Patents

Literature

126results about How to "Realize the driving effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel bar three-dimensional modeling and automatic calculation method based on BIM technology

PendingCN111177831AImplement parametric modelingSolve the errorGeometric CADDesign optimisation/simulationGraphicsProcess engineering

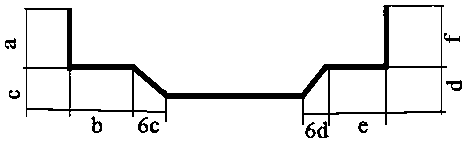

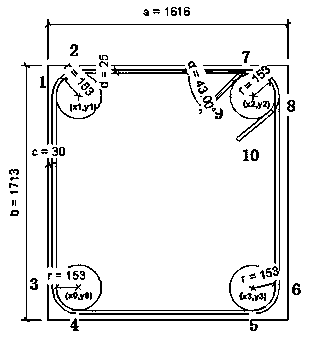

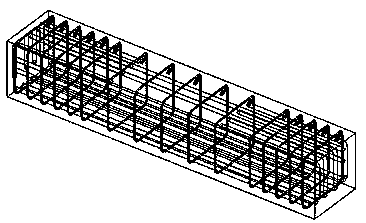

The invention discloses a steel bar three-dimensional modeling and automatic calculation method based on a BIM technology. The invention belongs to the field of building information models, the methodcomprises the following steps: firstly, researching a creation method of a novel parameterized component family different from an existing steel bar family on a Revit Stretch platform; secondly, realizing automatic generation of a steel bar detail table based on a parameterized component family, and finally finishing interactive modification with a Revit graph in an Excel table to realize visualmodification of component parameters. According to the invention, modification of geometric information and steel bar information of the component driven by parameters can be realized through creationof a parameterized component family; meanwhile, the nesting problem which cannot be completed by an existing steel bar family can be solved, the steel bar quantity list is automatically generated through parameter design, real-time control over the steel bar quantity is facilitated, steel bar discharging and bin dividing are conducted in a targeted mode, and waste of steel bar tailings is reduced.

