Patents

Literature

61results about How to "Realize the feeding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

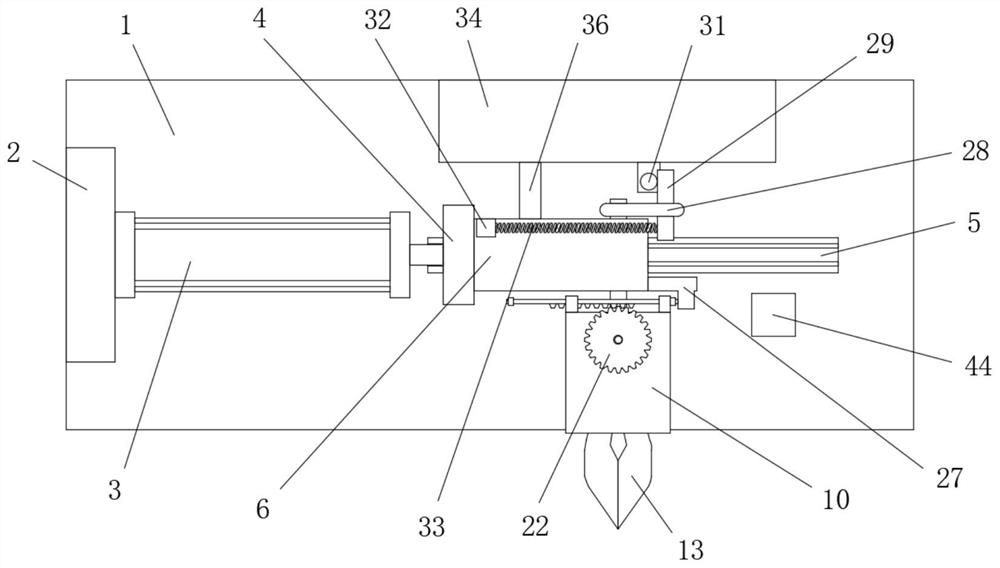

Medical cotton swab medicine applying equipment capable of achieving quick taking and using

PendingCN112807558ARealize the feeding effectRealize the effect of pushing back and forthRotary stirring mixersTransportation and packagingBiotechnologyBiomedical engineering

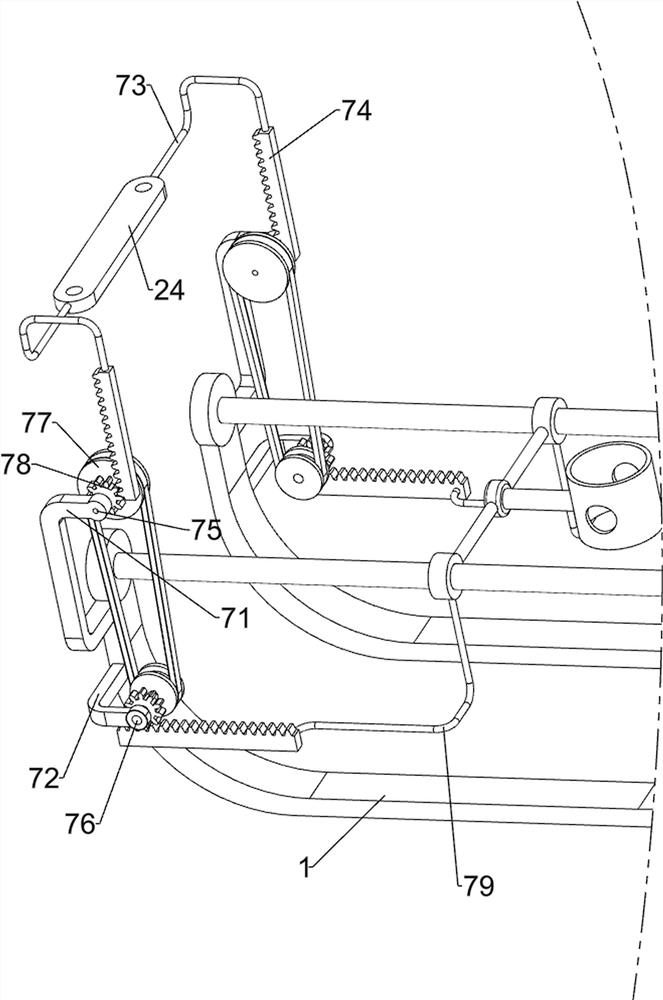

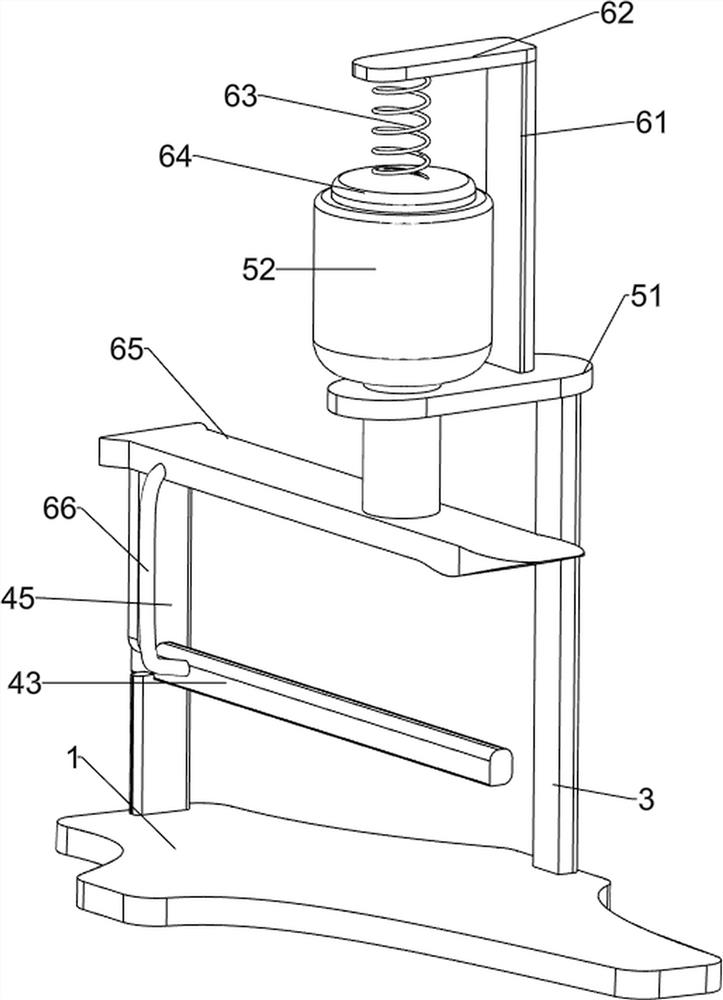

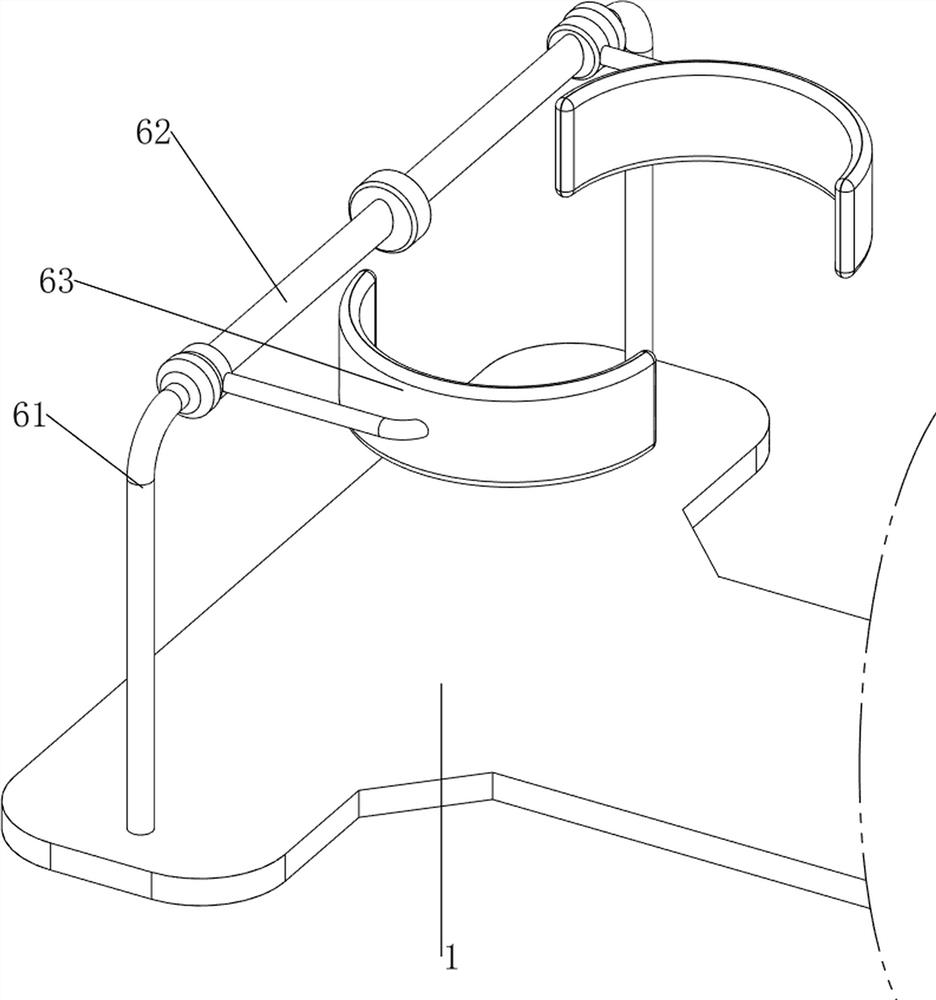

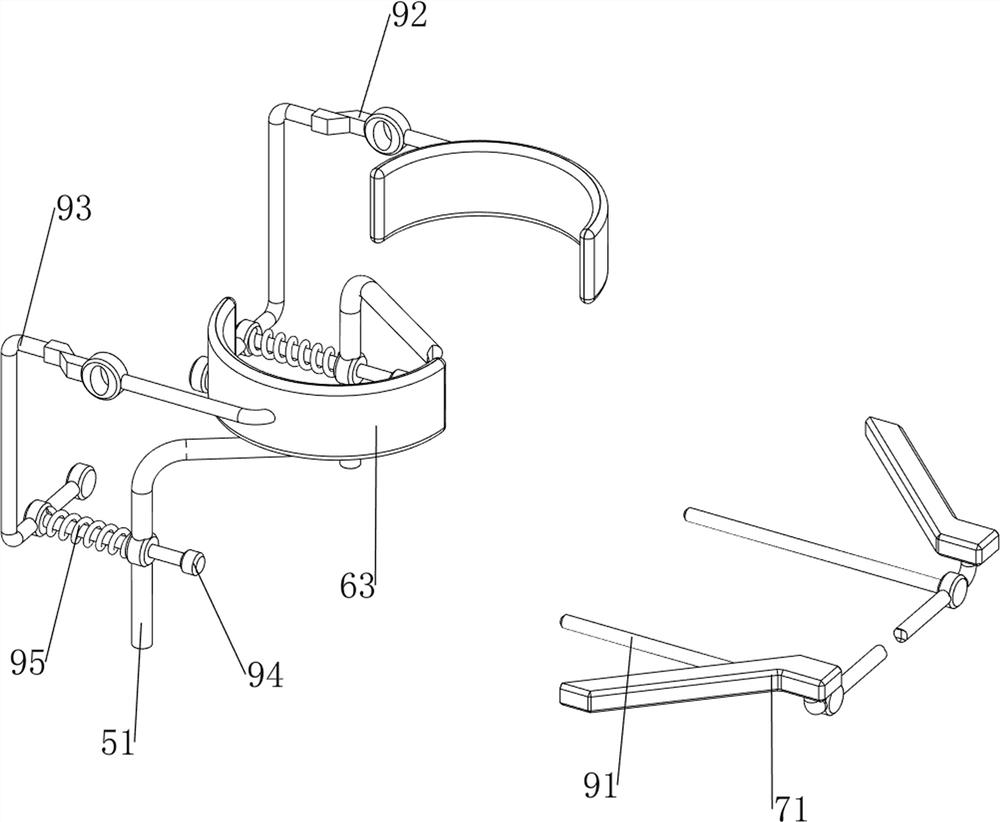

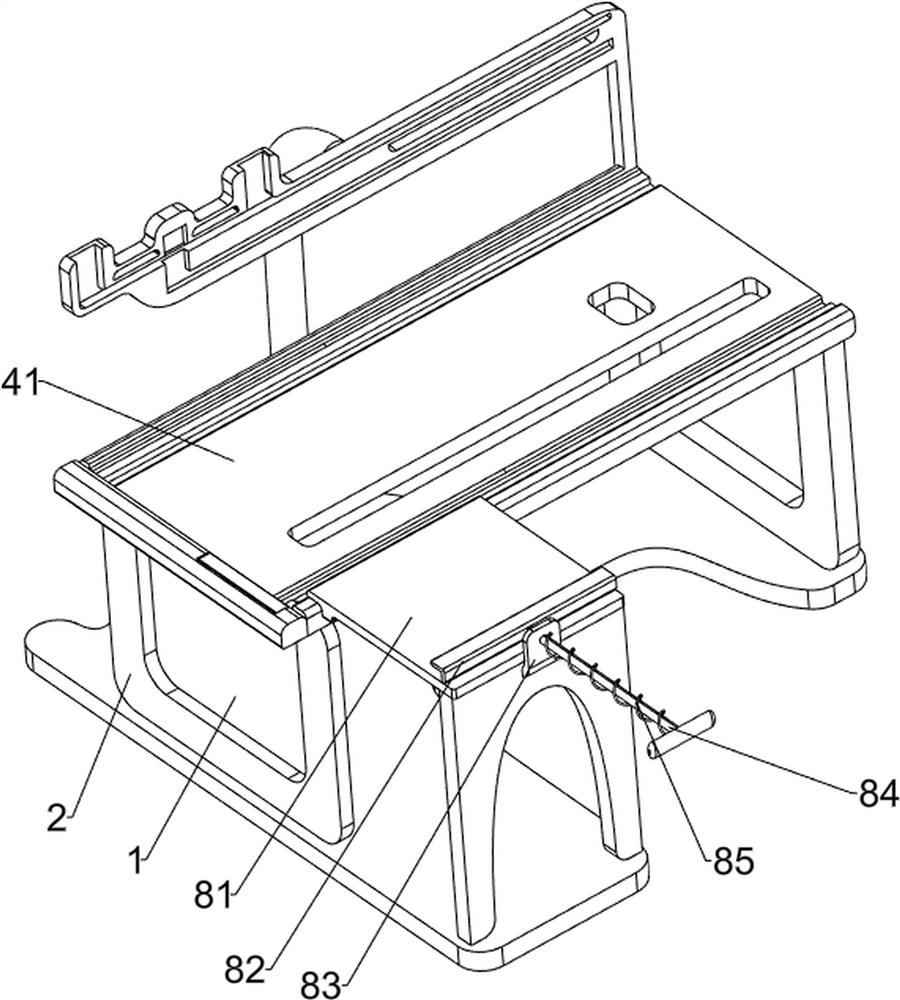

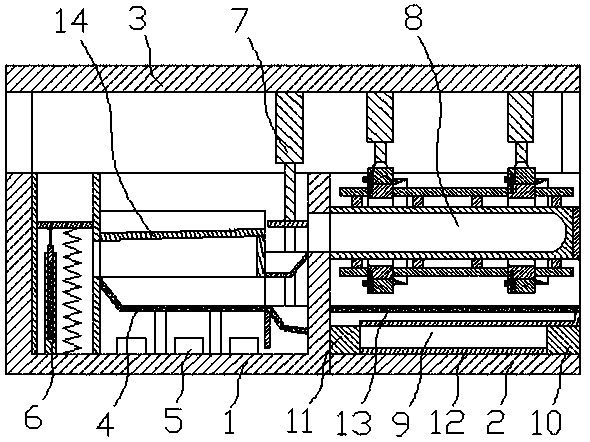

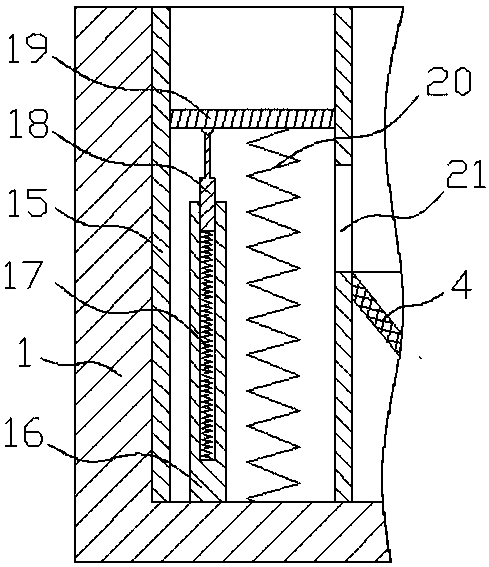

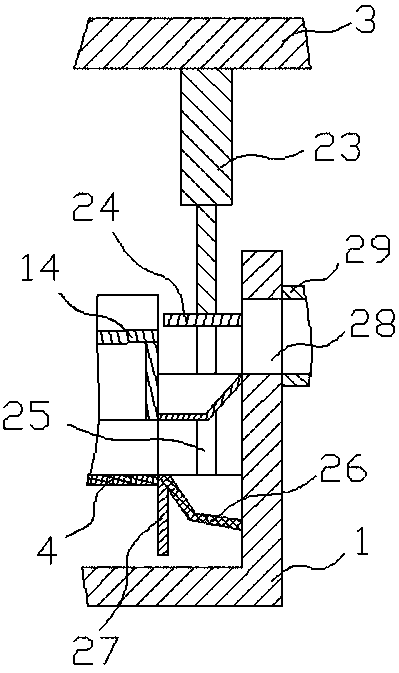

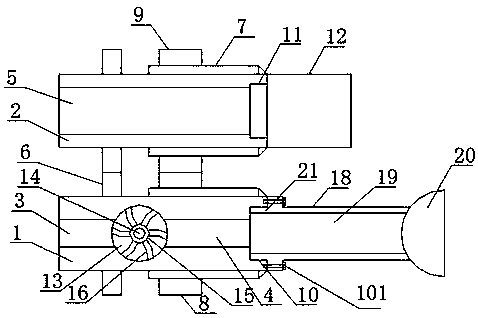

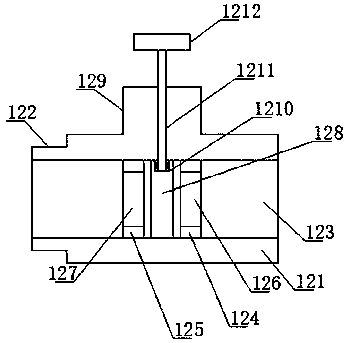

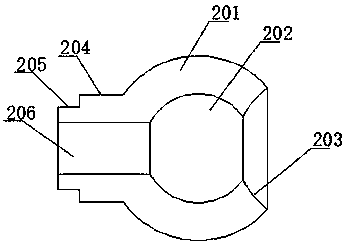

The invention relates to cotton swab medicine applying equipment, in particular to medical cotton swab medicine applying equipment capable of achieving rapid taking and using. The medical cotton swab medicine applying equipment capable of achieving rapid taking and using is capable of automatically applying medicine, convenient to operate and capable of automatically supplying liquid medicine. The medical cotton swab medicine applying equipment comprises a bottom plate, supporting columns, a feeding mechanism, a pushing mechanism, a rotating mechanism and a medicine applying mechanism, wherein the supporting columns are arranged at the top of the bottom plate; the feeding mechanism is arranged between the tops of the supporting columns on the rear side; the pushing mechanism is arranged between the top of the supporting column on the front side and the lower side of the feeding mechanism; and the rotating mechanism and the medicine applying mechanism are arranged on the pushing mechanism. After a first cotton swab is taken out through a rotating mechanism component, when another cotton swab needs to be taken out, a push rod is manually pulled to move forwards, a contraction spring is compressed, the rotating mechanism can take out the cotton swab again, and the feeding effect is achieved.

Owner:黄正豪

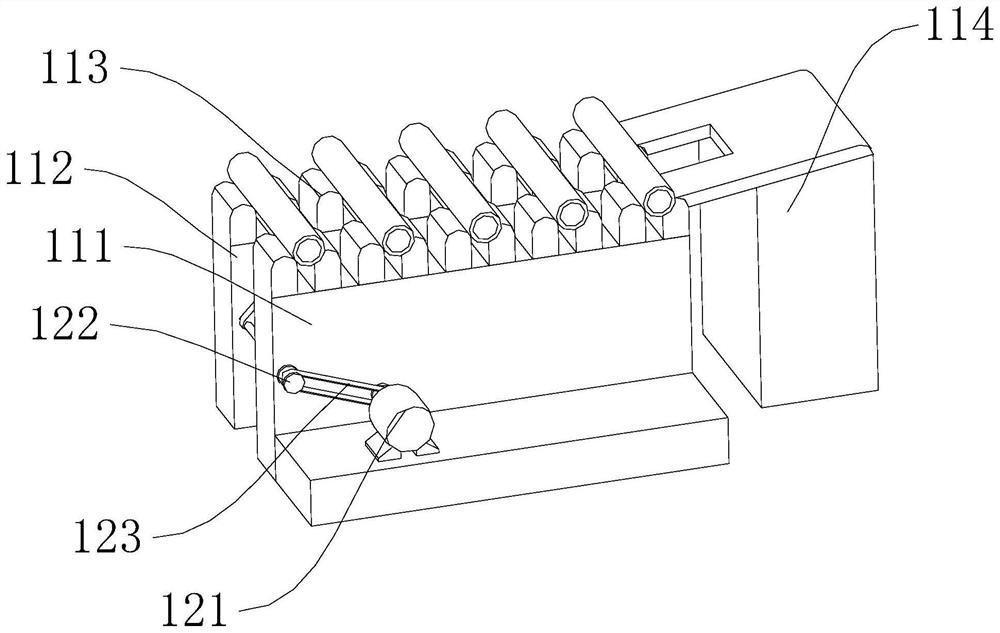

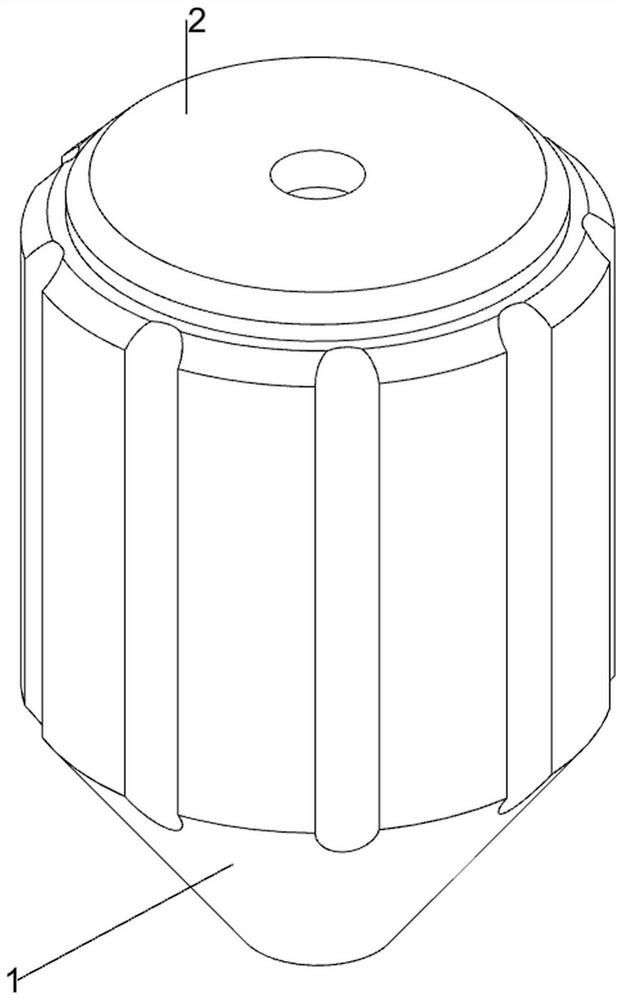

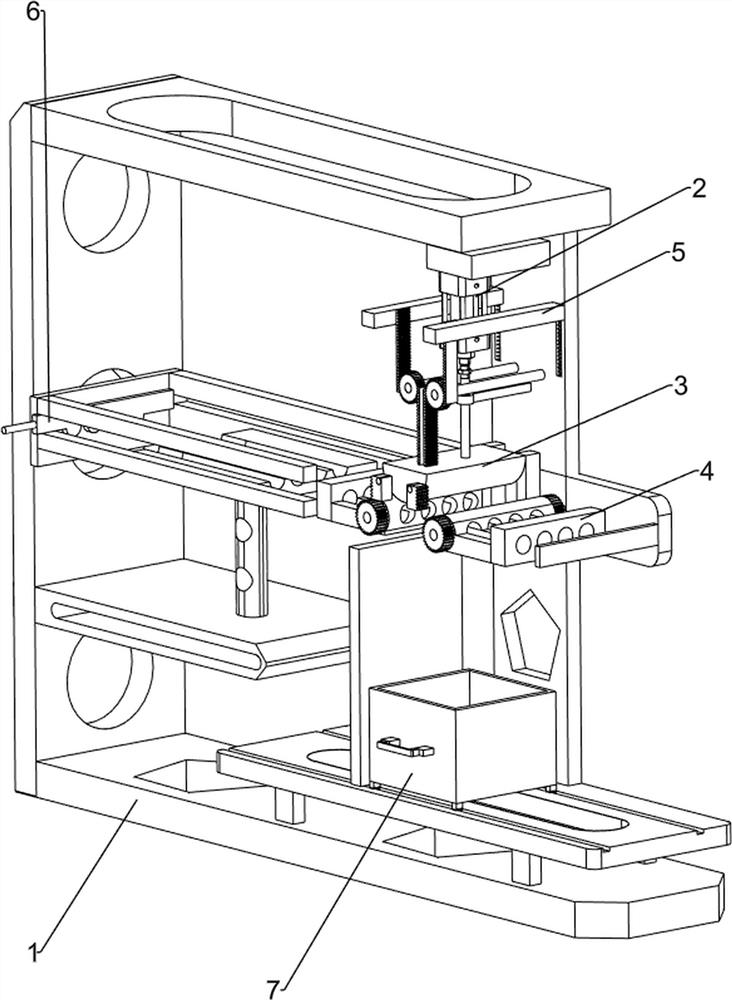

Multifunctional full-automatic rotary material taking and feeding mechanism

The invention belongs to the technical field of machining, and particularly relates to a multifunctional full-automatic rotary material taking and feeding mechanism. For the problems that in the priorart, the operation is tedious, the energy consumption is high, the manufacturing cost and the maintenance cost are greatly increased, the expansion of the scale of an enterprise is not facilitated, and meanwhile, the machining precision is not high due to the fact that an independent system and an independent power source are adopted for independently controlling each operation procedure, now thescheme is proposed as follows: the multifunctional full-automatic rotary material taking and feeding mechanism comprises a base, wherein a sliding rail is arranged at the top of the base; a mountingplate is fixedly connected to one side of the top of the base; and a telescopic cylinder is fixedly mounted at one side, close to the sliding rail, of the mounting plate. The clamping, material taking, feeding and rotating operation procedures can be achieved at the same time through one cylinder, so that an operation system is simplified, the operation mode is simple, the energy consumption is low, the manufacturing cost and the maintenance cost are greatly reduced, the expansion of the scale of the enterprise is facilitated, meanwhile, the machining precision is improved, and the developmentprospect is wide.

