Double-row chain transmission elliptical track printing device and application method thereof

An elliptical track and transmission track technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of poor transmission accuracy of the platen, forming a resultant force, difficult connecting rods, etc., achieving good accuracy, ensuring no shaking, ensuring The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

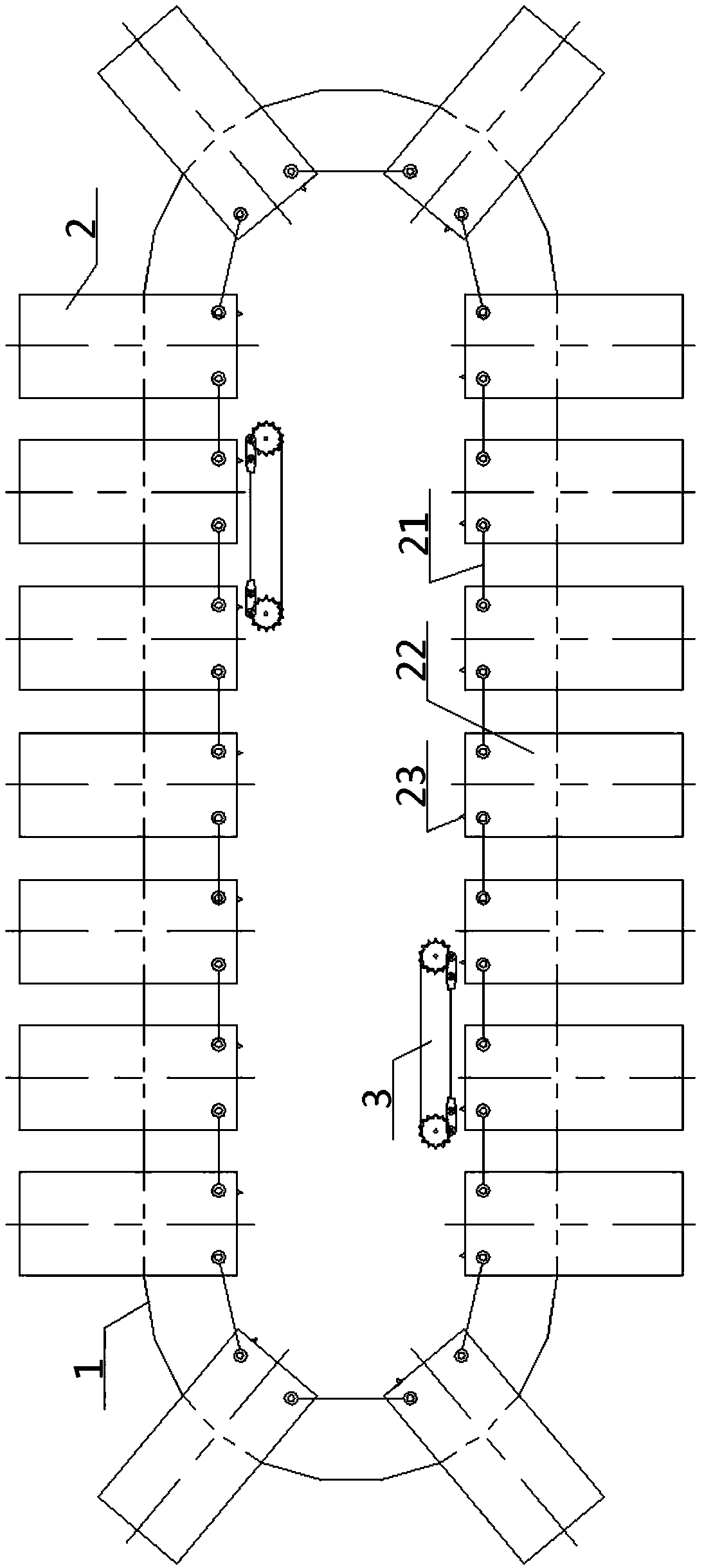

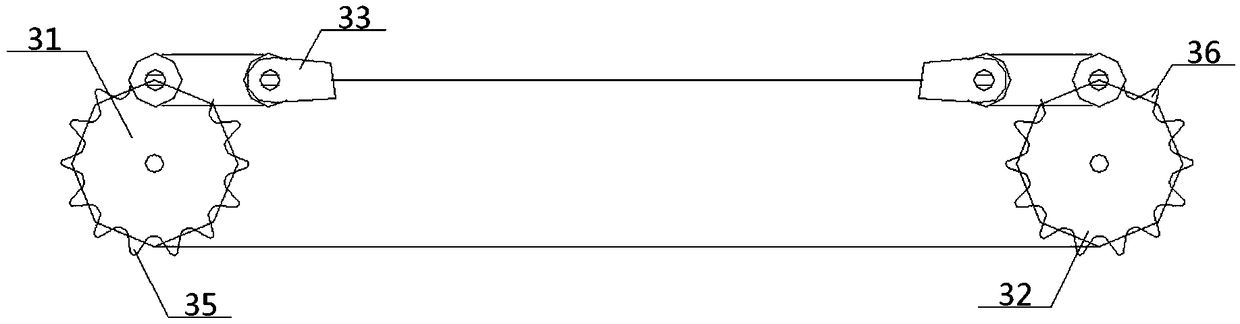

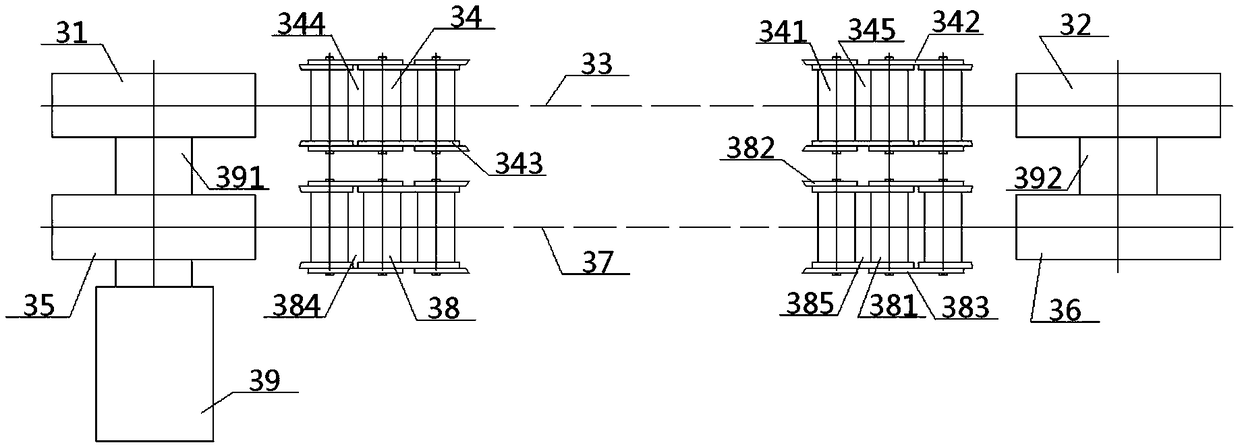

[0048] see Figure 1 to Figure 5 , an elliptical track printing device with double-row chain transmission, comprising a drive track 1 and a plurality of platens 2 with the same structure, the drive track 1 is a closed ring structure, the top of the drive track 1 and the bottom of the platen 2 Carry out sliding fit, and be connected by connecting rod 21 between adjacent platens 2; The elliptical track printing device of described double-row chain transmission also includes at least one platen driving device 3, and this platen driving device 3 is positioned at the transmission The inner side of the track 1; the platen driving device 3 includes an upper left sprocket 31, an upper right sprocket 32 and an upper chain 33, and the upper left sprocket 31 and the upper right sprocket 32 are smooth toothless sprockets, The left and right ends of the upper chain 33 are respectively wound around the upper left sprocket 31 and the upper right sprocket 32; The top and bottom ends of t...

Embodiment 2

[0051] Basic content is the same as embodiment 1, the difference is:

