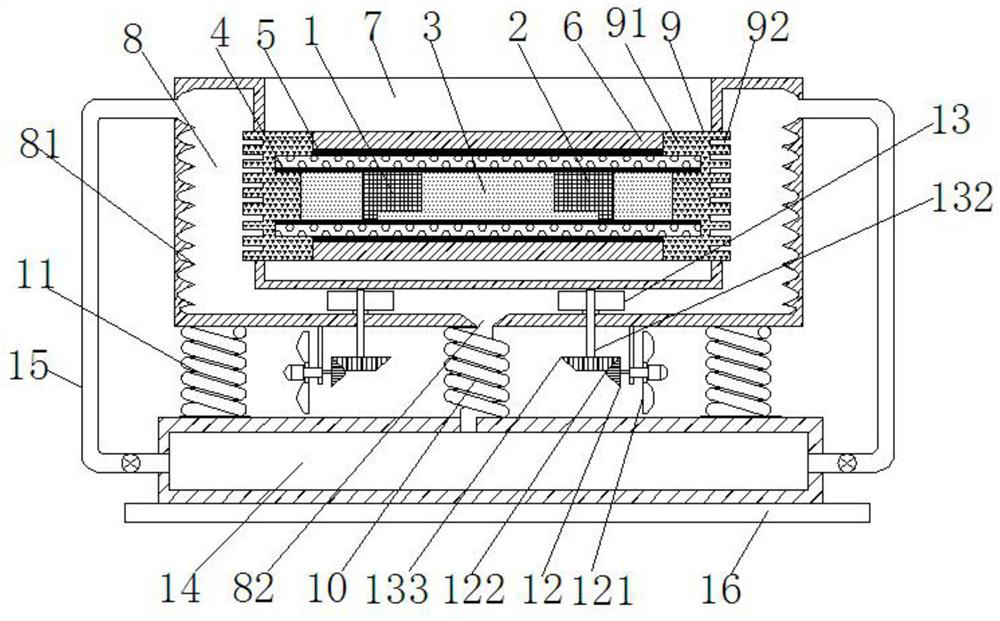

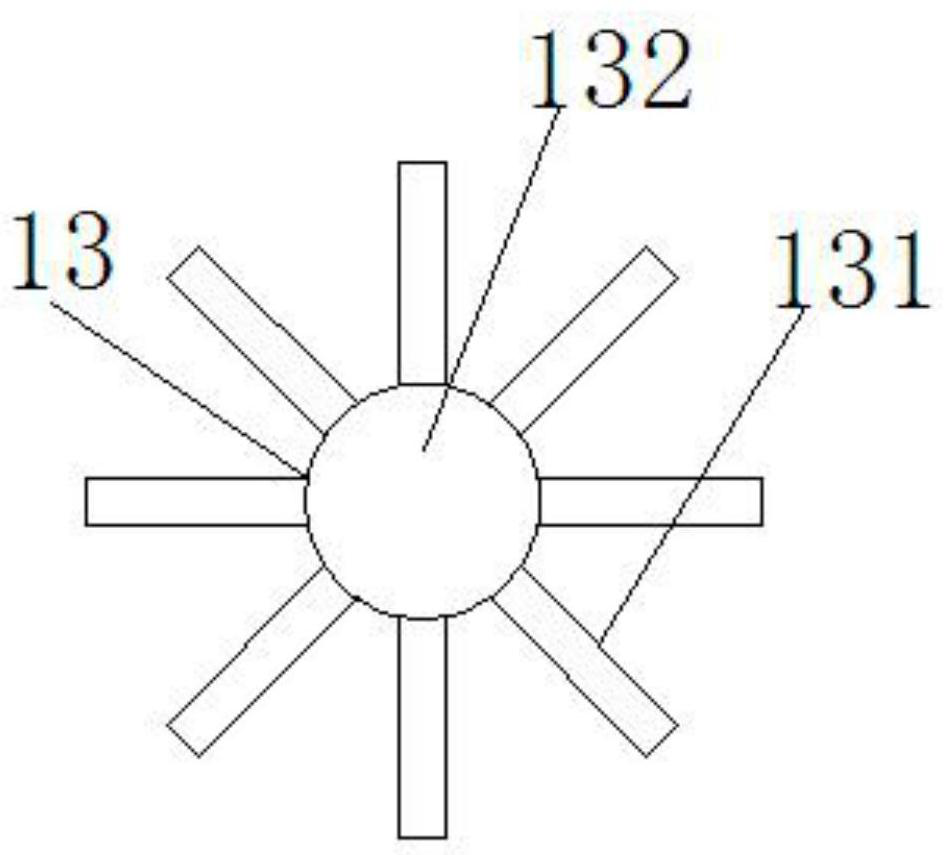

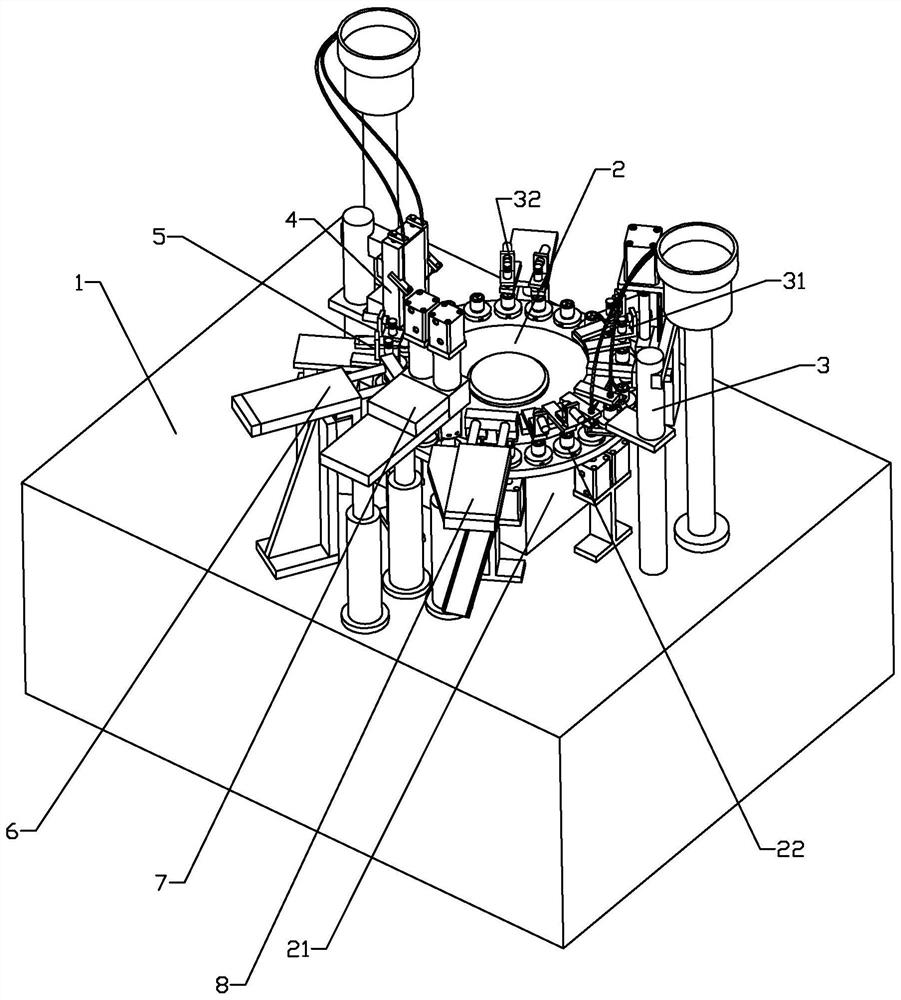

Steamed stuffed bun forming machine

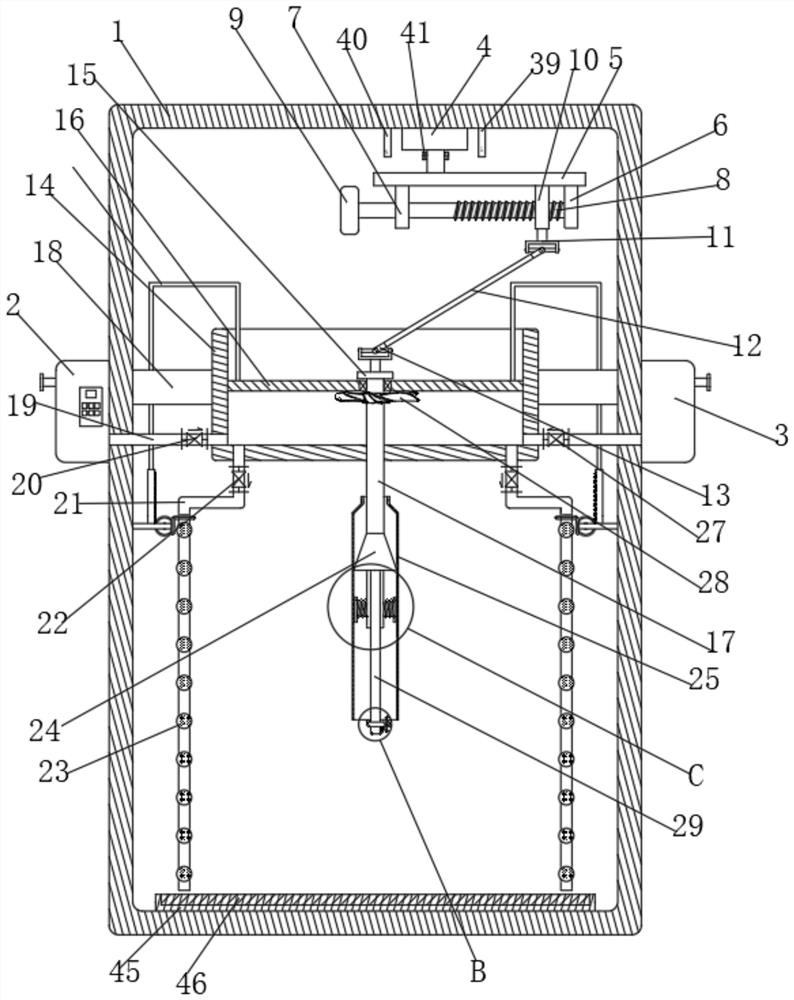

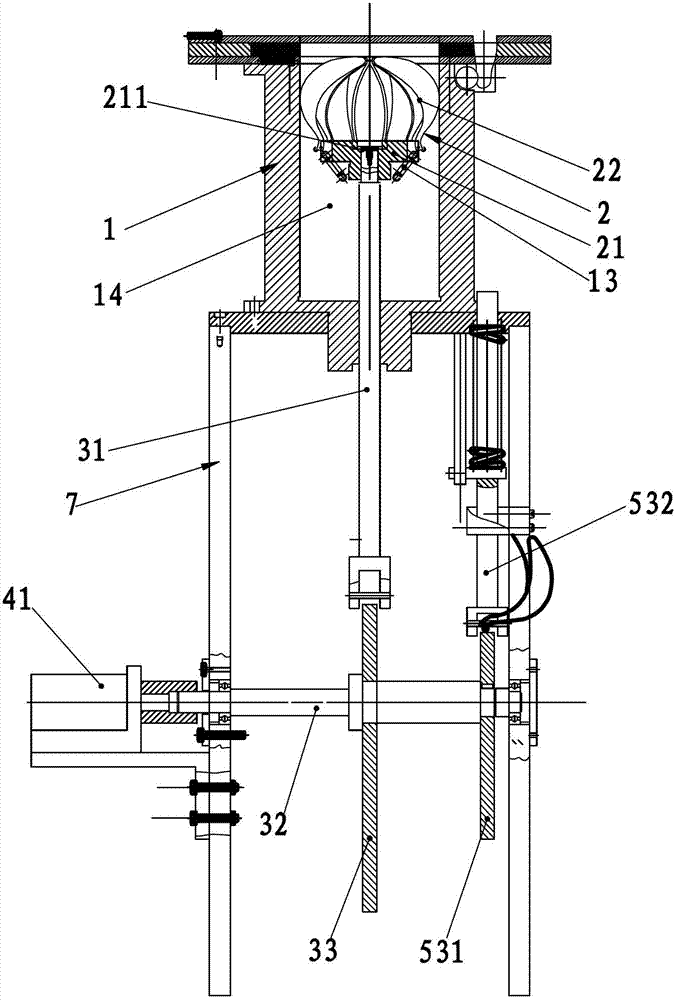

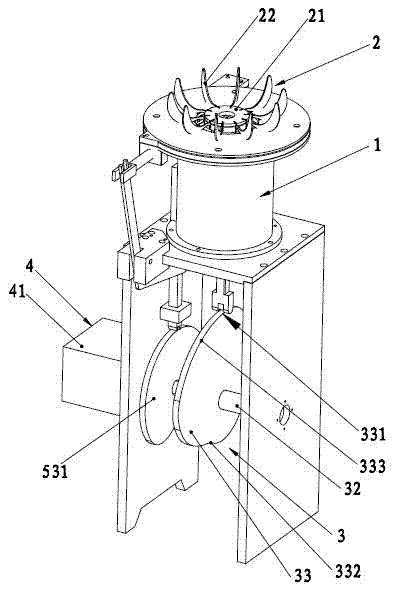

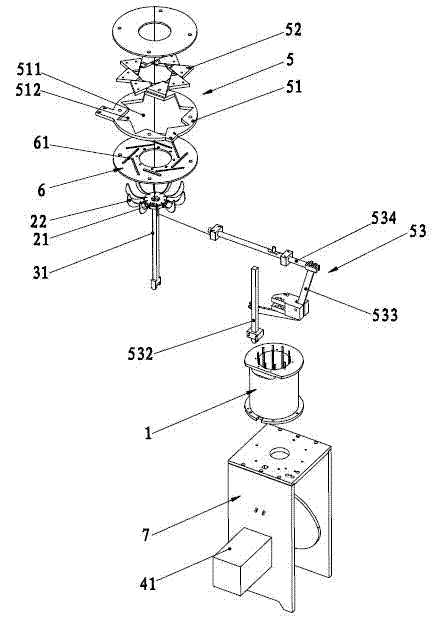

InactiveCN102058065AFast processingReduce manufacturing costFood shapingFood preparationDrive shaftFood processing

The invention relates to a food processing device, in particular to a steamed stuffed bun forming machine. In the technical scheme provided by the invention, the steamed stuffed bun forming machine is characterized by comprising a mounting base, a forming and covering mechanism, a transmission mechanism and a driving mechanism driving the transmission mechanism. The transmission mechanism is matched with the forming and covering mechanism to enable the forming and covering mechanism to reciprocate along the axial direction of the mounting base and to expand and fold. The forming and covering mechanism comprises a sliding disk and a swingable jack catch in circumferential hinge with the sliding disc. The transmission mechanism comprises a ejector rod, a transmission shaft linked to the driving mechanism and a transmission unit used for the linkage between the ejector rod and the transmission shaft. By using the above technical scheme, the invention provides the steamed stuffed bun forming machine which has high processing speed and reduced production cost.