Owner:SHENYANG POLYTECHNIC UNIV

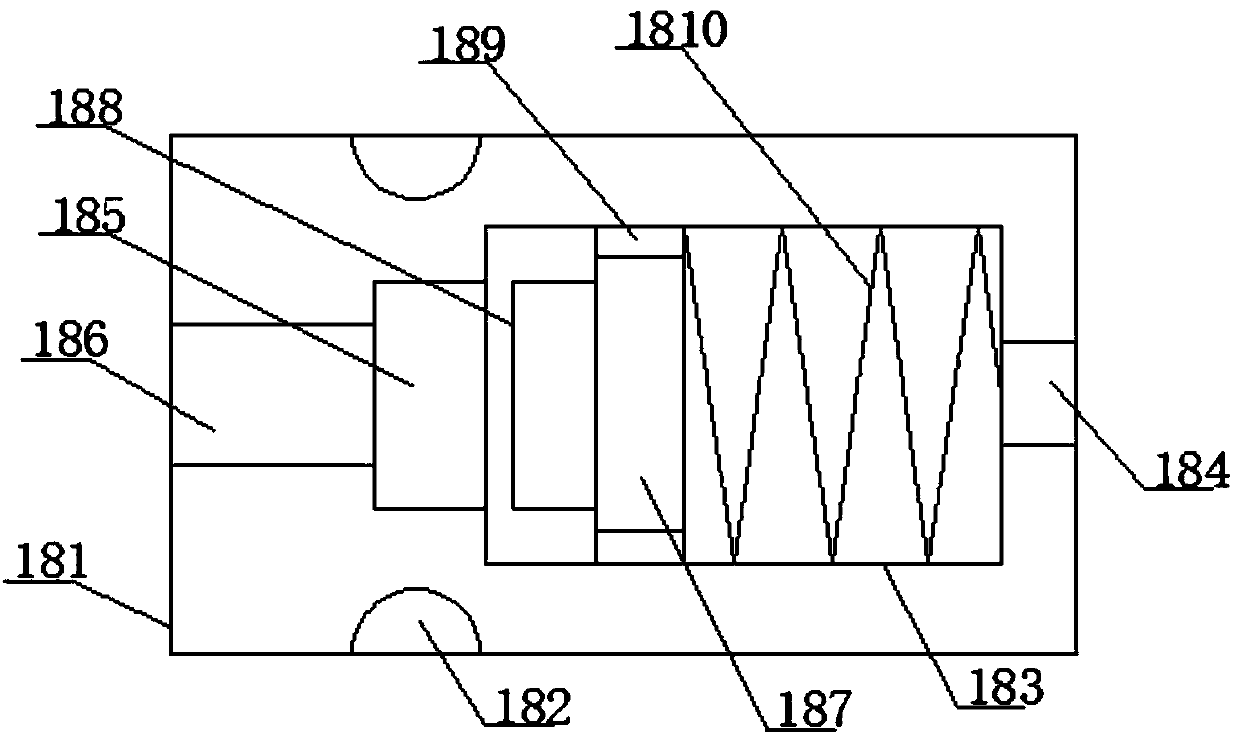

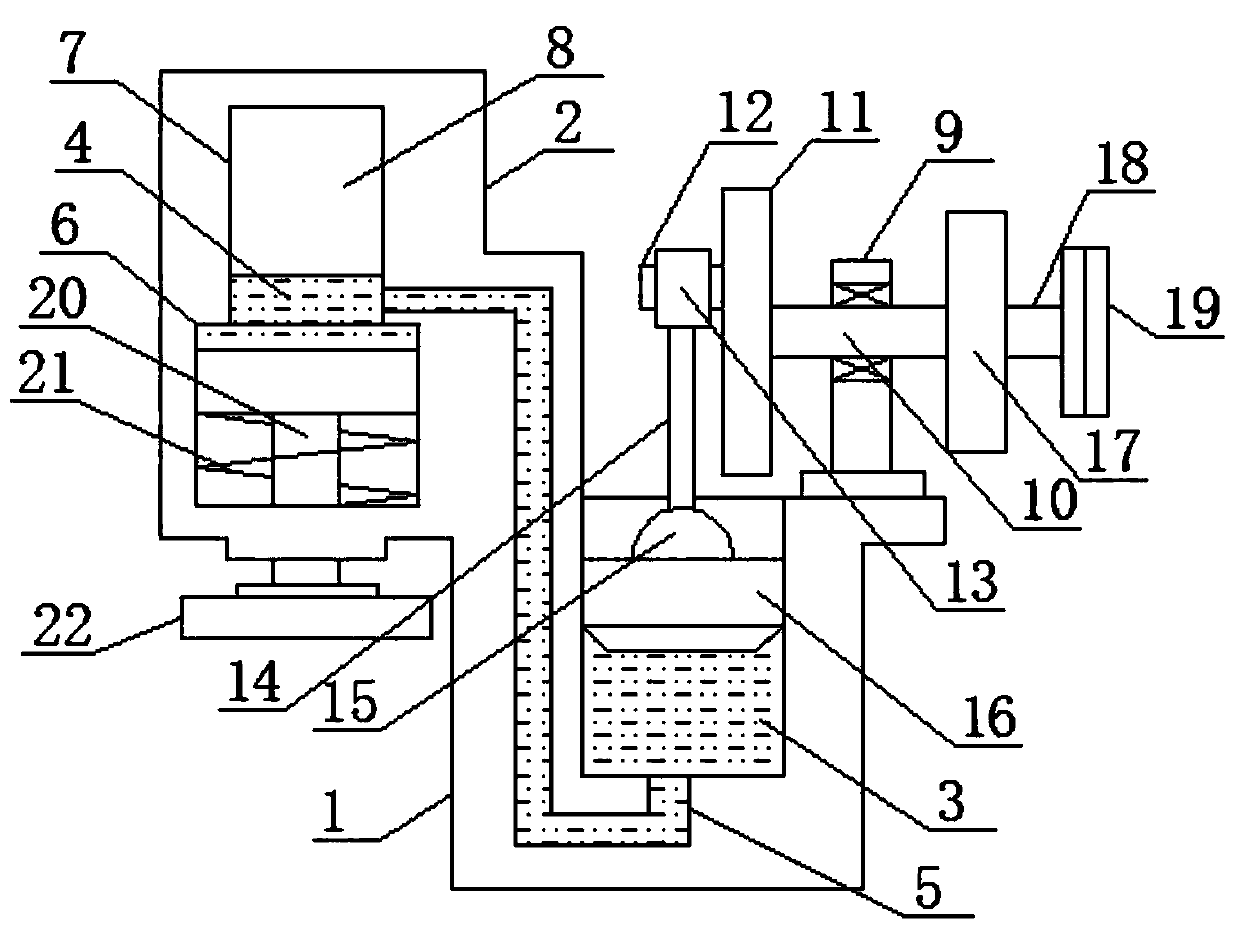

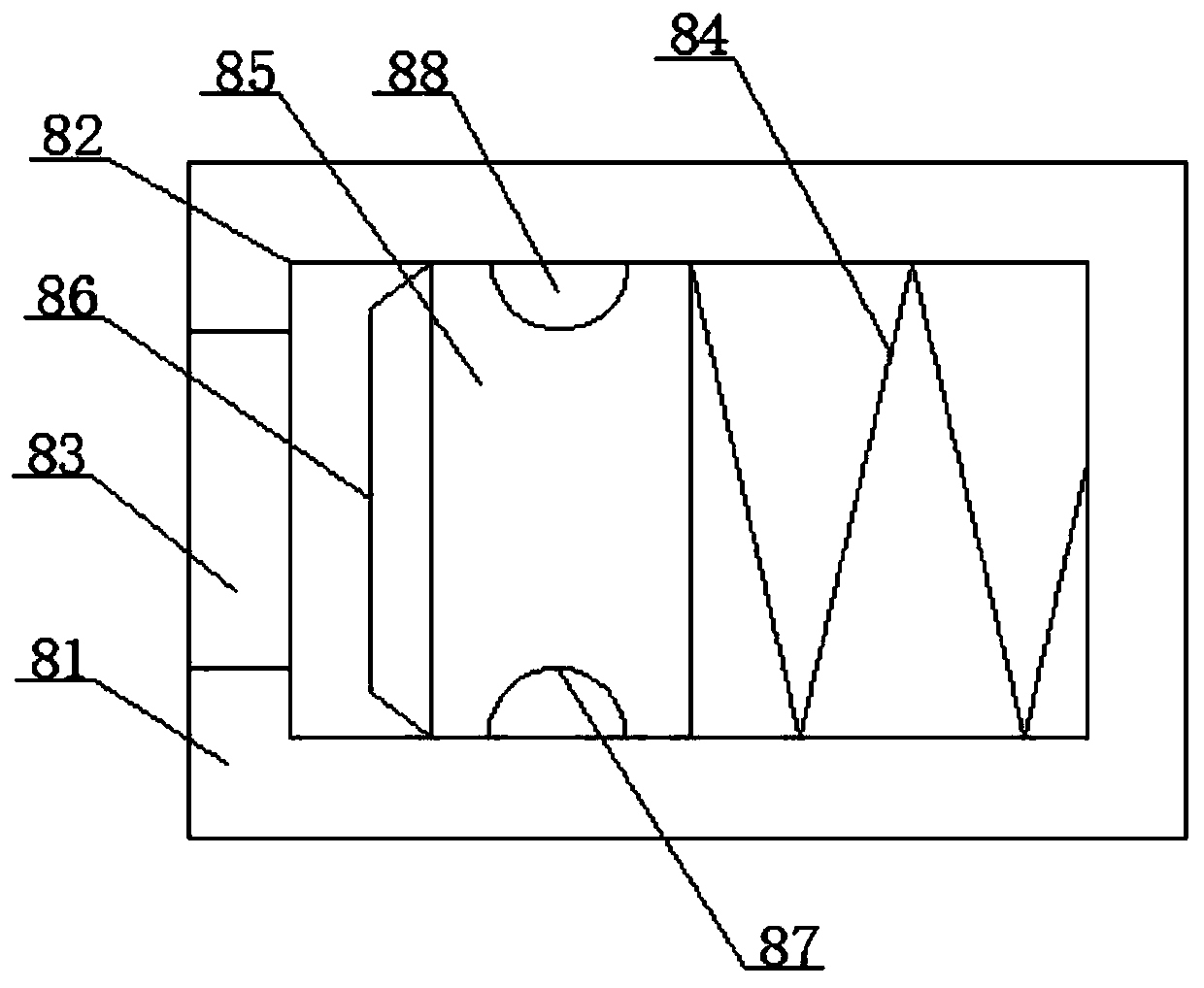

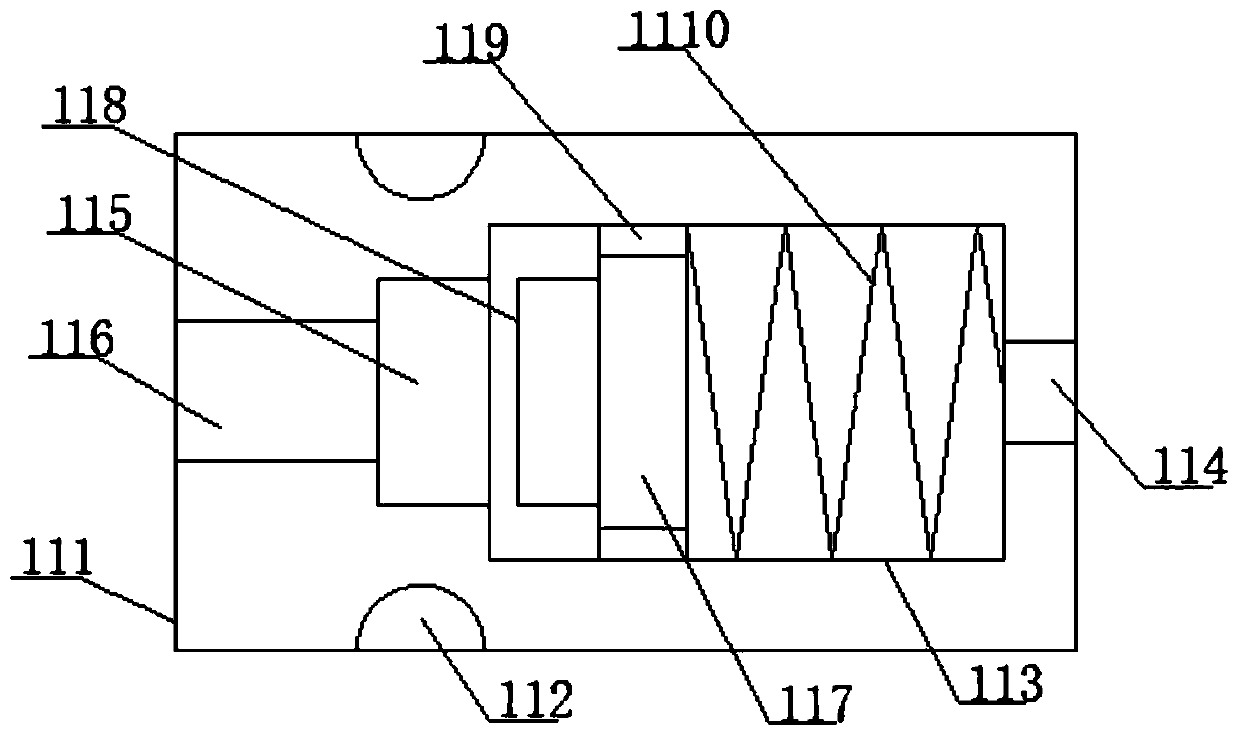

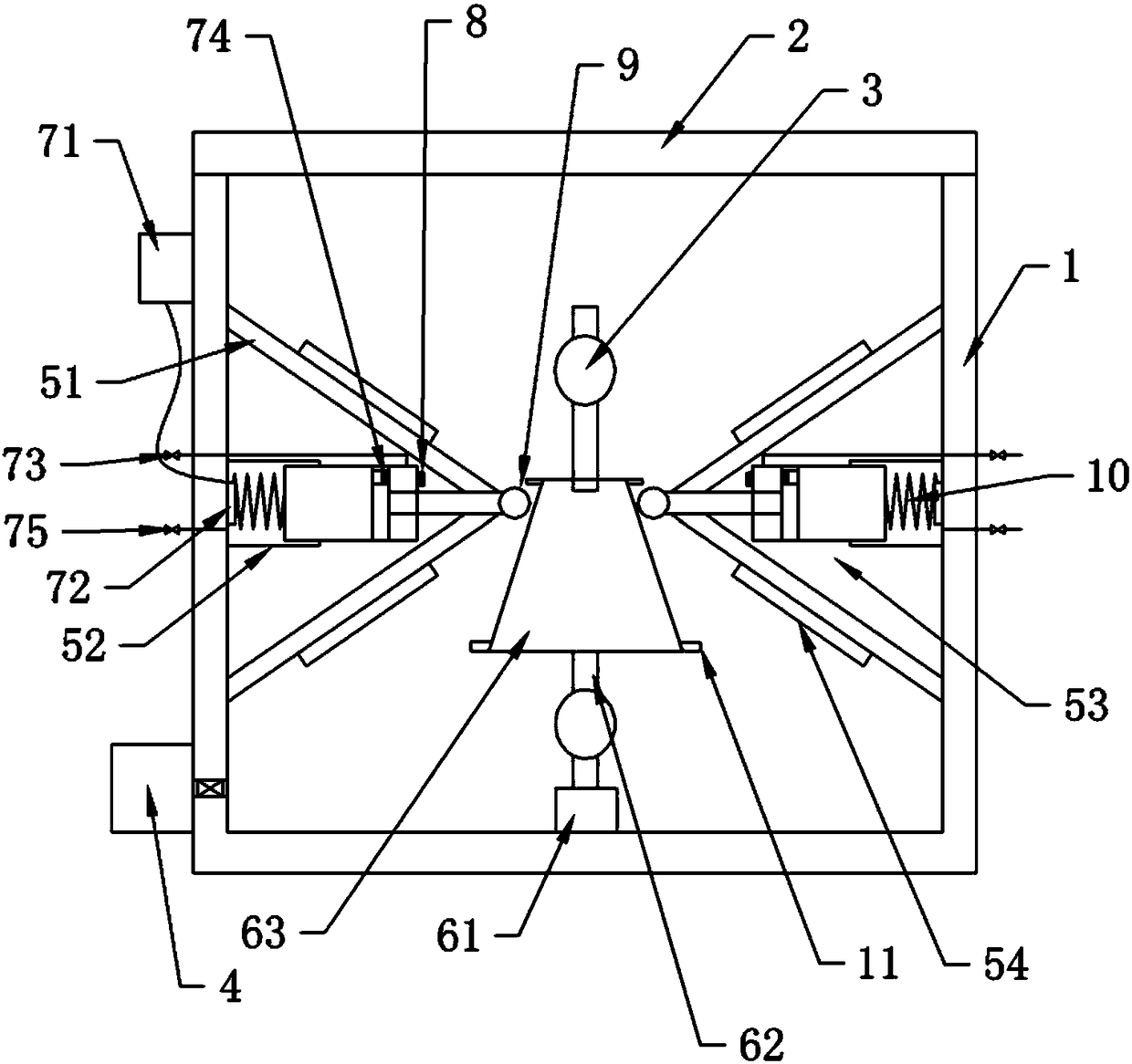

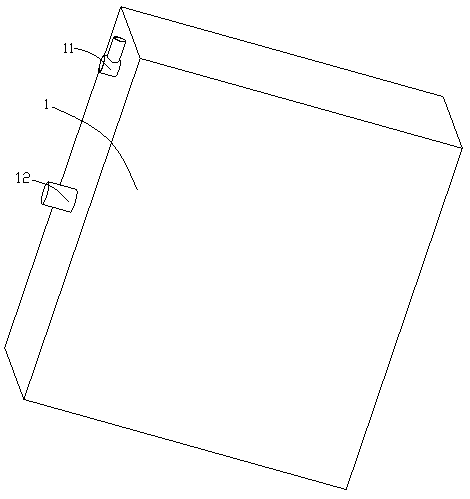

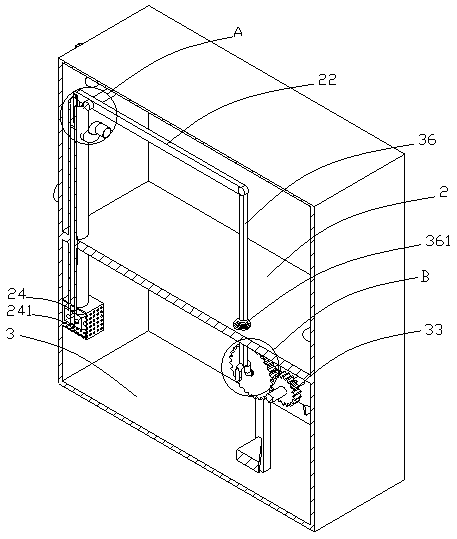

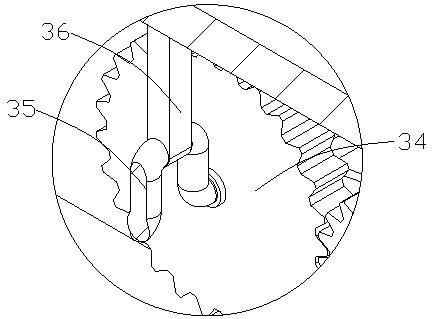

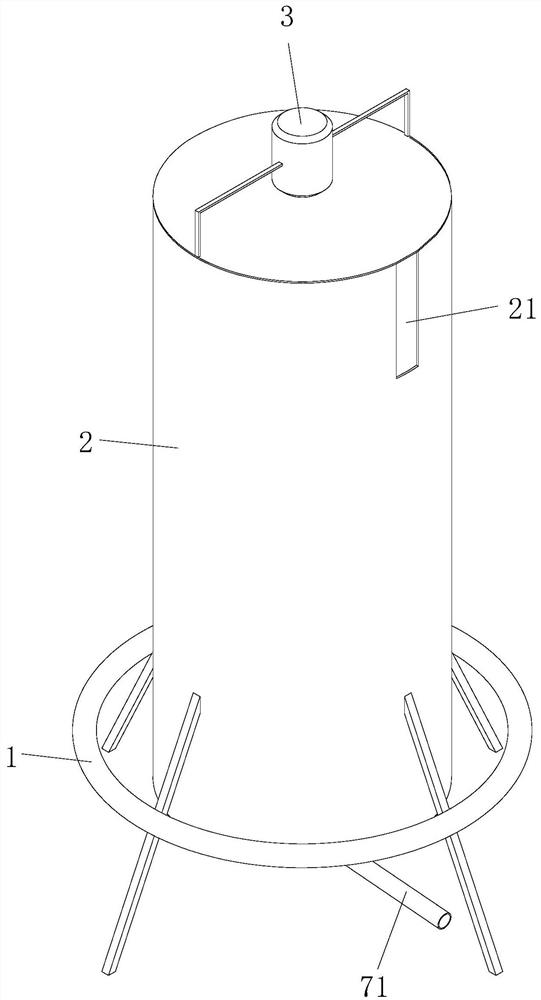

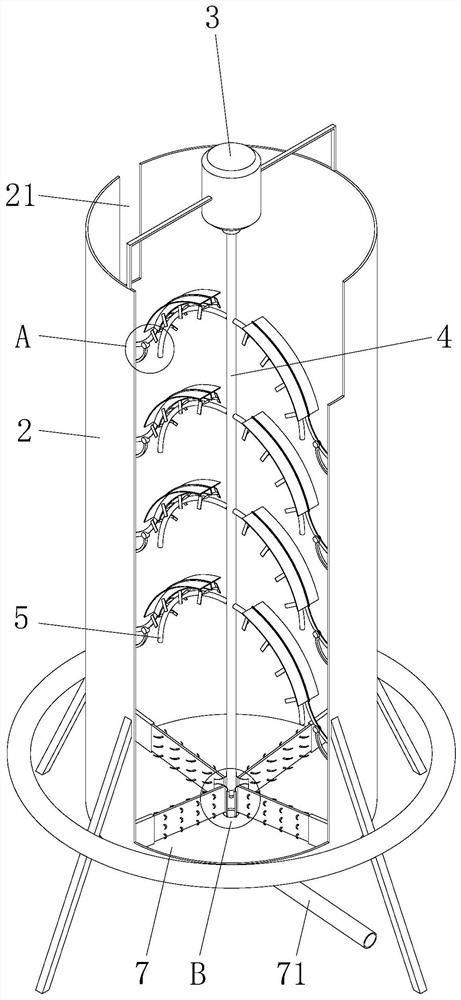

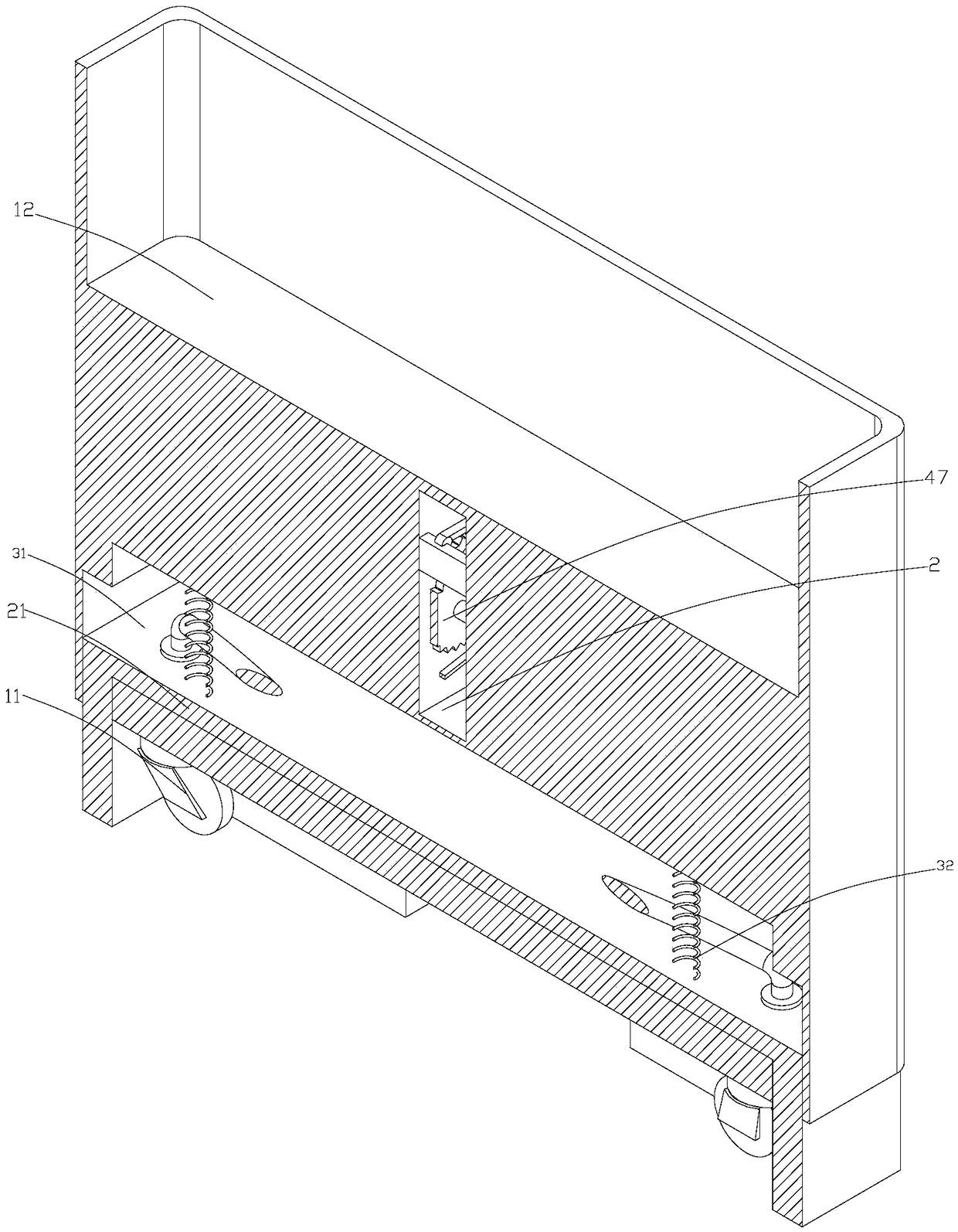

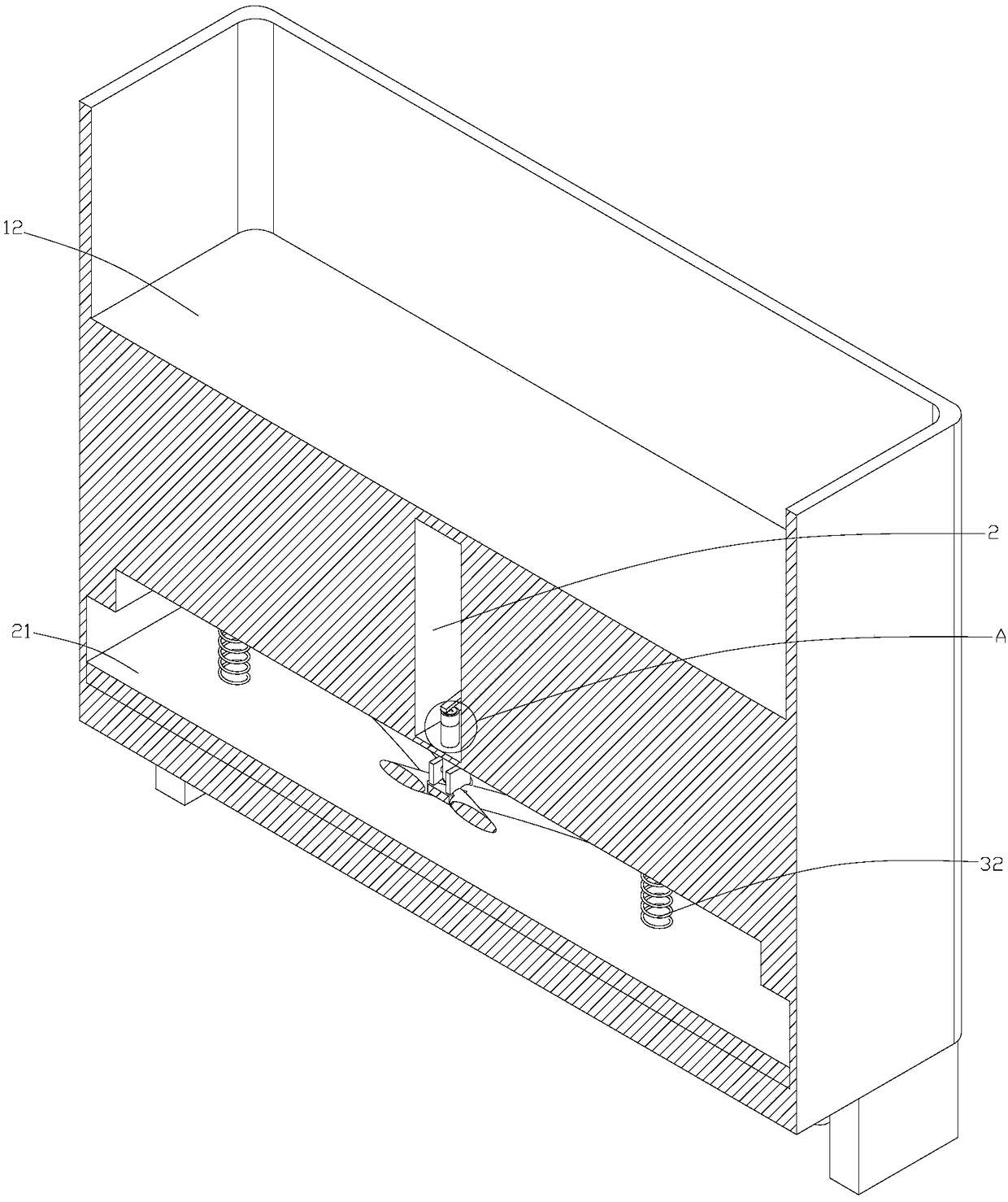

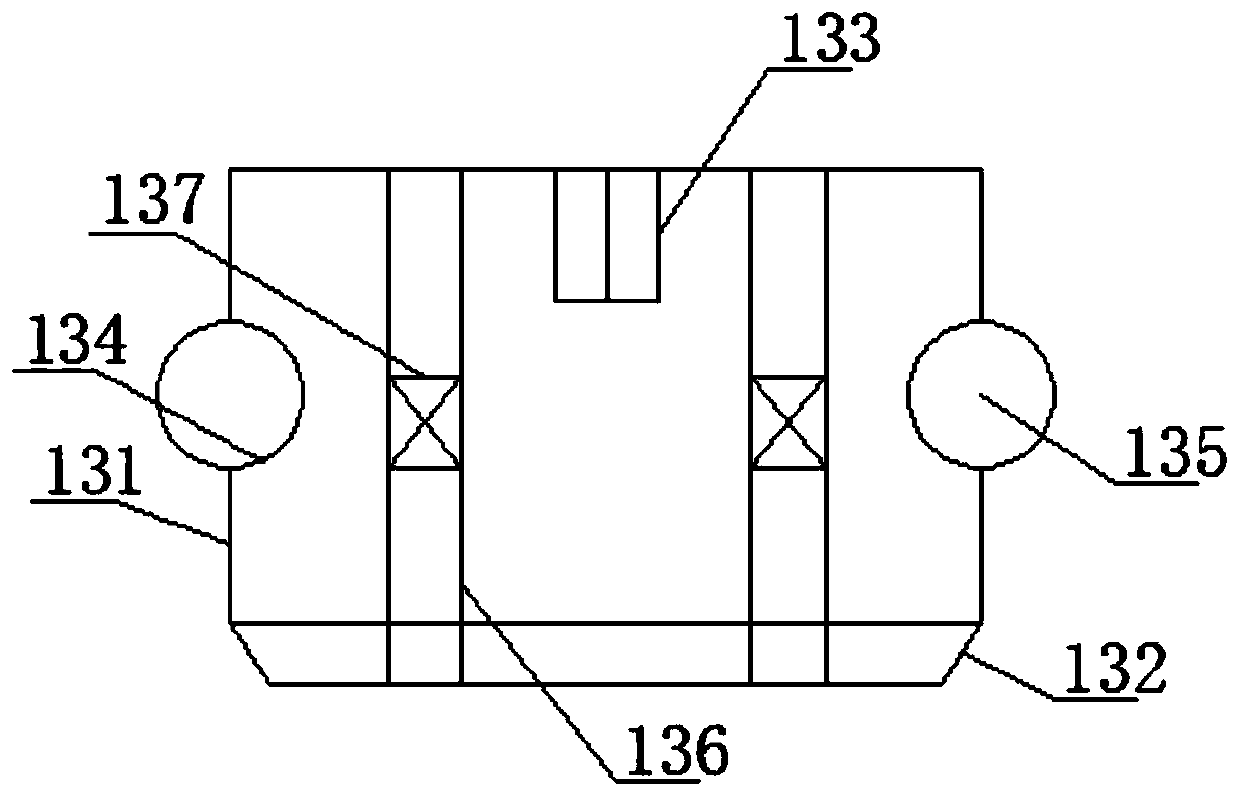

Rod-shaped component storage device for construction site

InactiveCN109610806AReduce the degree of mechanical declineAchieve dryingGas treatmentDispersed particle separationInternal pressureGas compressor

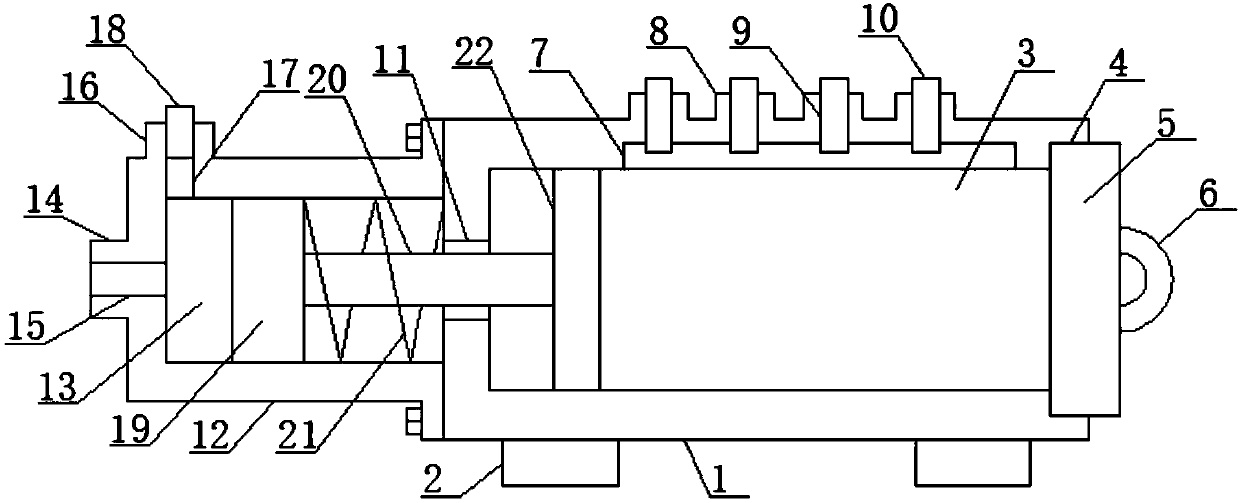

The invention discloses a rod-shaped component storage device for a construction site. The rod-shaped component storage device comprises a hollow storage outer shell. The rod-shaped component storagedevice is combined with an existing air compressor for use, can store rod-shaped components on the construction site, and can dry the surrounding air after storage, thereby reducing the mechanical degradation degree of the rod-shaped components and effectively protecting the rod-shaped components. When the components are taken for use, the collective discharge can be realized under the action of high-pressure air, taking and using are convenient, and practicability is high; moreover, the rod-shaped component storage device has a coil spring elastic pressure control type internal and external combined air pressure control mechanism, utilizes the elasticity of a coil spring, and the maximum internal pressure is controlled to prevent the internal components from being damaged due to excessivedriving pressure; and in addition, the rod-shaped component storage device is provided with a movable type internal gas compression mechanism of a piston-sealed structure, and a drive function and kinetic energy conversion are achieved under the action of compressed gas.

Owner:潘春亮

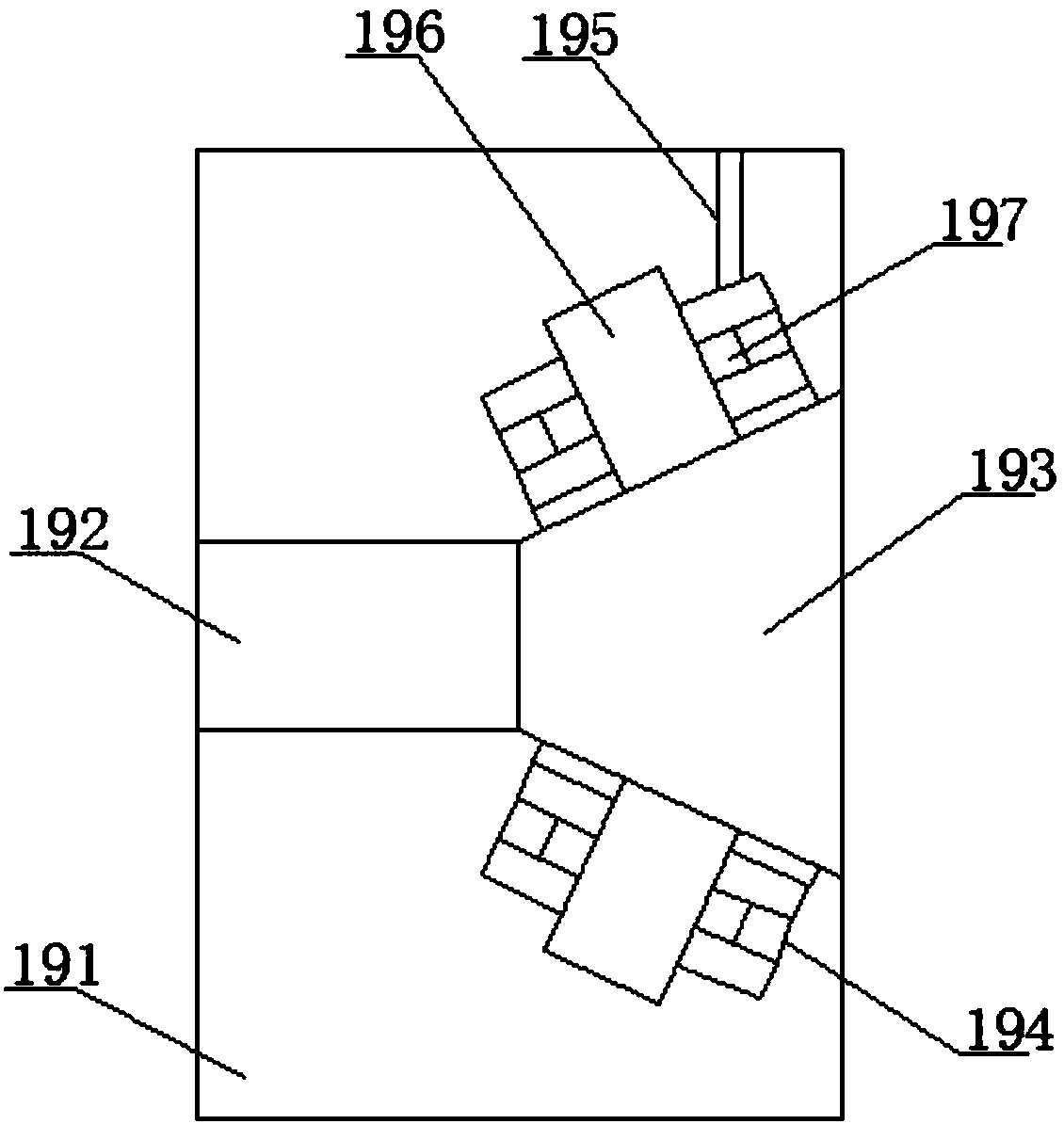

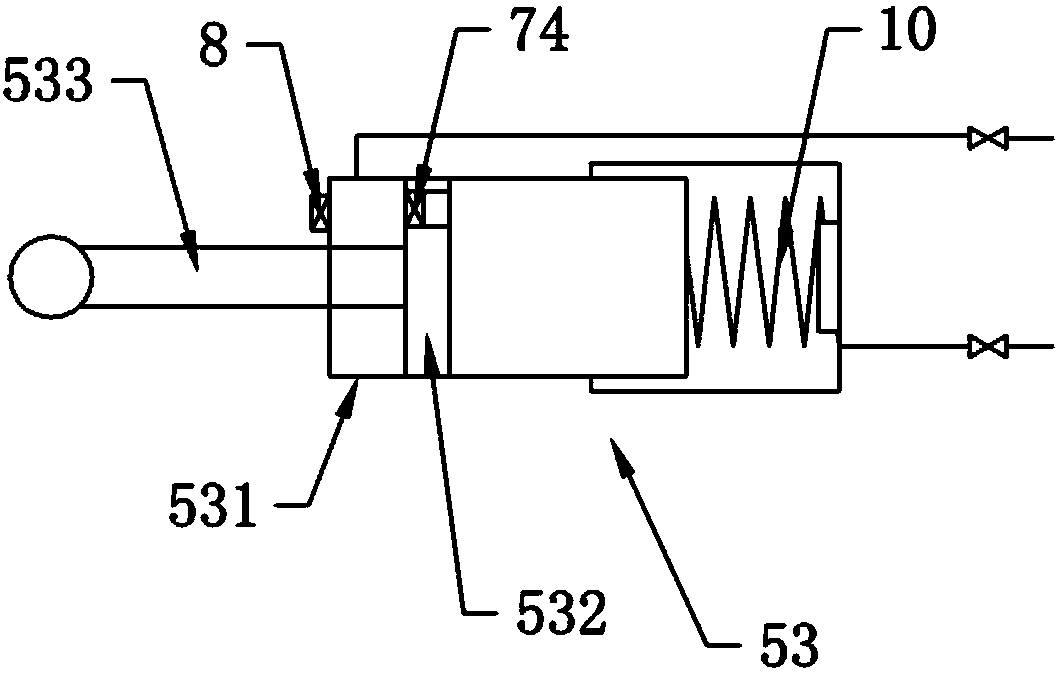

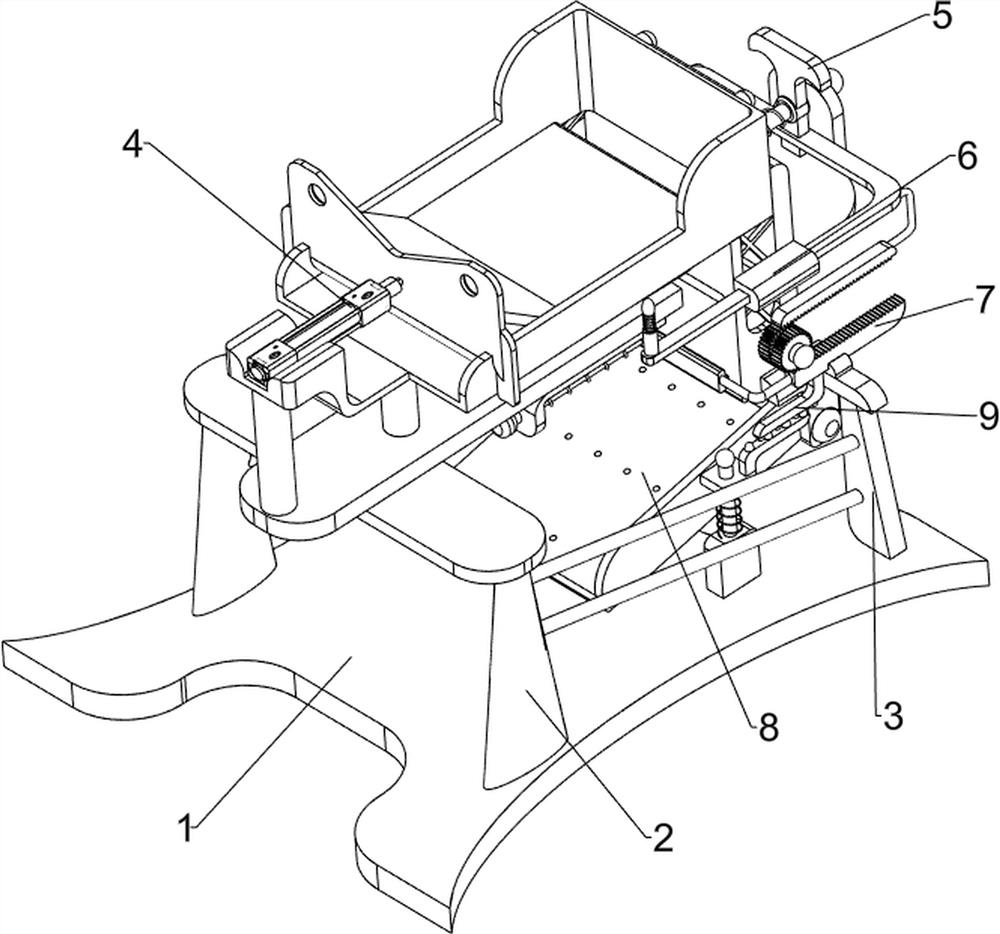

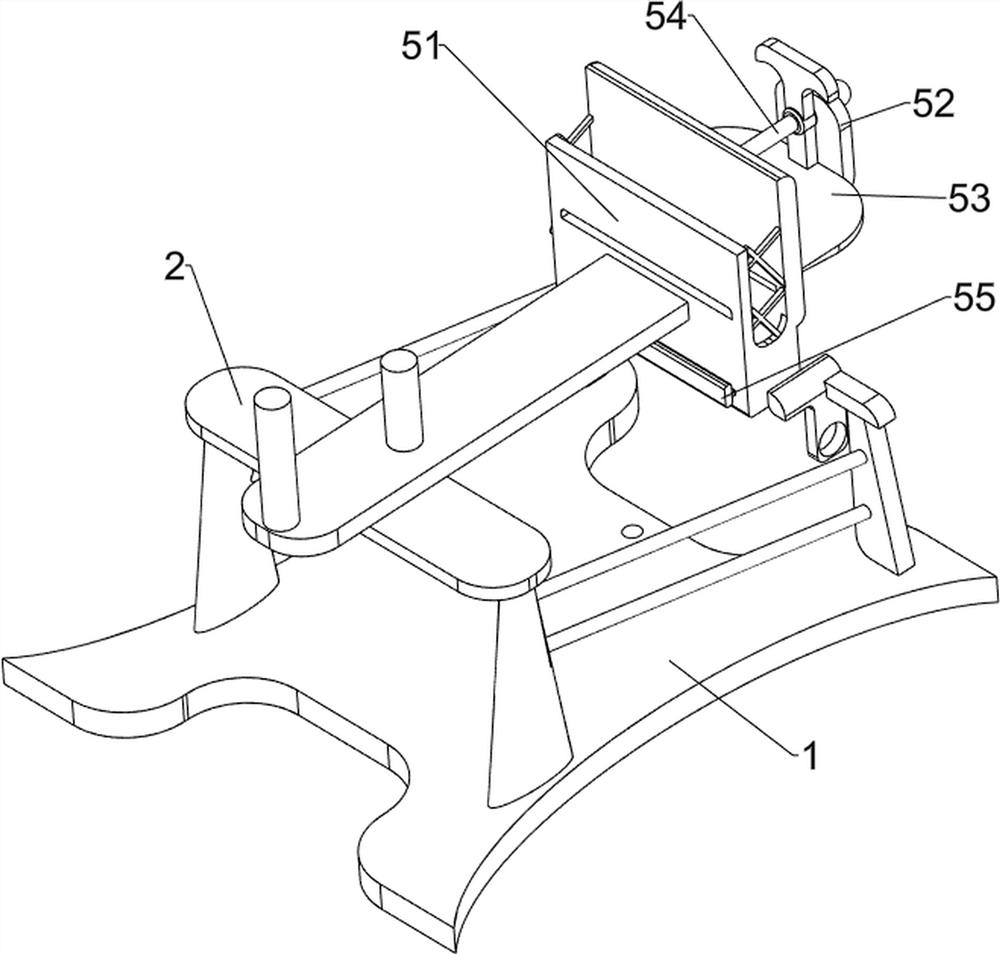

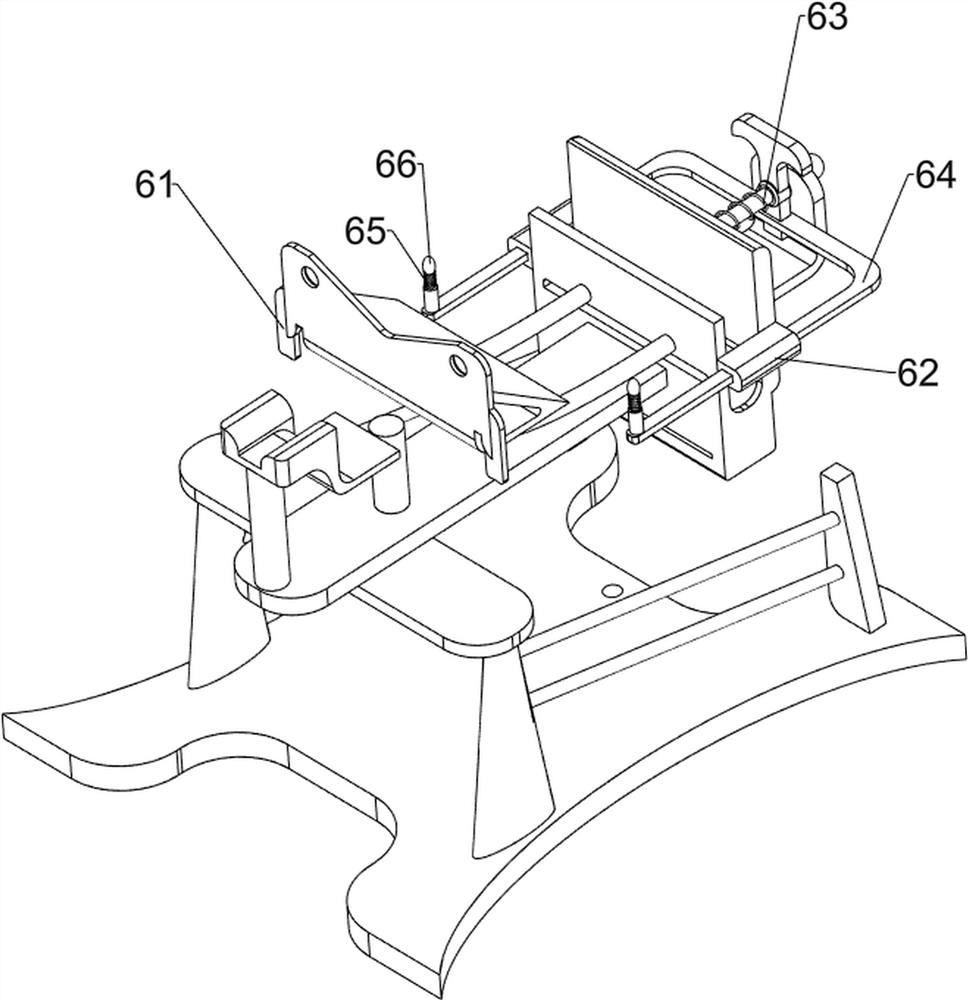

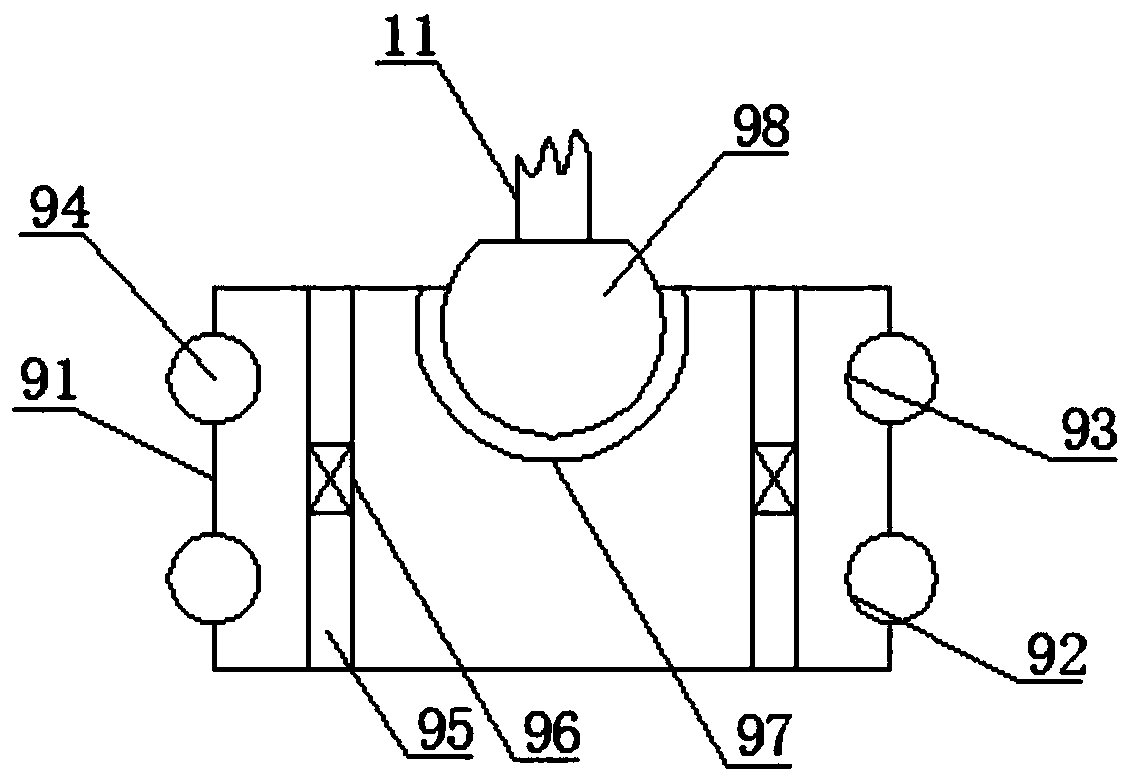

Controllable bench screw

The invention discloses a controllable bench screw which comprises a main body shell. The controllable bench screw can achieve bidirectional clamping by means of a driving source, and meanwhile, the working state of a clamping part can be selected voluntarily in bidirectional clamping according to actual condition, so that the clamping diversity and adaptability are achieved. When voluntary selection is made to the controllable bench screw, a valve switch in a corresponding part can be opened automatically according to the weight of a part in a preventing part, so that the simplicity and practicality are improved. Moreover, the controllable bench screw provided with a movement control mechanism of a liquid telescopic part of a valve rod can communicate spaces of key parts under influence of a high pressure liquid, so that the liquid in corresponding part flows to clamp by corresponding part. In addition, the controllable bench screw provided with a liquid telescopic liquid driving mechanism of the clamping part can drive the liquid under the action of the gravity of the clamping part, so that the working state of the related part is adjusted.

Owner:青岛市平度度威台钳有限责任公司

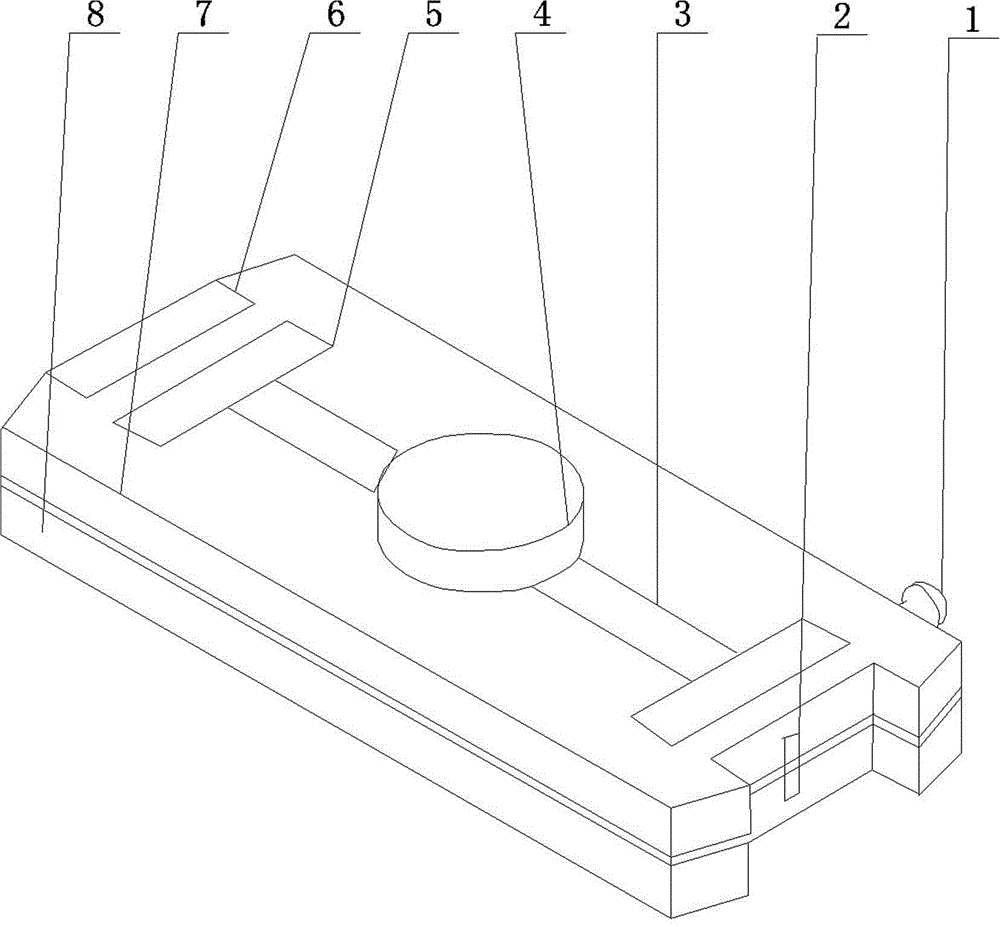

Intelligent electromagnetic processing part clamping device

PendingCN108466091APlay a role in resisting clampingPlay a driving rolePositioning apparatusMetal-working holdersEngineeringElectromagnetic field

The invention discloses an intelligent electromagnetic processing part clamping device which comprises a main mounting substrate, wherein a main bolt hole is formed in the main mounting substrate. Bymeans of the electromagnetic principle, a driving role is exerted. As a result of the electromagnetic principle, the device is high in driving efficiency, is of controllability, and is good in controleffect. The device has a permanent magnet multi-directional driven moving mechanism which can achieve driving action in the moving direction under the action of an electromagnetic field according tothe principle that like polarities repel each other and opposite charges attract each other. In addition, the device is provide with a side direction driving mechanism according to the electromagneticprinciple, and can convert electric power into a magnetic field according to the electromagnetic principle so as to drive the permanent magnet multi-directional driven moving mechanism to move in a fixed direction to play a clamping driving role. In addition, the device is provided with a longitudinal clamping part positioning and mounting mechanism to play roles of leaning and clamping the part.