Owner:翁宗享

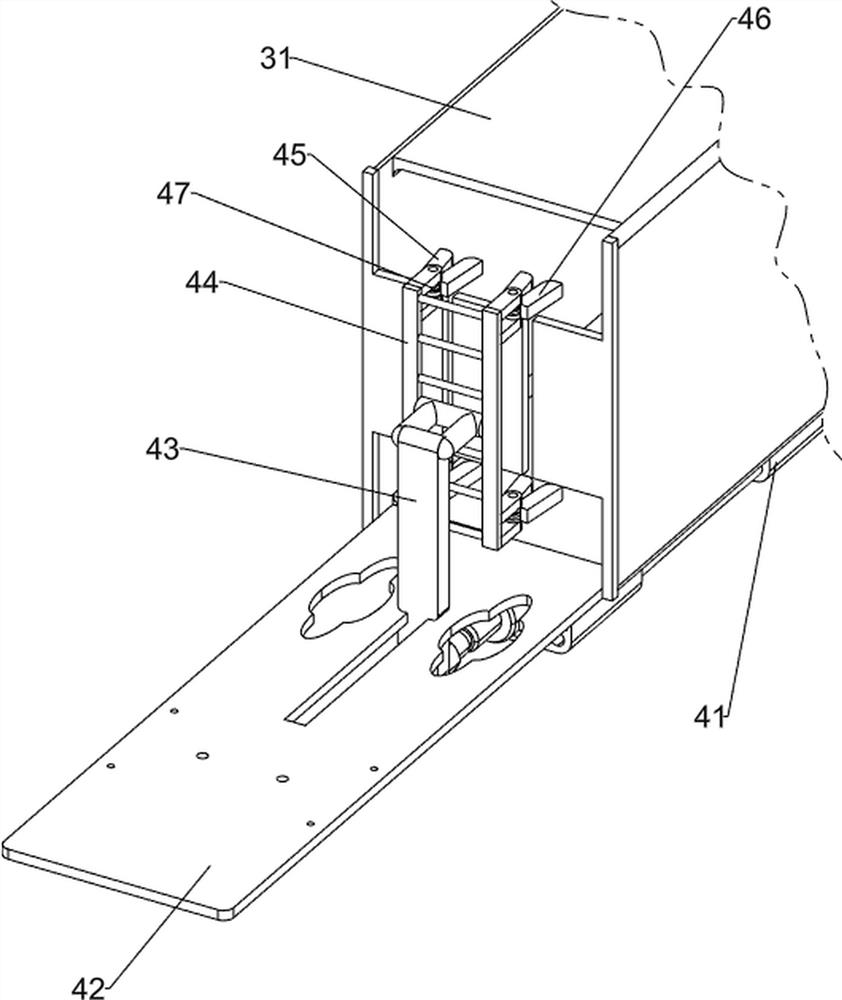

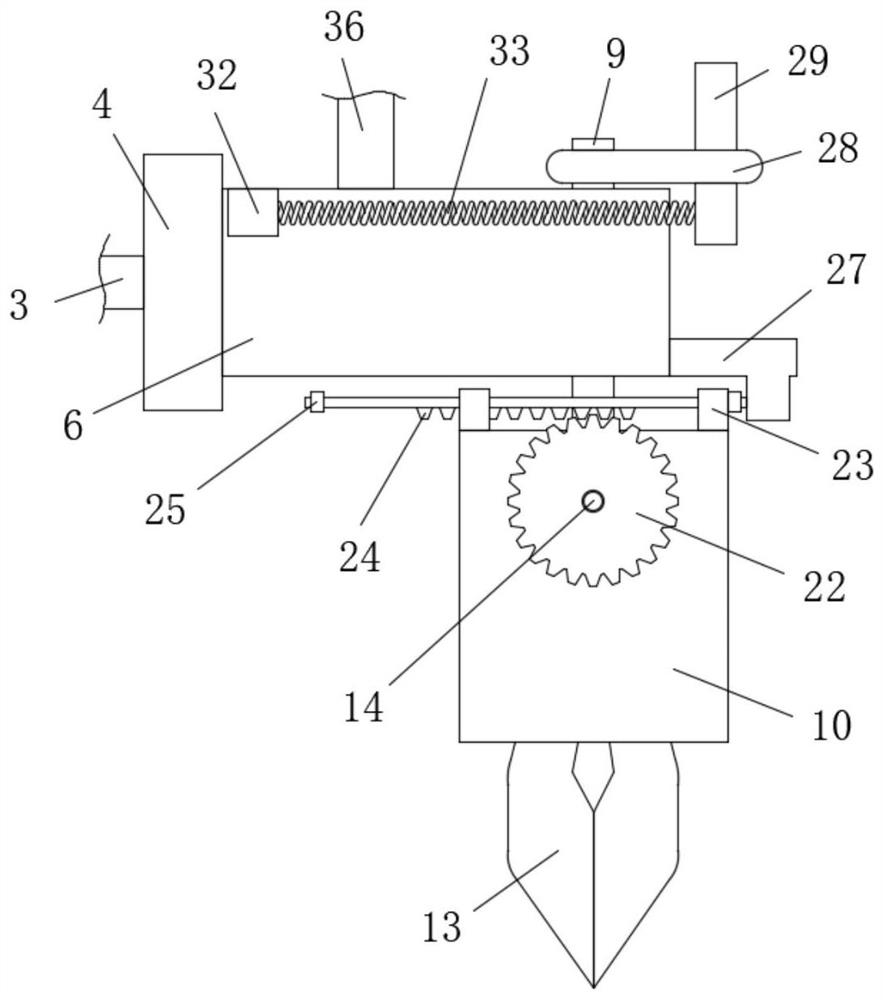

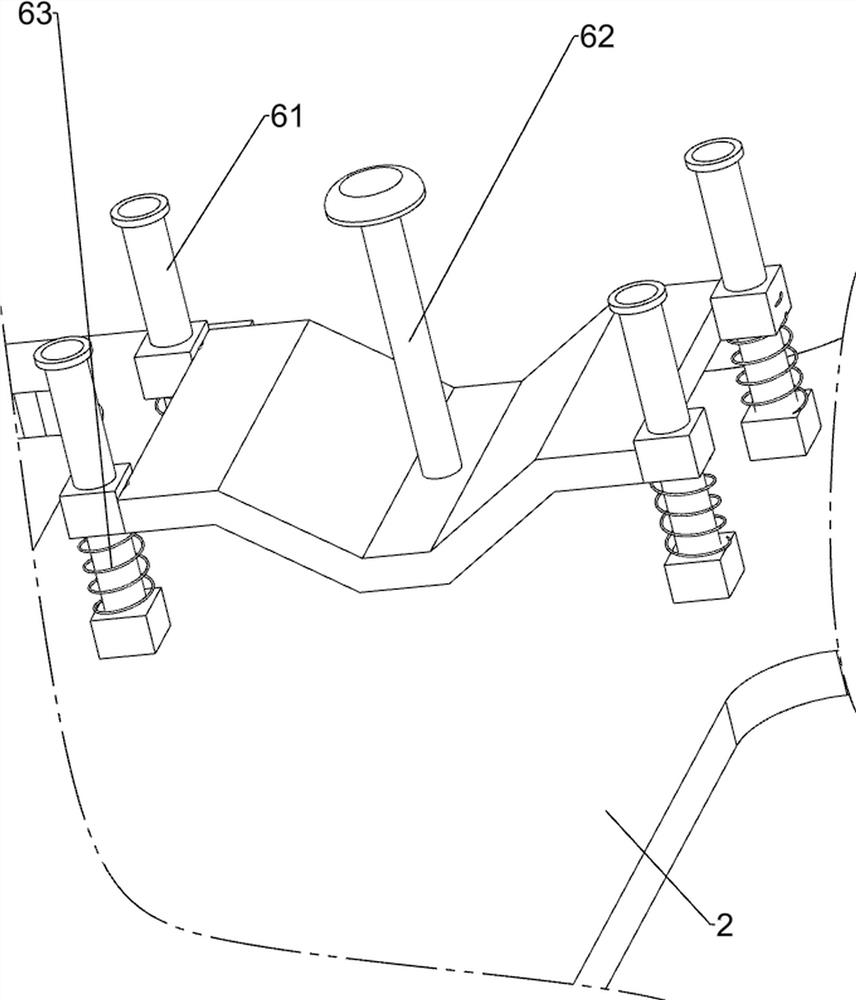

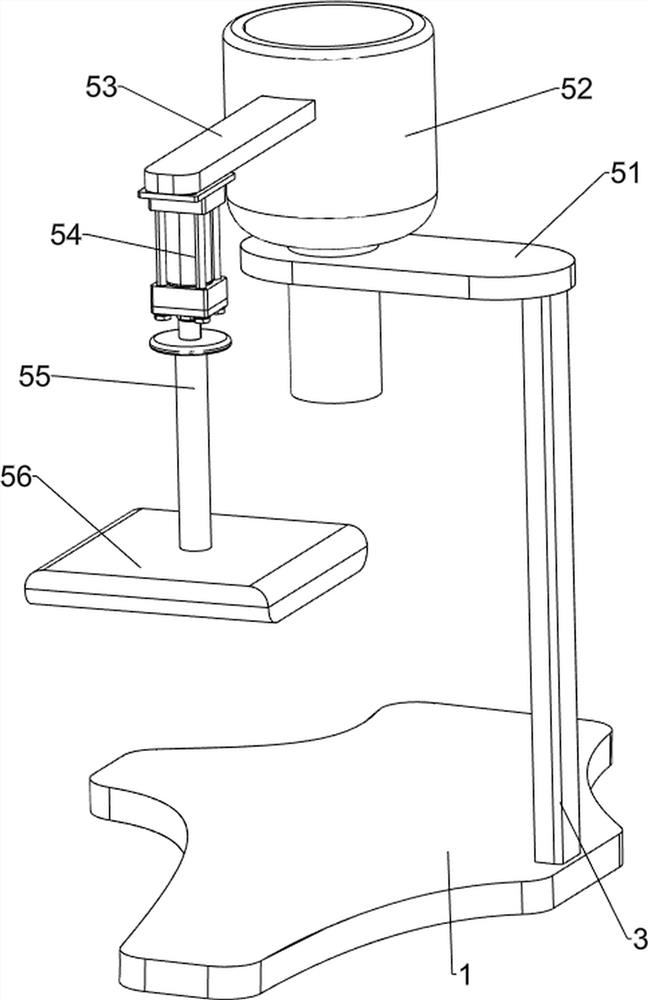

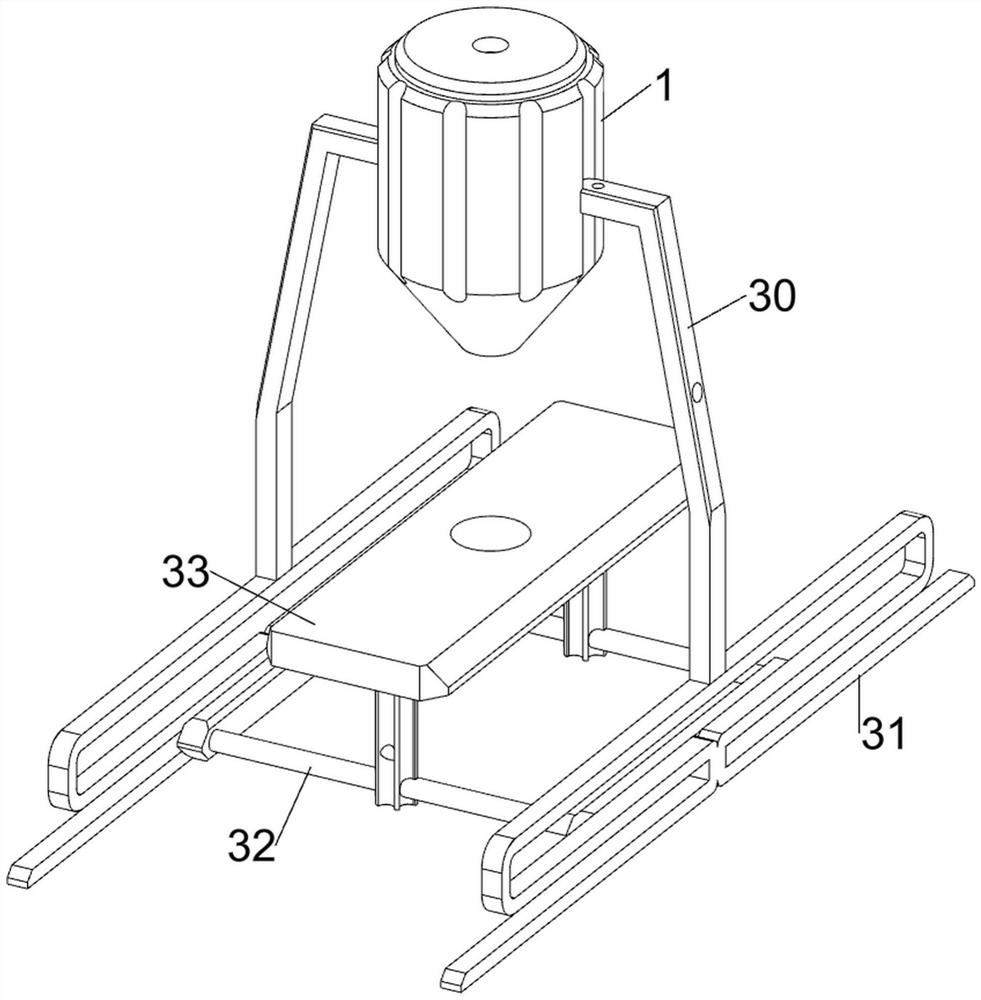

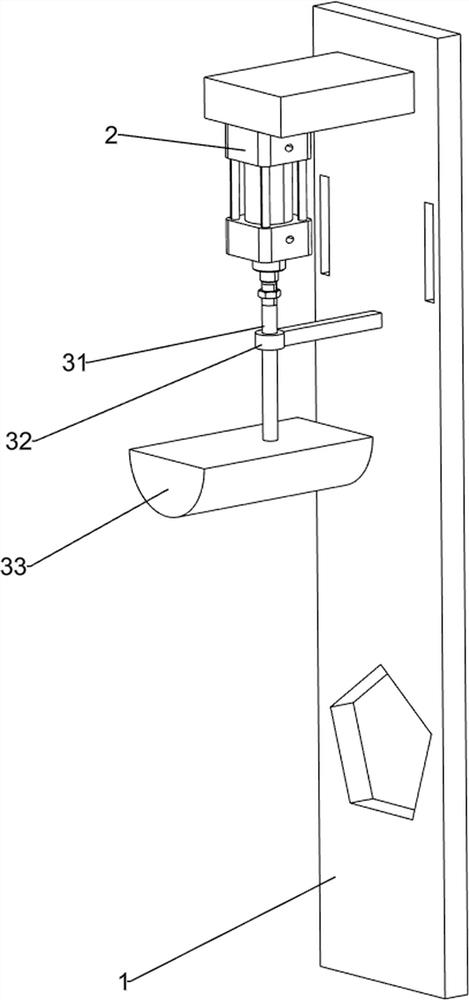

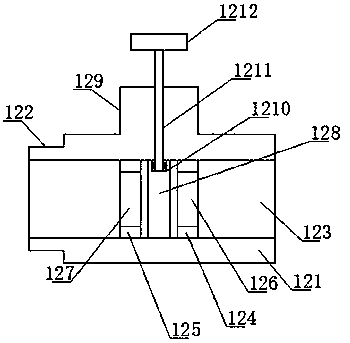

Pearl perforating equipment for jewelry processing

PendingCN113276287AControl altitudeAchieve drilling effectWorking accessoriesStone-like material working toolsDrill holeDrill bit

The invention relates to perforating equipment, in particular to pearl perforating equipment for jewelry processing. According to the pearl perforating equipment for jewelry processing, automatic multi-time perforating and automatic feeding are achieved, and operation is convenient. The pearl perforating equipment for jewelry processing comprises a base, a feeding mechanism and a clamping and positioning mechanism, wherein a drilling mechanism is arranged on the rear side of the base; the feeding mechanism is arranged on the upper front side of the base; and the clamping and positioning mechanism is arranged on the base. The descending height of a drill bit is controlled by controlling the stretching length of a telescopic rod of an air cylinder, then a user places a pearl below the drill bit, the drill bit punches the pearl, and the drilling effect is achieved; and by pushing a sliding support backwards, the sliding support moves backwards, so that a material containing box is driven to move backwards, a supporting plate and a check block are driven to move backwards, pearls are located below the drill bit, and the feeding effect is achieved.

Owner:董智扬

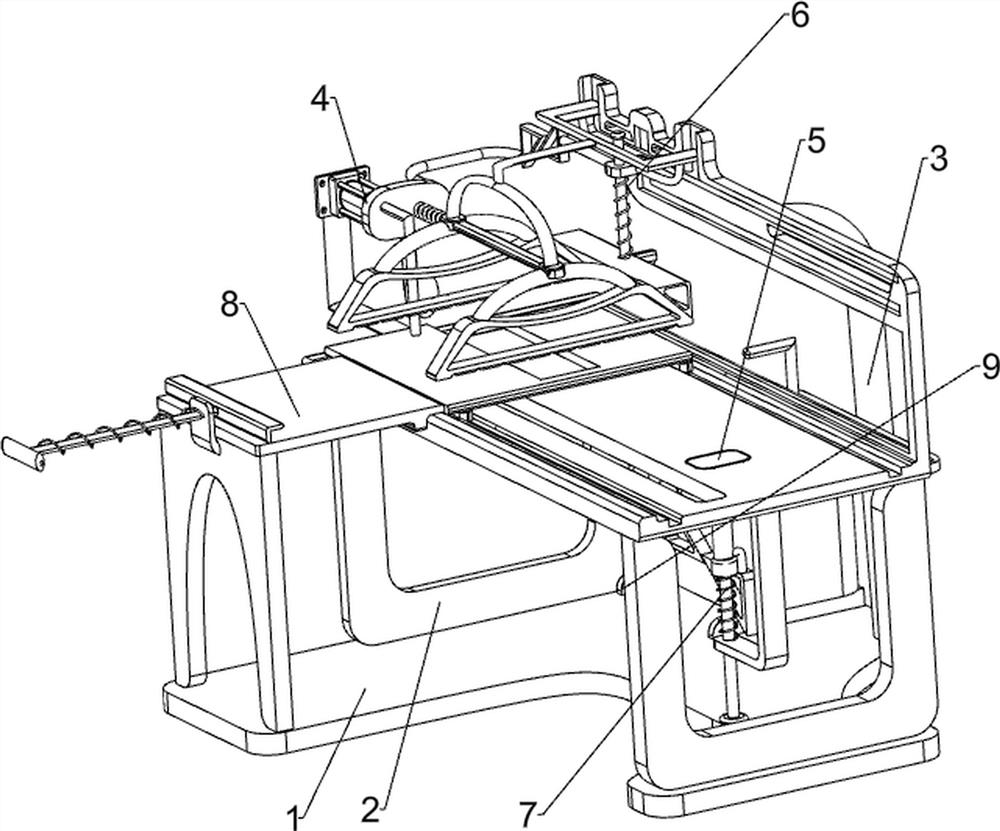

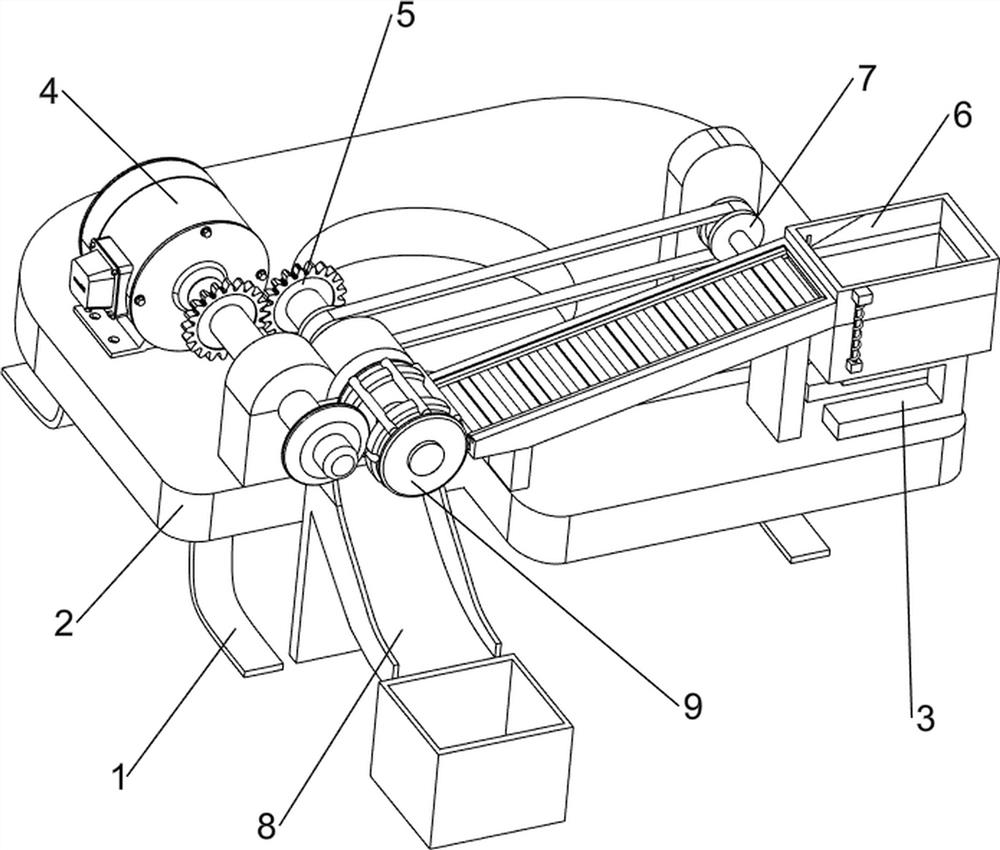

Cooling fin self-punching equipment for CPU radiator

ActiveCN112605246ARealize the operationRealize the feeding effectMetal-working feeding devicesEnergy efficient computingPunchingHeat sink

The invention relates to punching equipment, in particular to cooling fin self-punching equipment for a CPU radiator. According to the cooling fin self-punching equipment for the CPU radiator, the two hands are liberated, and the productivity is improved. The cooling fin self-punching equipment for the CPU radiator comprises a first supporting frame, second supporting frames, a discharging frame, third connecting supporting frames and a punching mechanism. The first supporting frame is arranged on the upper portion of a first supporting base. The second supporting frames are symmetrically arranged on the two sides of the first supporting base. The discharging frame is arranged on the first supporting frame. The two sides of the discharging frame are connected with the third connecting supporting frames, and the third connecting supporting frames are connected with the second supporting frames. The punching mechanism is arranged on the first supporting frame in a sliding manner. According to the cooling fin self-punching equipment, a cooling fin is placed under a punching cutter device by people, then a first round block rod is manually moved downwards, the punching cutter device is made to move downwards, and a first spring is compressed.

Owner:山东西努克机械科技有限公司

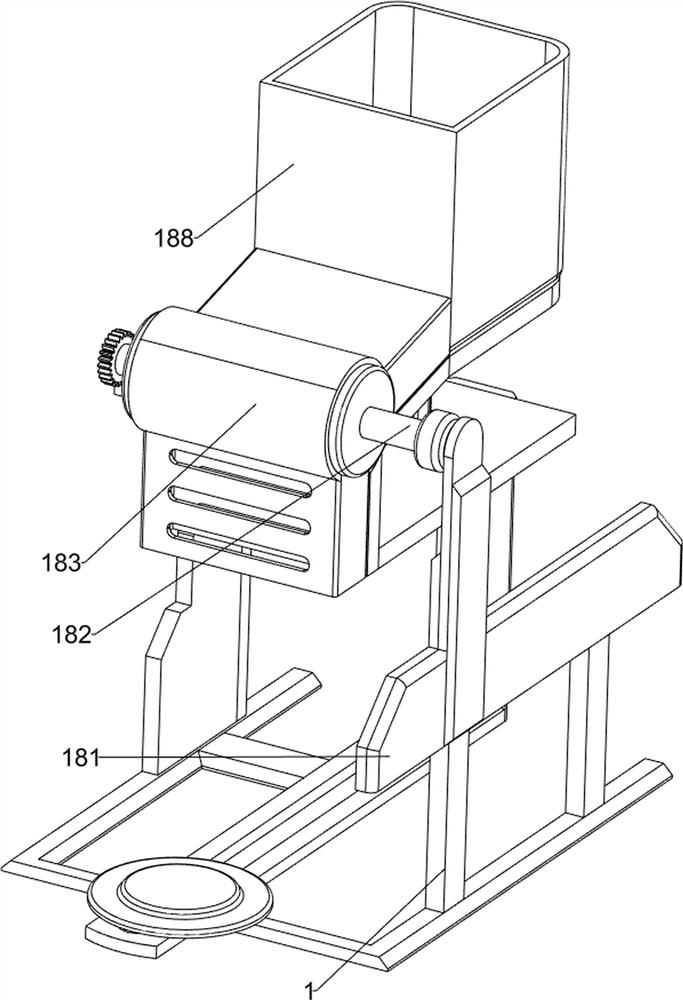

Quick flour subpackaging device for food processing

ActiveCN113044258ARealize the blanking effectRealize the feeding effectWrapper twisting/gatheringSolid materialSpiral bladeElectric machinery

The invention relates to a subpackaging device, in particular to a quick flour subpackaging device for food processing. The quick flour subpackaging device for food processing is convenient to package, easy to operate and wide in applicability. The quick flour subpackaging device for food processing comprises supporting legs and a workbench, and the workbench is arranged among the tops of the four supporting legs. A mounting frame is included and is arranged at the top of the workbench. A first discharging mechanism is included and is arranged at the top of the mounting frame. A second discharging mechanism is included and is arranged on the inner wall of the workbench. According to the quick flour subpackaging device for food processing, an output shaft of the motor rotates to drive a transmission shaft to achieve transmission, so that spiral blades are driven to rotate, the spiral blades can enable flour to fall off onto a bag through a discharging opening, and the discharging effect is achieved. And a torsion spring is reset to drive a second rotating shaft to rotate reversely, so that a rotating disc is driven to swing towards the inner side, people pull out the bags from the workbench intermittently, and the bag discharging effect is achieved.

Owner:山东咏禾食品有限公司

Steel plate surface painting equipment for metal processing

PendingCN112742648ARealize the clamping effectRealize the blanking effectGrinding carriagesSpray boothsSteel platesMetal working

The invention relates to painting equipment, in particular to steel plate surface painting equipment for metal processing. According to the steel plate surface painting equipment for metal processing, discharging is uniform, and automatic painting and automatic stirring painting are achieved. The steel plate surface painting equipment for metal processing comprises a first fixing plate, a collecting box, a clamping mechanism and a discharging mechanism; rails are arranged at the left side and the right side of the first fixing plate; the collecting box is arranged at the upper middle part of the first fixing plate; the clamping mechanism is arranged at the upper part of the collecting box; and the discharging mechanism is arranged on the first fixing plate. According to the steel plate surface painting equipment, by loosening clamping blocks and resetting a first spring, the two clamping blocks are driven to move oppositely, the clamping blocks make contact with a steel plate, the steel plate is clamped by the clamping blocks, and the clamping effect is achieved.

Owner:周成建

Extrusion type modified starch grinding device

PendingCN113083414ARealize the effect of pressing down and crushingGrind evenlyGrain treatmentsComposite materialManufacturing engineering

The invention relates to a grinding device, in particular to an extrusion type modified starch grinding device. The extrusion type modified starch grinding device can improve the production efficiency and has the function of grinding while extruding. The extrusion type modified starch grinding device comprises a first fixing plate, a first supporting plate, a first discharging frame, a pressing mechanism and a material pushing mechanism; the first fixing plate is provided with the first supporting plate; the first discharging frame is arranged on the first supporting plate; the pressing mechanism is arranged on the first discharging frame; and the material pushing mechanism is arranged on the first fixing plate. According to the extrusion type modified starch grinding device, when first connecting rods are pushed by hands to move downwards, first springs are driven to be stretched, and then a grinding plate is driven to move downwards, so that modified starch in the first discharging frame is extruded and ground, and the effects of pressing and grinding are achieved.

Owner:吁红

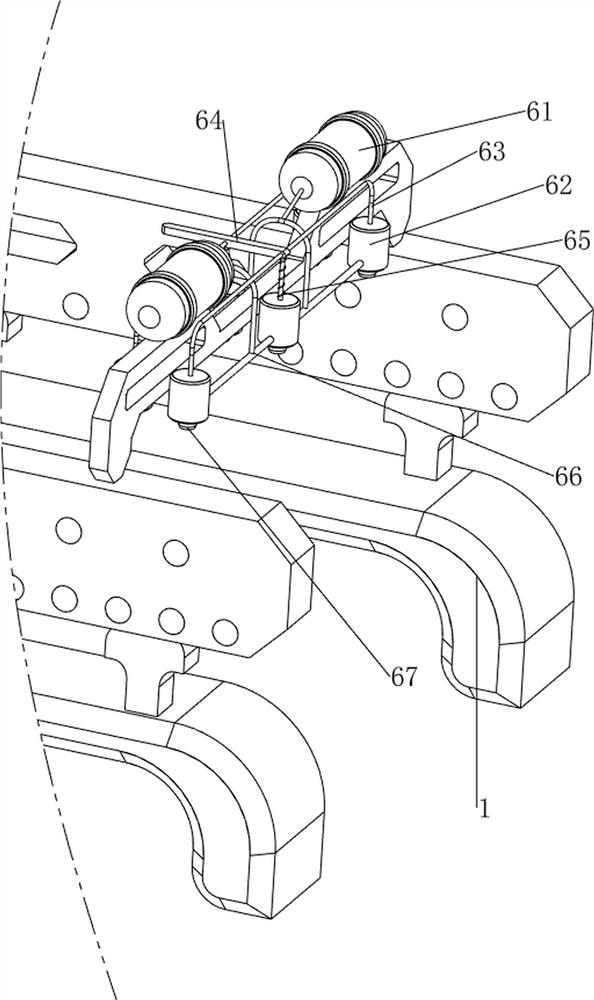

Medical infusion tube smashing treatment device

PendingCN113058971AAchieving a shattering effectRealize intermittent feeding effectSolid waste disposalMagnetic separationSurgeryBiomedical engineering

The invention relates to a smashing treatment device, in particular to a medical infusion tube smashing treatment device. The medical infusion tube smashing treatment device is good in control effect and capable of achieving automatic cutting-off and automatic smashing. The medical infusion tube smashing treatment device comprises a bottom plate, a guide frame, a cutting assembly and a cutting assembly, wherein a first supporting frame is arranged on the left side of the bottom plate, the guide frame is arranged at the right part of the rear side of the bottom plate, the cutting assembly is arranged on the upper portion of the first supporting frame, and the smashing assembly is arranged on the right portion of the front side of the bottom plate. According to the medical infusion tube smashing treatment device, a second cam is in contact fit with a tool rest, so that the tool rest is driven to move downwards, then a second tool is driven to move downwards, a first spring is compressed, the second tool crushes an infusion tube on a workbench, and the crushing effect is achieved.

