Patents

Literature

71 results about "Elasticity Testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

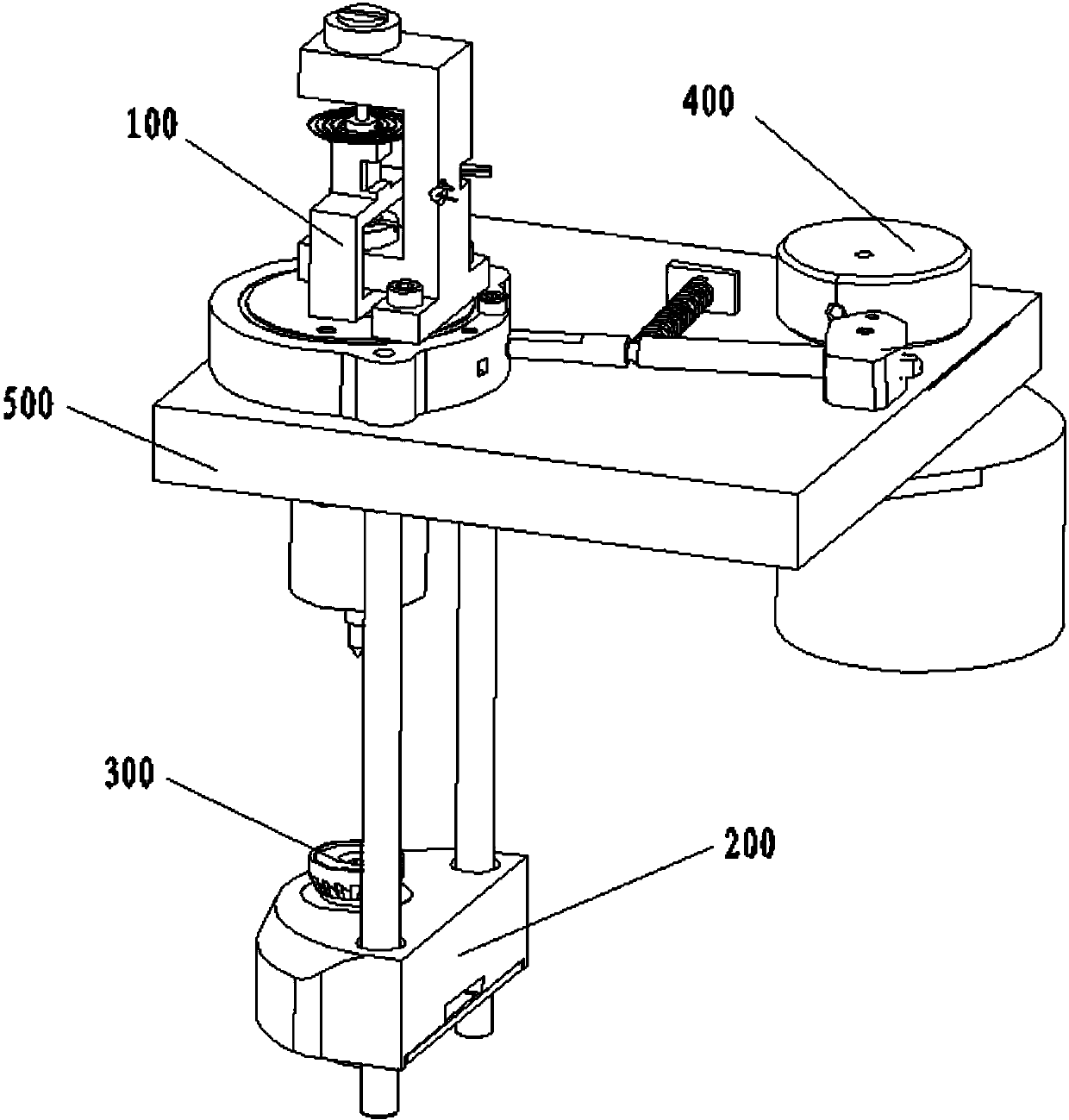

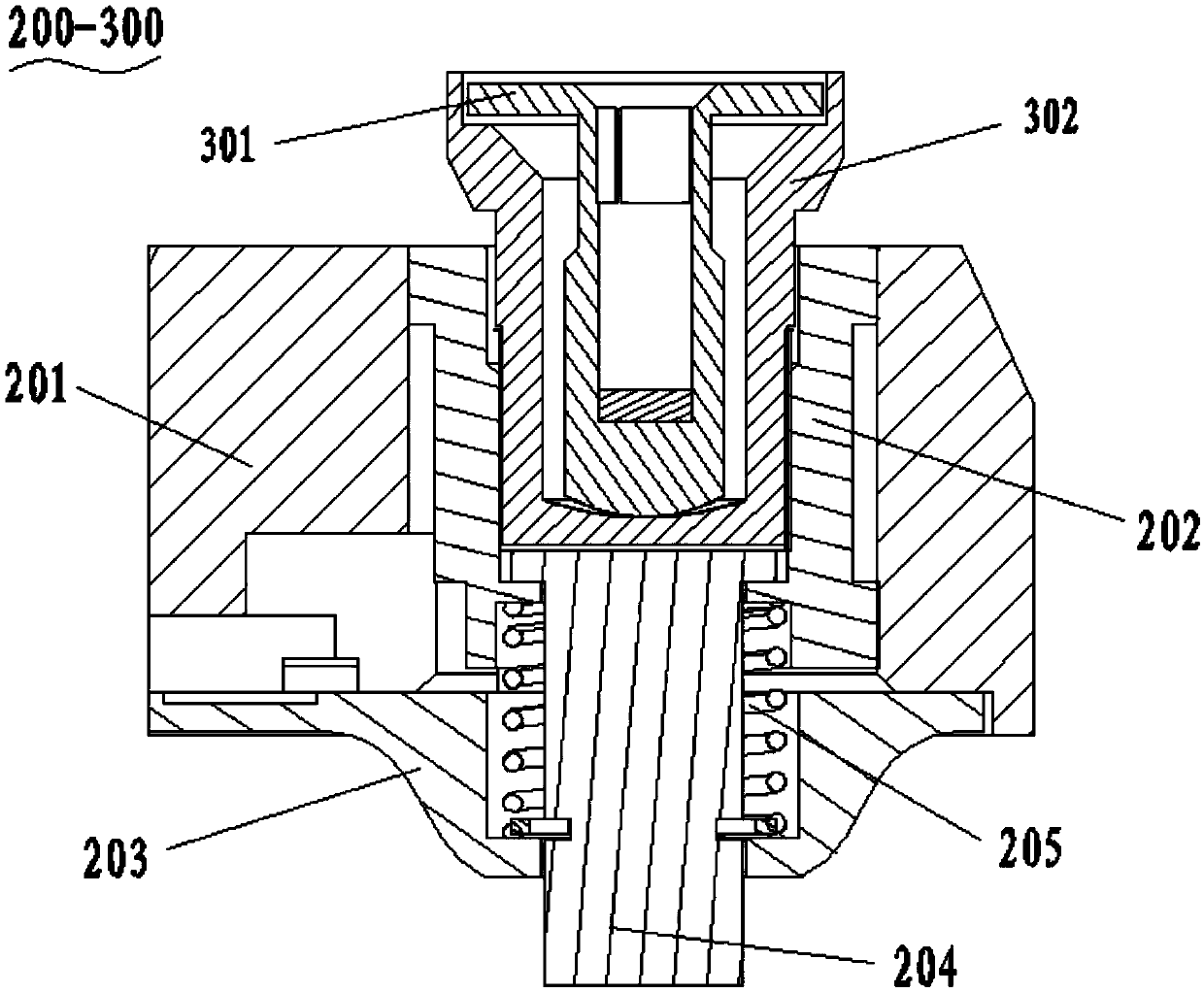

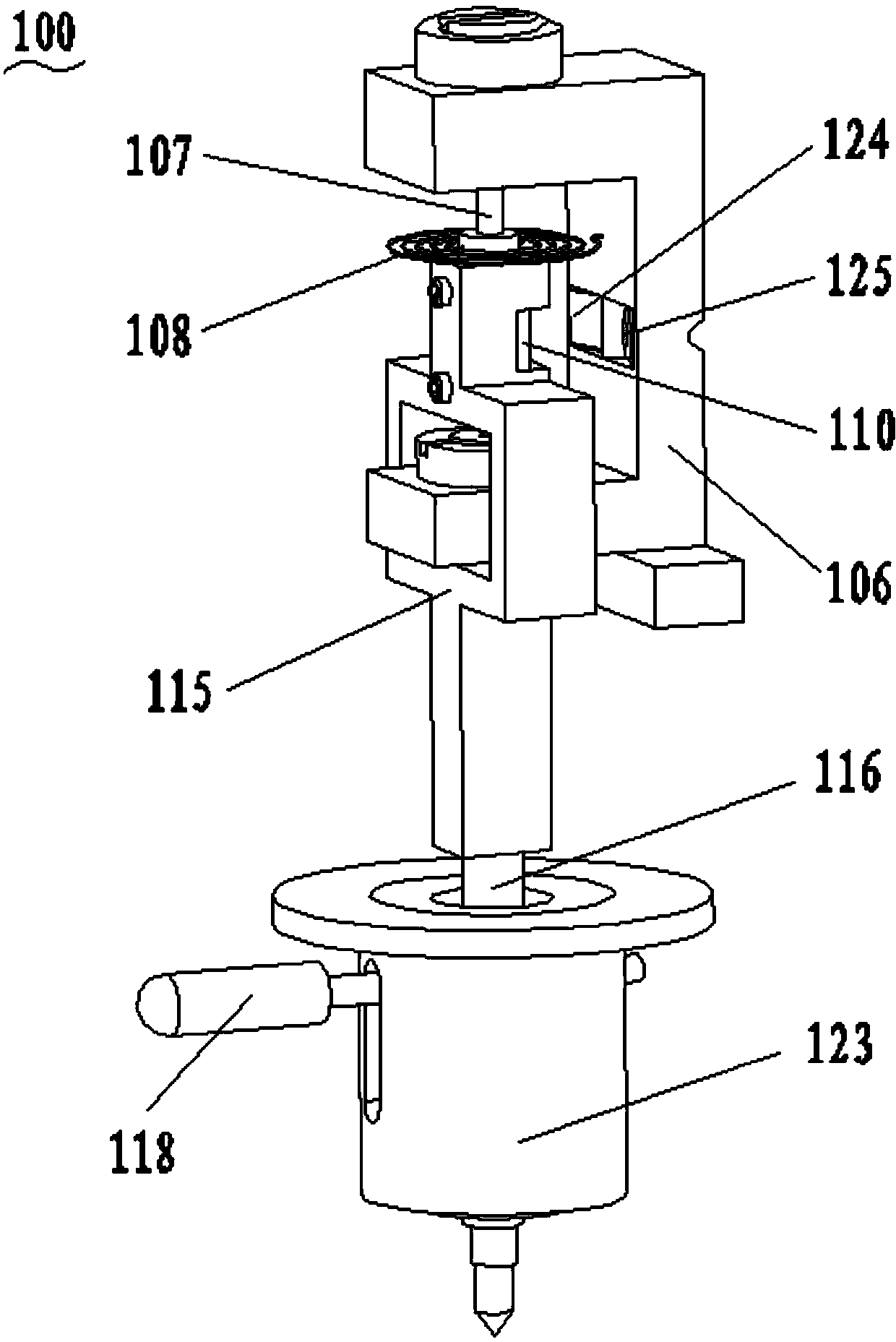

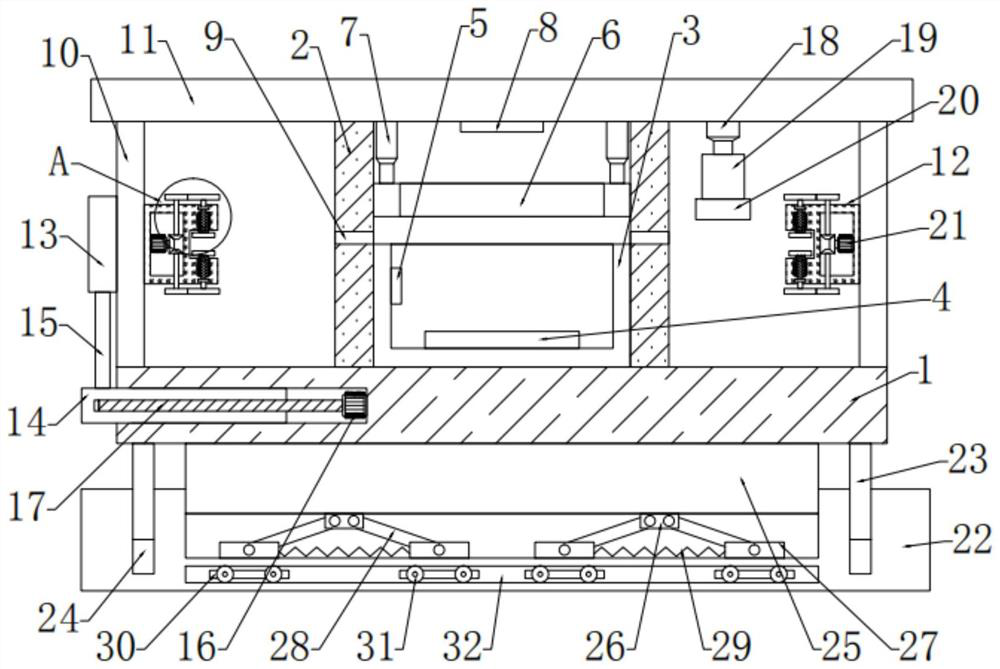

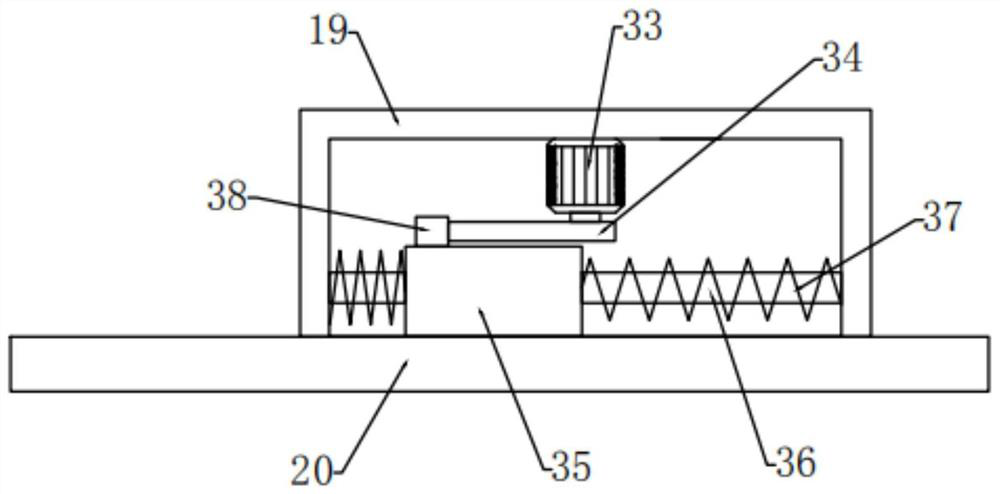

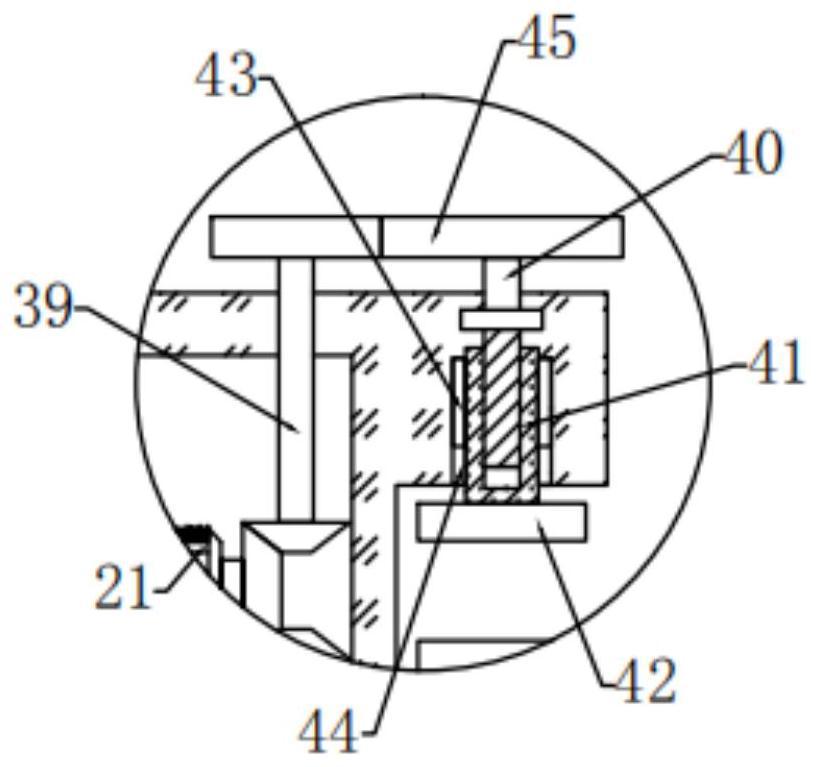

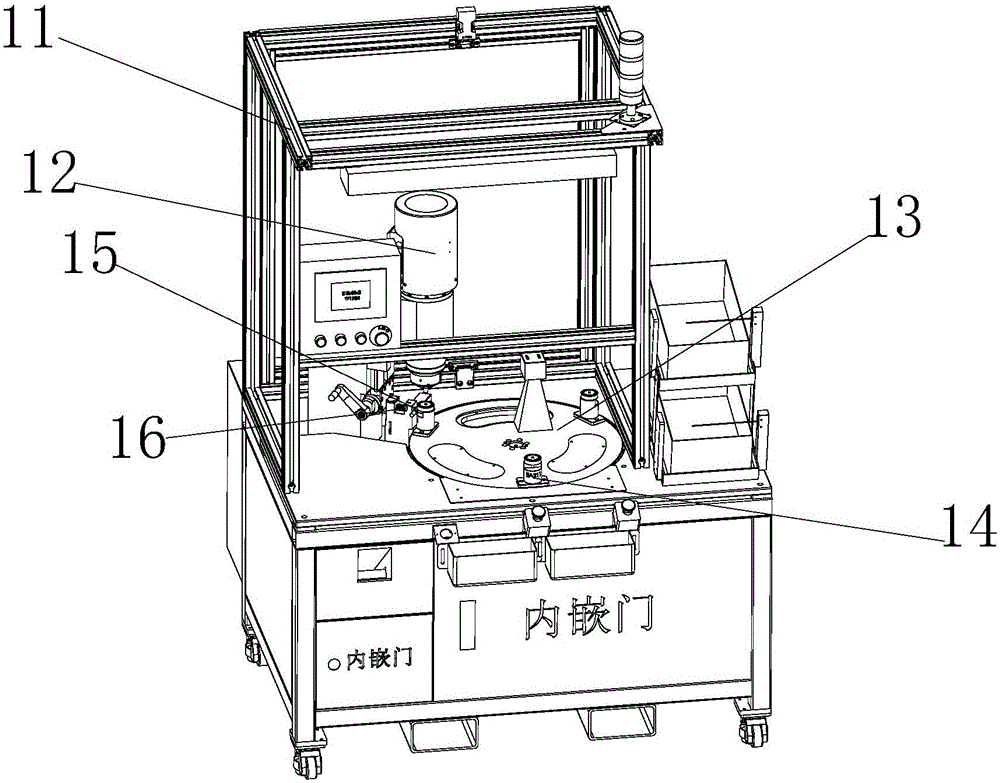

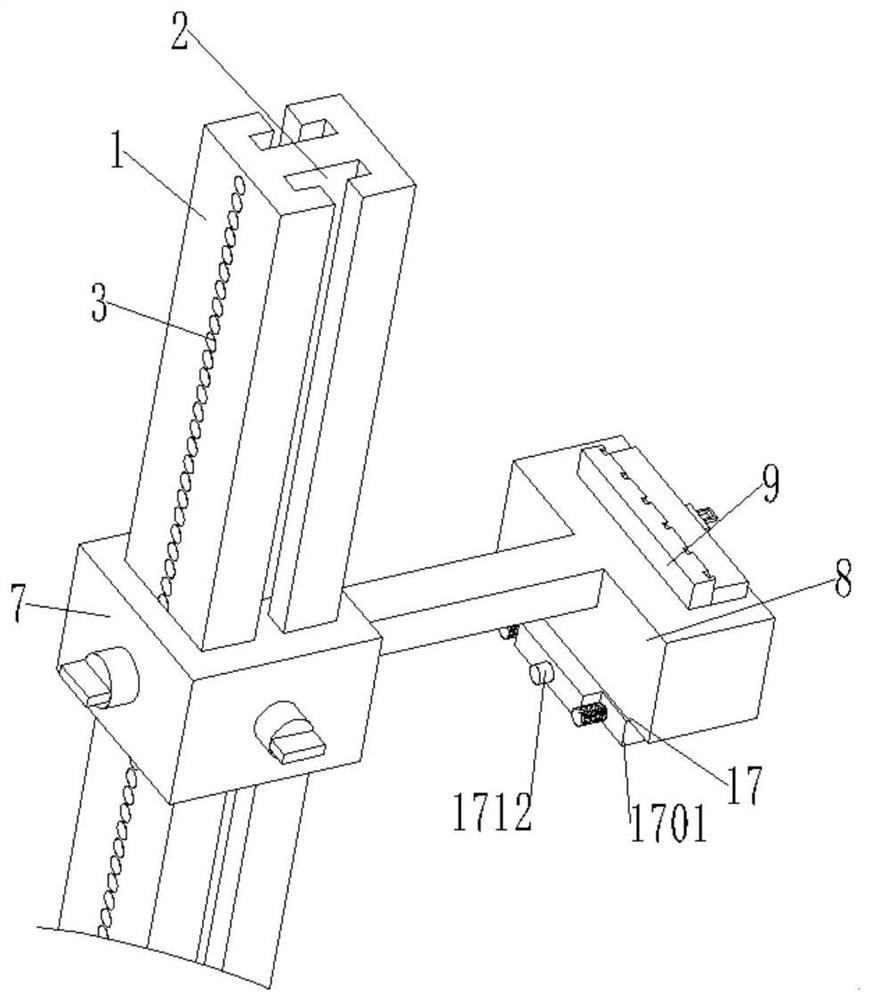

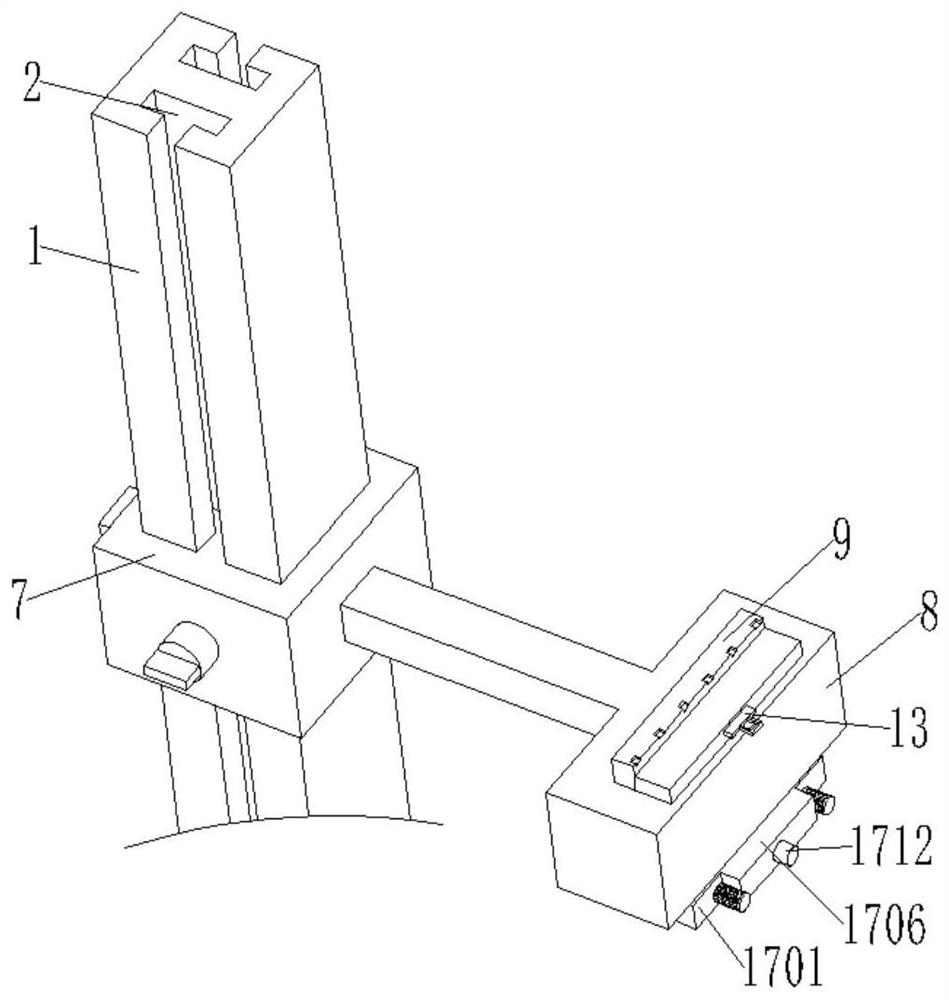