Owner:WENZHOU UNIVERSITY

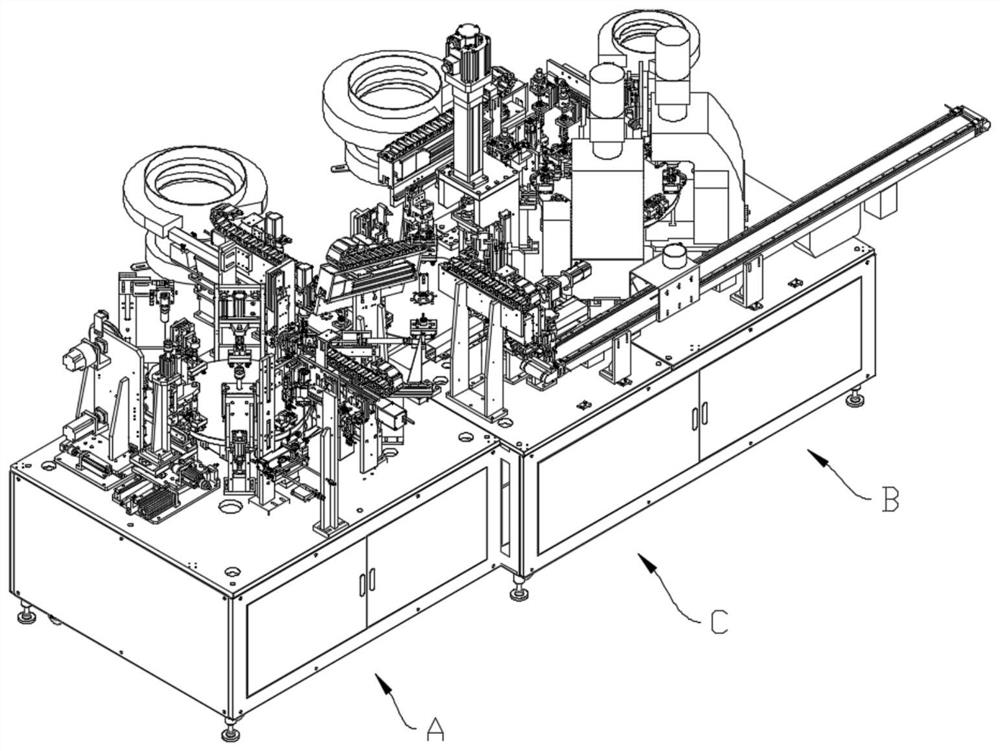

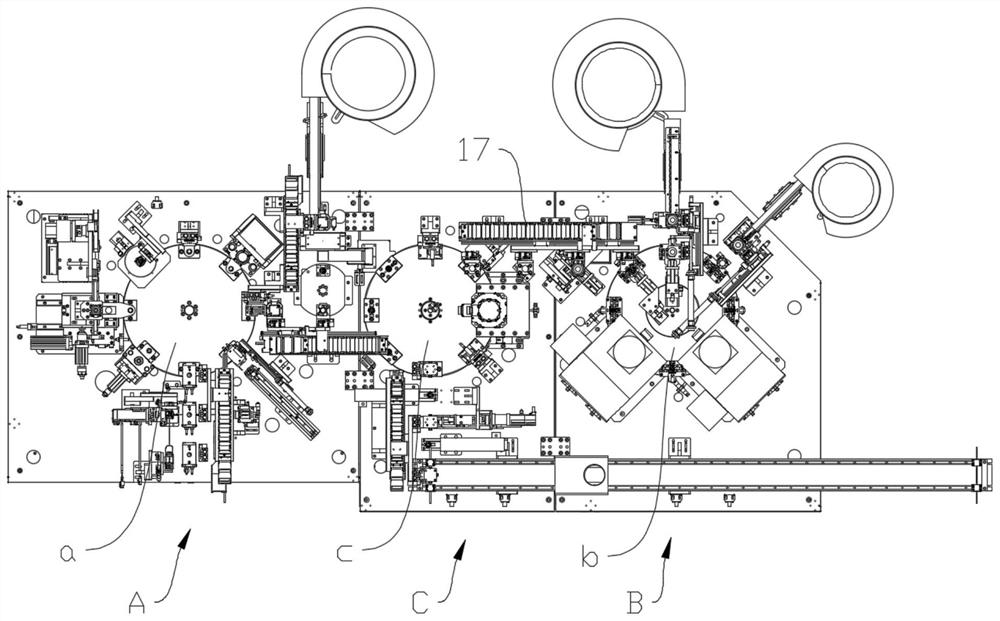

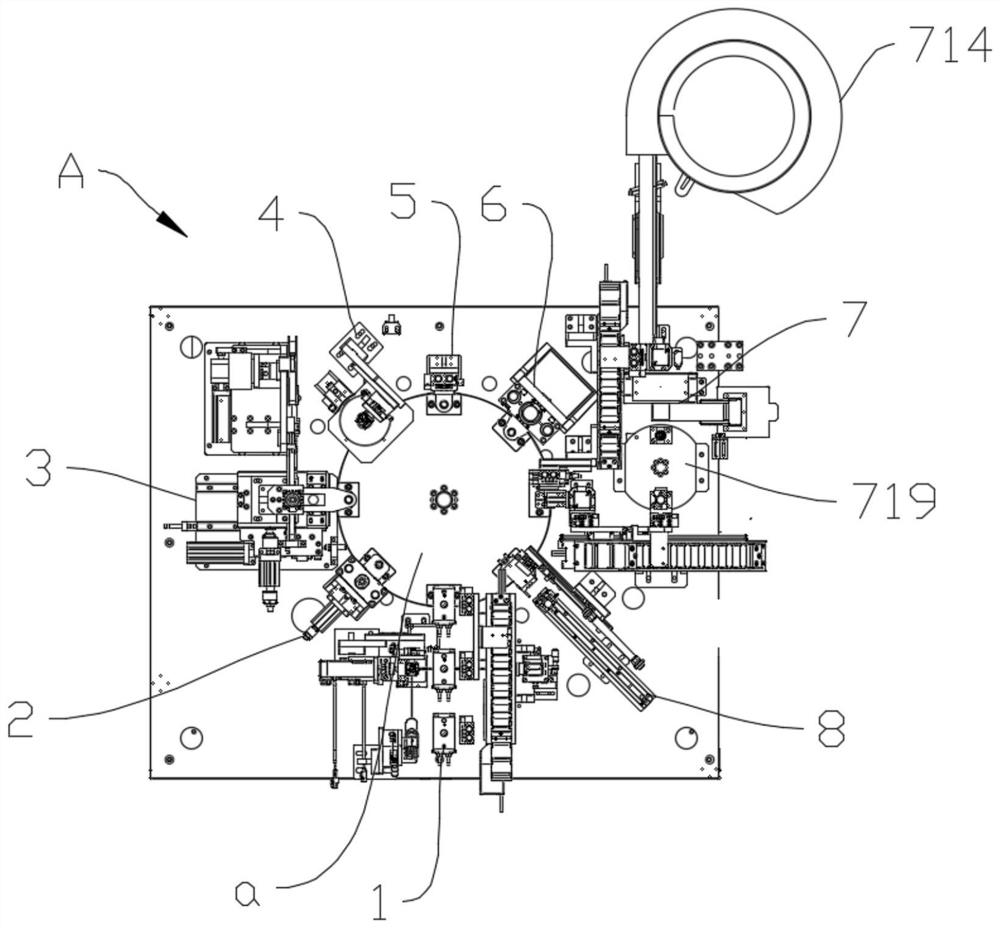

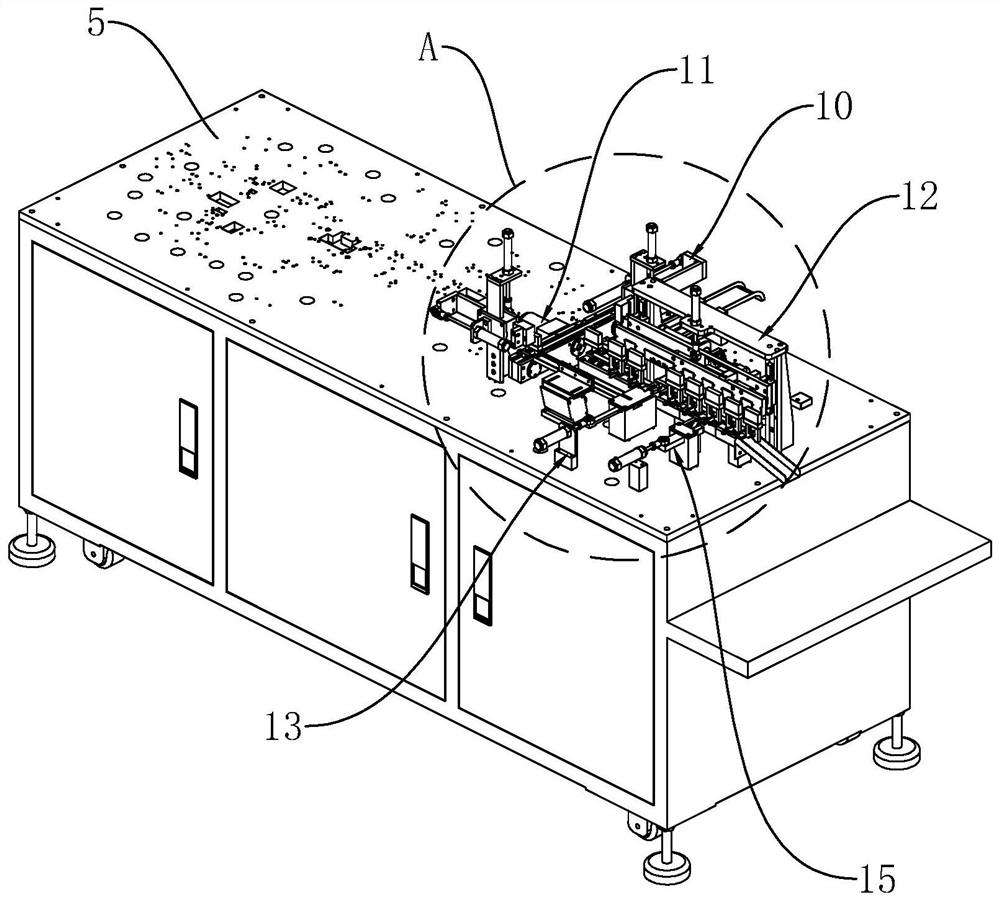

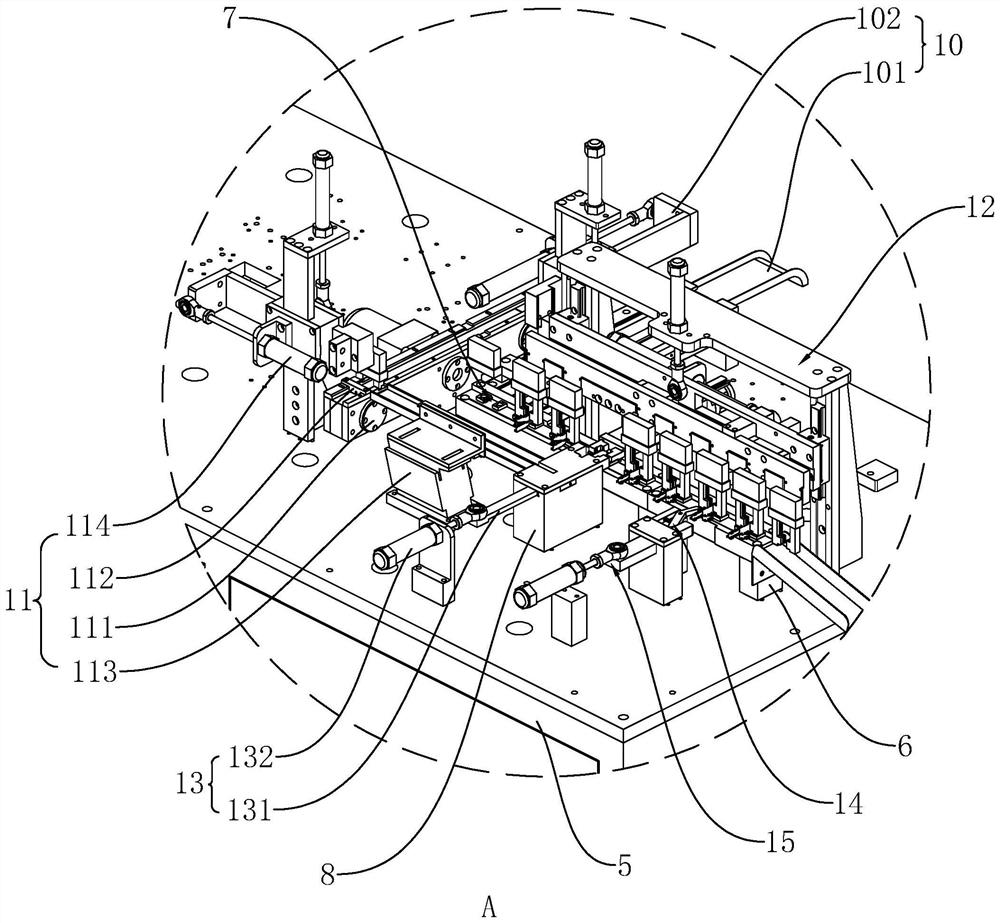

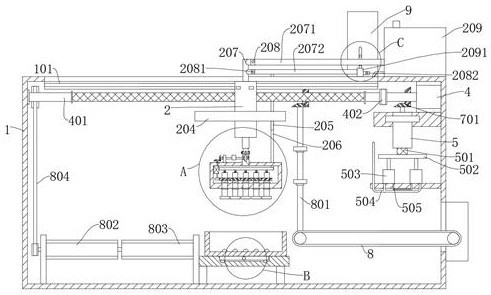

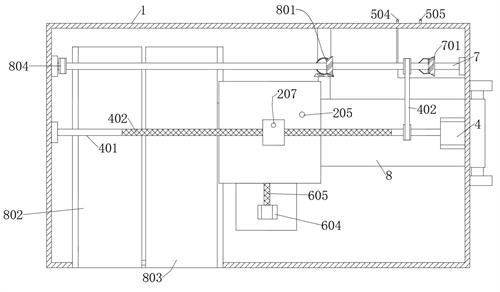

Electromagnetic valve coil automatic assembling equipment and assembling method

ActiveCN113695901AReduce transshipment processSmall footprintAssembly machinesOther manufacturing equipments/toolsStructural engineeringAssembly line

The invention discloses electromagnetic valve coil automatic assembling equipment and assembling method. The electromagnetic valve coil automatic assembling equipment comprises a coil welding testing mechanism A, an upper cover elastic piece combined pressing riveting mechanism B and a coil shell upper cover combined pressing fitting mechanism C, a coil shell assembling station of the coil welding testing mechanism A conveys an assembled coil to a coil feeding station of the coil shell upper cover combined press fitting mechanism C, an upper cover discharging station of the upper cover elastic piece combined press riveting mechanism B conveys an assembled upper cover to an upper cover feeding station of the coil shell upper cover combined press fitting mechanism C, the coil shell upper cover combined press fitting mechanism C performs press fitting on the coil and the upper cover and then outputs the coil and the upper cover, and a triple carrying mechanism is arranged between the upper cover discharging station and the upper cover feeding station and used for conveying the upper covers. Accordingi to the electromagnetic valve coil automatic assembling equipment and assembling method, the three assembly lines are ingeniously combined together, extra movement does not need, a driving source is saved, the whole occupied space is saved, efficiency is improved, and cost is reduced.

Owner:WUXI JINGSHENG AUTOMOTIVE ELECTRONICS

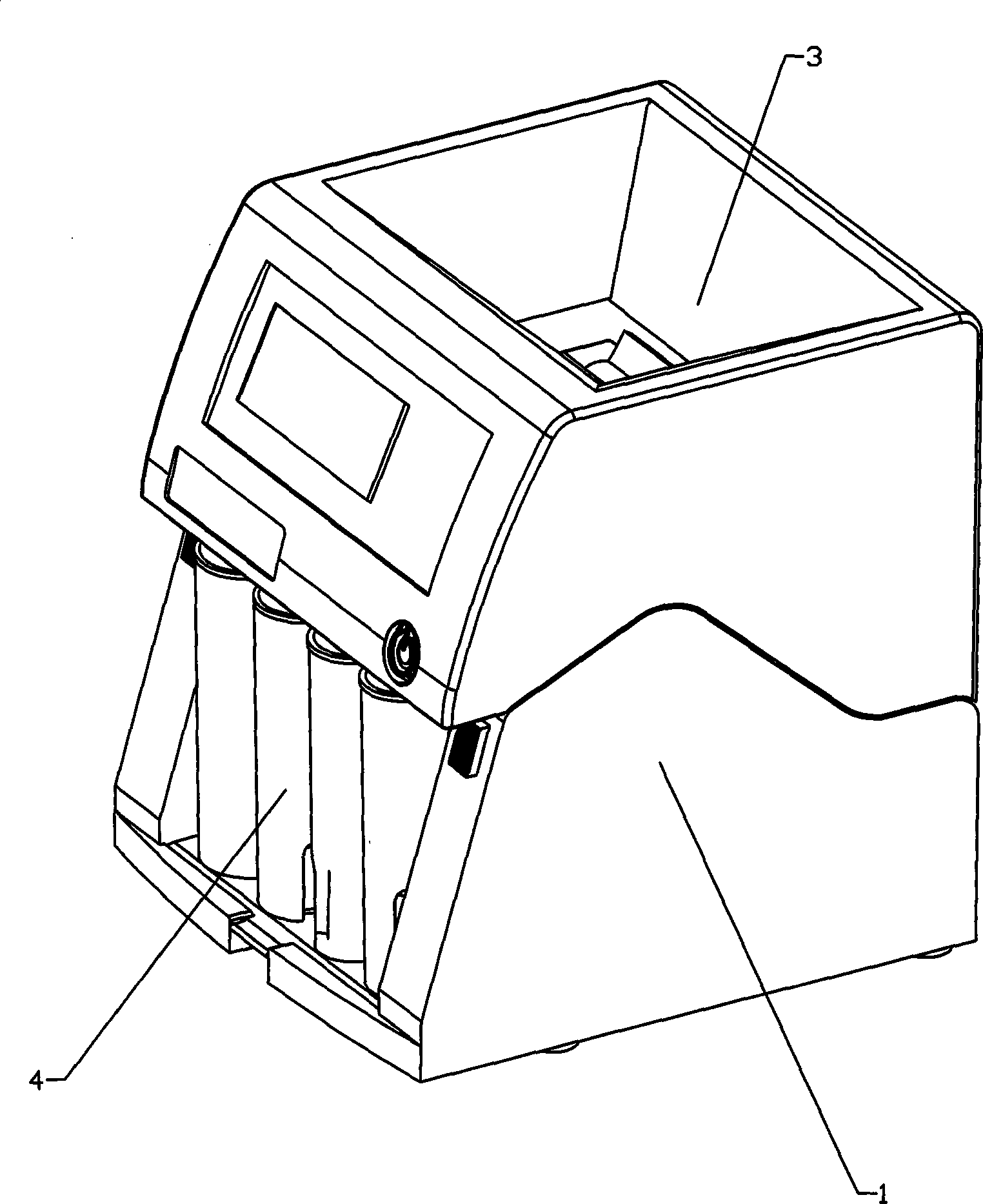

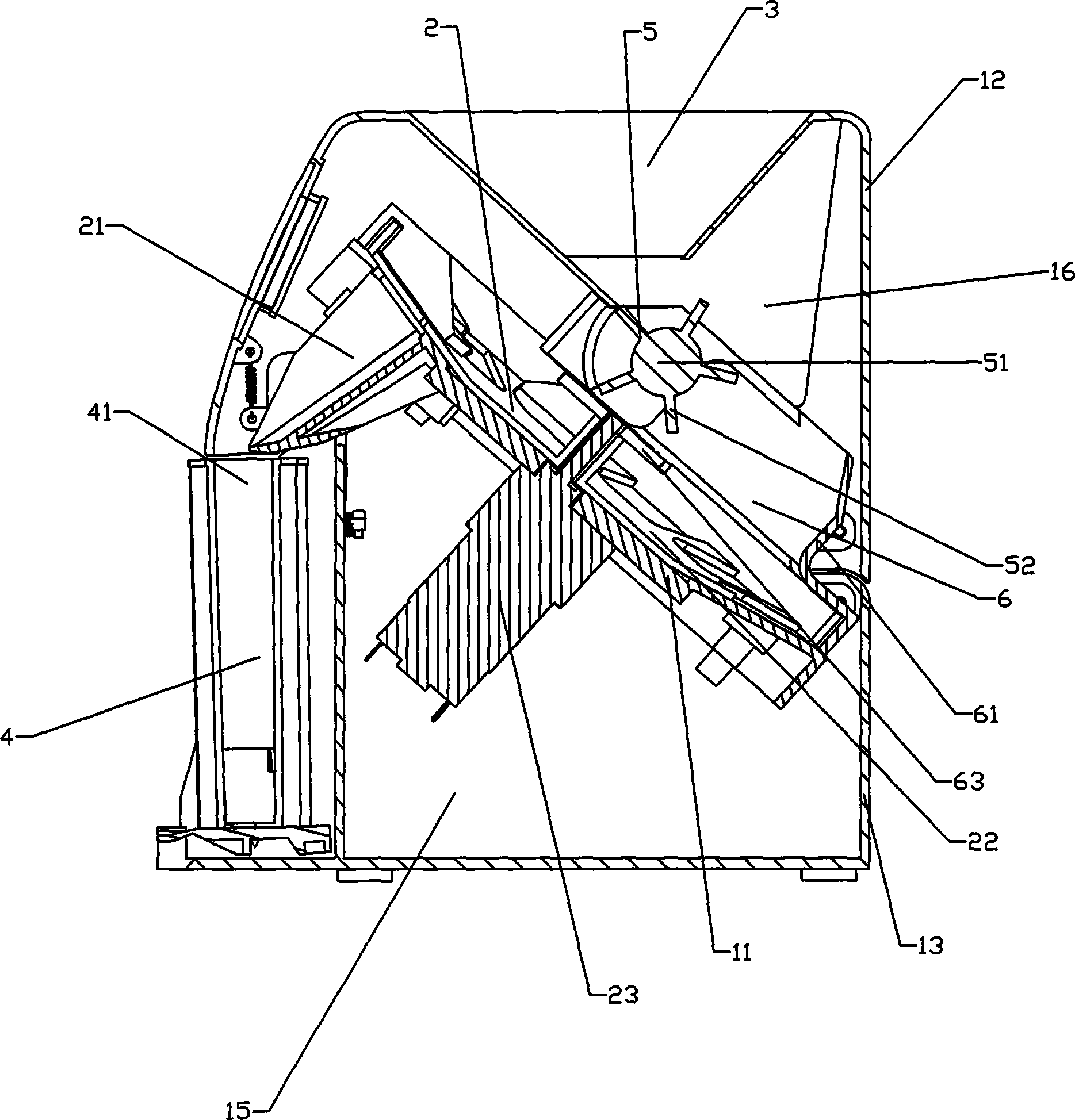

Coin sorting machine

InactiveCN104331982AEasy accessEasy maintenanceCoin/paper handlersMechanical engineeringLinkage concept

The invention relates to a coin sorting machine. The coin sorting machine comprises a shell, a sorting component arranged in the shell and used for sorting coins, a hopper located above the sorting component and used for storing coins, and a plurality of material barrels arranged below the sorting component in sequence and used for holding different sizes of coins, the sorting component comprises sorting holes through which different sizes of coins pass, a turn plate used for pushing coins to fall into the material barrels through different sorting holes, and a motor used for driving the turn plate to rotate and fixed in the shell, wherein the sorting holes are formed in the shell and corresponding to feed holes of the material barrels, a shifting component is arranged between the end of the hopper and the turn plate, the shifting component comprises a shifting shaft and shifting blocks which are uniformly arranged on the shifting shaft along the circumferential direction, and the shell is provided with a linkage component used for driving the shifting shaft to rotate by the aid of the turn plate. By means of said technical scheme, the coin sorting machine reduces the driving source use number.

Owner:俞劲峰

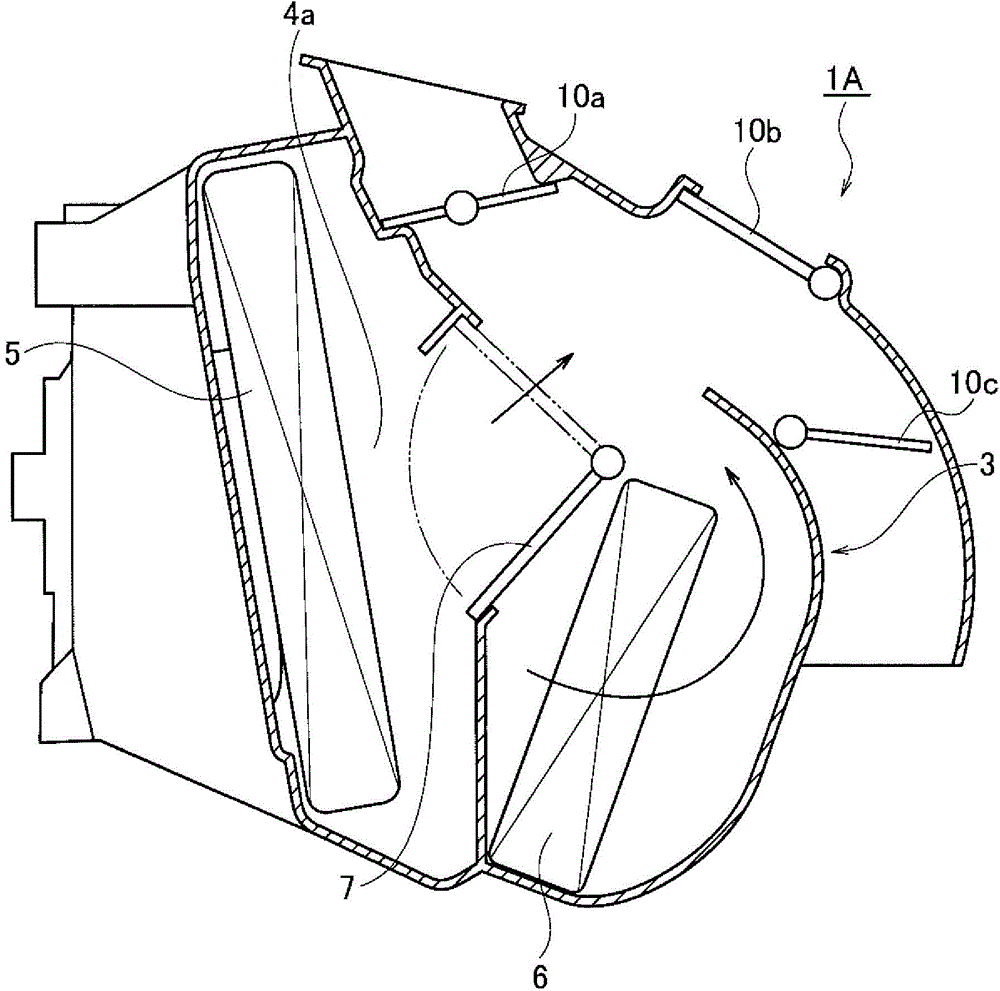

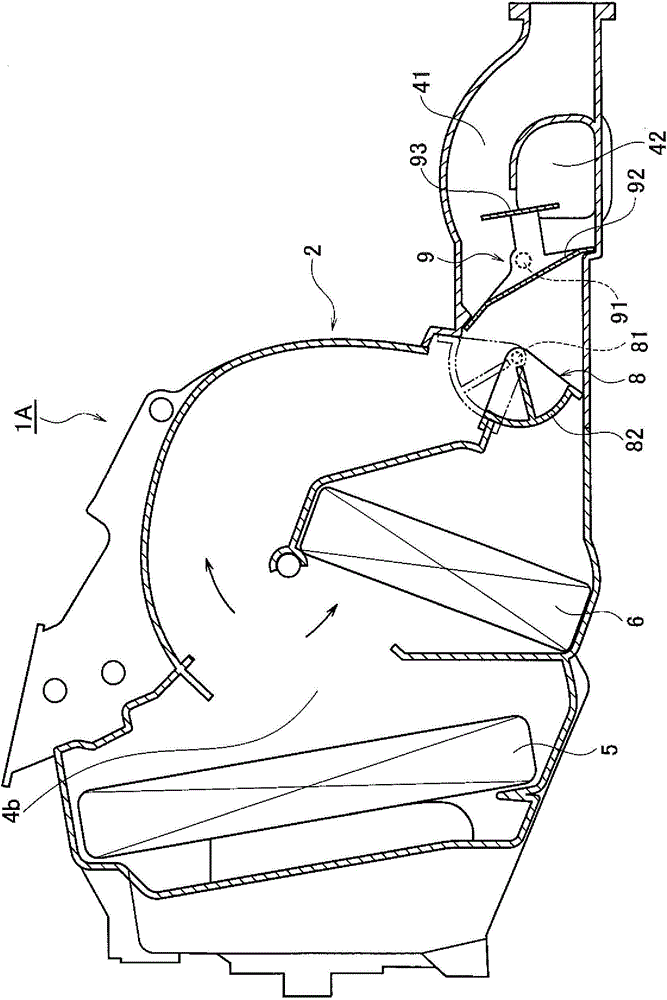

Vehicle air conditioner

InactiveCN104816605AReduce in quantityReduce the driving sourceAir-treating devicesVehicle heating/cooling devicesEngineeringMechanical engineering

Owner:CALSONIC KANSEI CORP

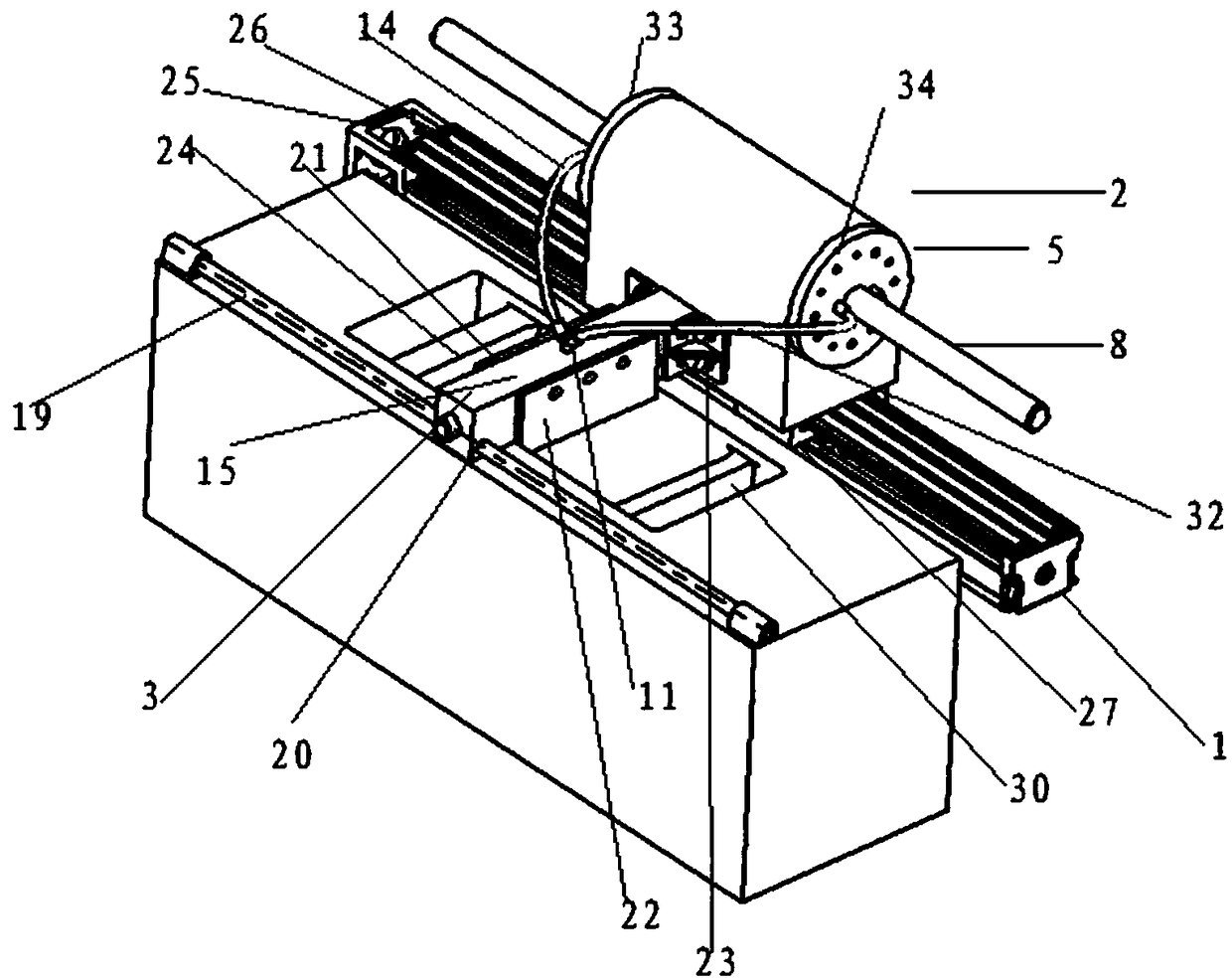

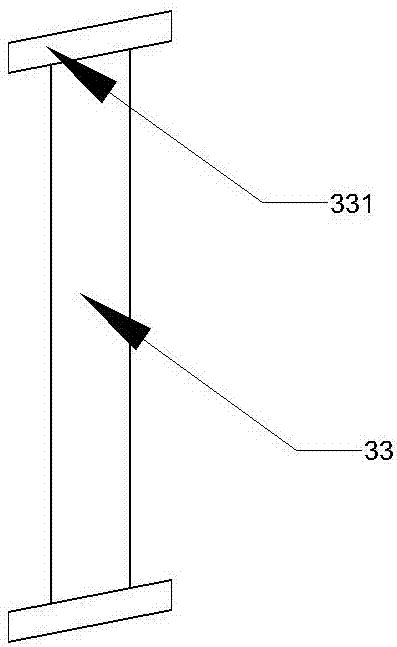

Seaweed cake making equipment

PendingCN106983166AImprove product qualityIncrease productivityFood treatmentProcess engineeringBiology

The invention discloses seaweed cake making equipment, and belongs to the technical field of seaweed processing equipment. The seaweed cake making equipment comprises a feeding trolley, a vegetable peeling device, a cake formation device, an initial dehydration shaping device, a dehydration device, a loosening device and a reclaiming trolley which are arranged in sequence, and an artificial vegetable taking space is formed between the vegetable peeling device and the cake formation device; the seaweed cake making equipment further comprises a tray conveying rod which is provided with a rack meshed with a driving gear, multiple pulling claws are arranged on the tray conveying rod at intervals and installed on the tray conveying rod in a hinged mode, and a pulling claw limit which corresponds to each pulling claw and limits clockwise rotation of the pulling claw is arranged on the tray conveying rod. Accordingly, the technical problems that in seaweed production, the cake quality is poor, and the production efficiency is low are solved, and the seaweed cake making equipment is widely applied in seaweed processing.