Owner:叶婷澜

Image processing method and device, electronic equipment and computer readable storage medium

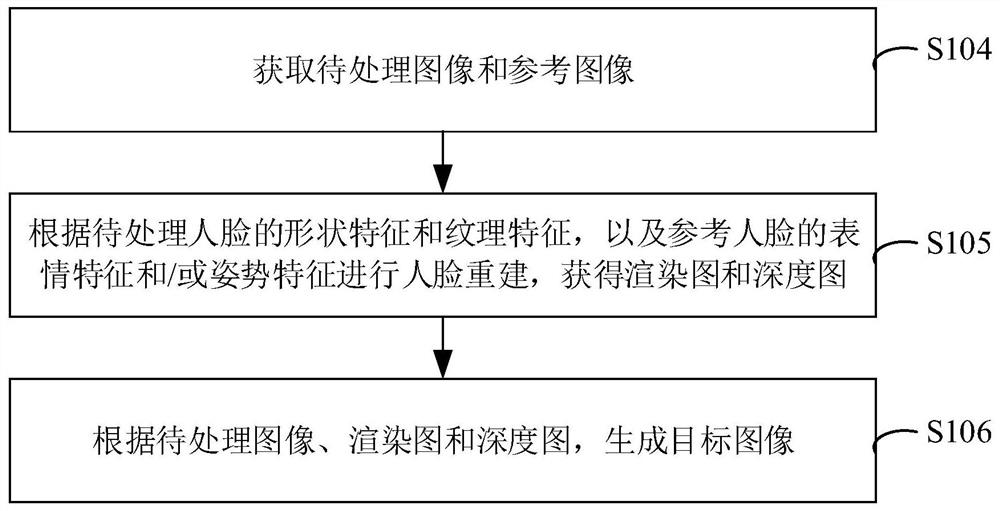

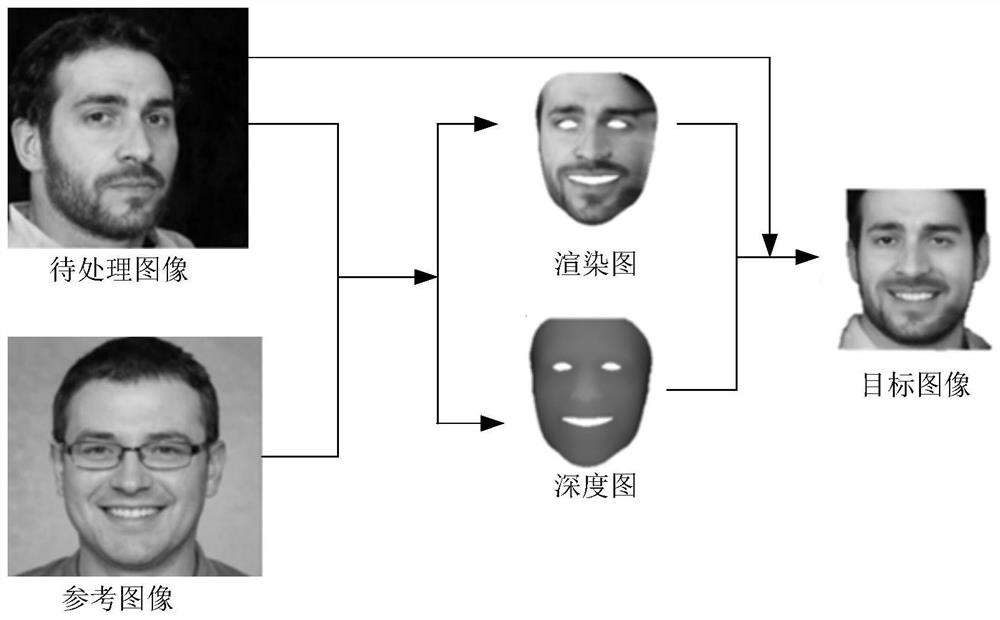

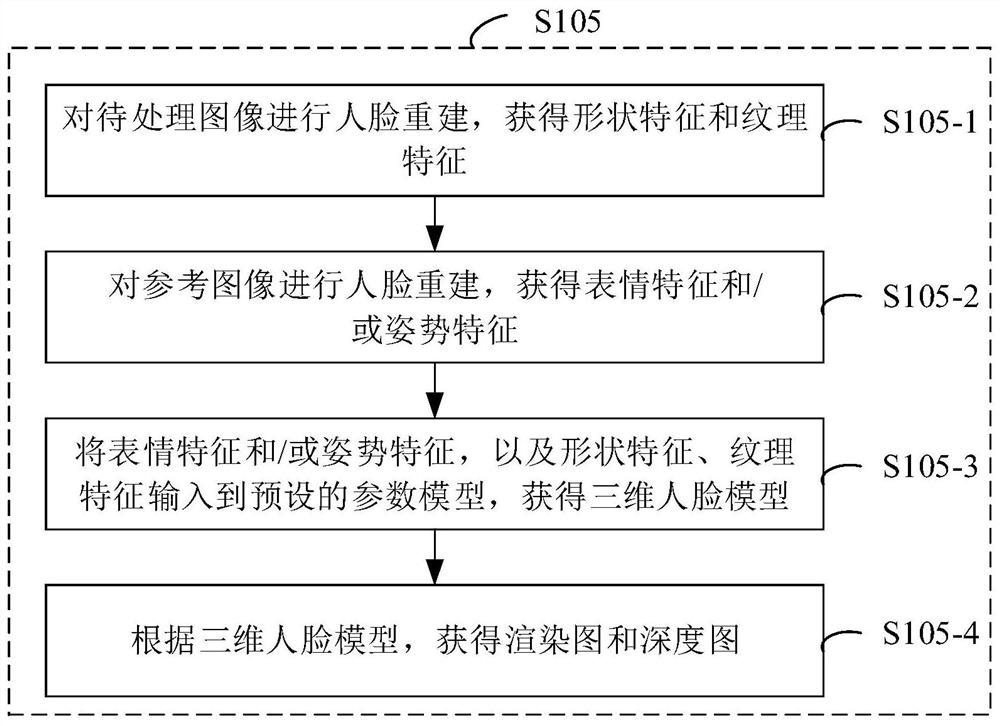

PendingCN113221847ARealize the driving effectRealize decoupling controlImage enhancementImage analysisImaging processingReference image

The invention provides an image processing method and device, electronic equipment and a computer readable storage medium. The method comprises the steps of obtaining a to-be-processed image and a reference image, enabling a to-be-processed face in the to-be-processed image to be the same as or different from a reference face in the reference image, performing face reconstruction according to the shape features and the texture features of the to-be-processed face and the expression features and / or the posture features of the reference face to obtain a rendering image and a depth image, and generating a target image according to the to-be-processed image, the rendering image and the depth image, wherein the target image has the to-be-processed face, and the to-be-processed face has expression features and / or posture features of the reference face. According to the embodiment of the invention, the target image with the to-be-processed face can be generated, and the to-be-processed face has the expression features and / or posture features of the reference face, so that the problem of face deformation in the prior art can be solved, and meanwhile, the effect of decoupling control of the head posture and the expression can be realized.

Owner:GUANGZHOU HUYA TECH CO LTD

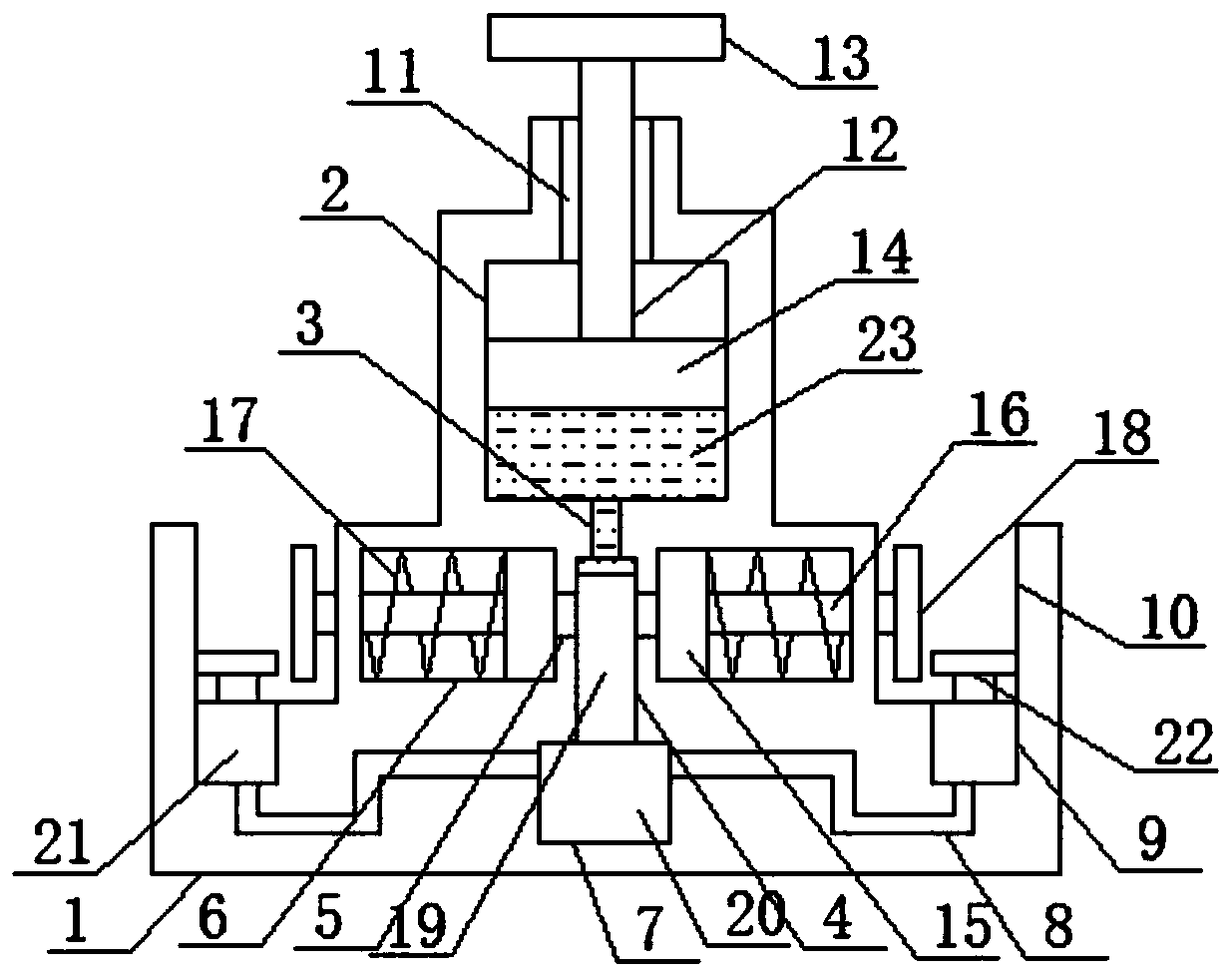

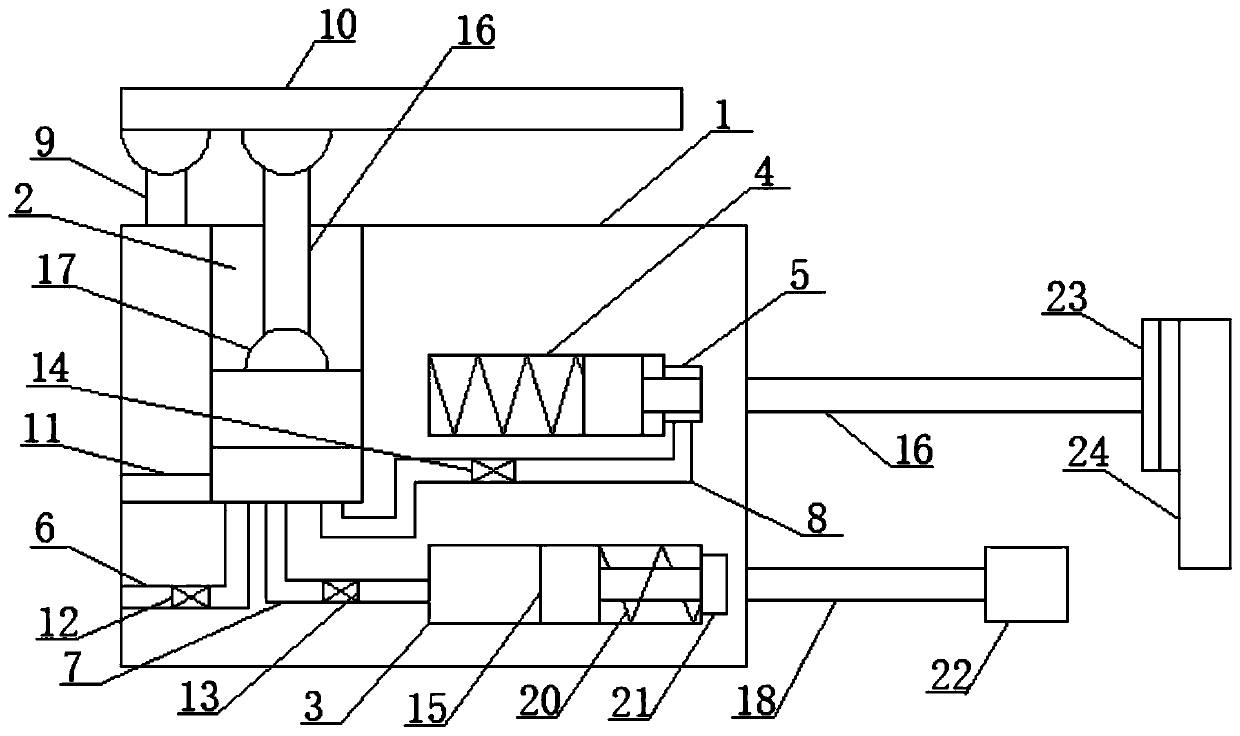

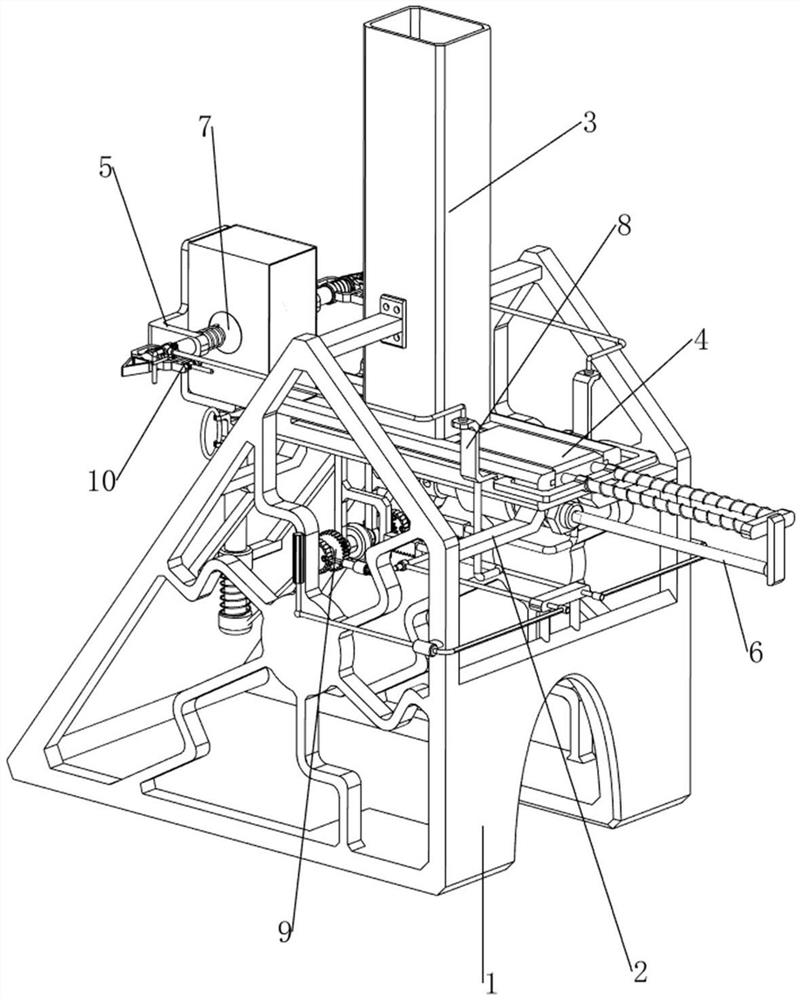

Welding device for high-end equipment manufacturing

PendingCN112743271ARealize the welding effectRealize the driving effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a welding device, in particular to a welding device for high-end equipment manufacturing. The welding device for high-end equipment manufacturing is higher in fixing stability and capable of achieving automatic splicing and automatic welding. The welding device for high-end equipment manufacturing comprises a supporting leg, first supports, a welding mechanism and a pushing mechanism, and a mounting plate is arranged on the supporting leg; each of the left side and the right side of the top of the mounting plate is provided with the two first supports. the welding mechanism is arranged among the four first supports; and the pushing mechanism is arranged on the front side of the top of the mounting plate. A first sliding sleeve is pushed backwards to move backwards, so that an electric welding gun is driven to move backwards, a first spring is stretched, and after the electric welding gun makes contact with two metal plates, the electric welding gun welds the two metal plates, and the welding effect is achieved.

Owner:吴彬

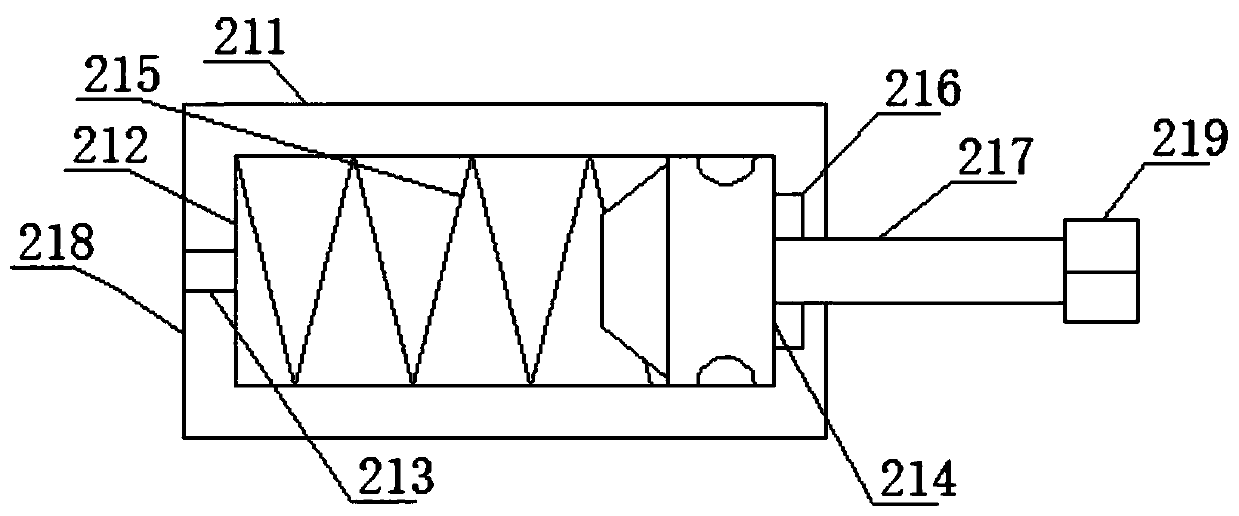

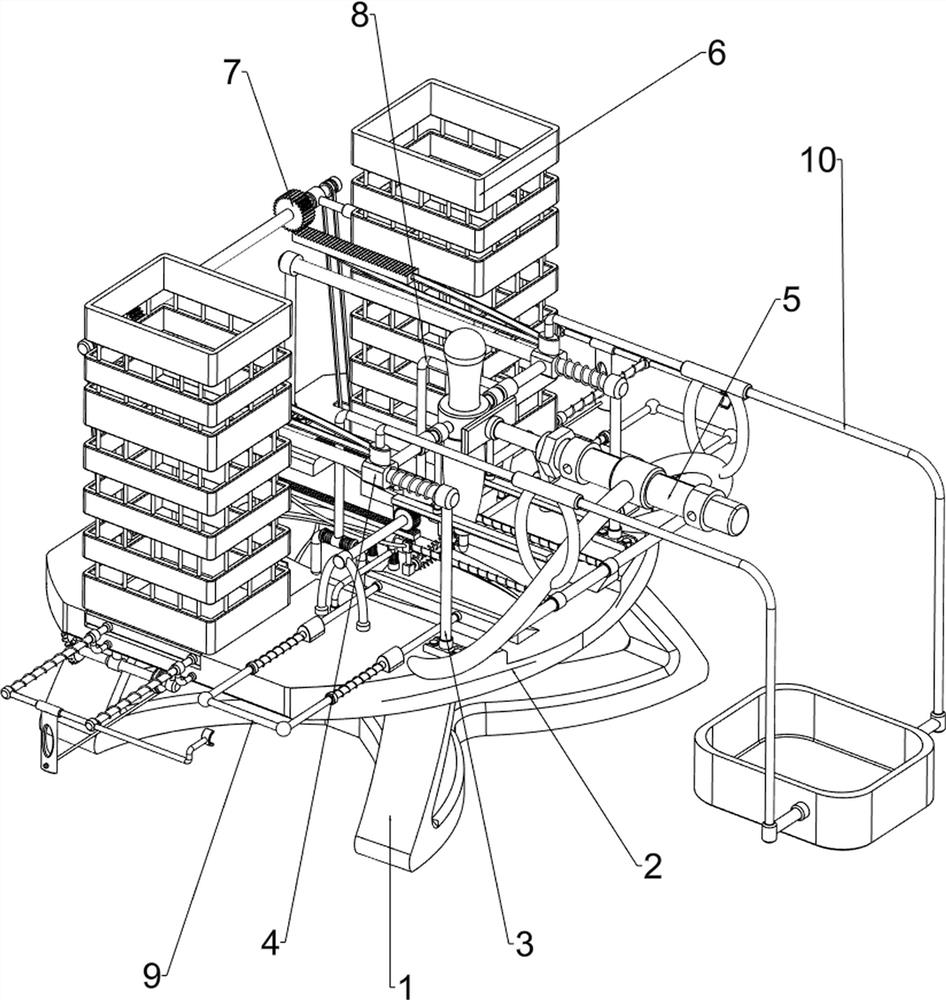

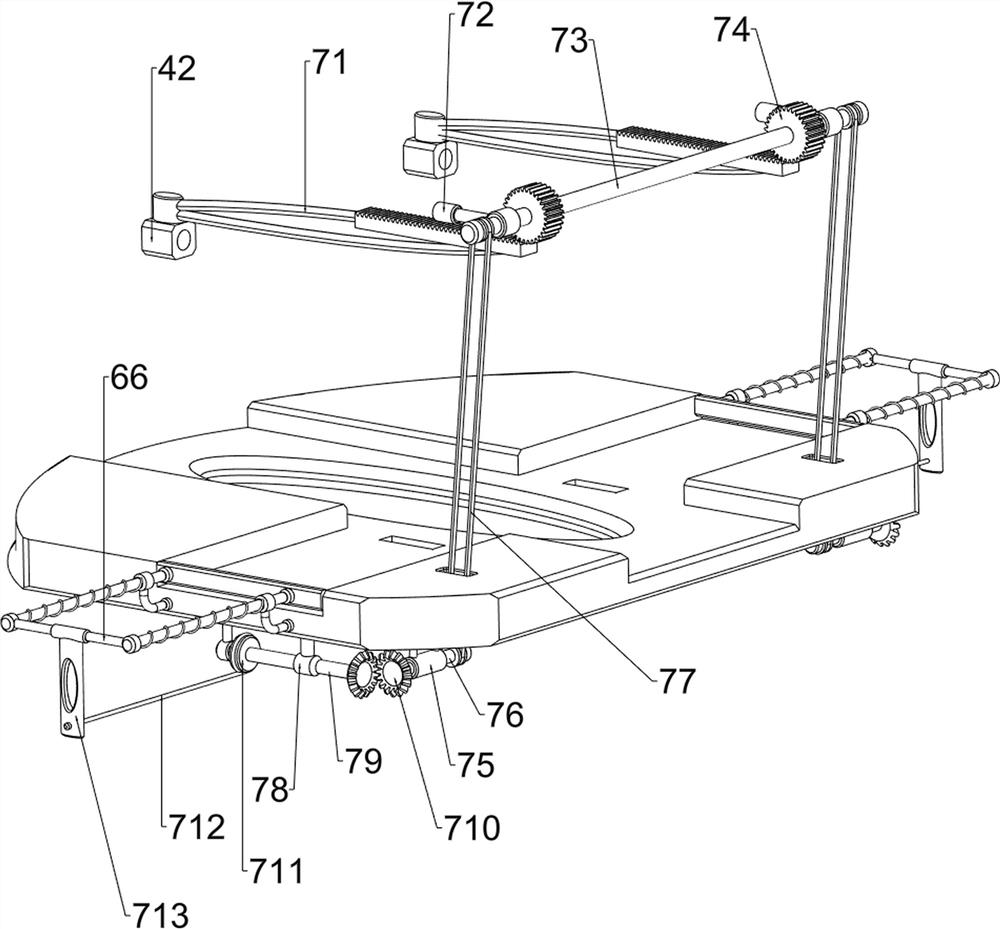

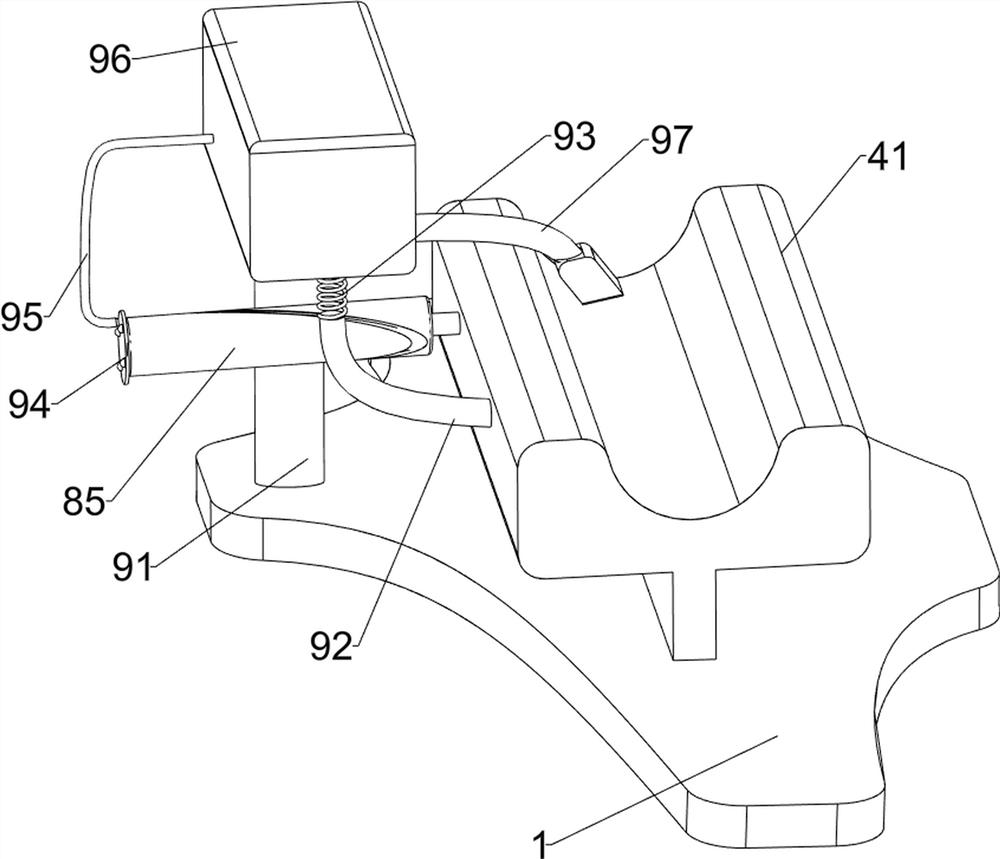

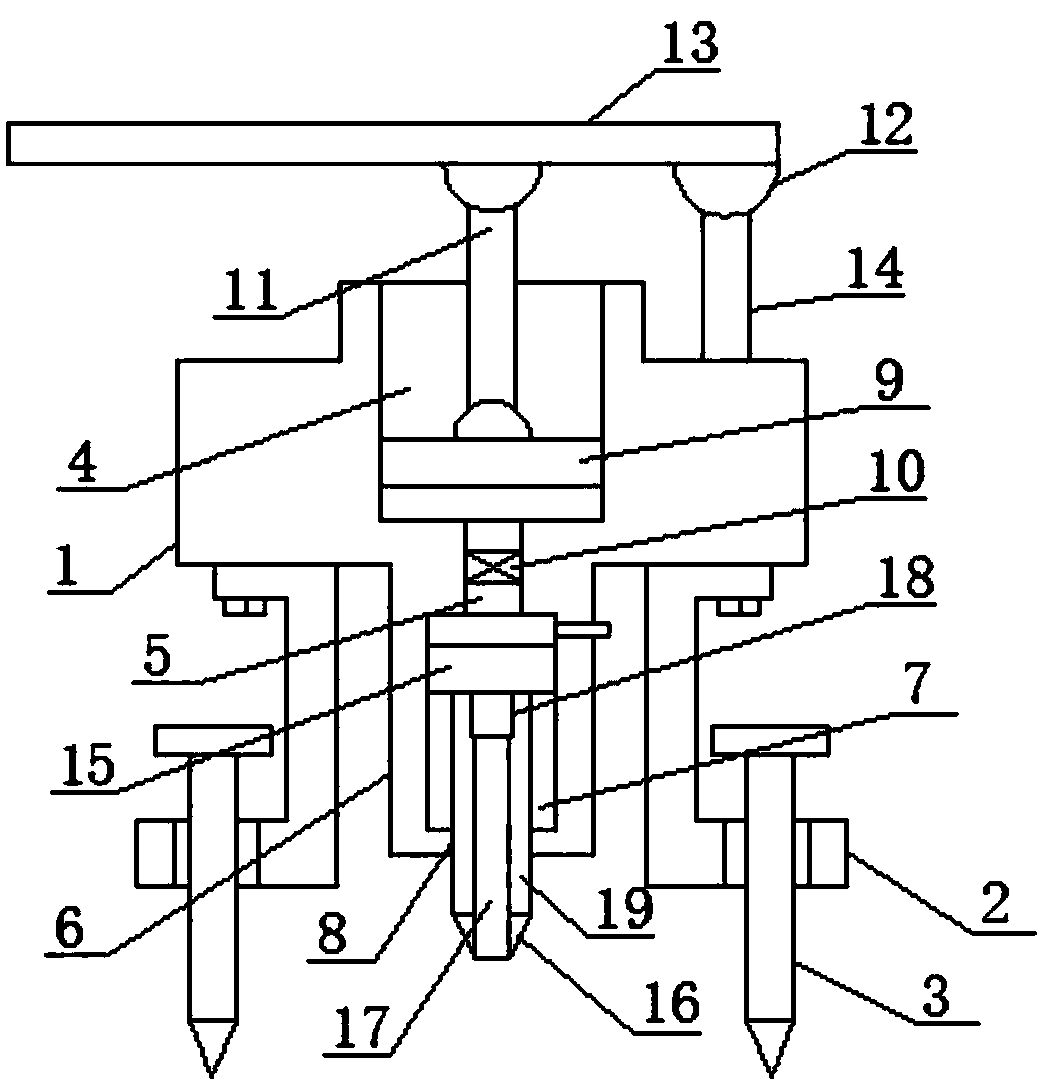

Rapid hydraulic type wood pile tamper

ActiveCN110565637AAvoid damage phenomenonGuaranteed to proceed normallyBulkheads/pilesElectric machineryCoil spring

The invention discloses a rapid hydraulic type wood pile tamper comprising a main body shell, wherein a driving motor used as an output power source has an objective fast impact effect, then, a liquidused as a connecting medium has the characteristics of low buffering property and low kinetic energy loss, the kinetic energy of a power source can be greatly utilized, moreover, the overall mass ofthe device is quite small, the structure is relatively simple, therefore, the lifetime limitation is relatively small, and the cost is small; the device is provided with a spiral spring elastic abutting type liquid buffer resetting mechanism, the maximum impact pressure of the internal liquid can be controlled, meanwhile, the liquid is reset, and normal operation of the tamping work is guaranteed;in addition, the device is provided with a piston body sealing ring type end liquid driving mechanism, and the driving effect can be achieved under the action of a certain liquid; and furthermore, the device is provided with a spring body ring array setting type maximum rotation force control mechanism, and the maximum rotation strength can be controlled.

