A chip flatness detection device and detection method

A detection device and flatness technology, applied in the field of chip flatness detection devices, can solve problems such as low detection efficiency, and achieve the effects of reducing failure rate, reducing loss and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

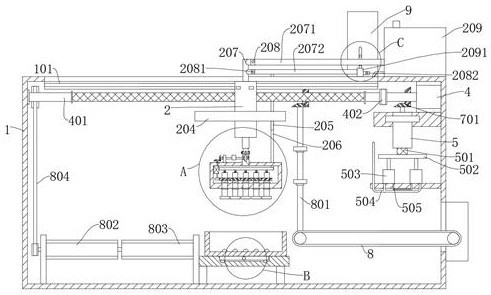

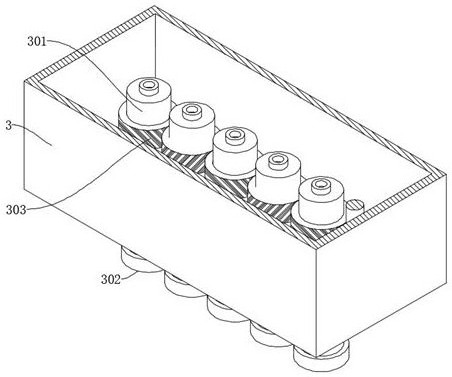

[0036] refer to Figure 1-6, a chip flatness detection device, including a mounting box 1, also includes: a chute 101 opened on the top of the mounting box 1; a pneumatic telescopic rod 2 sliding in the chute 101; Box 3; the connection cylinder 301 connected to the installation box 3 by rotation, wherein the bottom of the connection cylinder 301 extends to the outside of the installation box 3 and is fixedly connected with a suction cup 302, the connection cylinder 301 is provided with multiple groups, and the multiple groups of connection cylinders 301 are all fixed The first gear 303 is connected, and multiple sets of first gears 303 are meshed with each other; the power assembly is arranged in the installation box 3 for driving the connection cylinder 301 to rotate; the detection assembly is arranged in the installation box 1 for detecting the chip .

[0037] Multiple groups of suction cups 302 absorb multiple chips at a time, and send the chips to the top of the detection...

Embodiment 2

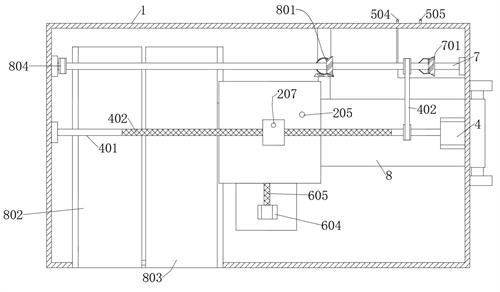

[0039] refer to figure 1 , image 3 with Figure 4 : A chip flatness detection device, which is basically the same as Embodiment 1, and furthermore, the power assembly includes a biaxial motor 304, and the first output shaft of the biaxial motor 304 is fixedly connected with a gear that meshes with the first gear 303 The second gear 305, the top of the installation box 3 is rotatably connected with a connecting shaft 307, the connecting shaft 307 is provided with a safety coupling 3071, and the connecting shaft 307 rotates through the first bevel gear set 306 and the second output shaft of the biaxial motor 304 Connected, the output end of the pneumatic telescopic rod 2 is fixedly connected with the ring gear 202 , and the end of the connecting shaft 307 away from the first bevel gear set 306 is fixedly connected with the third gear 308 meshing with the ring gear 202 .

[0040] Start the biaxial motor 304, the first output shaft of the biaxial motor 304 rotates the first gea...

Embodiment 3

[0042] refer to figure 1 , figure 2 with Figure 5 : A chip flatness detection device, which is basically the same as Embodiment 1, furthermore, the detection assembly includes a base 6, a groove body 602 is slidably connected to the base 6, a detector 603 is provided in the groove body 602, and a detector 603 is arranged on the base 6 A second motor 604 is fixedly connected, the output end of the second motor 604 is fixedly connected with a third reciprocating screw rod 605 , and a second threaded hole corresponding to the third reciprocating screw rod 605 is opened on the tank body 602 .

[0043] Start the tester 603 to detect the flatness of the chip. The tester 603 uses a laser measuring instrument to measure the surface characteristics of the chip by using a laser optical method, and measures the flatness without any contact. The motor 604, the second motor 604 makes the third reciprocating screw mandrel 605 rotate, and the third reciprocating screw mandrel 605 makes t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com