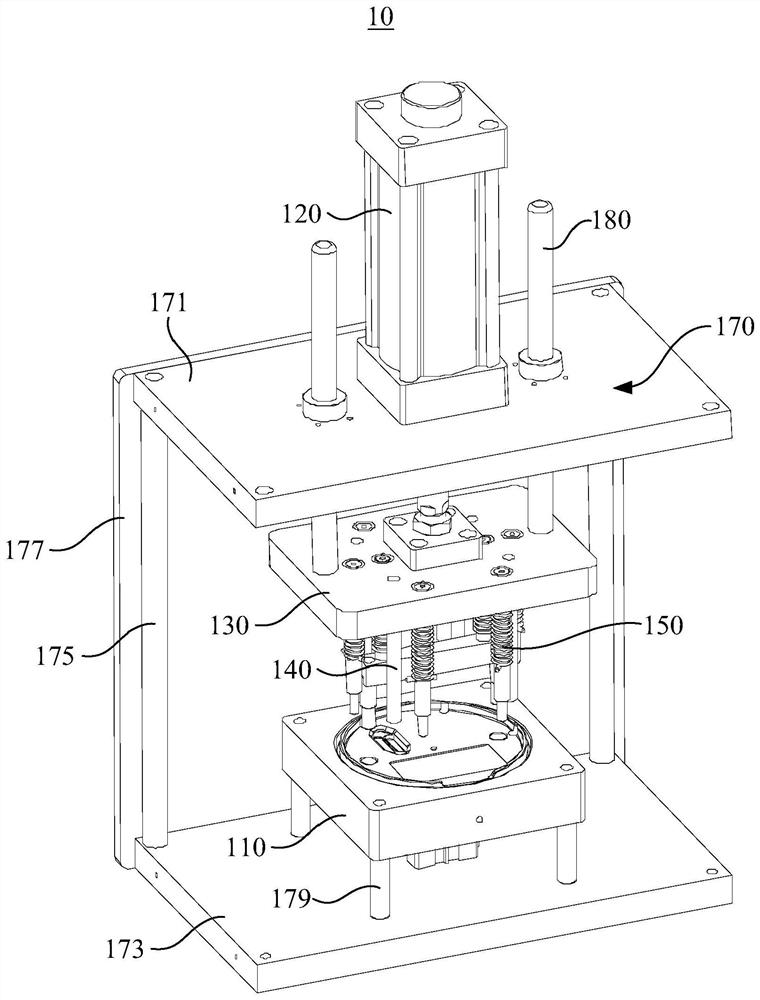

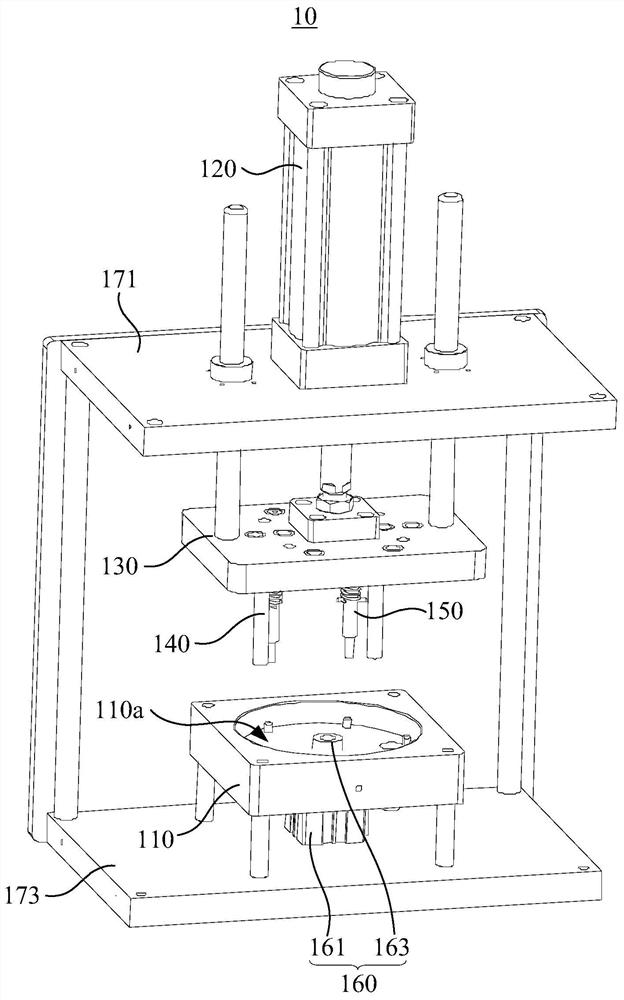

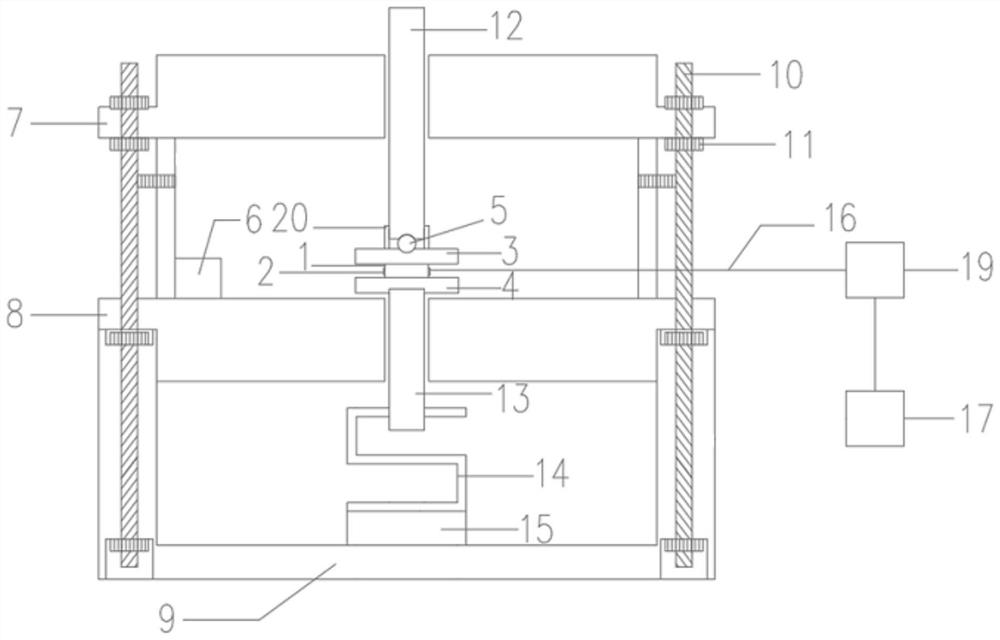

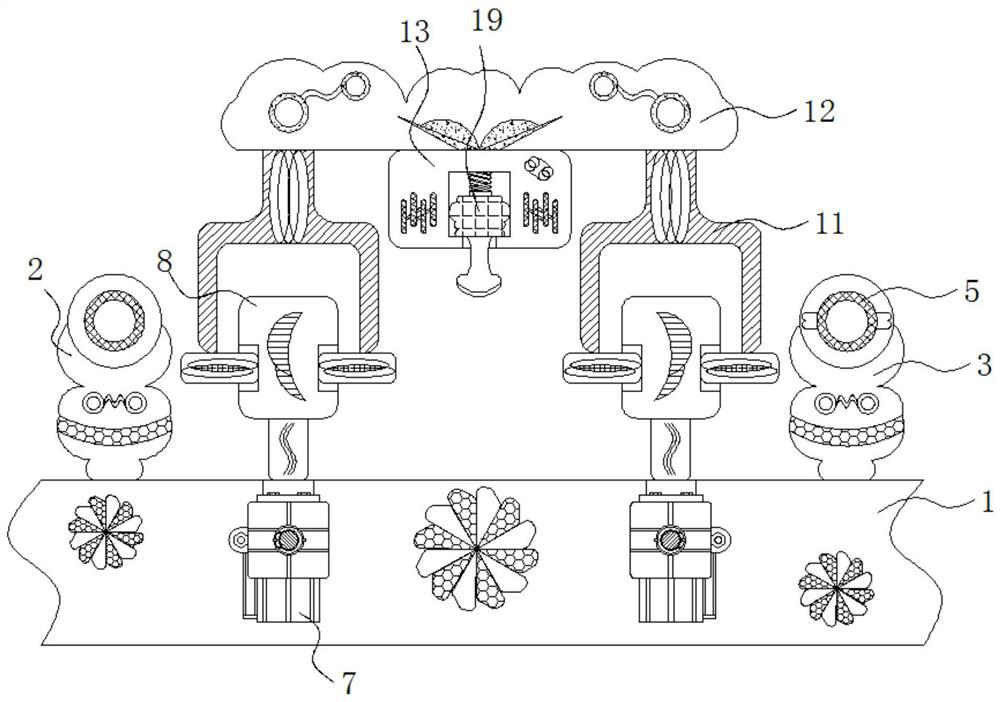

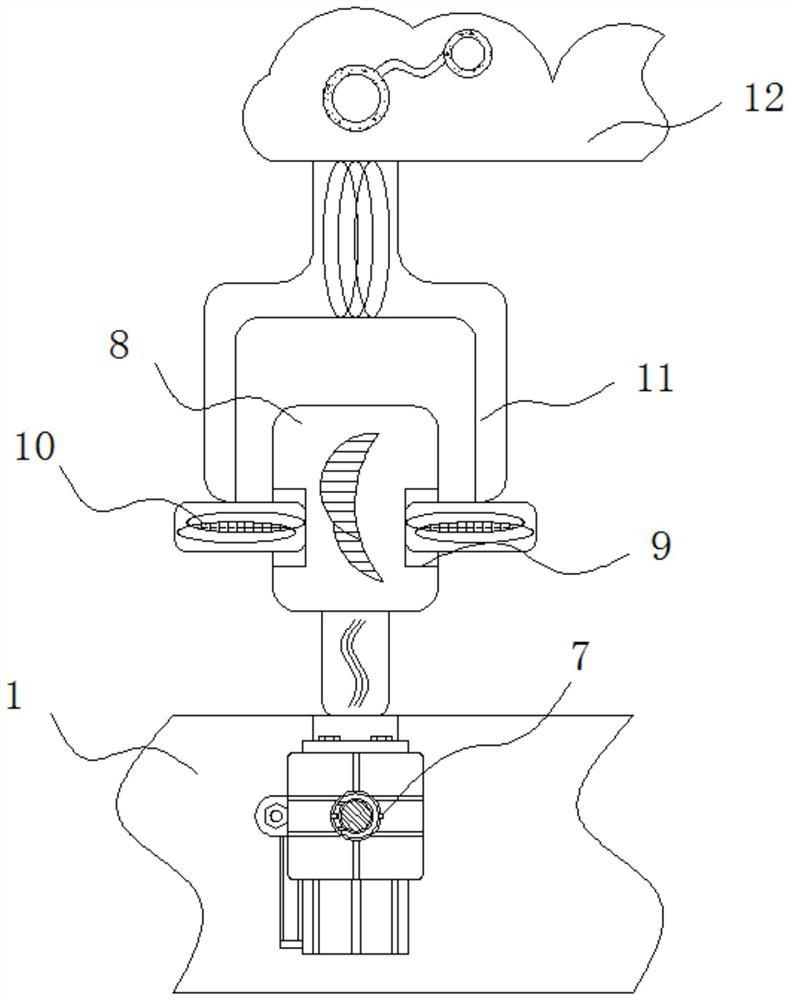

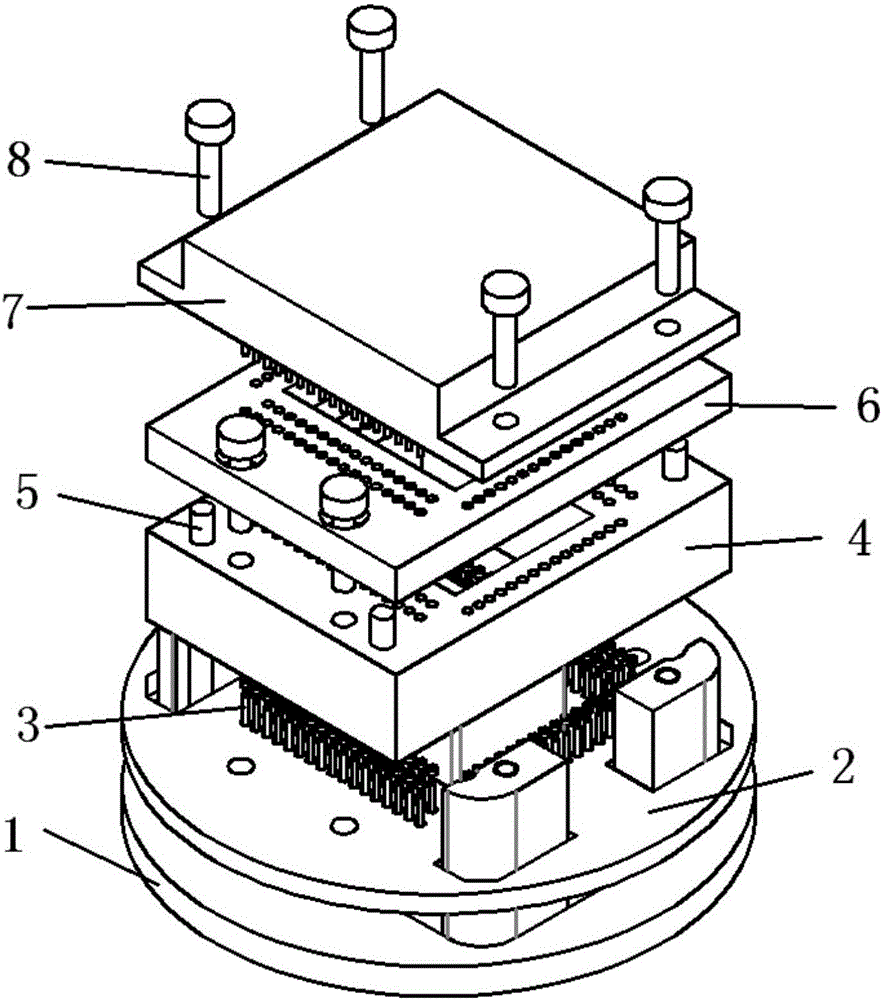

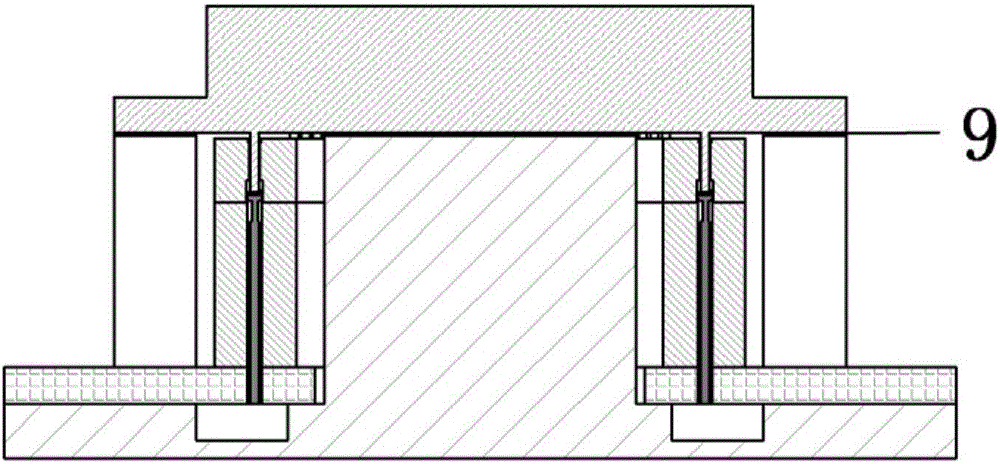

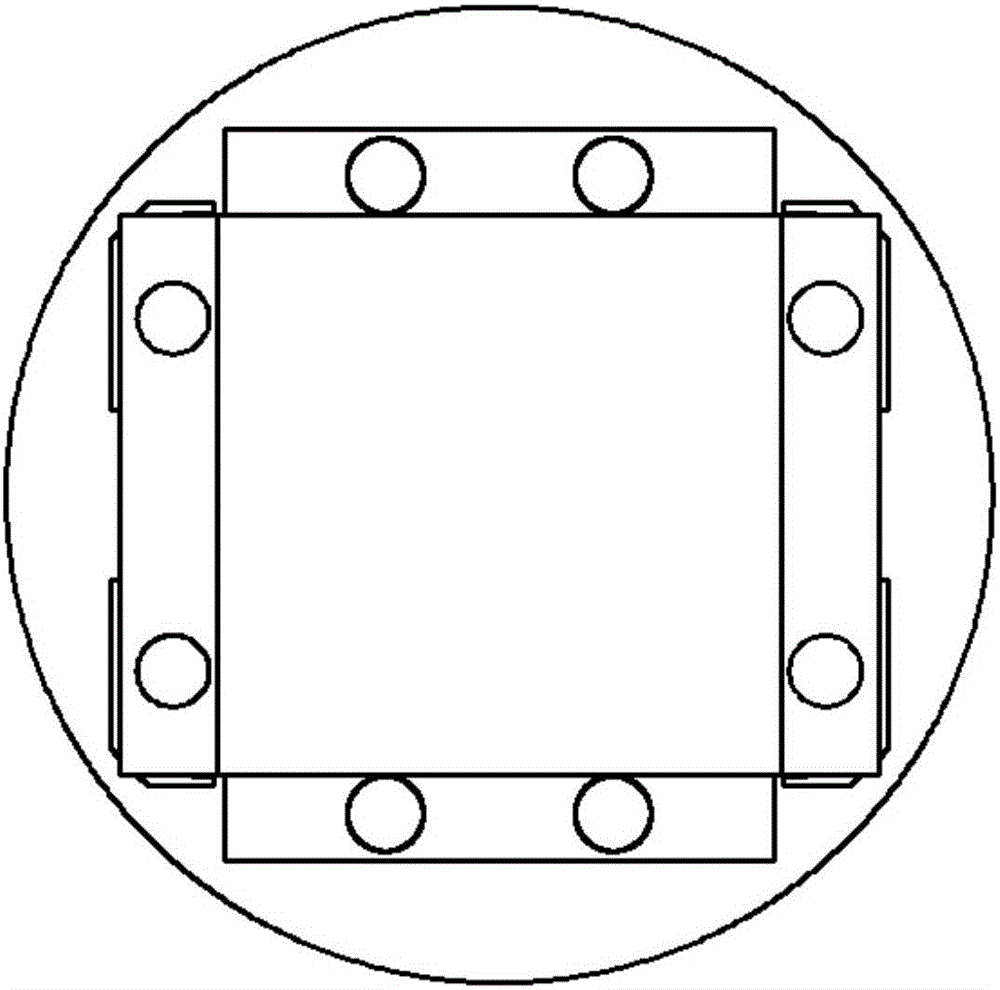

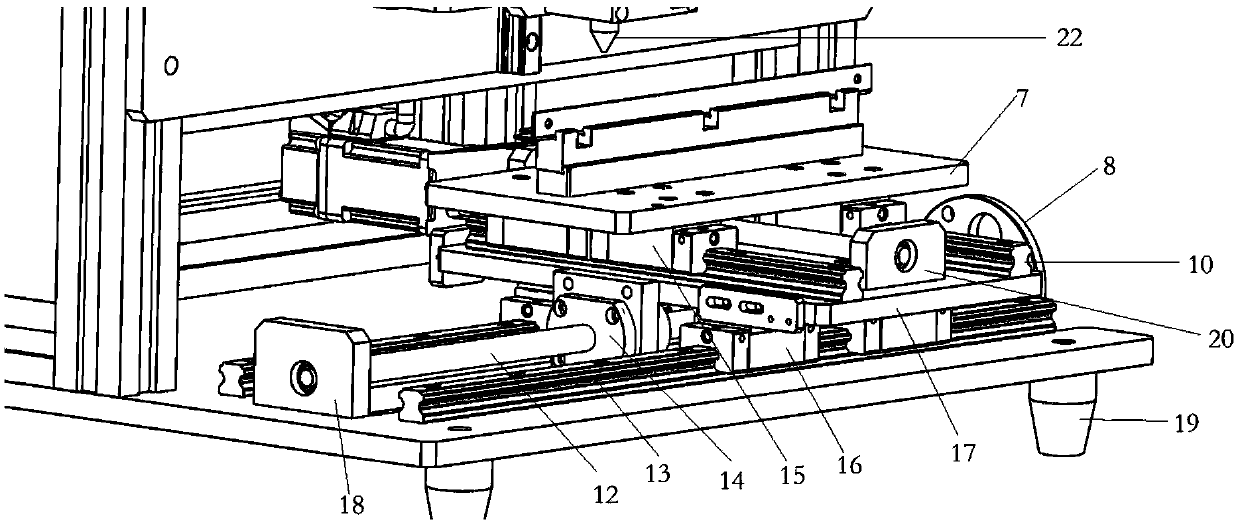

Thrombus elasticity testing device

ActiveCN104181311AIncreased measurement resolutionHigh sensitivityBiological testingMedicineThrombus