Owner:赖仕萌

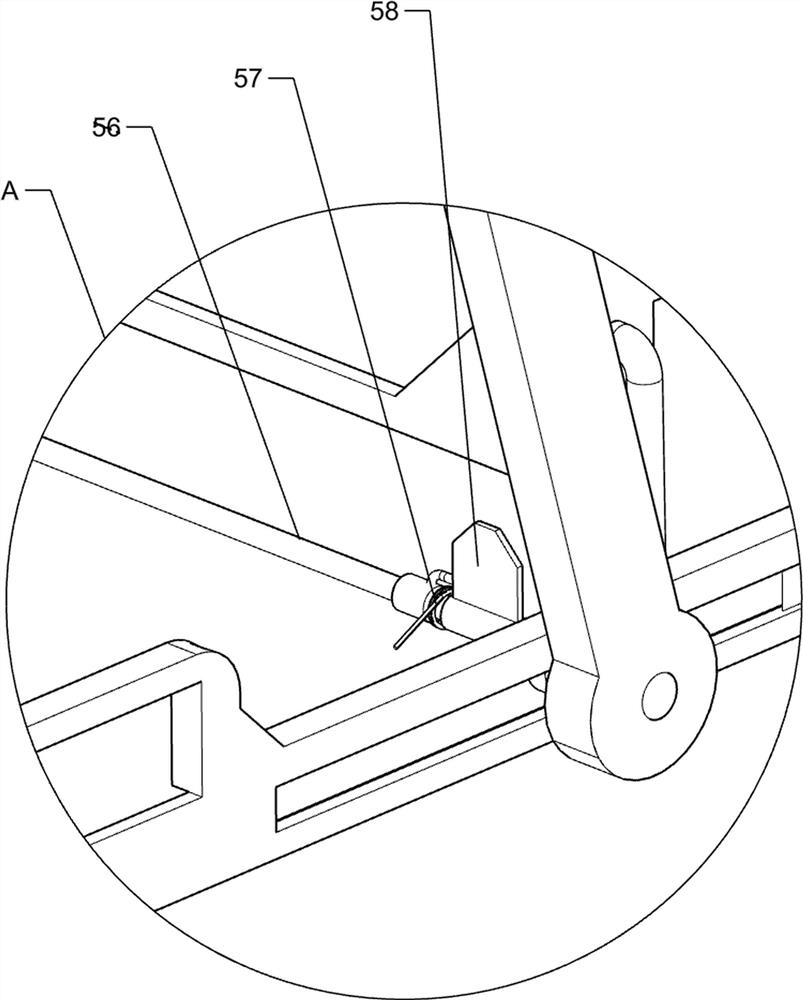

Steel plate bending resistance detection device for construction sites

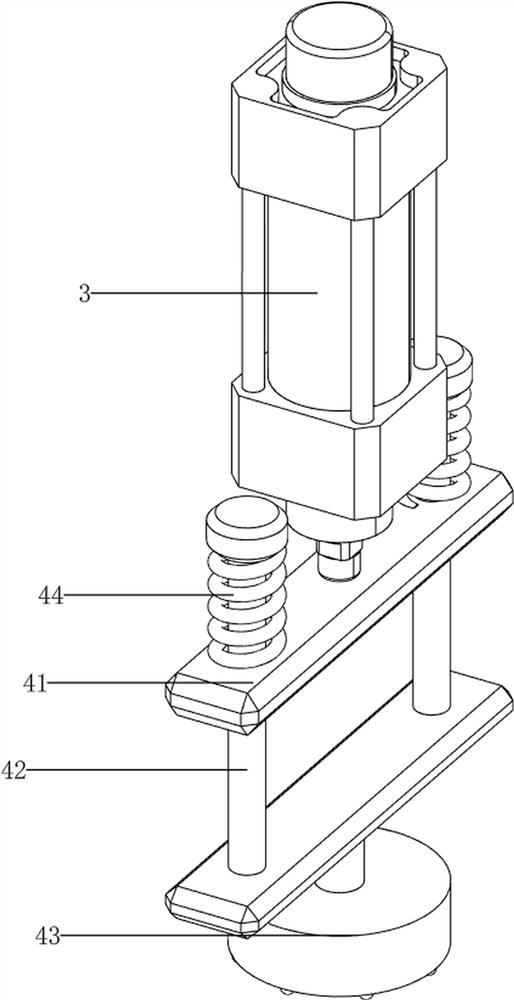

PendingCN113075054ARealize the effect of bending detectionRealize the feeding effectMaterial strength using steady bending forcesClassical mechanicsStructural engineering

Owner:赵毅明

Adjustable ceramic tile punching equipment for building materials

PendingCN113043476ARealize the effect of transmissionAvoid displacementCleaning using toolsWorking accessoriesBuilding materialCeramic tiles

The invention relates to punching equipment, in particular to adjustable ceramic tile punching equipment for building materials. According to the adjustable ceramic tile punching equipment for the building materials, automatic punching can be achieved, the work progress is accelerated, and operation is simple and easy to understand. The adjustable ceramic tile punching equipment for the building materials comprises a supporting frame and a downward pressing mechanism, wherein the downward pressing mechanism is arranged between the two sides of the supporting frame; and a conveying mechanism arranged on the supporting frame. According to the ceramic tile punching device, the downward pressing mechanism is arranged, the downward pressing mechanism can operate to conduct downward pressing and punching on ceramic tiles, people can manually adjust components of the downward pressing mechanism, the downward pressing mechanism can conduct punching according to the positions where people want to conduct punching, and the effects of downward pressing, adjusting and punching are achieved; and by arranging a hold-down mechanism, the hold-down mechanism is matched with the downward pressing mechanism, and the downward pressing mechanism operates to drive the hold-down mechanism, so that the hold-down mechanism can press the ceramic tiles, the ceramic tiles can be prevented from moving when the ceramic tiles are punched, and the pressing effect is achieved.

Owner:刘芬芬

Automatic dough cake forming device for food production

PendingCN112741128ARealize the driving effectRealize the pressure effectDough extruding machinesDough processingEngineeringMechanical engineering

Owner:JINING JINFENG FOOD

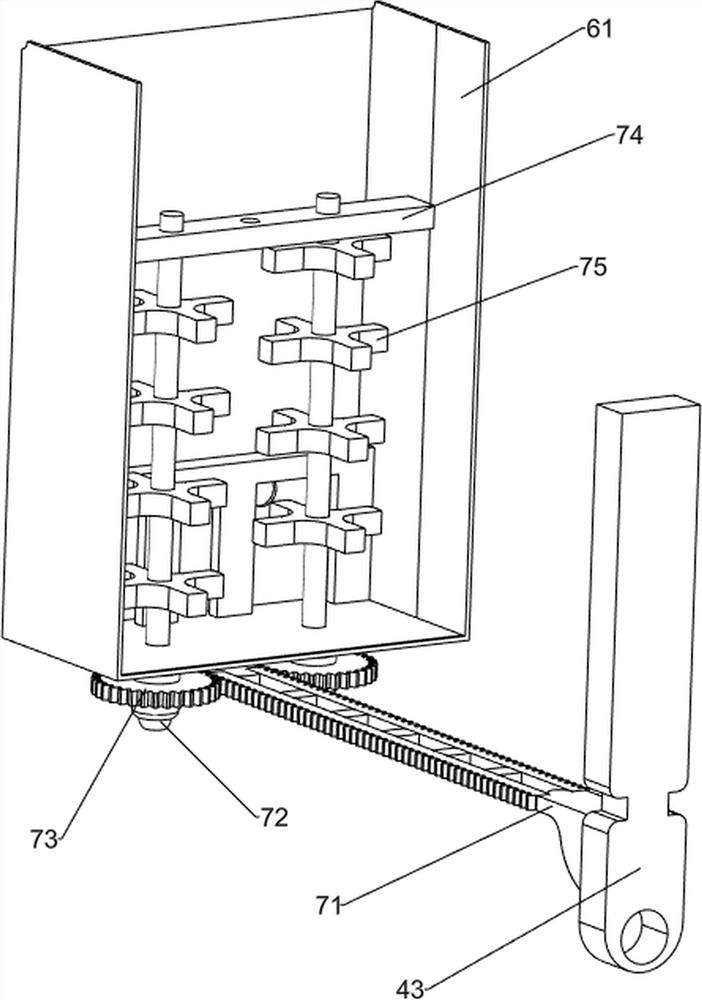

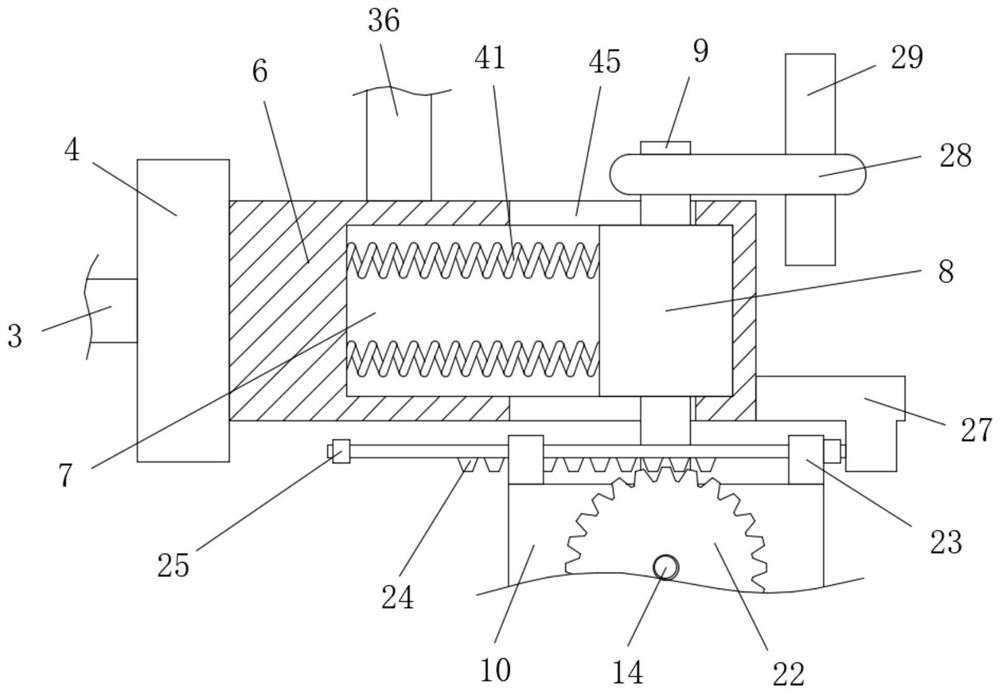

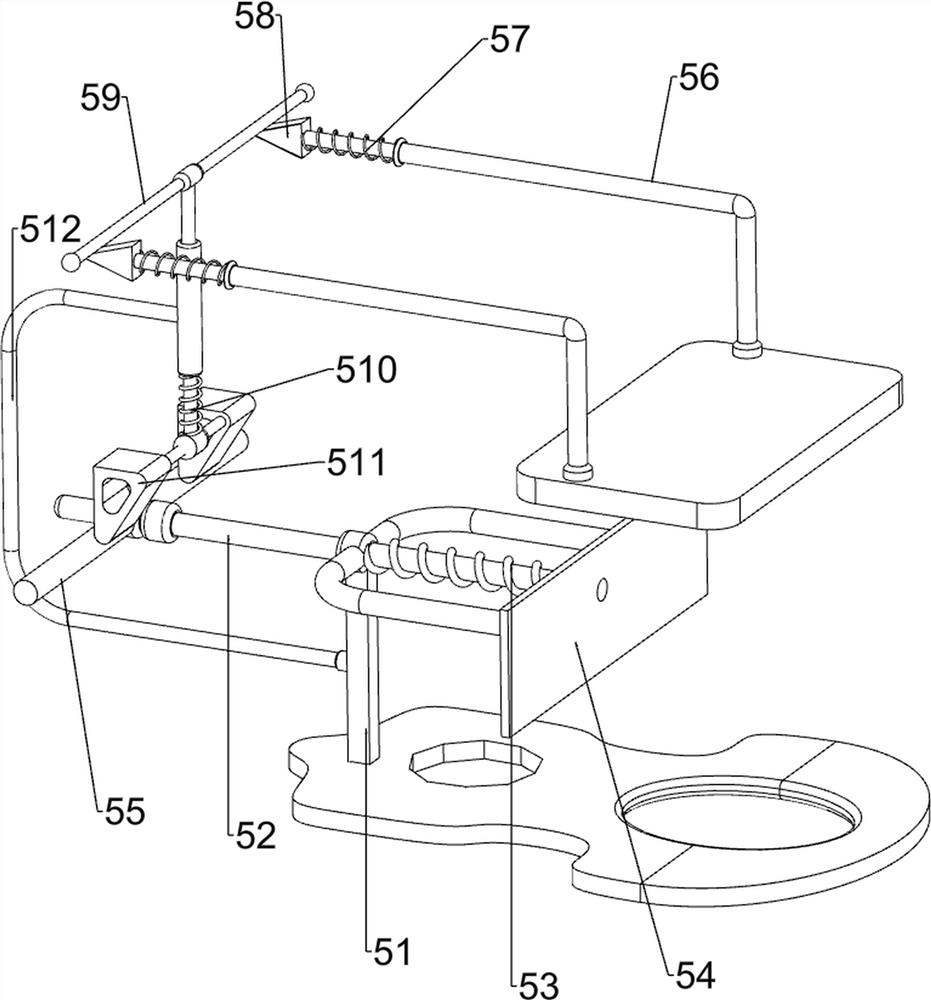

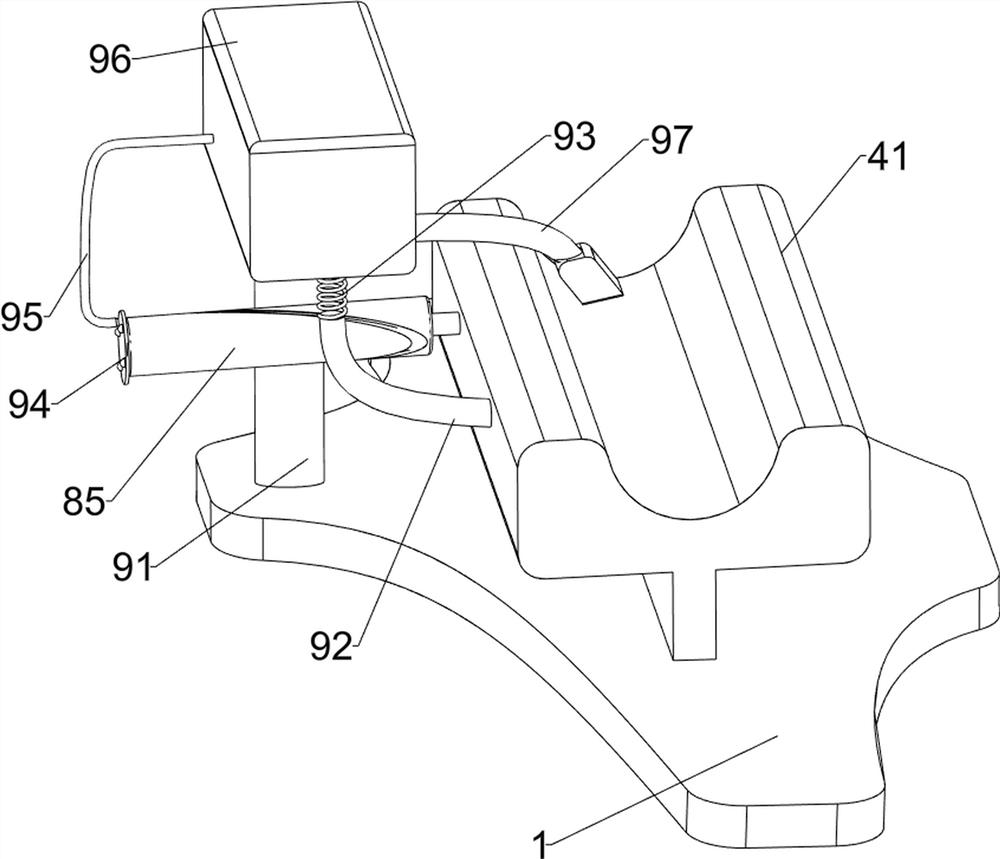

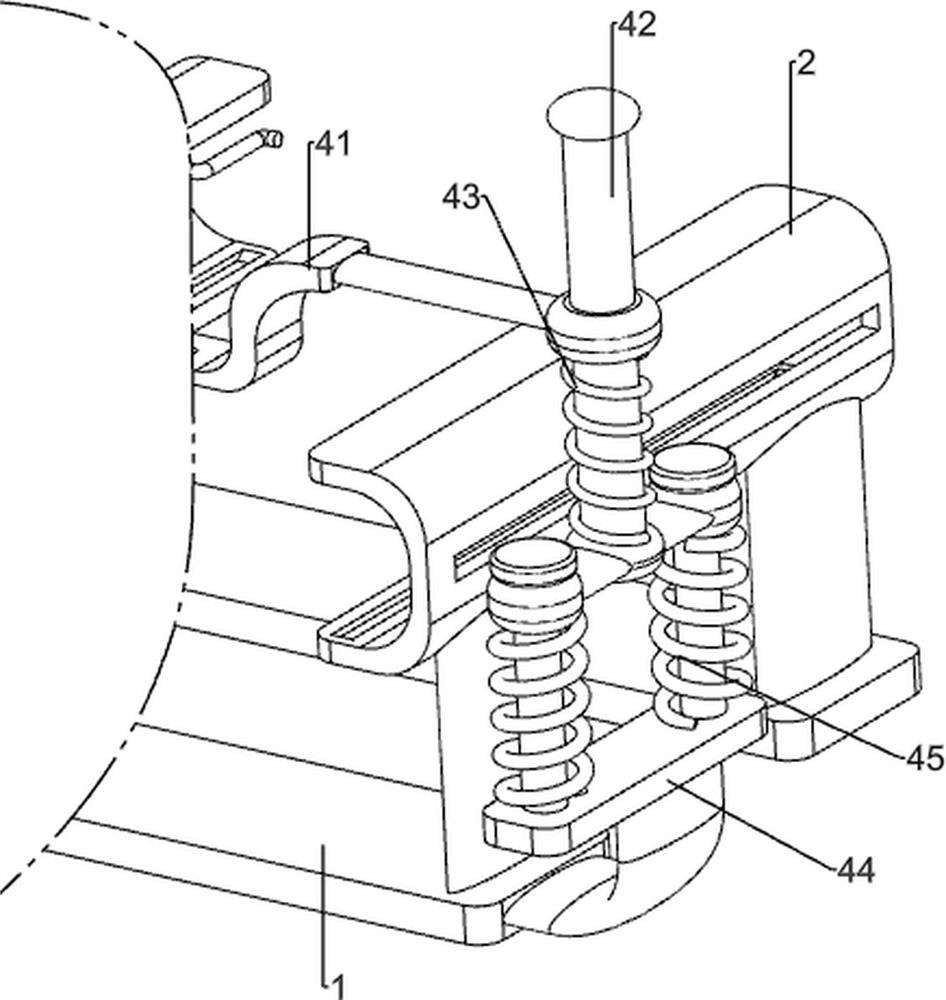

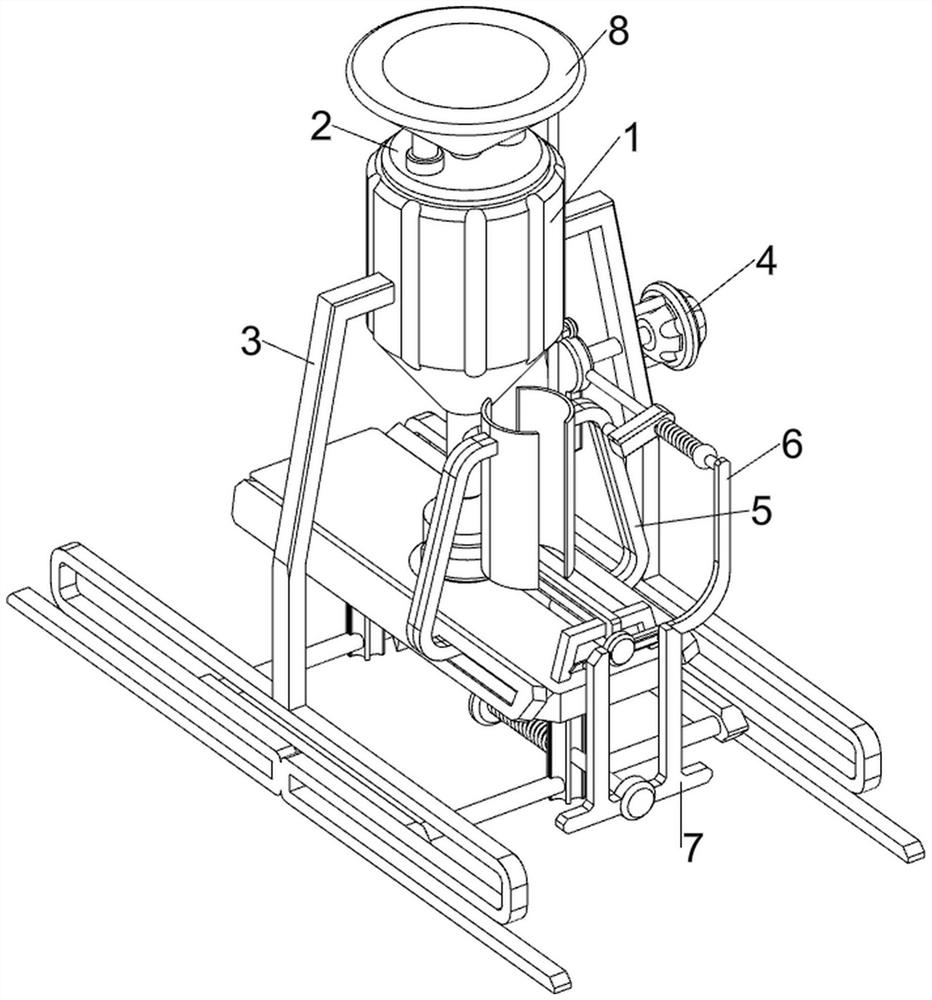

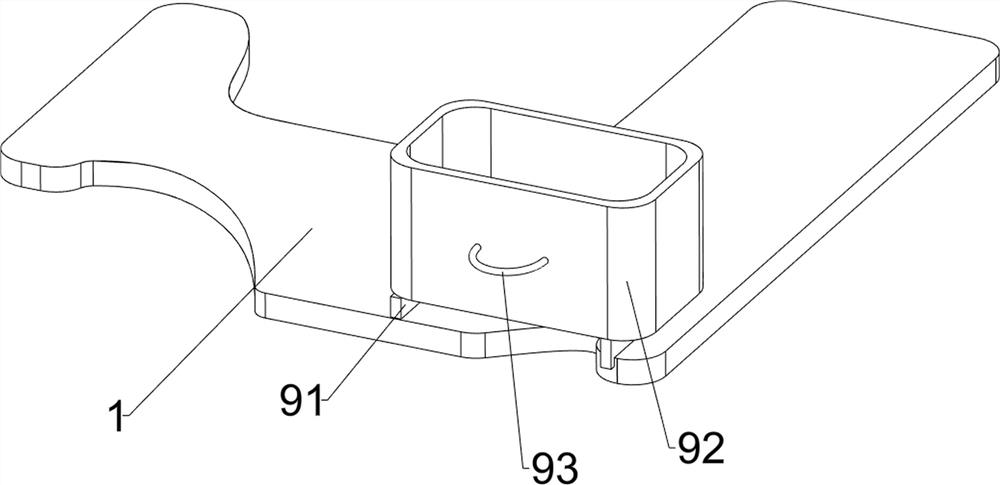

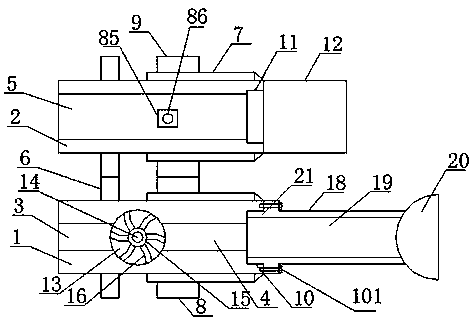

Tablet mashing equipment for pediatric department

PendingCN113042136AAchieve the crushed effectRealize the feeding effectGrain treatmentsMechanical engineeringBiomedical engineering

The invention relates to mashing equipment, in particular to tablet mashing equipment for the pediatric department, and provides the tablet mashing equipment which is used for the pediatric department, can realize automatic crushing, is healthy and sanitary and is convenient to use. The tablet mashing equipment for the pediatric department comprises a bottom plate, a first supporting frame arranged on the bottom plate, an air cylinder mounted on the upper side of the first supporting frame, a rolling mechanism arranged on the air cylinder, and a feeding mechanism arranged on the bottom plate. A telescopic rod of the air cylinder then moves downwards, so that a second supporting frame slides downwards, a first spring is stretched, a pressing block moves downwards, tablets can be crushed, and the crushing effect is achieved; a first sliding block drives a tray to move leftwards, the tray can be pushed to the position below a pressing block, and the feeding effect is achieved.