Owner:泰州润都农业供销有限公司

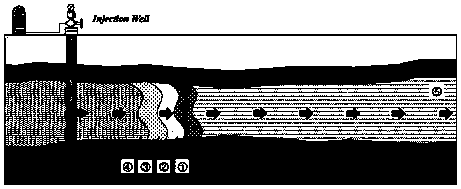

Oil field ultra-high water cut stage fly ash reinforced multiphase composite profile control and flooding method

ActiveCN110984933AEnhanced overall recoveryImprove microscopic heterogeneityFluid removalDrilling compositionActive agentOil phase

The invention discloses an oil field ultra-high water cut stage fly ash reinforced multiphase composite profile control and flooding method. The method comprises the following step: sequentially adopting fly ash reinforced foam, surfactant foam, microemulsion and water for profile control and flooding, wherein the fly ash reinforced foam is prepared from a gas phase and a liquid phase I; the liquid phase I is an aqueous solution of a foaming agent I, fly ash and a gas-liquid interface regulator; the surfactant foam is prepared from a gas phase and a liquid phase II; the liquid phase II is an aqueous solution of a foaming agent II; the microemulsion consists of a compound surfactant, a cosurfactant, an oil phase, an inorganic salt and water; and the compound surfactant is a compound of SDSand Tween 80. According to the method, through the action among the fly ash reinforced foam slug, the surfactant foam slug and the microemulsion slug, the opening and closing of a large pore channel can be regulated and controlled, the flow resistance is reduced, the regulation and flooding effect of blocking without blocking off is realized, the flow and production of crude oil are facilitated, and the purpose of economic and efficient development of an oil reservoir is achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

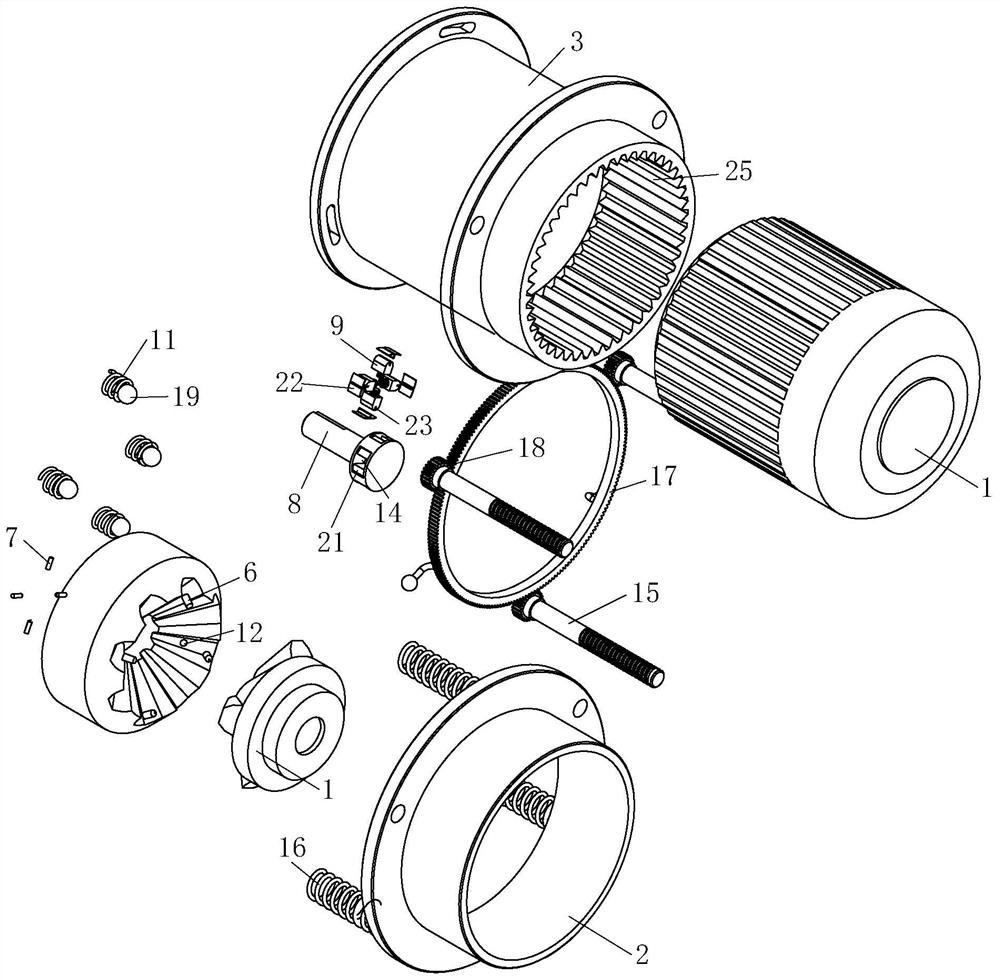

Bidirectional telescopic dismounting device for shaft body and shaft sleeve

InactiveCN111168627AAvoid damageImprove disassembly efficiencyMetal-working hand toolsMaximum pressureMechanical engineering

The invention discloses a bidirectional telescopic dismounting device for a shaft body and a shaft sleeve. The bidirectional telescopic dismounting device comprises a main body shell, by means of theair pressure and lever technology, external air can be injected to form high-pressure air, counter-acting force is formed between the shaft body and the shaft sleeve, the detaching efficiency is improved, meanwhile, due to the fact that detaching is in an abutting mode, damage is small, the device is provided with an elastic abutting type maximum pressure control mechanism, maximum air pressure ina component can be controlled, the phenomenon that an internal component is damaged due to fact that air pressure value is too large is avoided, in addition, the device is provided with a space sealing movable type air driving mechanism, the driving effect and the kinetic energy conversion can be achieved under the action of air, in addition, the device is provided with a bolt installation type shaft body clamping abutting moving mechanism, the bolt installation type shaft body clamping abutting moving mechanism can be clamped to the surface of a shaft body to perform abutting action on the shaft sleeve on the shaft body, thus realizing the driving effect on the shaft sleeve.

Owner:刘春平

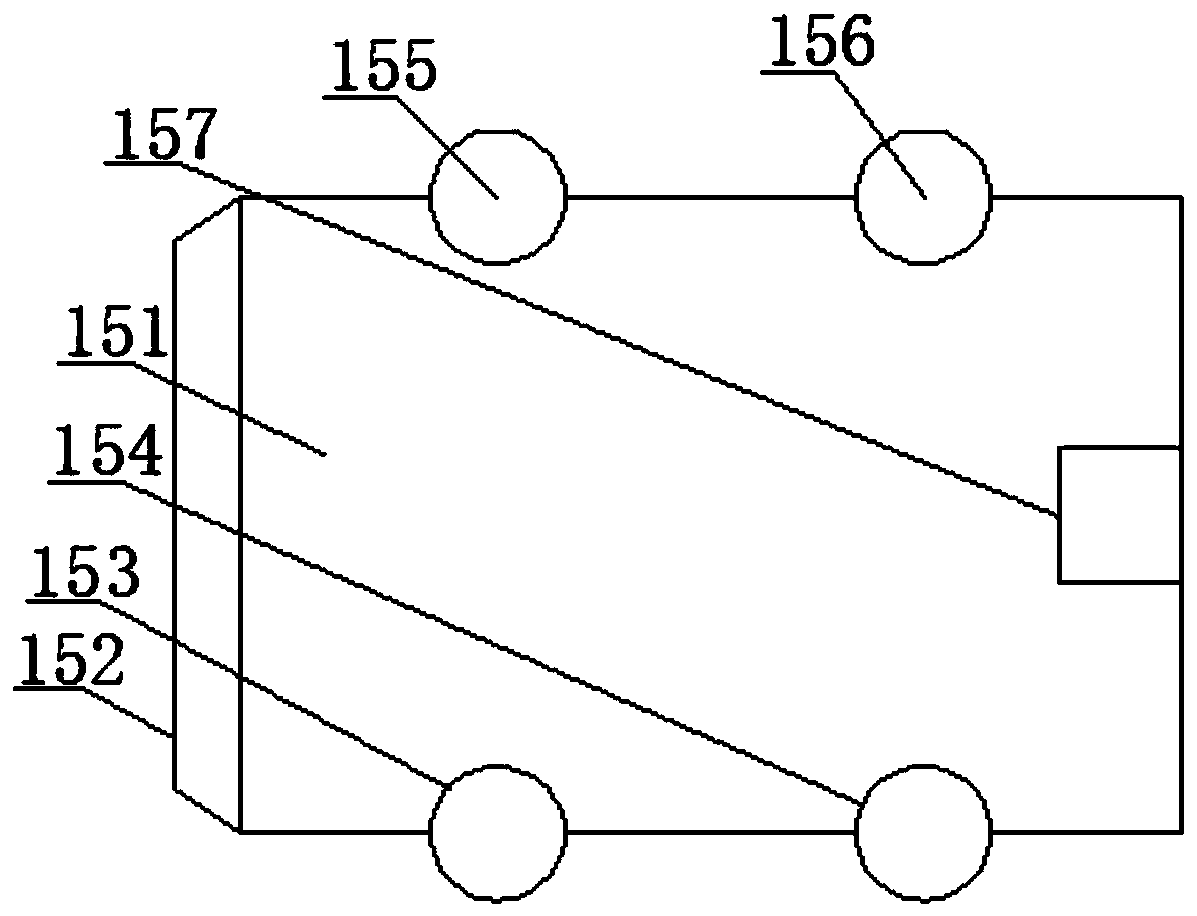

Automatic packaging device for circuit breaker production

ActiveCN112849519AAvoid displacementRealize the push effectPackagingPackaging CaseControl engineering

The invention relates to a packaging device, and particularly relates to an automatic packaging device for circuit breaker production. The automatic packaging device for circuit breaker production can achieve automatic packaging, reduces labor force of workers and is convenient to use. The automatic packaging device for circuit breaker production comprises supporting feet, a sliding rail plate, a discharging frame, a pushing mechanism and a moving mechanism, wherein the sliding rail plate is arranged between the two sides of the supporting feet, the discharging frame is arranged between the two sides of the supporting feet, the pushing mechanism is arranged on the sliding rail plate, and the moving mechanism is arranged on the sliding rail plate. According to the automatic packaging device, a first sliding rod is manually pushed to slide leftwards, a first spring is compressed, and therefore a sliding block is driven to move leftwards, a circuit breaker can be pushed out through the sliding block, and the pushing effect is achieved; and after the circuit breaker is pushed to a packaging box again through the sliding block, people need to push a supporting plate to move downwards again, and therefore a second sliding rod is driven to continue to slide downwards, a second spring continues to reset, and the moving effect is achieved.

Owner:江西双宏科技电气有限公司

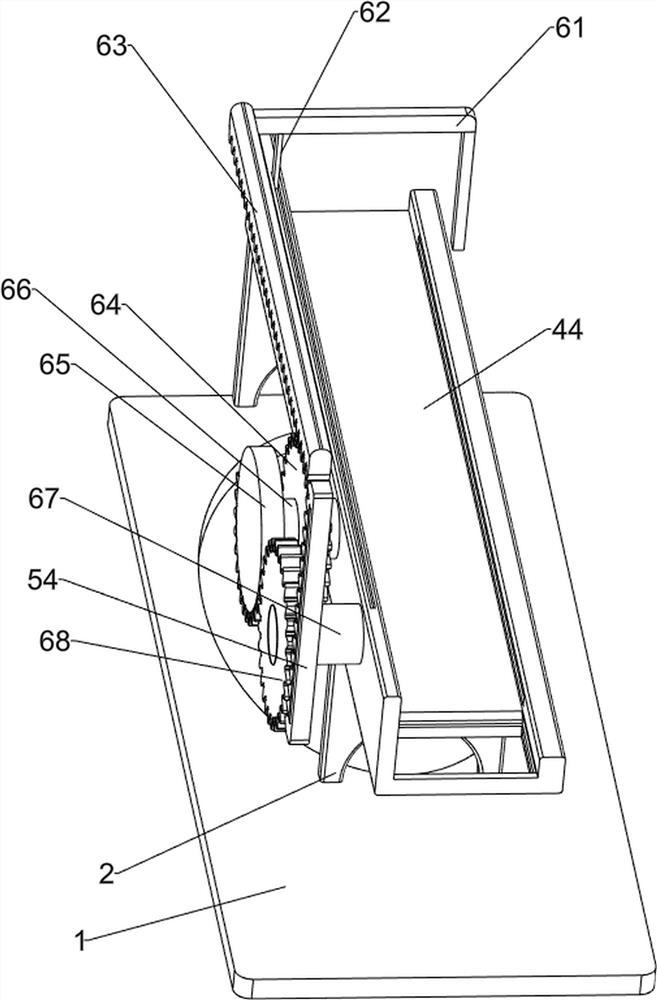

Exposure machine for printing

InactiveCN108132586AUniform drying board operationQuick inhalationPhotomechanical exposure apparatusMicrolithography exposure apparatusElectricitySlide plate

The invention discloses an exposure machine for printing. The exposure machine comprises a cabinet body, ultraviolet lamps, a vacuum pump and a sealing cover for covering the cabinet body, a pipelineis provided with a unidirectional-gas discharging one-way valve, the machine also comprises an exposure plate part, a driving part and a control part, the exposure plate part includes four slide plates, slide seats, gas suction members and exposure plate units, one ends of the slide plates are slidably connected to the sidewall of the cabinet body, and the gas suction parts are slidably connectedto the slide seat through springs; the driving part includes a power source, telescopic rods and a driving part, the driving part is connected to the telescopic rods and is used for driving the gas suction members to move, and the telescopic rods are provided with the ultraviolet lamps; and the control part comprises a controller, pressure sensors and first electronic control valves, the gas suction members are provided with gas discharging tubes, the first electric control valves are arranged on the gas discharging tubes, and the power source, the pressure sensors and the first electric control valves are respectively electrically connected with the controller. The exposure machine can ensure the uniformity of an exposure plate, and can avoid generated harmful gases from escaping in orderto ensure the health of operators.

Owner:启东市启秀蔬果专业合作社

Storing device for sewage

InactiveCN111005422AReduce forceReduce lossWater/sewage treatmentWater supply tanksSewageWater resource management

The invention discloses a storing device for sewage. The storing device for the sewage comprises a storing box used for storing sewage after external processing, a water entering pipeline used for conveying the sewage into the storing box, and a water outgoing pipeline used for discharging the sewage out of the storing box and performing reusing; the storing box is internally provided with a sewage circulating mechanism for driving the sewage to perform self-circulating flowing, a first cavity and a second cavity, and the first cavity and the second cavity are correspondingly used for storingthe sewage; due to the arrangement of the sewage circulating mechanism, the sewage stored in a storing chamber can achieve the self-circulating flowing effect, so that the sewage can continuously rollover on its own in the storing chamber, deterioration of the sewage can be avoided, spreading of bacteria in the sewage is reduced, and the healthiness of the sewage is improved; and due to the arrangement of the first cavity and the second cavity, emission of stench can be avoided, and the environment comfort degree is improved.

Owner:杨义之

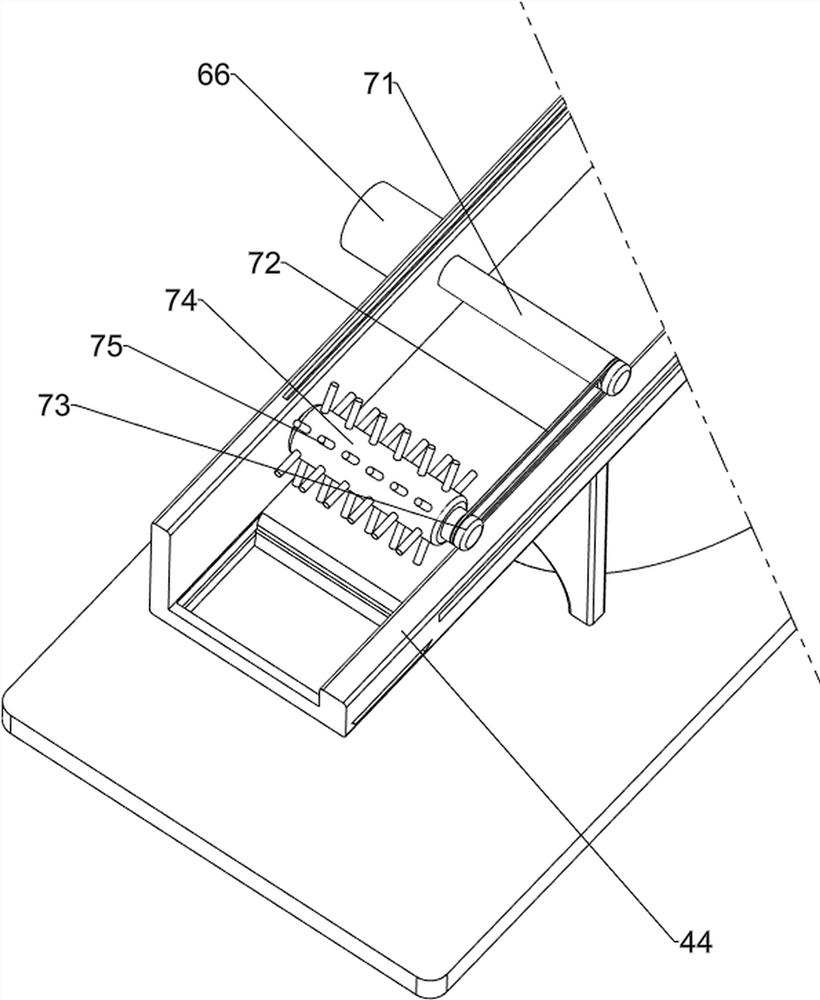

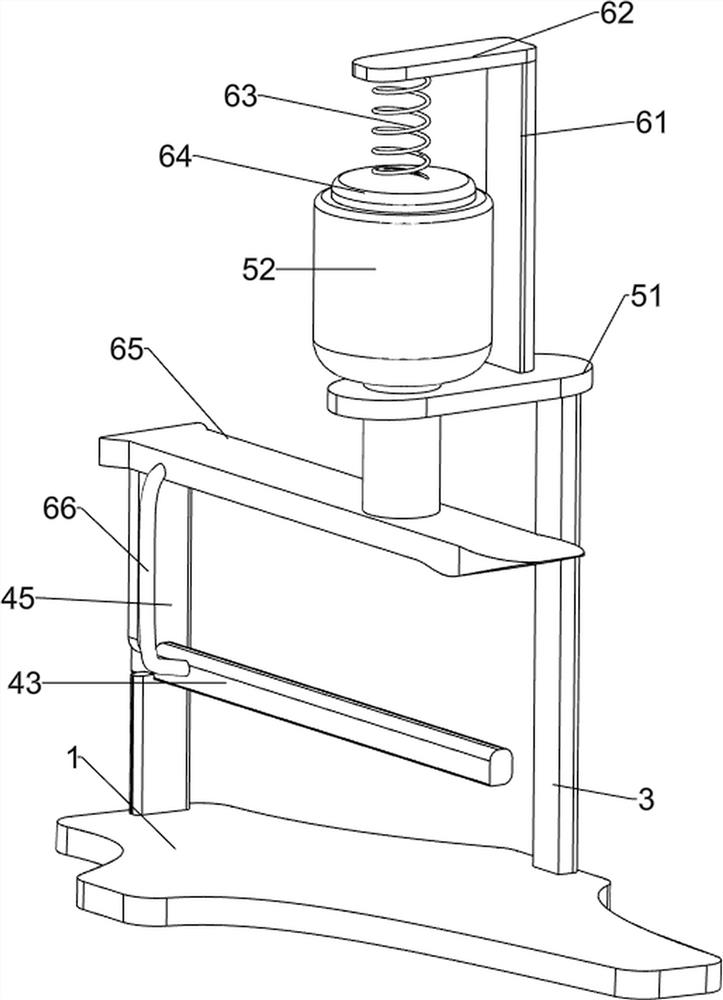

Agricultural automatic peanut shell breaking device

PendingCN112369618ARealize the driving effectTo achieve the extrusion effectHuskingHullingAgricultural scienceAgricultural engineering

The invention relates to a shell breaking device, in particular to an agricultural automatic peanut shell breaking device. The agricultural automatic peanut shell breaking device is low in labor intensity, high in working efficiency and free of damage to peanuts. The agricultural automatic peanut shell breaking device comprises a base, brackets, a pushing mechanism and an extrusion mechanism, wherein three first supporting columns are arranged on the base; the two brackets are arranged on the front side of the base; the pushing mechanism is arranged among the tops of the three first supportingcolumns; and the extrusion mechanism is arranged on the left side of the upper front part of the base. According to the agricultural automatic peanut shell breaking device, an air cylinder telescopicrod extends forwards to drive a discharging plate to move forwards, then a first sliding block is driven to move forwards, a user manually pulls a material blocking plate rightwards, and peanuts falloff from a discharging port; and a first connecting rod drives a first rack to move downwards, so that a second sliding block is driven to move downwards, a first spring is compressed to extrude thepeanuts on the material blocking plate, shells of the peanuts are broken, and the extrusion effect is achieved.