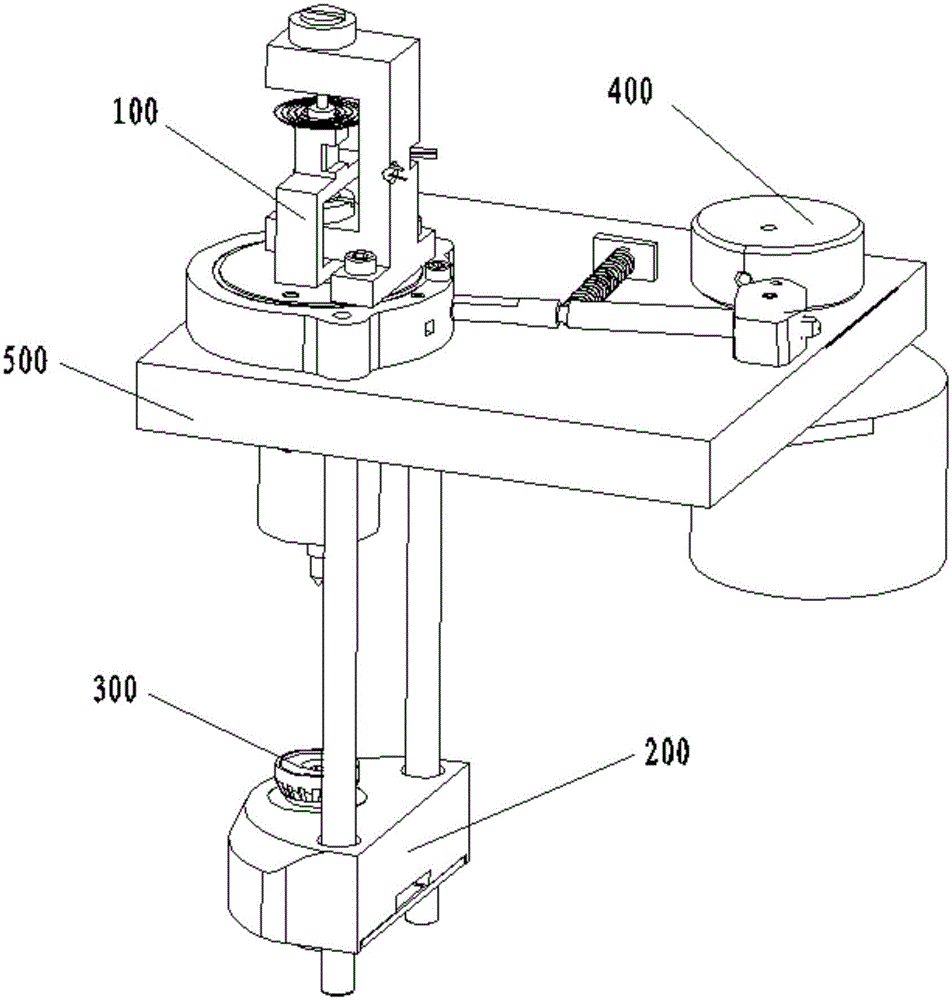

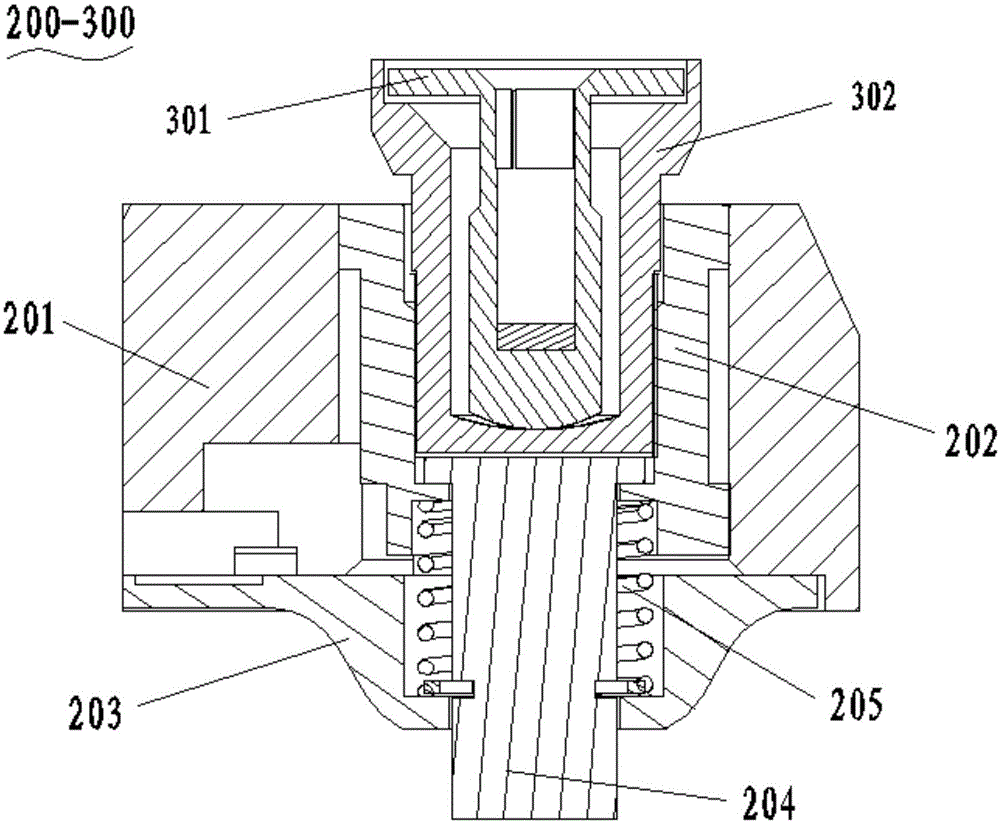

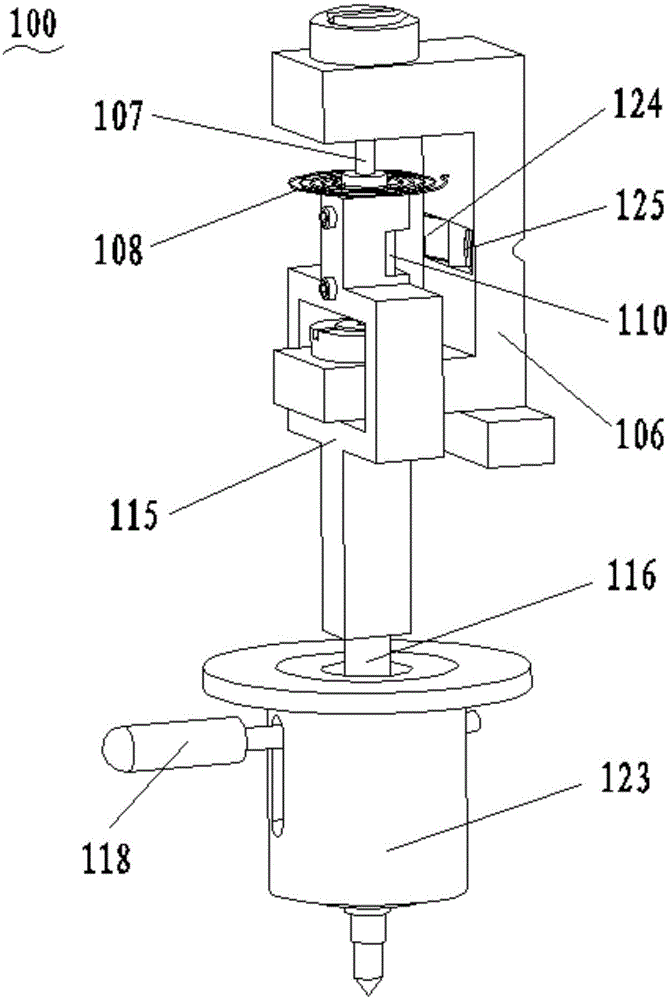

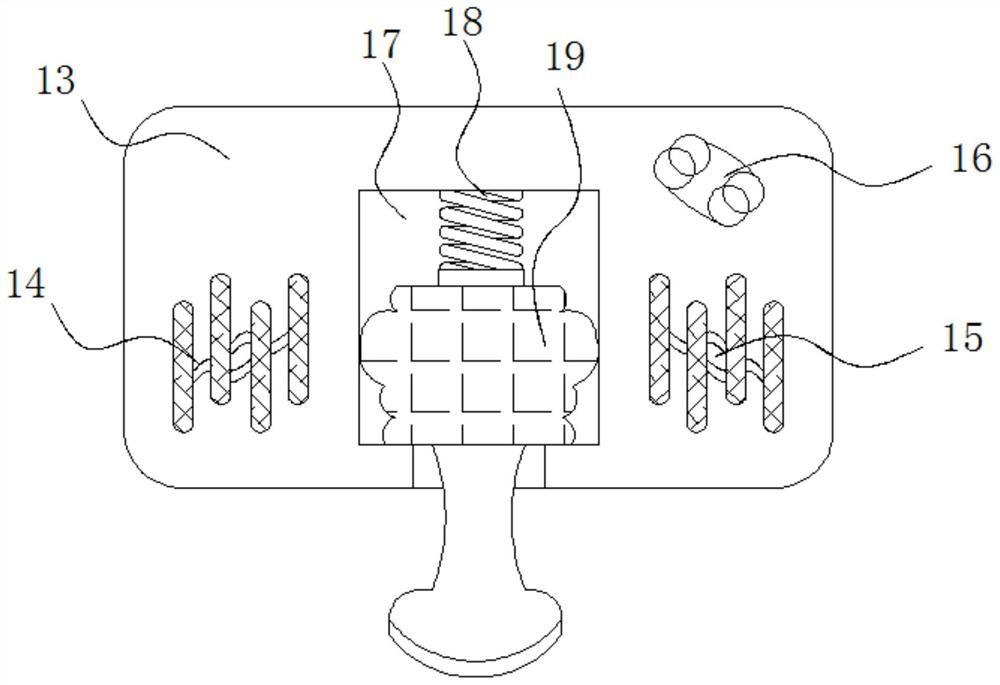

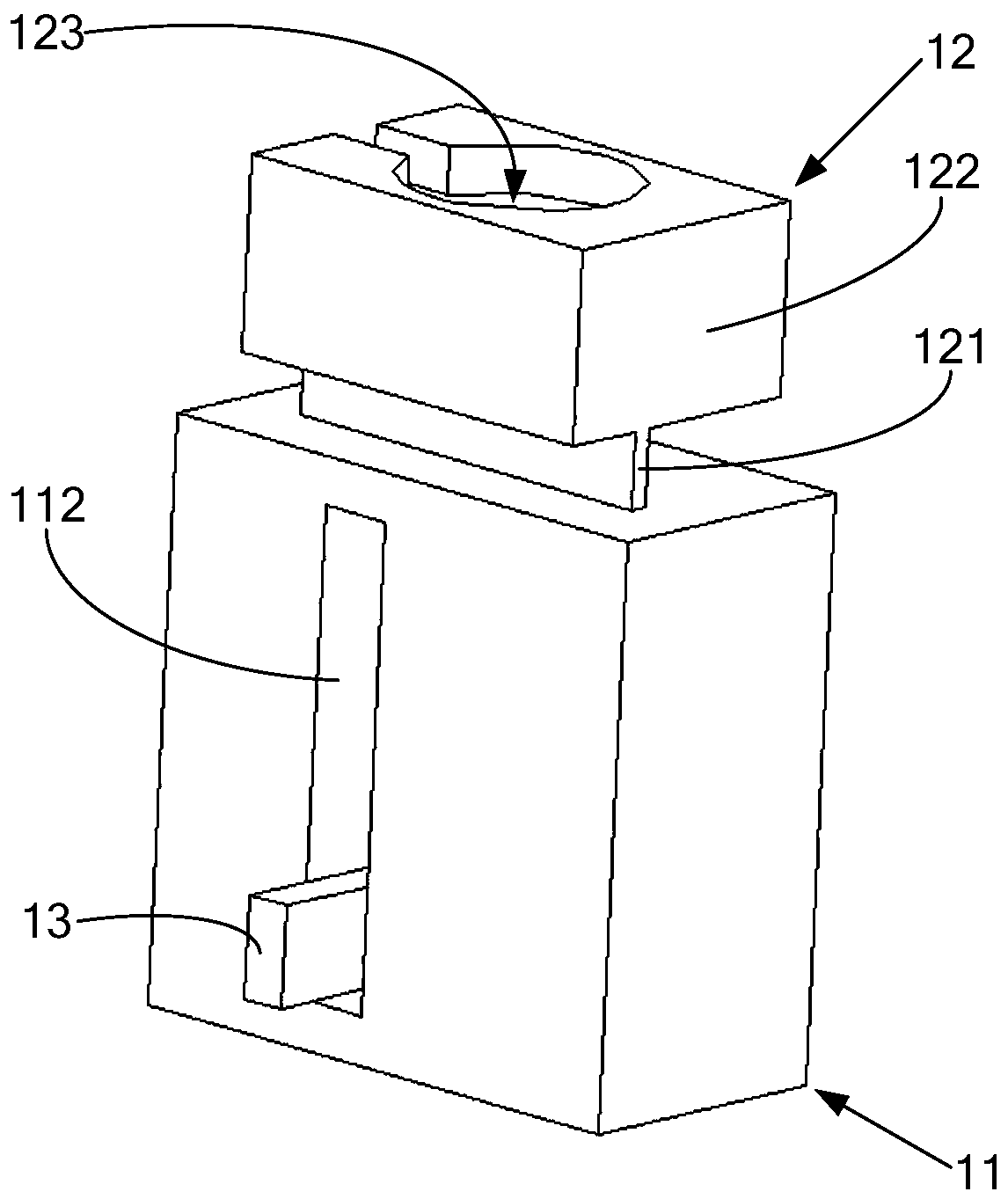

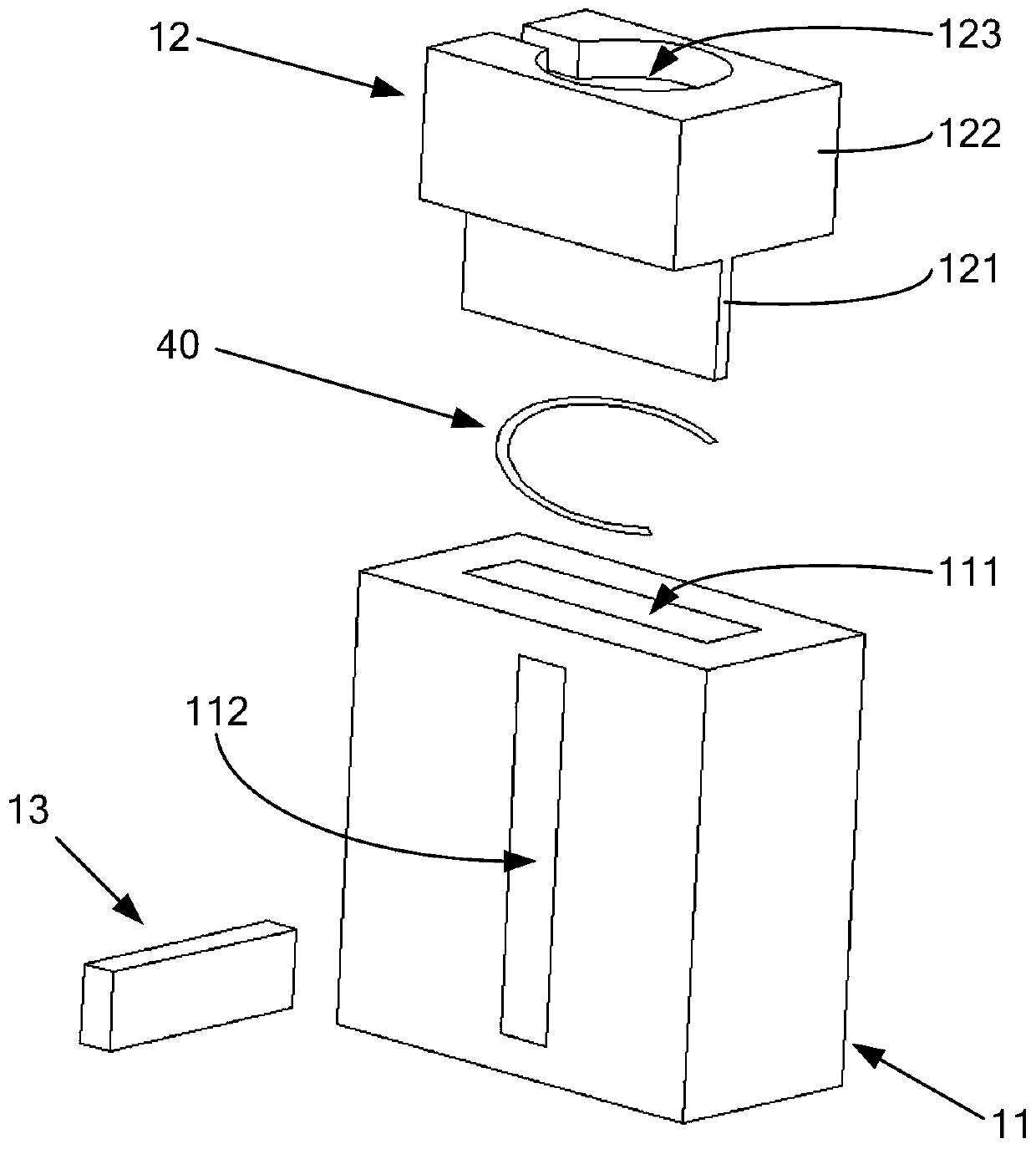

The invention discloses a thrombus elasticity testing device. The thrombus elasticity testing device comprises a supporting plate, a measuring unit, a driving unit and a cup holding unit, wherein the measuring unit and the driving unit are arranged on the supporting plate, and the cup holding unit is connected with the driving unit; the measuring unit comprises a base, a rotating part, a rotating shaft and a balance spring. According to the thrombus elasticity testing device, the driving unit is combined with the cup holding unit to carry out regular vibration on a blood sample in a measuring cup to simulate a physiological thrombus formation environment in vivo, thereby guaranteeing an accurate and reliable test result; by virtue of a structure consisting of the conical tip-shaped rotating shaft and the balance spring in the measuring unit, friction generated during vibration of the measuring unit is decreased sharply, and the shock resistance of the complete device is greatly improved on the premise of guaranteeing restoring force, so that the measurement reliability is high; by virtue of an optical lever measuring mechanism, the resolving ability and sensitivity of thrombus elasticity measurement are effectively increased, so that the measuring accuracy is remarkably improved; by virtue of a measuring cup loading-unloading mechanism, the operation is convenient and reliable.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

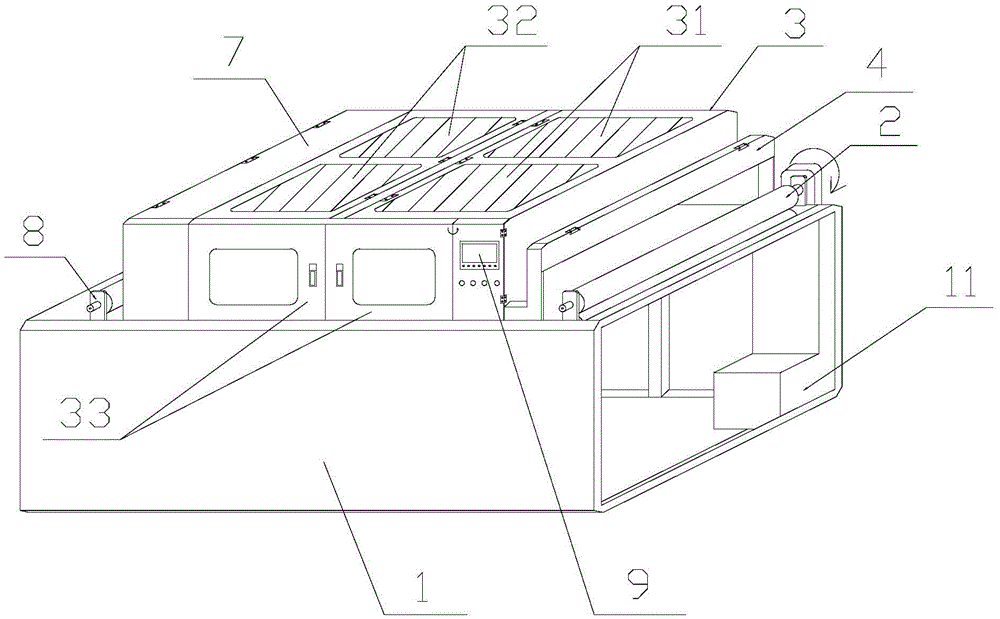

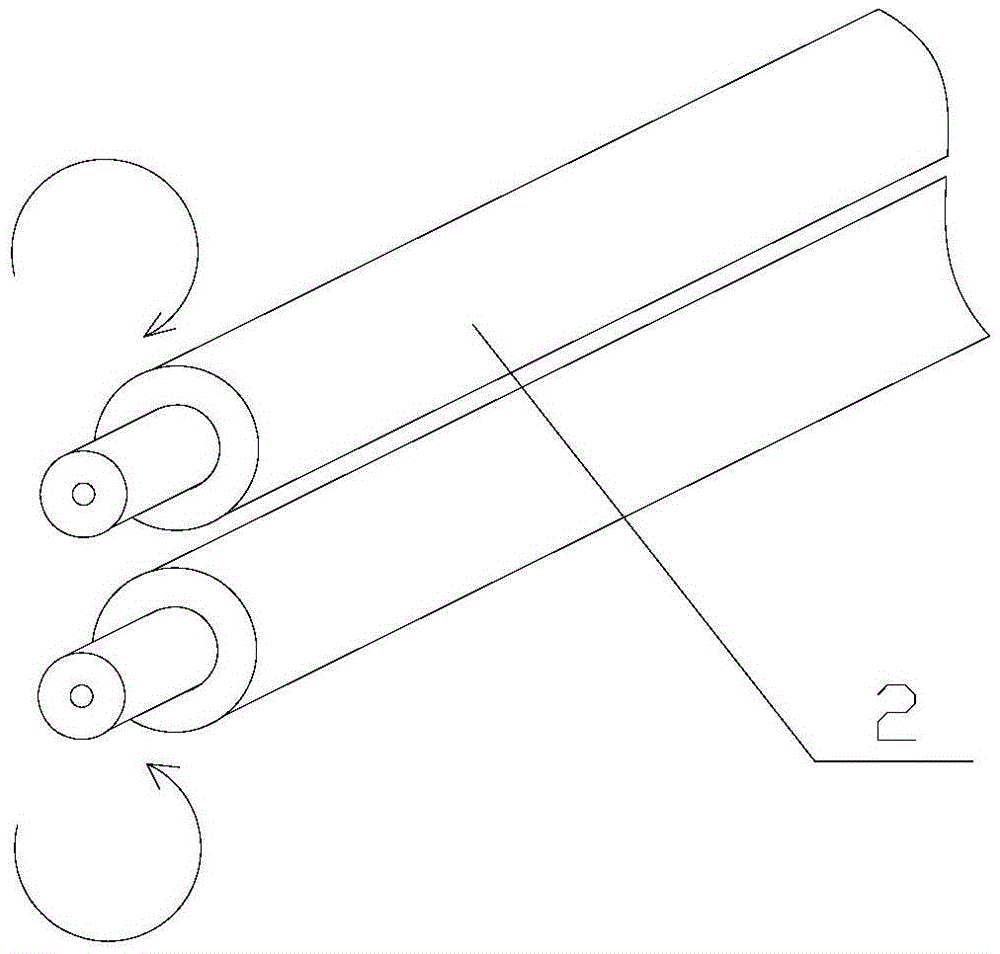

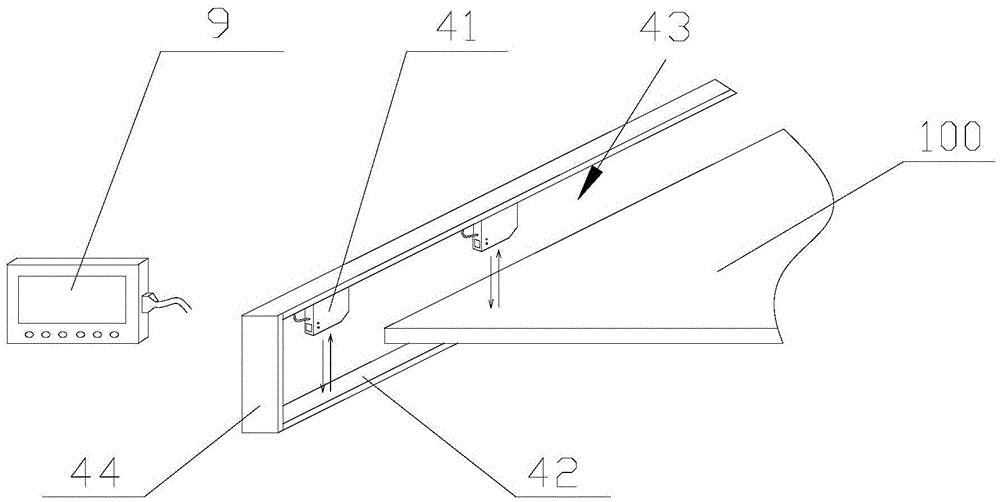

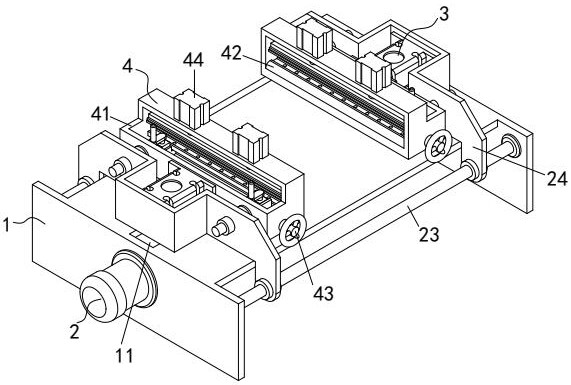

Splitting machine used for cutting sponges or vertical cotton

The invention discloses a splitting machine used for cutting sponges or vertical cotton. The splitting machine comprises a machine frame. A feeding roller, a thickness testing device, a longitudinal cutting mechanism, a transverse cutting mechanism, elasticity testing devices and a discharging roller are arranged on the machine frame. The longitudinal cutting mechanism comprises a longitudinal cutter device capable of sliding in the transverse direction to regulate the position. A longitudinal vertical blade reciprocating up and down in the vertical direction is arranged on the longitudinal cutter device. The transverse cutting mechanism comprises a transverse cutter device arranged in the manner that the transverse cutter device can reciprocate in the transverse direction. A transverse vertical blade reciprocating up and down in the vertical direction is arranged on the transverse cutter device. The splitting machine overcomes the defects of traditional splitting devices with circular blades, product thicknesses and elasticity of sponges or vertical cotton are quite conveniently detected during cutting, the production efficiency is greatly improved, and the service life of the blades is prolonged. In addition, the thickness testing device and the elasticity testing devices are added, and therefore operators can conveniently master the characteristics of sponges or vertical cotton in real time.