Owner:蔡腾

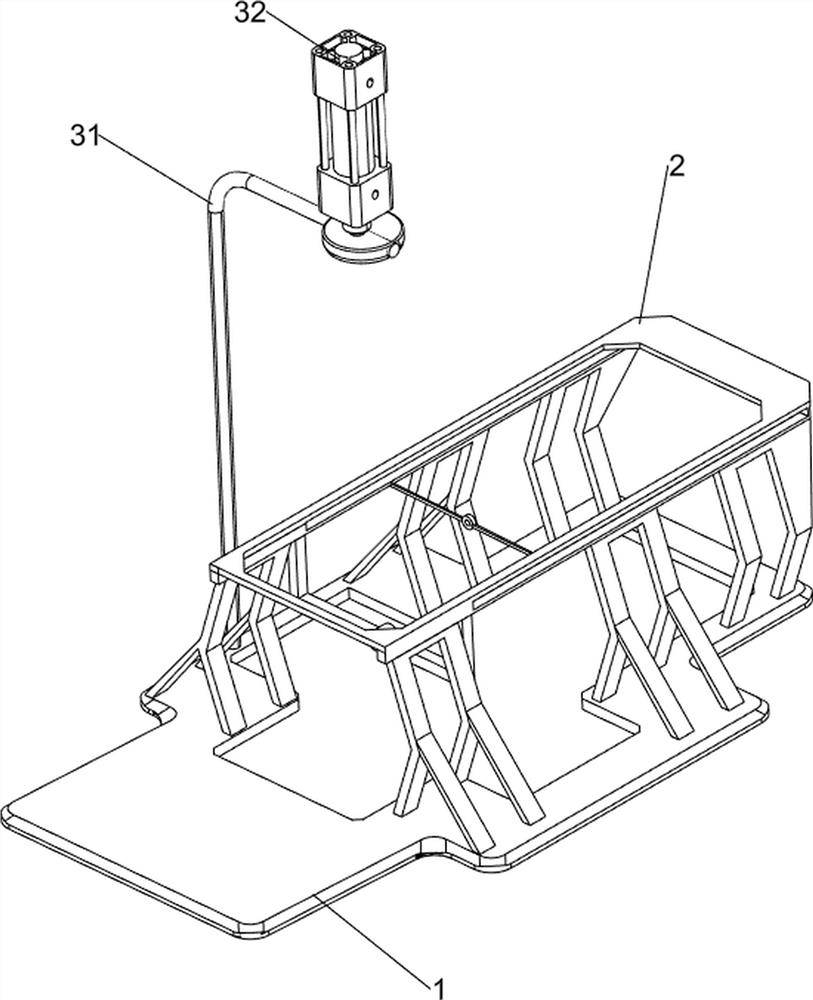

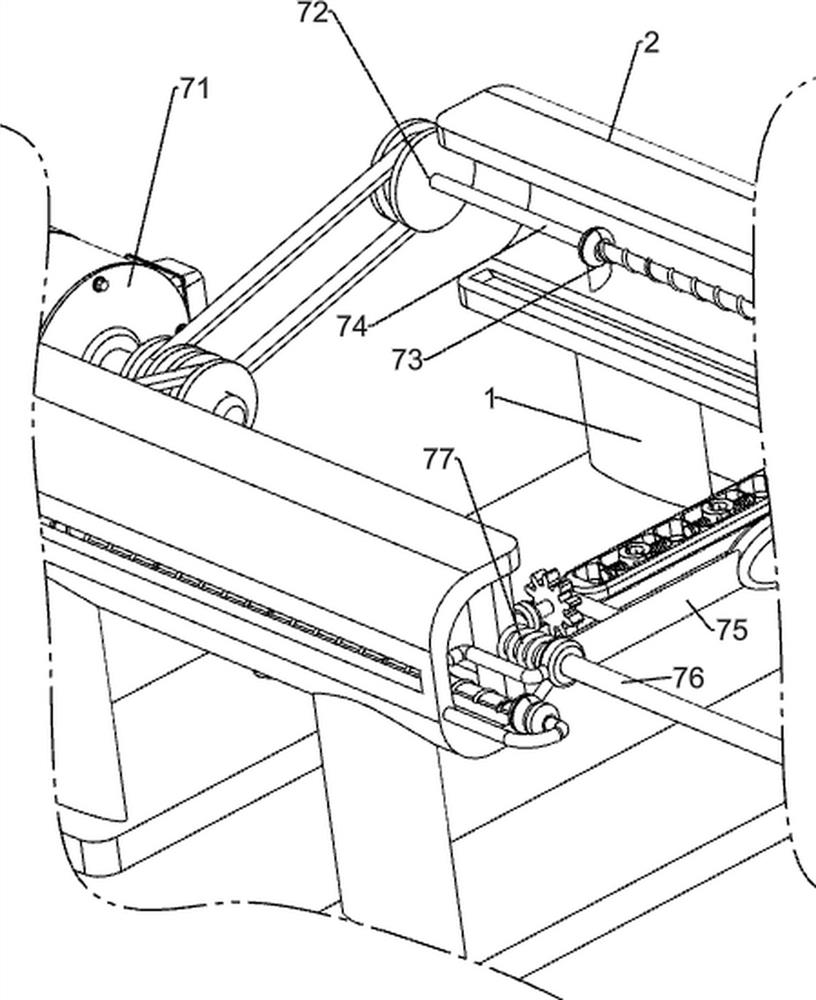

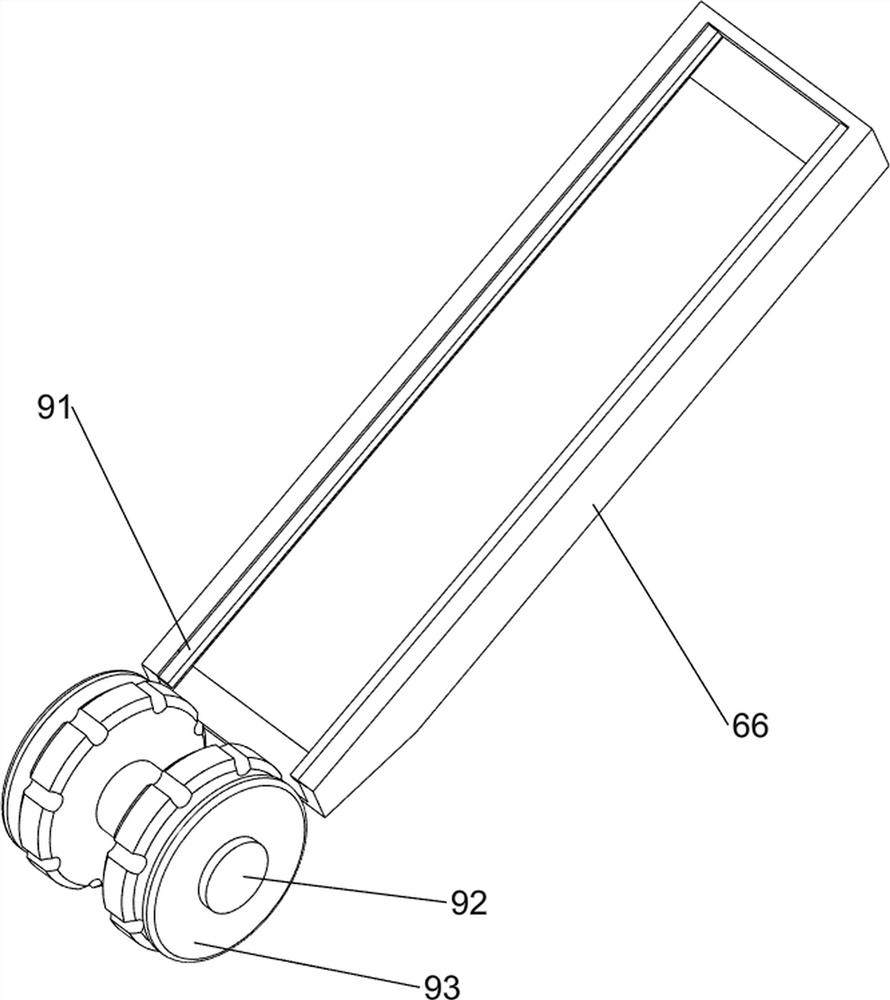

Rolling type ground cement leveling device for building

ActiveCN112282325ARealize the moving effectRealize the feeding effectBuilding constructionsRoads maintainenceElectric machineryStructural engineering

The invention relates to a cement leveling device, in particular to a rolling type ground cement leveling device for a building. The rolling type ground cement leveling device for the building is highin working efficiency, low in labor intensity and convenient to move. The rolling type ground cement leveling device for the building comprises a bottom plate, a motor, a feeding mechanism and a pushing mechanism, wherein a mounting frame is arranged on the left portion of the upper rear side of the bottom plate, the motor is mounted at the top of the mounting frame, the feeding mechanism is arranged on the rear side of the bottom plate, and the pushing mechanism is arranged on the left side of the bottom plate. According to the rolling type ground cement leveling device, cement is injected into a material box, first sliding blocks are pushed forwards, so that first connecting rods are driven to move forwards, then the material box is driven to move forwards, the cement is sprayed out from a discharging opening of the material box to cover the ground, and the feeding effect is achieved.

Owner:安徽雄风建设集团有限公司

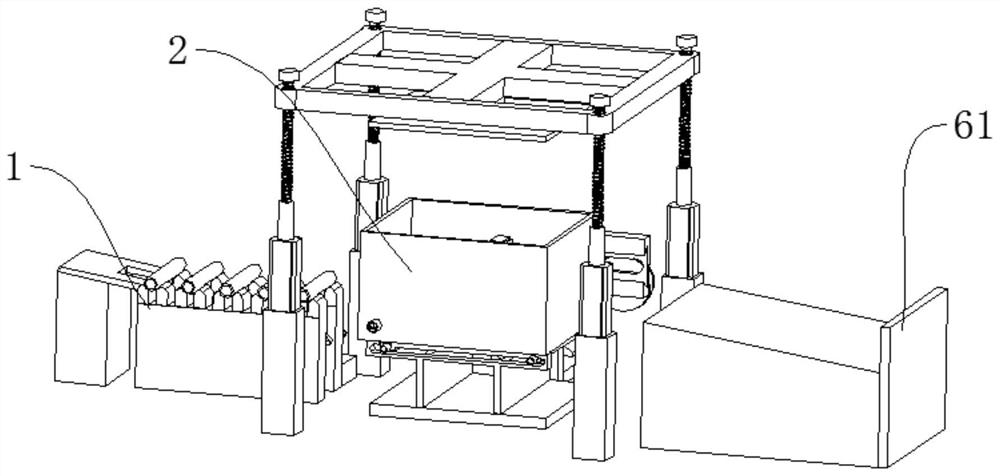

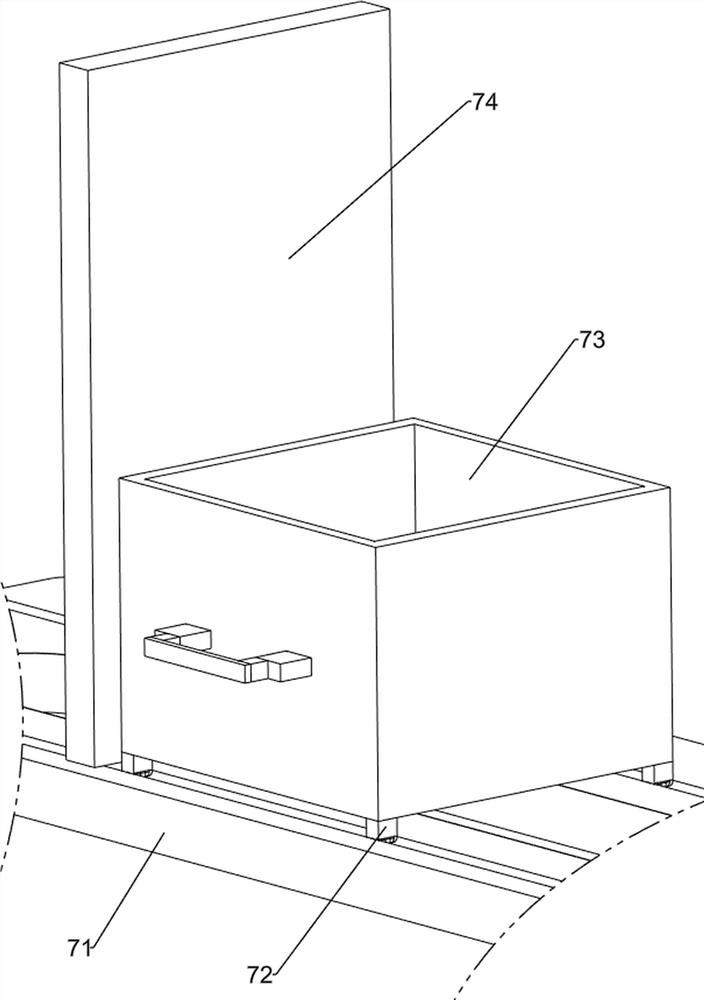

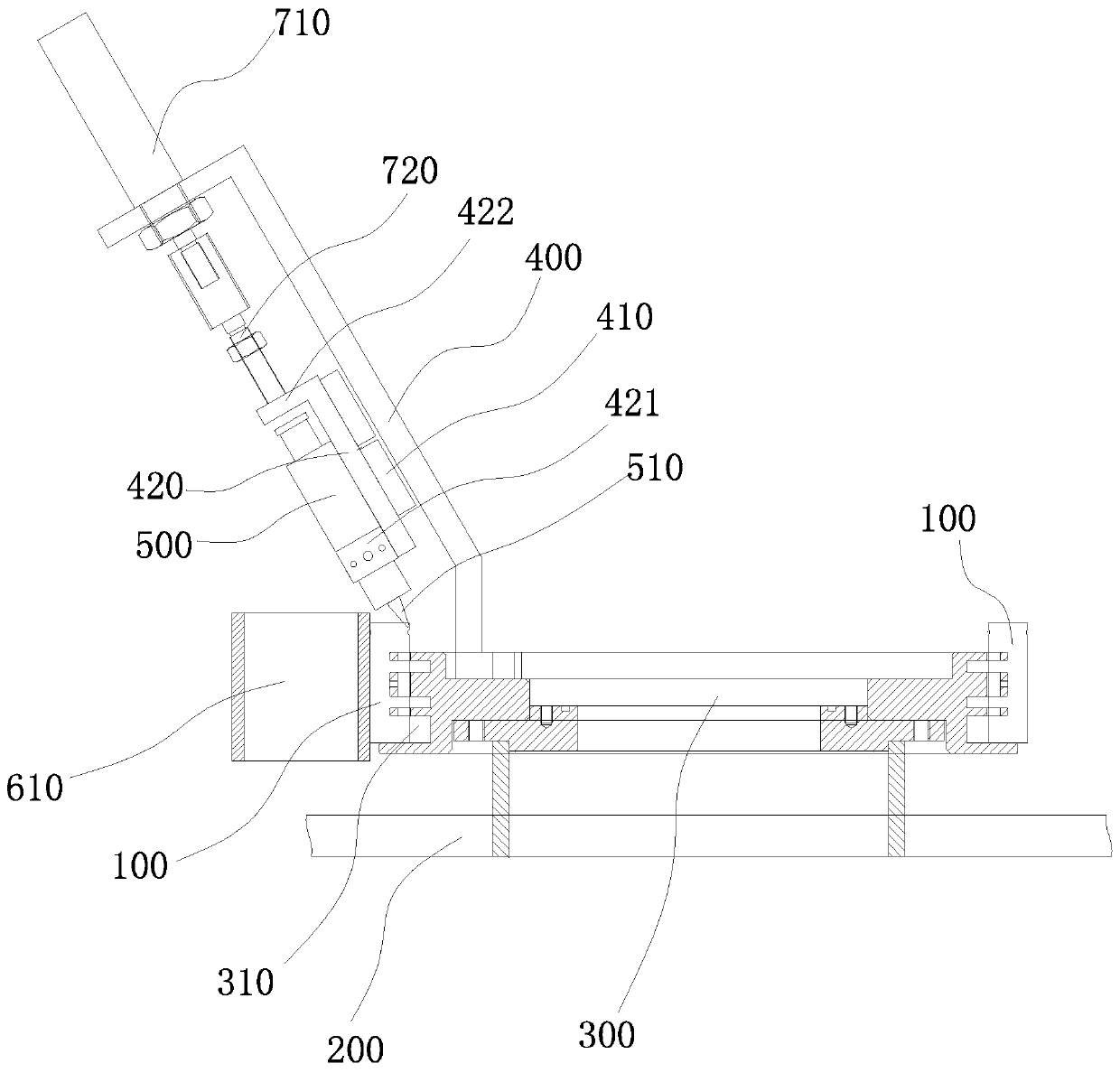

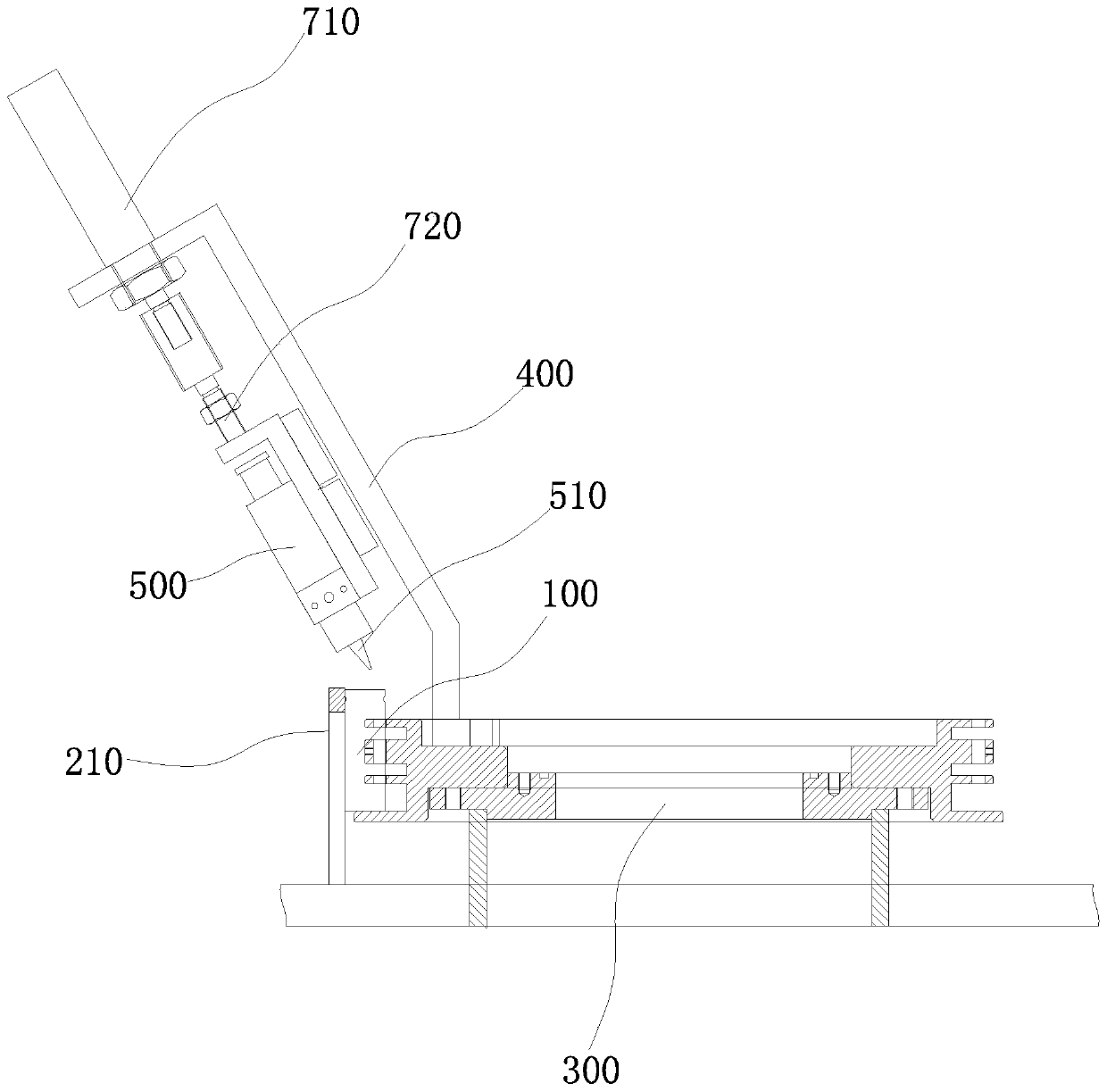

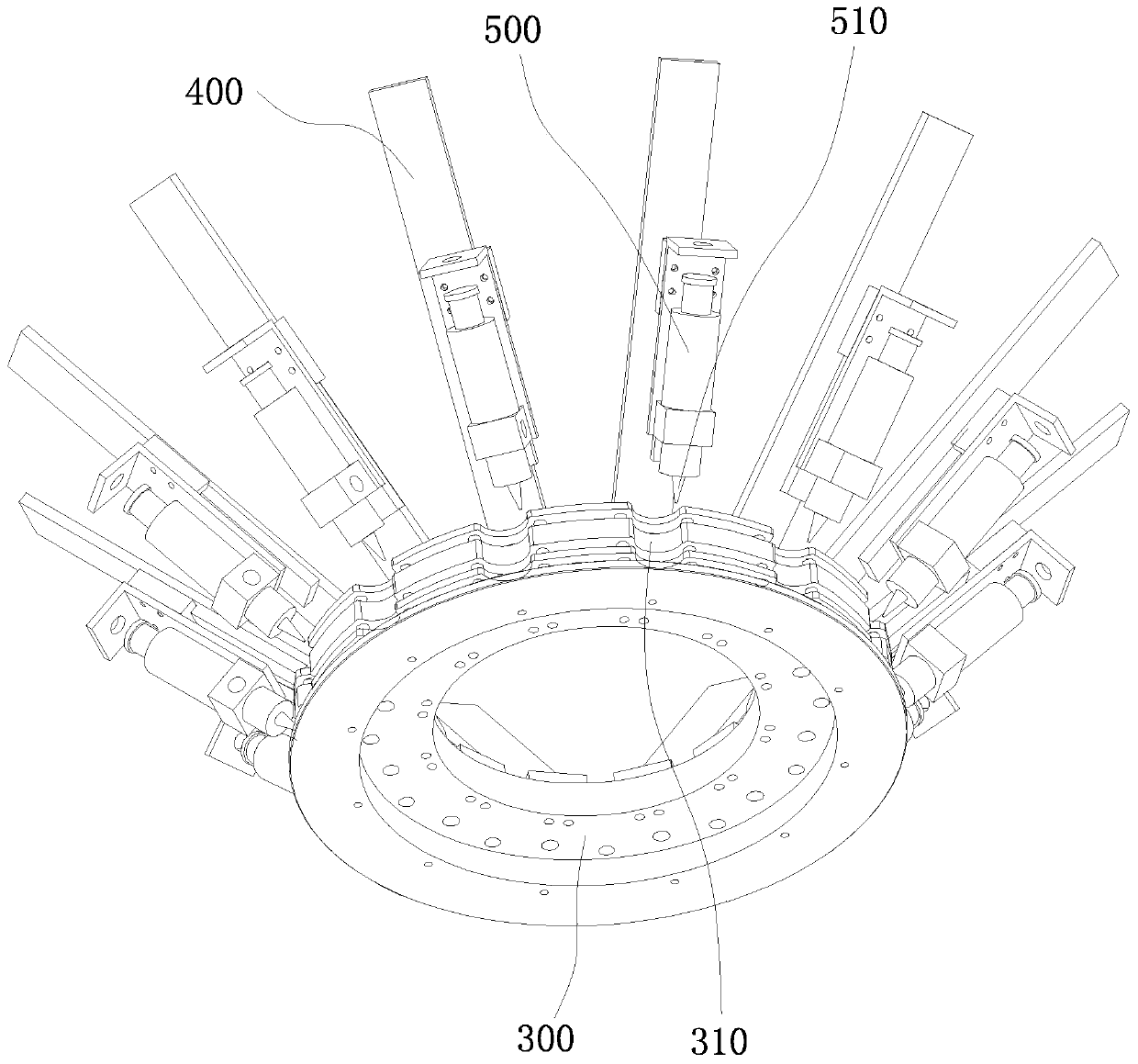

Welded pipe air tightness detection system and detection process thereof

PendingCN112924113AIntuitive and precise detection methodIncrease water pressureMeasurement of fluid loss/gain rateStructural engineeringEnvironmental engineering

The invention discloses a welded pipe air tightness detection system and a detection process thereof, and belongs to the technical field of welded pipe detection. The welded pipe air tightness detection system comprises a feeding device, a detection water tank, a clamping assembly, a water tank turnover device, a water pressure supercharging device and a discharging table. The feeding device is arranged on the ground, and the water tank turnover device is installed at one side of the feeding device; the detection water tank is mounted at the top of the water tank turnover device, the clamping assembly is mounted in the detection water tank, the water pressure supercharging device is mounted at one side of the feeding device, and the discharging table is arranged at the side, away from the feeding device, of the detection water tank. According to the method, the two ends of a welded pipe are blocked, the welded pipe is placed in the detection water tank filled with water, the detection time is set to be five minutes, the water pressure in the detection water tank is increased, the welded pipe is taken out after five minutes, the water in the detection water tank is pumped out, and the water inflow amount entering the welded pipe is calculated by comparing the reduction amount of the water amount, so that whether the air tightness of the welded pipe is qualified or not is judged through the method.

Owner:查晶晶

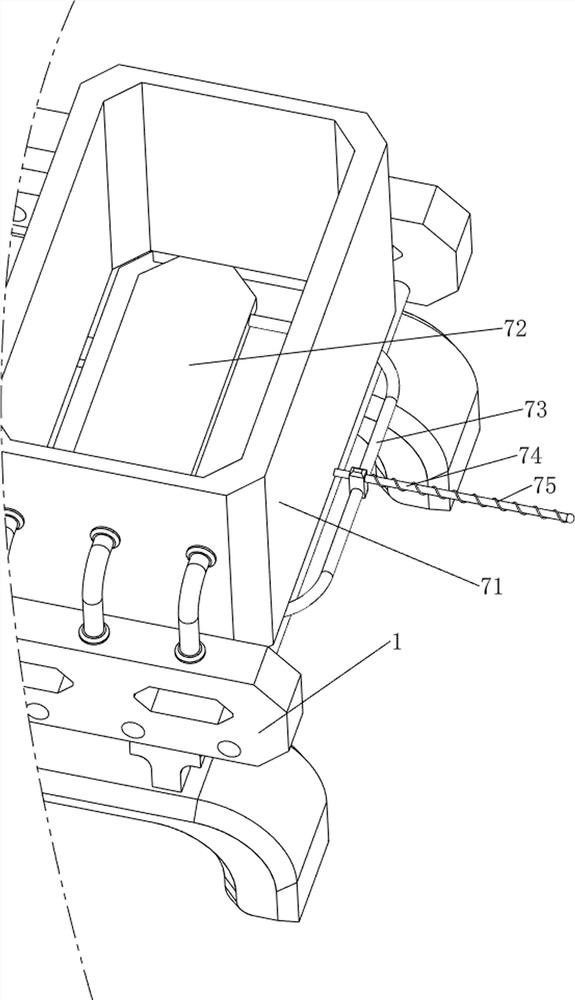

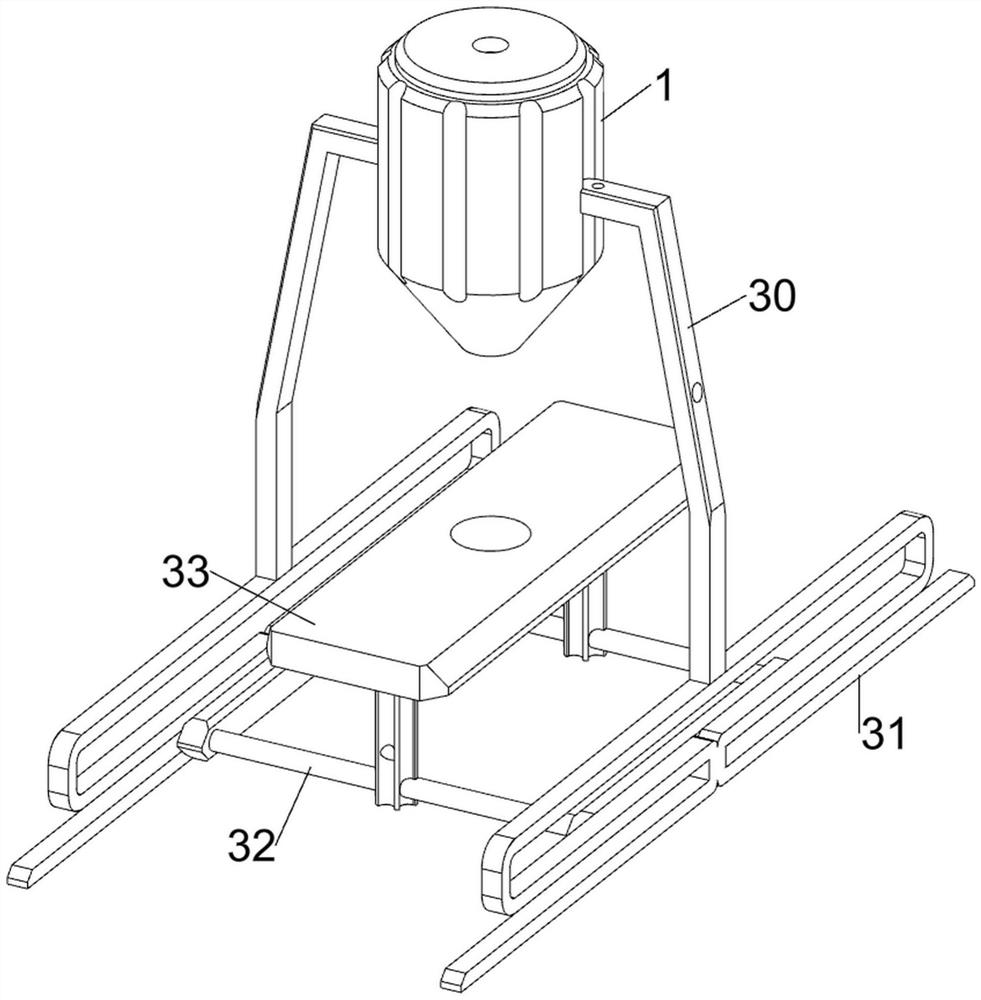

Locatable punching device with regard to ceiling and used for indoor decoration

ActiveCN112705752ARealize the operationRealize the feeding effectFeeding apparatusPositioning apparatusPunchingReciprocating motion

The invention relates to a punching device, and especially relates to a locatable punching device with regard to a ceiling and used for indoor decoration. The invention provides a locatable punching device with regard to a ceiling and used for indoor decoration, and capable of liberating the two hands, increasing the efficiency, and realizing accurate locating. The locatable punching device with regard to the ceiling and used for indoor decoration comprises a supporting frame, a pressing mechanism, a punching mechanism and a loading mechanism, wherein a support frame is arranged on the upper part of the base; the pressing mechanism is arranged on the upper part of the base; the punching mechanism is arranged at the lower side of the pressing mechanism; and the loading mechanism is arranged at the upper side of the supporting frame. According to the invention, by starting an air cylinder, a telescopic rod of the air cylinder drives the punching mechanism to move up and down in a reciprocating mode, and the operation of pressing the punching mechanism downwards is achieved.

Owner:四川润邦建材有限公司

Comprehensive disinfection equipment for small instruments in clinical laboratory

ActiveCN112808654ARealize the pressure effectAchieve fixationCleaning using toolsMedicineEngineering

The invention relates to disinfection equipment, in particular to comprehensive disinfection equipment for small instruments in a clinical laboratory. The comprehensive disinfection equipment for the small instruments in the clinical laboratory is convenient to operate, short in service time and thorough in cleaning and disinfection. The comprehensive disinfection equipment for the small instruments in the clinical laboratory comprises a base, first connecting rods, downward pressing mechanisms and a cleaning mechanism, wherein first sliding rails are arranged on the left side and the right side of the base; the first connecting rods are arranged on the left side and the right side of the base on the front side; the downward pressing mechanisms are arranged at the upper tops of the first connecting rods; and the cleaning mechanism is arranged on the downward pressing mechanisms. First guide rods on the left side and the right side are manually pressed, so that a first supporting frame is driven to move downwards, a first spring is compressed, then a second spring is compressed, and the downward pressing effect is achieved.