[0052] The platen driving device 3 also includes a lower left sprocket 35, a lower right sprocket 36 and a lower chain 37, and the left and right ends of the lower chain 37 are wound around the outer circumference of the lower left sprocket 35 and the lower right sprocket 36 , the lower left sprocket 35 and the lower right sprocket 36 are toothed sprockets, the middle part of the upper left sprocket 31 is connected with the driving motor 39 by the drive shaft 391, and the middle part of the drive shaft 391 is covered with the lower left sprocket 35, Upper left sprocket wheel 31, lower left sprocket wheel 35 are arranged parallel to each other up and down, the middle part of upper right sprocket wheel 32 is connected with the middle part of lower right sprocket wheel 36 by linkage shaft 392, upper right sprocket wheel 32, lower right sprocket wheel 36 up and down arranged parallel to each other.

[0053] Firs...

Embodiment 3

[0055] Basic content is the same as embodiment 2, the difference is:

[0056] The top of the upper chain shaft 341 is fixedly connected with the upper upper shaft plate 346, and the bottom end of the upper chain shaft 341 is fixedly connected with the upper and lower shaft plates 347. The group plates 342 are movably connected, and the bottom ends of the upper chain shaft group 34 are movably connected with the upper and lower group plates 343 . The lower chain 37 is an annular structure, including a plurality of lower chain shaft groups 38 with the same structure, and the top and bottom ends of the adjacent lower chain shaft groups 38 are respectively connected by the lower upper group plate 382 and the lower lower group plate 383, There is a lower group gap 384 between adjacent lower chain shaft groups 38. One lower chain shaft 381 includes two mutually parallel lower chain shafts 381. The lower chain shafts 381 are vertical columnar structures. The same group of lower chain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com