Owner:苏州爱美纤维科技有限公司

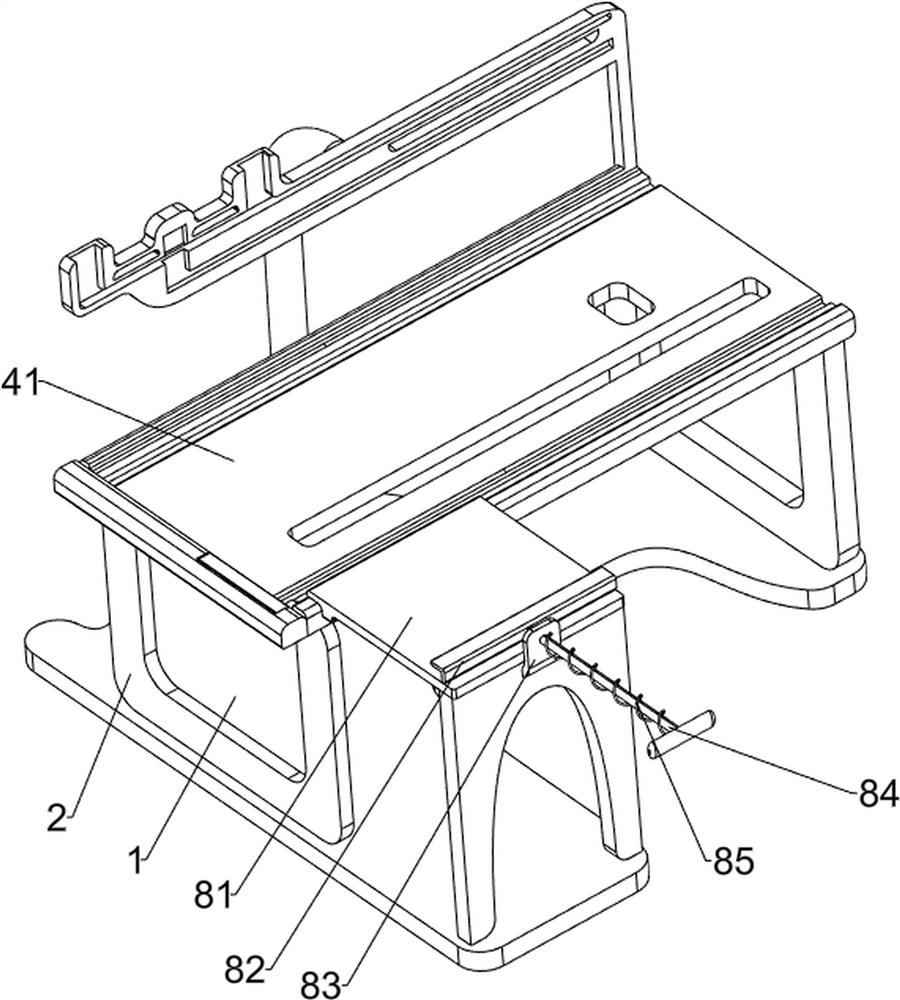

Multifunctional performance testing device for textiles

InactiveCN112285149AImprove functionalityGuaranteed accuracyMaterial thermal conductivityMaterial strength using tensile/compressive forcesThermal insulationEngineering

The invention relates to the technical field of textile detection, and in particular relates to a multifunctional performance testing device for textiles. The device comprises a testing table, a heatinsulation performance testing mechanism is arranged at the top end of the testing table, an elasticity testing mechanism is arranged on the left side of the heat insulation performance testing mechanism, a wear resistance testing mechanism is arranged on the right side of the heat insulation performance testing mechanism, a bottom plate is arranged on the lower side of the testing table, and a damping mechanism is arranged between the bottom plate and the testing table. According to the testing device, by arranging the thermal insulation performance testing mechanism, the textiles are fixed between a connecting frame and a heating box; when a heater operates, a first temperature sensor and a second temperature sensor are used for measuring the temperature of the two sides of the cloth; the heat insulation performance of the textiles can be detected; the elasticity testing mechanism is arranged, a first motor can drive a movable plate to move, a clamp pulls the textiles to move outwards, and elasticity testing of the textiles can be completed; and friction testing can be conducted on the textiles through the wear resistance mechanism.

Owner:SUZHOU SAIYA INTELLIGENT TECHNOLOGY CO LTD

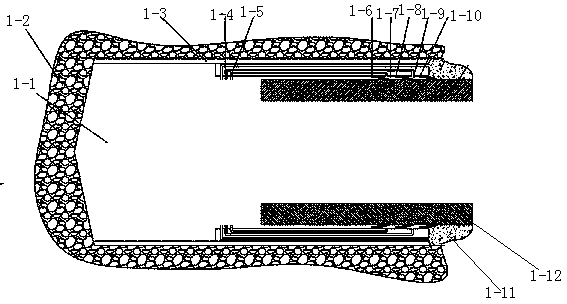

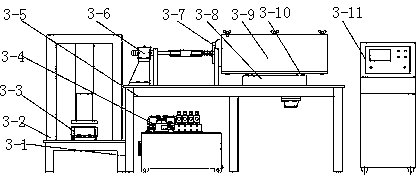

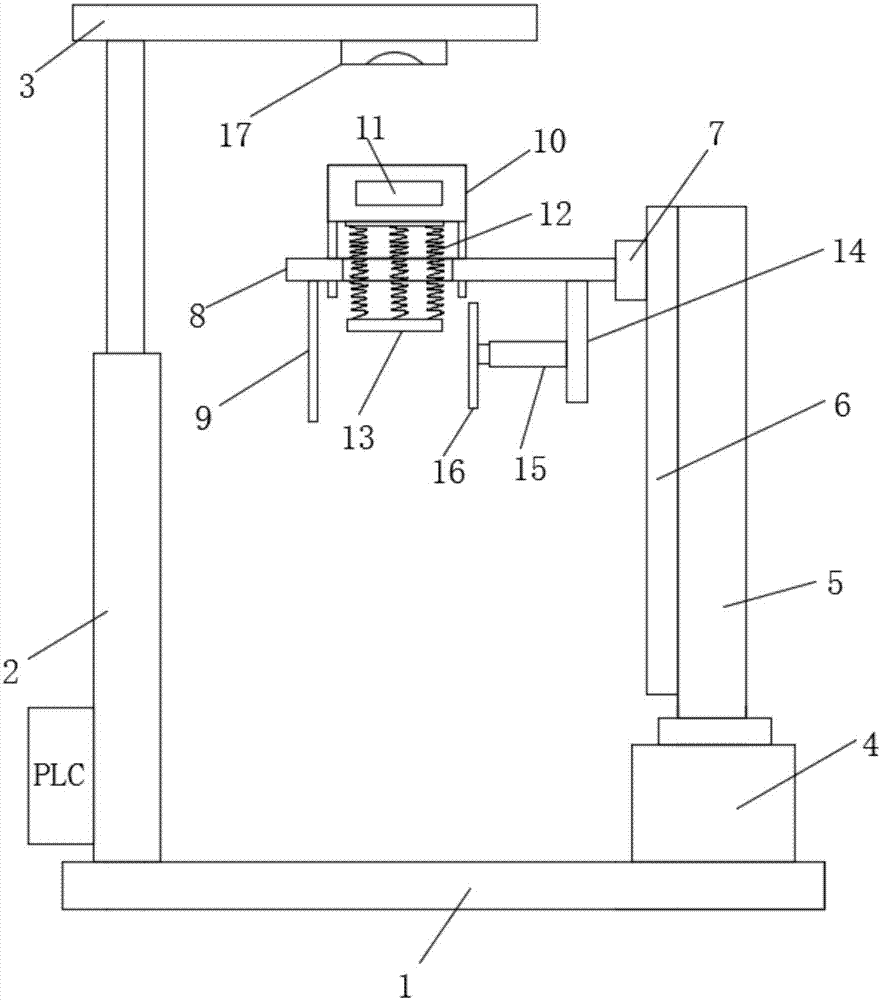

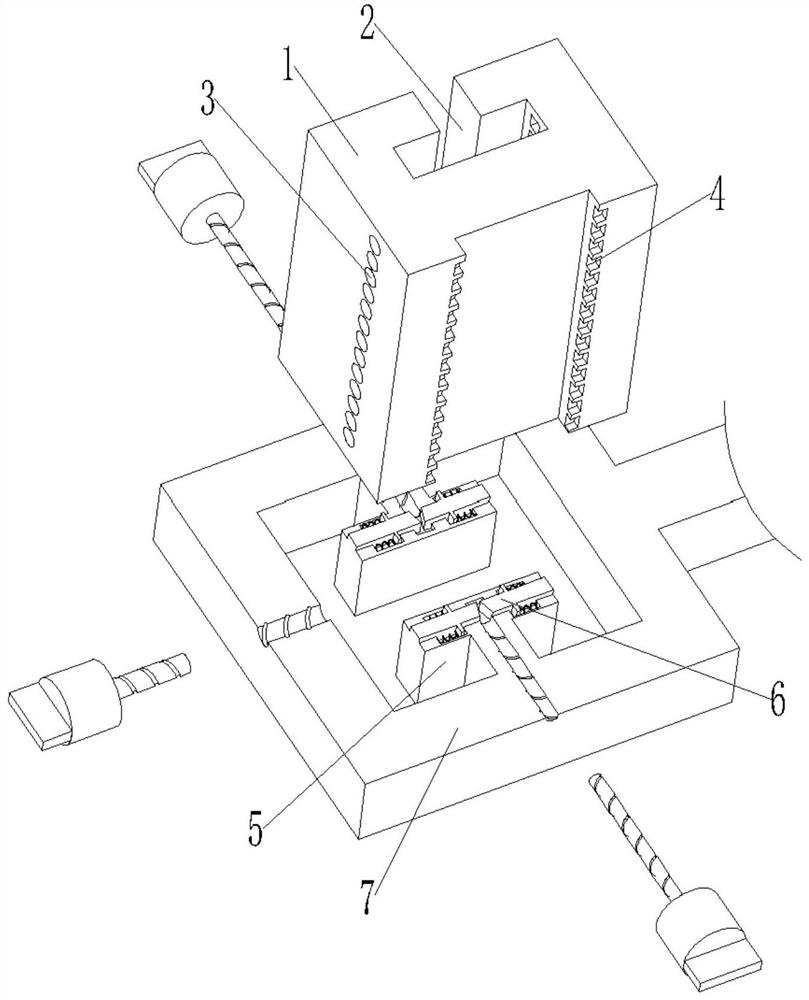

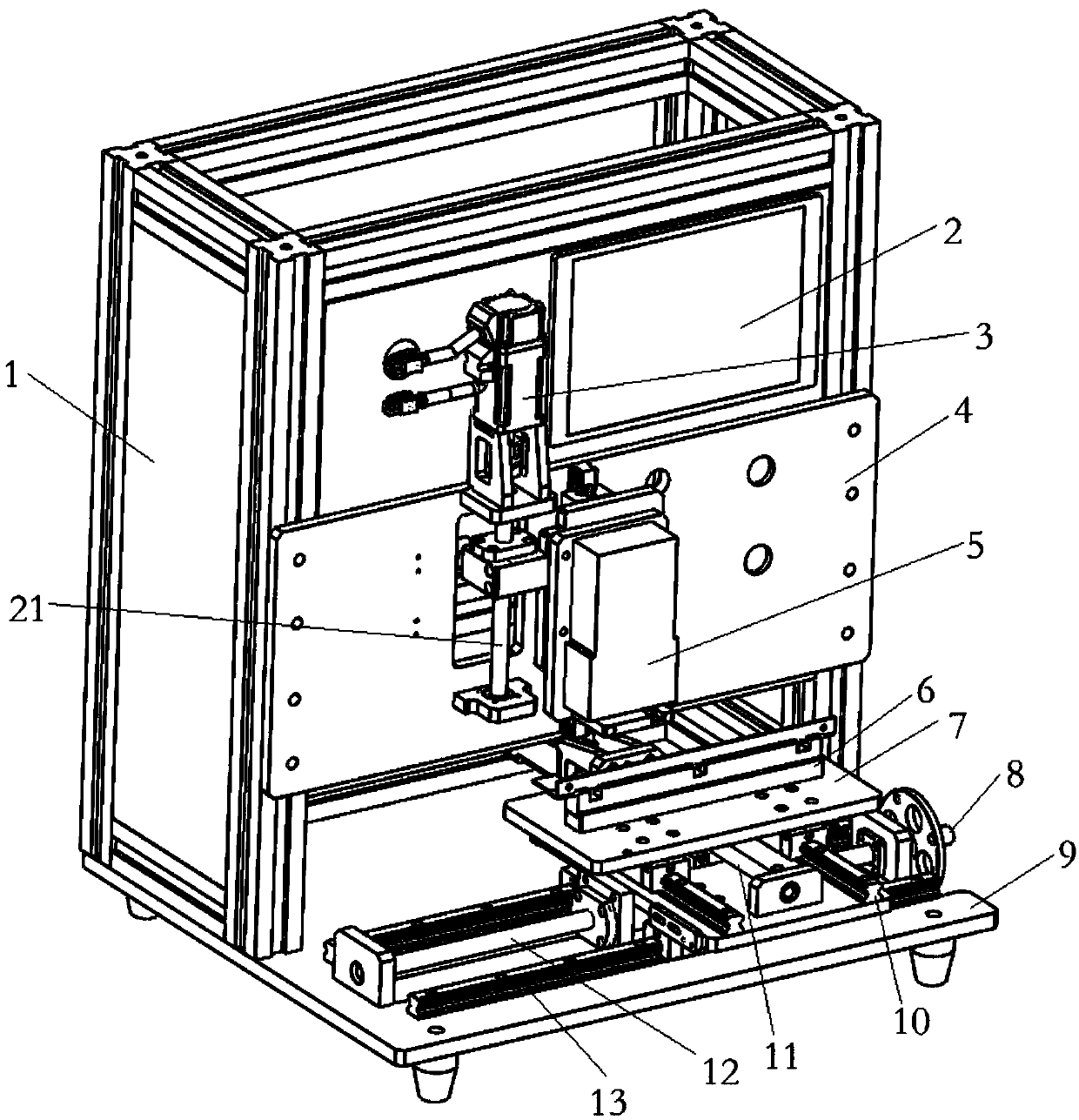

Experimental equipment for shield tail brush

ActiveCN103437773AAvoid security risksEasy to analyzeTunnelsHydraulic motorProgrammable logic controller

The invention belongs to the technical field of the shield tail brush performance detection and mainly relates to experimental equipment for a shield tail brush. The experimental equipment comprises a hydraulic pump station (3-4), an abrasive resistance testing mechanism (3-5), an elastic testing mechanism (3-2) and a PLC (Programmable Logic Controller) (3-11), wherein the abrasive resistance testing mechanism (3-5) comprises an experiment bench (3-1), a hydraulic motor (4-9), a hydraulic motor output gear (4-4), a pivoting support (3-8), a concrete brush table (3-9) and a lead screw-nut mechanism (3-6); the elastic testing mechanism (3-2) comprises a shield tail brush fixing device (10-1), a portal frame (10-6), a telescopic outer sleeve (10-5), a telescopic inner sleeve (10-4), an oil cylinder (10-7) and a pressing plate (10-3). The experimental equipment for the shield tail brush realizes testing on the performance of the shield tail brush products and prevents security risks caused by improper selection of the products.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Basketball elasticity testing device

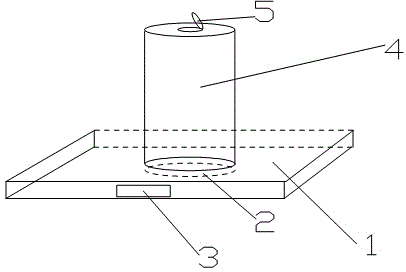

InactiveCN107421700ANovel structureIngenious designElasticity measurementEngineeringDistance sensors

The invention discloses a basketball elasticity testing device, which comprises a bottom plate. A telescopic rod is arranged on one side of the top of the bottom plate through a bolt. A cross rod is arranged at the top of the telescopic rod. A distance sensor is arranged on one side of the bottom of the cross rod. A rotary air cylinder is arranged at the top of the bottom plate far away from the telescopic rod. A pressure sensor is arranged above an opening part through a support. The output end of the pressure sensor is arranged downwards. A spring is fixed at the bottom of the pressure sensor. A pressing plate is fixed at the lower end of the spring. A first baffle plate and a second baffle plate are respectively arranged on the two sides of the pressing plate. The first baffle plate and the second baffle plate are arranged on the two sides of the bottom of a mounting plate. One side of the second baffle plate, positioned closer to the first baffle plate, is provided with a push rod motor. The push rod motor and the second baffle plate are perpendicular to each other. One end of the push rod motor, far away from the second baffle plate, is provided with a third baffle plate. The device is novel in structure, ingenious in design, reasonable in structure and suitable for popularization.

Owner:浙江傲博体育用品有限公司

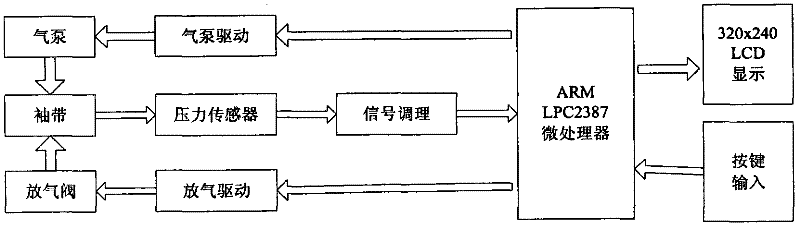

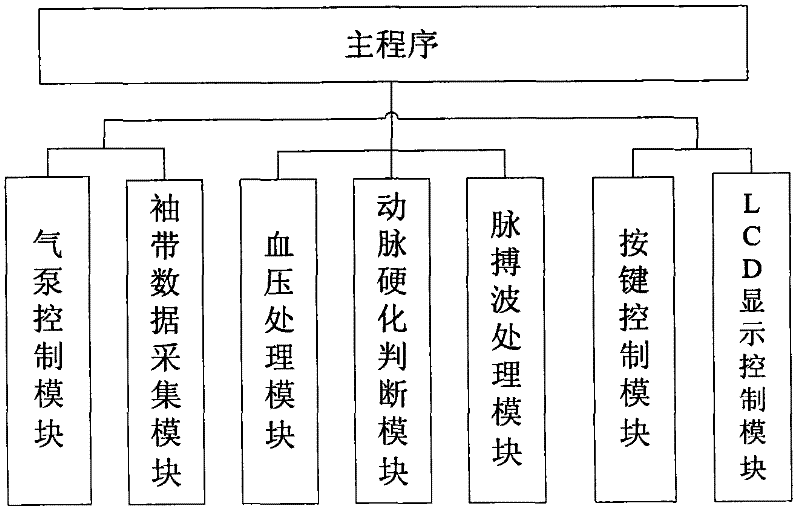

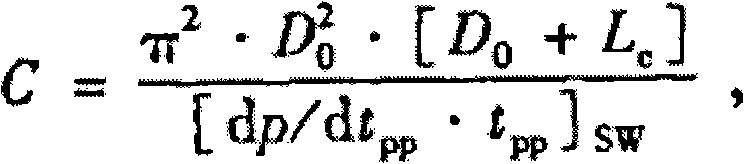

Pulse wave-based cardiovascular elasticity testing and arteriosclerosis early warning system

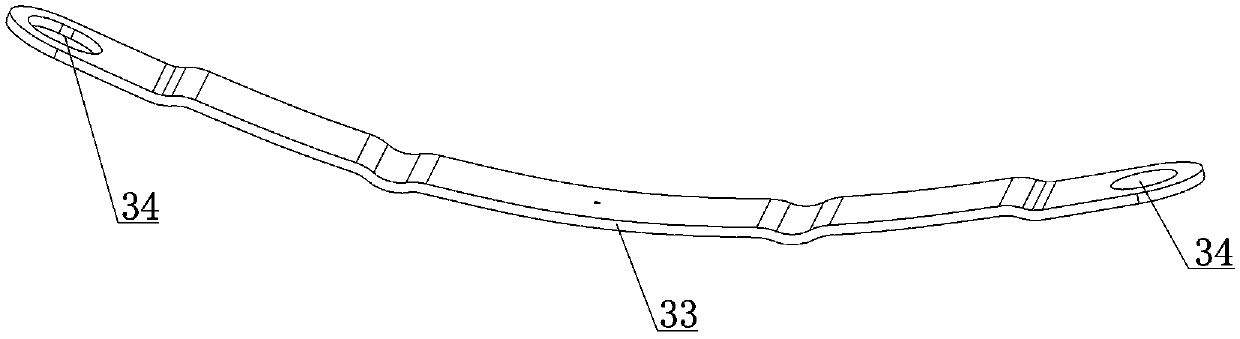

The invention discloses a pulse wave-based cardiovascular elasticity testing and arteriosclerosis early warning system. The system comprises a cuff, an air pump, an air release valve, a pressure sensor and a microprocessor, wherein the air pump, the air release valve and the pressure sensor are arranged in the cuff; the air pump is used for inflating the cuff when driven by an air pump driving circuit; the pressure sensor is used for detecting pressure value of the cuff in real time; when a preset inflation pressure is achieved, an air release driving circuit is controlled by the microprocessor to open the air release valve so as to discharge air in the cuff according to a preset speed; in such process, a pressure signal of the cuff is continuously acquired by the pressure sensor, is processed through a conditioning circuit and is separated to obtain a pulse wave signal and a cuff pressure signal through a capacitive direct current blocking circuit, and the pulse wave signal and the cuff pressure signal are transmitted to two paths of A / D (Analog / Digital) converters in a microcontroller for processing respectively; and when the pulse wave signal disappears, a one-time measurement process is finished.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