Owner:江秀燕

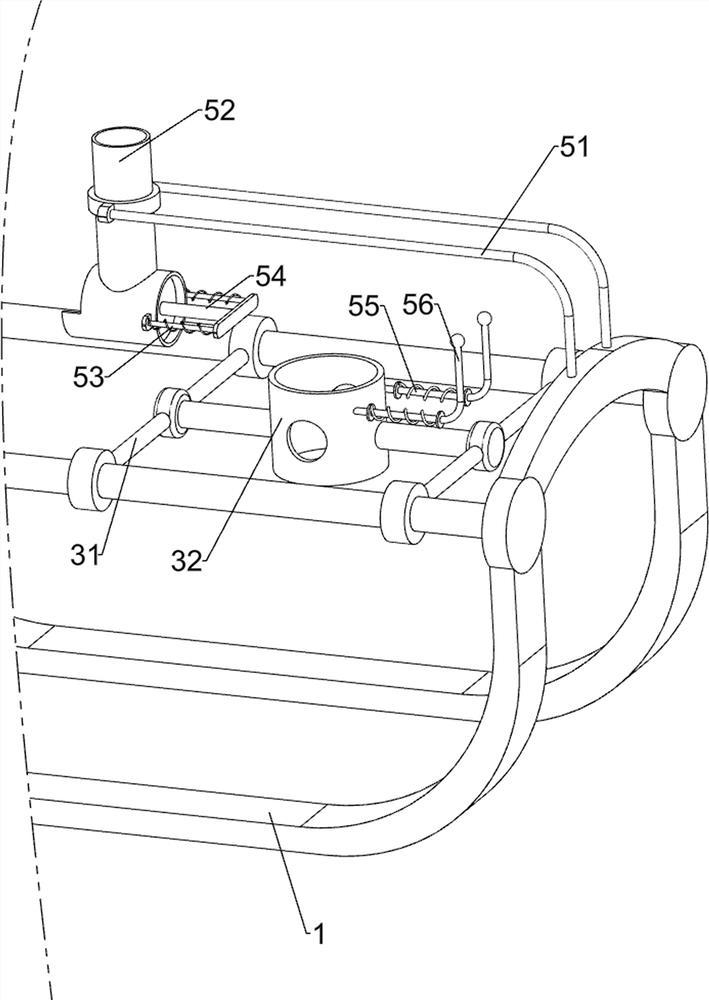

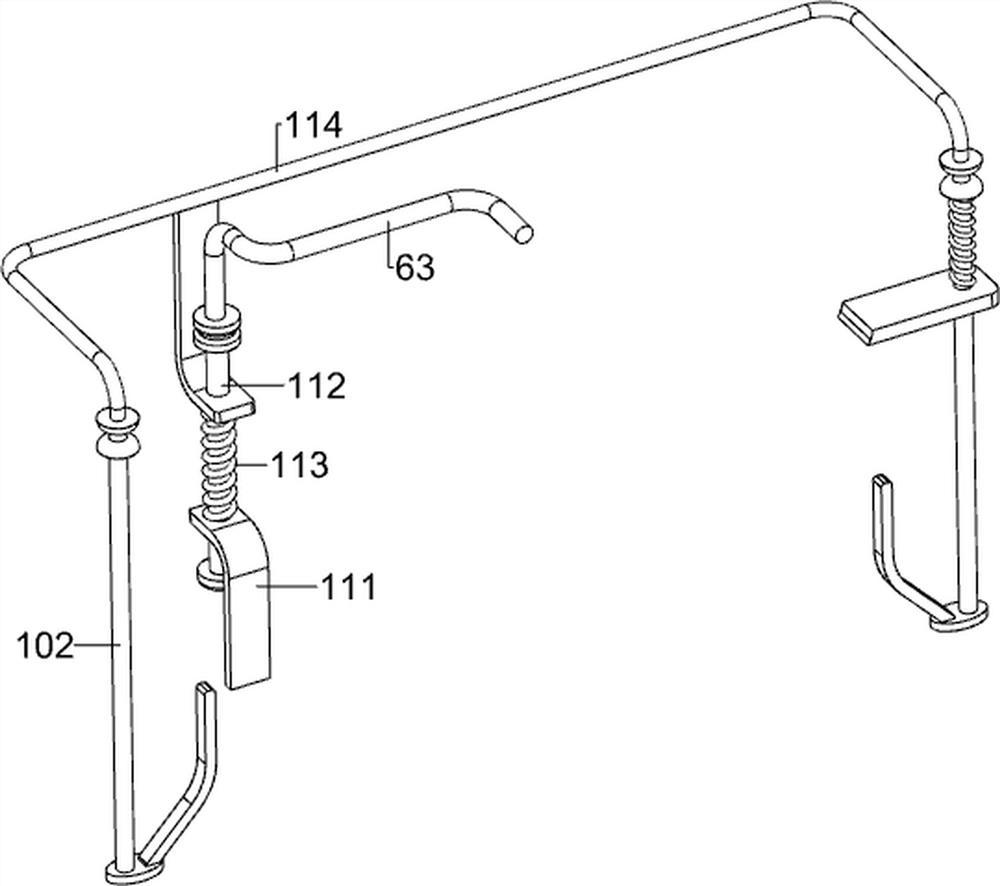

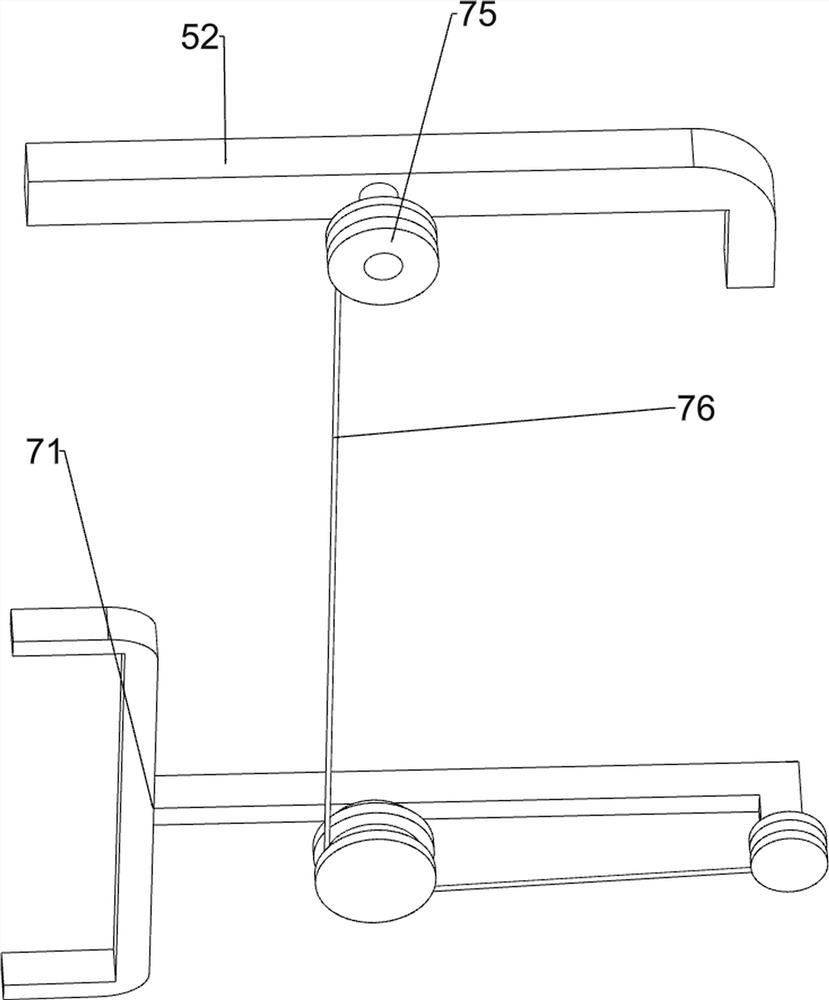

Wood wax oil applying device for wood floor for house decoration

ActiveCN112916291AAchieve fixationRealize the feeding effectLiquid surface applicatorsCoatingsPulp and paper industrySupport plane

The invention relates to a wax oil device, in particular to a wood wax oil applying device for a wood floor for house decoration. The wood wax oil applying device for wood floor for house decoration is few in operation actions, short in consumed time and capable of evenly applying wood wax oil. Th wood wax oil applying device for wood floor for house decoration comprises a base, first supporting frames, a fixing mechanism and a feeding mechanism; sliding rails are arranged on the left side and the right side of the base; the first supporting frames are arranged on the left portion and the right portion of the upper front side of the base; the fixing mechanism is arranged between the rear sides of the two sliding rails; and the feeding mechanism is arranged on the first supporting frames. According to the device, a clamp is pushed towards the outside of the device, a first spring stretches out, a wood floor is placed in the clamp, then the clamp is loosened, and the first spring returns, so that a fixing effect is achieved.

Owner:南京欣三人行网络科技有限公司

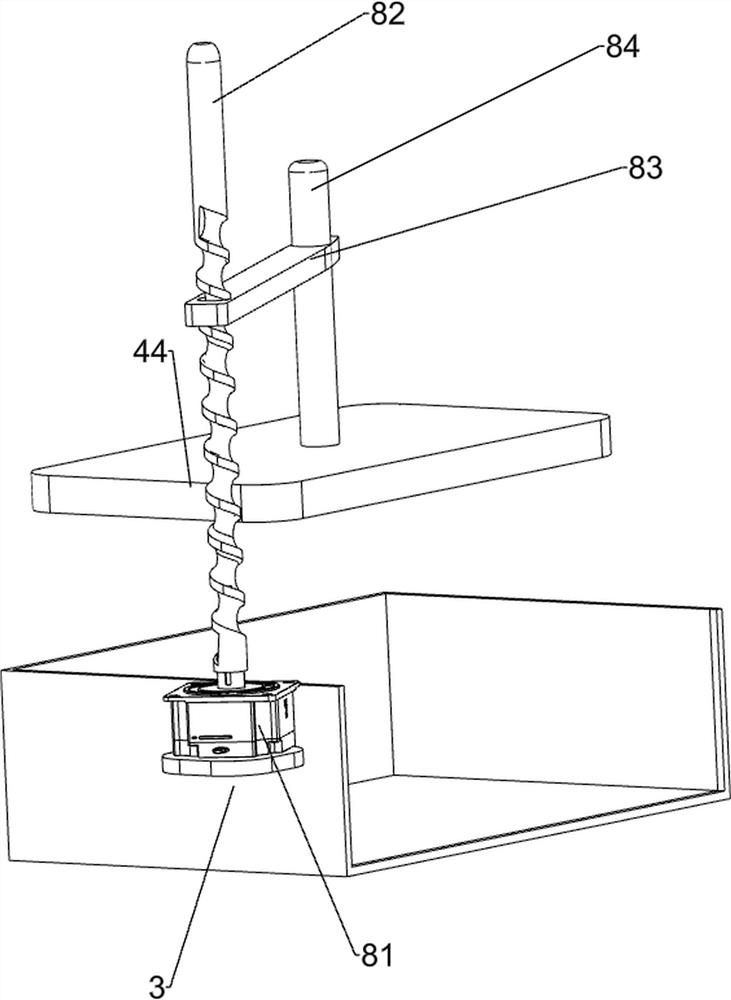

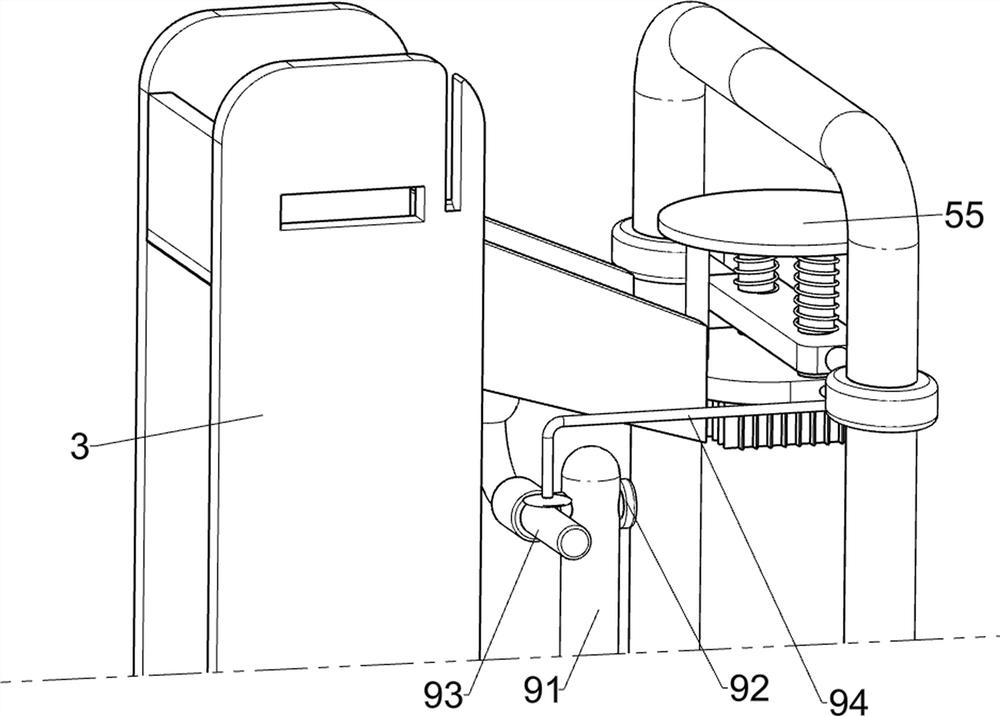

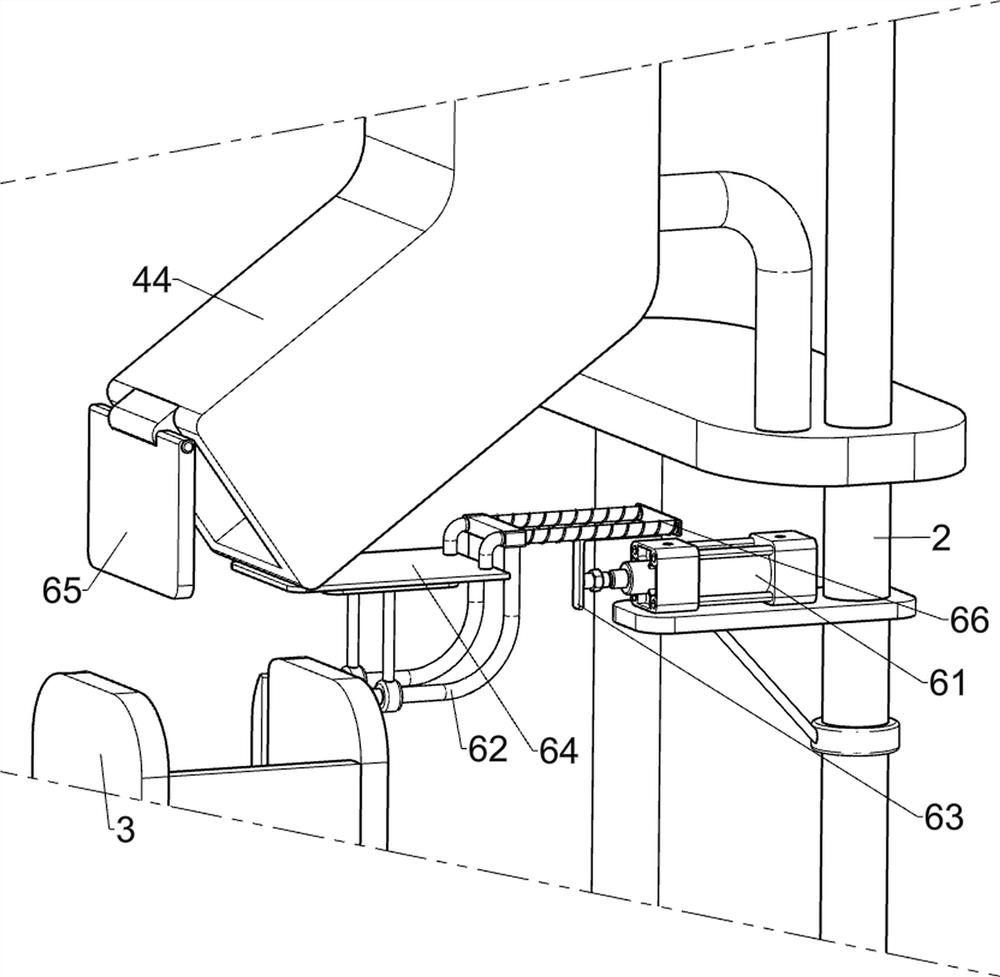

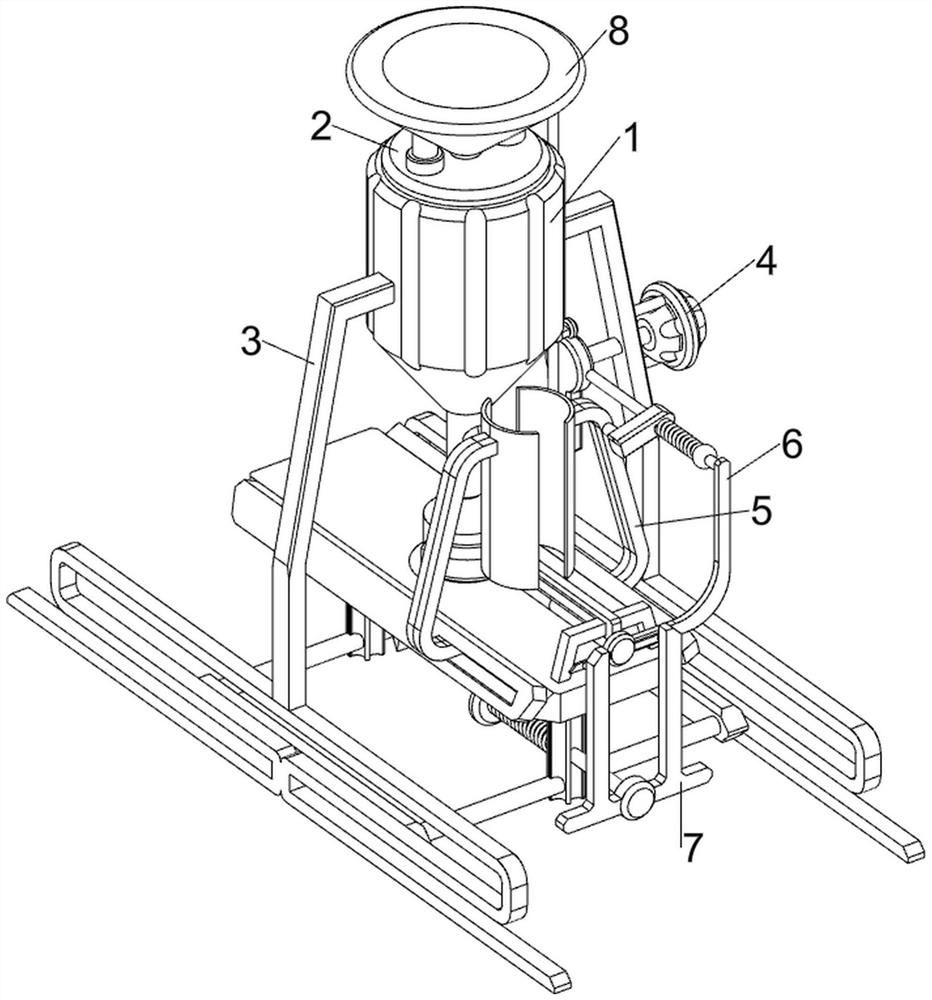

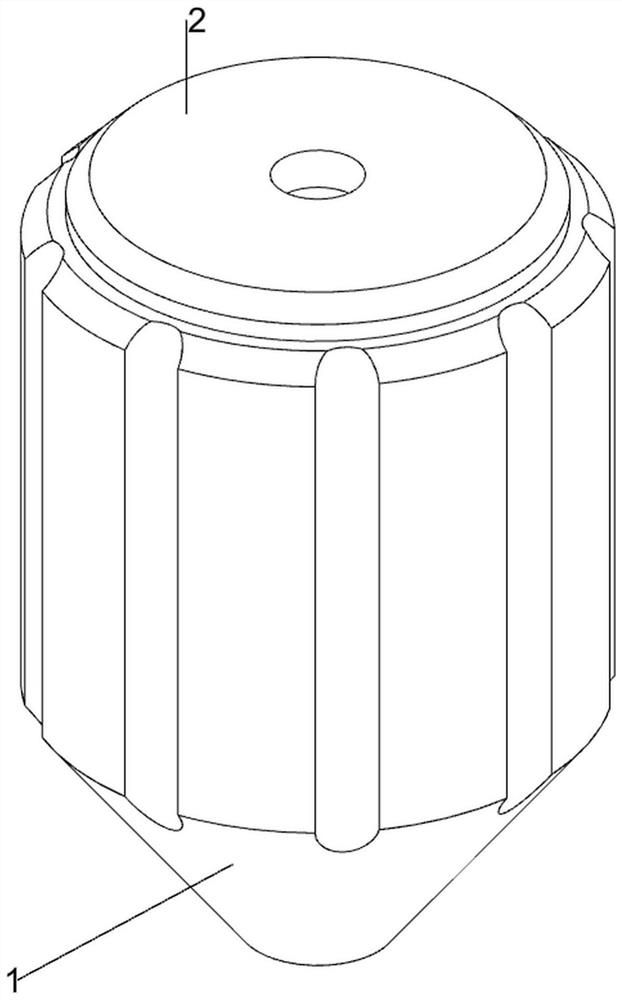

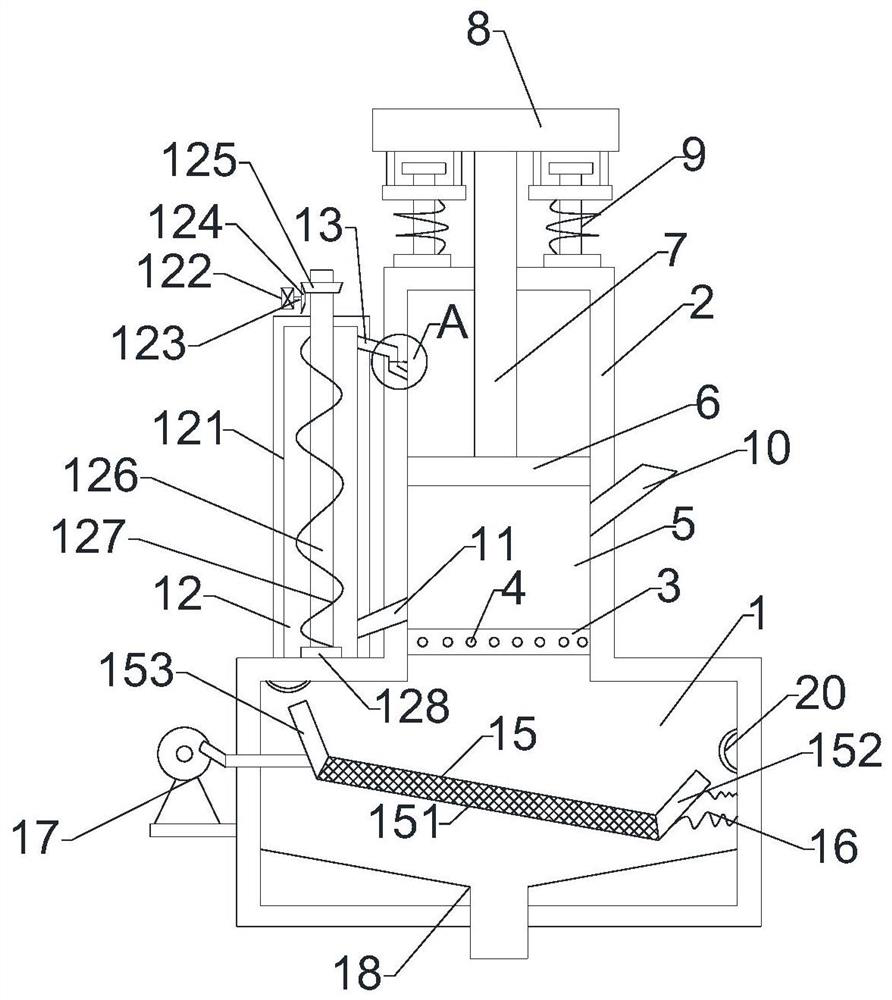

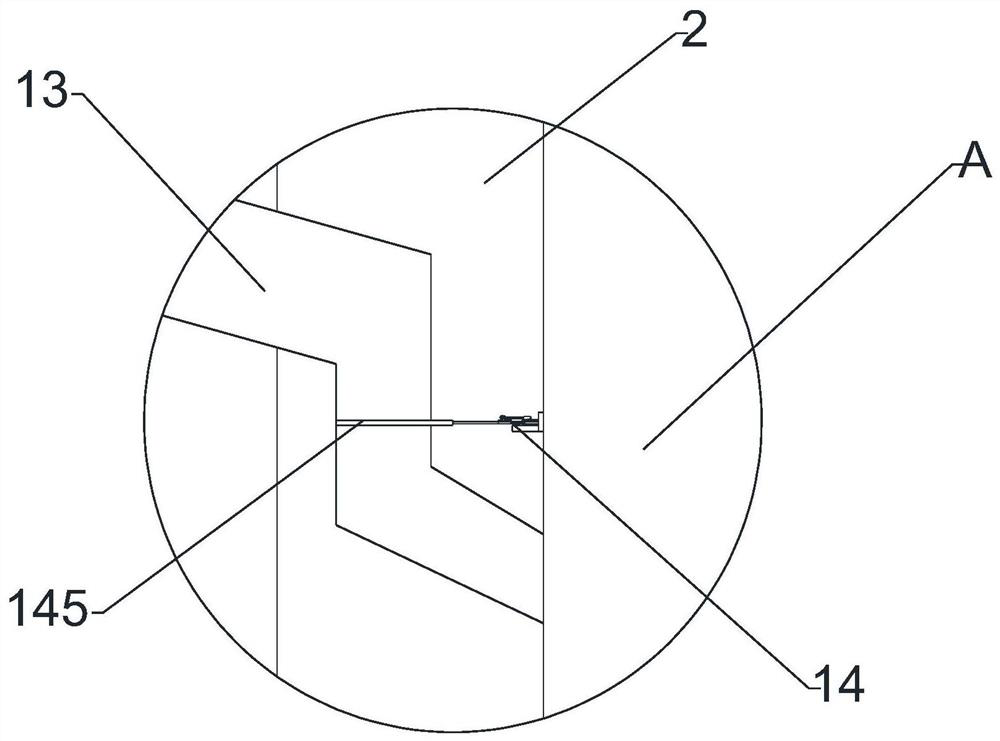

Solid chili sauce canning machine

ActiveCN113291498ARealize the effect of automatic canningRealize the feeding effectSolid materialChilli con carneProcess engineering

The invention relates to a canning machine, in particular to a solid chili sauce canning machine. The technical problem to be solved by the invention is to provide the solid chili sauce canning machine which can achieve automatic discharging and has the function of automatically shaking cans. According to the technical scheme, the solid chilli sauce canning machine comprises a chilli sauce storage tank, a cover plate, a chilli sauce placing mechanism and an automatic discharging mechanism, the top of the chilli sauce storage tank is covered with the cover plate, the chilli sauce placing mechanism is arranged on the chilli sauce storage tank, and the automatic discharging mechanism is arranged on the chilli sauce placing mechanism. Through cooperation between the chili sauce placing mechanism and the automatic discharging mechanism, the effects of automatically discharging chili sauce at intervals and automatically canning the chili sauce can be achieved.

Owner:青岛新绿农产有限公司

Automatic cloth elasticity testing device for workshop production

ActiveCN112609426ARealize automatic pushRealize the effect of automatic testingInspecting textilesProcess engineeringMechanical engineering

The invention relates to an automatic cloth elasticity testing device, in particular to the automatic cloth elasticity testing device for workshop production. The automatic cloth elasticity testing device for the workshop production can relieve arm ache, improve the testing efficiency and prevent cloth from being broken. The automatic cloth elasticity testing device for the workshop production comprises a base, first supports, a second support, a pushing mechanism and an extrusion mechanism, the first supports are arranged on the two sides of the base, the second support is arranged on the base, the pushing mechanism is arranged between the tops of the two first supports and the top of the second support, and the extrusion mechanism is arranged at the bottom of the pushing mechanism. By arranging the pushing mechanism, the pushing mechanism conveys the elastic cloth forwards to complete detection and pushes elastic cloth backwards to complete reset material taking, and the effect of automatically pushing the elastic cloth is achieved.

Owner:宜春酷加运动用品有限公司

Washing and wipe-drying machine available for discharging and collecting at same station

InactiveCN108414321AReduce manpower consumptionSimple structurePreparing sample for investigationFood treatmentTextileButt joint

The invention relates to a washing and wipe-drying machine available for discharging and collecting at a same station. The washing and wipe-drying machine comprises a washing frame, a wipe-drying frame and an upper supporting frame above the washing frame and the wipe-drying frame. A washing mesh trough is arranged in the washing frame through supporting rods, a washing lifting device is fittinglyarranged on the right side of the washing mesh trough, a right side plate of the washing frame is provided with a wipe-drying feeding port matched with the washing lifting device, a wipe-drying device matched with the wipe-drying feeding port is arranged in the washing frame, and a washing vibration source is arranged in the washing frame. A collection trough matched with the washing lifting device is arranged above the washing mesh trough, the wipe-drying device comprises a wipe-drying cloth pipe in butt joint with the wipe-drying feeding port, two cloth pipe inclination adjusting cylindersin bilateral abreast arrangement are fittingly hinged to the upper portion of the wipe-drying cloth pipe, and the right end of the wipe-drying cloth pipe is a sealed concave arc block. By structural design of the wipe-drying device and structural design of the collection trough, washed and wipe-dried potatoes can be re-transported to a discharging position, so that discharging and collecting at the same station is realized, and labor consumption is greatly saved.