Owner:纪合溪

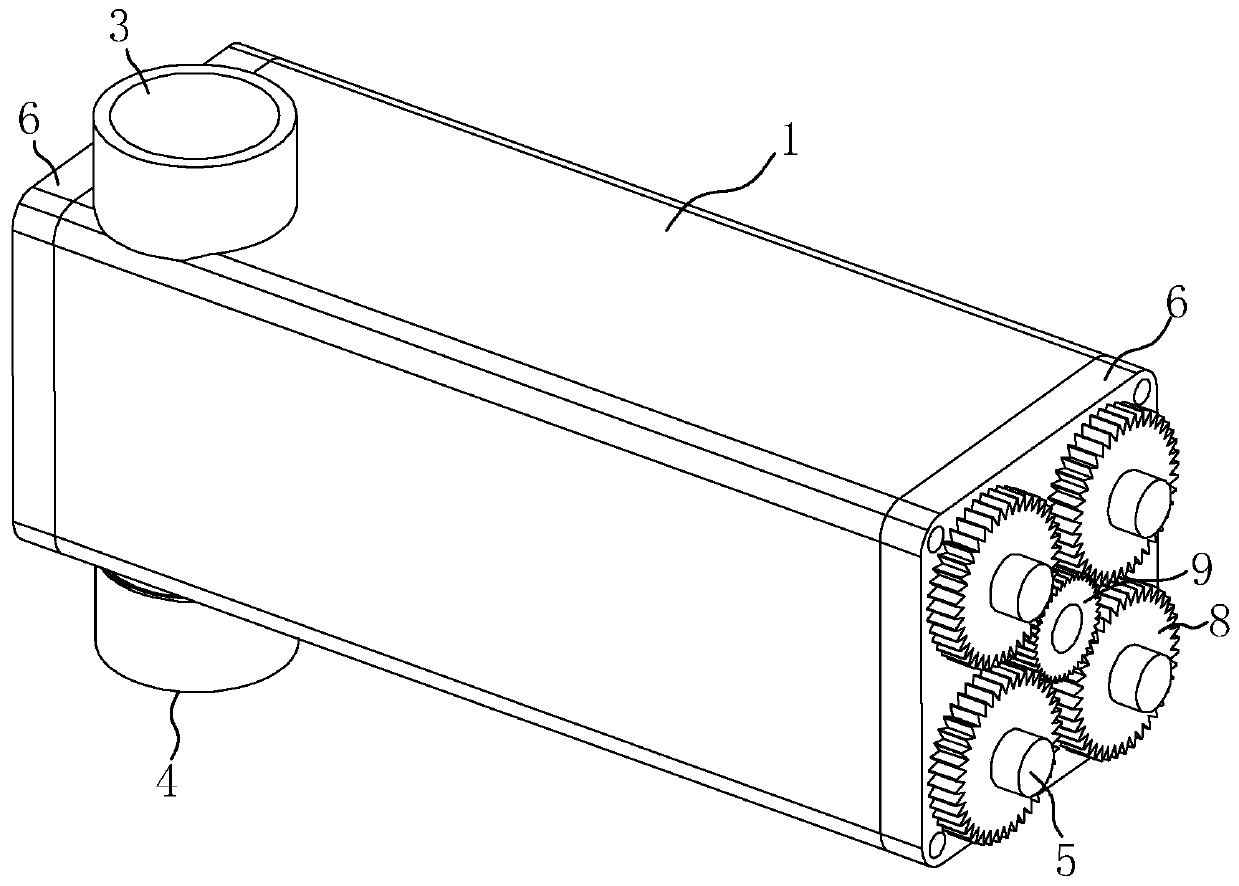

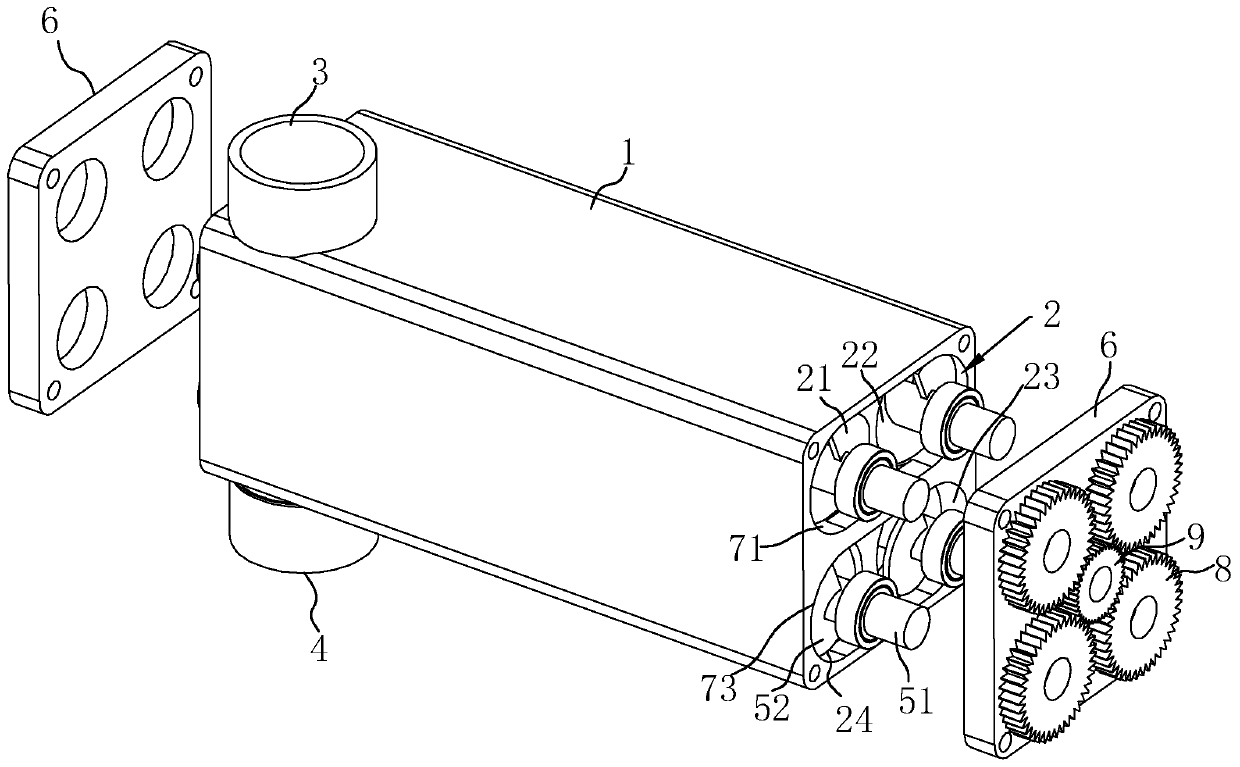

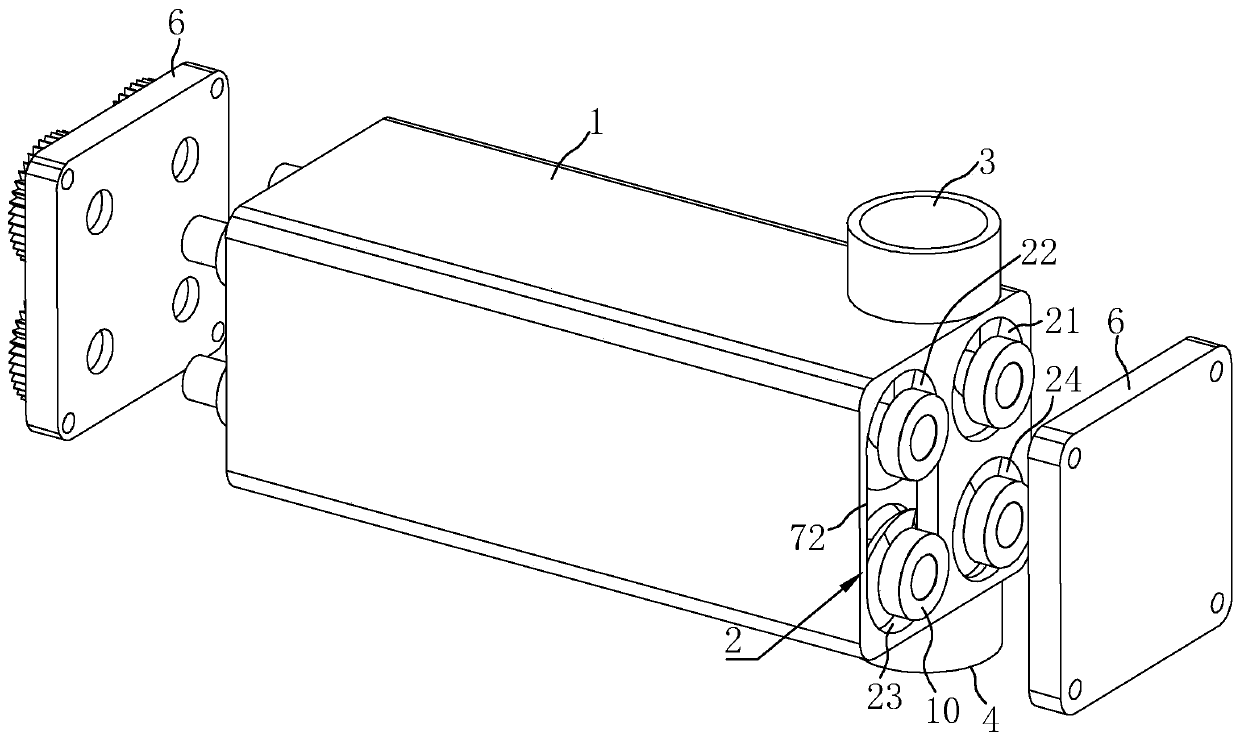

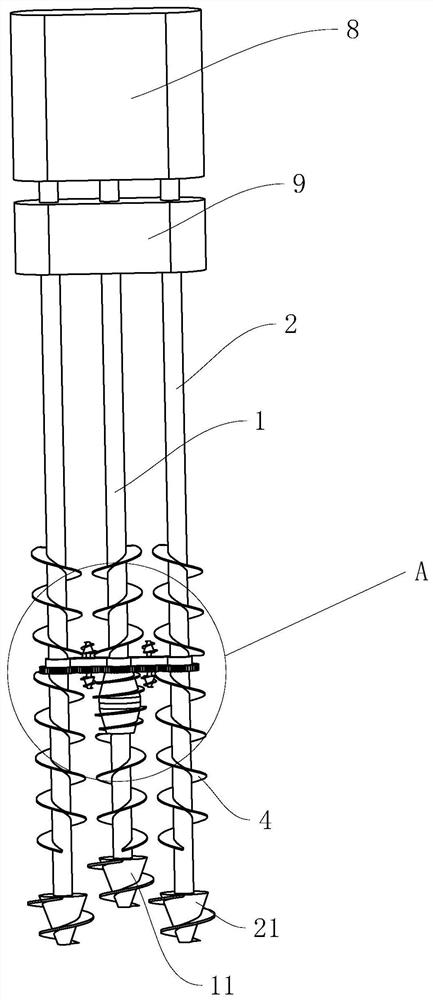

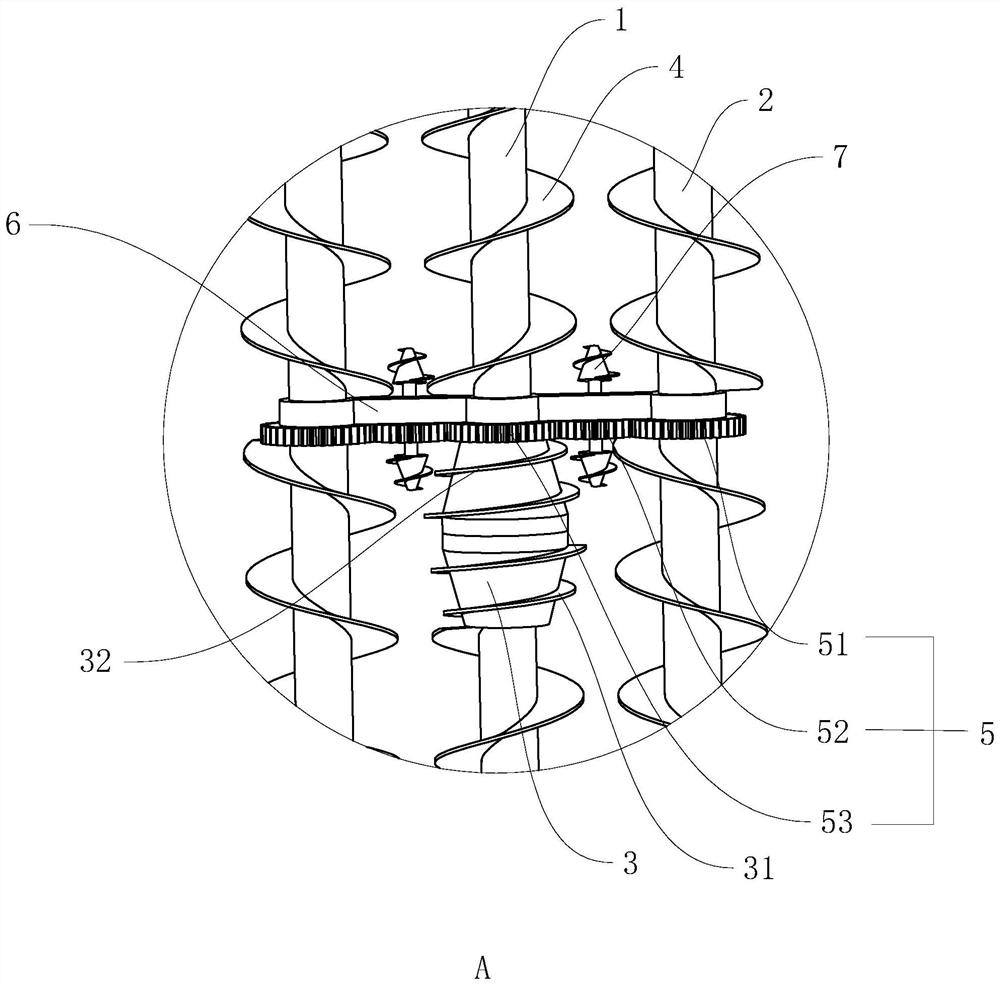

Spiral conveying device

The invention relates to a spiral conveying device. The spiral conveying device comprises a machine body, conveying cavities are formed in the machine body, an inlet and an outlet are formed in the machine body, the number of the conveying cavities is at least two, the conveying cavities communicate with one another, a spiral conveying rod is rotationally arranged in each conveying cavity, and theconveying directions of the adjacent conveying cavities are different. According to the spiral conveying device, the conveying cavities which communicate with one another and have different flow directions are arranged, so that the total length of materials flowing through the conveying cavities can be effectively increased, then the materials continuously pass through each conveying cavity to achieve the purpose of pressurization, and the phenomenon of material backflow in the conveying process is effectively improved; and due to the fact that the conveying directions of the adjacent conveying cavities are different and bent positions are formed at communicating positions, a promoting effect can be achieved for preventing materials from flowing back, and due to the fact that the conveying cavities are not overall linear, so that the overall structure is more compact, and storage, movement and use are convenient.