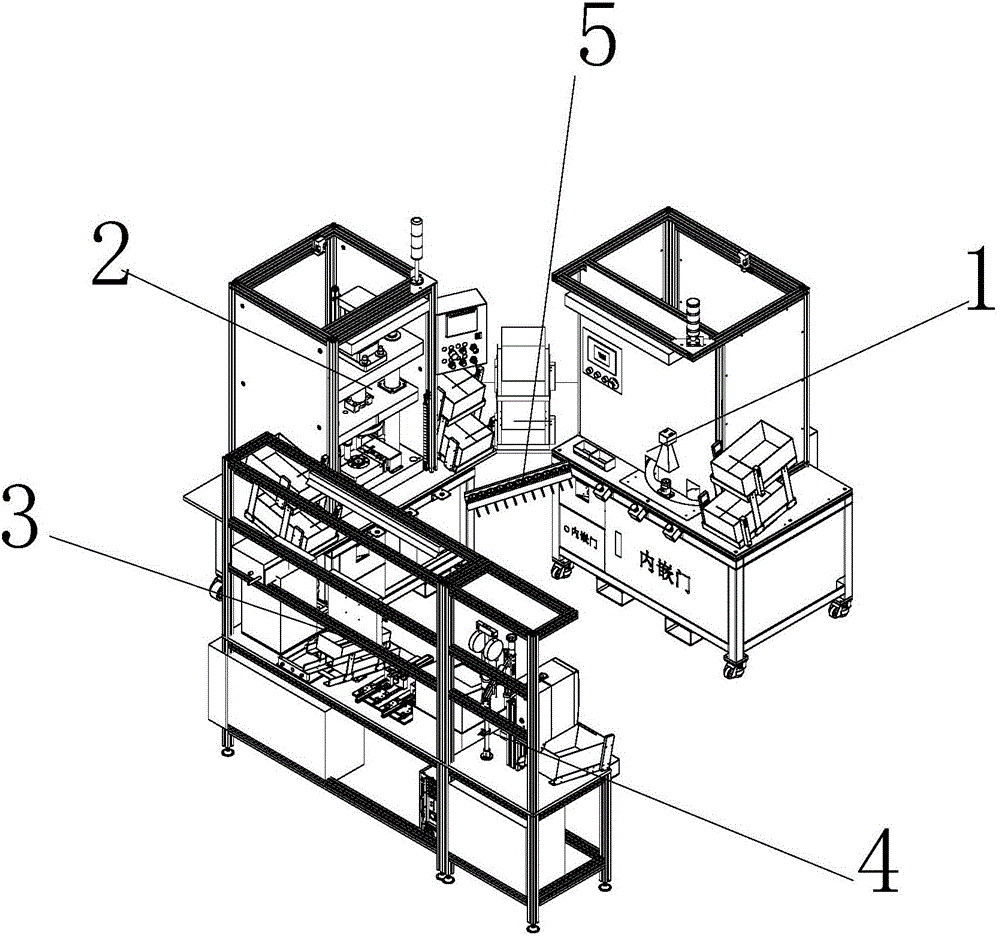

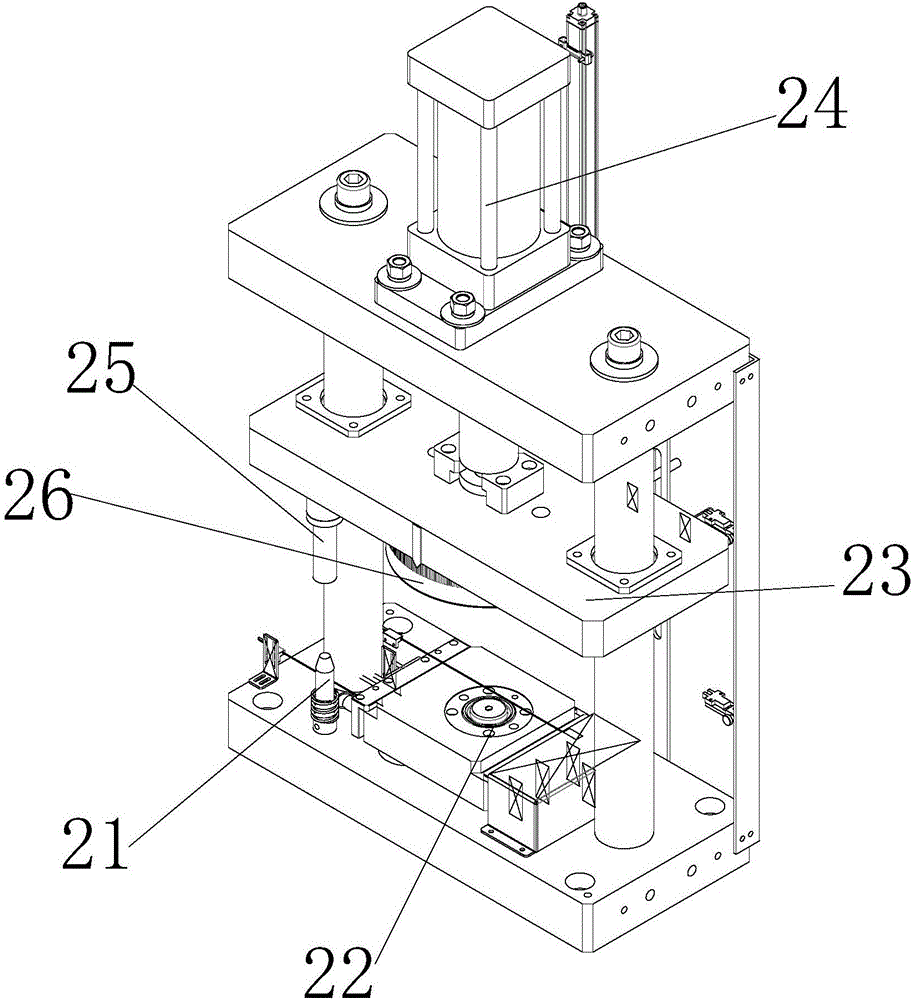

Actuator assembly line and assembly method

ActiveCN106271610ARealize the assemblyImprove assembly efficiencyAssembly machinesVehicle componentsAssembly lineEngineering

The invention discloses an actuator assembly line and an assembly method. The actuator assembly line mainly comprises a spin-riveting device, a hemming device, a detecting device and a tightening device which are arranged in sequence, wherein the spin-riveting device comprises a first machine frame, a spin-riveting gun is arranged in the first machine frame, a product turnplate and a turnplate driving mechanism driving the product turnplate to rotate are arranged below the spin-riveting gun, multiple first product accommodating tools are arranged in the peripheral direction of the product turnplate, and a clamping device is arranged below the spin-riveting gun. According to the assembly line, an actuator is assembled through combination of mechanical structures, actuator assembly efficiency is improved, and physical strength of workers is saved; a spring in the actuator is subjected to elasticity testing in advance, so that the quality of the spring is guaranteed; furthermore, hemming is also conducted during elasticity testing, operation is convenient and quick, and energy consumption is reduced.

Owner:YANGZHOU CHAONENG ELECTRIC VALVE CO LTD

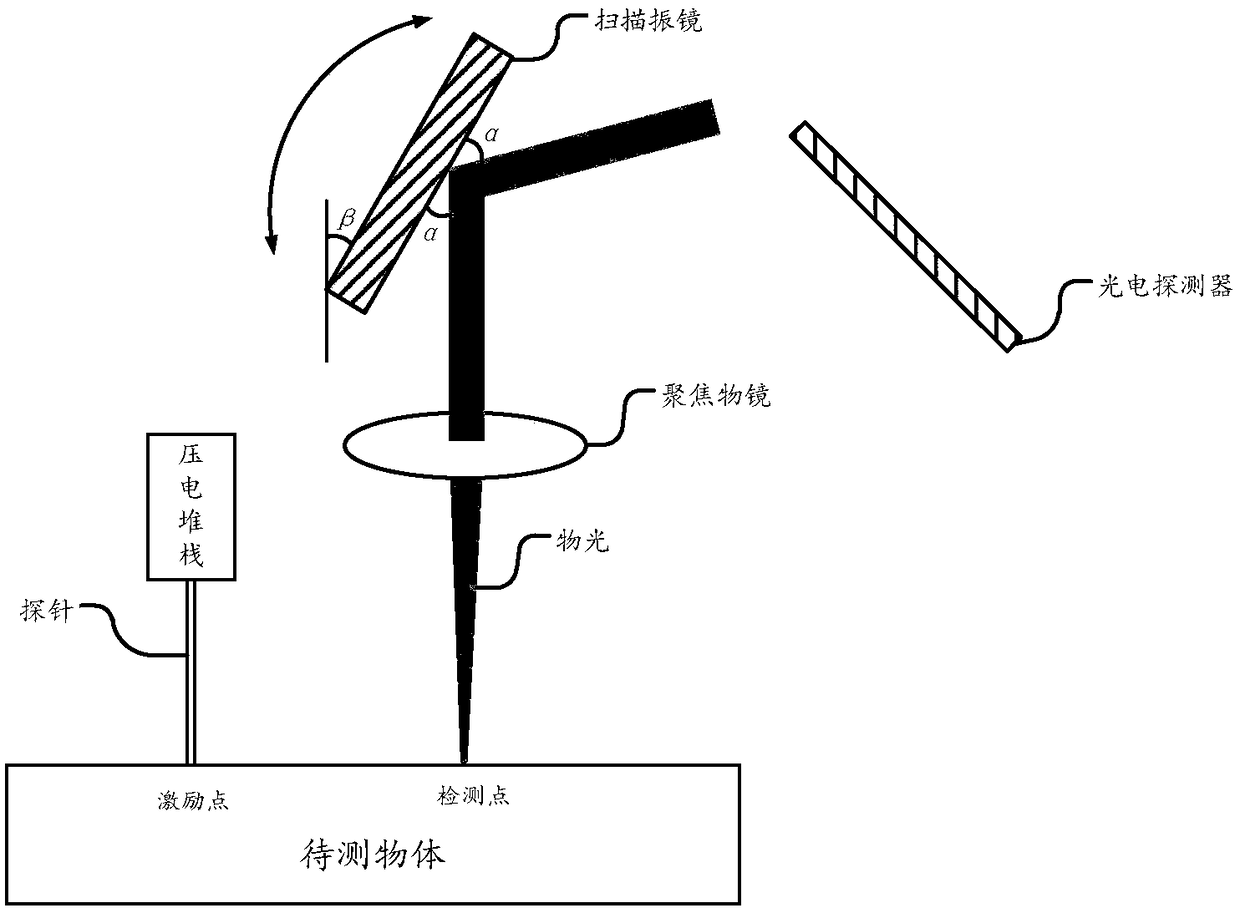

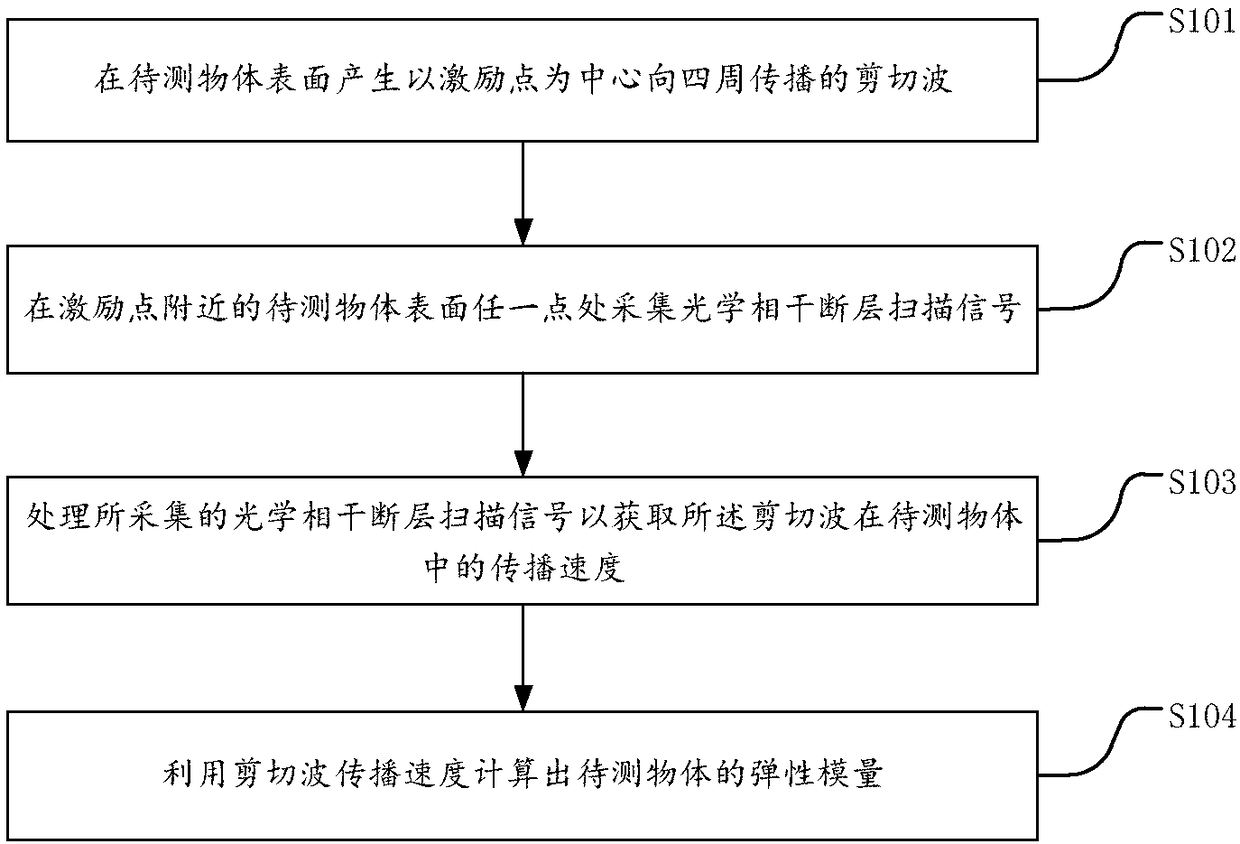

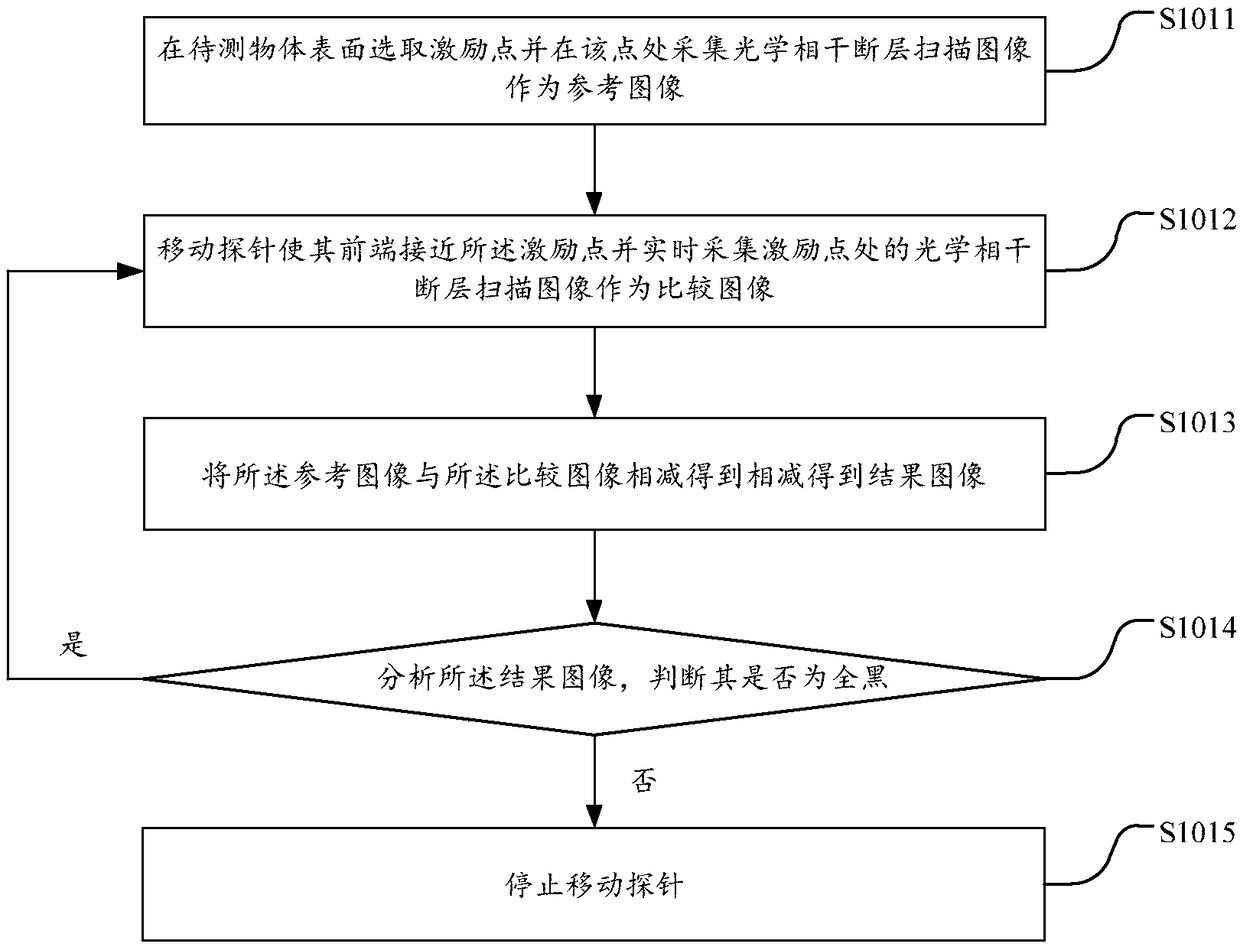

Optical elasticity test method

ActiveCN108445077ASo as not to damageSmall loadAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial analysis by optical meansPropagation timePhase analysis

The invention provides an optical elasticity test method including the following steps: 1) generating a shear wave, which is propagated with an exciting point as center to all around, and collecting an optical coherence tomography signal at any one point on the surface of a to-be-tested object nearby the exciting point; 2) processing the OCT signal to obtaining propagation speed of the shear wavein the to-be-tested object; 3) calculating elasticity modulus of the to-be-tested object according to the propagation speed. The method is small in loading amplitude and short in time and is free of damaging the to-be-tested object. The propagation time of the shear wave is extracted through phase analysis, so that the propagation speed of the shear wave is calculated accurately, thus obtaining the elasticity modulus of the to-be-tested object. The calculation load is greatly reduced and test time is shortened.

Owner:TIANJIN UNIV

Garment elasticity detection device

InactiveCN111999175AResilience testing is easyAvoid location location tagging hassleTextile testingStrength propertiesStructural engineeringControl theory

The invention discloses a garment elasticity detection device. According to the garment elasticity detection device, a convex sliding groove and a positioning circular groove are formed in a supporting vertical rod, and a convex sliding block and a movable frame are arranged on the supporting vertical rod, thus the position of a mechanism, namely an L-shaped clamping plate, arranged at the upper end of the supporting vertical rod can be adjusted and controlled according to the length of a to-be-measured garment, the phenomena that position marking is troublesome and even measurement cannot becarried out in testing are avoided, convenience is provided for the elasticity testing of the garment, then the elasticity testing can be carried out according to the actual situation of the garment,and the working efficiency is improved; and by arranging a clamping and locking mechanism on the L-shaped clamping plate, a good locking effect is achieved on the garment in the clamping state, the sliding phenomenon of the garment in the clamping state is avoided, then the accuracy of the position distance of the garment after elastic stretching is guaranteed, deviation is avoided, and the work quality of elastic testing is guaranteed.

Owner:陆文坤

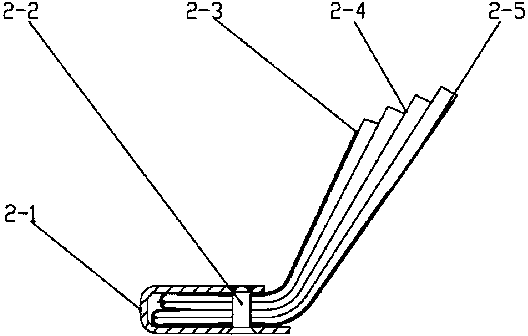

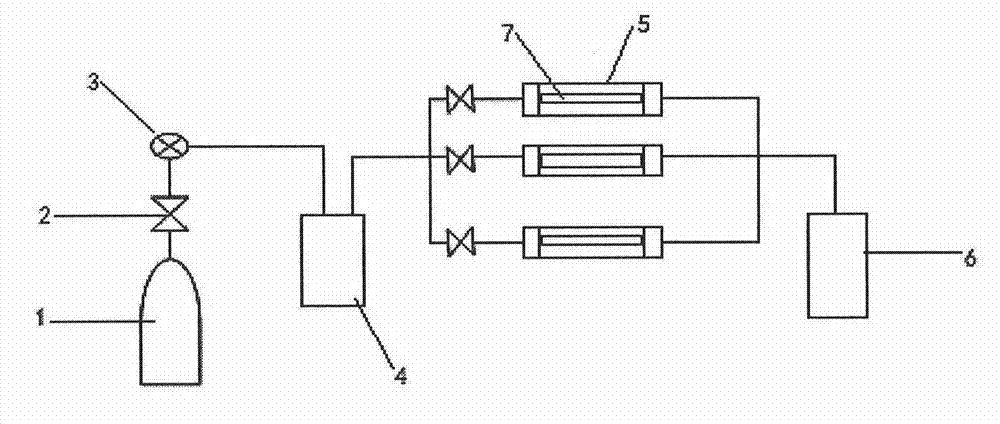

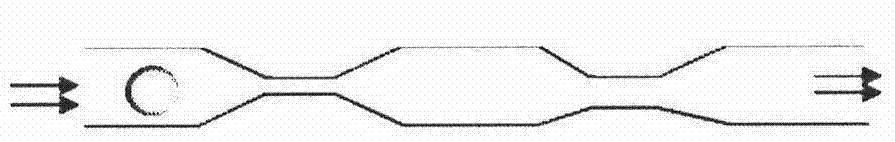

Visible elasticity testing instrument and testing method for elastic microsphere

InactiveCN104749037AMaterial strength using tensile/compressive forcesCapillary networkStructure of the Earth

The invention relates to a visible elasticity testing instrument and testing method for an elastic microsphere and belongs to a technology for evaluating a modifying and flooding agent for tertiary oil recovery in an oil field. The visible elasticity testing instrument mainly comprises a gas source, an intermediate container, 2-5 reducer pipes and a receiving container, wherein one reducer pipe comprises 2-3 different reducing parts to simulate a porous stratum system. The strength of the elastic microsphere is characterized through recording the maximal pressure acting on the elastic microsphere passing through the reducing parts, meanwhile, the average strength of one group of elastic microspheres and a number of the elastic microspheres passing through the reducer pipes under different pressures can be measured so as to select elastic microspheres suitable for different stratums. The visible elasticity testing instrument has the advantage of well simulating a capillary network structure in which wide and narrow holes in the stratums are strung together. In addition, the instrument is simple to operate.