Owner:DONGGUAN UNIV OF TECH

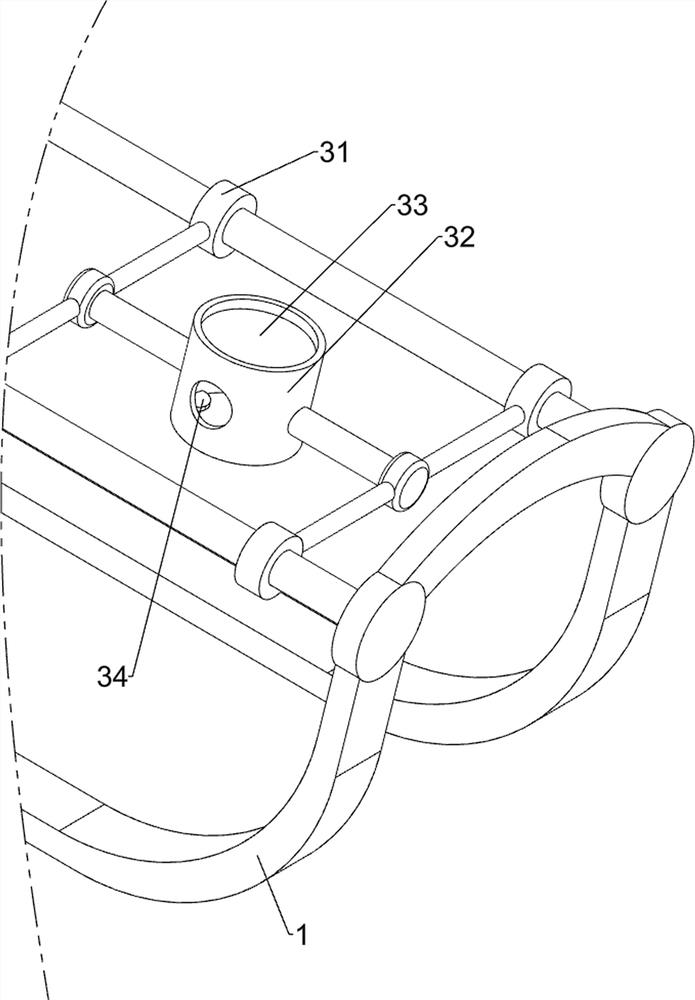

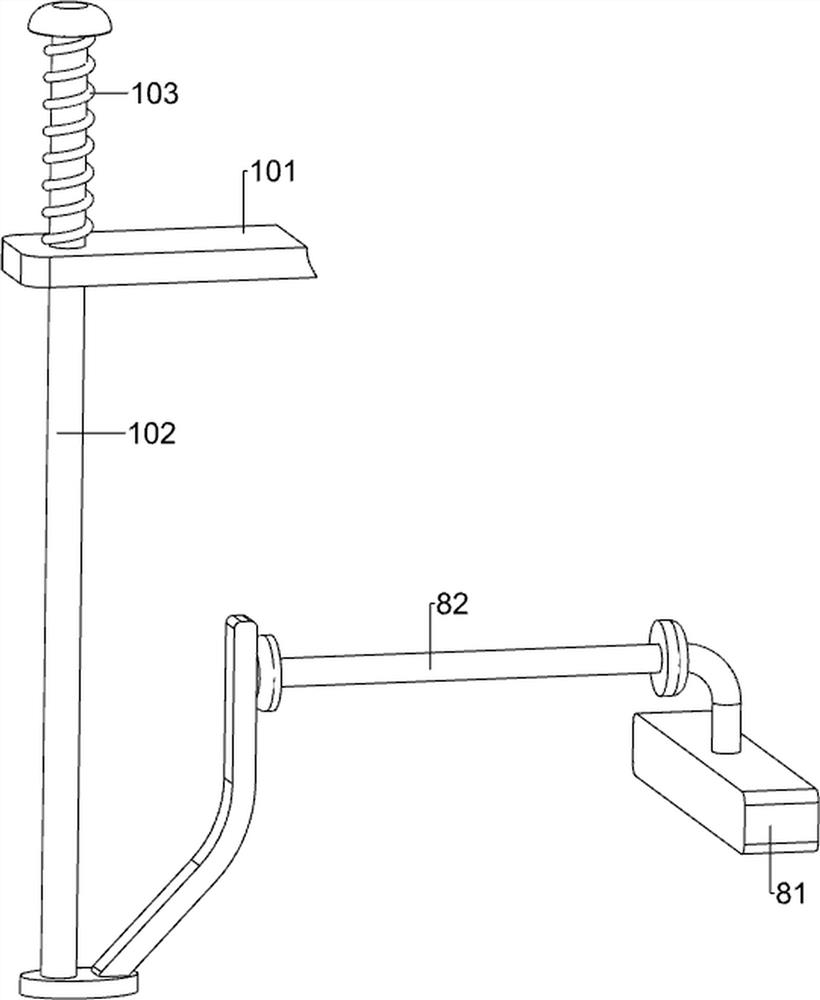

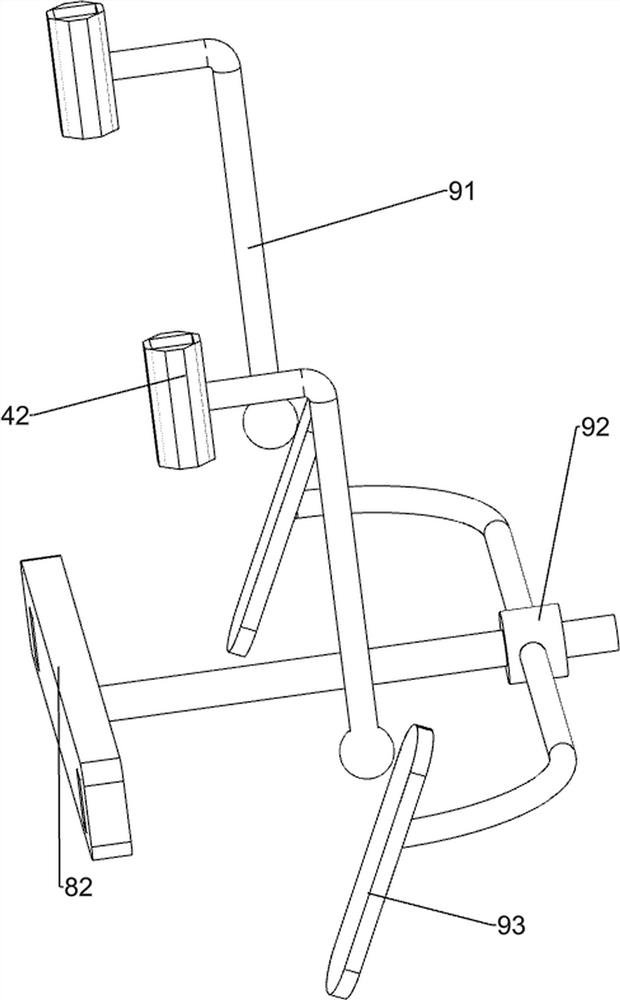

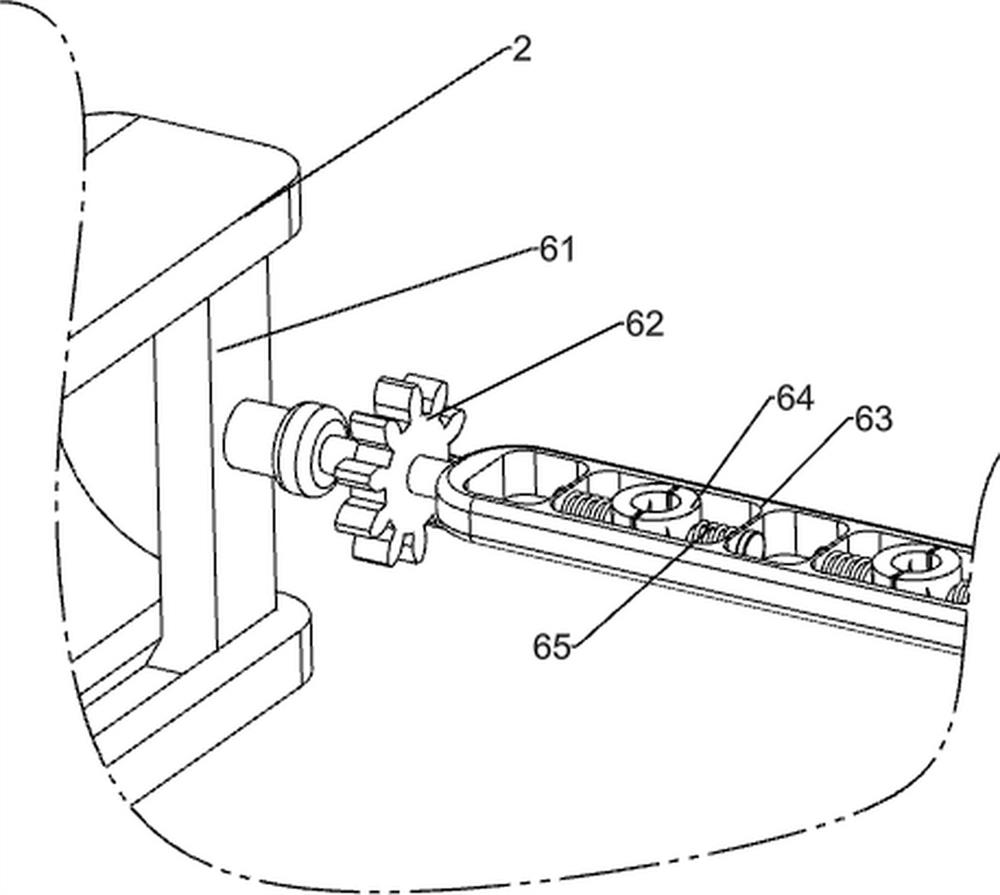

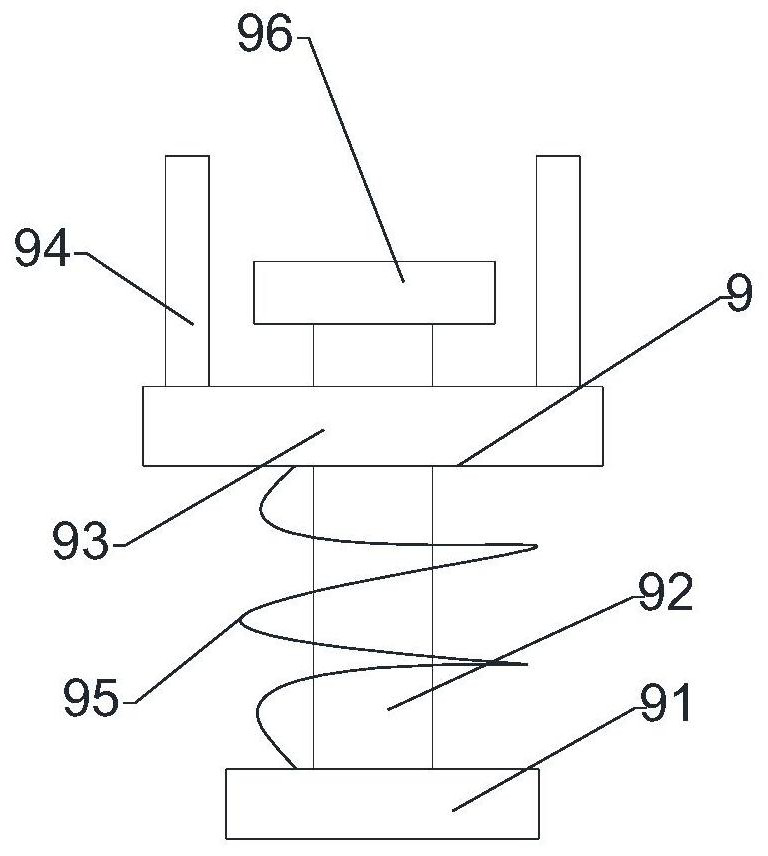

Industrial steel pipe bending device

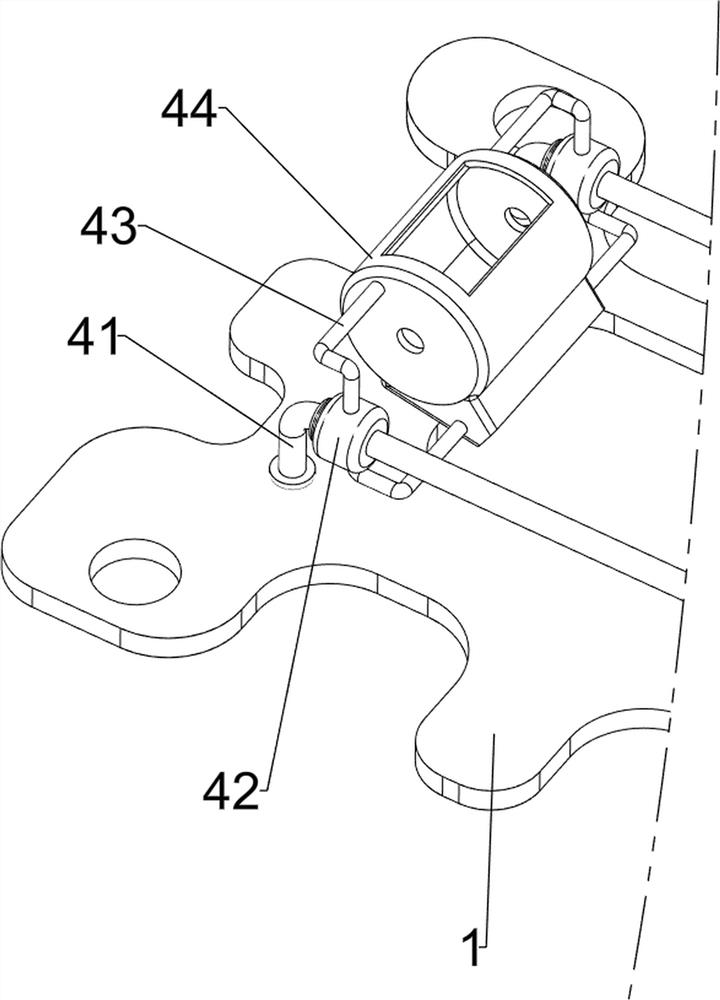

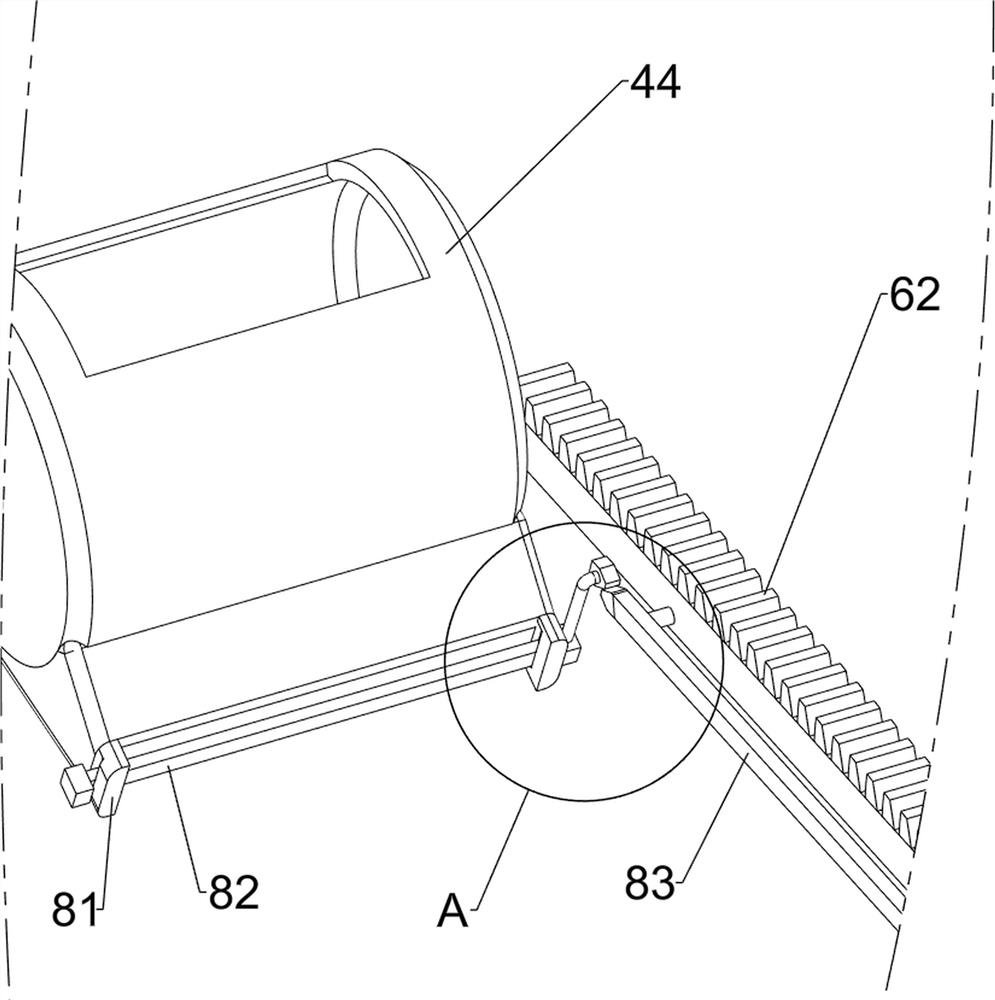

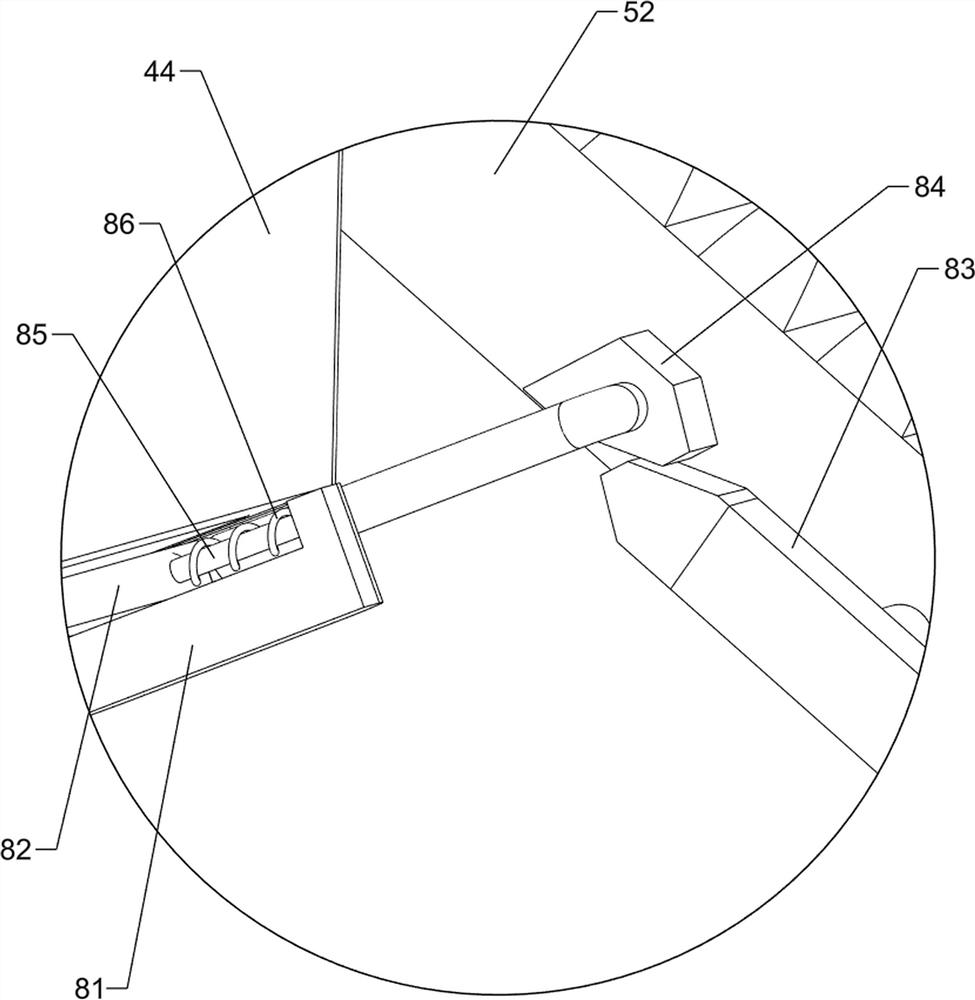

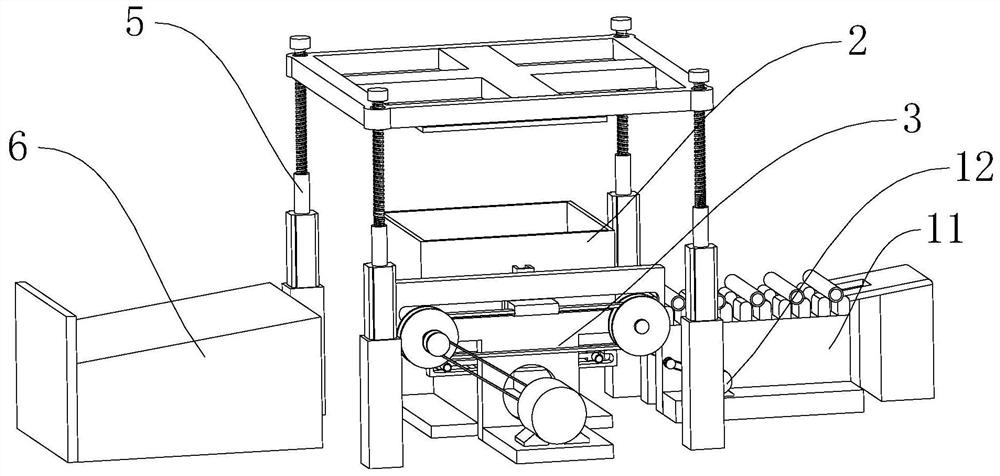

ActiveCN112872130ARealize the effect of pressing downRealize the bending effectMetal-working feeding devicesPositioning devicesGear wheelClassical mechanics

The invention relates to a bending device, in particular to an industrial steel pipe bending device. The invention provides the industrial steel pipe bending device which can achieve automatic discharging and automatic collecting and is convenient to operate. The industrial steel pipe bending device comprises a first supporting frame, an air cylinder, a downward pressing mechanism, a bending mechanism and the like; and the air cylinder is installed on the upper side of the right portion of the first supporting frame, the downward pressing mechanism is arranged between the upper side of the right portion of the first supporting frame and the air cylinder, and the bending mechanism is arranged between the middle of the right portion of the first supporting frame and the downward pressing mechanism. According to the industrial steel pipe bending device, a telescopic rod of the air cylinder moves downwards to drive a first supporting column to move downwards, so that a U-shaped hammer is driven to move downwards to press a steel pipe downwards, thereby achieving the pressing effect; and a first rack moves downwards to drive a first straight gear on the front side to rotate, so that first rotating shafts are driven to rotate, then first fixing frames are driven to turn inwards to bend the steel pipe, and the bending effect is achieved.

Owner:安徽泓鞍机械制造有限公司

Facility for environmentally friendly paint

InactiveCN108097155AVariableRealize the feeding effectTransportation and packagingMixer accessoriesDischarge efficiencyEngineering

The invention discloses a facility for environmentally friendly paint. The facility comprises a feed pipe part and a discharging pipe part; one end of the feed pipe part and one end of the dischargingpipe part are provided with clamping plates which are fixedly arranged on the ends, the middle part in the feed pipe part is provide with a first cavity and a second cavity, and the middle part in the discharging pipe part is provided with a third cavity; the middle part in the feed pipe part is provided with an installing chamber between the first cavity and the second cavity, and parts of the feed pipe part at double ends of the installing cavity is penetrated by a rotating rod. The product can realize charging and discharging effects, in addition, the apparatus can change charging efficiency, realize discharging efficiency, so that regulation and control between charging and discharging have changeability, changing scope is wide, and practicality is high.