Owner:SHENZHEN MPD HITECH CO LTD

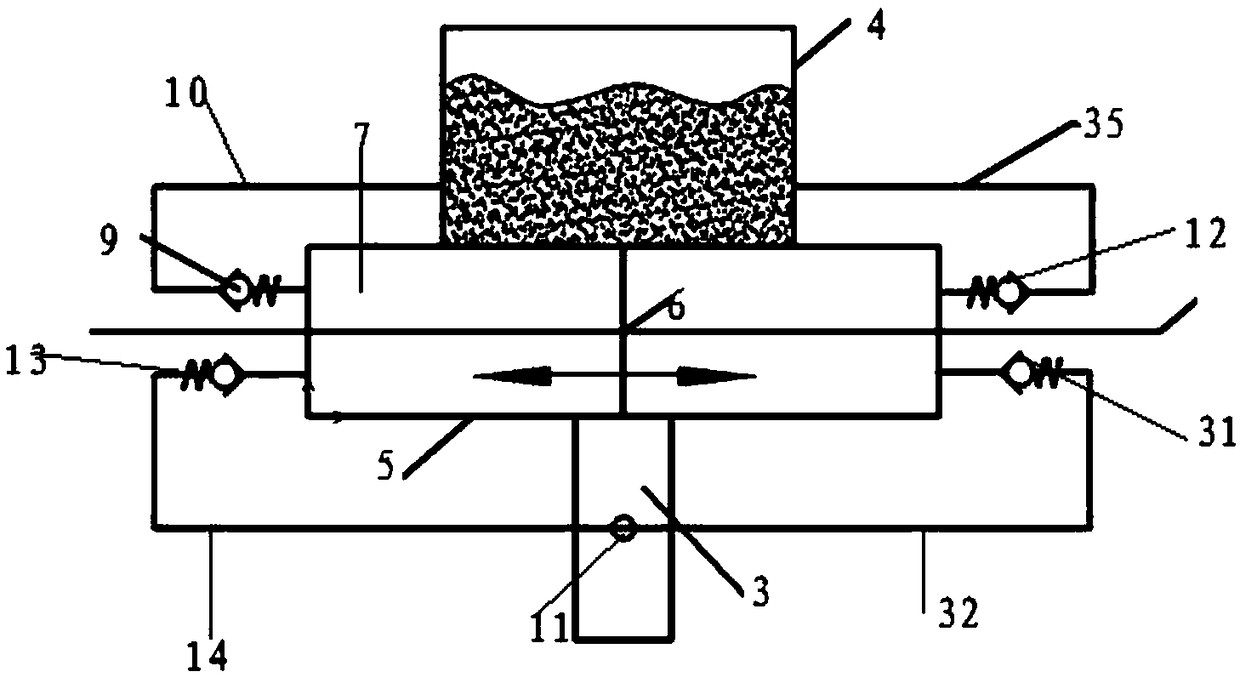

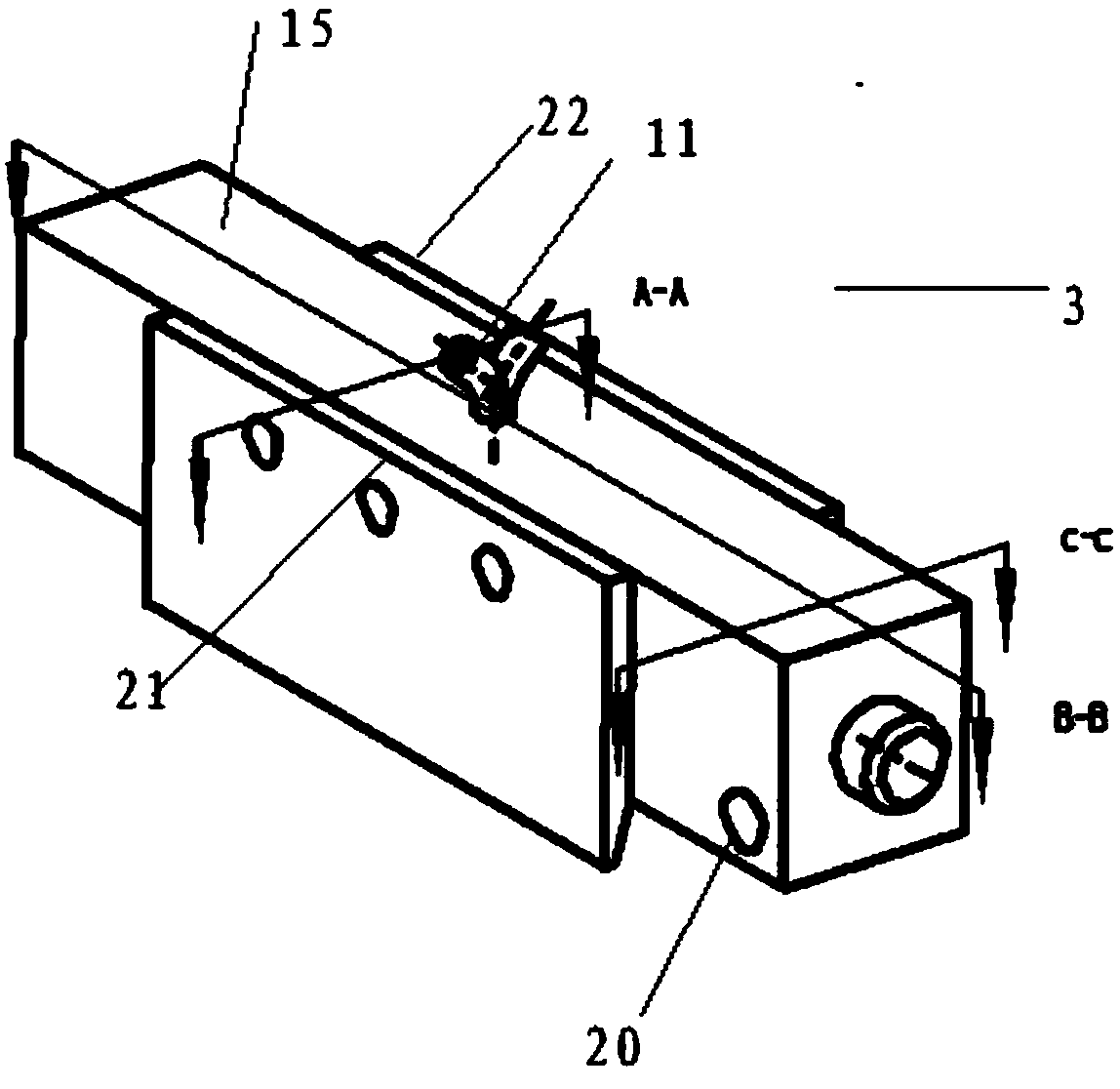

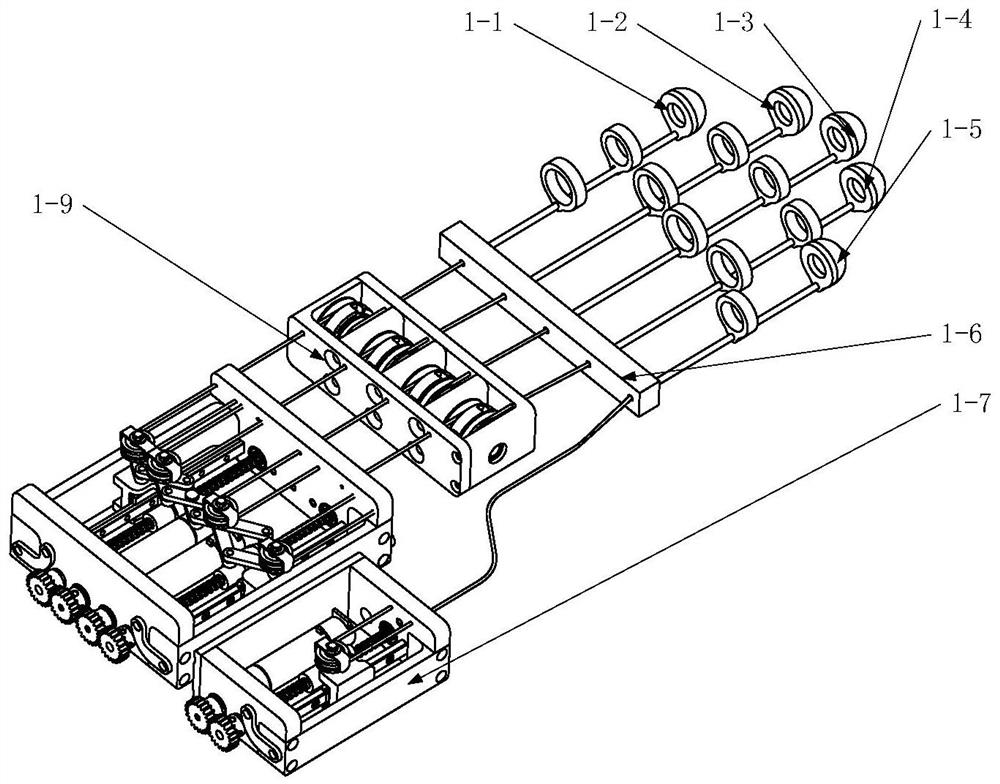

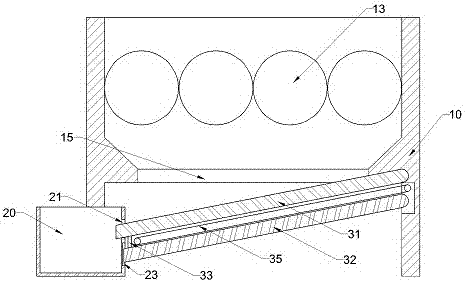

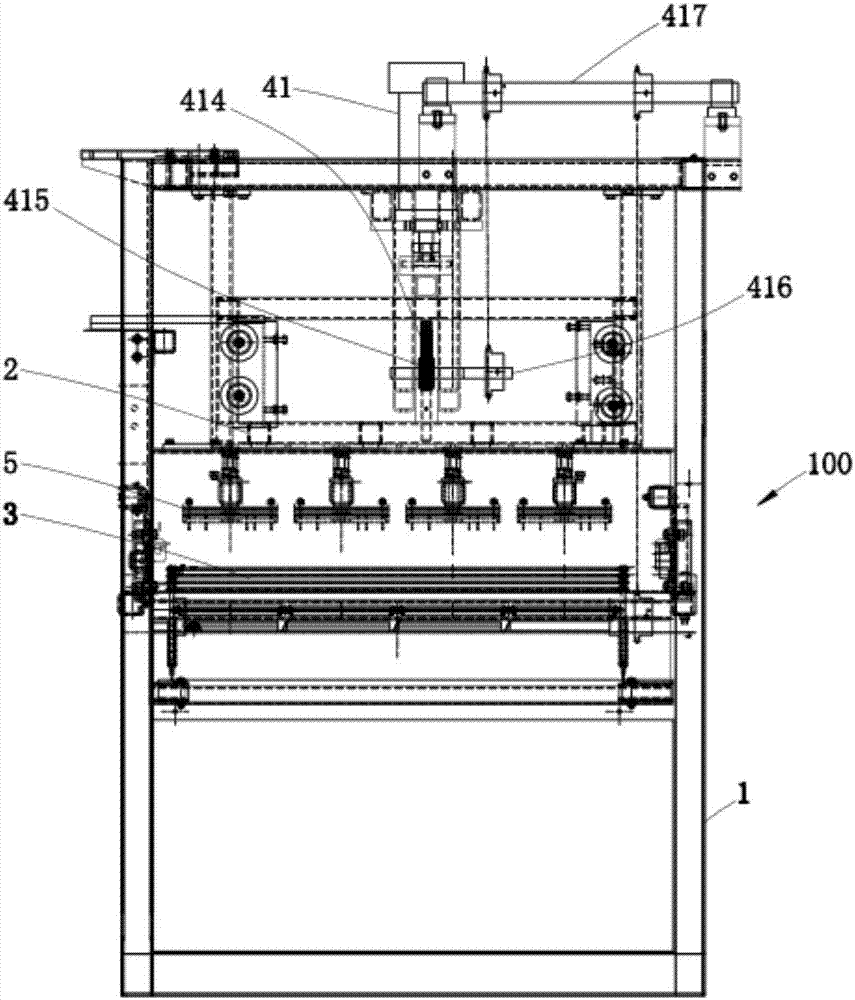

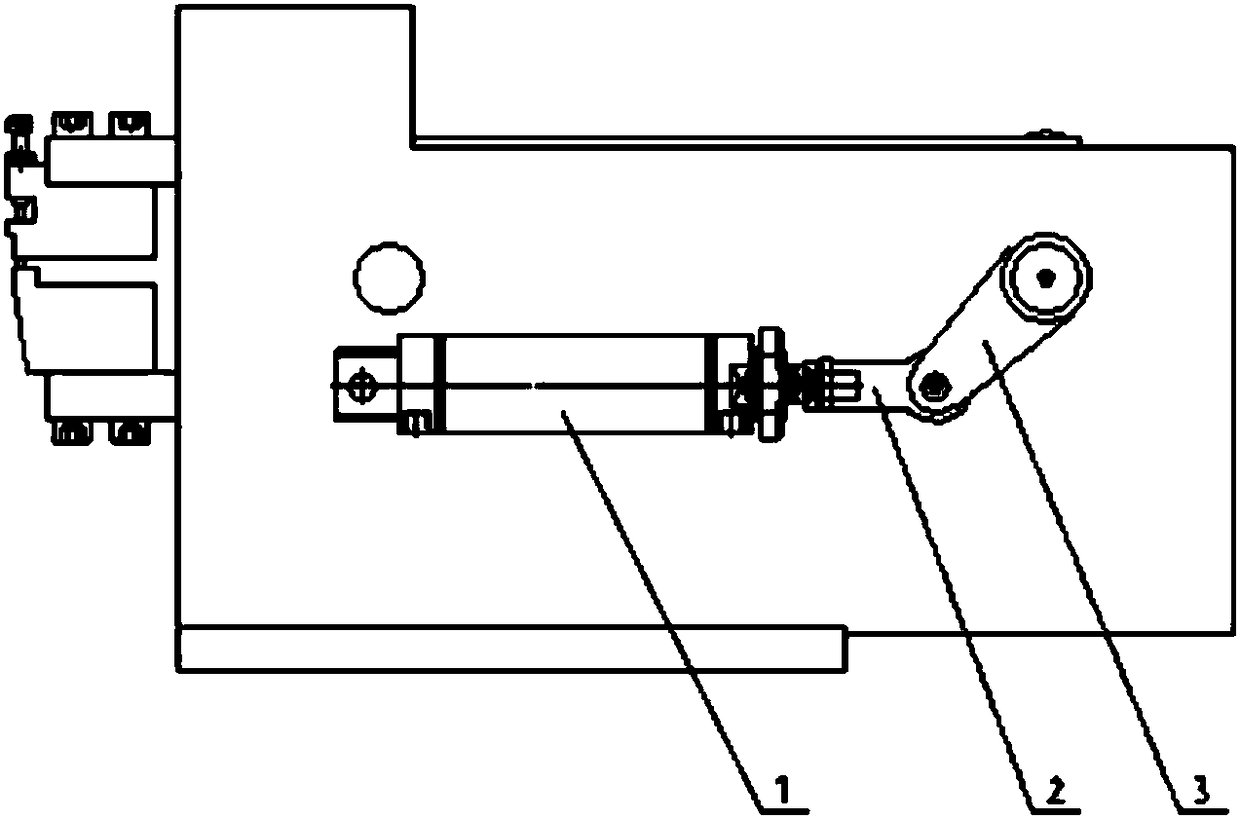

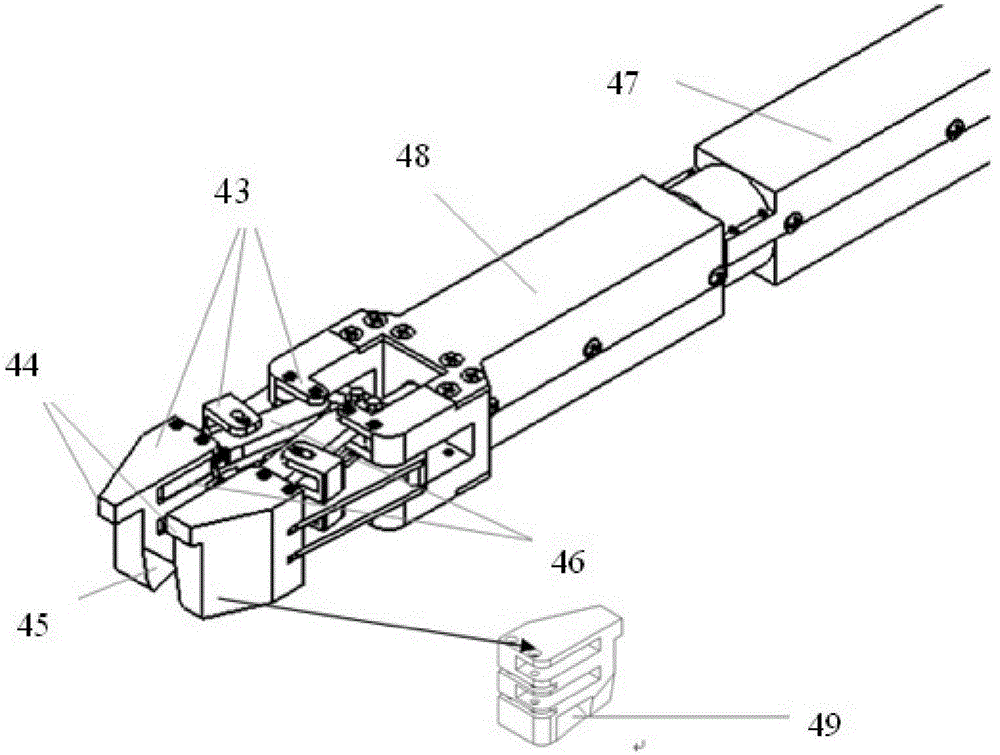

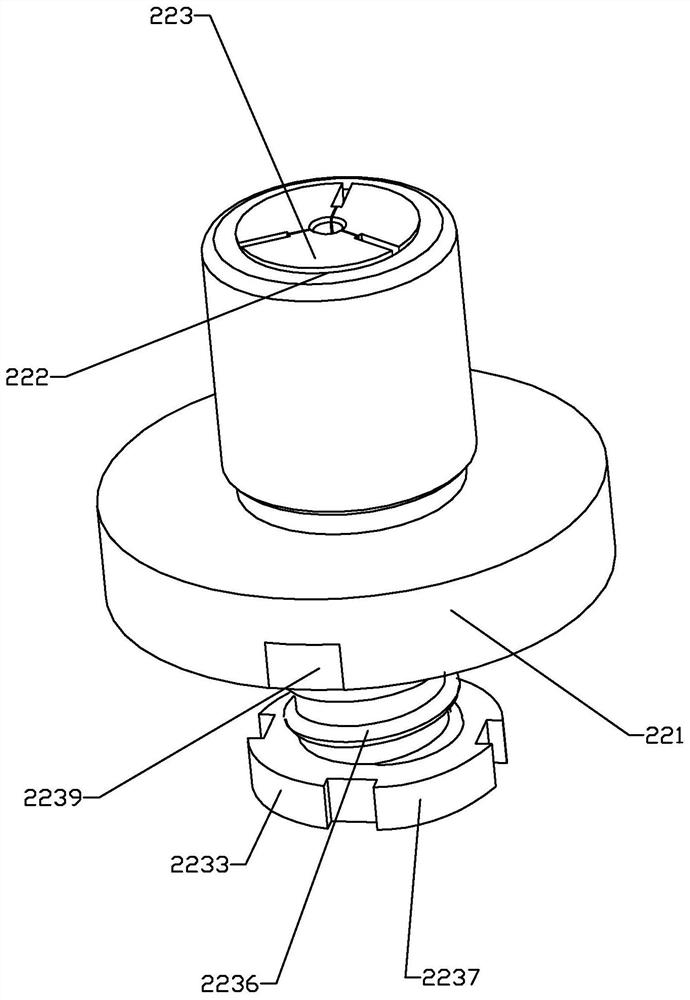

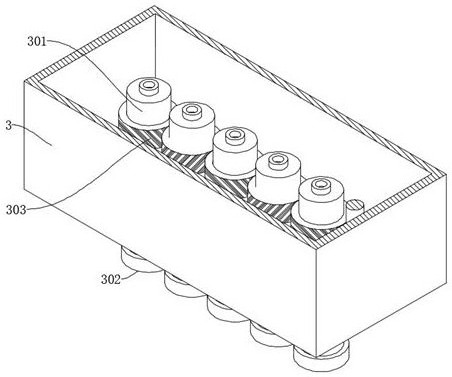

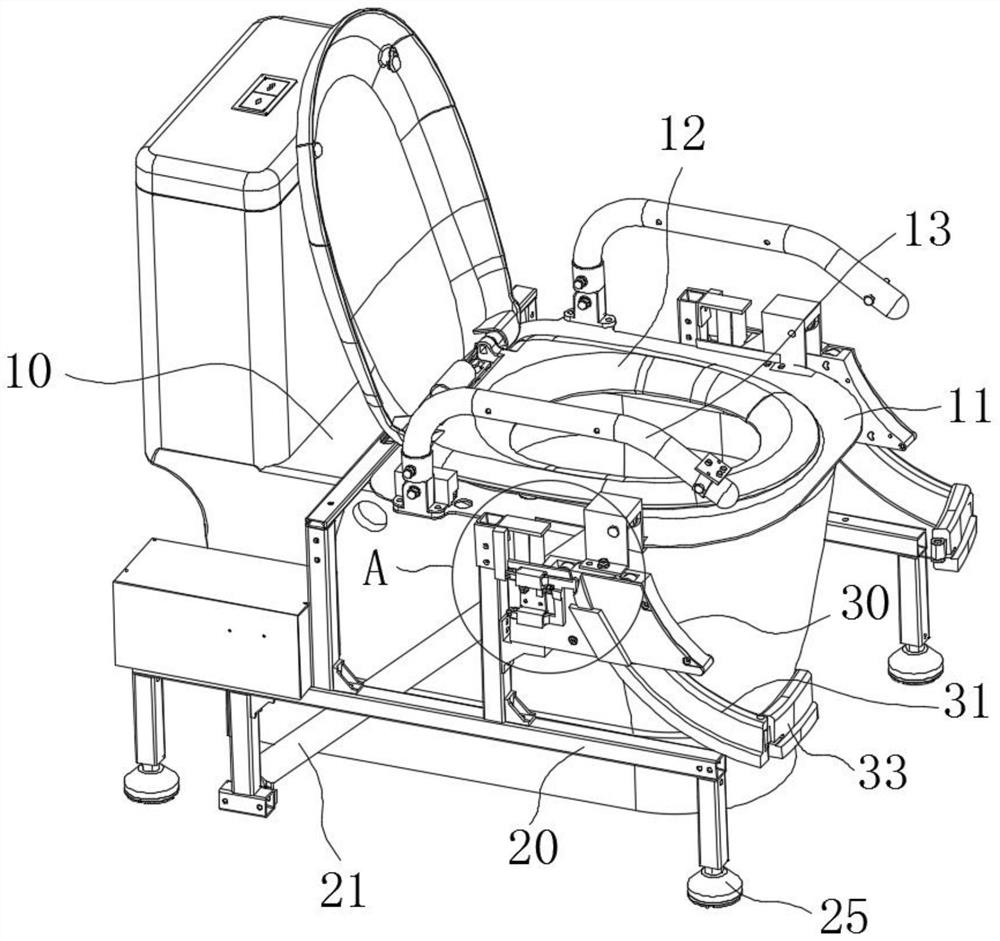

Feeding device and method of ceramic 3D printing machine and 3D printing machine

InactiveCN108544634AReduce the driving sourceImprove efficiencyAdditive manufacturing apparatusCeramic shaping apparatusPistonPiston cylinder

The invention discloses a feeding device and method of a ceramic 3D printing machine and the 3D printing machine. The feeding device comprises a linear movement mechanism (1) for driving a cyclic supply cylinder, the cyclic supply cylinder (2) for continuously conveying ceramic printing materials to a scraper mechanism (3), and the scraper mechanism (3) with a continuous discharge function and a simultaneous scraping function. When a movable piston cylinder body (5) moves leftwards relative to a piston (6), the ceramic printing materials in a material box (4) enter a piston cavity (7) througha first feeding hose (10) via a first one-way valve (9) and enter a first discharge hose (32) through a second one-way valve (31) to reach a junction station (11), and when the movable piston cylinderbody (5) moves rightwards relative to the piston (6), the ceramic printing materials enter the piston cavity (7) through a second feeding hose (35) via a third one-way valve (12) and enter a second discharge hose (14) through a fourth one-way valve (13) to reach the junction station (11).