Owner:山东石大油田技术服务股份有限公司

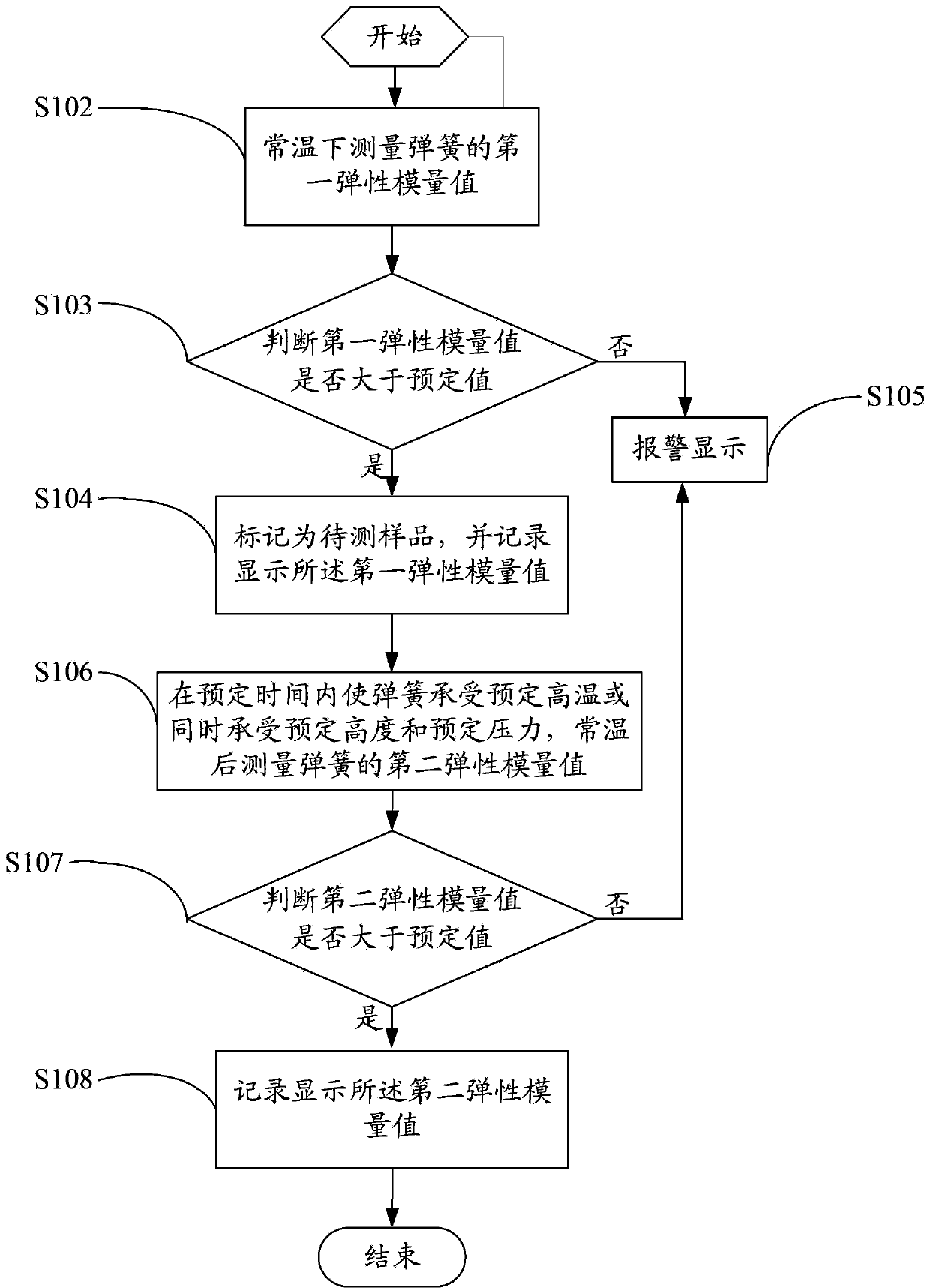

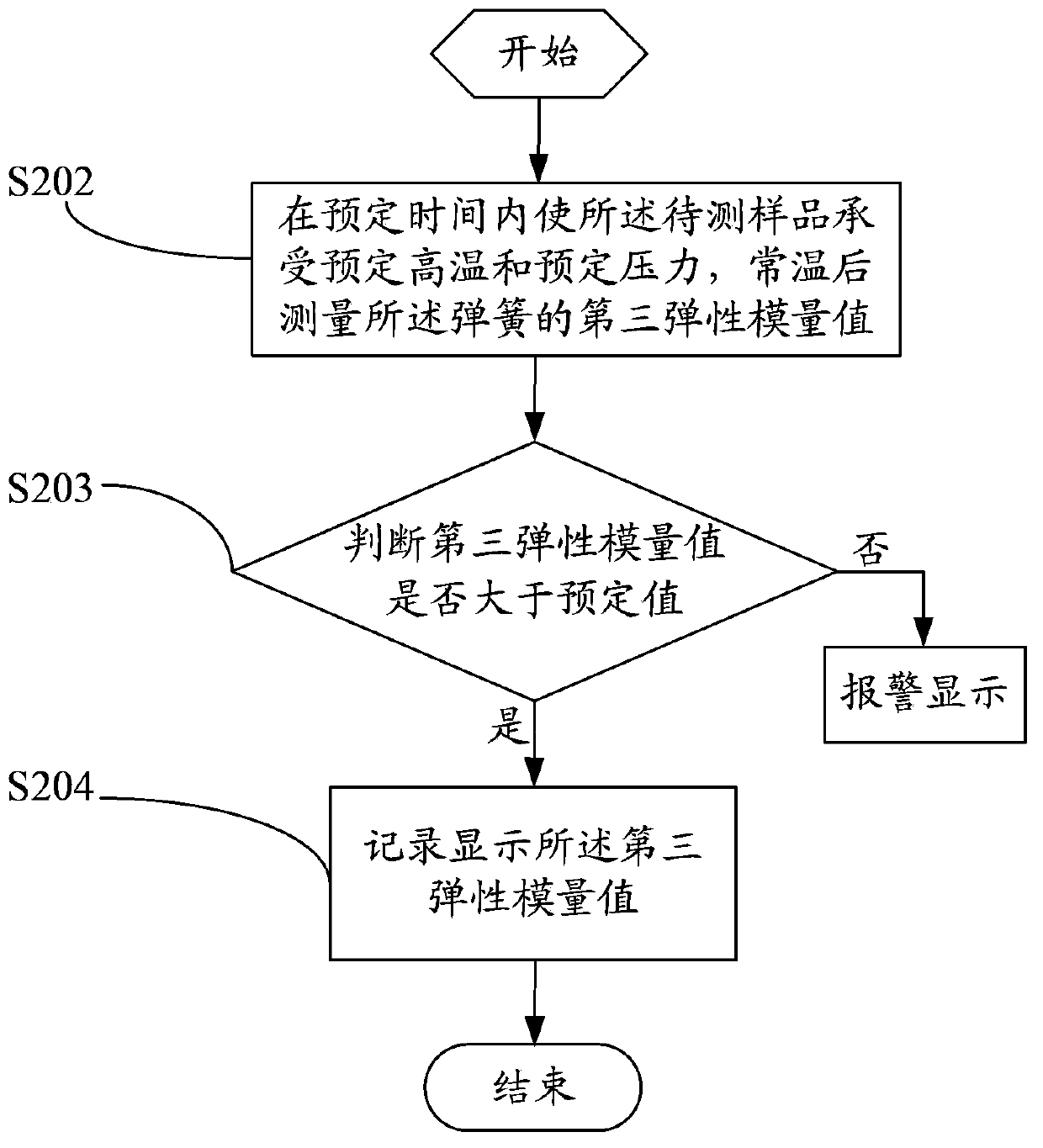

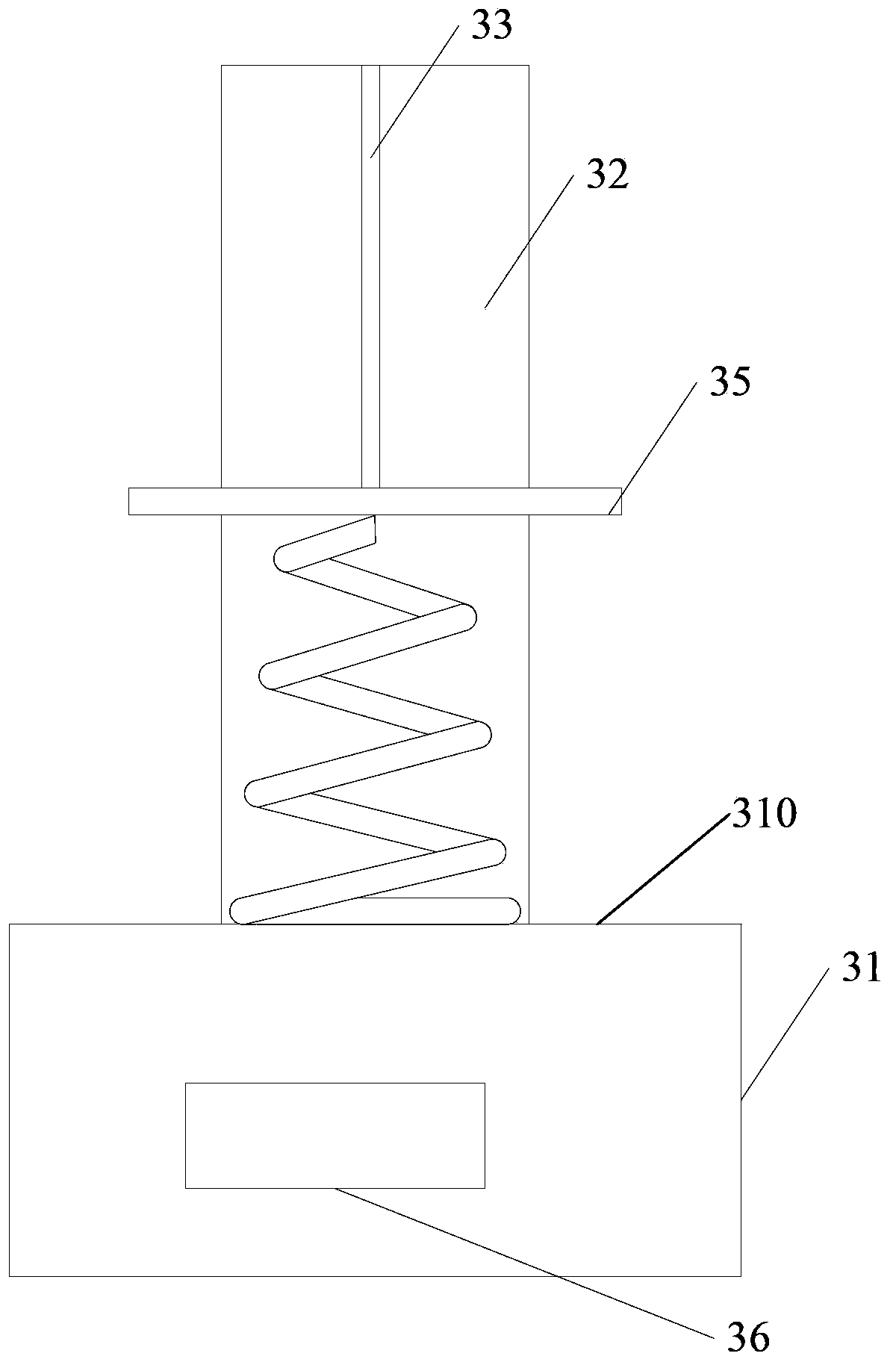

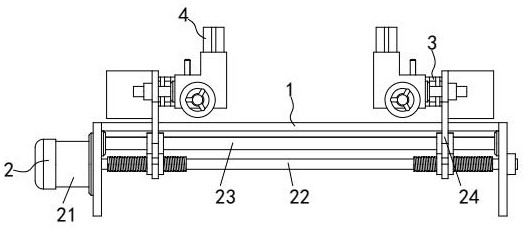

Spring testing method and spring elasticity testing device

InactiveCN104181051AFind out the designFind manufacturing defectsMaterial strength using tensile/compressive forcesTest sampleRoom temperature

The invention discloses a spring testing method comprising the steps: measuring a first elastic modulus value of a to-be-tested spring at room temperature; judging whether the first elastic modulus value is greater than a predetermined value; if the first elastic modulus is greater than the predetermined value, marking the to-be-tested spring as a to-be-tested sample, and recording and displaying the first elastic modulus value, and otherwise carrying out arm reminding; allowing the to-be-tested sample to bear a predetermined high temperature or bear a predetermined height and a predetermined pressure simultaneously within predetermined time, after reaching the room temperature, measuring a second elastic modulus value of the to-be-tested sample; and judging whether the second elastic modulus value is greater than a predetermined value, if the second elastic modulus value is greater than the predetermined value, recording and displaying the second elastic modulus value, and otherwise carrying out arm reminding. The invention also provides a spring elasticity testing device. The spring testing method and the testing device utilize the two conditions of the room temperature and the predetermined high temperature to measure the elastic modulus values of the spring, and thus the elastic property of the spring can be effectively tested, then defects of spring design and manufacture can be found out, and the reliability of a product is improved.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

A kind of thrombus elasticity testing device

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

POGOPIN probe elasticity test equipment

The invention relates to a probe elasticity testing device, in particular to a POGOPIN probe elasticity testing device. The invention aims to provide the POGOPIN probe elasticity testing equipment which is time-saving and labor-saving. The POGOPIN probe elasticity testing equipment comprises bases, fixing frames, a placement mechanism, a displacement mechanism, an extrusion mechanism and the like, the fixing frames are arranged on the tops of the bases on the left side and the right side, the placement mechanism used for fixing a POGOPIN probe is arranged between the middles of the fixing frames, the displacement mechanism used for driving the placement mechanism to move is arranged on the placement mechanism, and the extrusion mechanism is arranged on the left side and the right side of the base. An extrusion mechanism is arranged at the top of the base. A plurality of POGOPIN probes can be supported through the placing plate, then the electric push rod is used as a driving force to drive the connecting rod and the first ejector rod to move backwards so as to drive the first sliding block to move backwards, the first sliding block can drive the pressing plate to move downwards to extrude the POGOPIN probes, the pressing plate does not need to be manually pressed, and time and labor are saved.

Owner:鹰潭市云探电子科技有限公司

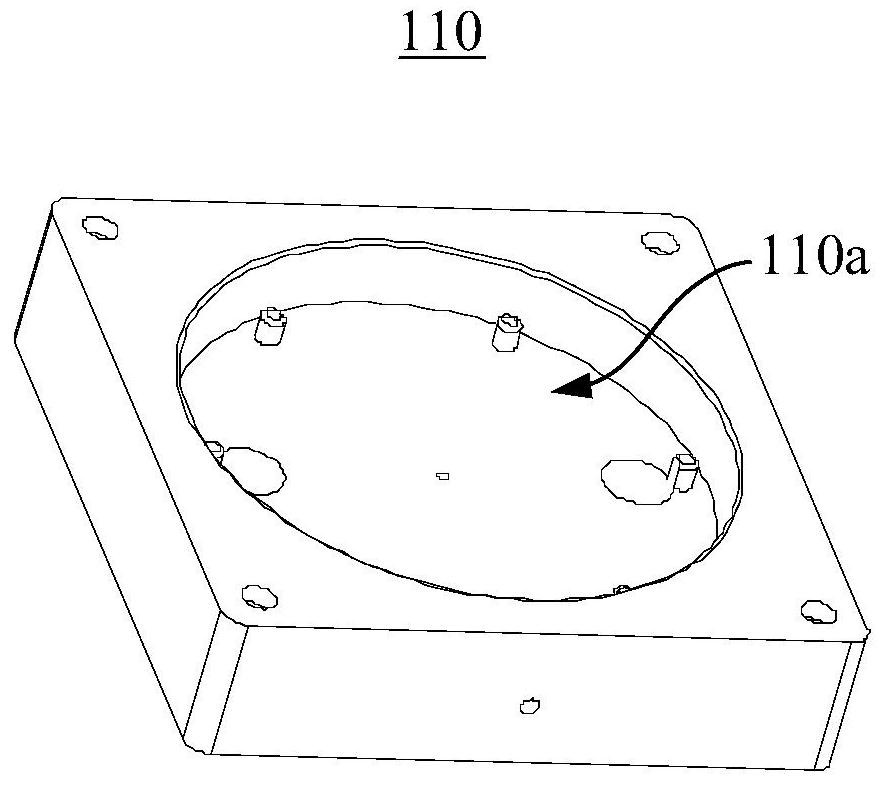

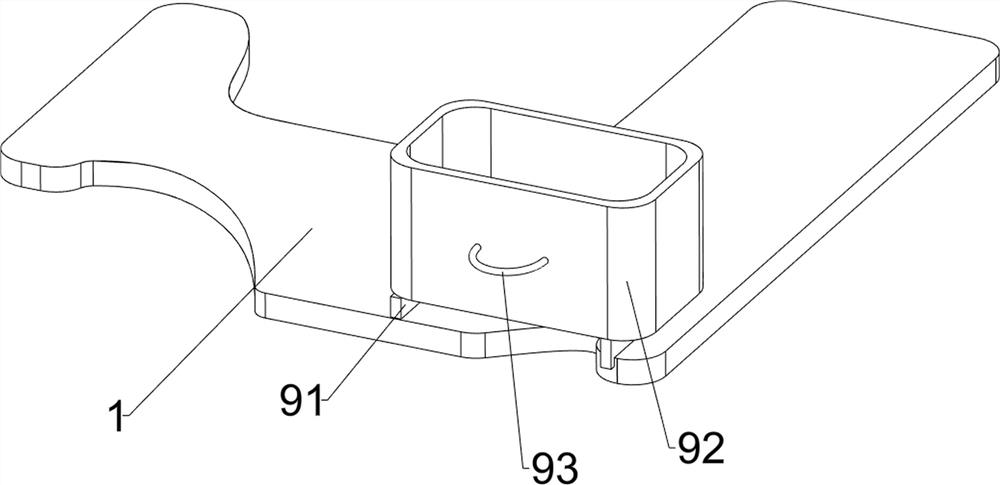

Air tightness test fixture

PendingCN112378587AAir tightness test implementationFluid-tightness measurement using fluid/vacuumClassical mechanicsEngineering

The invention relates to an air tightness test fixture, which comprises a storage seat, a driver, a push plate, an ejector rod and an elastic test assembly, and is characterized in that a groove is formed in the storage seat, the groove is provided with an opening, and a product to be tested is assembled at the opening of the groove; the driver is in transmission connection with the push plate, the ejector rod is fixedly connected to the push plate, the elastic test assembly is movably connected to the push plate, the push plate is arranged corresponding to the storage seat and suspended abovethe storage seat, and the driver drives the push plate to move in the direction close to or away from the storage seat to drive the ejector rod and the elastic test assembly to be close to or away from the storage seat; the elastic test assembly comprises a supporting rod, a rubber plug and an elastic piece, a through hole is formed in the push plate, and the supporting rod is assembled and fixedin the through hole and movably connected to the push plate; the rubber plug is arranged at the end, away from the push plate, of the supporting rod and used for sealing the through hole; and one endof the elastic piece abuts against the push plate, and the other end abuts against the end, provided with the rubber plug, of the supporting rod. The air tightness test fixture can carry out air tightness test on a product with a through hole.

Owner:SHENZHEN BESTEK TECH CO LTD

Mechanical grabbing type elasticity testing device for paper diaper

InactiveCN106596273AImplement resiliency testingQuality assuranceMaterial strength using tensile/compressive forcesEngineeringElasticity Testing

The invention discloses a mechanical grabbing type elasticity testing device for a paper diaper. The device comprises a base, a fixing base is arranged over the base, the fixing base is fixedly connected through a connecting base, two relatively-inclined columns are fixedly installed on the top of the fixing base, and the paper diaper can be arranged on the columns in a sleeving mode and matched with the outer wall of the fixing base; vertical strip-shaped openings are formed in the two sides of the fixing base respectively, fixing blocks are arranged at the two sides of the fixing base respectively, a vertical rod is fixedly installed at the top end of each fixing block, a horizontal air cylinder is fixedly installed on each vertical rod, a connecting rod is fixedly installed at the end of a movable rod of each air cylinder, and two mechanical grippers are fixedly installed at the end of each connecting rod, wherein an electric pushing rod is arranged between each mechanical gripper and the connecting rod, one end of each electric pushing rod is fixedly connected with the connecting rod, the end of a movable rod of each electric pushing rod is fixedly connected with the outer side face of the corresponding mechanical gripper, the electric pushing rods can control opening and closing of the mechanical grippers, and the mechanical grippers can be matched with an upper port and a lower port of the corresponding strip-shaped opening. The two columns penetrate through two holes of the paper diaper, then the paper diaper is fixed to the fixing base, and therefore the device is convenient to use.

Owner:深圳中健永明生物科技有限公司

Home decoration curtain cloth fabric elasticity test system and test method

ActiveCN114371079AAvoid under-openingControl consistencyMaterial strength using tensile/compressive forcesStructural engineeringHome improvement

The invention relates to the technical field of cloth fabric processing, in particular to a home decoration curtain cloth fabric elasticity testing system and method.The system comprises a testing table, an elastic stretching mechanism is assembled on the testing table, and the elastic stretching mechanism comprises two stroke frames which are arranged in a reverse driving movement mode; tension sensors are correspondingly and fixedly installed on the two stroke frames, the two tension sensors are correspondingly connected with traction mechanisms, and the two traction mechanisms are arranged in a mirror image opposite mode. The system provided by the invention is simple in structure, can realize automatic opening of the tested fabric under manual auxiliary operation, can avoid insufficient opening of the fabric in the non-elastic stretching direction, can effectively control the consistency of the opening amplitude of the fabric, facilitates the elastic force test of the fabric, and improves the accuracy and effectiveness of the elastic force test of the fabric.

Owner:XUZHOU PUSU INTERIOR DECORATION MATERIAL CO LTD

Soil body tester based on soil body elasticity test and test method thereof

PendingCN112881179AAvoid error effectsStrain parameters are accuratePreparing sample for investigationMaterial strength using tensile/compressive forcesSoil scienceTest sample