Owner:牟立勇

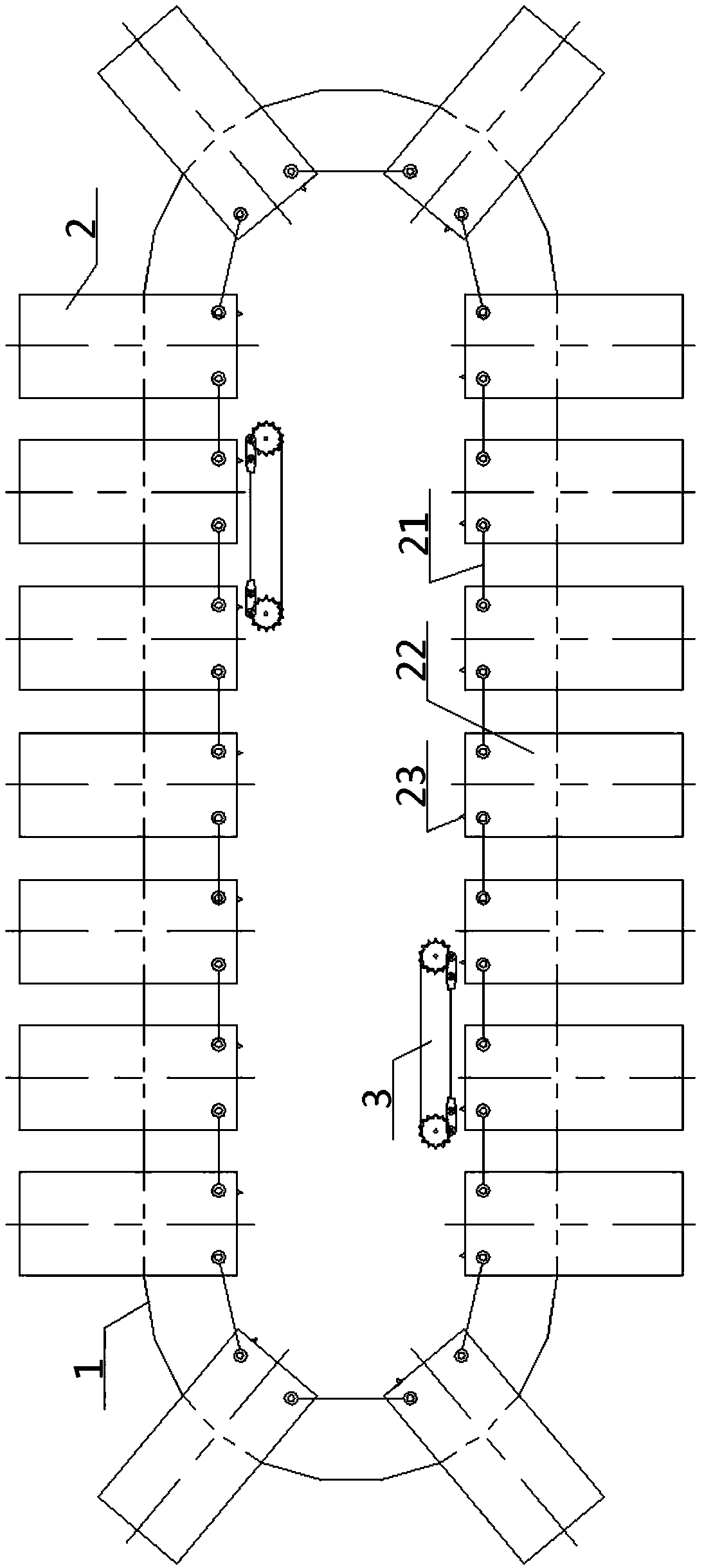

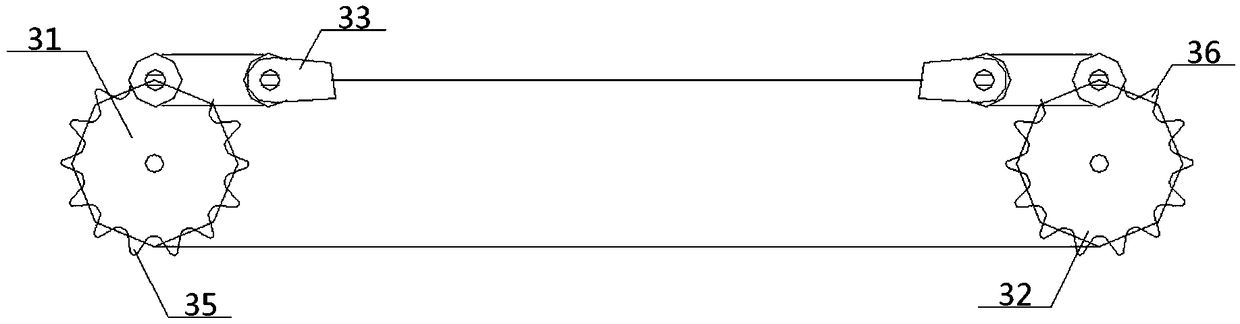

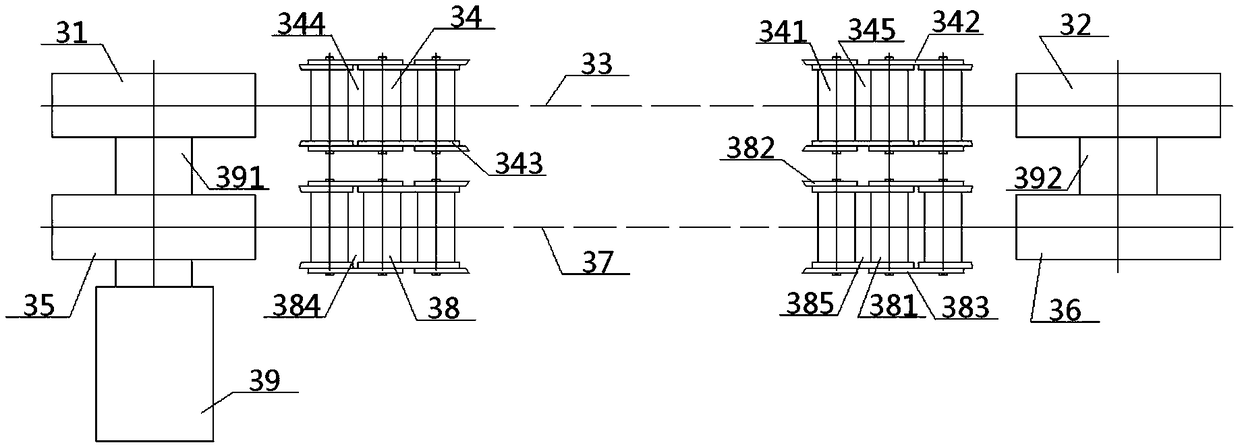

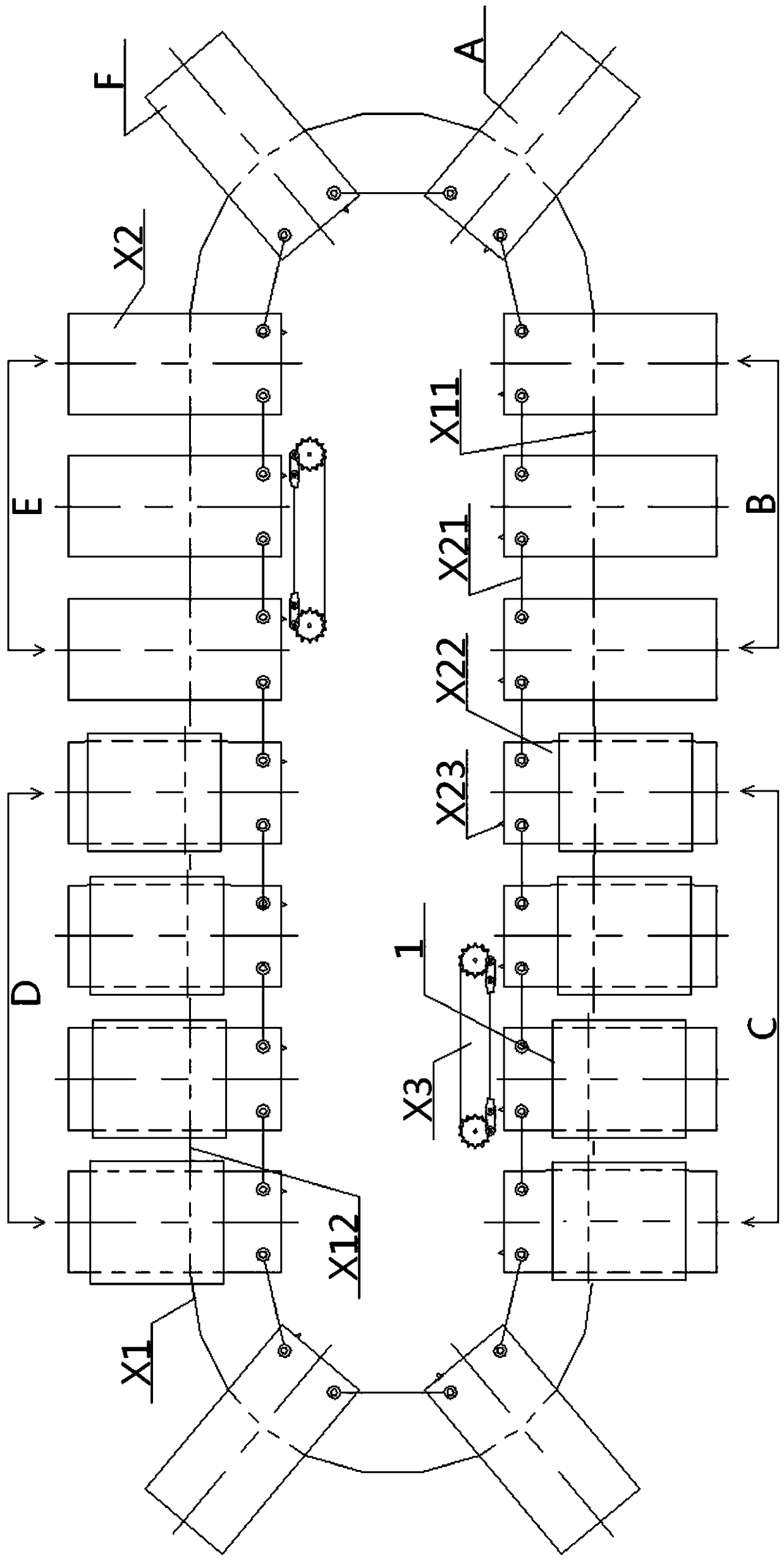

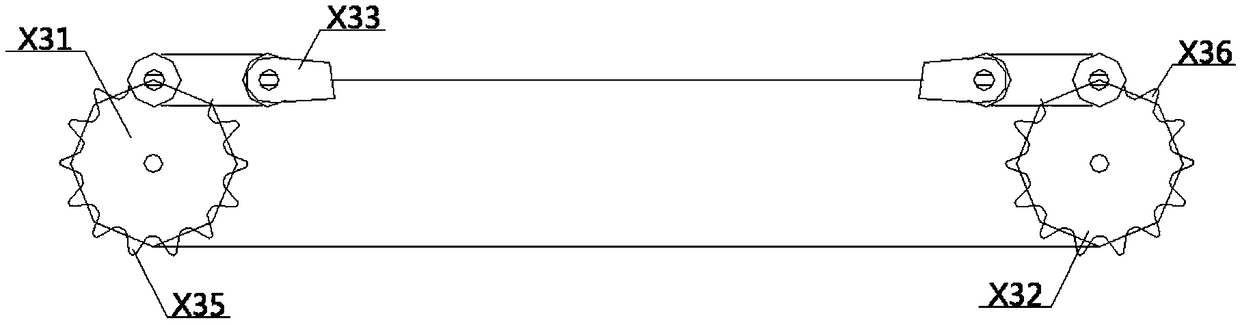

Double-row chain transmission elliptical track printing device and application method thereof

ActiveCN108944002AGuaranteed accuracyImprove accuracyScreen printersAgricultural engineeringSprocket

The invention provides a double-row chain transmission elliptical track printing device. The double-row chain transmission elliptical track printing device comprises a transmission track, at least onedesk board driving device and a plurality of desk boards of the same structure. Every two adjacent desk boards are connected through a connecting rod. Each desk board driving device comprises an upper left chain wheel, an upper right chain wheel and an upper chain, wherein the upper left chain wheel and the upper right chain wheel are both smooth toothless chain wheels; the left and right ends ofthe upper chain are wound around the peripheries of the upper left chain wheel and the upper right chain wheel correspondingly. The upper chain is of an annular structure and comprises a plurality ofupper chain axle sets of the same structure; upper set gaps are formed between the adjacent upper chain axle sets; each upper chain axle comprises two parallel upper chain axles; an upper axle gap isformed between the upper chain axles of the same set. Plate racks arranged on the desk boards are inserted into the upper set gaps and the upper axle gaps in a matched mode. According to the double-row chain transmission elliptical track printing device, the transmission accuracy of the desk boards is good, the desk boards can form resulting force with the connecting rods and is not likely to shake. The linkage effect of the connecting rods can be given full play to.

Owner:WUHAN TEXTILE UNIV

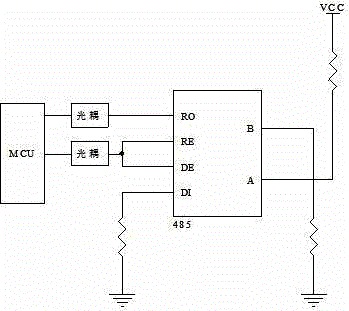

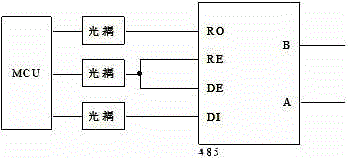

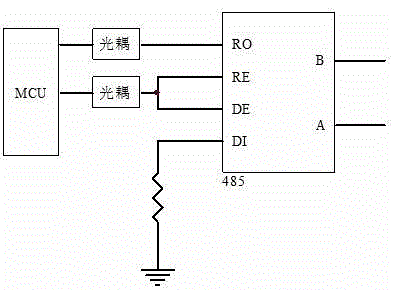

Special driving method of RS485 circuit in dual opto-isolator periphery application

ActiveCN103338031ARealize the driving effectPull-up and pull-down resistance reductionElectronic switchingLogic circuit coupling/interface arrangementsPower gridEngineering

The invention discloses a special driving method of an RS485 circuit in dual opto-isolator periphery application, which comprises the steps as follows: when the signal of an RE / DE port is '1', the RS485 circuit is in a normal driver mode; when the signal of the RE / DE port is changed from '1' into '0', the RS485 circuit is in a special driving mode, at the moment, the RS485 circuit generates a driving signal of '1' or '0', if the RE / DE port always retains the signal of '0', a counter continues counting until the counter is full, the RS485 circuit quits the special driving mode and returns to the normal operation mode, and a normal communication function is continuously realized; if the signal of the RE / DE port recovers '1', the RS485 immediately recovers the normal driver mode, and normal driving is kept going. The method can realize driving ability of three opto isolators, has a periphery application mode of dual opto-isolator, is suitable for a new national power grid standard, saves opto isolators, pull-up resistors and pull-down resistors, and lowers cost.

Owner:CRM ICBG (WUXI) CO LTD

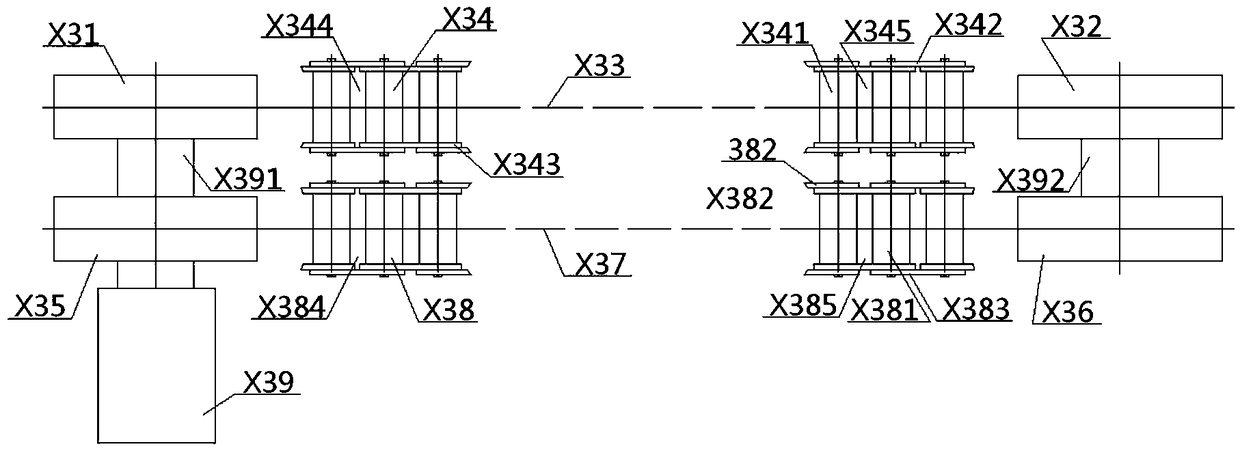

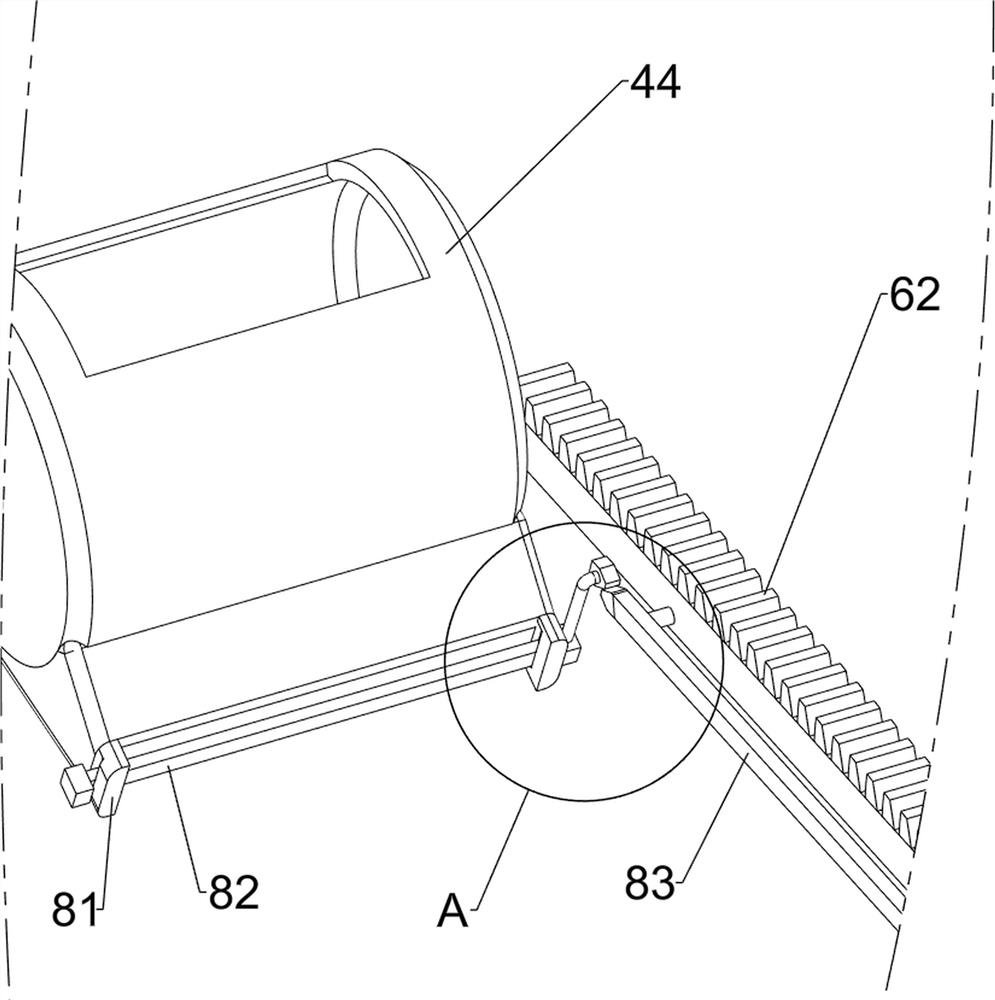

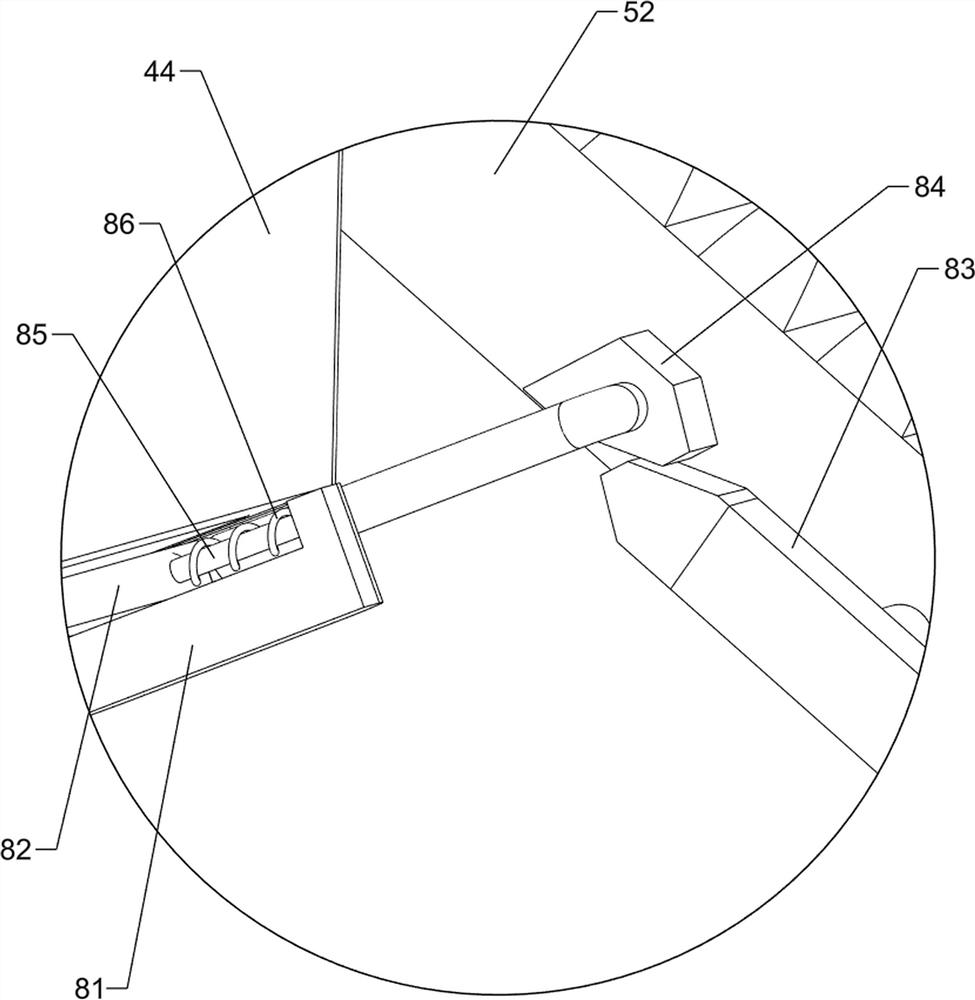

Internal driving type mucilage printing and flocking rail system

ActiveCN108973310AReduce difficultyReduce failureLiquid surface applicatorsScreen printersEngineeringMechanical engineering

The invention relates to an internal driving type mucilage printing and flocking rail system. The internal driving type mucilage printing and flocking rail system comprises a traditional rail and cloth laying stations, release agent printing stations, upper mucilage printing stations, lower mucilage printing stations, flocking stations and cloth clothing stations which are sequentially arranged along the traditional rail and connected; platen drive devices are arranged on front straight rail side where the release agent printing stations and the upper mucilage printing stations are located andon the inner side of the rear straight rail side where the lower mucilage printing stations and the flocking stations are located and are parallel with the straight rail sides, each station comprisesat least one platen, a screen frame is arranged right above each platen in the upper mucilage printing stations and the lower mucilage printing stations, screen frame longitudinal adjusting devices are connected to the left side and the right side of each screen frame, a first scraper and a second scraper which are connected with a scraper base plate are arranged above each screen frame, and thetop of each scraper base plate is connected with transverse and longitudinal displacement devices. The internal driving type mucilage printing and flocking rail system has the advantages that the system is simple in procedures, high in work efficiency, good in platen transmission accuracy, good in printing quality, high in printing efficiency, high in adjustability and wide in application range, and the platens and connecting rods can be well coordinated.

Owner:WUHAN TEXTILE UNIV

Paint raw material stirring and mixing device

InactiveCN113559738AReduce cleaning frequencyReduce the difficulty of cleaningRotary stirring mixersMixture aftertreatmentComposite materialDrive motor

The invention discloses a paint raw material stirring and mixing device, and relates to the technical field of building raw material processing. The paint raw material stirring and mixing device comprises a base, a stirring barrel and a driving motor, wherein the base is fixed to the outer wall of the stirring barrel, two feeding ports are formed in the side surface of the top of the stirring barrel, a body of the driving motor is fixed to the top of the stirring barrel, and an output shaft is located at the bottom of the driving motor and fixed to the top end of a stirring shaft. According to the paint raw material stirring and mixing device, elastic stirring blades are arranged on stirring strip, so that the contact area between the stirring strips and paint raw materials can be increased, the paint raw materials in the stirring barrel are fully stirred and mixed, the stirring strips and the elastic stirring blades are still in a rotating state in the discharging process, the elastic stirring blades collide with a separating mechanism, so as to enable the stirring strips and the separating mechanism to generate certain vibration, and the vibration can promote paint attached to the stirring strips and the separating mechanism to drop.

Owner:胡和建

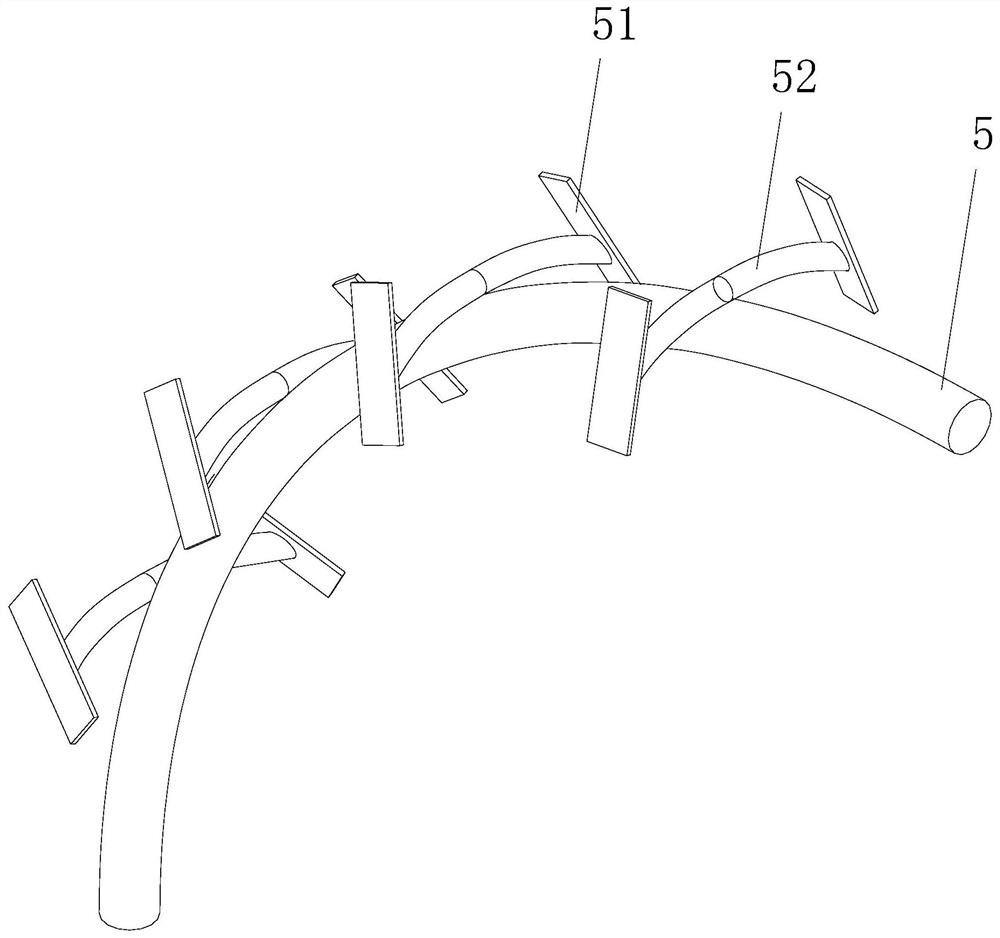

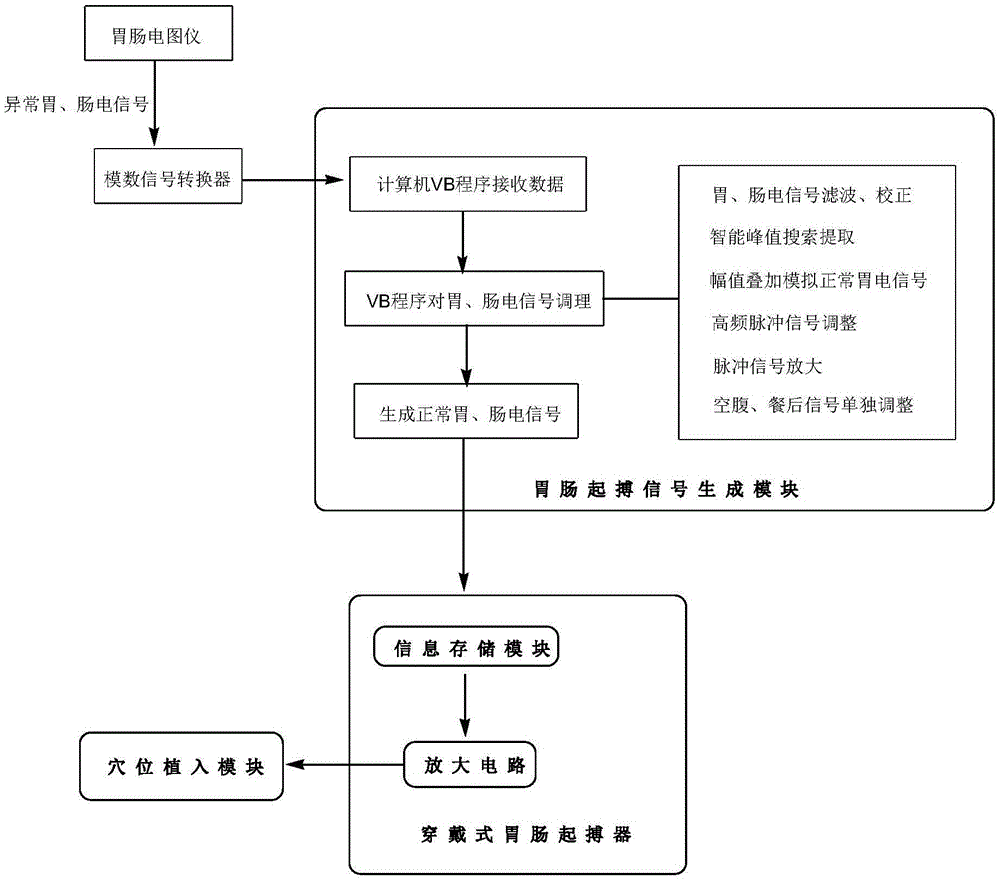

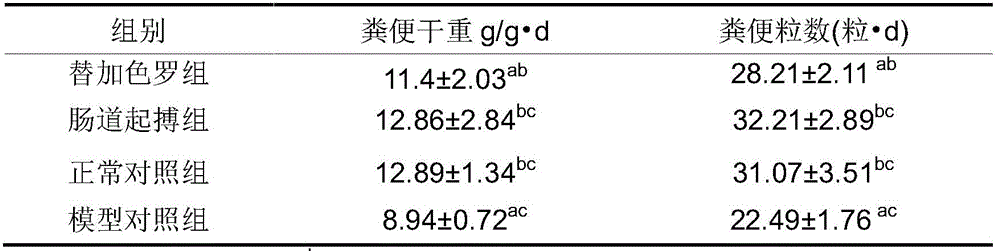

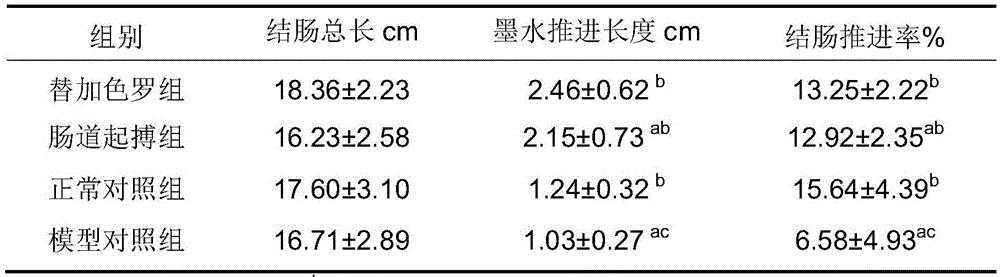

Digital gastrointestinal pacemaker

InactiveCN105617530AReturn to normal rhythmAchieve the goal of minimally invasive treatment of gastrointestinal motility disordersExternal electrodesDigestive electrodesMotion sicknessDisease

The invention provides a digital gastrointestinal pacemaker. A gastrointestinal pacing signal generation component calculates normal stomach and intestine electric signals according to abnormal stomach electric signals or intestine electric signals acquired by a gastrointestinal electrographic instrument; the normal stomach and intestine electric signals are stored in a memory stick of the gastrointestinal pacemaker, the memory stick transmits the normal stomach and intestine electric signals to an acupoint implantation component, and the acupoint implantation component drives gastrointestinal pacing points according to the normal stomach and intestine electric signals. The digital gastrointestinal pacemaker uses an acupoint implantation electrode as a therapeutic electrode, and with the help of the gastrointestinal electric pacing signals of the digital gastrointestinal pacemaker and the therapeutic effects of the acupoint itself, gastrointestinal pacing is driven. The device can be used for treating gastrointestinal motility disorders, and particularly preventive treatment for gastrointestinal side effects after an operation, radiotherapy and chemotherapy, preventive treatment for serious motion sickness, and gastrointestinal motility disorders with serious vomitus gravidarum and poor drug treatment effects.