Owner:XI AN JIAOTONG UNIV

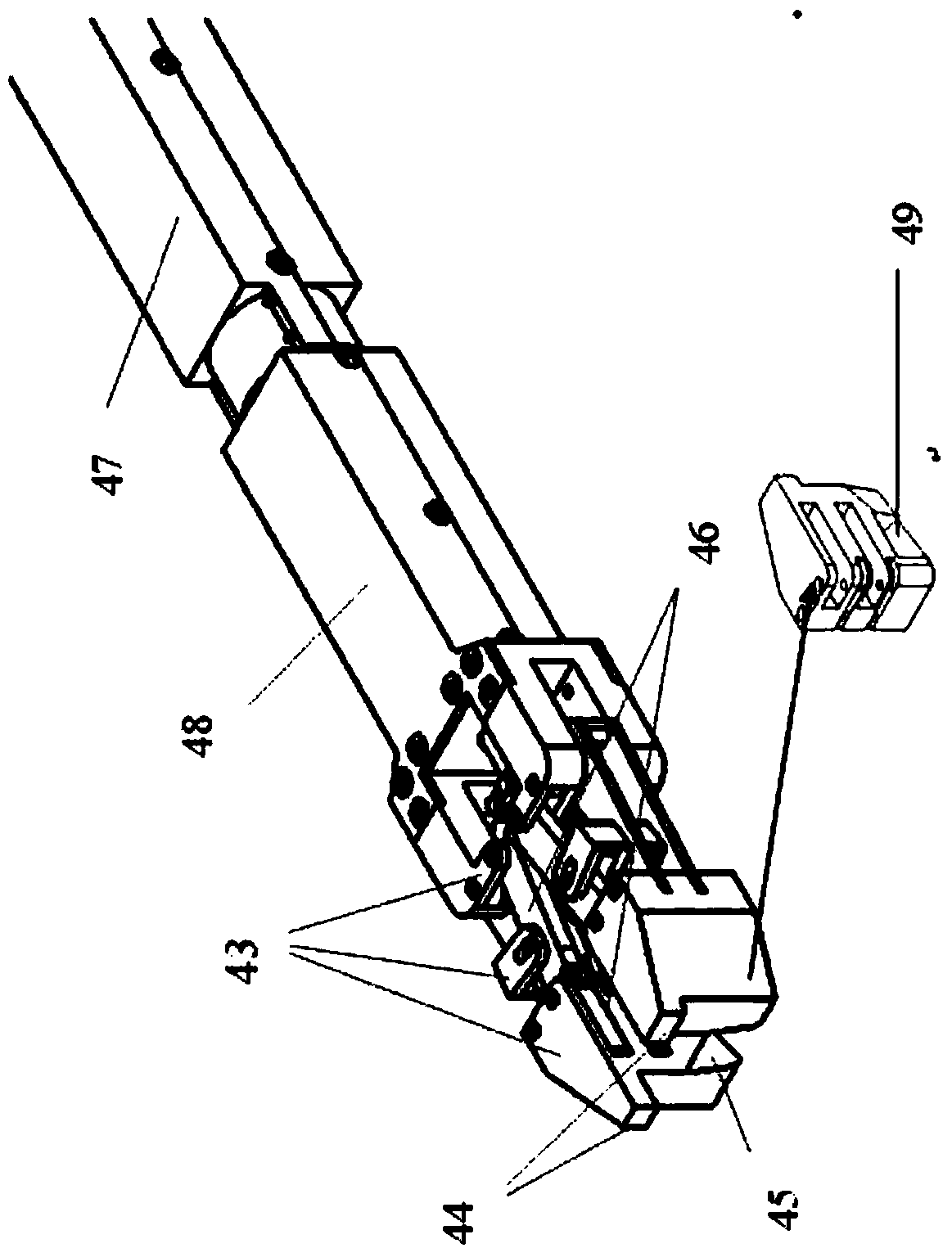

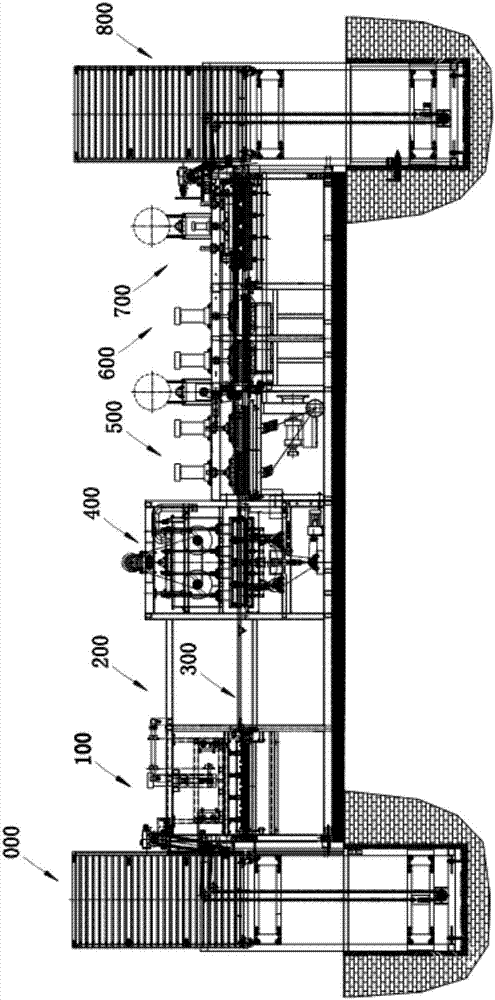

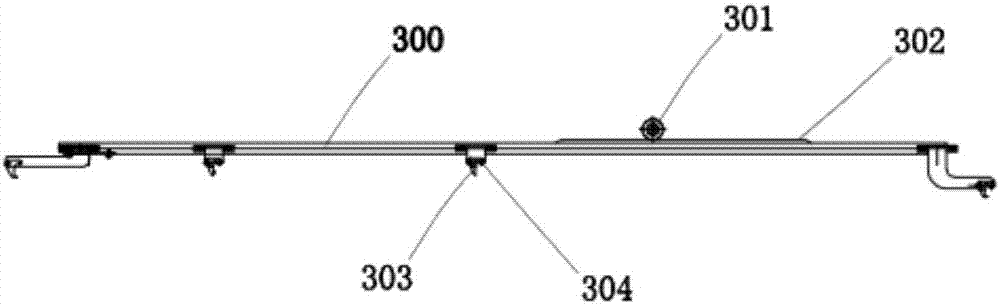

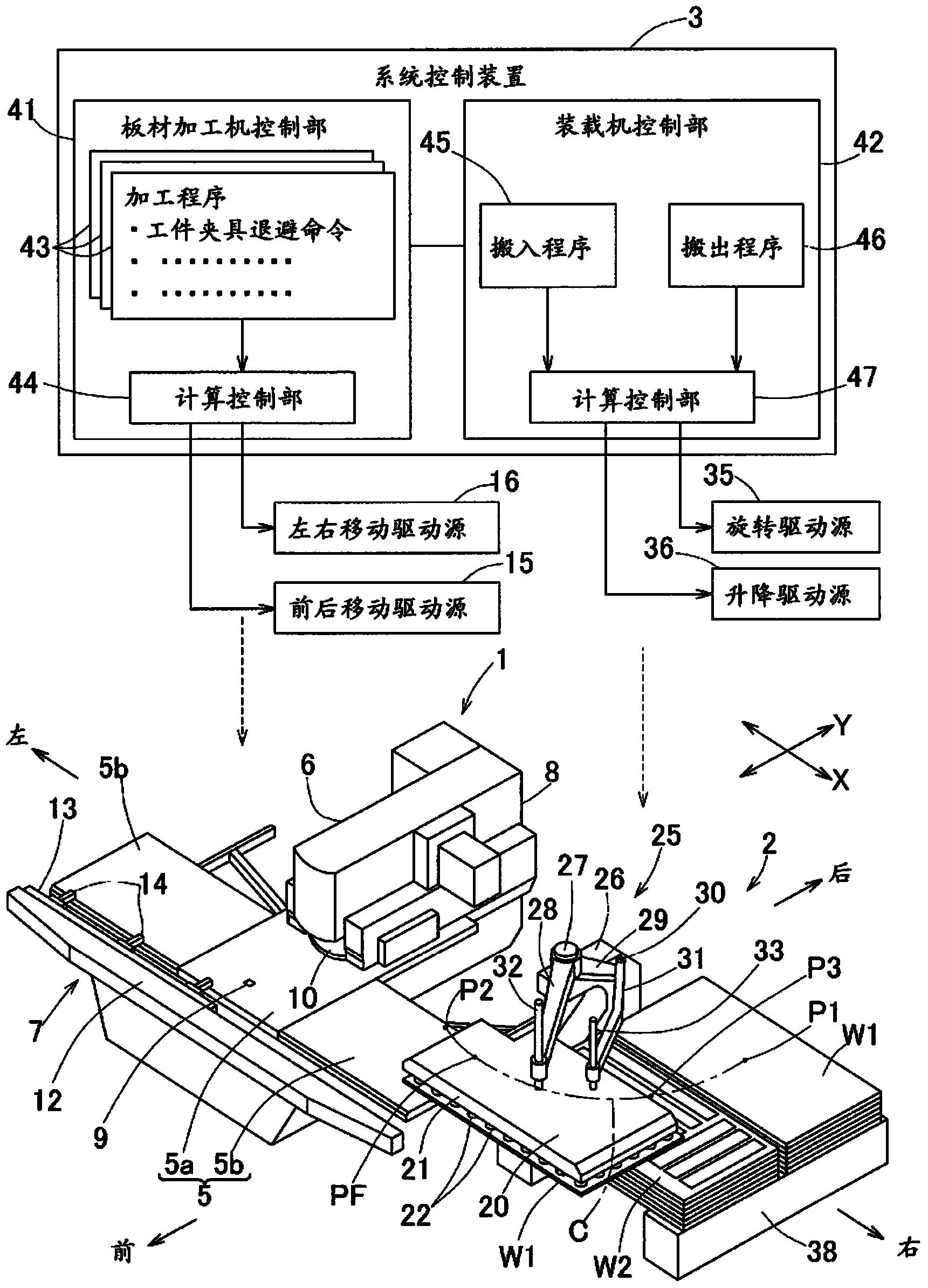

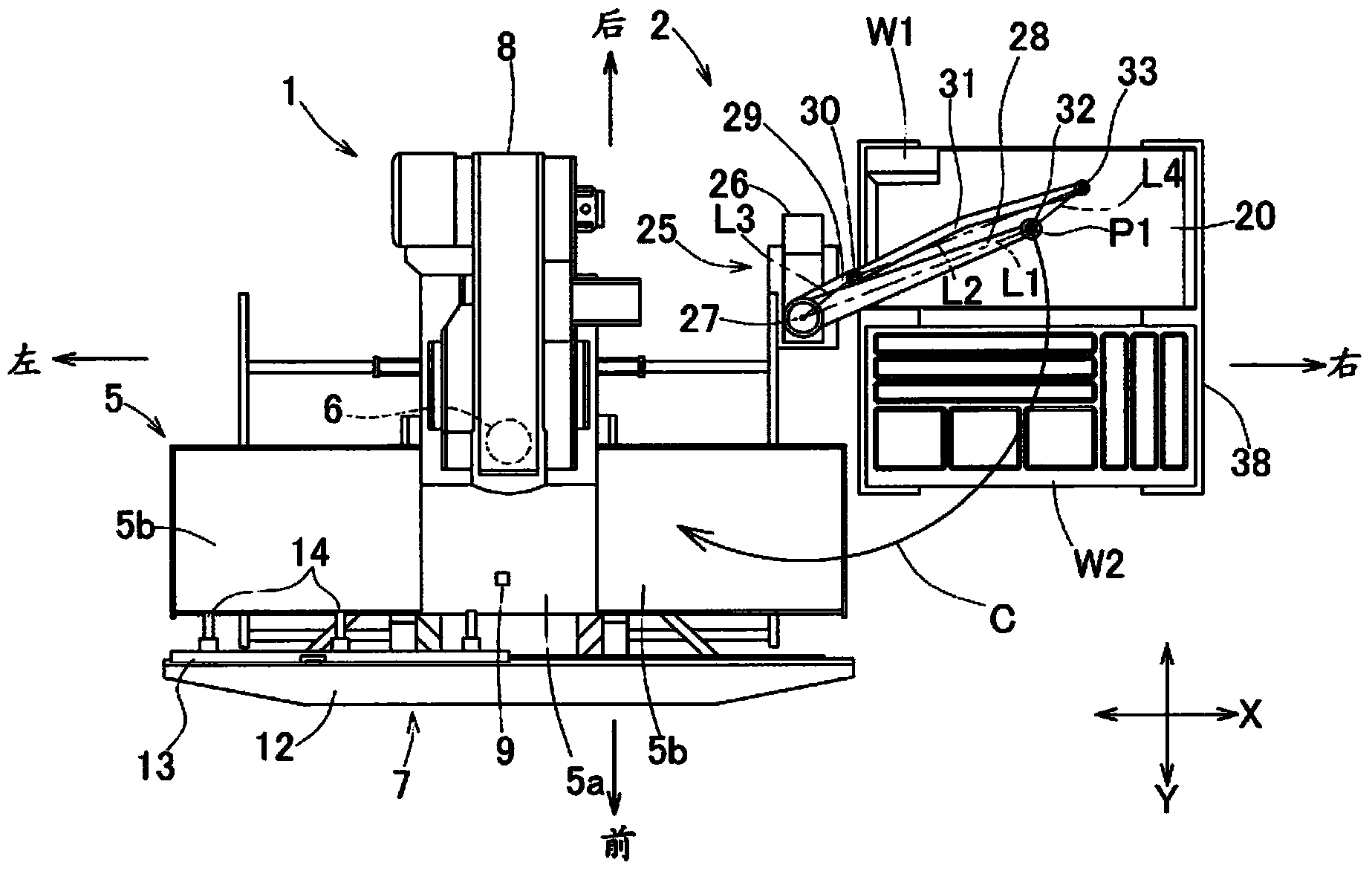

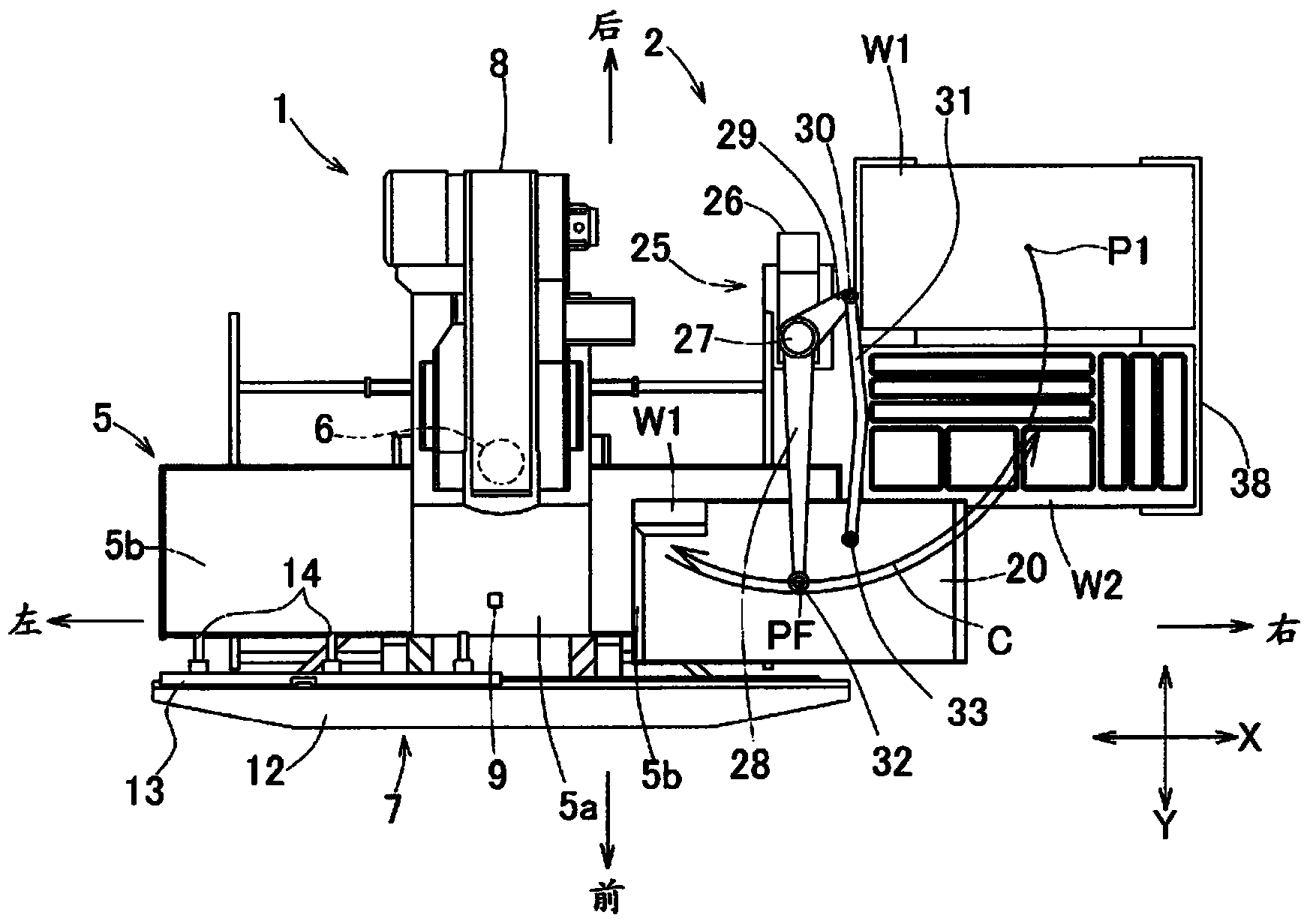

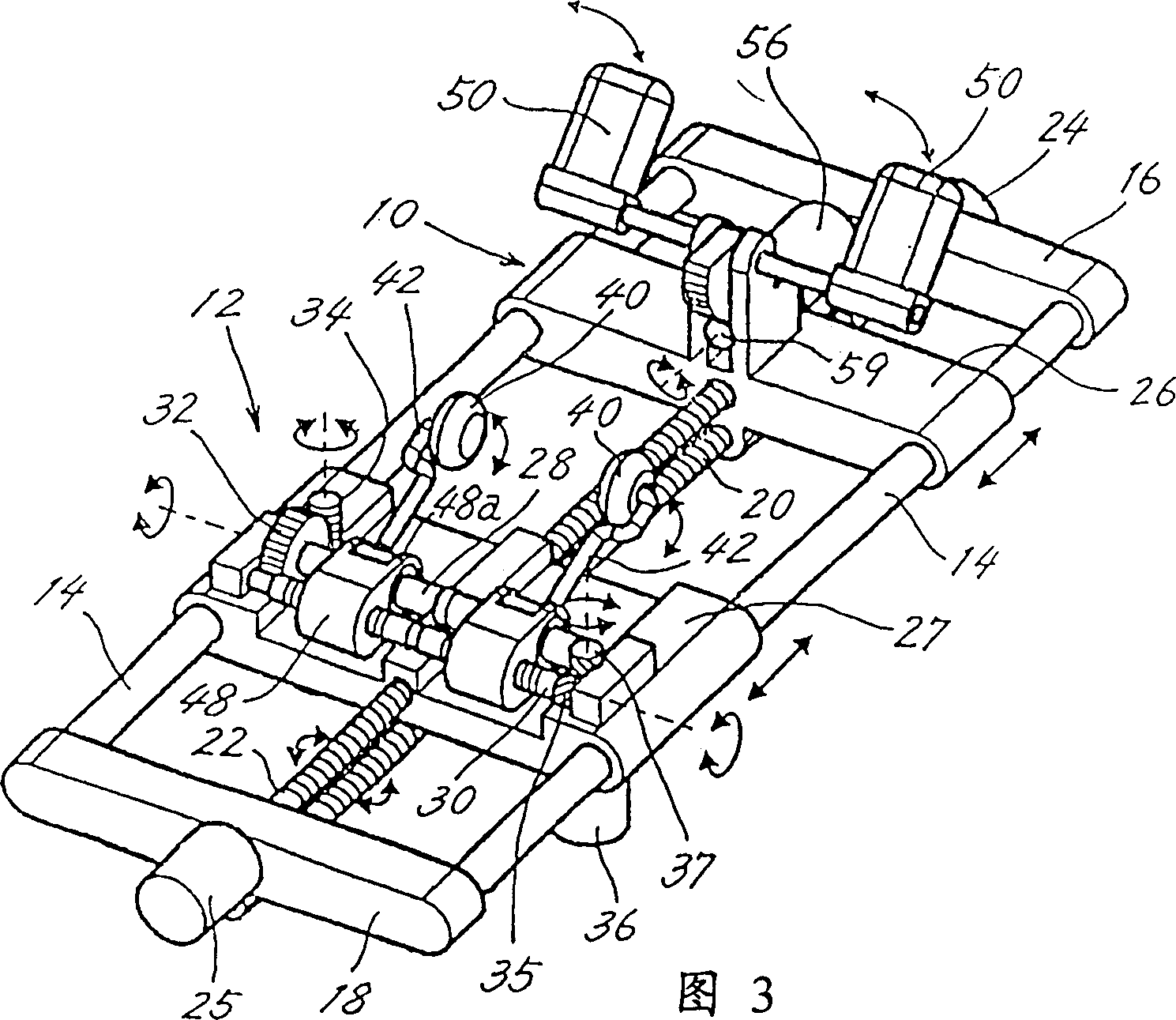

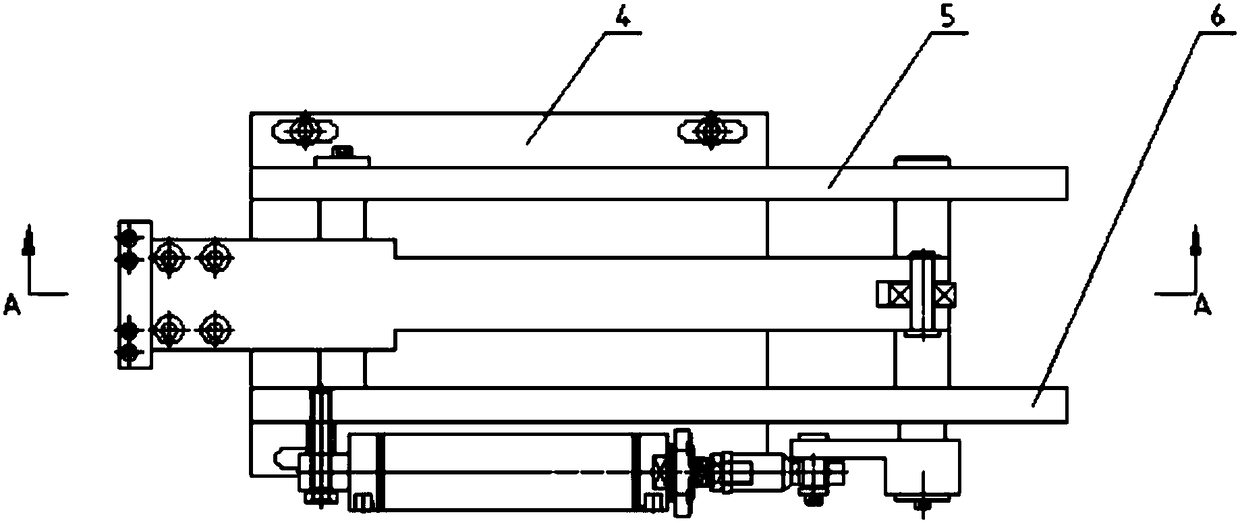

Plate material processing system

InactiveCN103547391AReduce the driving sourceLow costMetal-working feeding devicesMetal working apparatusEngineeringMaterials processing

This plate material processing system is equipped with a plate material processing machine (1) and a loader (2). The plate material processing machine (1) grasps the front end of an unprocessed plate material (W1) by means of a work holder (14) and moves the unprocessed plate material (W1) to the front / back / left / right on a table (5). The loader (2) is equipped with a plate material adsorption body (20) and a rotating mechanism (25) that rotates this plate material adsorption body (20) along a predetermined arc-shaped trajectory (C), with the plate material adsorption body maintaining the same orientation in a planar view. The position of the plate material adsorption body (20) switches between an unprocessed plate material loading position (P2) and an unprocessed plate material waiting position (P1). When the plate material adsorption body (20) is in the foremost position (PF), the work holder (14) is positioned to the other side in the left-right direction of the unprocessed plate material loading position (P2) with respect to a processing head (6), thus preventing interference between the work holder (14) and the plate material adsorption body (20).