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

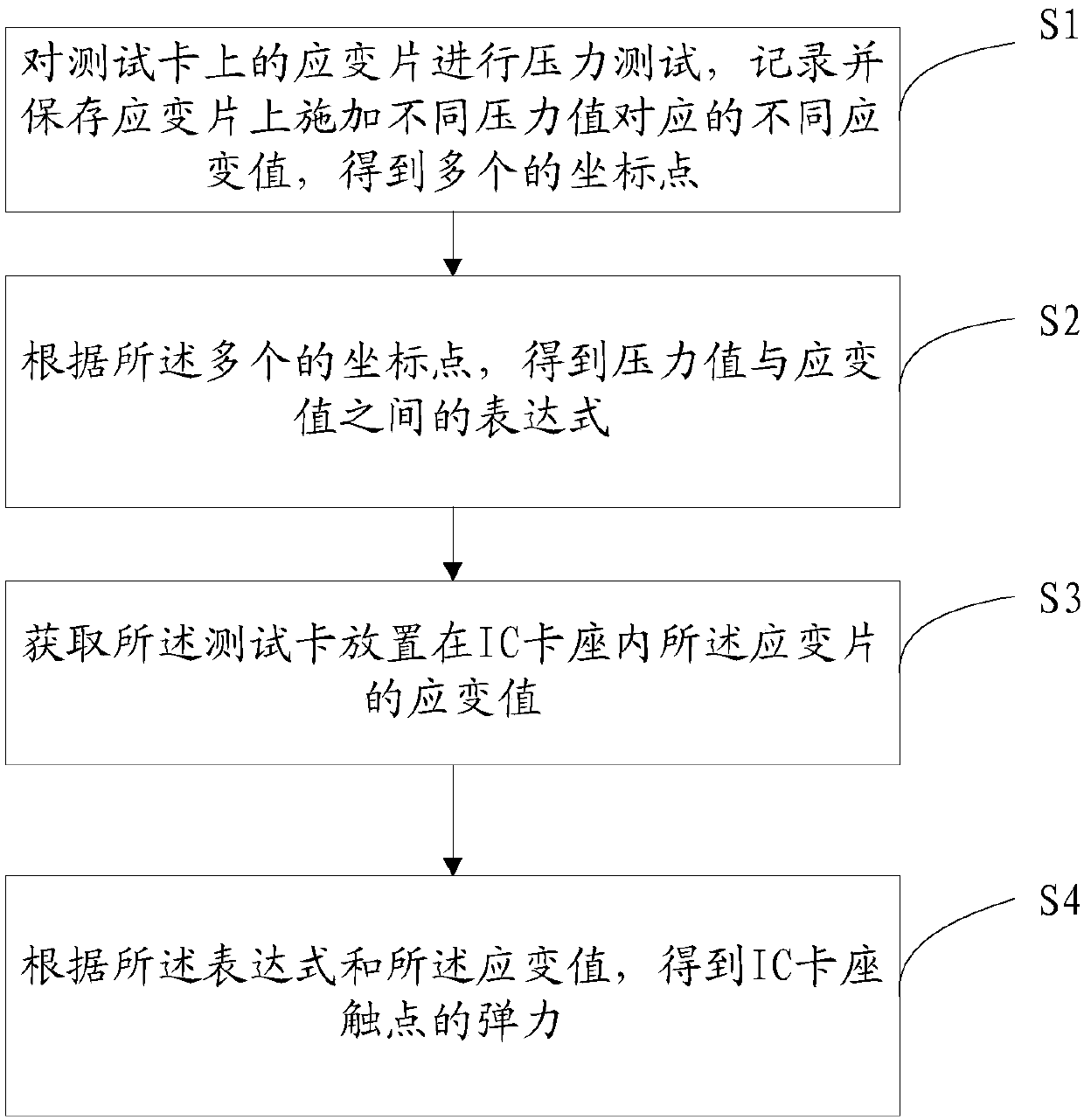

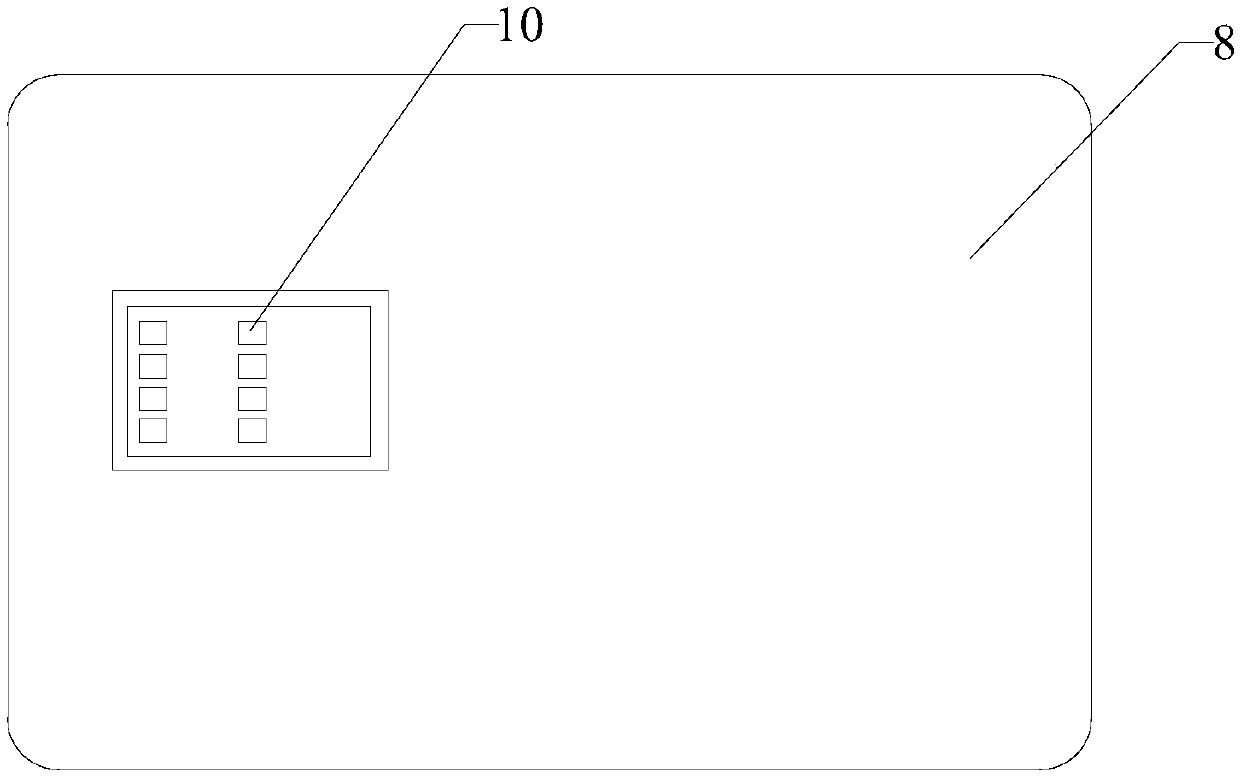

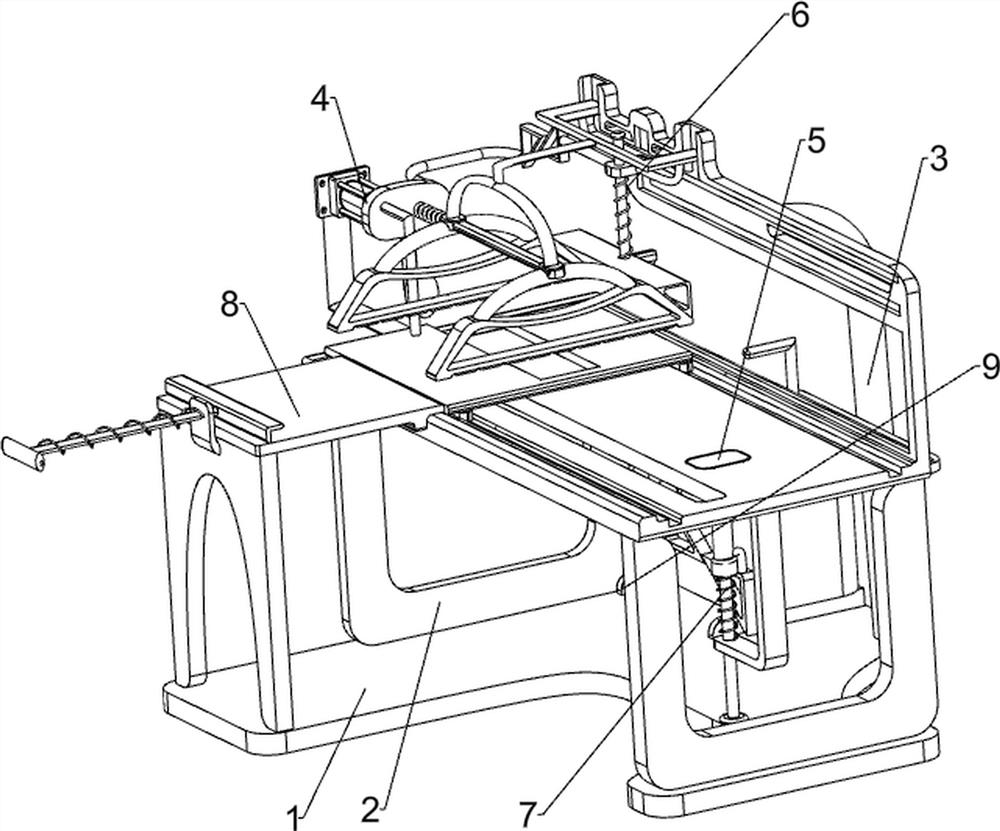

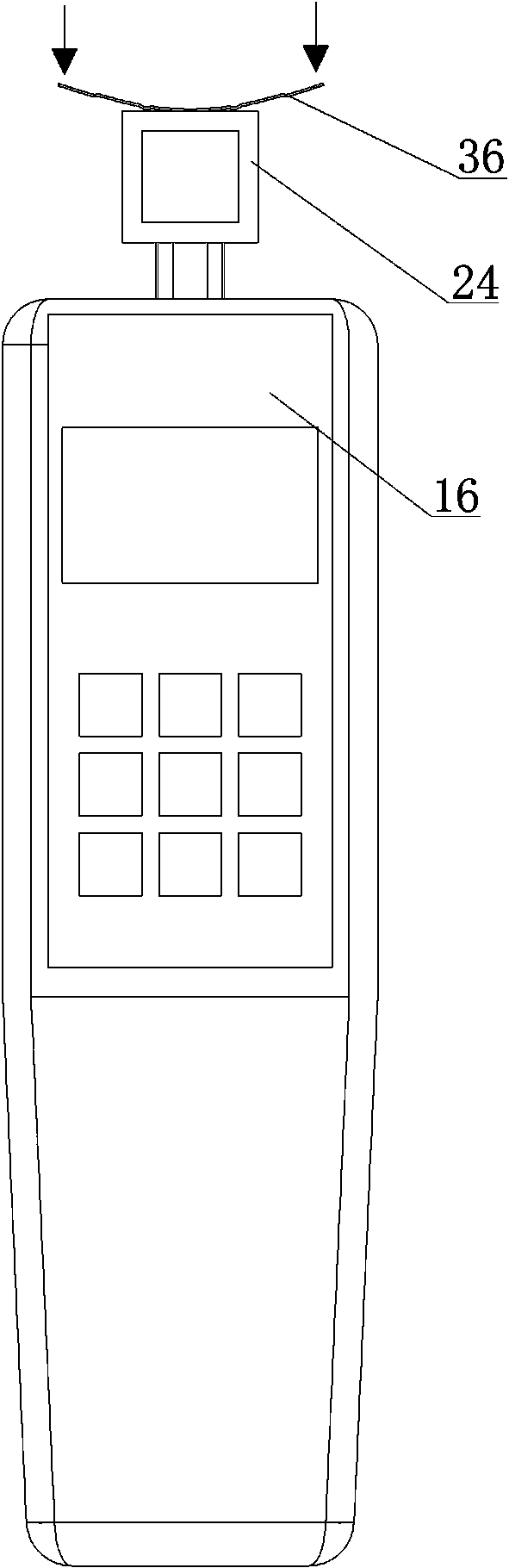

IC card connector elasticity testing method and terminal, and testing card and testing machine

InactiveCN107643134ARequirements for Efficient Assessment of ResilienceWon't hurtForce measurementTest efficiencyEngineering

The invention relates to the field of pressure testing, and especially relates to an IC card connector elasticity testing method and terminal, and a testing card and a testing machine. The IC card connector elasticity testing method comprises carrying pressure testing on a strain gauge on the testing card, recording and saving different strain values corresponding to different pressure values applied to the strain gauge, and obtaining a plurality of coordinate points; obtaining an expression between the pressure value and the strain value according to the plurality of coordinate points; obtaining the strain value of the strain gauge when the testing card is placed in the IC card connector; and obtaining the elasticity of the contact of the IC card connector according to the expression andthe strain value. According to the invention, the elasticity value of the contact in the IC card connector can be tested, and therefore whether the IC card connector meets the demand of an EMV standard on the elasticity of the contact of the IC card connector is effectively estimated, during the testing process, the IC card connector is not damaged, once a model between the strain gauge and the pressure is established, the elasticity of metal contacts in a batch of IC card connectors can be tested, the testing efficiency is improved, and the usage cost is reduced.

Owner:FUJIAN LANDI COMML EQUIP CO LTD

Automatic cloth elasticity testing device for workshop production

ActiveCN112609426ARealize automatic pushRealize the effect of automatic testingInspecting textilesProcess engineeringMechanical engineering

The invention relates to an automatic cloth elasticity testing device, in particular to the automatic cloth elasticity testing device for workshop production. The automatic cloth elasticity testing device for the workshop production can relieve arm ache, improve the testing efficiency and prevent cloth from being broken. The automatic cloth elasticity testing device for the workshop production comprises a base, first supports, a second support, a pushing mechanism and an extrusion mechanism, the first supports are arranged on the two sides of the base, the second support is arranged on the base, the pushing mechanism is arranged between the tops of the two first supports and the top of the second support, and the extrusion mechanism is arranged at the bottom of the pushing mechanism. By arranging the pushing mechanism, the pushing mechanism conveys the elastic cloth forwards to complete detection and pushes elastic cloth backwards to complete reset material taking, and the effect of automatically pushing the elastic cloth is achieved.

Owner:宜春酷加运动用品有限公司

Automatic yarn elasticity recovery degree testing device

The invention relates to the technical field of yarn processing equipment, and discloses an automatic yarn elastic recovery degree testing device, which comprises an operation base plate and a testing pressing block, wherein a fixed spool is fixedly connected to the top of the operation base plate, a limiting spool is fixedly connected to the top of the operation base plate, and a limiting clamping groove is formed in the limiting spool; a winding clamping spool is movably connected into the limiting clamping groove, an electromagnet is fixedly connected into the limiting spool, and a driving motor is fixedly connected into the operation base plate. According to the automatic yarn elasticity recovery degree testing device, after the working voltage of a piezoresistor is reached, a driving motor drives a rotary driving shaft to rotate, so that a rotating block freely rotates in a wave-shaped groove, a driving supporting rod is driven to reciprocate up and down, yarn is pressed downwards through a testing pressing block, and the reciprocating elasticity testing process is achieved; and when the yarn elasticity recovery value reaches the limit, the yarn loses elasticity, the dielectric plate slides down again, the driving motor is turned off, the test process is completed, and the test result is recorded.

Owner:郑婷婷

Ping-pong ball elasticity testing device

ActiveCN104089749AMeasure the number of bounces in real timeSimple structureElasticity measurementEngineeringComputer engineering

The invention discloses a ping-pong ball elasticity testing device. The ping-pong ball elasticity testing device comprises a base, an impact sensor, a display screen, a testing barrel and a cover body, wherein the testing barrel is arranged on the base, a ping-pong ball entering hole is formed in the top end of the testing barrel and provided with the cover body, the bottom of the testing barrel is provided with the impact sensor and a counter, the display screen is installed on the side face of the base, and the impact sensor, the counter and the display screen are connected in sequence. The ping-pong ball elasticity testing device is simple in structure, convenient to implement and capable of being produced on a large scale.