Owner:佛山拓达科技有限公司

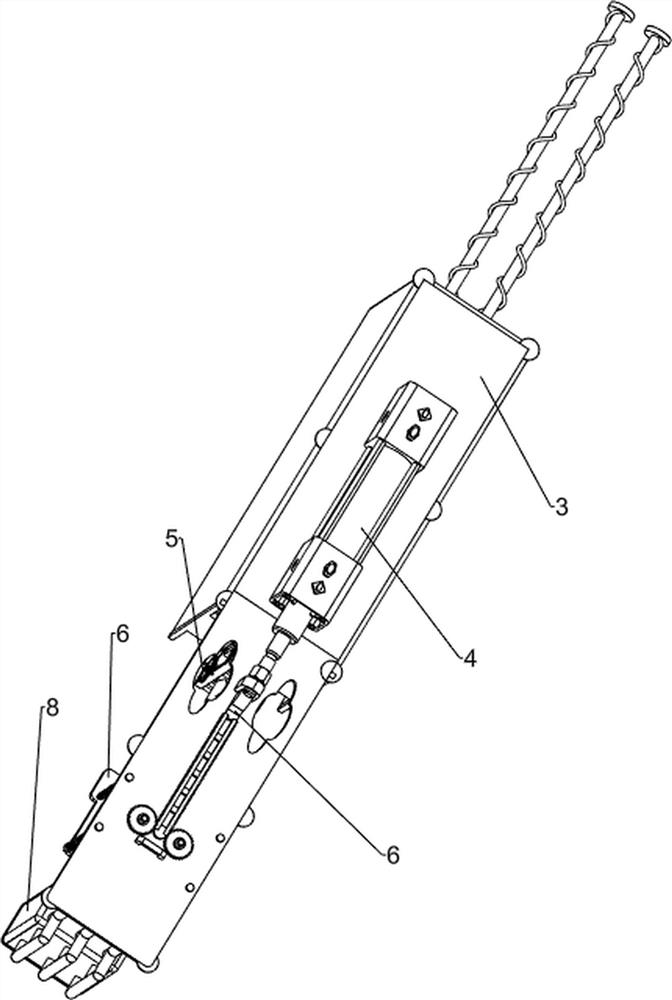

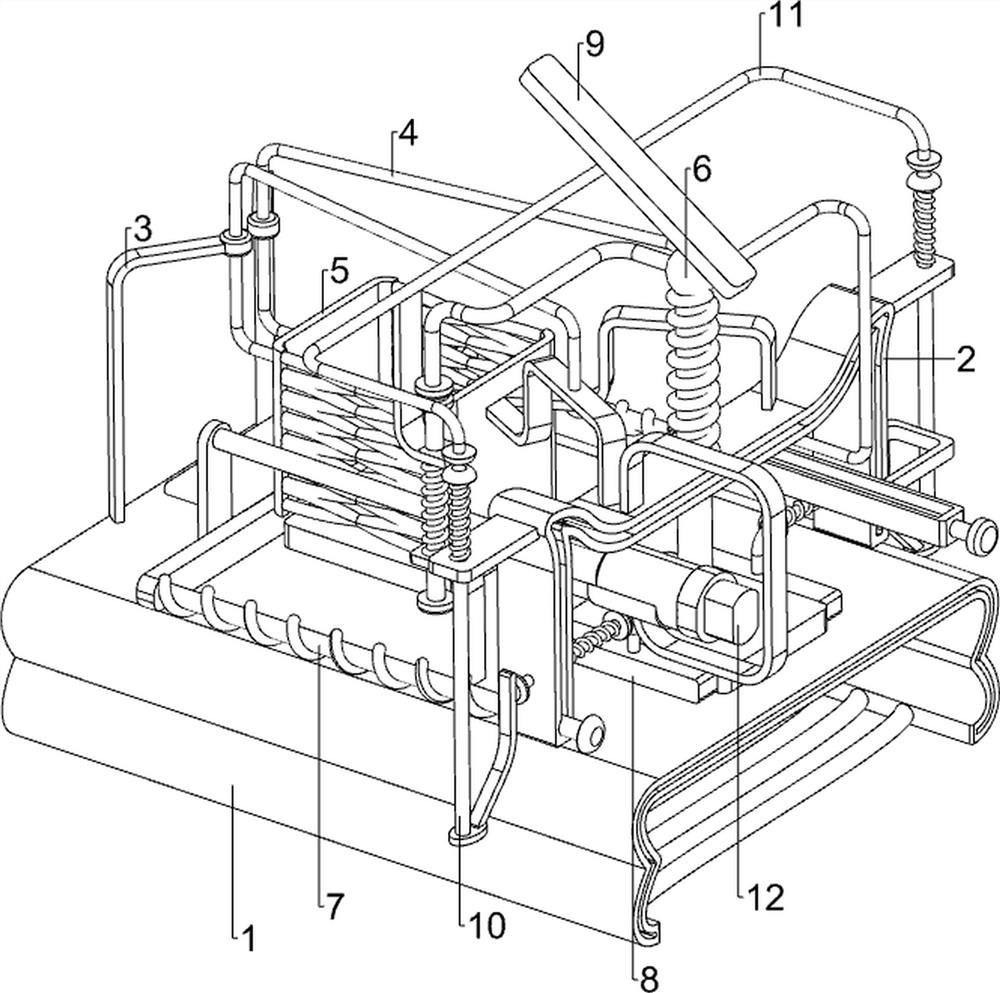

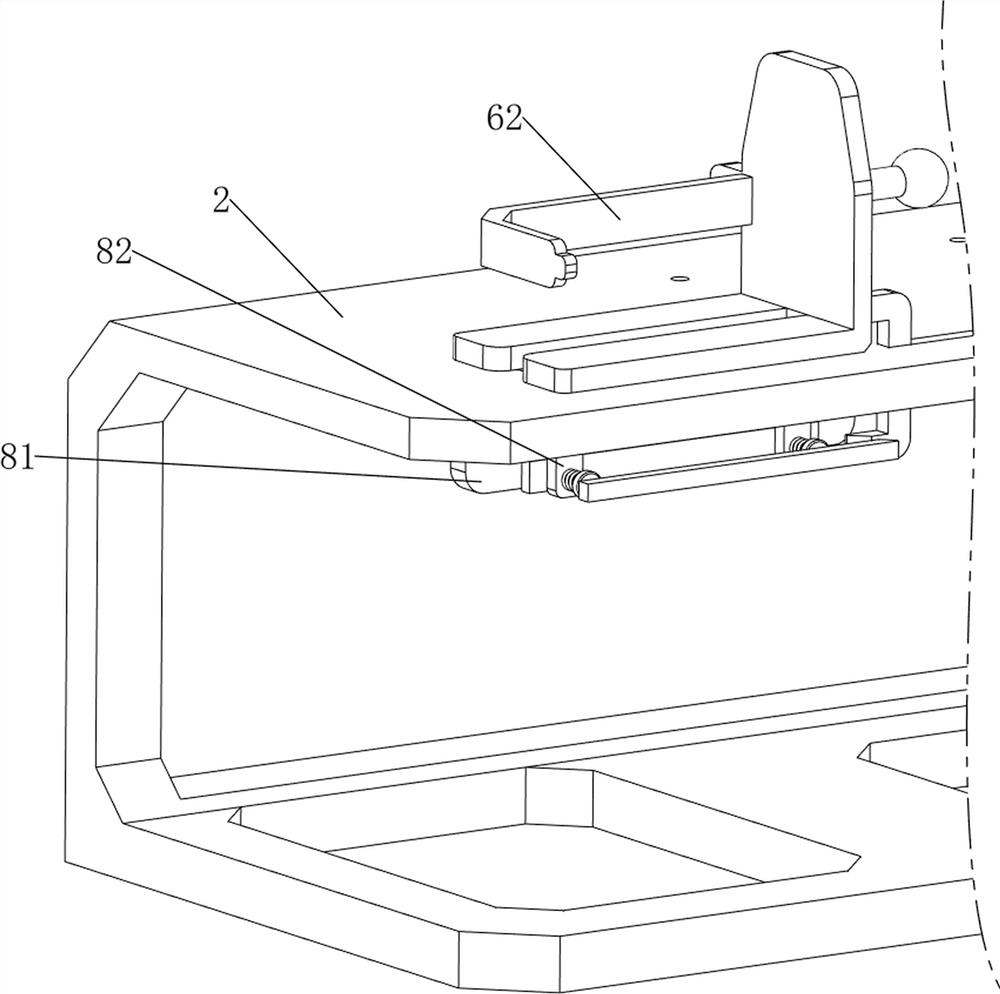

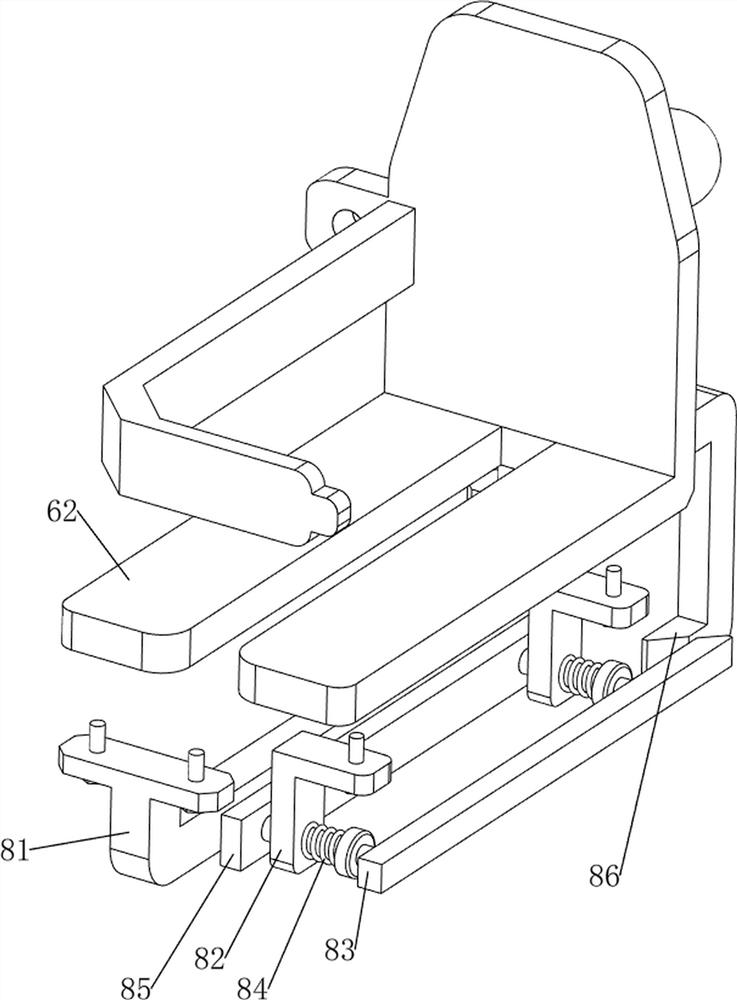

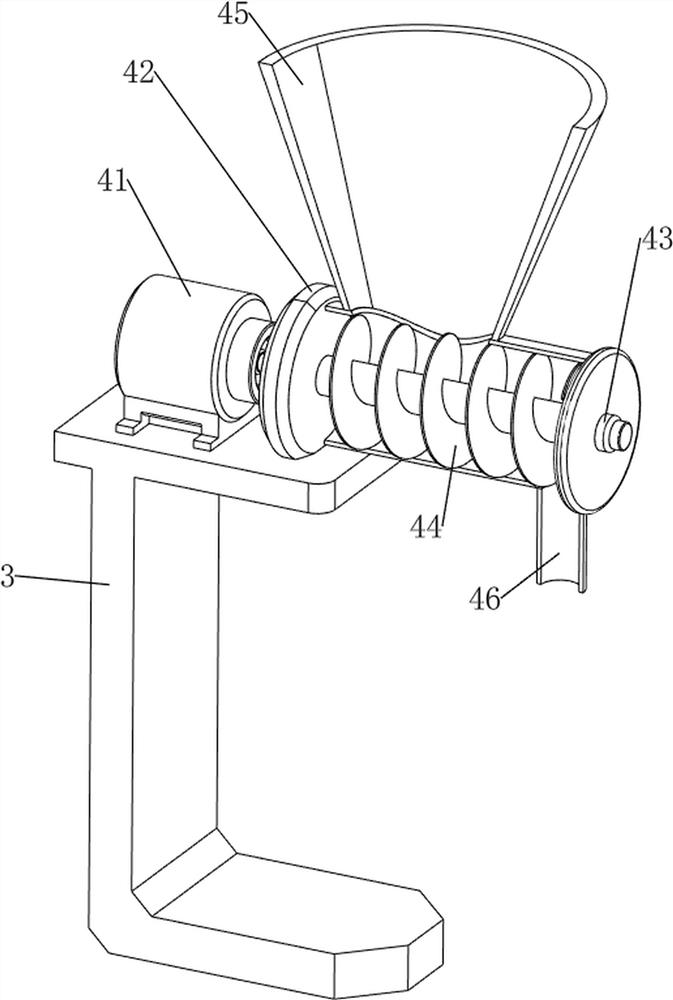

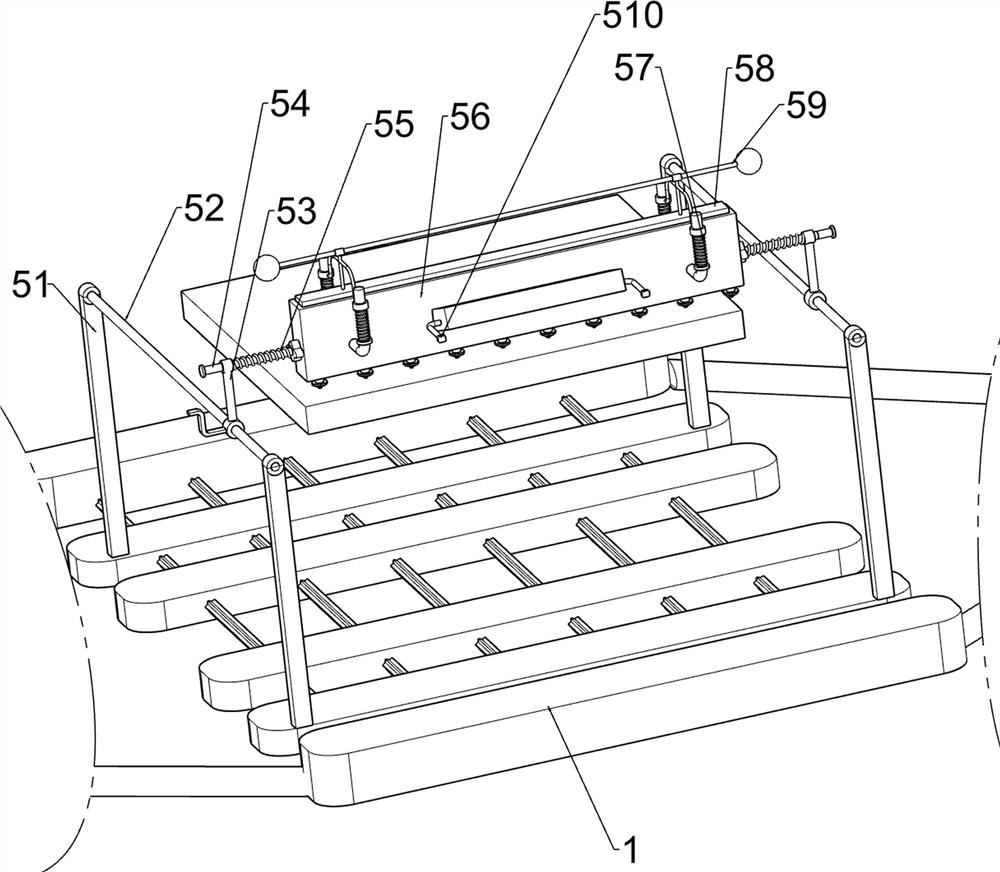

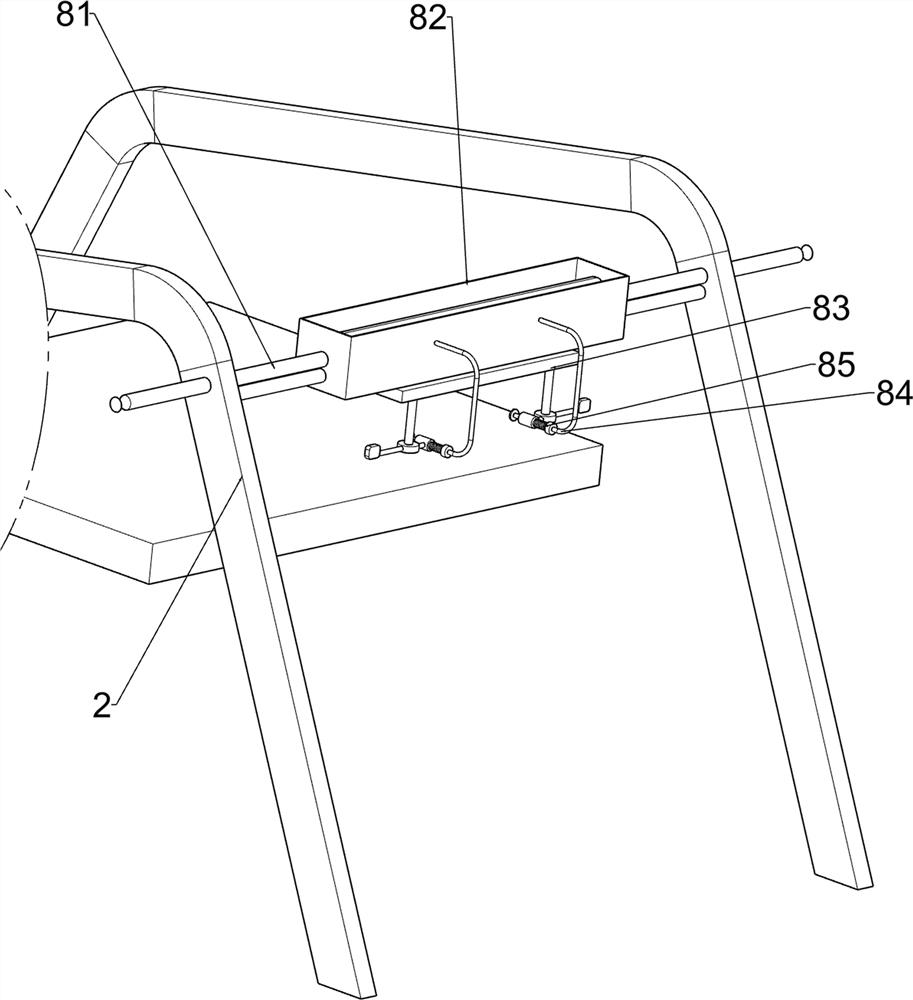

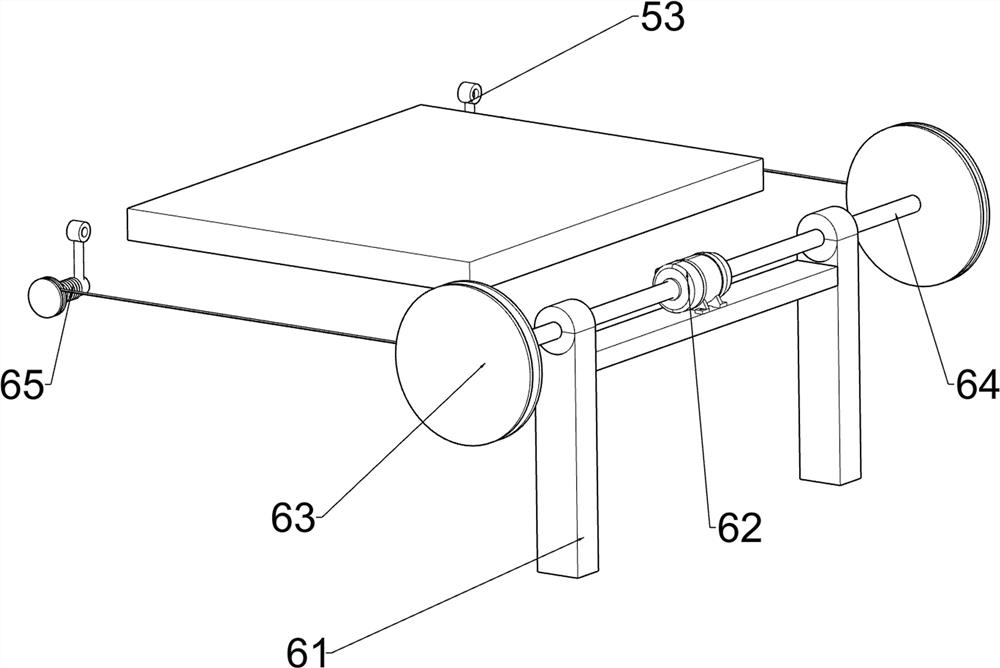

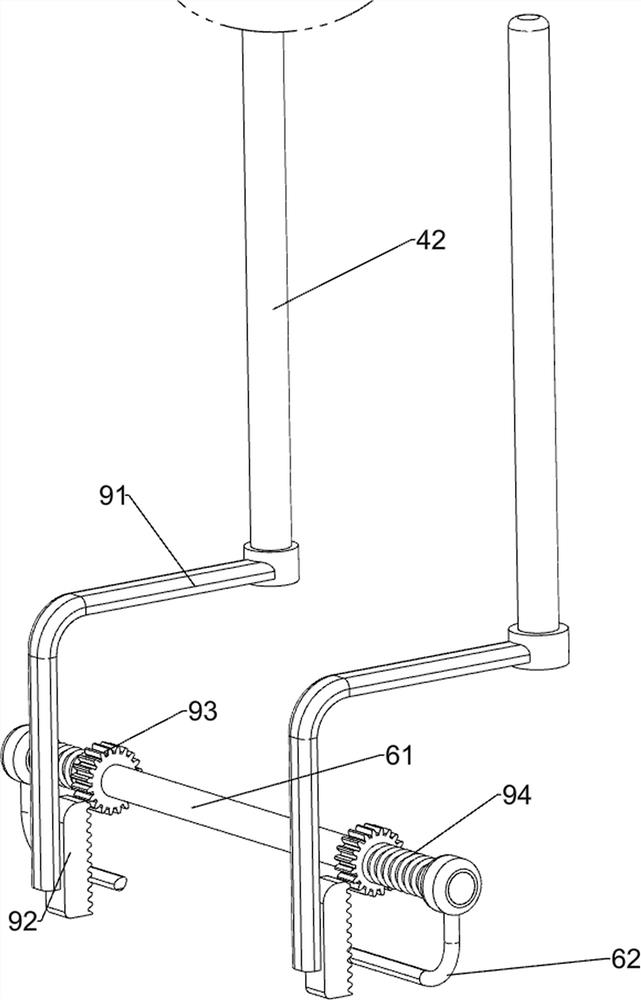

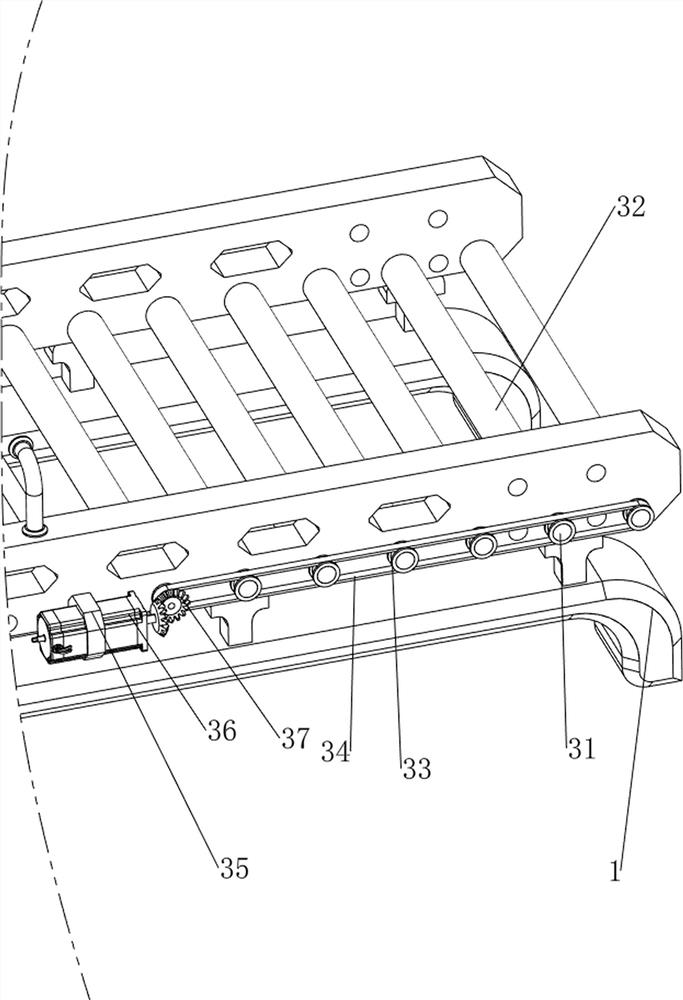

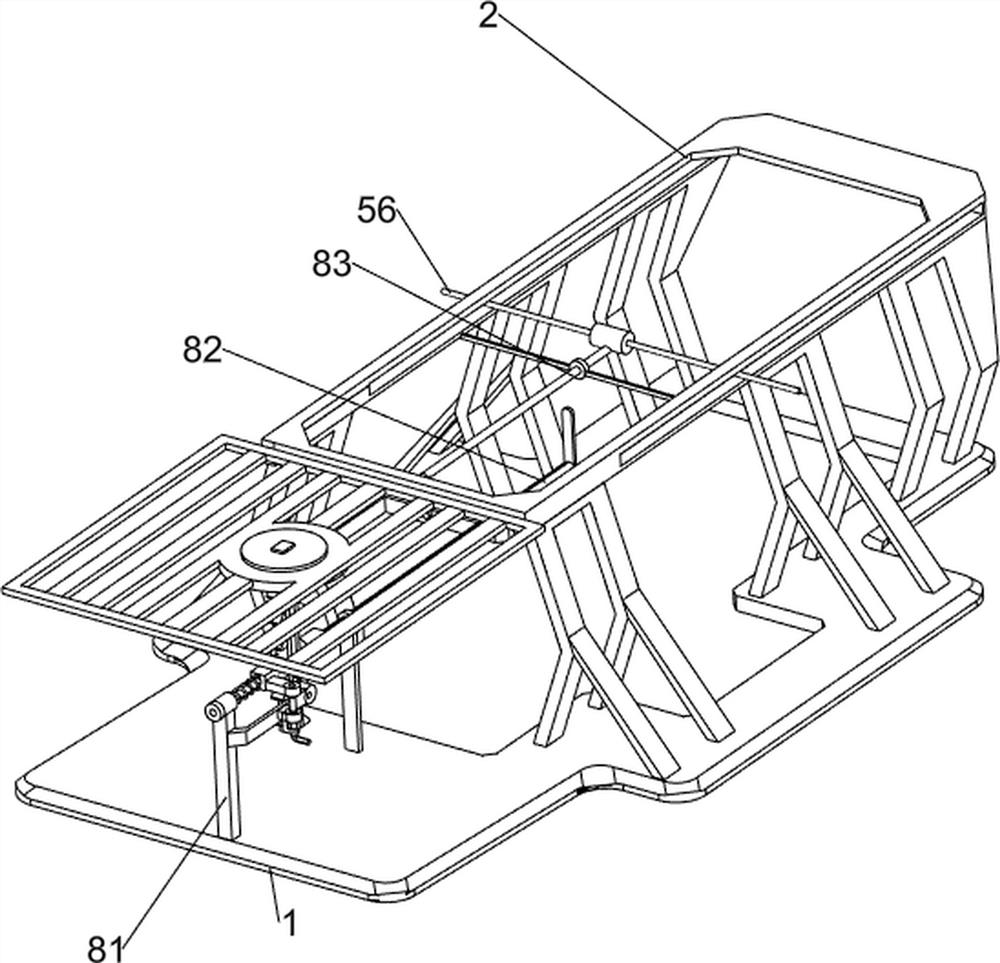

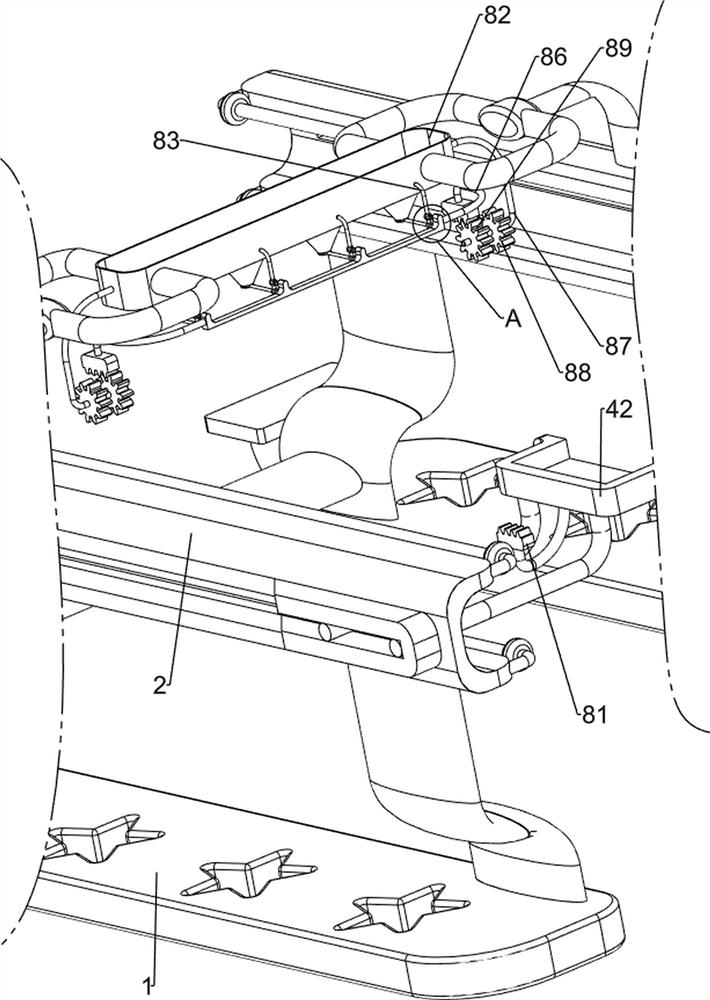

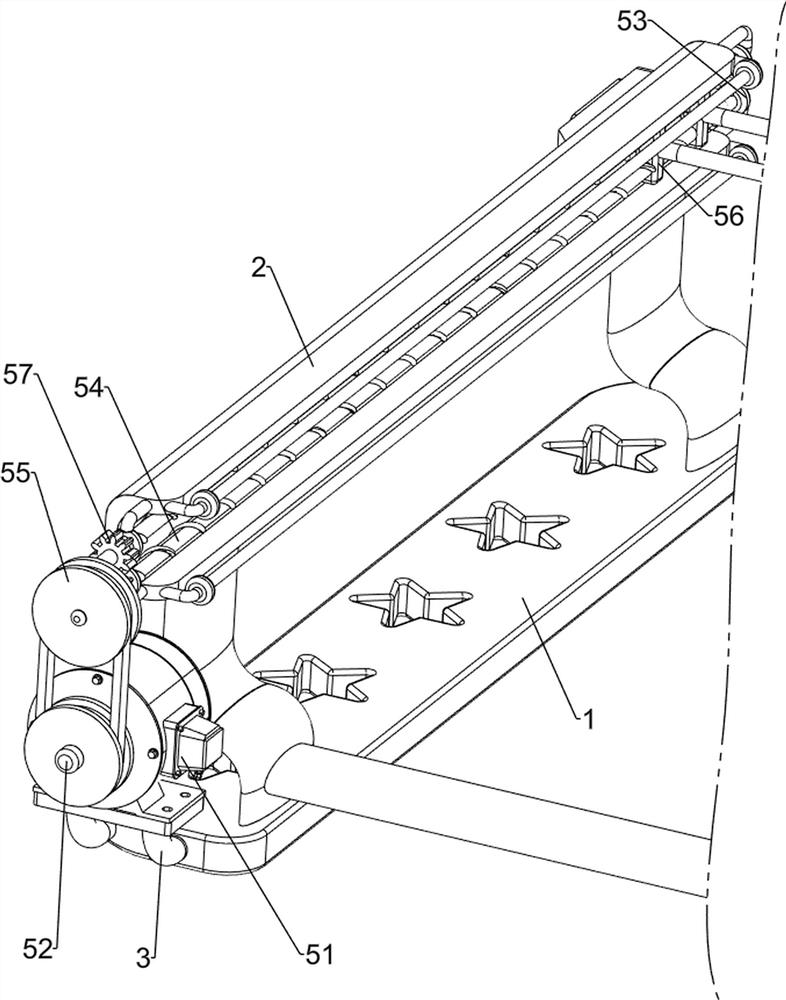

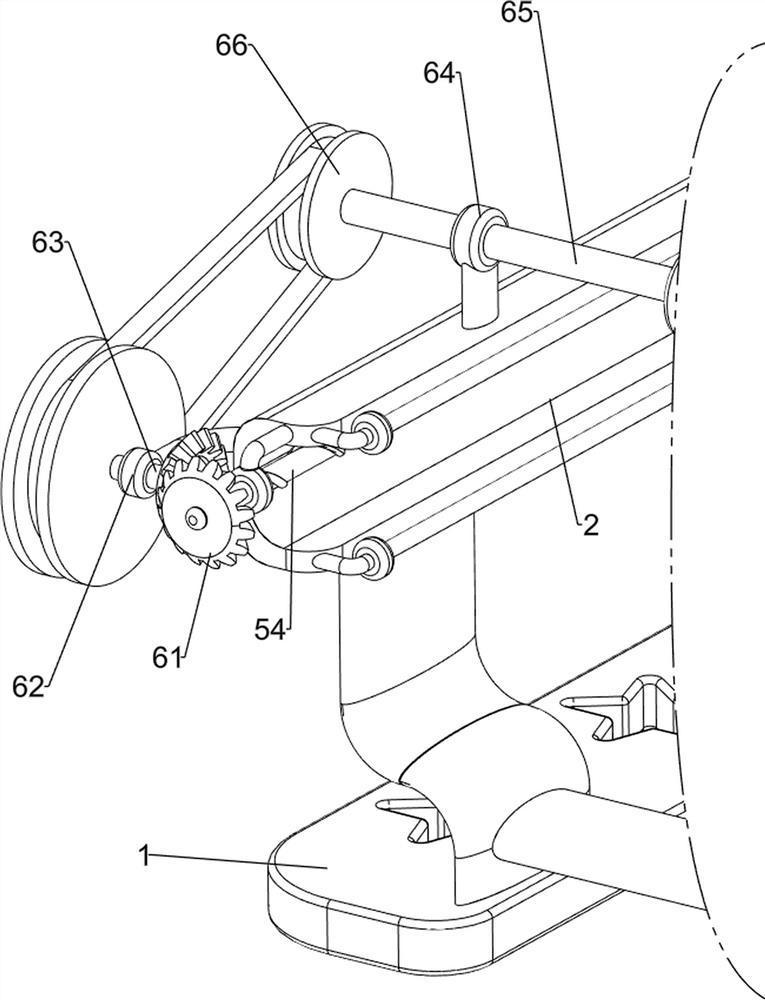

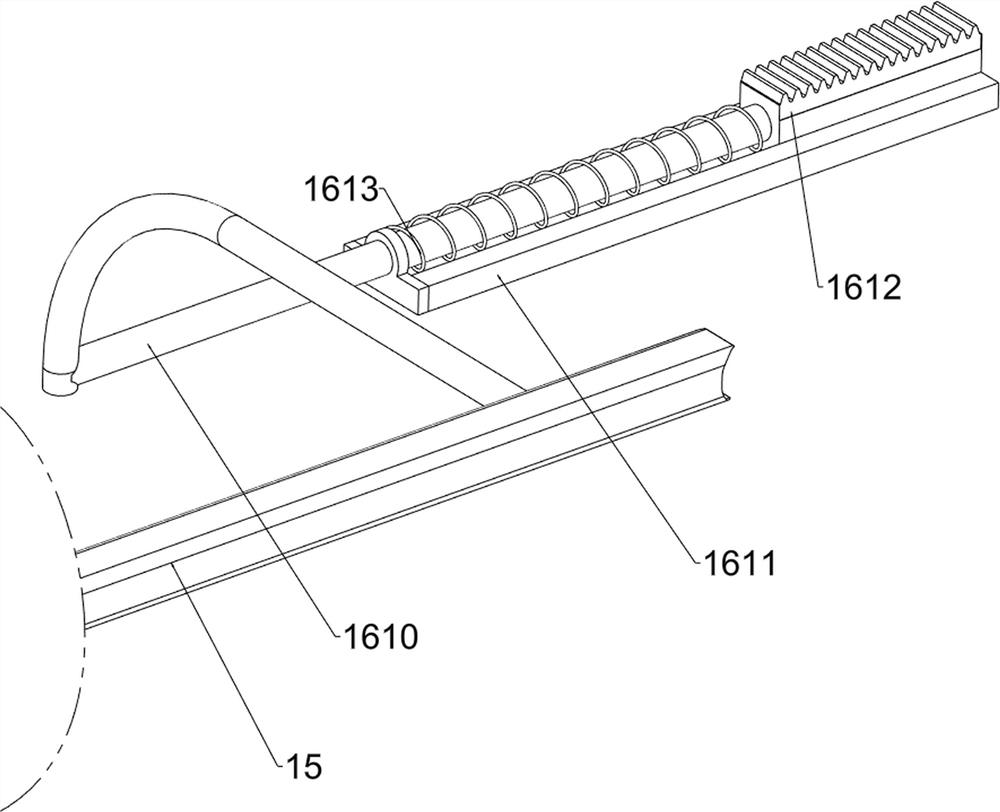

Arch-shaped toothed nail forming device for rice and wheat thresher roller

PendingCN112719131ARealize the bending effectRealize the feeding effectSaving energy measuresAgricultural engineeringElectric machinery

The invention relates to an arch-shaped toothed nail forming device, in particular to an arch-shaped toothed nail forming device for a rice and wheat thresher roller. The arch-shaped toothed nail forming device for the rice and wheat thresher roller is high in working efficiency, high in machining precision and capable of achieving bending of a plurality of toothed nails. The arch-shaped toothed nail forming device for the rice and wheat thresher roller comprises foot stands, a workbench, an installation frame, a bending mechanism, a feeding mechanism and the like, wherein four foot stands are evenly arranged at the bottom of the workbench, two mounting frames are arranged at the top of the right side of the workbench, the bending mechanism is arranged at the top of the left side of the workbench, and the feeding mechanism is arranged at the top of the left side of the workbench. According to the device, a motor output shaft drives a first transmission shaft to rotate so as to drive an extrusion roller to rotate, a user puts a manual toothed nail on the extrusion roller, and the extrusion roller bends the toothed nail.