Owner:MURATA MASCH LTD

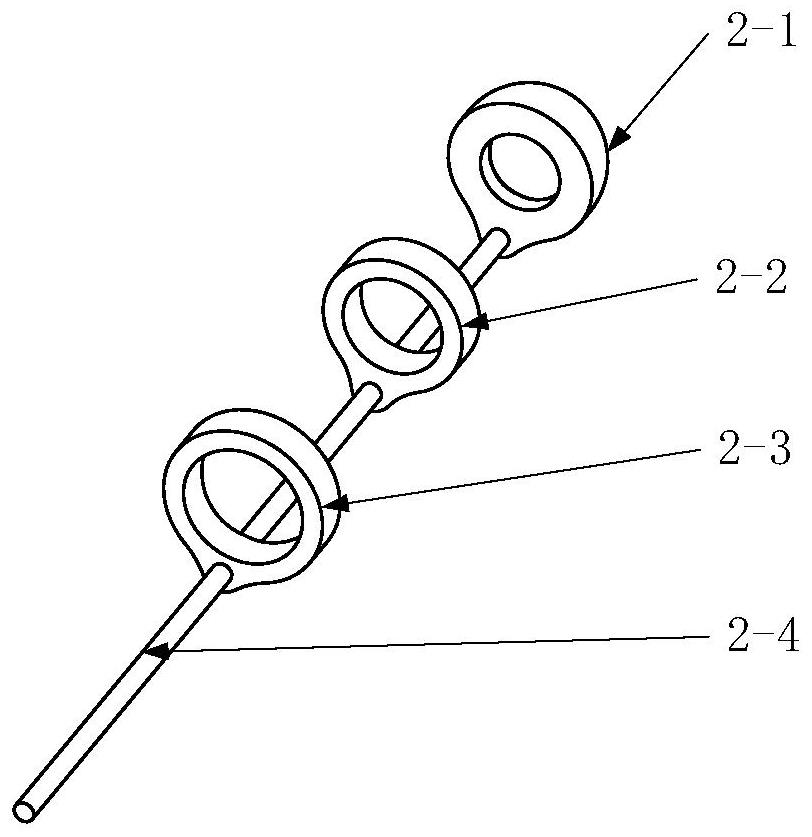

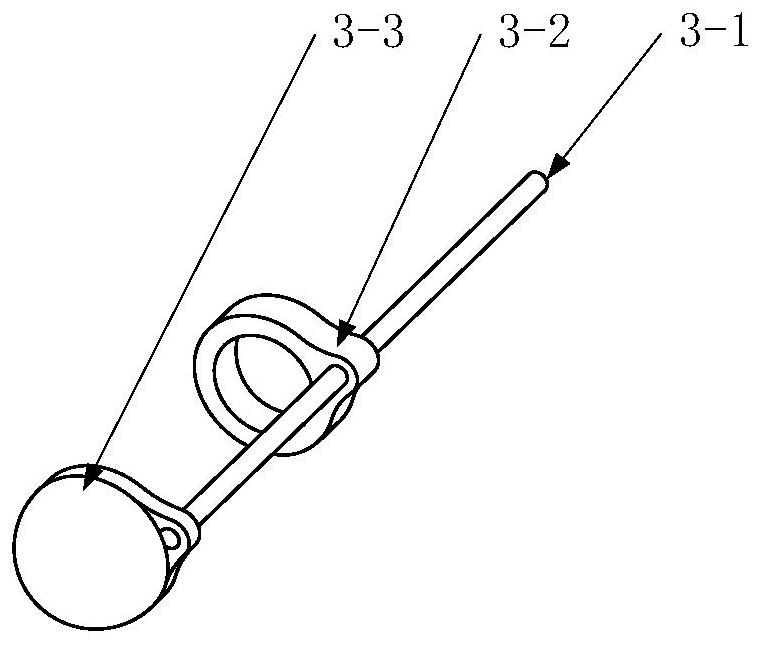

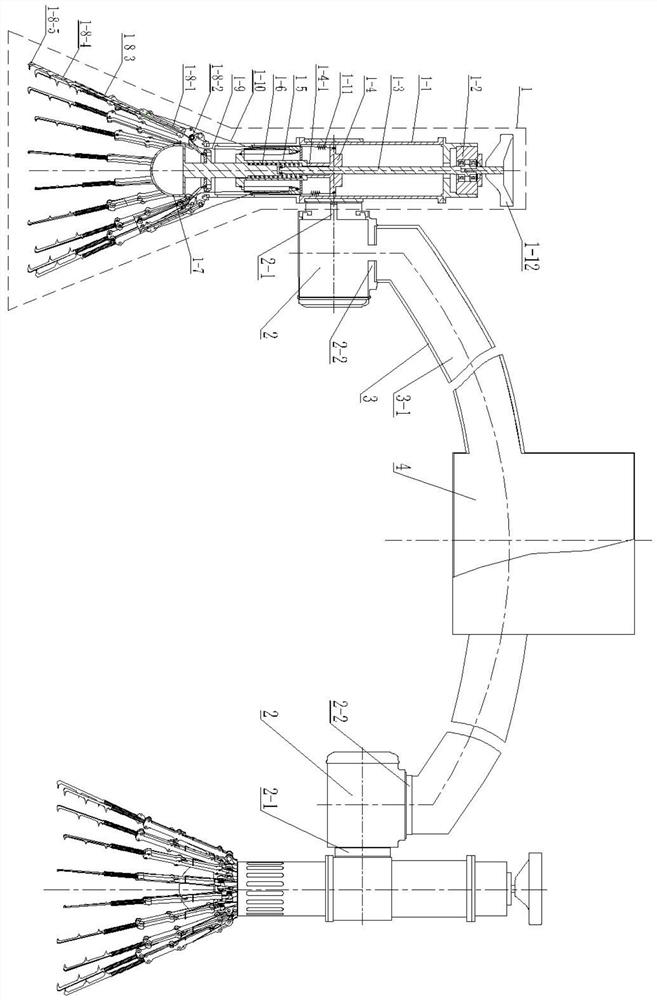

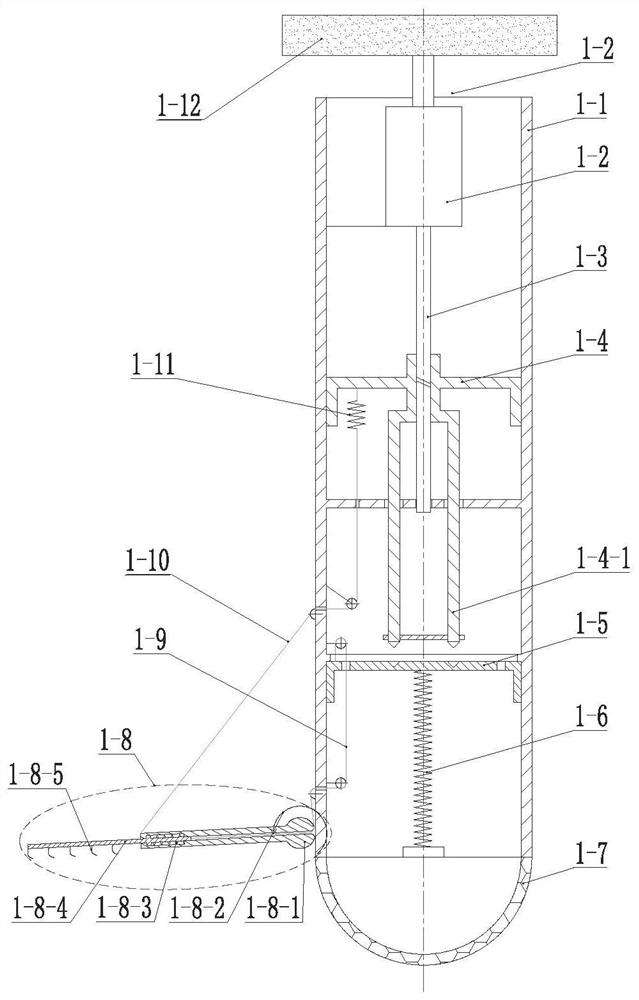

Hand exoskeleton device with under-actuated traction function

ActiveCN114259383AReduce quality problemsReduce volumeChiropractic devicesLittle fingerMedical equipment

The invention belongs to the technical field related to medical equipment, and discloses a hand exoskeleton device with an under-actuated traction function, the hand exoskeleton device comprises an exoskeleton body, a thumb driving mechanism, a four-finger driving mechanism and a fastening torsion spring mechanism, the thumb driving mechanism is connected to the exoskeleton body, and the four-finger driving mechanism is connected to the fastening torsion spring mechanism; the four-finger driving mechanism is connected to the exoskeleton body through the fastening torsion spring mechanism; the exoskeleton body comprises a thread combining block, a little finger, a ring finger, a middle finger, an index finger and a thumb, the little finger, the ring finger, the middle finger, the index finger and the thumb are connected to the thread combining block, the thread combining block is connected to the fastening torsional spring mechanism, and the thumb is connected to the thumb driving mechanism through the thread combining block; the middle finger comprises a fingertip fingerstall, a middle finger ring, a near finger ring and a first four-finger traction nylon rope, one end of the first four-finger traction nylon rope is sequentially strung in the near finger ring, the middle finger ring and the fingertip fingerstall, and the other end of the first four-finger traction nylon rope is connected to the thread combining block. The size is reduced, and the flexibility is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Manufacturing method of wine-brewing grain crushing device

InactiveCN107497534AReduce cleaning operationsShorten processing timeSievingElectrostatic separationEngineeringFiltration mechanism

The invention relates to the field of the manufacturing process of wining making equipment and provides a manufacturing method of a wine-brewing grain crushing device in order to solve the problems that broken grains appear in the crushing process of an existing grain crushing device and can be attached to a screen net to block the screen net. The manufacturing method of the wine-brewing grain crushing device, provided by the invention, comprises the steps of manufacturing of the crushing device, manufacturing of a collection box, manufacturing of a dust filtration mechanism and the like, wherein the manufacturing process of the collection tank includes the steps of selecting a box as the collection box, and forming a collection port and a collection groove in one sidewall of the collection box; the manufacturing process of a screen plate includes the steps of hinging one end of the screen plate to a machine case, and stretching the other end of the screen plate into the collection port of the collection box; the manufacturing process of the dust filtration mechanism includes the steps of selecting a friction plate and a dust removal film, connecting one end of the friction plate to the machine case, placing the other end of the friction plate into the collection groove of the collection box so that the friction plate can vibrate; the dust removal film is arranged above the friction plate so that the friction plate can make contact with the dust removal film when vibrating, and one end of the friction plate is also connected with the screen plate through a connecting part.

Owner:ZUNYI JINHONG METAL EQUIP

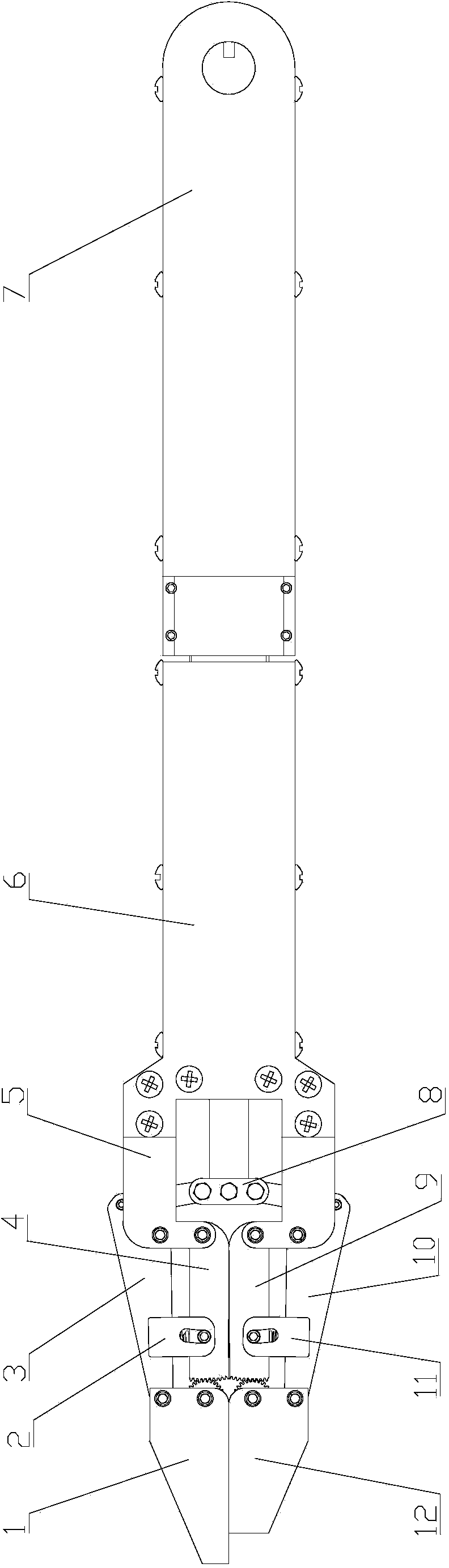

Climbing robot for planet surface detection and using method thereof

PendingCN113075743ARealize climbing movementImprove adaptabilityToolsGeological measurementsShape-memory alloyStructural engineering

The invention provides a climbing robot for planet surface detection and a using method thereof. The robot comprises two identical grabbing and attaching mechanisms, two identical double-end output joints, a section of hollow shape memory alloy and an instrument platform, and the instrument platform is fixedly connected to the middle of the shape memory alloy; the two ends of the shape memory alloy are fixedly connected with the second output ends of the two double-end output joints correspondingly, and the first output ends of the double-end output joints are fixedly connected with the grabbing and attaching mechanism. In order to solve many technical problems existing in a planet surface robot in the prior art, the invention provides a mobile robot capable of carrying out self-adaptive flexible grabbing and climbing on a planet surface, and the mobile robot is used for realizing mobile detection on the planet surface, realizing grabbing on the planet surface through claw thorns and flexible fingers, and realizing bending, climbing and the like of a robot body through shape memory alloy. The robot can realize grabbing movement in a microgravity planet surface, a cliff, an abrupt slope pit and the like, and can carry out sampling such as grabbing and grinding after moving to a target position.

Owner:HARBIN INST OF TECH

Wine-making grain smashing device with dust removal function

InactiveCN107469915AImprove crushing efficiencyReduce cleaning operationsSievingElectrostatic separationCause blockageEngineering

The invention relates to the field of wine making equipment and provides a wine-making grain smashing device with a dust removal function. The wine-making grain smashing device with the dust removal function aims at solving the problem that as for an existing grain device, fragments generated in the smashing process adhere to a screen to cause blockage of the screen. The wine-making grain smashing device with the dust removal function comprises a machine shell; a feed inlet is formed in the upper end of the machine shell, a discharge outlet is formed in the lower end of the machine shell, and a smashing cavity is formed in the machine shell; a sieve plate capable of vibrating is connected to the side wall of the machine shell; one end of the sieve plate is hinged to the side wall of the machine shell, a collecting box is arranged at the other end of the sieve plate, and the sieve plate extends into the collecting box; a dust removal mechanism is arranged below the machine shell and comprises a friction plate and a dust removal film, the dust removal film is located above the friction plate, and the friction plate can make contact with the dust removal film in the vibrating process; one end of the friction plate is connected to the machine shell; a collecting groove is formed in the side wall of the collecting box, and the height of the collecting groove is greater than the thickness of the friction plate; the other end of the friction plate extends into the collecting groove; and the friction plate is connected with the sieve plate through a connector.

Owner:ZUNYI JINHONG METAL EQUIP

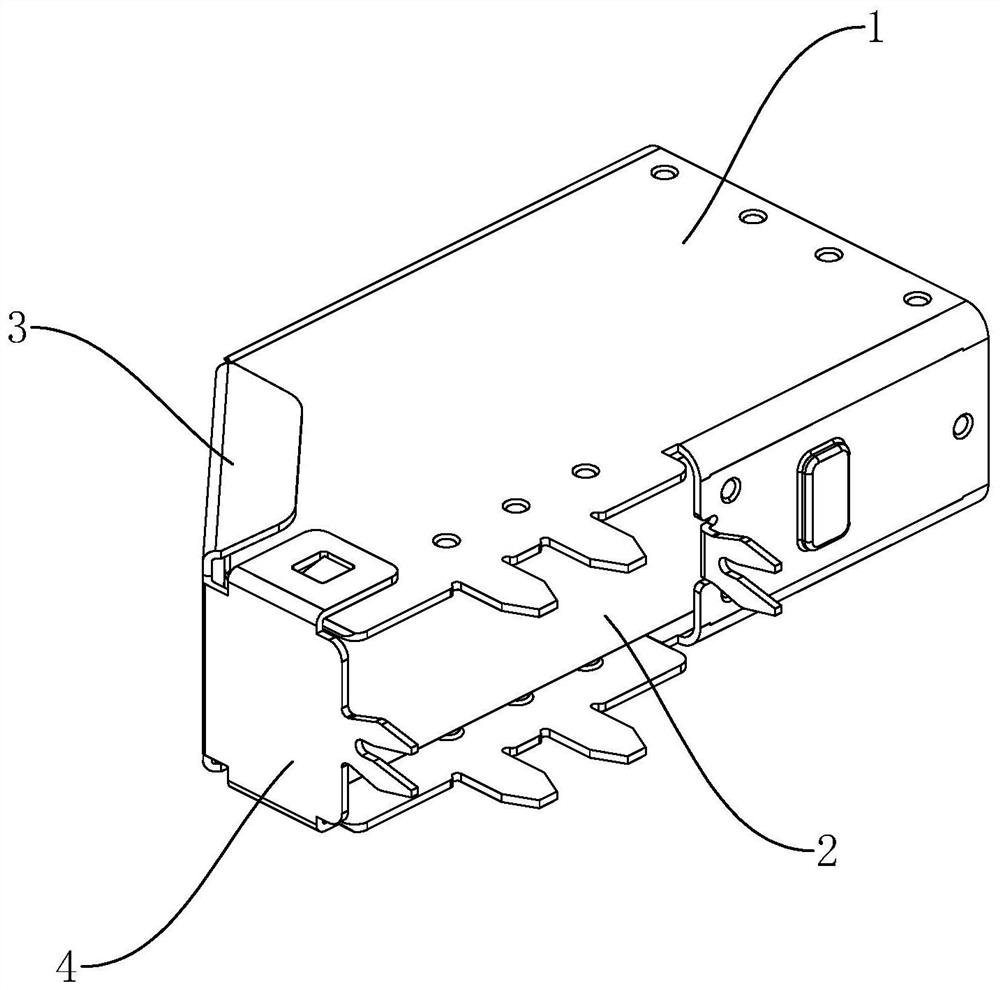

Automatic assembling equipment for USB interfaces

PendingCN113829056ARealize automated assembly operationsReduce workloadAssembly machinesEngineeringTransfer mechanism

The invention relates to automatic assembling equipment for USB interfaces. The automatic assembling equipment comprises a workbench, and the workbench is provided with a bearing frame, a plurality of positioning grooves, a supporting block, a transferring mechanism, an assembling mechanism, a cover plate arranging mechanism and a pressing plate arranging mechanism; a plurality of positioning grooves are respectively formed in the bearing frame; a supporting hole is formed in the supporting block, and the supporting hole is aligned with the positioning groove in the middle of the bearing frame; the transferring mechanism is used for grabbing and transporting shells in the multiple positioning grooves and enabling the shells to advance in sequence; the assembling mechanism is used for pushing out terminal bodies in the supporting hole and enabling the terminal bodies to be clamped into the shells; the cover plate arranging mechanism is used for pushing cover plates to be bent; and the pressing plate arranging mechanism is used for pushing pressing plates to be bent. Through the arrangement of the cover plate arranging mechanism and the pressing plate arranging mechanism, after the terminal bodies are clamped into the shells, the cover plate arranging mechanism and the pressing plate arranging mechanism conduct bending operation on the cover plates and the pressing plates correspondingly, the cover plates and the pressing plates abut against the terminal bodies correspondingly, and therefore automatic assembling operation of the USB interfaces is achieved, the workload of production personnel can be reduced, and the production efficiency can be improved.

Owner:温州圣彼得电子科技有限公司

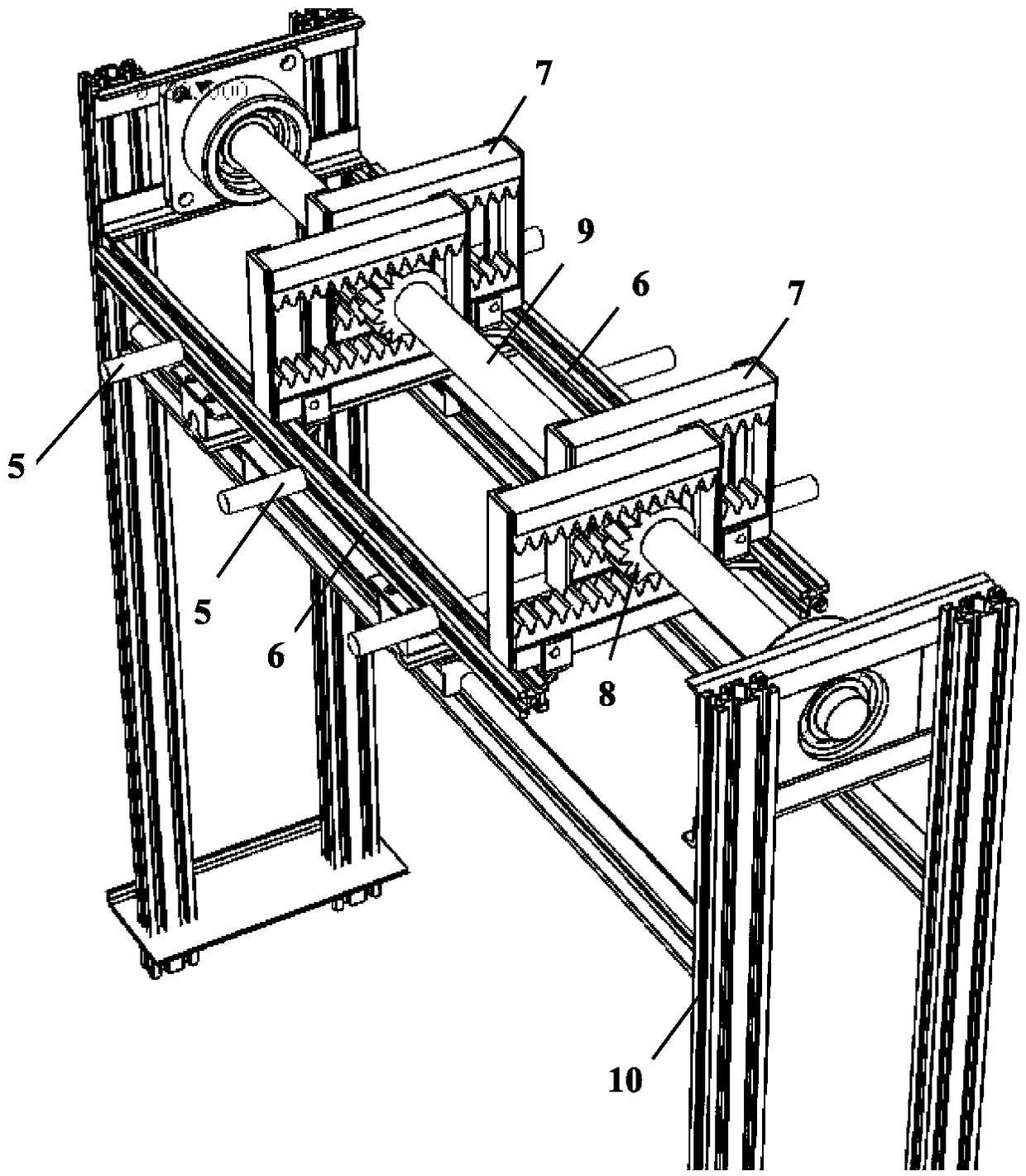

Unidirectionally-driven three-dimensional three-linkage-period stepping mechanism

ActiveCN109479463ARealize the driving effectAchieving common driveTransplantingAgriculture gas emission reductionGear wheelEngineering

The invention discloses a unidirectionally-driven three-dimensional three-linkage-period stepping mechanism. The stepping mechanism comprises seedling ejecting needle assemblies, a telescopic drivingmechanism, a moving driving mechanism, a stepping descending driving mechanism and a total power mechanism, wherein each seedling ejecting needle assembly comprises a plurality of seedling ejecting needles and a fixed component; the telescopic driving mechanism comprises a first reciprocating driving frame, a first incomplete gear and a first gear shaft; the moving driving mechanism comprises a first pushing component, a second reciprocating driving frame, a second incomplete gear and a second gear shaft; and the stepping descending driving mechanism comprises a blocking rod assembly and a movable mechanism. According to the unidirectionally-driven three-dimensional three-linkage-period stepping mechanism, the problems that a seedling ejecting needle driving mechanism is large in driving force and inflexible during the driving can be solved, the problem of top exposure in the descending motion of a grid seedling disc can be solved, and each seedling ejecting needle assembly and relevant assemblies can be driven only through one driving mechanism, so that the stepping mechanism has the advantage of high driving efficiency.