Owner:THE FIRST AFFILIATED HOSPITAL OF XIAN JIAOTONG UNIV

Novel underpinning construction method for steel pipe under existing building foundation

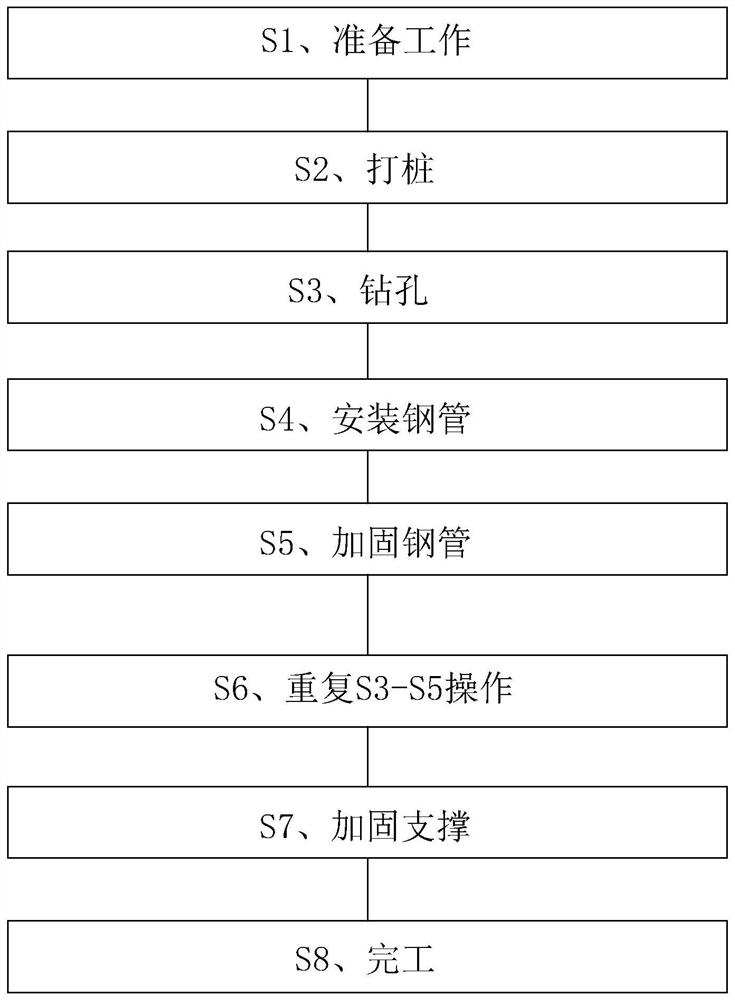

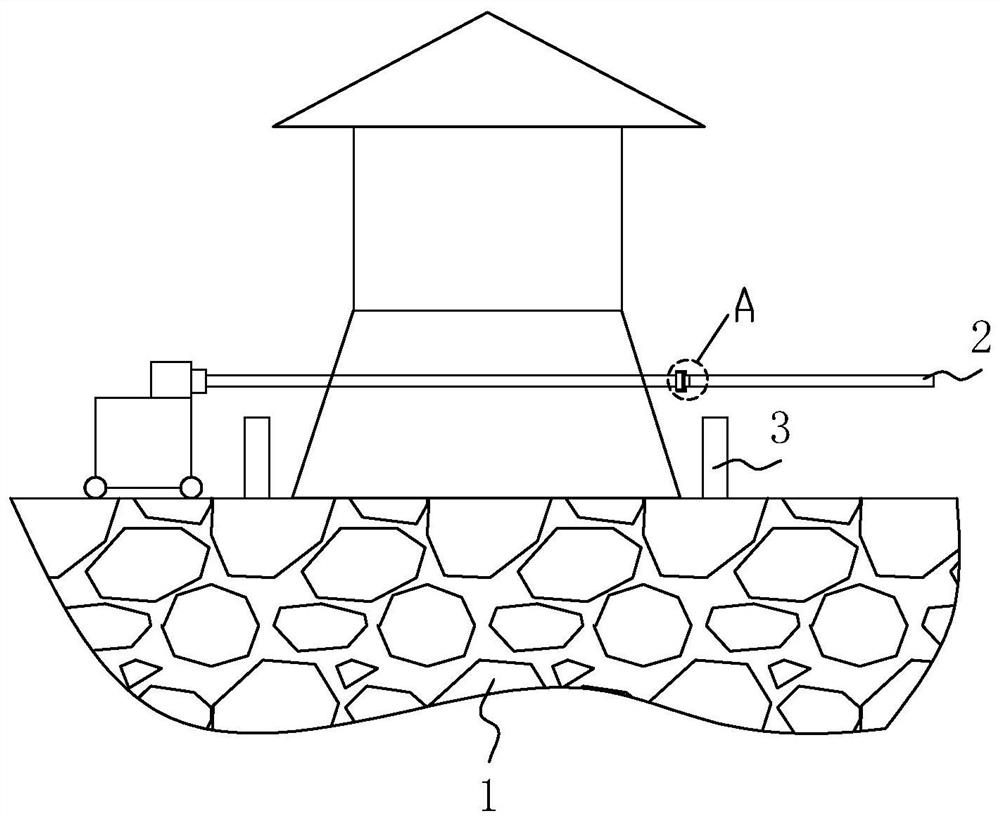

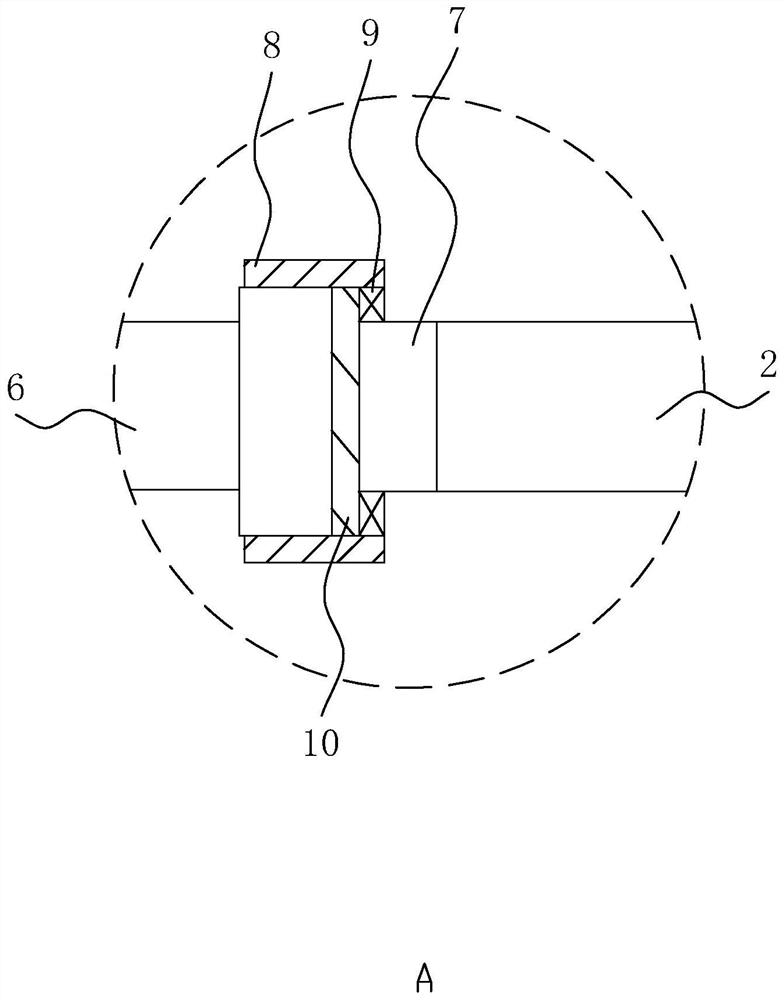

ActiveCN113323011AGuaranteed load strengthGuaranteed fixed effectBuilding repairsFoundation engineeringArchitectural engineeringSteel columns

The invention relates to a novel underpinning construction method for a steel pipe under an existing building foundation, and relates to the field of foundation construction. The novel underpinning construction method comprises the following steps of S1, carrying out preparation work; S2, piling; S3, drilling; S4, installing the steel pipe; S5, reinforcing the steel pipe; S6, repeating the operations from S3 to S5; S7, reinforcing and supporting; and S8, finishing. The novel underpinning construction method has the effects that the supporting strength of the steel pipe is improved, then the load strength of the steel pipe is achieved, the operation structure is simple and materials are environmentally friendly while the efficient underpinning of a steel column is ensured, and the construction cost is reduced.

Owner:武汉武建机械施工有限公司

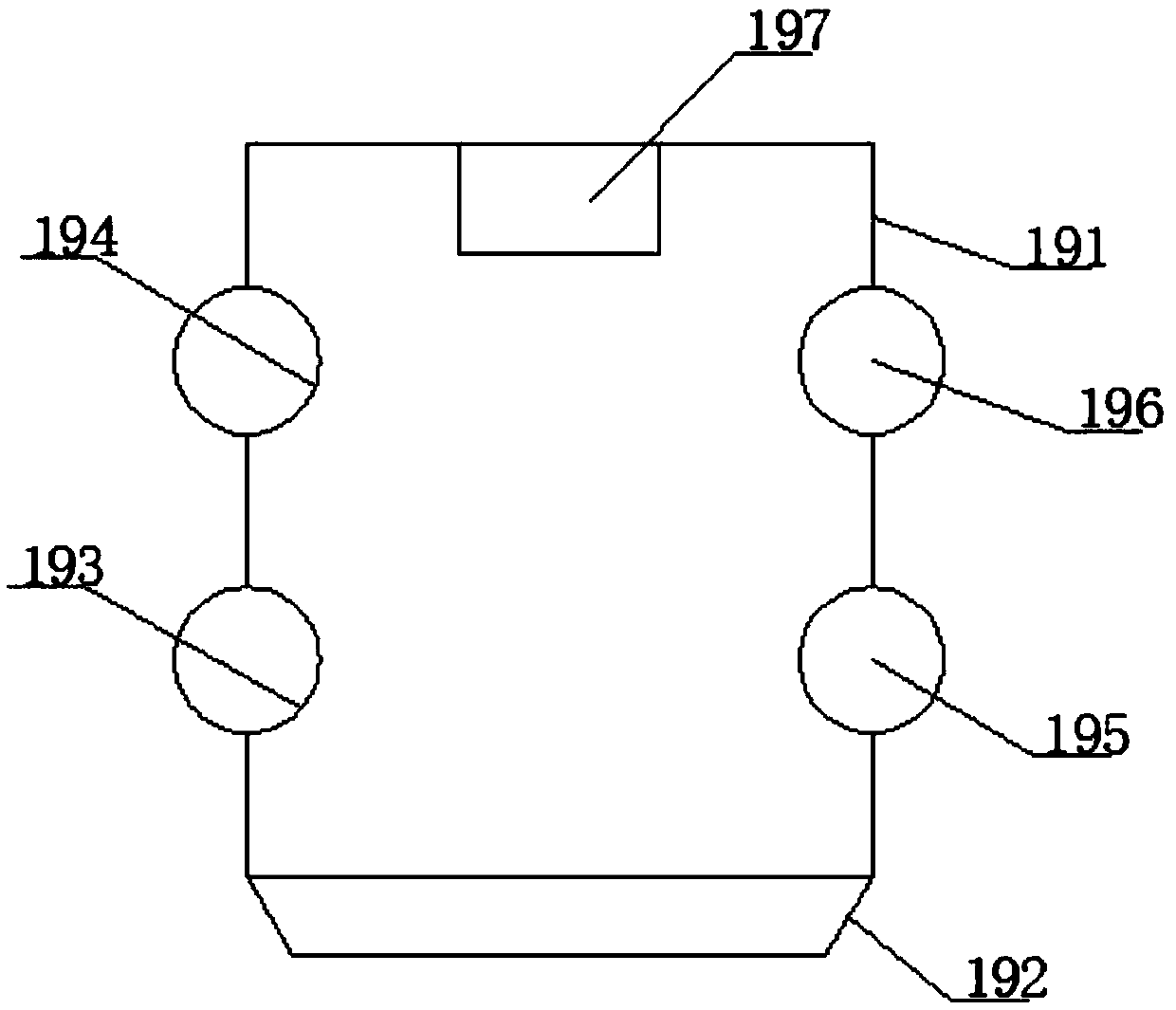

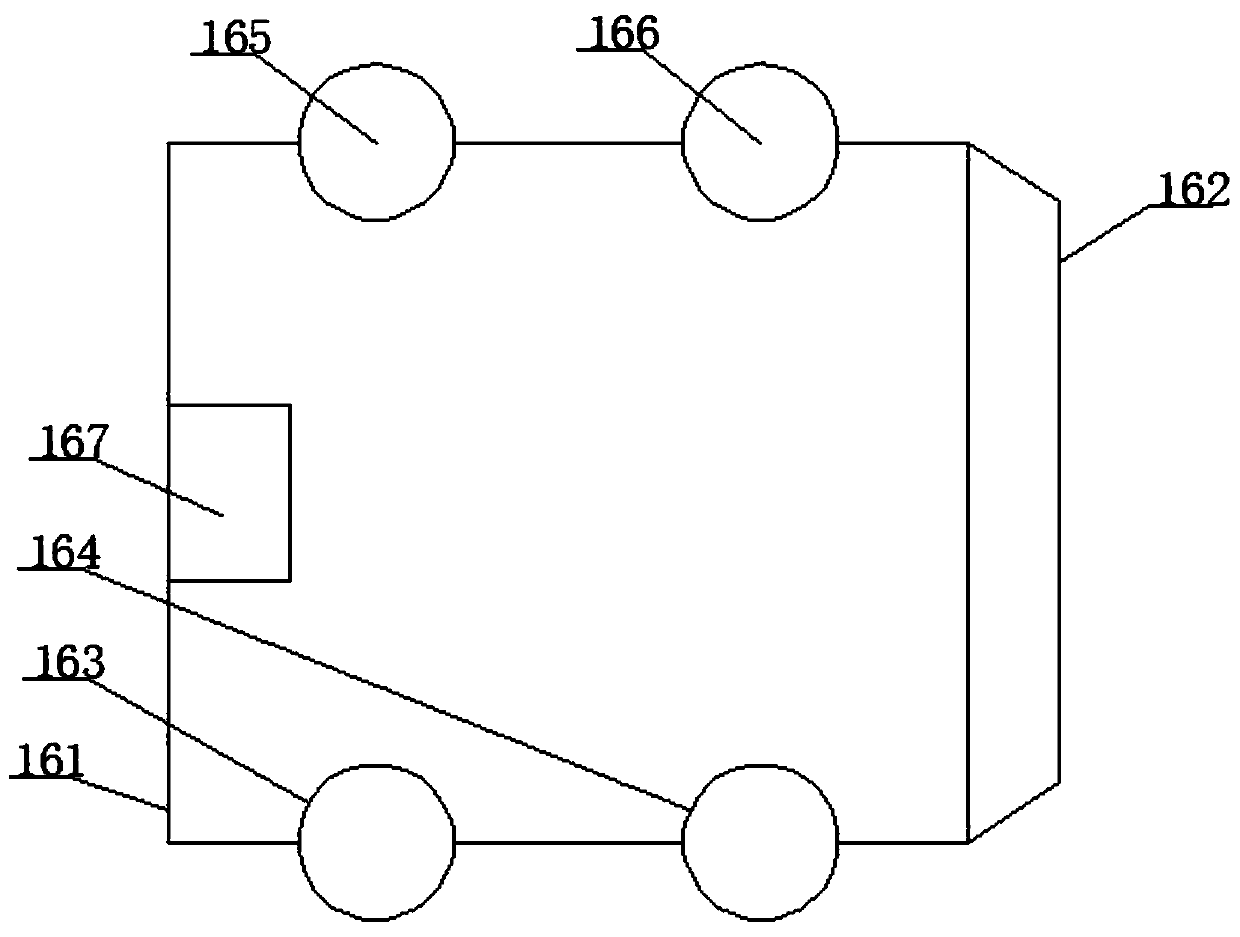

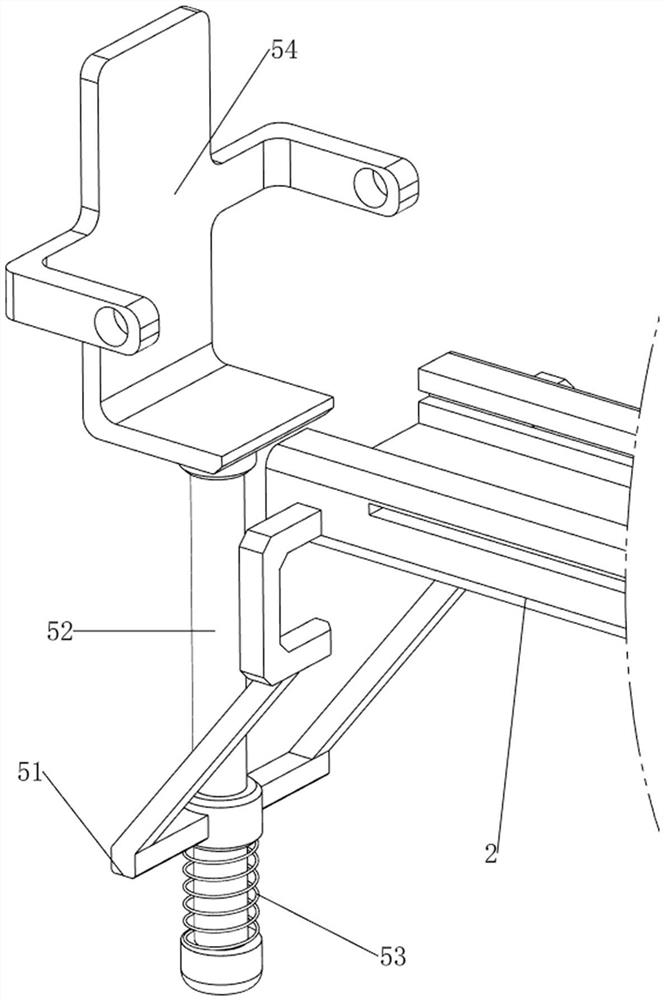

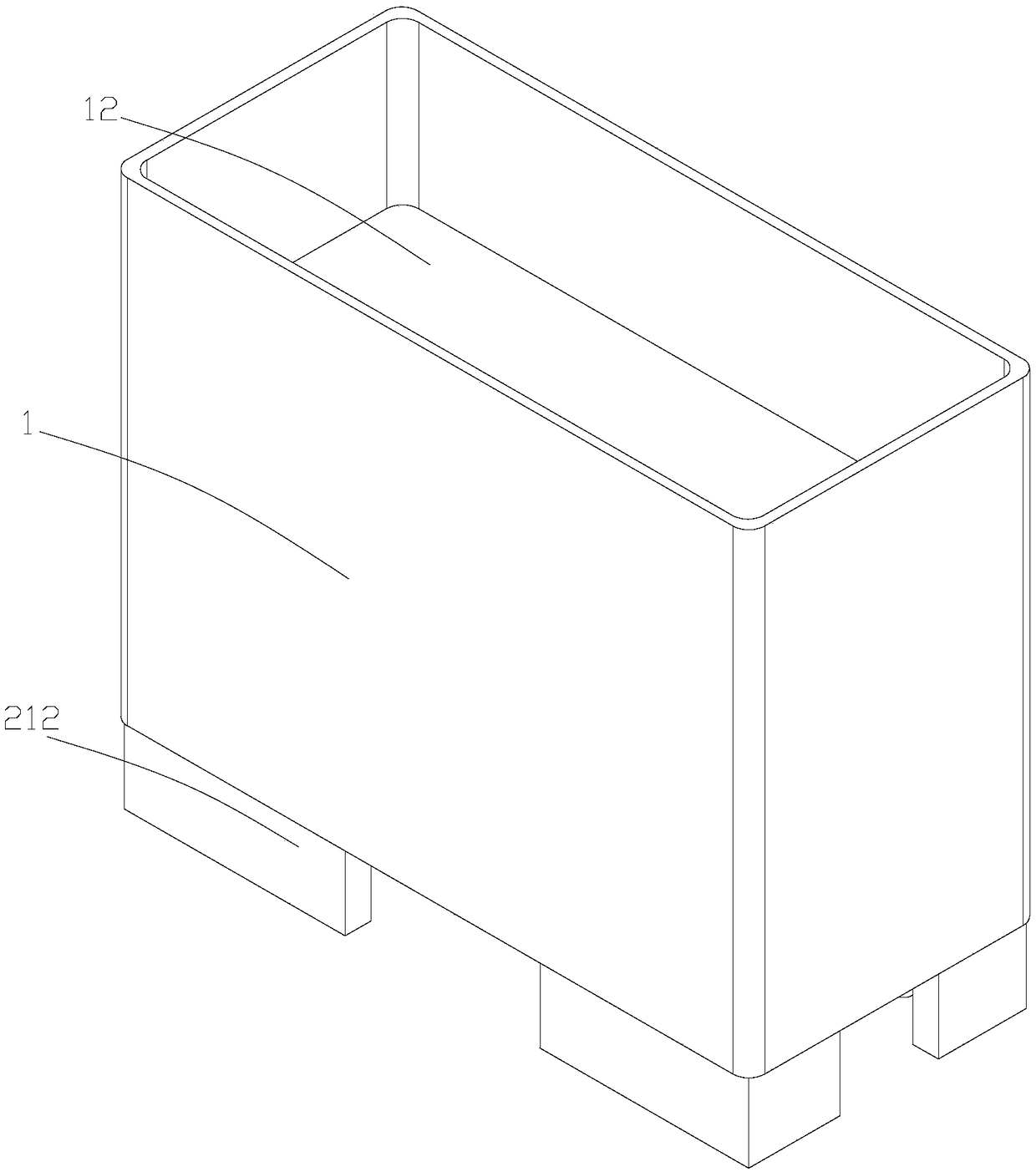

Movable planting box for garden engineering

The invention discloses a movable planting box for garden engineering, comprising a planting box body for planting plants, wherein the bottom of the planting box body is provided with a plurality of universal wheel sets for assisting movement of the planting box body, a planting chamber for planting plants is arranged in the planting box body, and the planting box body is provided with a braking mechanism for fixing the planting box body on designated ground and a braking chamber for accommodating working of the braking mechanism. Through arrangement of the above structure, carrying and fixingof the planting box can be effectively realized, carrying movement of the planting box is more easy and labor-saving, and the carrying efficiency of the planting box is improved. And the planting boxcan be reliably braked and fixed after carried, so that the planting box can be stably placed on the designated ground, deviation of the planting box when placed is avoided, and the stability of theplanting box is strengthened.

Owner:南京幸庄科技创新产业园管理有限公司

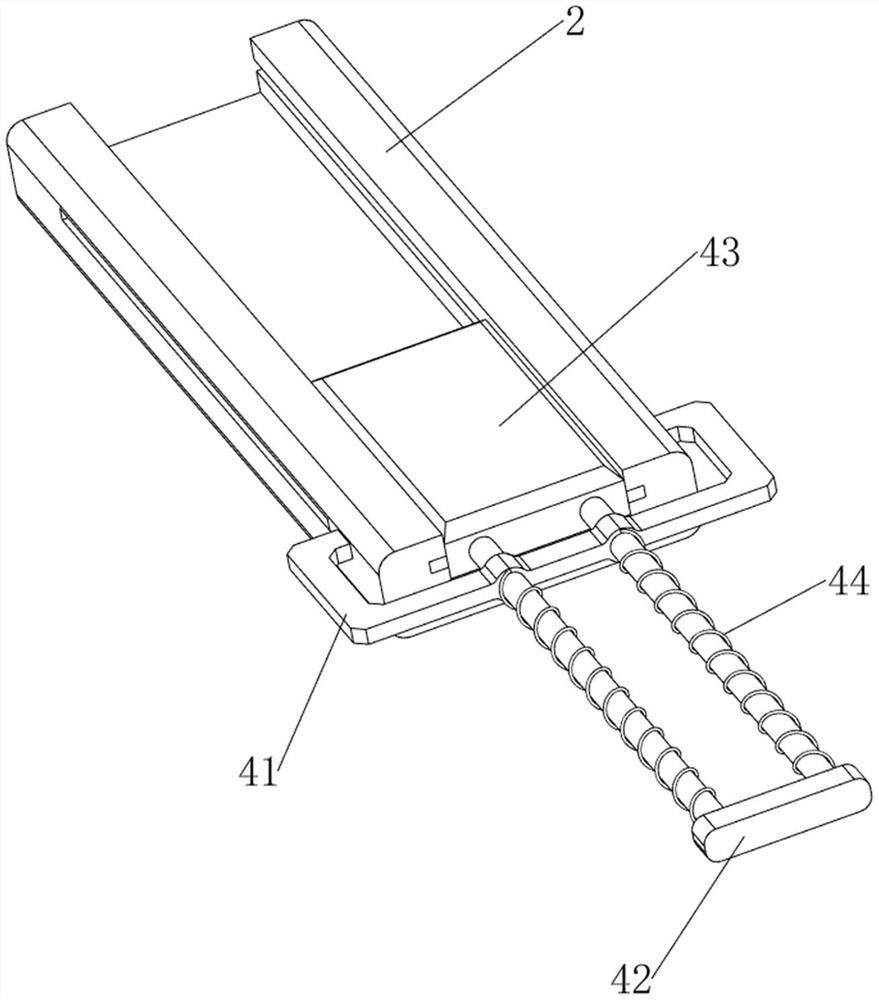

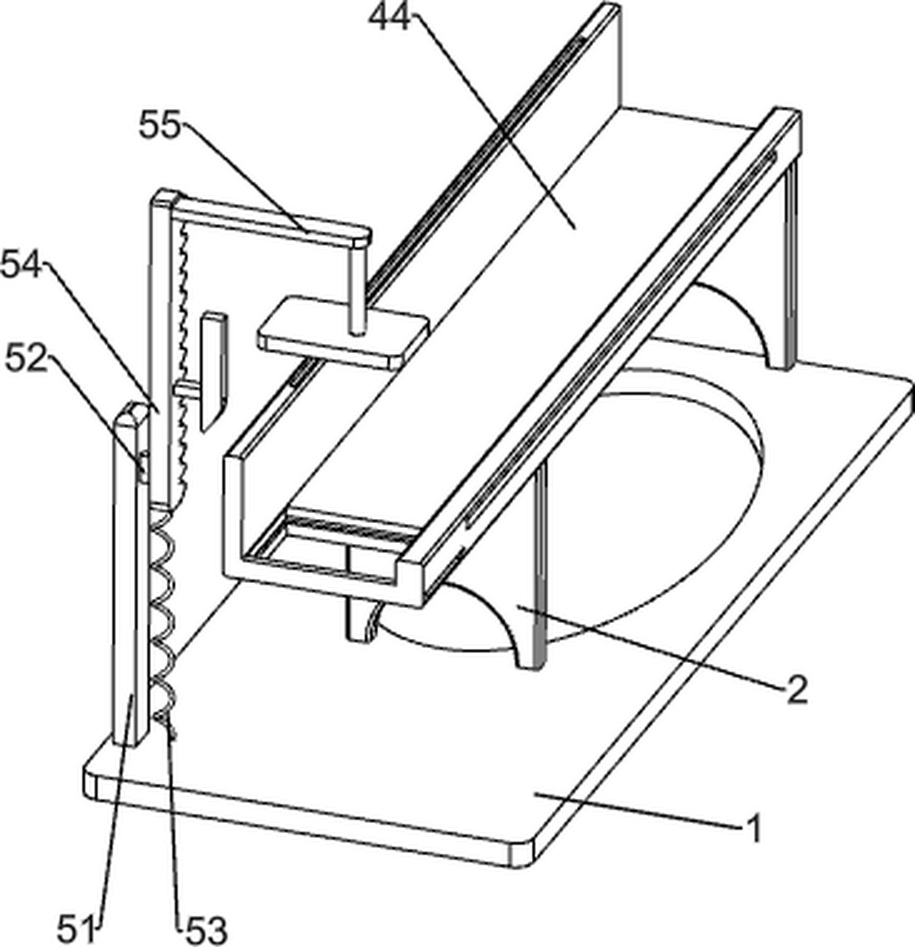

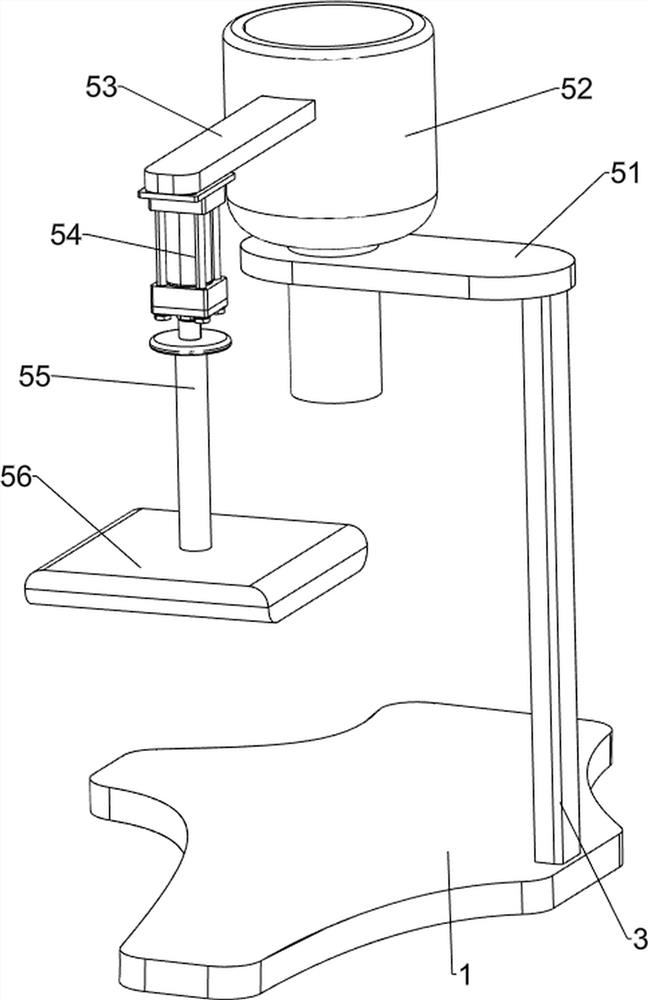

Industrial automatic dicing device for plywood

ActiveCN112743637ARealize the driving effectAchieve cutting effectProfiling/shaping machinesSupport planeManufacturing engineering

The invention relates to a dicing device, in particular to an industrial automatic dicing device for plywood, and aims to provide the industrial automatic dicing device which is used for the plywood and is convenient to operate, complete in cutting surface and relatively high in cutting quality. The industrial automatic dicing device for the plywood comprises a base, first fixing frames, a pushing mechanism and a cutting mechanism; a supporting frame is arranged on the base; the two first fixing frames are arranged on one side of the base and are connected with the supporting frame; the pushing mechanism is arranged at the top of the supporting frame; and the cutting mechanism is arranged between the two first fixing frames. An air cylinder telescopic rod extends backwards and drives a first pushing frame to move backwards, the first pushing frame pushes the plywood backwards, and the pushing effect is achieved.