Owner:安徽环宇米业股份有限公司

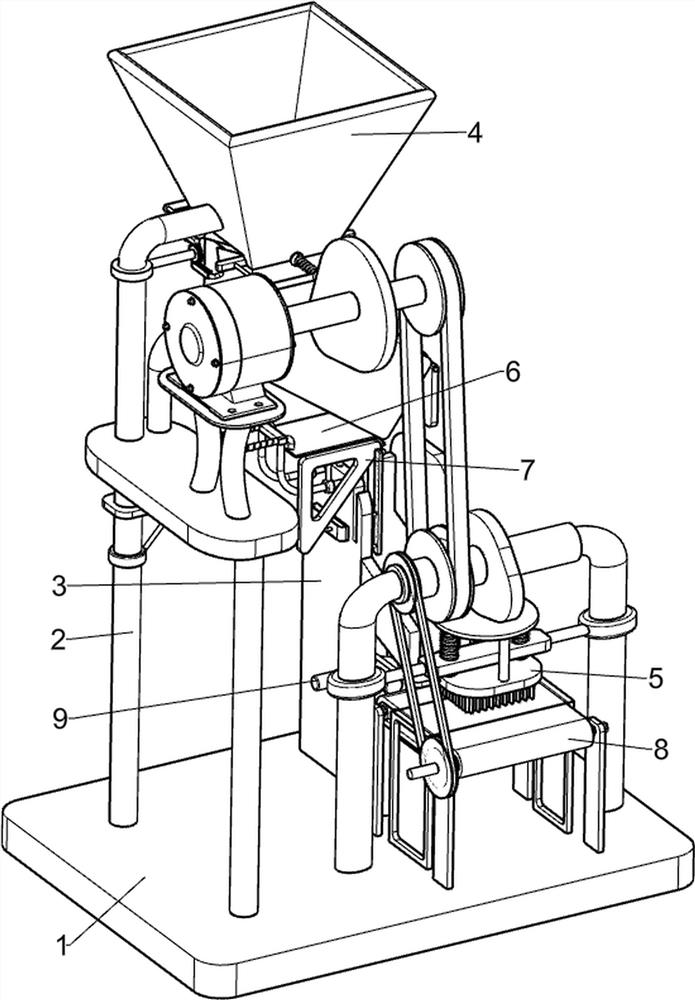

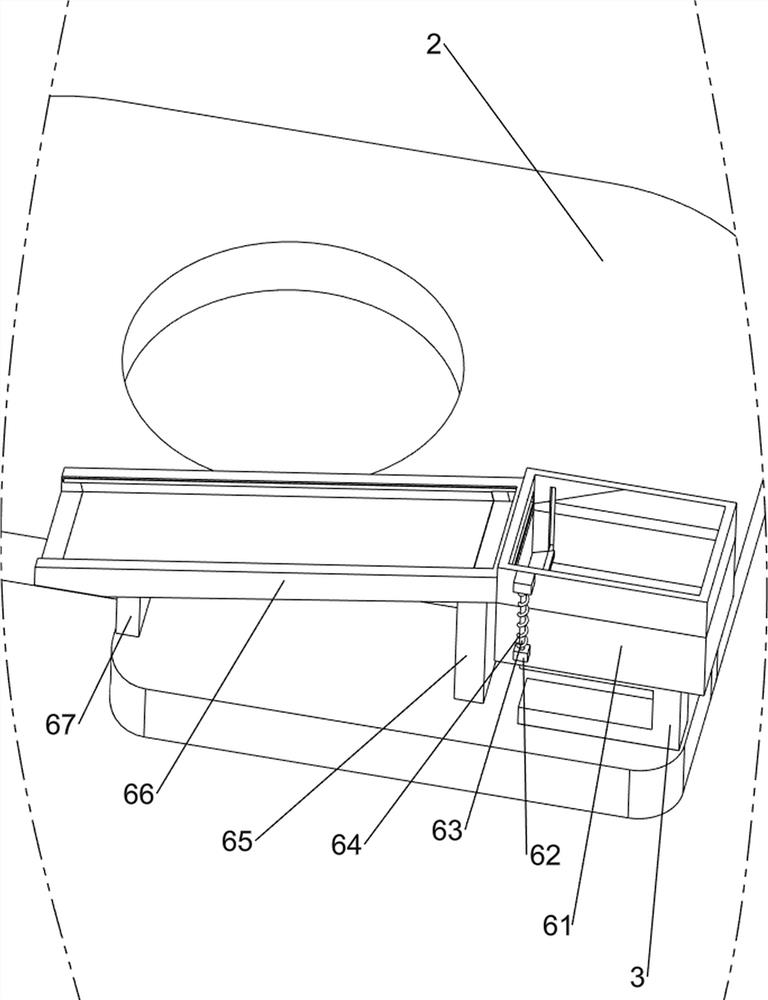

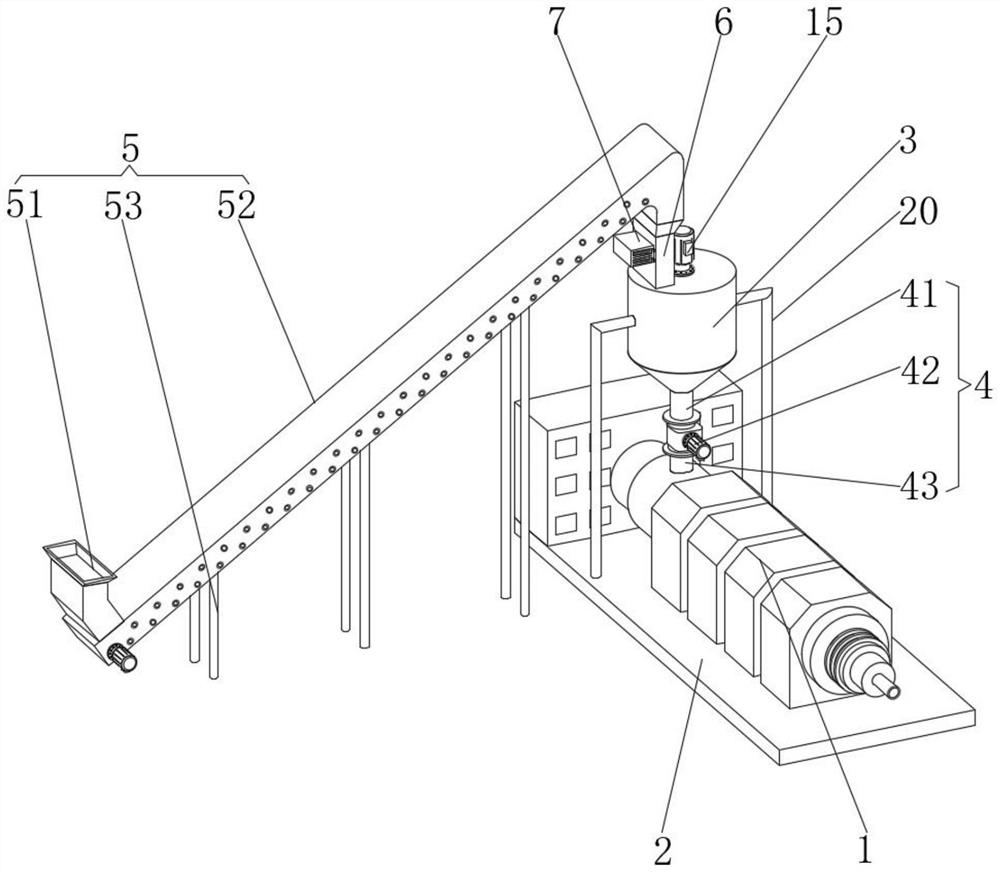

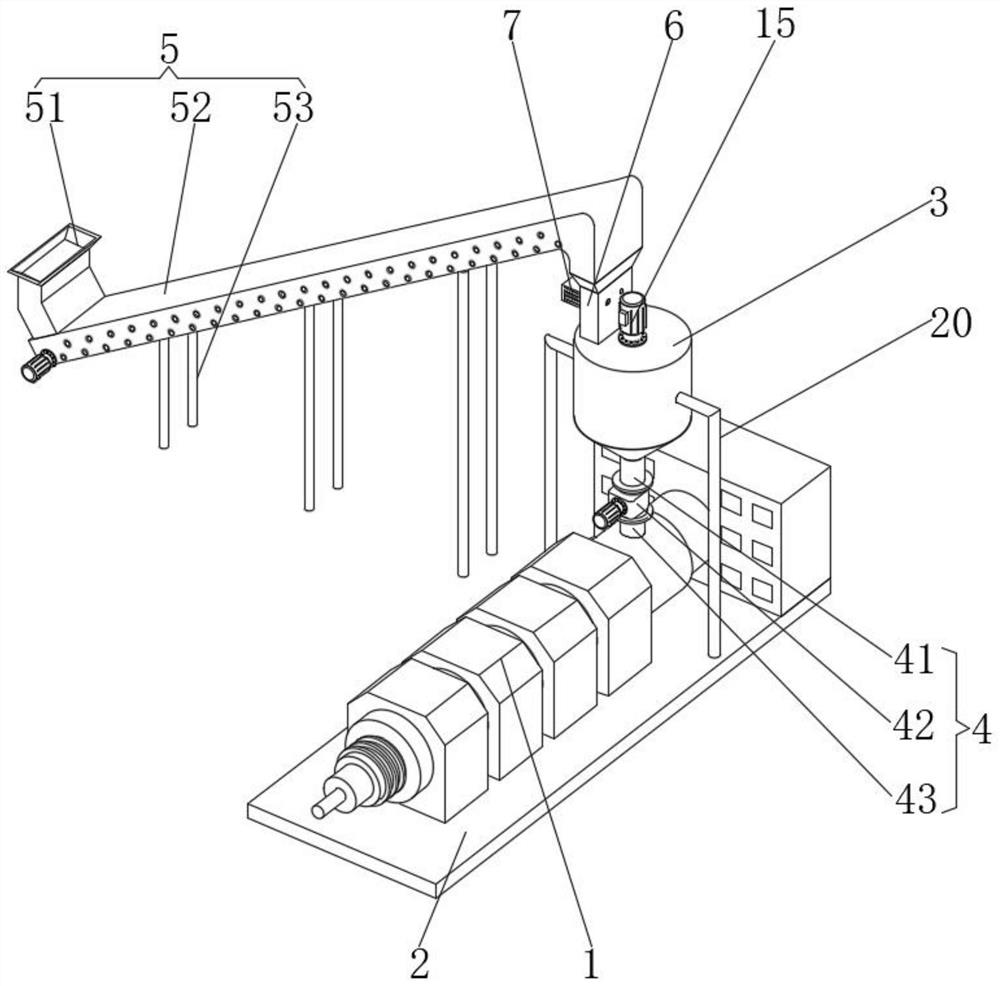

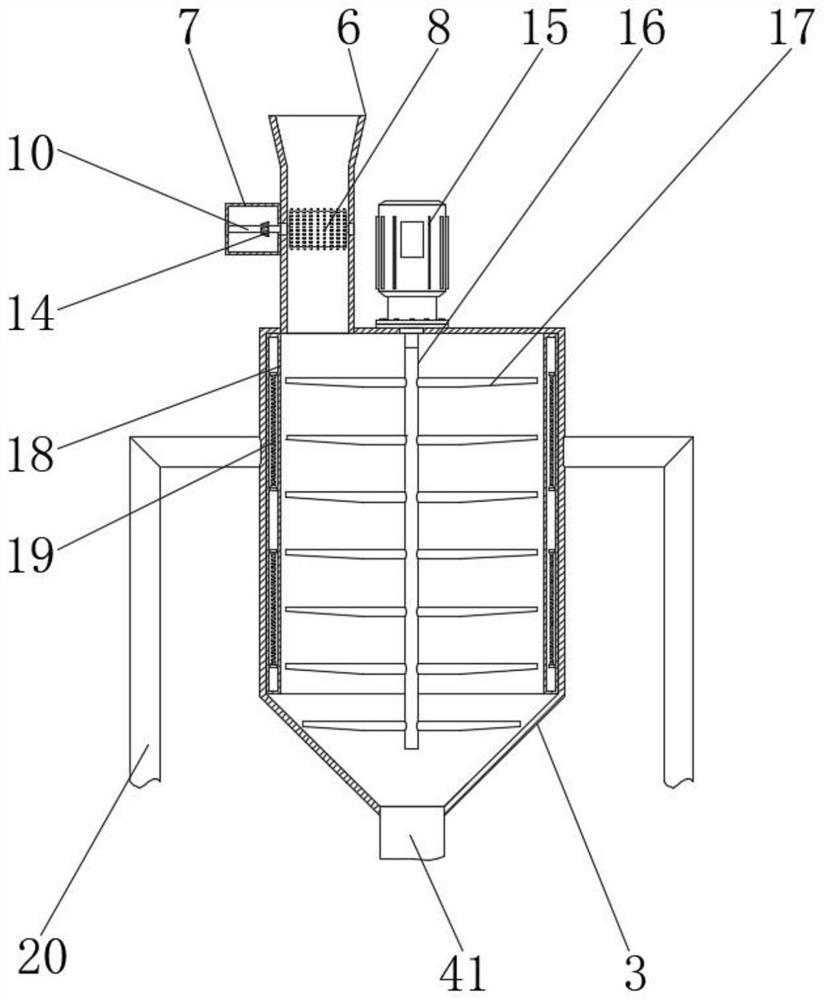

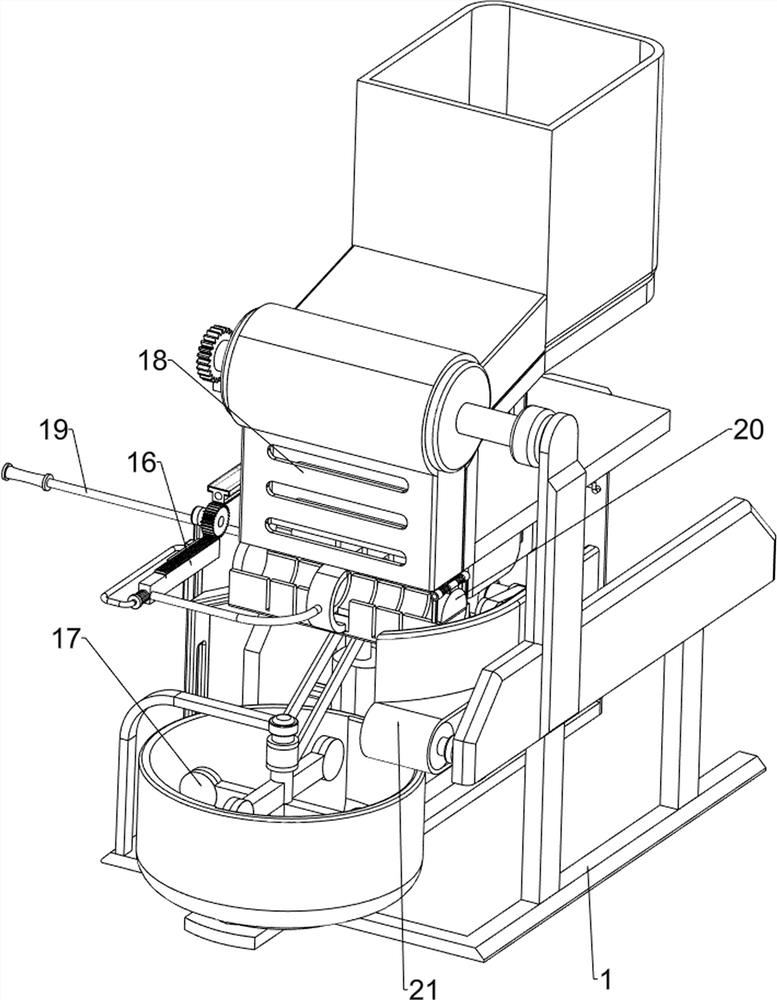

Full-degradable straw starch plastic and preparation system thereof

The invention provides a full-degradable straw starch plastic and a preparation system thereof, belongs to the technical field of plastic production and preparation, and solves the problems that the current plastic does not have a degradable function and pollutes the environment. The fully-degradable straw starch plastic is prepared from the following raw materials in parts by weight: 2 to 10 parts of straw, 60 to 70 parts of resin, 3 to 8 parts of polyvinyl alcohol fiber, 30 to 45 parts of corn starch, 4 to 9 parts of calcium powder, 6 to 15 parts of titanium dioxide and 0.5 to 6 parts of vegetable oil, wherein the resin is biodegradable starch resin. The full-degradable straw starch plastic provided by the invention can be naturally degraded in a natural environment, the degradation is more complete, and the pollution to the environment is avoided; meanwhile, the system provided by the invention can integrate two functions of stirring and extruding on one device, so that the space occupied by the device is reduced; and in the feeding process, fixed body raw materials can be crushed again, and large-particle-size and blocky raw materials are prevented from participating in stirring.

Owner:湖南登科材料科技有限公司

Coating machine

PendingCN110624773AEasy to fixImprove gluing effectLiquid surface applicatorsCoatingsEngineeringCoating

The invention provides a coating machine and belongs to the technical field of battery production equipment. The coating machine comprises a mounting table, a glue coating rotary disk and glue coatingvalves. The coating rotary table is rotatably arranged on the mounting table. The glue coating rotary disk is provided with a plurality of first clamping ports and mounting supports. The first clamping ports are located on the edge of the glue coating rotary disk and are used for clamping a battery shell. The mounting supports are in one-to-one correspondence with the first clamping ports. The glue coating valves are arranged on the mounting supports and face the first clamping ports. Each glue coating valve is provided with a discharge nozzle. The discharge nozzles are used for conducting glue coating on an upper edge opening of the inner wall of the battery shell. The coating machine has the beneficial effects of being capable of conducting glue coating on the upper edge opening of theinner wall of the battery shell so that a sealing ring can be fixed to the upper edge opening of the inner wall of the battery shell better.

Owner:NINGBO BEITERUI ENERGY TECH

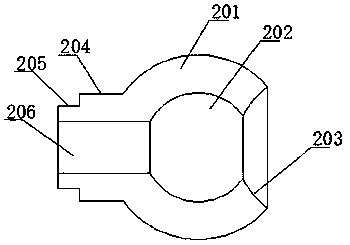

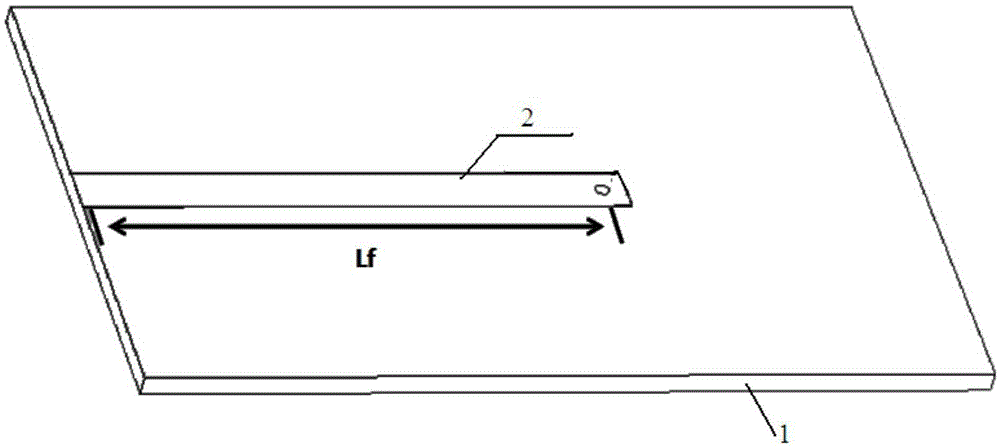

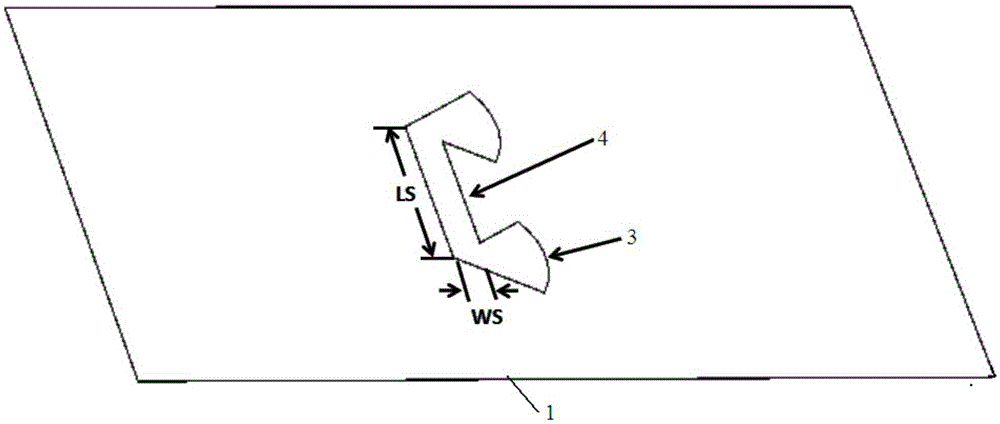

Feed structure of air integrated waveguide

ActiveCN105305057AGuaranteed normal transmissionRealize the feeding effectRadiating elements structural formsPhysicsWaveguide

A feed structure of an air integrated waveguide relates to a feed structure of a waveguide and solves the conflict between miniaturization and low loss of ultrathin waveguides in the prior art. A waveguide slot and a feed slot are carved in the upper surface of a rectangular waveguide plate. The depth of the feed slot is greater than that of the waveguide slot, and the feed slot is arranged near the waveguide slot. A metal plate covers the waveguide slot and the feed slot from the top and is electrically connected with the rectangular waveguide plate. The metal plate, the waveguide slot and the feed slot form a waveguide chamber and a feed chamber. A coupling slit is carved in the metal plate above the feed chamber. The coupling slit is a rectangular through hole. A fan-shaped through hole is carved at each of two ends of the coupling slit. A microstrip line is arranged above the rectangular waveguide plate. A starting end of the microstrip line is aligned with a short side of the rectangular waveguide plate, a tail end of the microstrip line is above the waveguide chamber, and the body of the microstrip line is above the coupling slit. The feed structure is suitable for being used as an electromagnetic wave feed structure of a waveguide.

Owner:HARBIN INST OF TECH

A solid chili sauce canning machine

ActiveCN113291498BRealize the effect of automatic canningRealize the feeding effectSolid materialChilli con carneProcess engineering

Owner:青岛新绿农产有限公司

A traditional Chinese medicine dregs extruder and its application method

ActiveCN110871584BRealize the buffering effectReduce manual laborPressesMechanical engineeringTraditional Chinese medicine

The invention discloses an extruder for traditional Chinese medicine dregs, which comprises a collection box and an extrusion box. The extrusion hole, the extrusion plate and the inner wall of the extrusion box form an extrusion cavity, and an extrusion block slides in the extrusion cavity, and an extrusion rod is connected to the top of the extrusion block, and the extrusion rod passes through the extrusion box and is connected outside the extrusion box There is a pressing plate, and a buffer mechanism is arranged between the pressing plate and the extrusion box, and a feeding hopper is arranged on one side of the extrusion box. The liquid medicine in the medicine dregs of the present invention enters the collection frame from the extrusion hole, and the filter screen can further filter the medicine liquid, thereby removing impurities in the medicine liquid, and the medicine dregs in the squeeze box can be sent to It enters the extrusion box to realize cyclic extrusion, and the buffer guide rod drives the sleeve block to move downward in the buffer sleeve column, and the buffer spring squeezes, thereby realizing the buffer effect, and the buffer spring resets at the same time, which can reduce manual labor.

Owner:阿克塞哈萨克族自治县人民医院

A kind of environmental protection coating equipment

ActiveCN107700806BVariableRealize the feeding effectBuilding constructionsDischarge efficiencyMechanical engineering

The invention discloses an environment-friendly painting device which comprises a feeding pipe part and a discharging pipe part. One ends of the feeding pipe part and the discharging pipe part are provided with clamping plates which are fixedly mounted at the ends of the feeding pipe part and the discharging pipe part correspondingly, and a first cavity and a second cavity are formed in the middleof the interior of the feeding pipe part; a third cavity is formed in the middle of the interior of the discharging pipe part, and a mounting cavity is formed in the position, between the first cavity and the second cavity, of the middle of the interior of the feeding pipe part; and a rotary rod penetrates through the position, located at the two ends of the mounting cavity, of the feeding pipe part. According to the environment-friendly painting device, the feeding effect can be achieved, and the discharging effect can also be achieved; and additionally, the feeding efficiency can be changed, the discharging efficiency can also be improved, thus variability is achieved on adjusting between feeding and discharging, the variable range is wide, and the practicability is high.

Owner:JIANGSU TONGSHUAI PAINT CO LTD

Household sugarcane cutting and cleaning equipment

ActiveCN114347111APrevent rolloutAchieve cleaningClimate change adaptationMetal working apparatusGear wheelAgricultural engineering

The invention relates to cleaning equipment, in particular to household sugarcane cutting and cleaning equipment. The invention provides household sugarcane cutting and cleaning equipment with automatic cutting and automatic cleaning functions. The household sugarcane cutting and cleaning equipment comprises a bottom plate and a first supporting column, the first supporting column and a material collecting frame are arranged on the bottom plate, and the material collecting frame is arranged at the top of the first supporting column; the second supporting column is arranged in the middle of the bottom plate; the first rotating shaft is rotationally arranged at the top of the second supporting column; the motor is mounted on the bottom plate; the bevel gear set is arranged between the output shaft of the motor and the first rotating shaft; and the first rotating shaft is provided with the missing gear. By arranging the fixing mechanism, the blade drives the fixing mechanism to operate, so that the fixing mechanism blocks sugarcanes, and the sugarcanes are prevented from being pushed out forwards when being cut.

Owner:南京至善骏达科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com