Owner:SOUTH CHINA AGRI UNIV

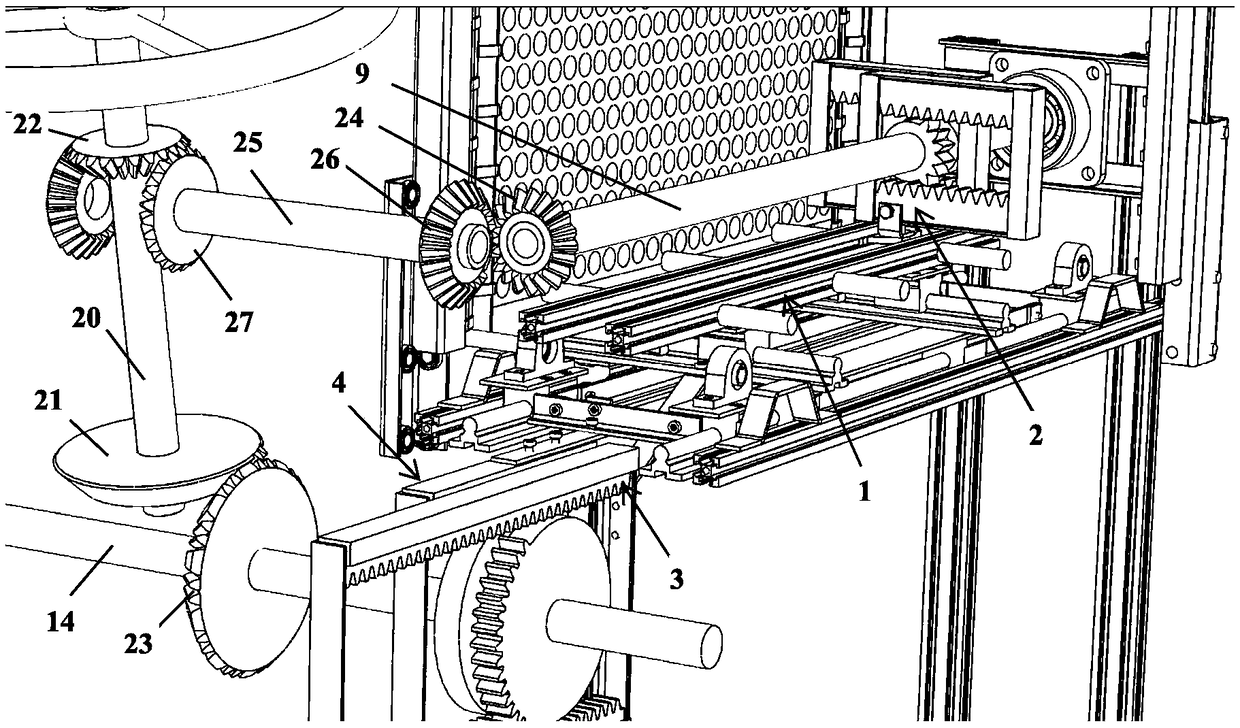

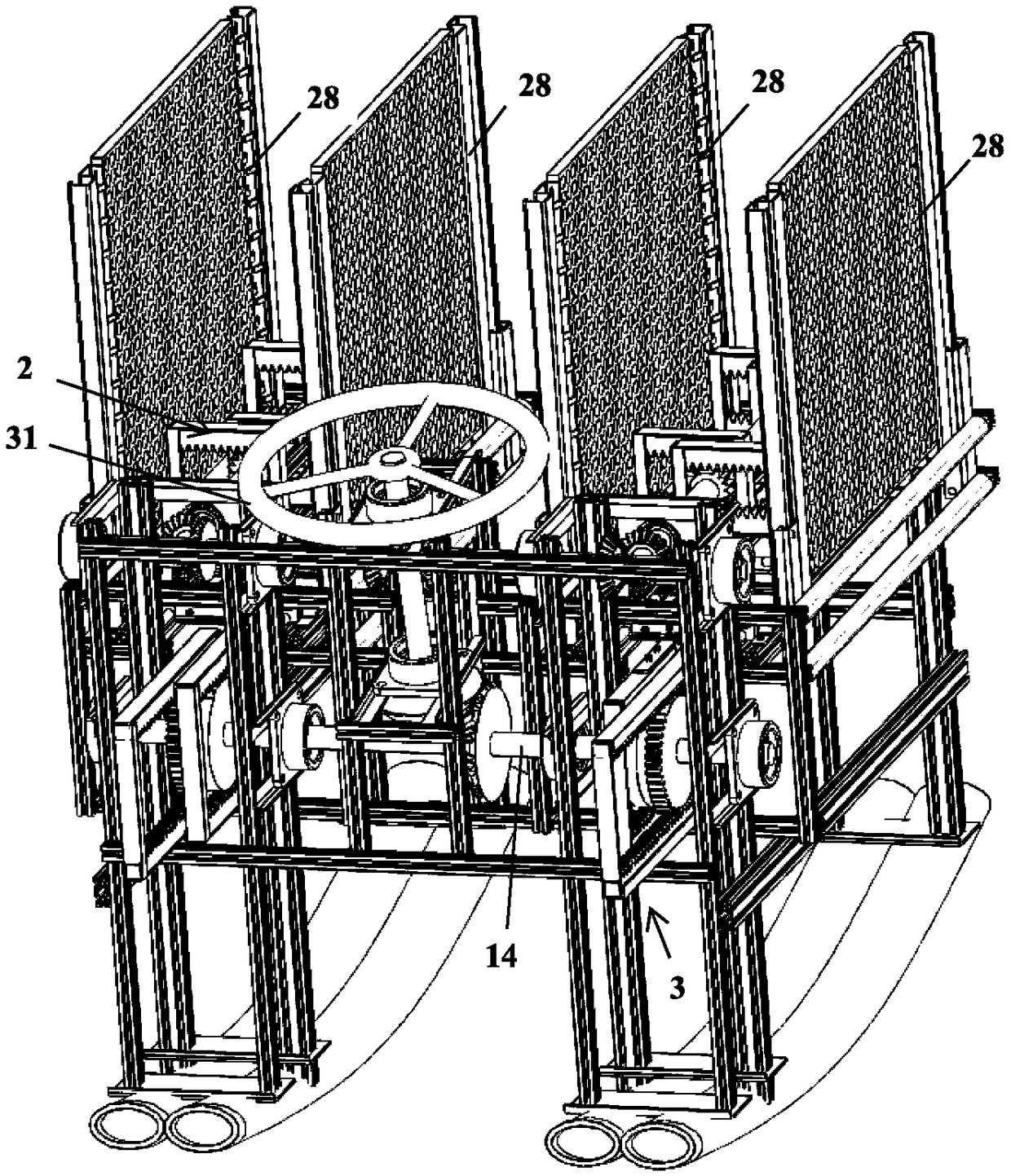

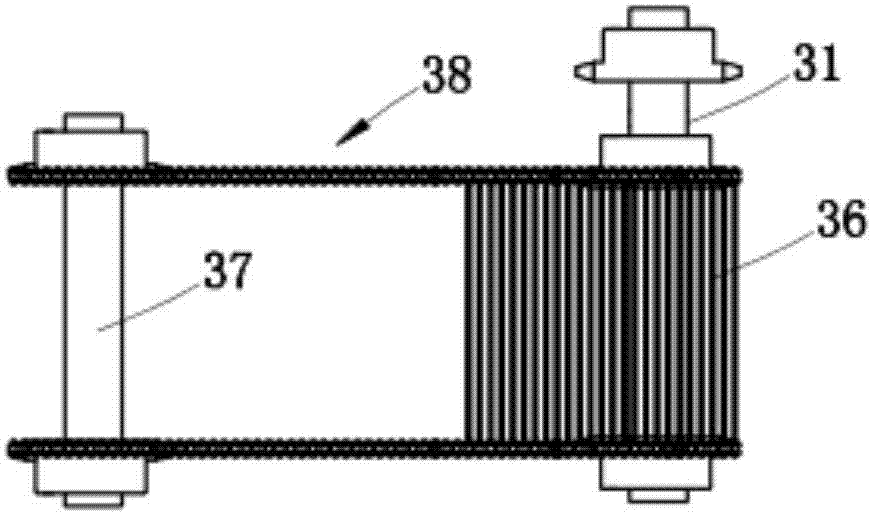

Vegetable stripping device and laver processing device

PendingCN106983098AImprove reliabilityImprove securityFood scienceProcess engineeringMechanical engineering

The invention discloses a vegetable stripping device and a laver processing device and belongs to the technical field of laver processing. The vegetable stripping device comprises a frame, a lifting mechanism, a conveying platform, a transferring device and a driving device. The driving device comprises a driving source, a first driving assembly and a second driving assembly. The driving source is linked to the first driving assembly. The second driving assembly is linked to the first driving assembly. The first driving assembly is connected to the lifting mechanism. The first driving assembly is used for driving the lifting mechanism to move up and down. The second driving assembly is connected to the transferring device and is used for driving the transferring device to rotate. The vegetable stripping device solves the problem that the traditional laver production device has poor reliability and low production efficiency, and can be widely used in laver processing.

Owner:纪合溪

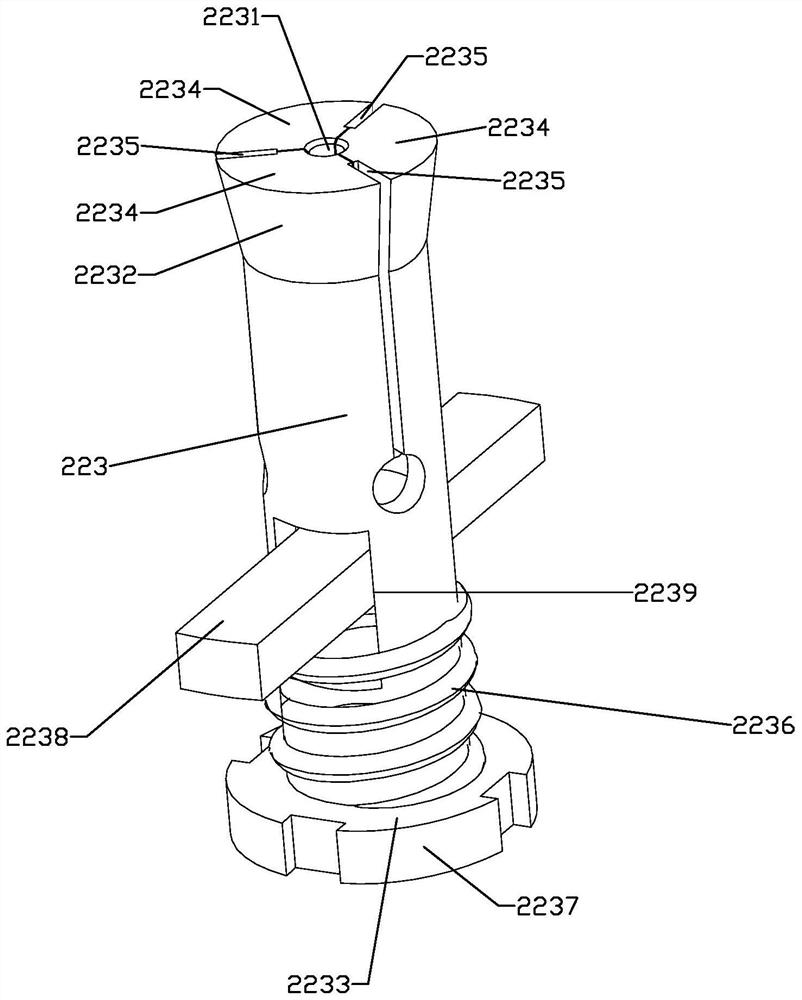

Assembly equipment for air valve

ActiveCN113579677ARealize automatic tightening operationReduce workloadMetal working apparatusEngineeringMotor control

The invention relates to assembly equipment for an air valve, and relates to the technical field of air valve production equipment. The assembly equipment comprises a workbench, a feeding mechanism, a transferring mechanism, a limiting mechanism, a feeding mechanism and a tightening mechanism, wherein the tightening mechanism comprises: a mounting frame fixed to the upper end of the workbench; a supporting frame which is vertically and slidably connected to the side wall of the mounting frame; a sleeve which is vertically and rotationally connected to the mounting frame, wherein a nut is clamped in the sleeve independently; a driving part which is arranged on the mounting frame and is used for driving the supporting frame to vertically move; and a control piece which is arranged on the supporting frame and used for driving the sleeve to rotate; and the transferring mechanism can transport the valve body to the position below the sleeve, and enables a screw to be aligned with the sleeve. According to the assembly equipment, the supporting frame is driven by the driving piece to drive the sleeve to vertically move, meanwhile, the sleeve is driven by the control piece to rotate, and then the sleeve can be automatically matched with the screw, so that automatic nut tightening operation is achieved, the workload of production personnel can be reduced, and the production efficiency can be improved.

Owner:温州东一机械制造有限公司

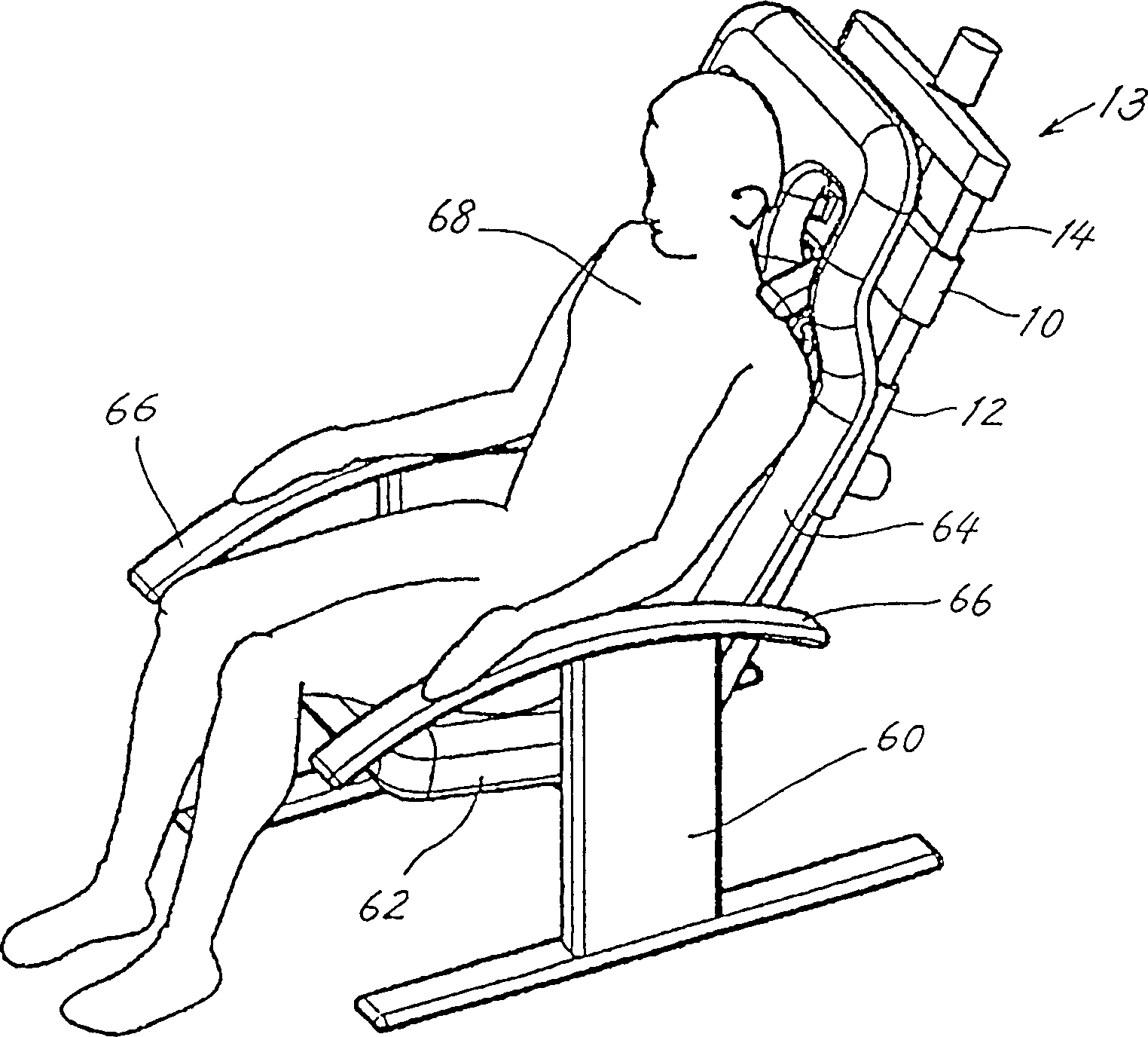

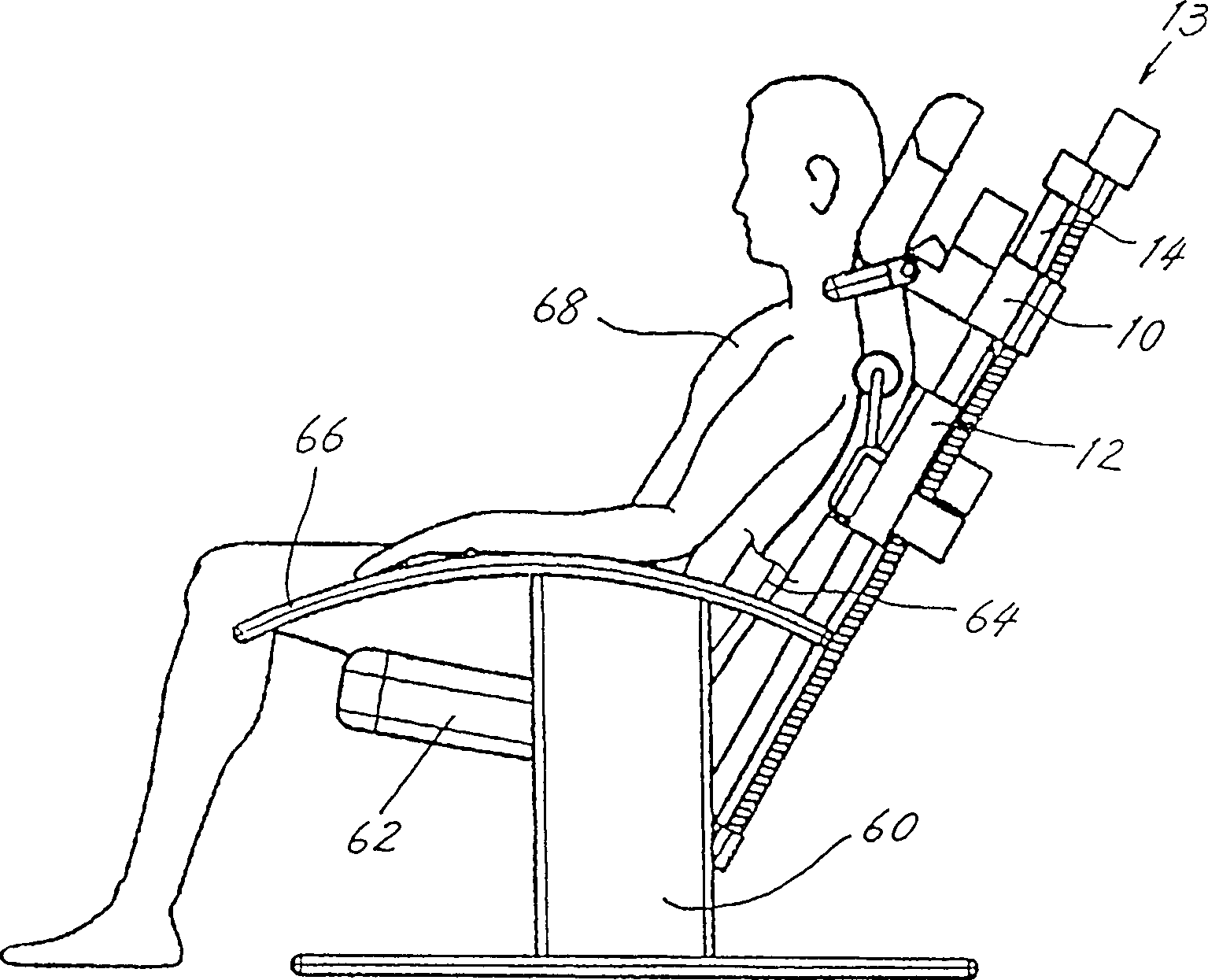

Chair like massage machine

InactiveCN1141078CAccurate and effective massageReduce the driving sourceVibration massageRoller massageMassageBack rests

To provide a chair-type massage machine which is capable of performing various kinds of massage operation more effectively. This chair-type massage machine comprises massage units with a pair of right / left massage fingers for applying a massage treatment to a person to be treated and guide frames, formed along the back rest of a chair, on which the massage units are arranged in a freely movable manner. On the guide frames the plural massage units which are independently movable or can be positioned are arranged.

Owner:SANYO ELECTRIC CO LTD

Fully automatic lamp foot guide wire riveting machine

PendingCN109256651AReduce frictionExtended service lifeLine/current collector detailsDrive shaftWear resistant

The invention provides a fully automatic lamp foot guide wire riveting machine which comprises a bottom plate, A left side plate and a right side plate are arranged on that top of the bottom plate, Adrive cylinder is arranged on one side of the right side plate, At one end of that drive cylinder, a fish-eye joint is arranged, At one end of that fish-eye joint, a driving rock arm is rotatably connected, At one end of that drive rocker arm, a drive shaft penetrate the left and right plates, a cam is arranged on the drive shaft, a rotating shaft is fixed between the left and right plates on oneside of the drive shaft, two wear-resistant sleeves are sleeved on the rotating shaft, and upper and lower connecting rods are respectively arranged on the wear-resistant sleeves. The wear-resistant sleeve and the wear-resistant pad are adopted, The utility model has the advantages of small friction, long service life, adopting a cam to drive the upper connecting rod and the lower connecting rod to rotate simultaneously, realizing two actions by one driving cylinder, compact and simple in structure, reducing driving source, riveting the lamp leg guide wire while supporting the lamp leg, and realizing automatic riveting without manual participation, reducing manpower and saving cost. The utility model has the advantages of small friction and long service life, and adopts a cam to drive theupper connecting rod and the lower connecting rod to rotate simultaneously, and realizes two actions by one driving cylinder.

Owner:南京合力电光源设备制造厂

Graphene water-cooling heat dissipation packaging structure of IGBT module

InactiveCN113725178AExtension of timeImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesGraphene coatingCooling effect

The invention discloses a graphene water-cooling heat dissipation packaging structure of an IGBT module, and the structure comprises a first chip, a second chip and filling resin; the outer sides of the first chip and the second chip are filled with the filling resin, and the top and bottom of the filling resin are provided with ceramic copper plates (high-performance Cu-MAX materials). The first chip and the second chip are welded between the ceramic copper plates; the substrate is installed on the sides, away from the filling resin, of the ceramic copper plates; the radiator is installed on the side, away from the ceramic copper plates, of the substrate; and the top surface and the bottom surface of each ceramic copper plate are both coated with graphene coatings. The invention specifically relates to the technical field of IGBT modules. The cooling effect is improved by arranging the cold box and the circulating box for water cooling heat dissipation, the spring pipe is arranged between the water cooling box and the circulating box, the spring pipe can enable water in the inner cavity of the water cooling box to pass through the bent spring pipe for heat dissipation, the time for the water in the inner cavity of the water cooling box to enter the inner cavity of the circulating box is prolonged, and the heat dissipation time is shortened.

Owner:山姆泰酷半导体科技(苏州)有限公司

A terminal structure of a multipurpose manipulator

InactiveCN103448070BSimple structureFlexible structureGripping headsWheelchairs/patient conveyanceKey pressingDrive motor

The invention discloses a tail end structure of a multipurpose manipulator. The tail end structure of the manipulator can be used for finishing delicate action such as picking of paper, operating keys, grabbing of small pills and the like besides the grabbing action of a general clamping manipulator, and can be used for finishing other life operation such as opening and closing of doors in cooperation with the arm of the manipulator. According to the tail end structure, all actions of fingers are finished by using one motor, so that the number of driving motors for the manipulator is reduced, the weight of the manipulator can be effectively reduced, unnecessary energy consumption is reduced, and a plurality of operating functions are completed on the premise of keeping a simple structure.