Owner:临沂汇丰木业有限公司

Automatic dough cake forming device for food production

PendingCN112741128ARealize the driving effectRealize the pressure effectDough extruding machinesDough processingEngineeringMechanical engineering

Owner:JINING JINFENG FOOD

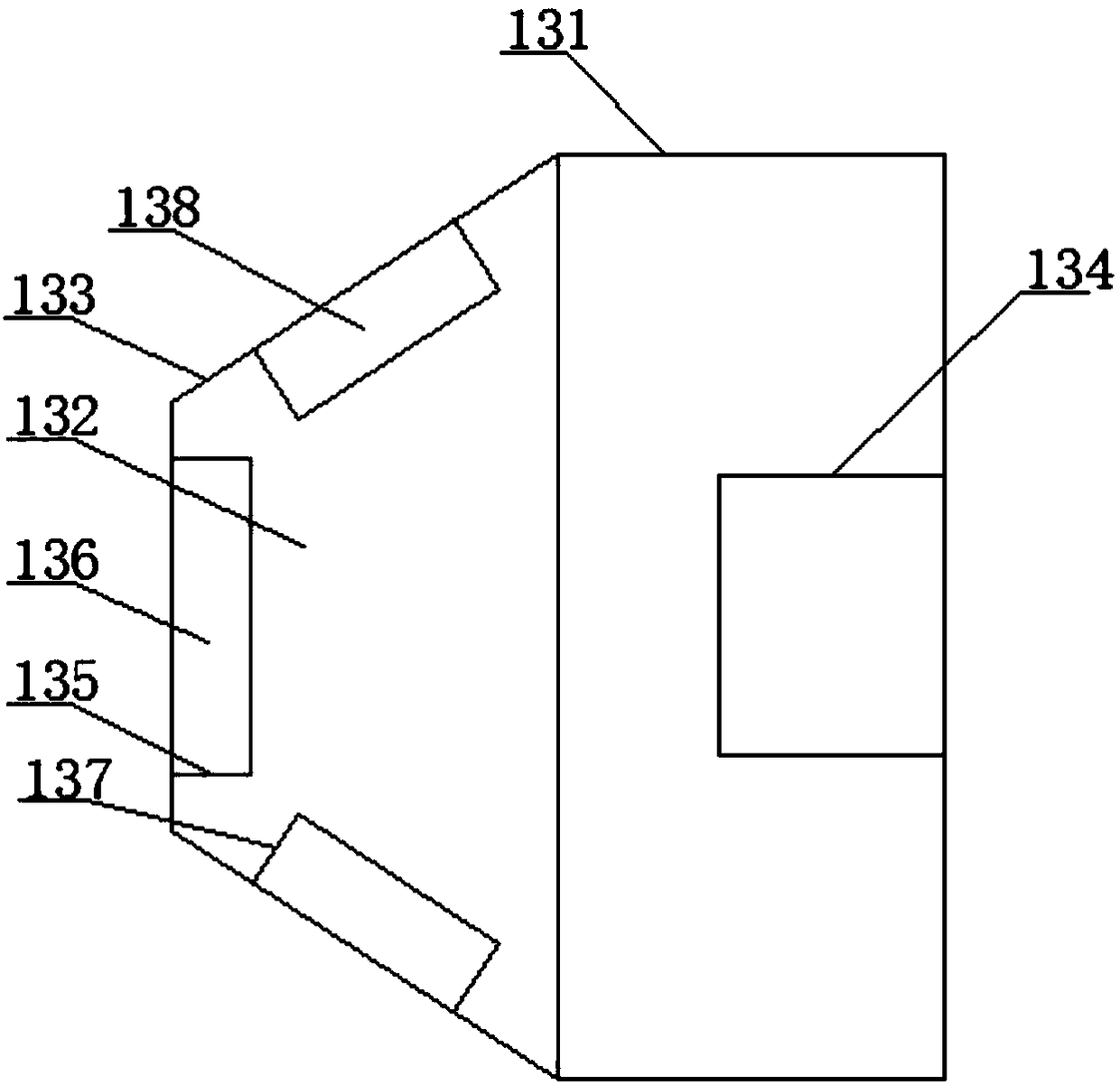

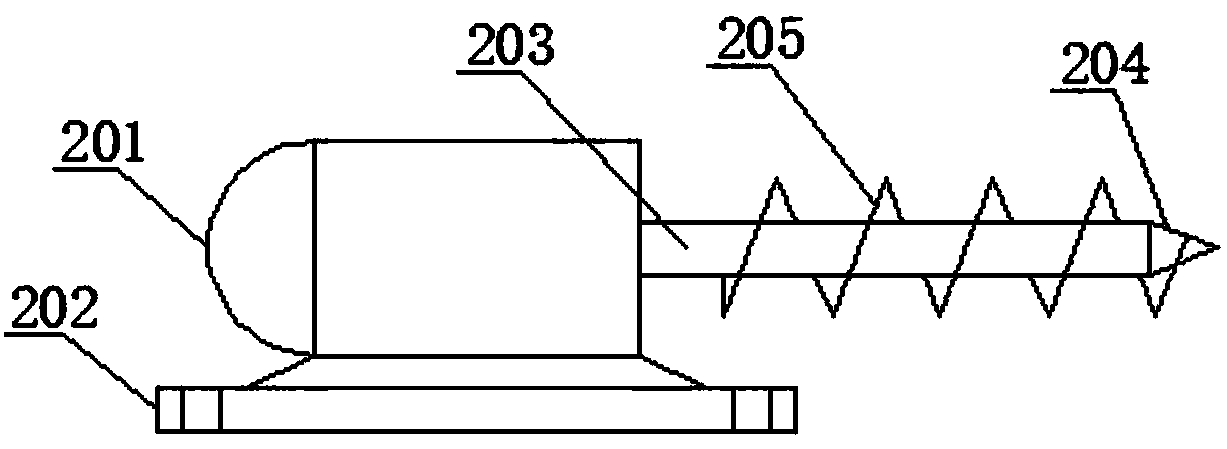

Perforating device for power installation

ActiveCN108386130ARealize the assemblyAchieve disassemblyEarth drilling toolsConstructionsSludgeButt joint

The invention discloses a perforating device for power installation. The device comprises a main hollow shell body, a columnar cylinder and a columnar cylinder sludge exporting mechanism, wherein theside face of the bottom of the main hollow shell body is provided with a supporting plate through a bolt. According to the perforating device for power installation, other energy sources are not needed as power sources, the device utilizes a lever principle to achieve the injection of air pressure, the device is characterized in that the labor intensity of force application each time is reduced, the operation is convenient and simple, and the practicability is strong; in addition, the device is provided with the columnar cylinder sludge exporting mechanism, and the columnar cylinder sludge exporting mechanism can directly clear away the sludge in the columnar cylinder, thereby continuing working; the device is provided with an air unidirectional compression mechanism, on the premise of driving, the air unidirectional compression mechanism can utilize the available air to achieve aerodynamic compression, thereby performing driving; the device is also provided with a driven movable buttjoint mechanism, the driven movable butt joint mechanism is in threaded connection with the columnar cylinder used for working, thereby driving the columnar cylinder, the assembly and disassembly of the columnar cylinder can also be achieved, and the utilization rate is improved.

Owner:威海成达电力设备安装工程有限公司

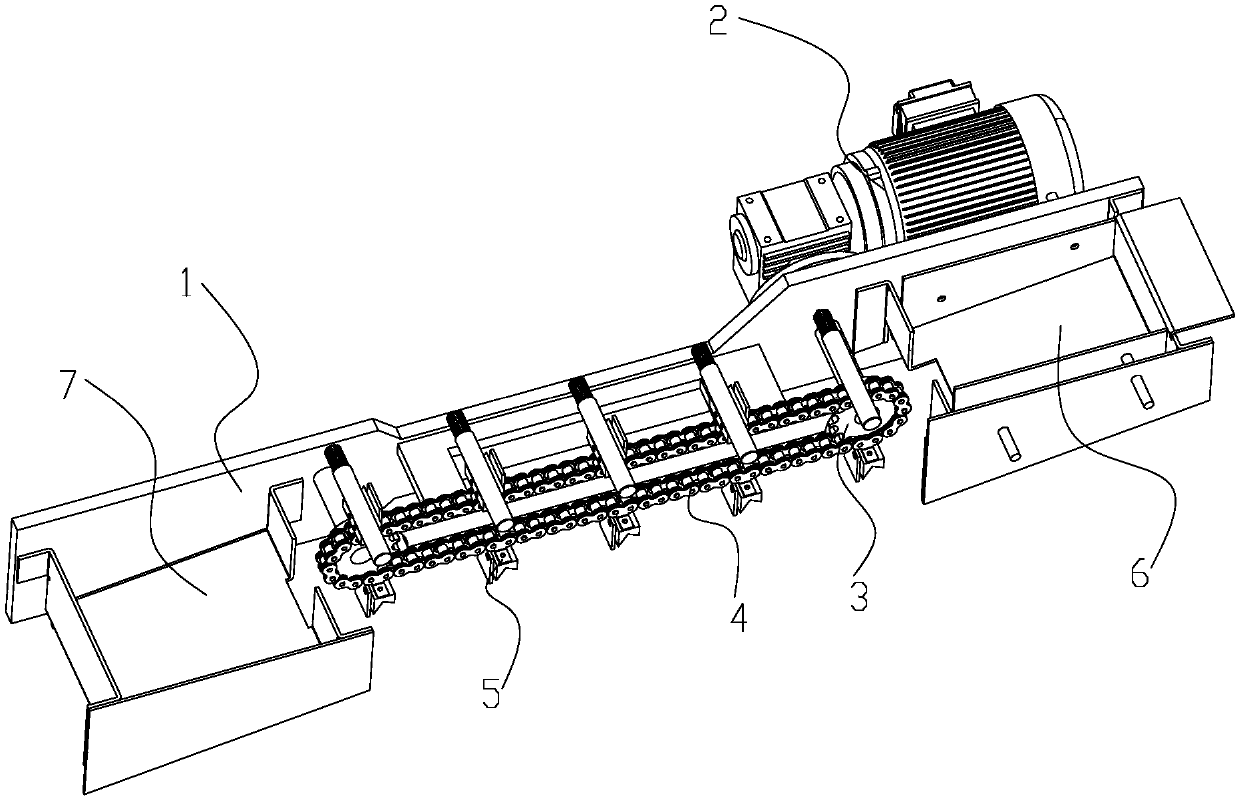

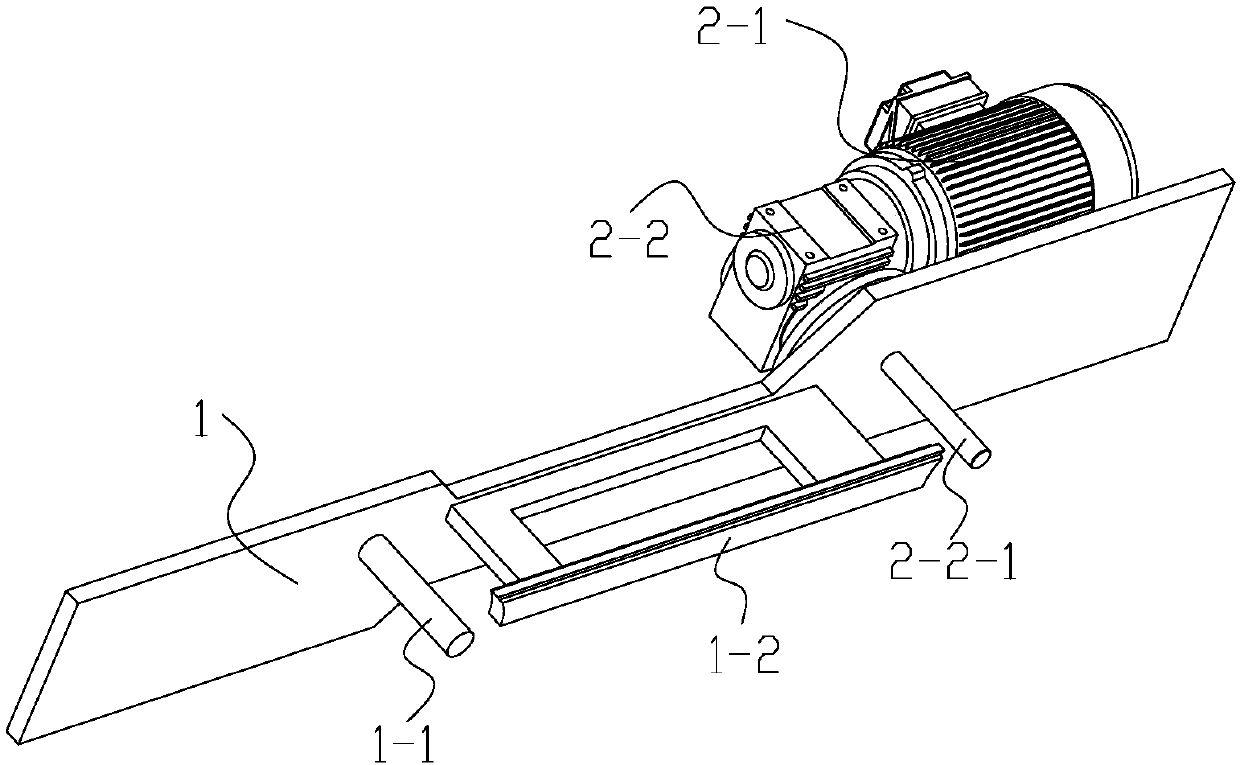

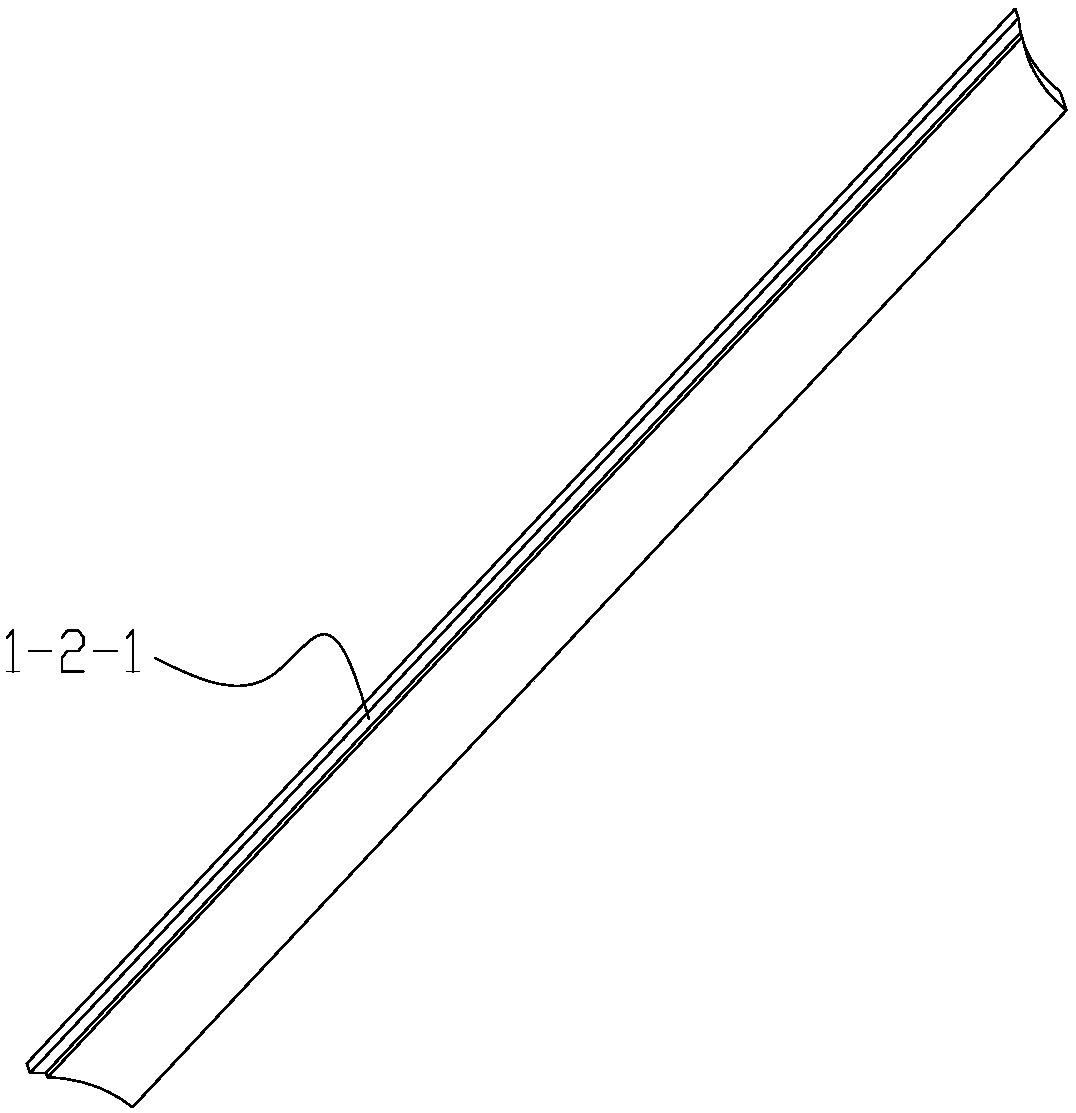

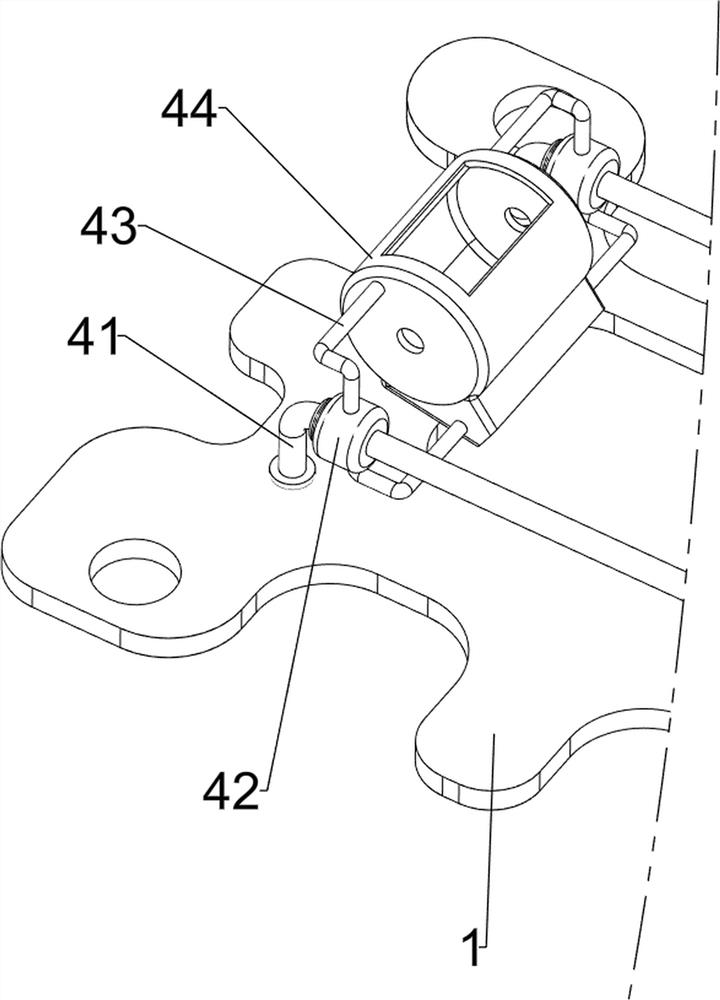

Automatic conveying mechanism for conveying carbon rod

InactiveCN110194351ATo achieve the prop up effectRealize the driving effectConveyorsSprocketEngineering

The invention provides an automatic conveying mechanism for conveying a carbon rod. The automatic conveying mechanism is characterized in that a driving mechanism is fixed on a frame plate, a first output shaft of the driving mechanism penetrates through the frame plate, erection columns extend from one side of the frame plate, the planes where the axis of the first output shaft and the axes of the erection columns are located are horizontal, an erection plate is arranged between the two erection columns, the erection plate is fixedly connected with the frame plate, and clamping convex stripsare arranged on the erection plate; and a chain wheel is arranged and is fixed to the first output shaft in a sleeving mode, another chain wheel is rotatably arranged on the erection columns in a sleeving mode, a chain is clamped on the two chain wheels, the clamping convex strips are clamped in the chain, a plurality of material taking parts are arranged on the chain, a material taking cavity isfixed on one side of the chain, the material taking parts are suitable for taking out a tubular material in the material taking cavity, a material storage cavity is fixed on the other side of the chain, and the material taking parts are suitable for placing the polished tubular material. According to the automatic conveying mechanism, the effects of automatic material taking and automatic materialplacing can be realized conveniently.

Owner:江苏双辉环境科技有限公司

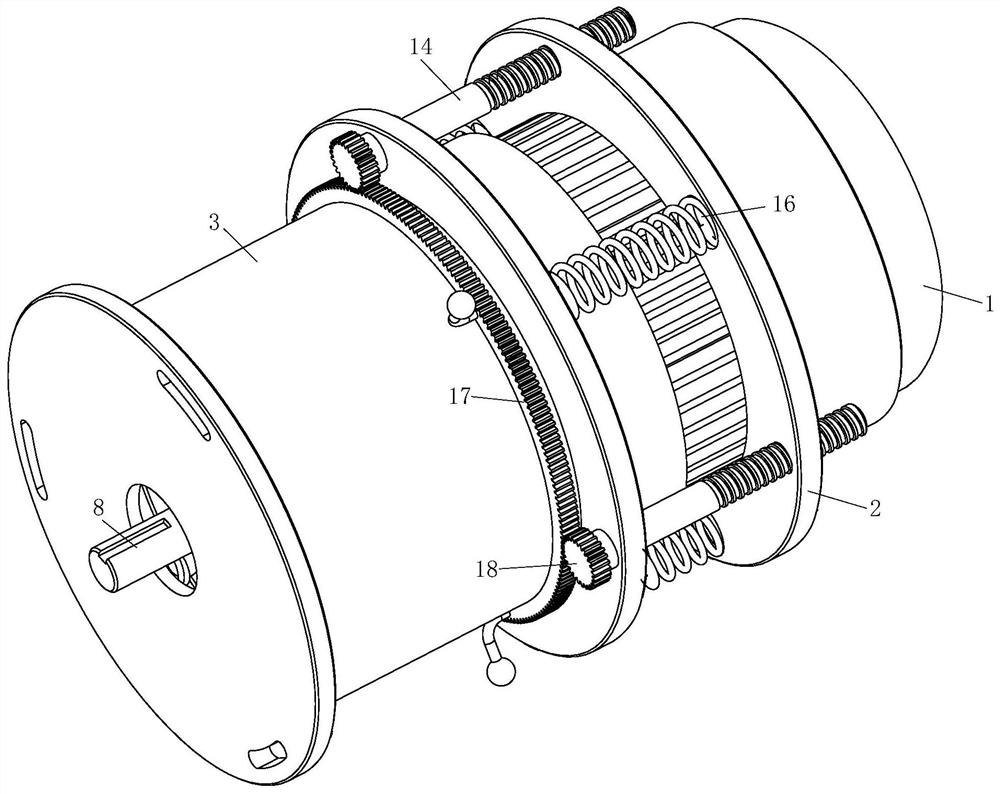

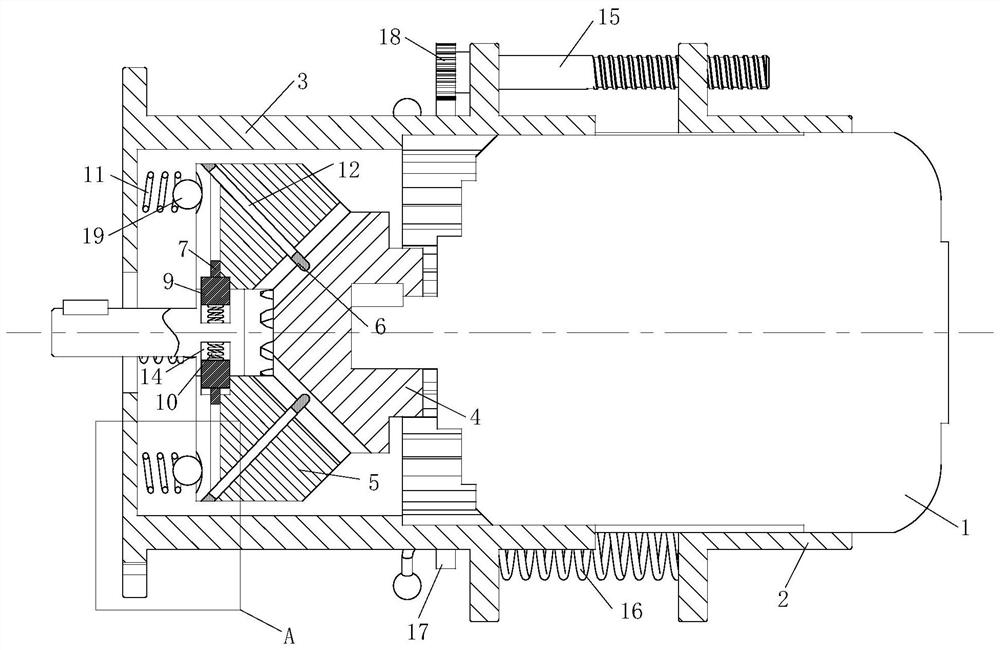

Overload protection motor for load-carrying machinery

InactiveCN113241901ARealize the driving effectPlay the effect of protecting the motorMechanical energy handlingStructural associationControl engineeringElectric machinery

The invention belongs to the technical field of motors, and particularly relates to an overload protection motor for load-carrying machinery, which comprises a driving motor, a fixed seat, a movable seat, a first connecting piece, a second connecting piece, a first convex block, a second convex block, an output shaft, a stop block, a first spring and a second spring. When the output shaft is locked, the driving motor drives the first connecting piece to rotate relative to the second connecting piece, so that teeth on the first connecting piece are meshed with the tooth surface, provided with the first convex block, of the second connecting piece, the first convex block is compressed into the pressure cavity, and the second convex block at the other end of the pressure cavity is extruded out; the stop block completely enters the sliding groove in the output shaft, then the output shaft and the second connecting piece are not restrained in the rotating direction, then the motor is separated from a force transmission path of the load end through a mechanical structure, overload protection of the motor is achieved, the structure is simpler, the number of needed parts is smaller, and cost is lower.

Owner:王显正

Rolling type ground cement leveling device for building

ActiveCN112282325ARealize the moving effectRealize the feeding effectBuilding constructionsRoads maintainenceElectric machineryStructural engineering

The invention relates to a cement leveling device, in particular to a rolling type ground cement leveling device for a building. The rolling type ground cement leveling device for the building is highin working efficiency, low in labor intensity and convenient to move. The rolling type ground cement leveling device for the building comprises a bottom plate, a motor, a feeding mechanism and a pushing mechanism, wherein a mounting frame is arranged on the left portion of the upper rear side of the bottom plate, the motor is mounted at the top of the mounting frame, the feeding mechanism is arranged on the rear side of the bottom plate, and the pushing mechanism is arranged on the left side of the bottom plate. According to the rolling type ground cement leveling device, cement is injected into a material box, first sliding blocks are pushed forwards, so that first connecting rods are driven to move forwards, then the material box is driven to move forwards, the cement is sprayed out from a discharging opening of the material box to cover the ground, and the feeding effect is achieved.

Owner:安徽雄风建设集团有限公司

Piezoelectric type stepping precision rotation driver

InactiveCN104467531AAchieve clampingRealize the driving effectPiezoelectric/electrostriction/magnetostriction machinesControl systemClassical mechanics

The invention belongs to the hydraulic field, particularly relates to a hydraulic control system, provides a piezoelectric type stepping precision rotation driver and aims to realize properties of minimum driving displacement and large enough resolution and motion stroke. The piezoelectric type stepping precision rotation driver comprises an upper mechanism and a lower mechanism. The piezoelectric type stepping precision rotation driver is characterized in that the upper mechanism is sequentially provided with a driving piezoelectric stack, a pre-tightening mechanism, an upper piezoelectric stack and a pre-tightening screw, and the upper mechanism and the lower mechanism are connected through a flexible hinge.

