A system for detecting the flatness of building ground surface

A detection system and ground surface technology, applied in sustainable buildings, measurement devices, renewable energy integration, etc., can solve the problems of cumbersome, high production cost, inconvenient identification, etc., and achieve the effect of improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following is further described in detail by specific embodiments:

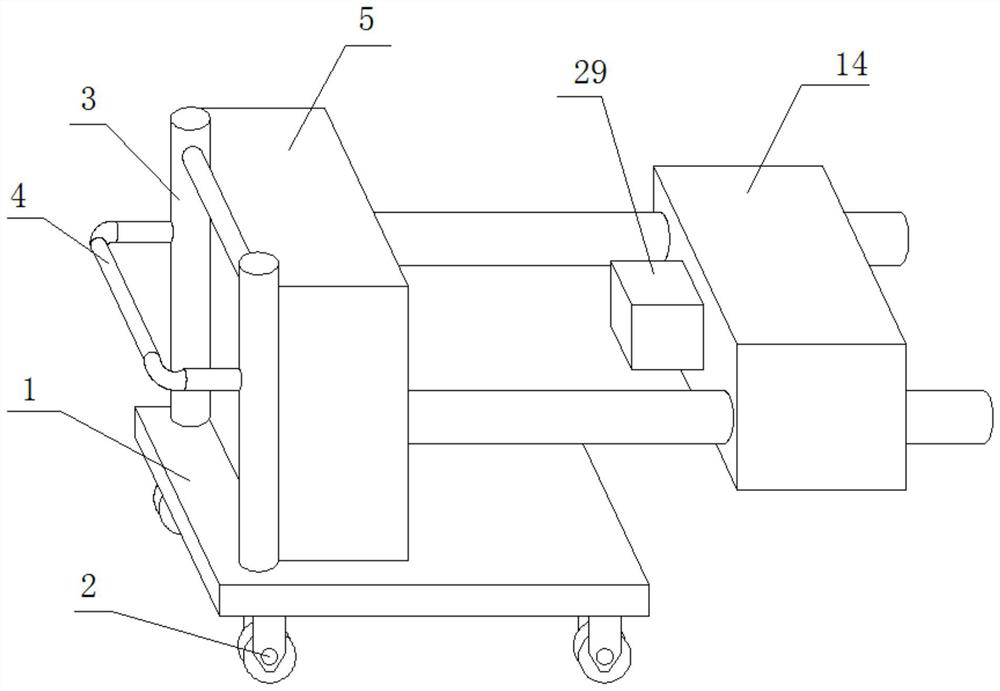

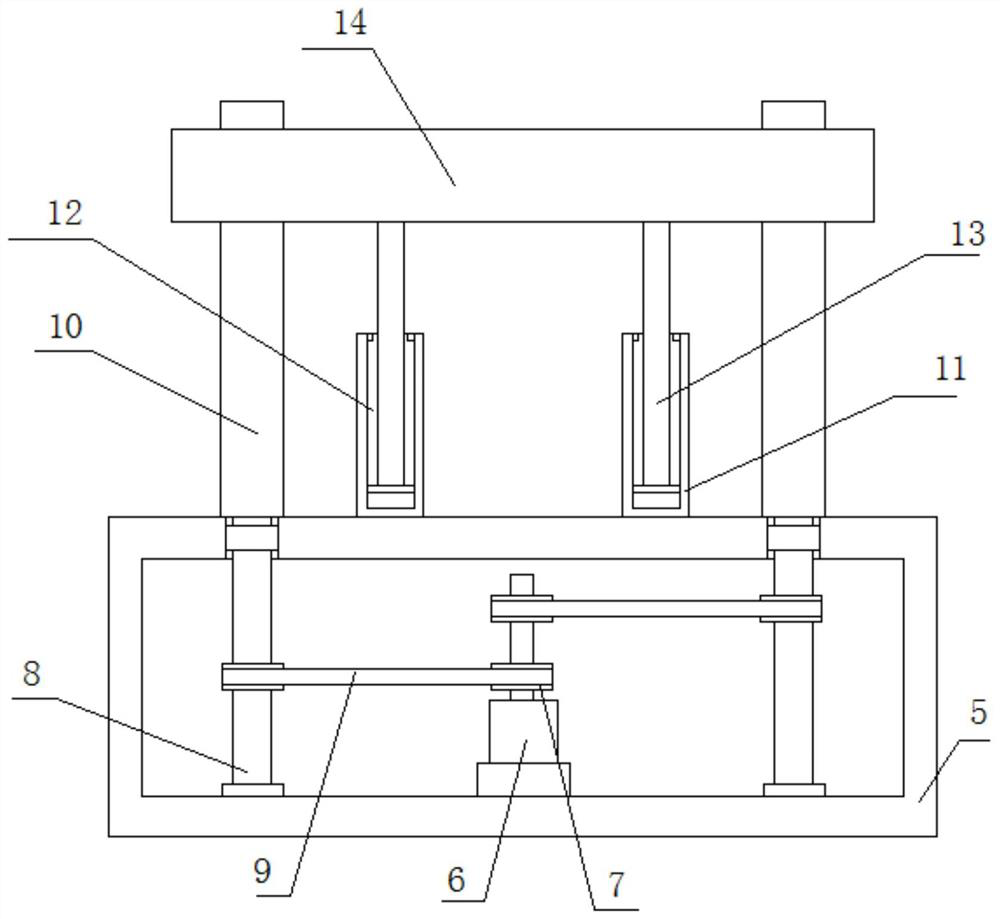

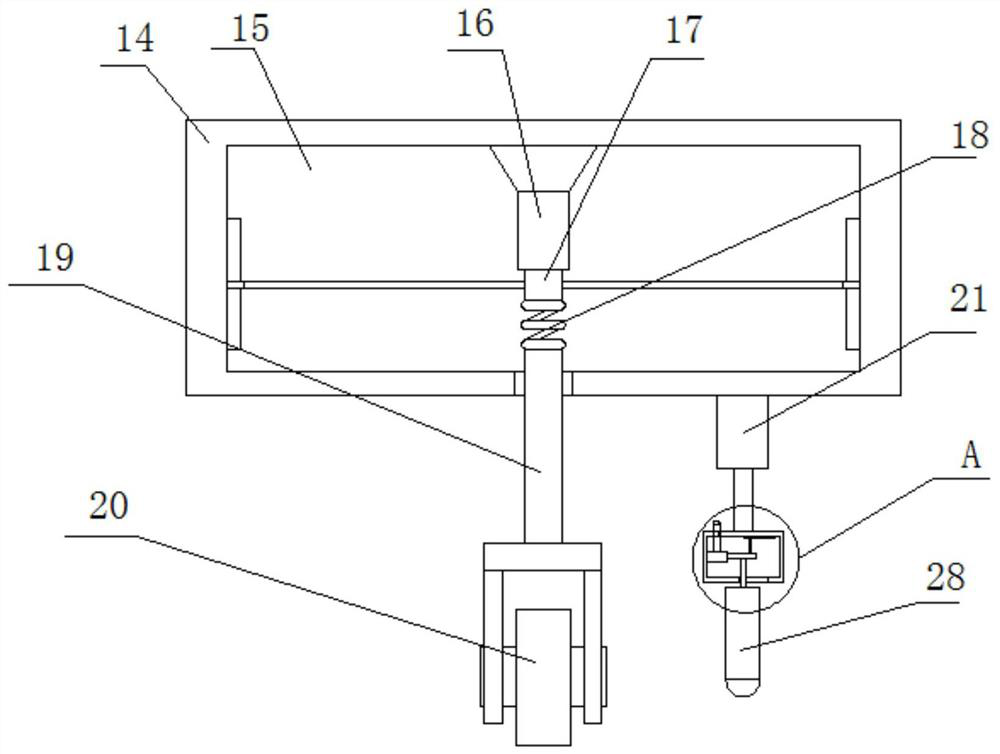

[0028] like Figure 1-5A system for detecting the flatness of a building ground surface, which includes a base 1, the bottom of the base 1 is provided with four brake wheels 2, and the four brake wheels 2 are symmetrically arranged on both sides of the bottom of the base 1, and the top of the base 1 is provided. Two symmetrically arranged uprights 3 are fixedly installed, one side of the two uprights 3 close to each other is fixedly installed with the same reinforcing rib, and one side of the two uprights 3 is fixedly installed with the same handle 4, and the top of the base 1 is fixedly installed There is a drive block 5, the drive block 5 is hollow, and two drive shafts 8 symmetrically arranged on one side of the inner wall of the drive block 5 are rotatably installed, and the two drive shafts 8 are connected with the same drive assembly. The drive motor 6 installed on the inner wall of one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com