Owner:SOUTH CHINA UNIV OF TECH

Ballpoint pen spring nib assembly device

ActiveCN111251749BQuality assuranceUniform deformationPen repairingBall-point pensElectric machineryEngineering

The invention relates to a ballpoint pen spring nib assembly device, which comprises an assembly platform, an assembly turntable and a turntable motor. The edge of the assembly turntable is provided with a transmission fixture for clamping the nib for transmission. The nib feeding device for the transmission fixture, the first nib detection device for detecting whether there is a nib on the transmission jig, the second nib detection device for detecting whether the nib on the transmission jig conforms to the standard, and placing the spring on the transmission jig The spring feeding device on the nib, the spring detection device to detect whether the spring is assembled in place, the waste discharge device to take away the unqualified nib, squeeze the side of the qualified nib to make the spring limit in the nib The deformation device and the qualified product discharge device for removing the deformed nib. By adopting the above solution, the present invention provides a ballpoint pen spring nib assembly device that improves the rate of good products, improves assembly efficiency, and reduces processing costs.

Owner:WENZHOU UNIV +1

A chip flatness detection device and detection method

ActiveCN113237442BEasy to check flatnessEasy to detectBase supporting structuresBraking devices for hoisting equipmentsComputer hardwareMechanical engineering

The invention discloses a chip flatness detection device and a detection method, belonging to the technical field of chip detection equipment. A chip flatness detection device, including a mounting box, also includes: a chute set on the top of the mounting box; a pneumatic telescopic rod sliding in the chute; a mounting box connected to the output end of the pneumatic telescopic rod; The connecting cylinder on the top, wherein, the bottom of the connecting cylinder extends to the outside of the installation box and is fixedly connected with a suction cup. The connecting cylinder is provided with multiple sets, and the multiple sets of connecting cylinders are fixedly connected with first gears, and the multiple sets of first gears mesh with each other; The assembly is arranged in the installation box and is used to drive the connection cylinder to rotate; the detection assembly is arranged in the installation box and is used to detect the chip; the invention adjusts the relative position of the chip and the detector by making the connection shaft and the installation box rotatable. Surface, so that the bottom surface and side wall of multiple groups of chips can be tested for flatness at the same time, thereby improving the detection efficiency.

Owner:江苏澳芯微电子有限公司

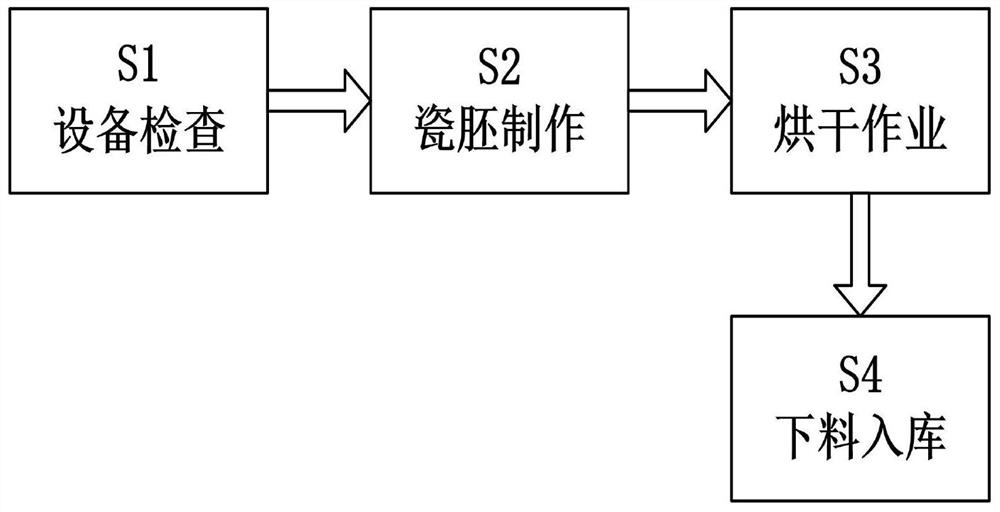

A kind of reinforcement construction method of ultra-deep muddy soil layer triaxial stirring pile

ActiveCN112854239BImprove construction qualityImprove replacement efficiencyExcavationsBulkheads/pilesSoil scienceStructural engineering

This application relates to a construction method for strengthening three-axis mixing piles in ultra-deep muddy soil layers, which includes the following steps: S1, removing underground obstacles, and leveling the site; S2, measuring and setting out lines, and determining pile positions; S3, excavating trenches , pile position review; S4, pile driver in place, leveling and straightening; S5, mud mixing; S6, mixing, spraying, sinking and lifting; S7, spoil treatment; S8, cleaning pipeline and mixing head; In the S6 step, at first analyze according to the previous geological exploration results, use the three-axis stirring pile machine to carry out spiral drilling, when the stirring head of the three-axis stirring pile machine enters the muddy stratum, increase the stirring of the three-axis stirring pile machine head speed. The application has the effect of improving the reinforcement quality, so that the construction quality of the three-axis stirring pile in the deep soft soil is better.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

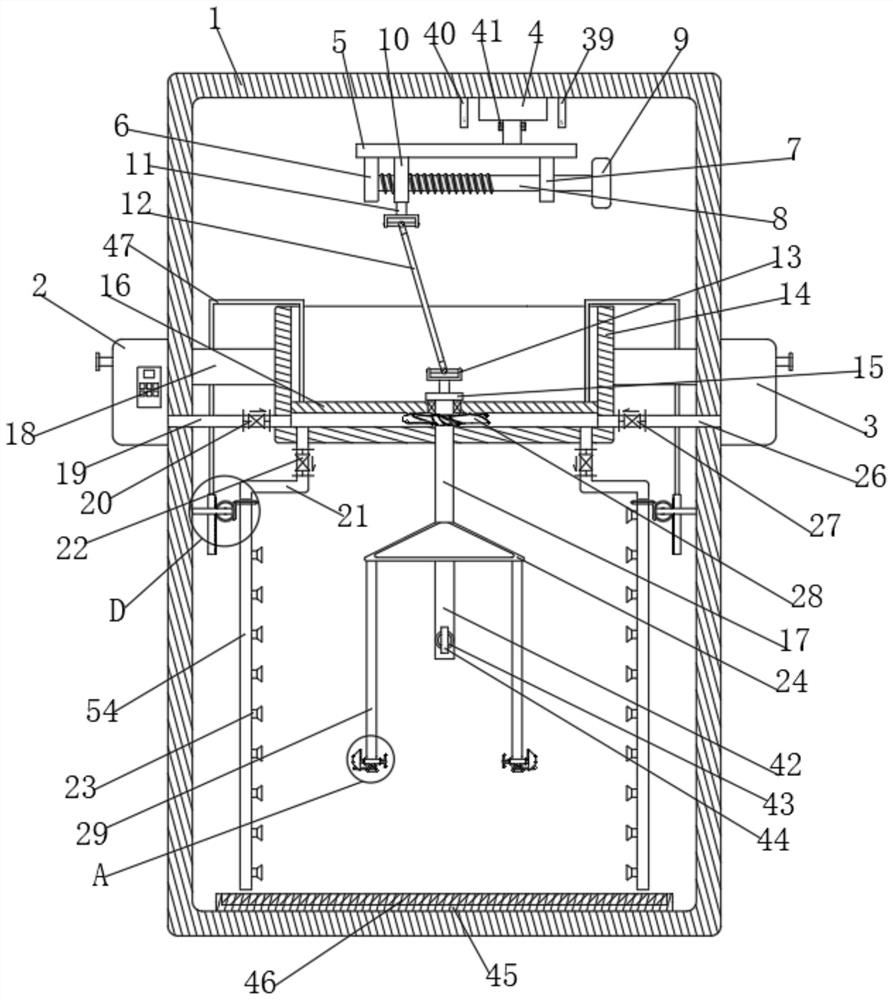

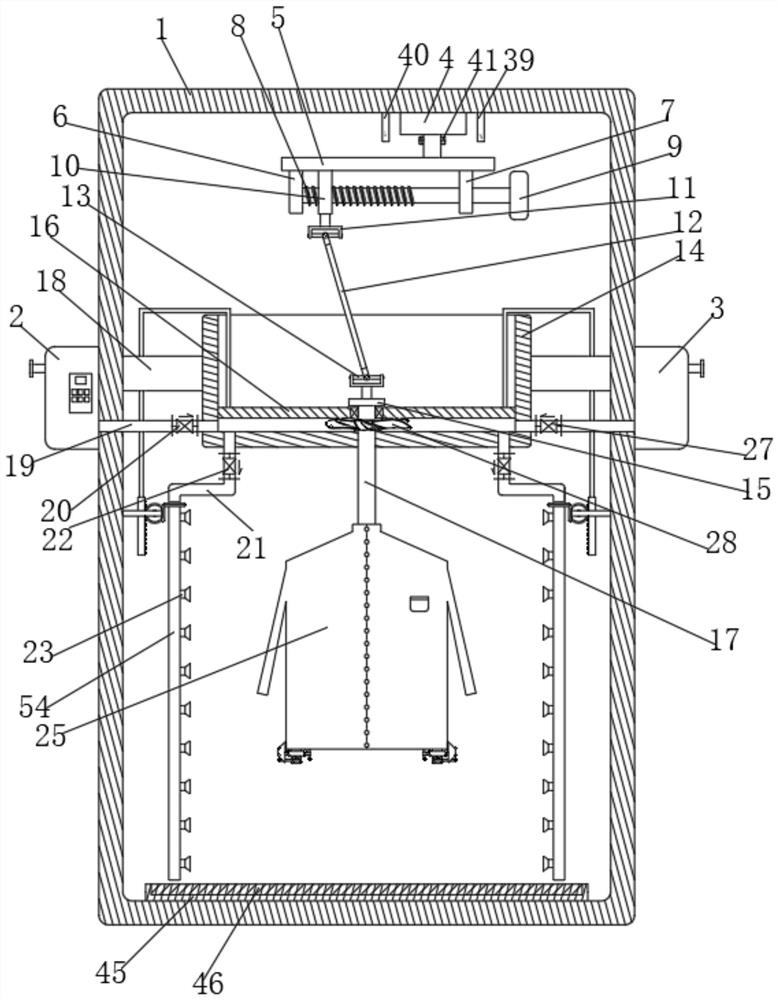

Jet-propelled rotary garment ironing device

InactiveCN113622174ABest ironing positionAchieve ironing effectMechanical cleaningPressure cleaningMechanical engineeringPleat

The invention discloses a jet-propelled rotary garment ironing device, and relates to the technical field of garment ironing. The jet-propelled rotary garment ironing device comprises a frame; the lower end of a gasket is fixedly connected with a rotating rod; the side wall of the frame is fixedly connected with a cross rod; the end part of the cross rod is fixedly connected with a mixing barrel; the inner wall of the mixing barrel is slidably connected with a piston; the surface of the piston is provided with a second rotating hole used for the rotating rod to penetrate through and rotationally connected with a fixed shaft of the piston; the lower surface of the mixing barrel is provided with an opening used for the rotating rod to penetrate through and connected with the mixing barrel in a sliding and sleeving mode; the lower end of the rotating rod is fixedly connected with a supporting frame; and the device further comprises a stretching part used for preventing a garment from being wrinkled when the garment is ironed, and a mixed ironing part for performing mixed ironing on the garment and removing the peculiar smell. The device has the effects that the optimal ironing position is reached through movement of a thread bushing, garments of different lengths can be adapted, the garment is prevented from being in contact with the ground, all-directional no-dead-corner ironing can be carried out, and the peculiar smell is removed in the ironing process.

Owner:温州信杰服饰有限公司

Steamed stuffed bun forming machine

InactiveCN102058065BFast processingReduce manufacturing costDough shapingFood shapingDrive shaftMolding machine

The invention relates to a food processing device, in particular to a steamed stuffed bun forming machine. In the technical scheme provided by the invention, the steamed stuffed bun forming machine is characterized by comprising a mounting base, a forming and covering mechanism, a transmission mechanism and a driving mechanism driving the transmission mechanism. The transmission mechanism is matched with the forming and covering mechanism to enable the forming and covering mechanism to reciprocate along the axial direction of the mounting base and to expand and fold. The forming and covering mechanism comprises a sliding disk and a swingable jack catch in circumferential hinge with the sliding disc. The transmission mechanism comprises a ejector rod, a transmission shaft linked to the driving mechanism and a transmission unit used for the linkage between the ejector rod and the transmission shaft. By using the above technical scheme, the invention provides the steamed stuffed bun forming machine which has high processing speed and reduced production cost.

Owner:WENZHOU UNIV

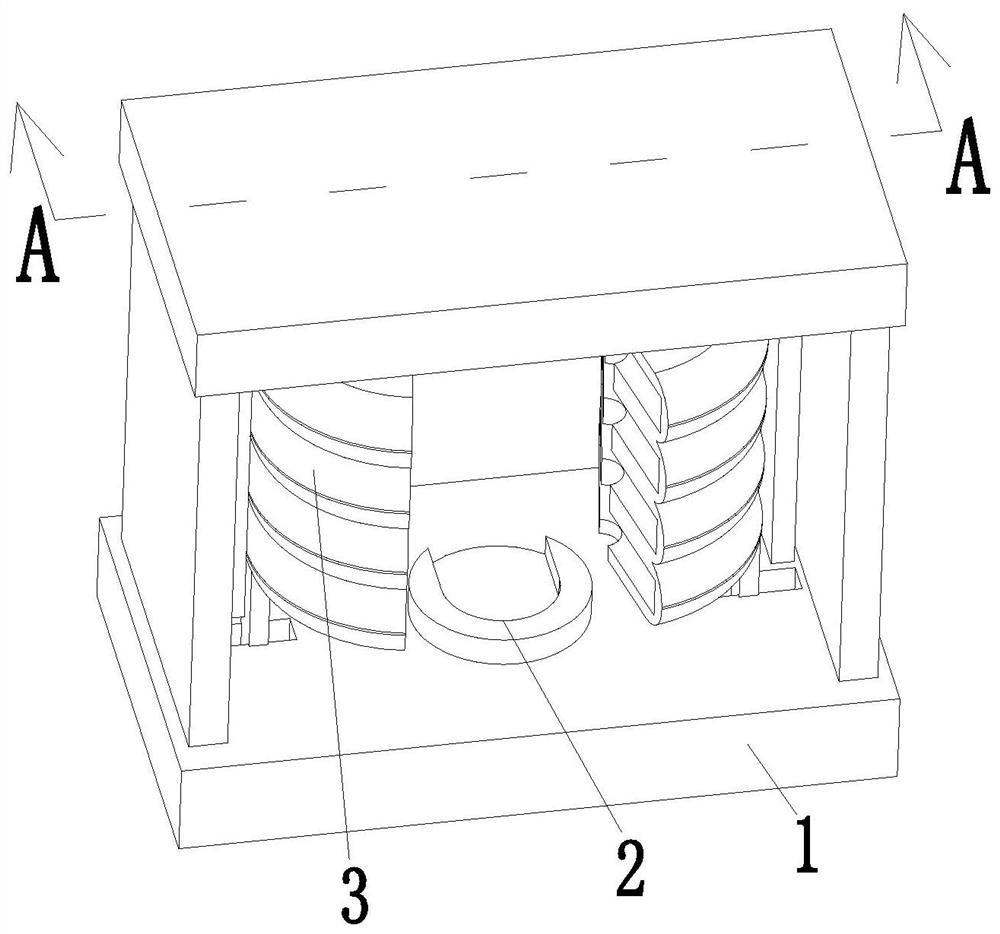

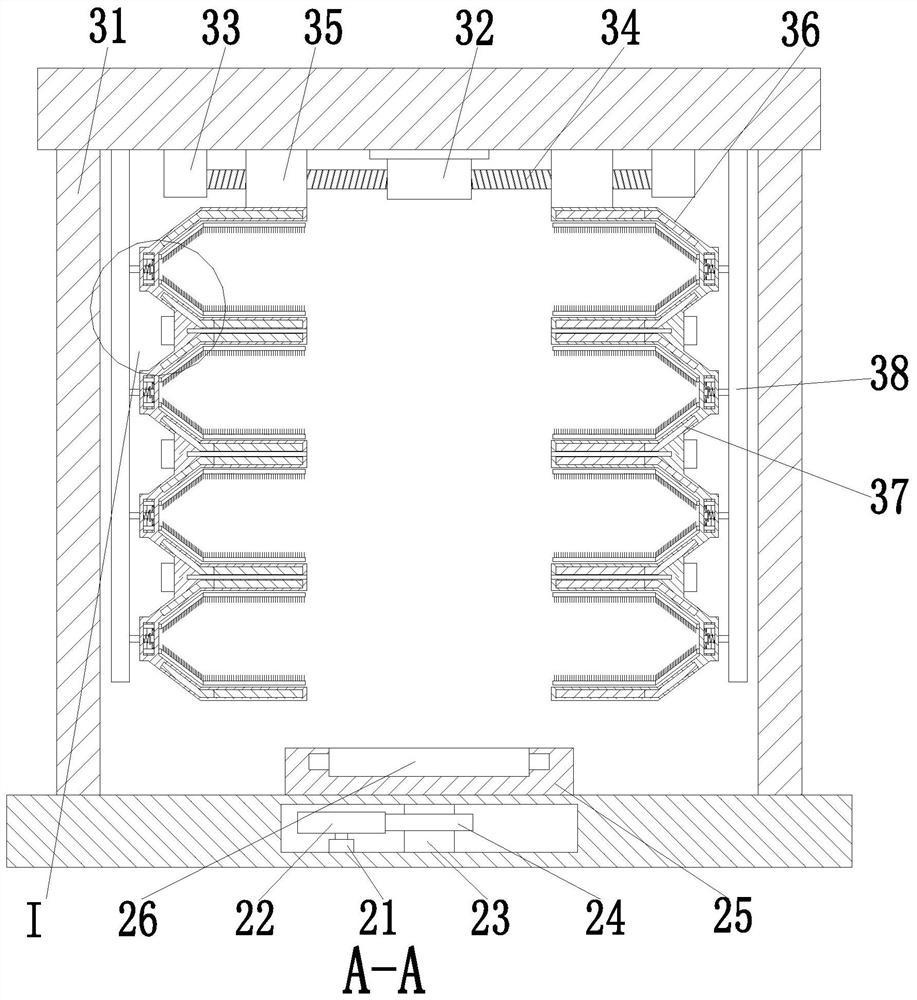

Transformer insulating material electroceramic forming processing technology

ActiveCN112967879AFastReduce the driving sourceTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureProcess engineeringMechanical engineering

The invention relates to a transformer insulating material electroceramic forming processing technology. Electroceramic drying equipment is used, the electroceramic drying equipment comprises a base, a fixed rotating device and a drying and cleaning device, the fixed rotating device is arranged on the inner wall of the lower end of the base, and the drying and cleaning device is arranged at the upper end of the base. According to the method, an electroceramic blank is directly wrapped with a heating end for heating and drying, so that the drying temperature of the surface of the electroceramic blank can be adjusted, and the problems that the temperature in a furnace is constant, the electroceramic forming speed is high, and excessive drying is easily caused after too long time are solved; and a cleaning mechanism is driven to operate through linkage of feeding of the heating end, so that a large number of driving sources are saved, and the problem that the cost is greatly increased due to the fact that multiple driving sources are often needed for separate cleaning of all the discs is solved.

Owner:新昌县新明实业有限公司 +1

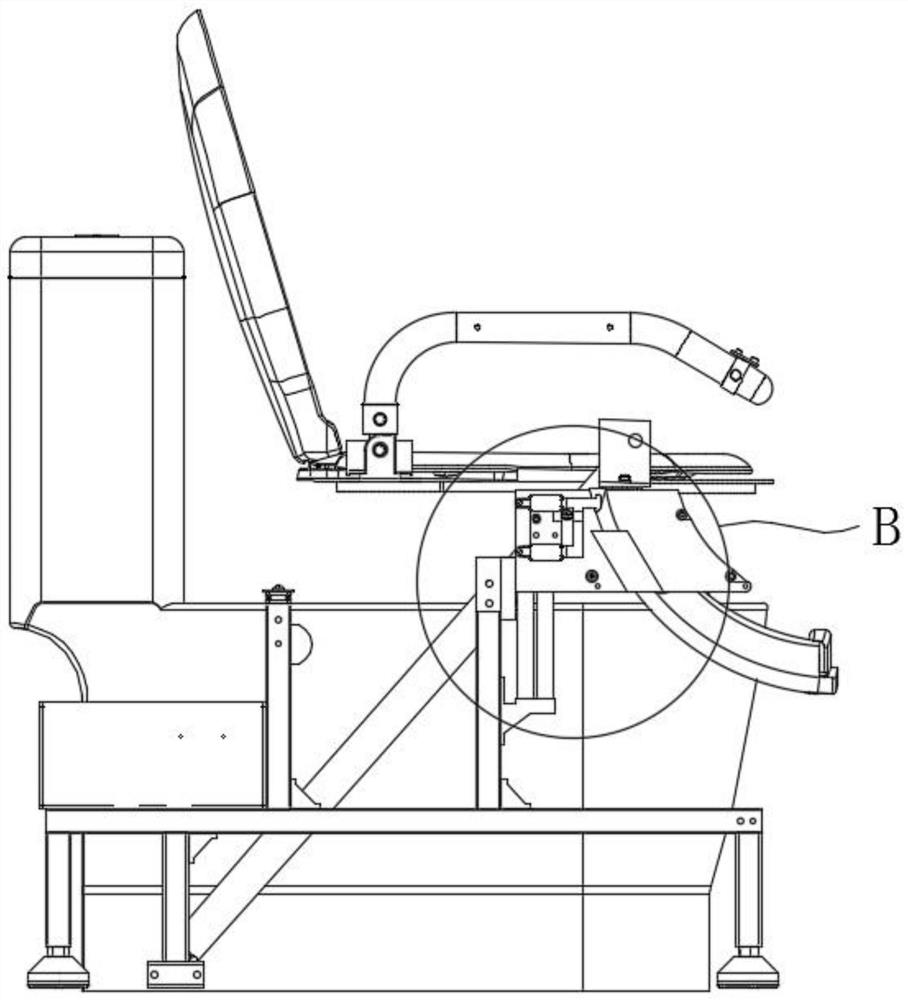

A toilet aid

The invention discloses a toilet aid, which comprises a seat cushion supporting base and two toilet auxiliary mechanisms, the two toilet auxiliary mechanisms are arranged symmetrically with respect to the seat cushion support base, and the toilet auxiliary mechanism comprises a bracket, An electric push rod, a first track rod, a guide, a connector and a lock assembly; one end of the electric push rod is connected to the bracket, the other end of the electric push rod is connected to the shaft of the connector, and the first track rod It is fixed with the cushion support seat through a connecting piece; the guide rail vertically arranged on the support, the upper and lower sides of the guide rail are respectively provided with an upper limit block and a lower limit block, and the guide piece is sleeved on the guide rail and Can move up and down along the guide rail, the inside of the guide is provided with an arc-shaped guide groove, the first track bar is passed through the guide slot, and the lock assembly is arranged on the first track bar between the guides. It guarantees the safety and auxiliary effect of the elderly in the whole process of going to the toilet, and has good stability.

Owner:JIANGSU JICUI MICRO NANO AUTOMATION SYST & EQUIP TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com