Owner:田荣侠

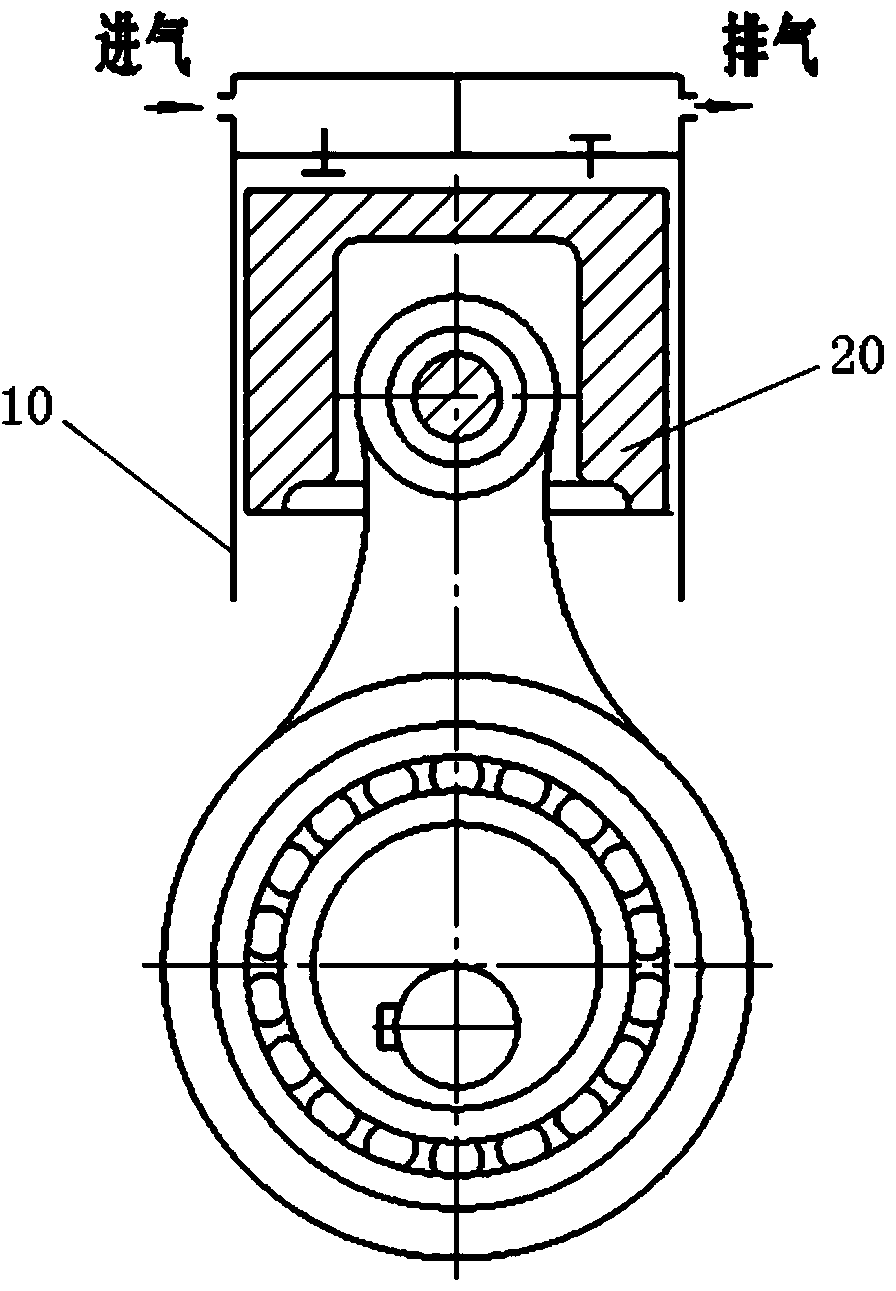

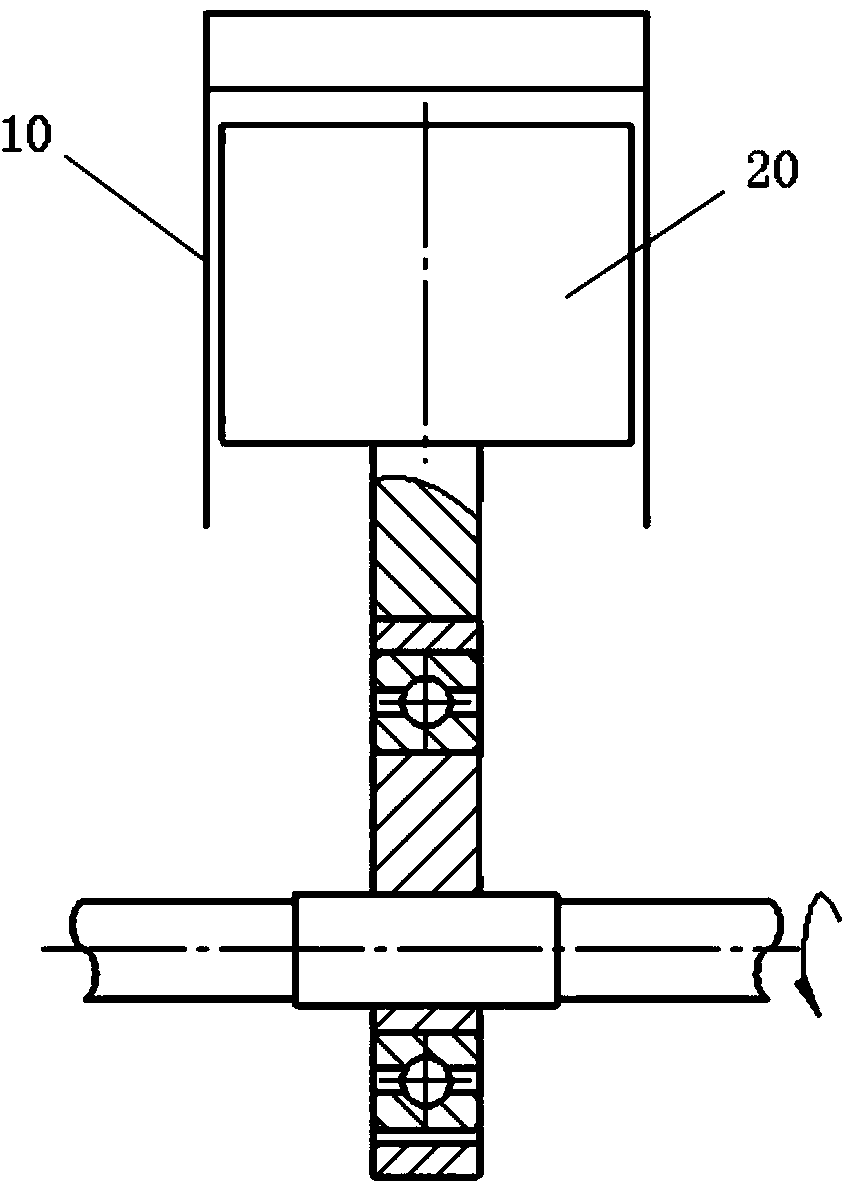

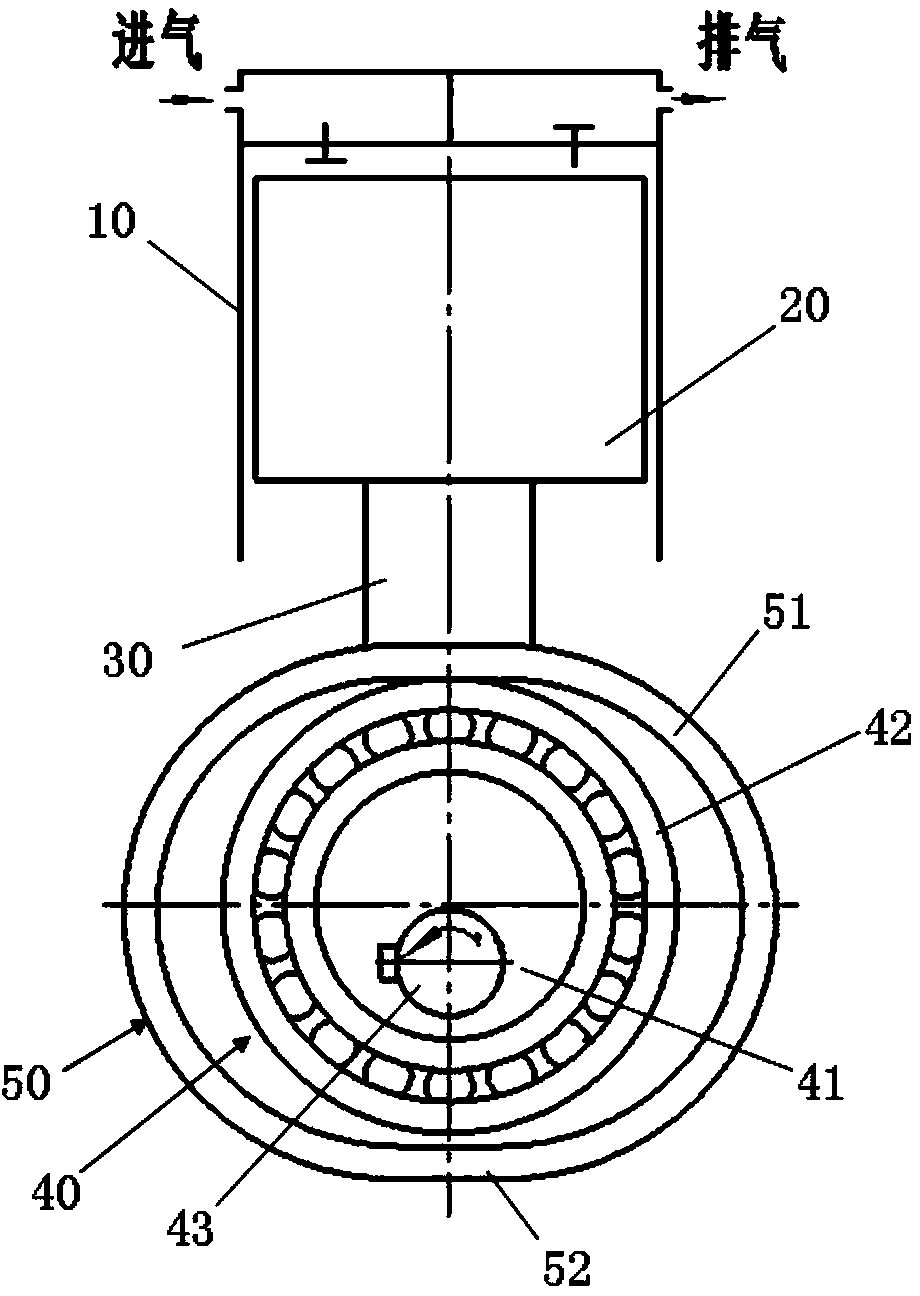

Transmission mechanism used for reciprocating compressor

InactiveCN103807141AEliminate friction and wearSimple structurePositive displacement pump componentsPositive-displacement liquid enginesReciprocating motionDriven element

The invention relates to the field of mechanical transmission, in particular to a transmission mechanism used for a reciprocating compressor. The transmission mechanism comprises a piston which is connected to the inside of a cylinder in an inserted mode and can move in a reciprocating mode in the axis direction of the cylinder. The transmission mechanism further comprises a connecting rod and an eccentric portion used for a drive element, wherein the eccentric portion, the connecting rod and the piston form crank block matching, the end, matched with the eccentric portion, of the connecting rod is provided with a transmission yoke attached to the outer edge of the eccentric portion, the transmission yoke at least comprises two yoke edges which are sequentially arranged from top to bottom in the axis direction of the piston, the eccentric portion rotates in the area between the two yoke edges so as to abut against the inner surfaces of the yoke edges and drive the piston to move in a reciprocating mode, and when the piston moves in a reciprocating mode, the inner surfaces of the two yoke edges are in line contact matching with the outer edge of the eccentric portion in turn. The transmission mechanism is long in service life and simple in structure and can solve the problem that due to the fact that matching portions of components are multiple, maintenance is frequently carried out.

Owner:HEFEI GENERAL MACHINERY RES INST

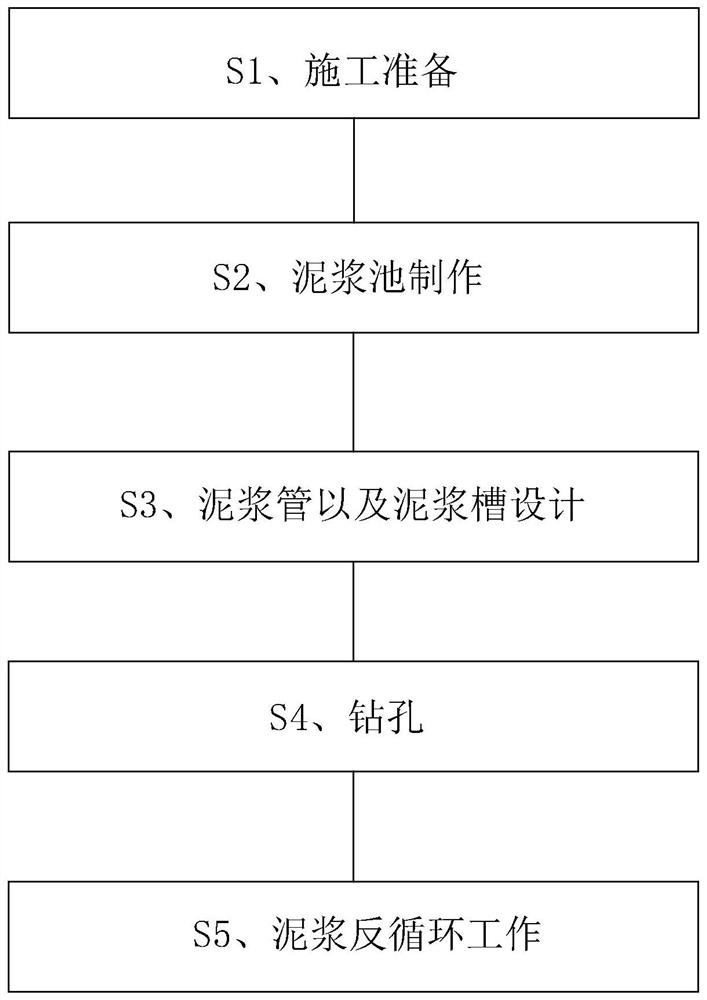

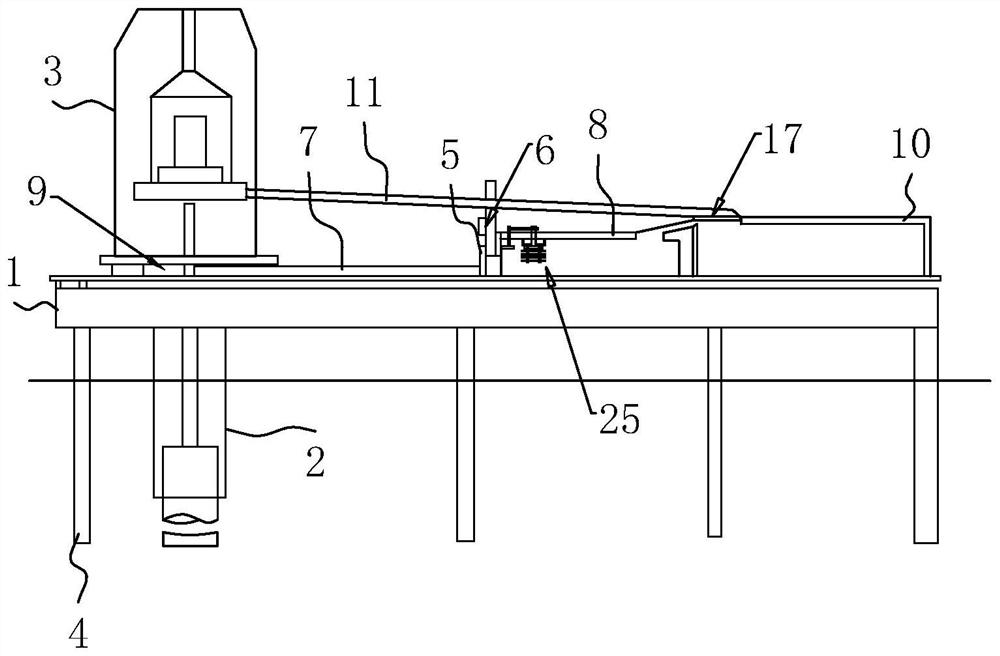

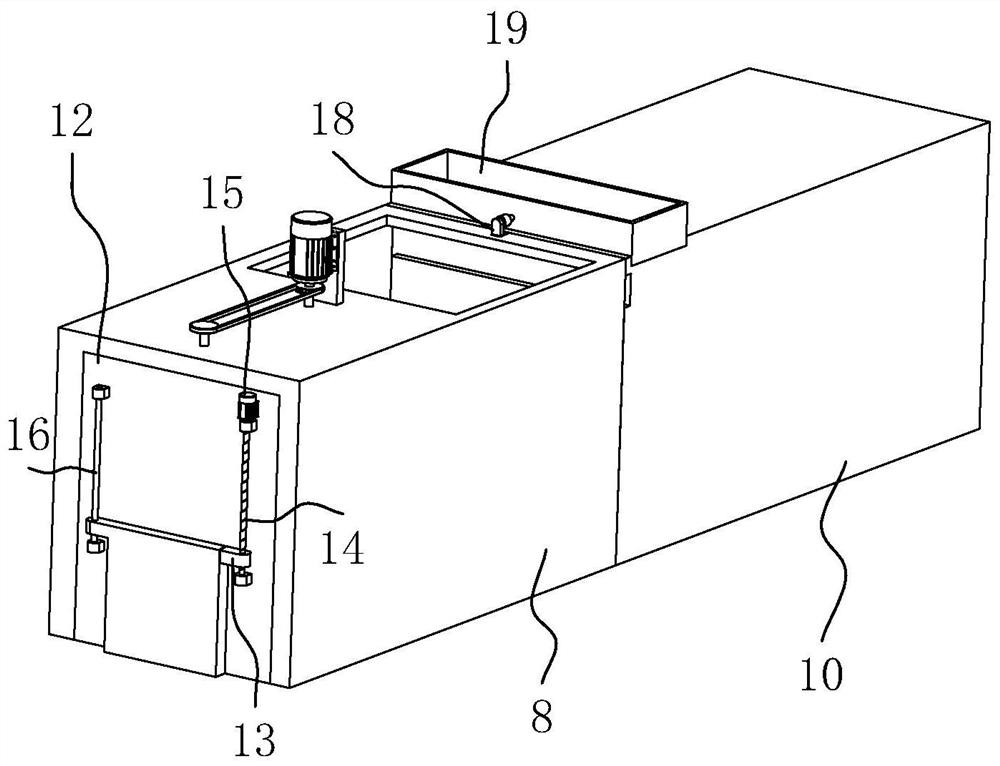

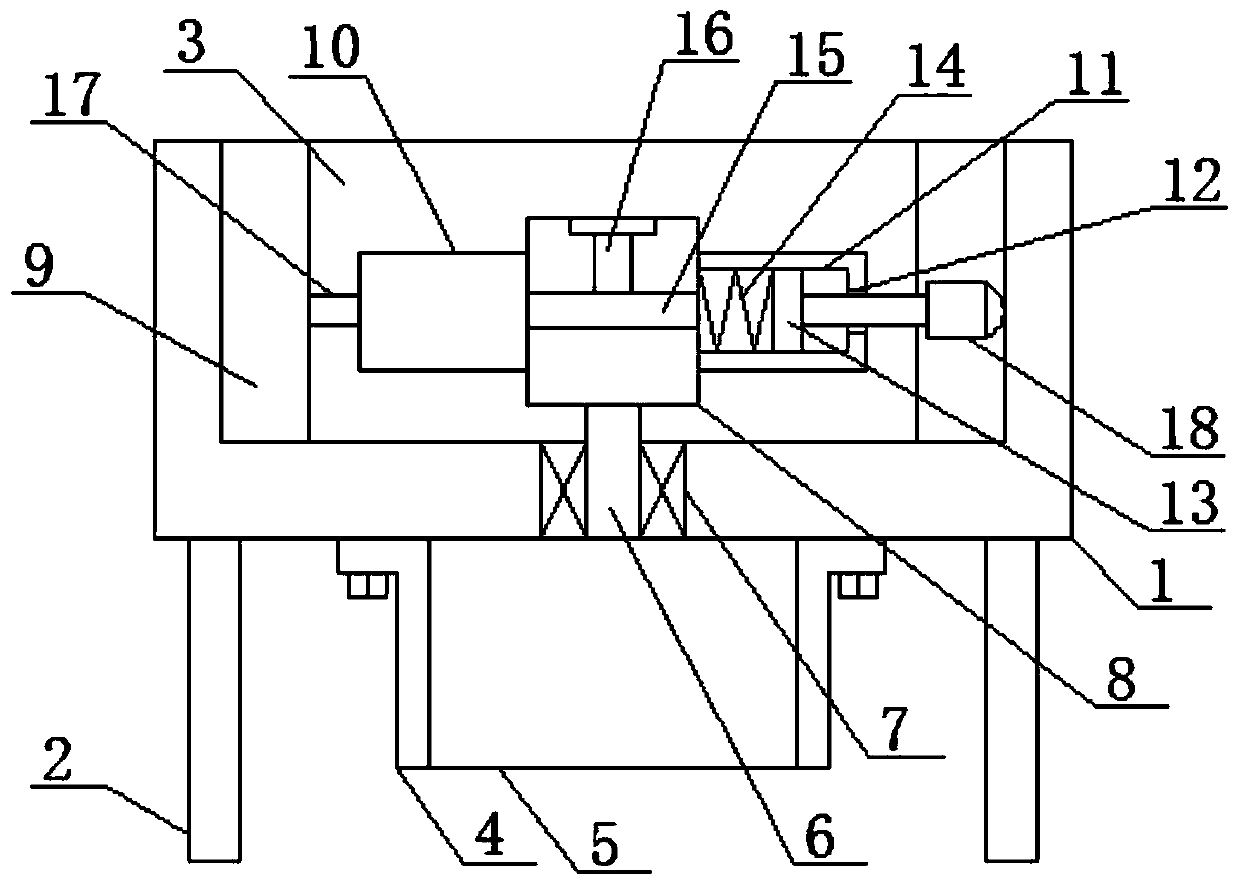

Underwater cast-in-situ bored pile reverse circulation efficient hole-forming construction device and method

PendingCN113464052AAchieve fixationRealize the driving effectEarth drilling toolsUnderwater drillingDrill holeStructural engineering

The invention relates to an underwater cast-in-situ bored pile reverse circulation efficient hole-forming construction device and method, and relates to the field of cast-in-situ bored pile construction. The underwater cast-in-situ bored pile reverse circulation efficient hole-forming construction method comprises the following steps that construction is prepared; a mud pit is manufactured; a slurry pipe and a slurry groove are designed; holes are drilled; slurry reverse circulation work is carried out; and slurry firstly enters a settling pond before entering a slurry pit, and the slurry in the settling pond overflows into the slurry pit. According to the underwater cast-in-situ bored pile reverse circulation efficient hole-forming construction device and method, the slurry pit is arranged on a drilling platform in situ, so that the arrangement of a complex slurry long-distance pipeline is avoided, the construction difficulty is reduced, and the construction efficiency is improved; and a gate is adopted to control slurry feeding and stopping of the slurry pit, meanwhile, a slurry differential reverse circulation system is utilized to enable a water head in a steel casing to get rid of control over the slurry surface of the slurry pit, the hole collapse risk is reduced, and the hole forming efficiency is improved.

Owner:衡阳公路桥梁建设有限公司

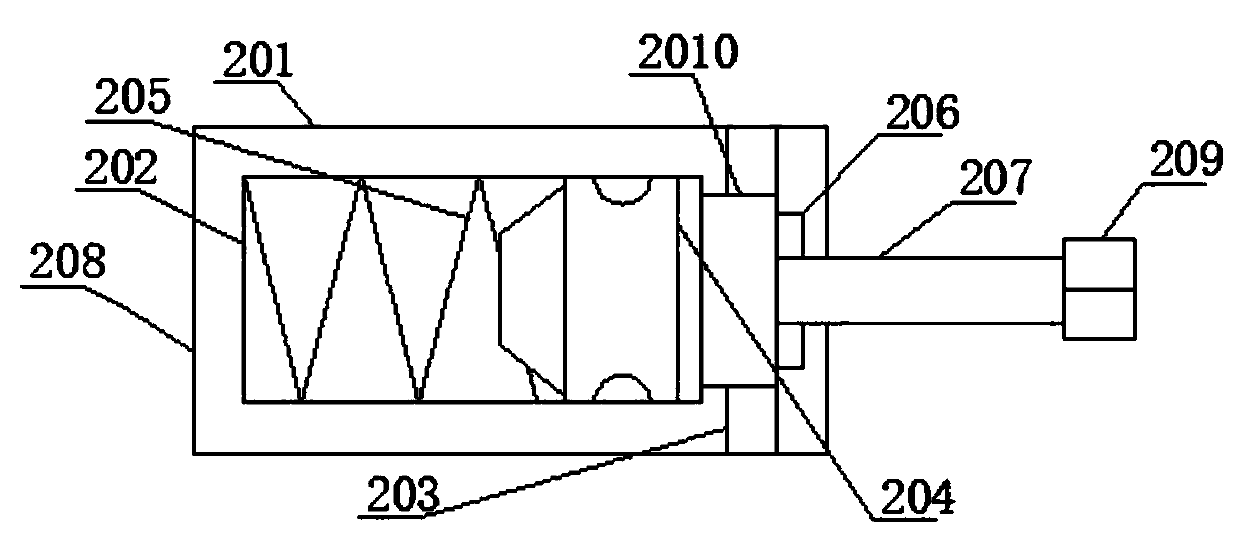

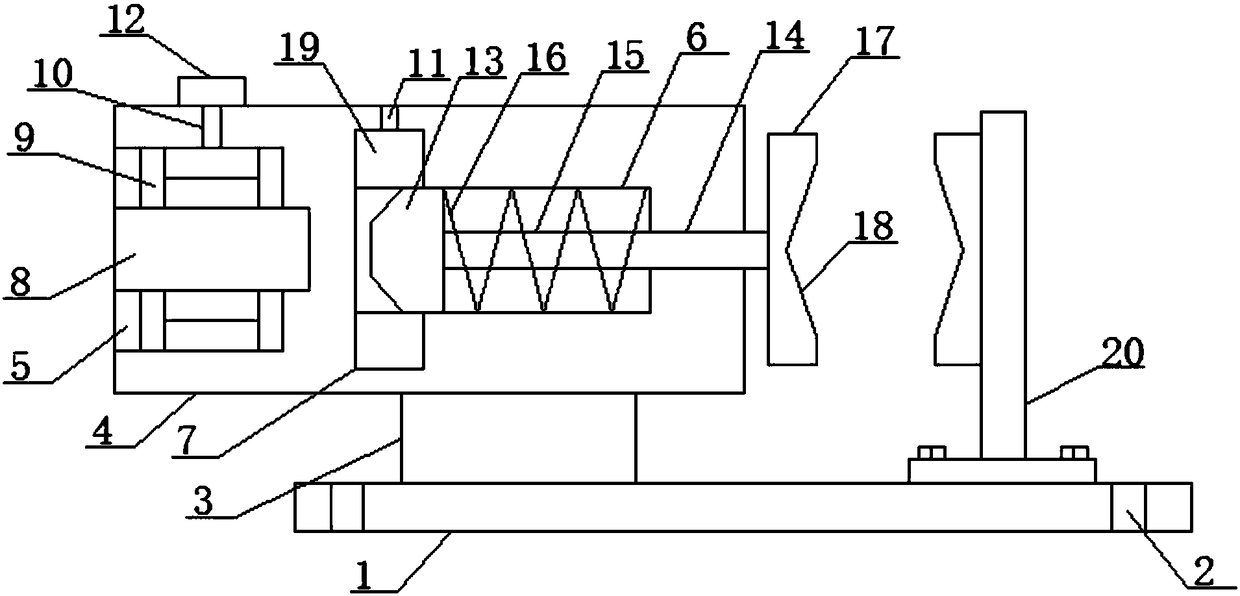

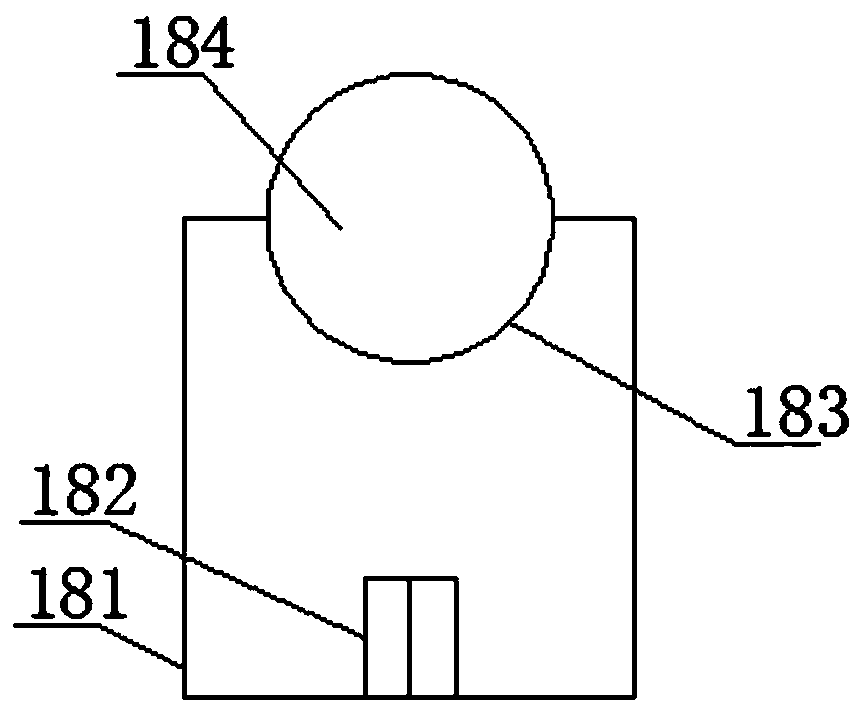

Rotary type rapid inflation device

InactiveCN111075689AAchieve entryRealize the driving effectPositive displacement pump componentsCheck valvesPhysicsPiston

The invention discloses a rotary type rapid inflation device. The rotary type rapid inflation device comprises a main hollow shell with supporting legs installed at the bottom, and a main hollow structure is arranged in the center of the main hollow shell. According to the rotary type rapid inflation device, a rotary driving motor is used for carrying out necessary driving, then the collision telescopic principle between multiple triangular protrusion structures and a rod body is combined, multiple times of air supplement can be achieved when a main shaft of the driving motor rotates by one circle, and therefore the rapid inflation function is achieved, the efficiency is high, the device is provided with a piston valve sealed space movable type air one-way driving mechanism, one-way flowing of internal air can be achieved while moving is realized, so that air entering is achieved, in addition, the device is provided with a spherical body sliding friction movable type rod body installation mechanism which can be installed at the end of the rod body and meanwhile achieves rolling between a touch surface, therefore, energy loss is reduced, kinetic energy is converted into pressure during inflation, and a driving effect is achieved.

Owner:王欣欣

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com