Owner:WUXI CITY CHONGAN DISTRICT TECH ENTREPRENEURSHIP SERVICE CENT

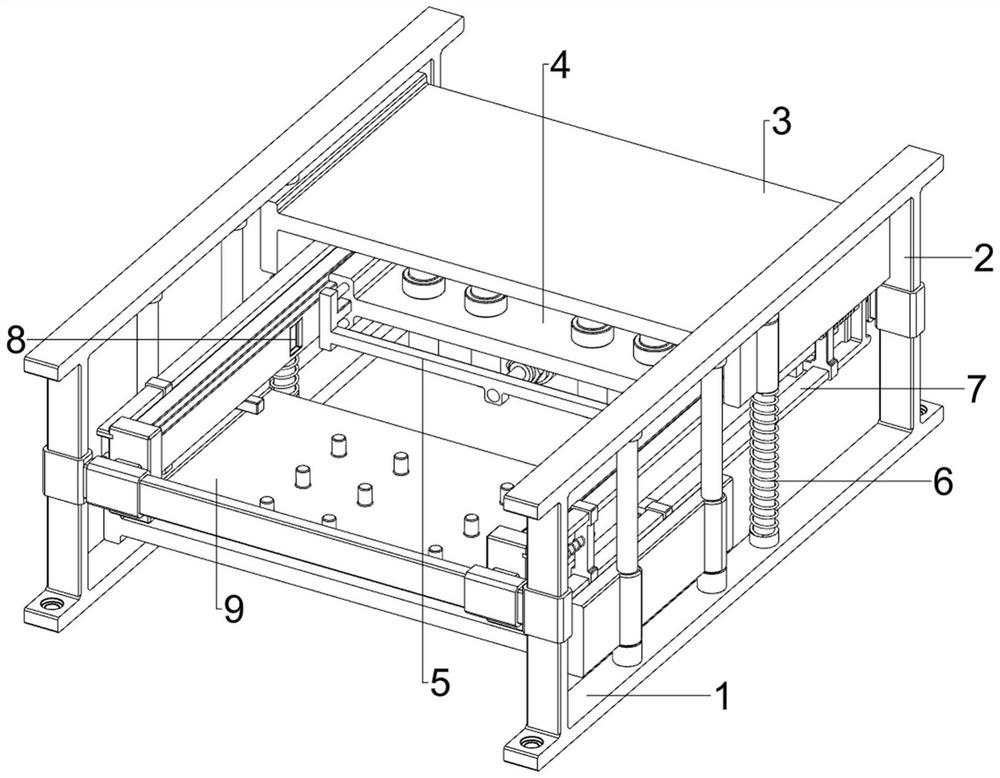

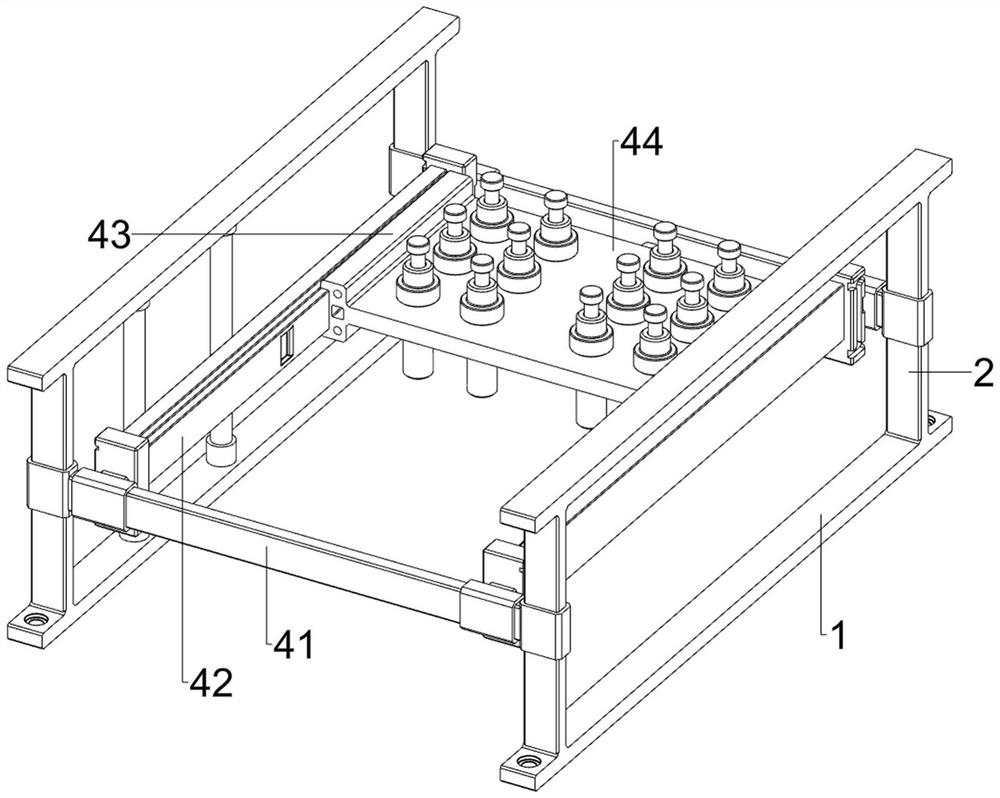

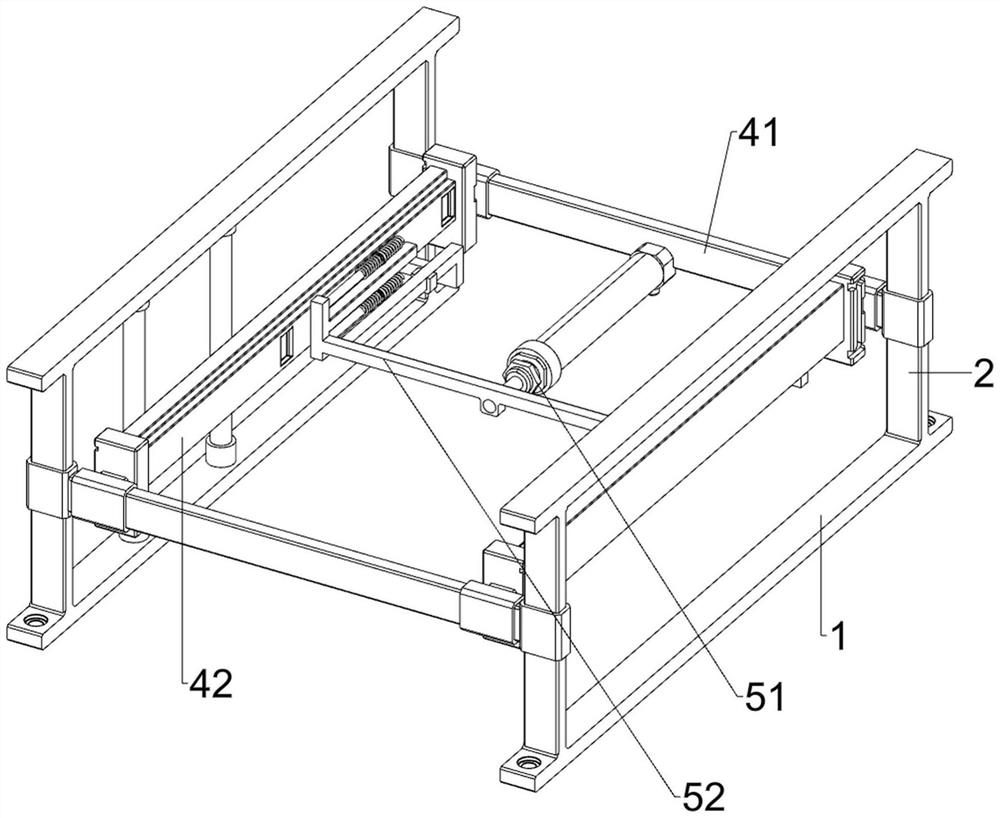

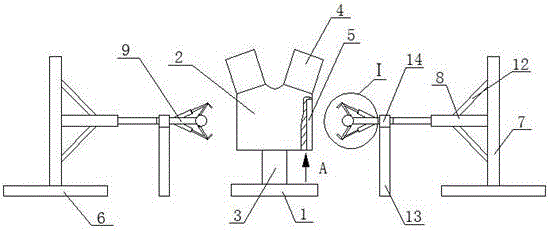

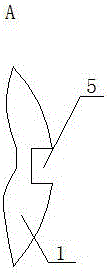

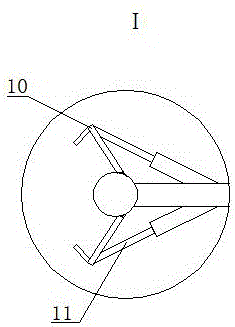

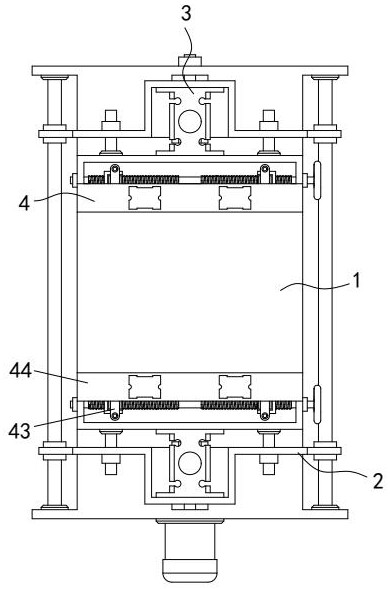

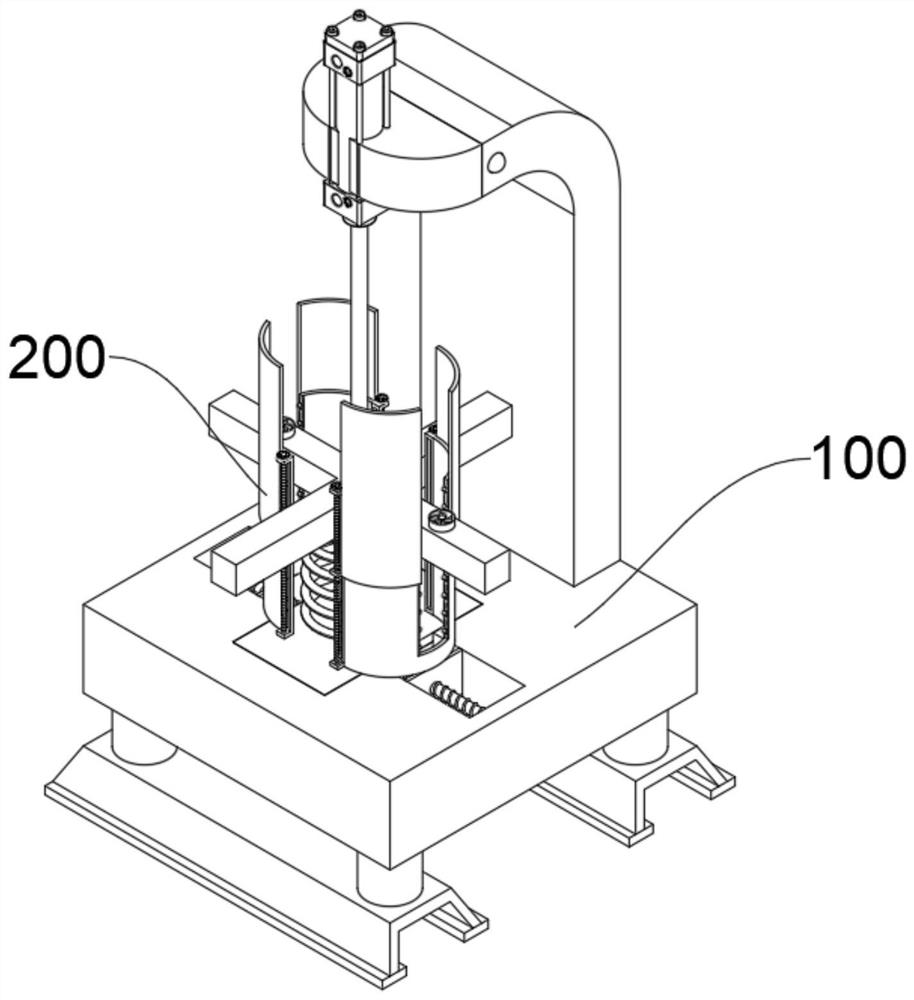

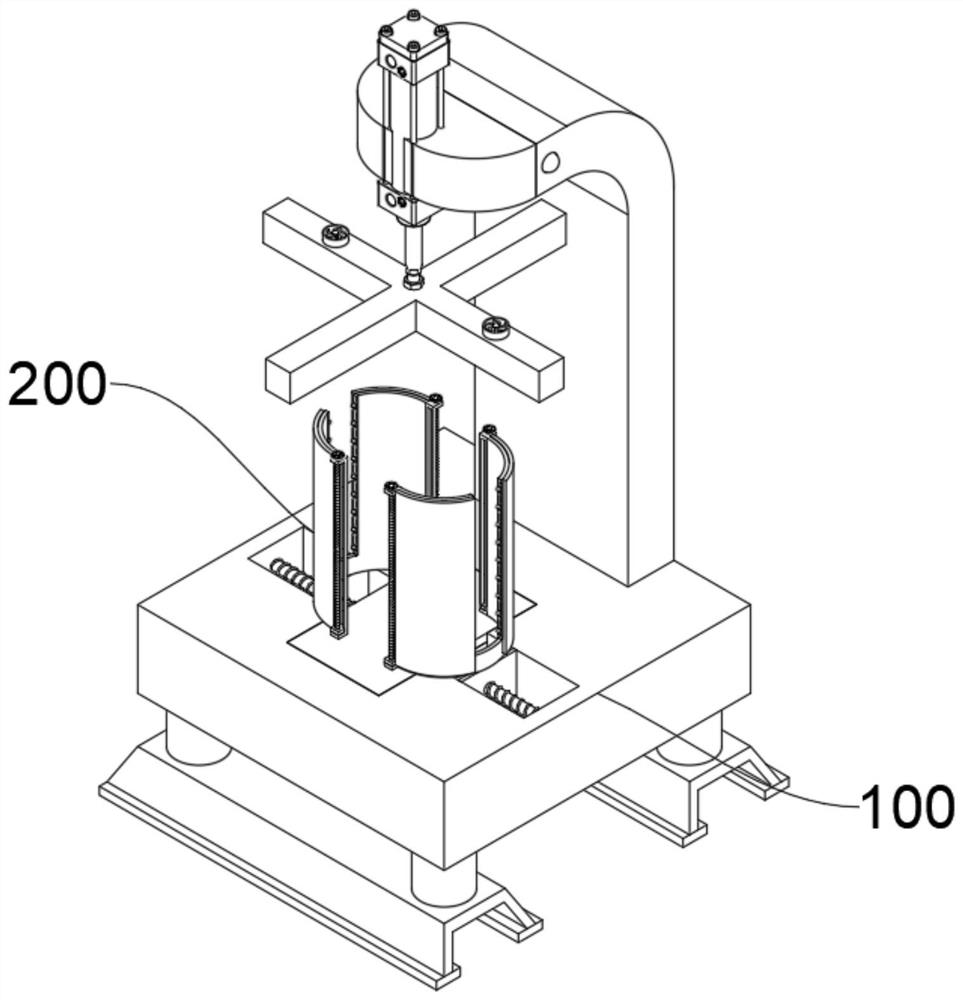

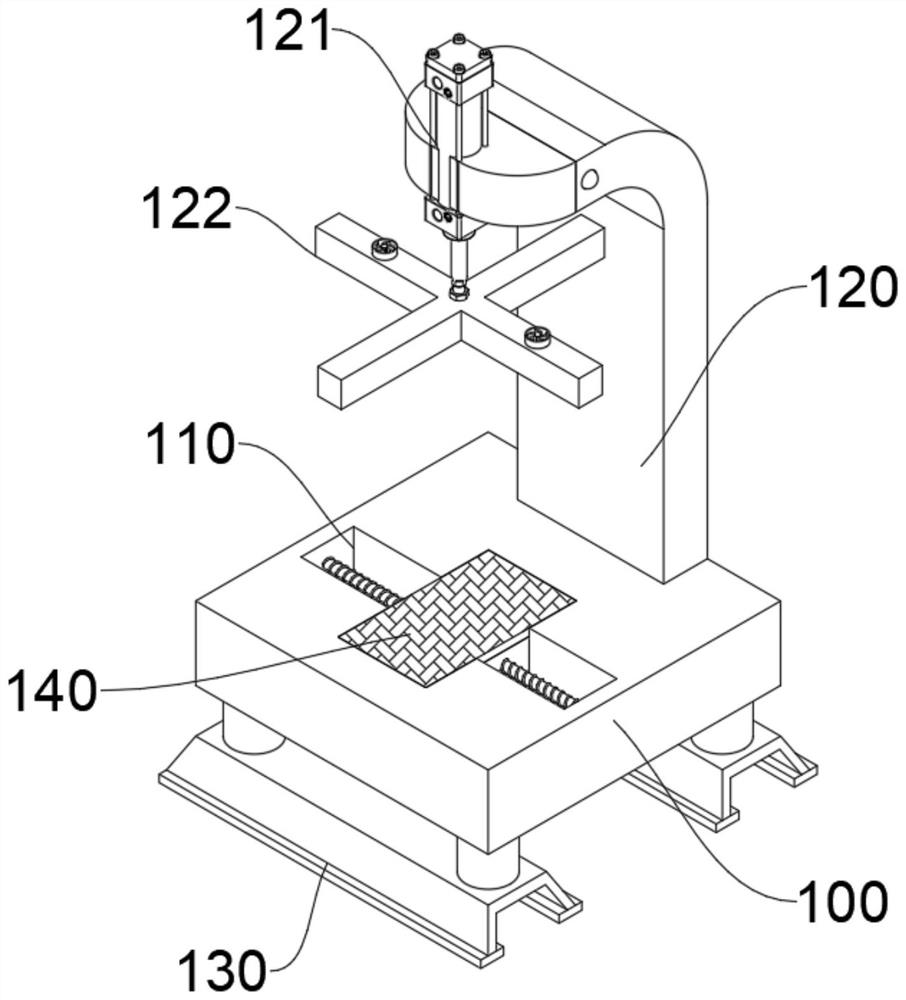

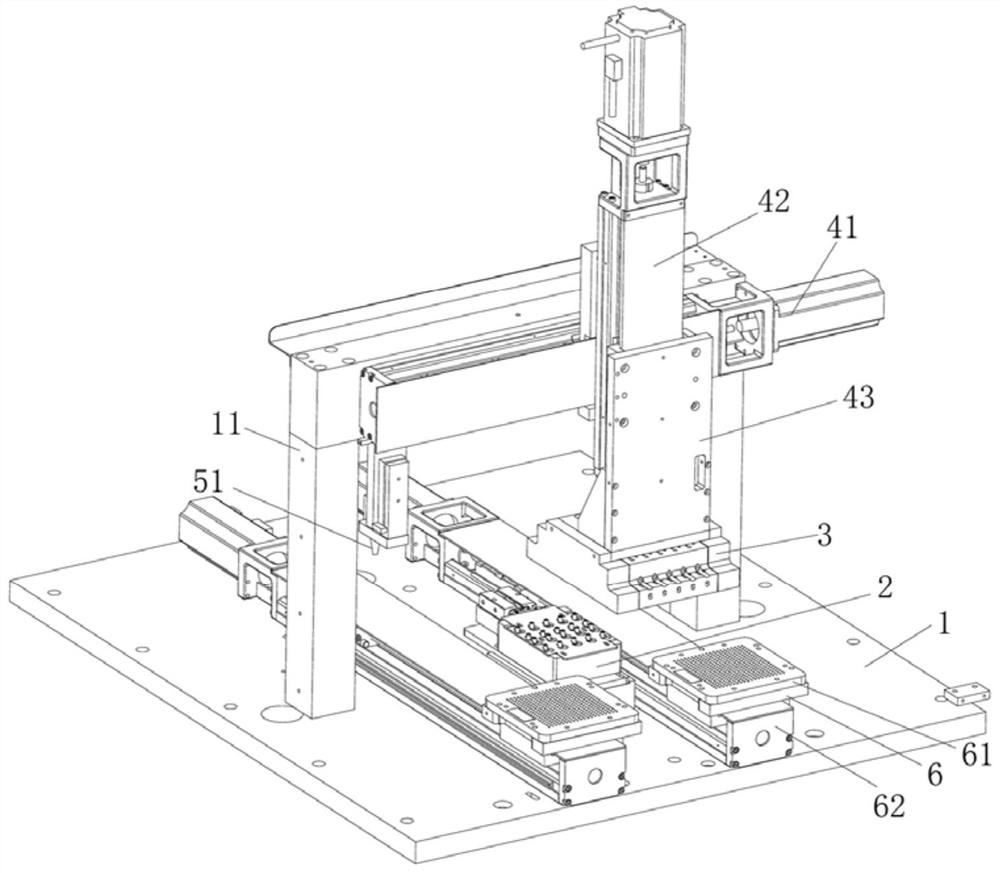

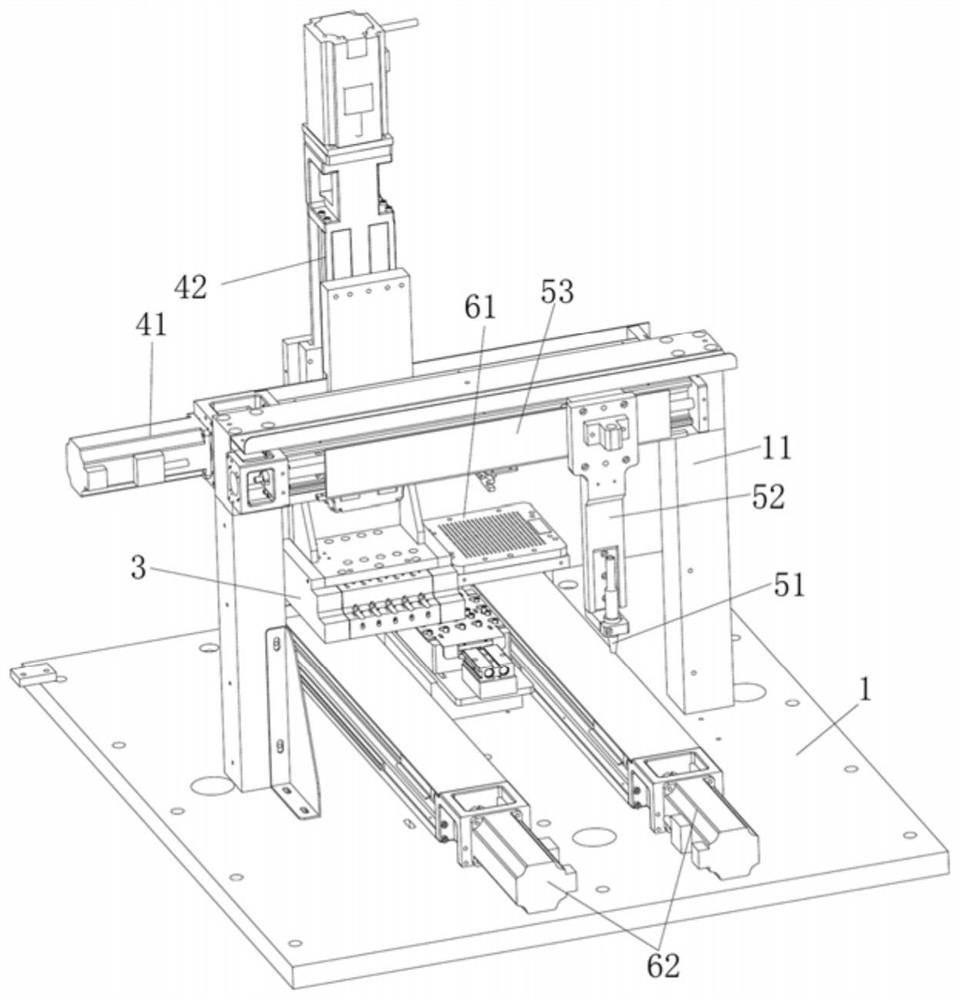

Online testing device for elastic force of bent elastic sheet

PendingCN111537214AImprove test efficiencyCompact structureMachine part testingMaterial strength using steady bending forcesTest efficiencyReduction drive

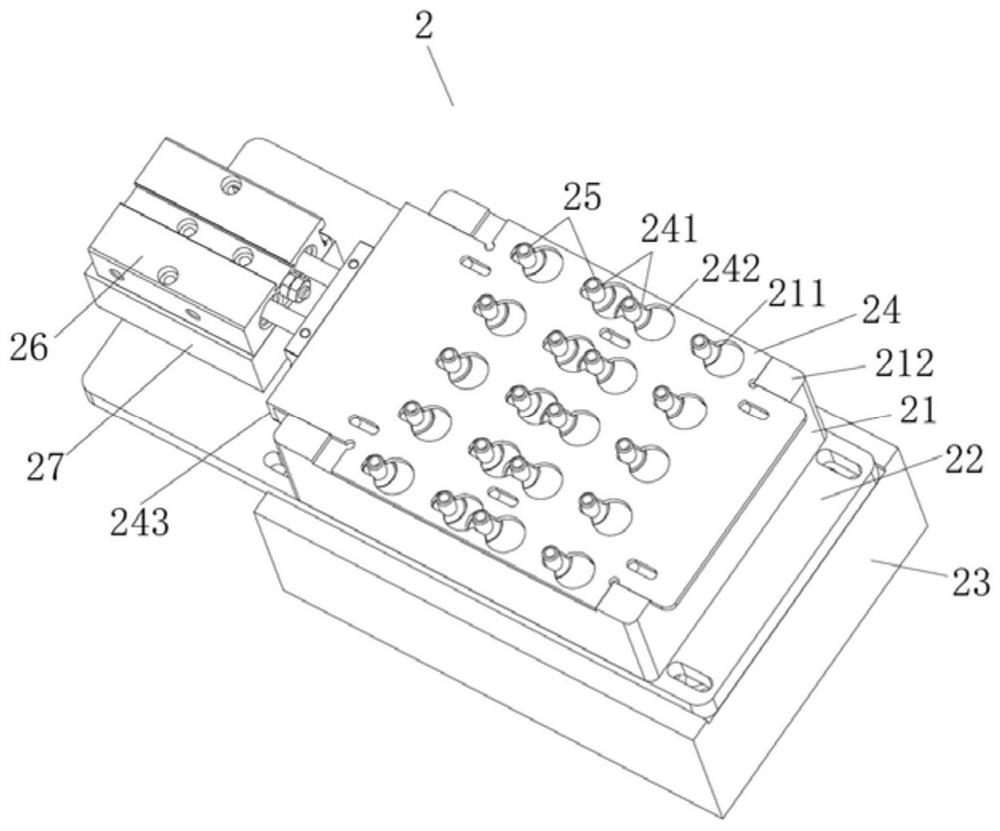

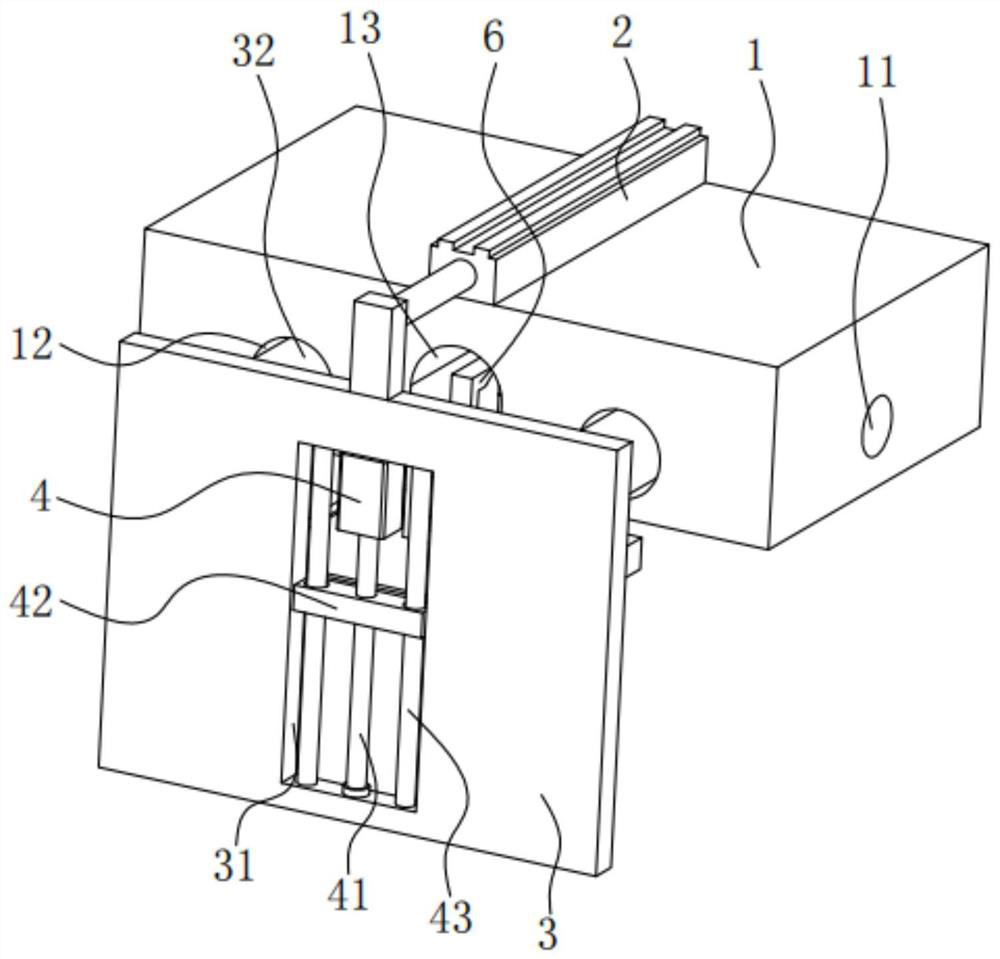

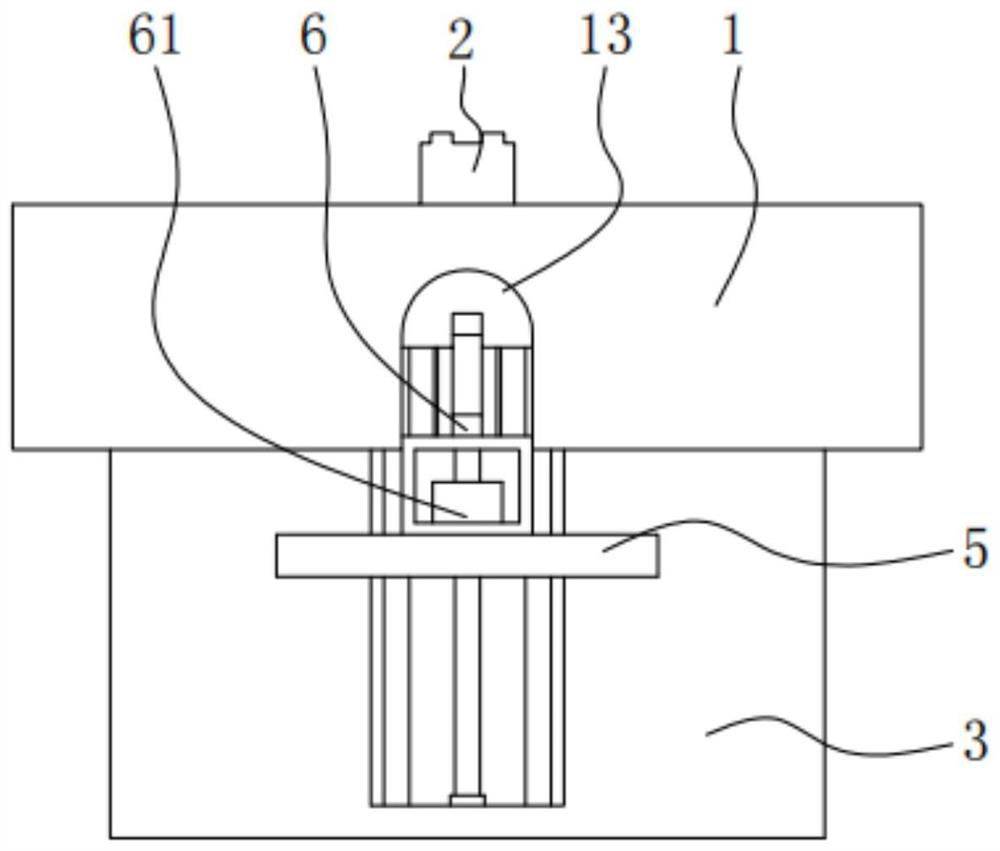

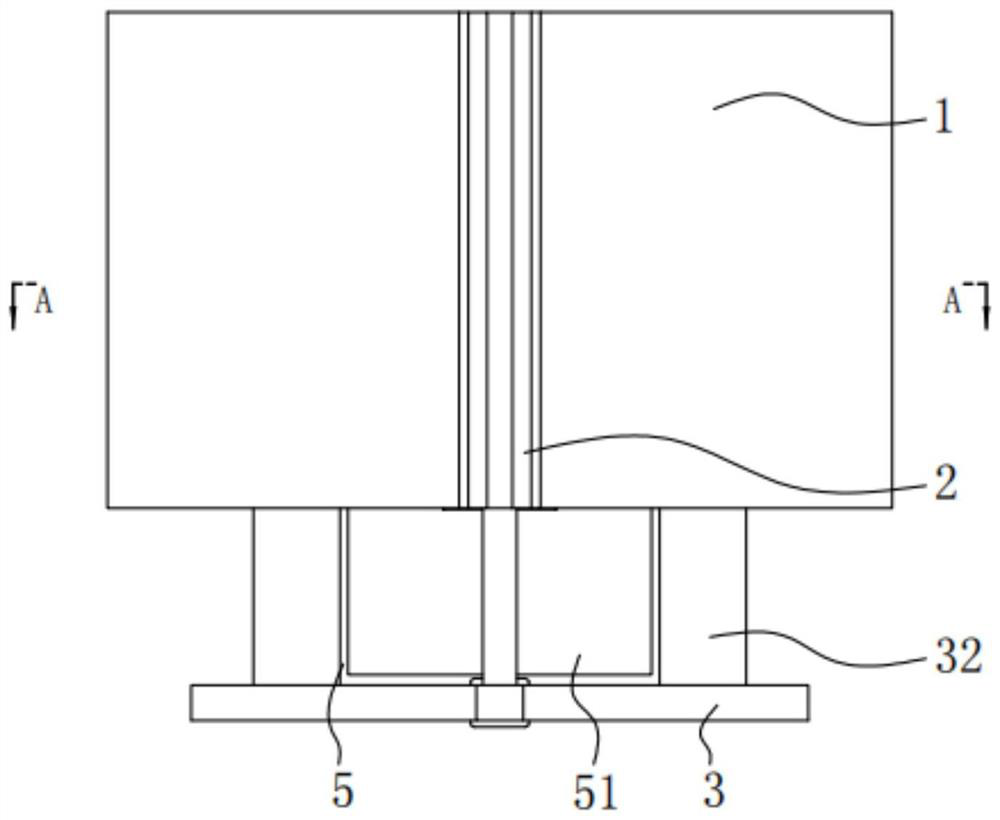

The invention discloses an online testing device for elastic force of a bent elastic sheet. The device comprises a workbench (1), wherein an elastic sheet transfer device (2) and an elastic sheet elasticity testing device (3) are arranged on the workbench (1); the elastic sheet transfer device (2) comprises a stepping motor (4) and a speed reducer (5) which are fixedly arranged on the workbench (1); an output shaft of the stepping motor (4) is connected with an input shaft of the speed reducer (5) through a coupler; an output shaft is arranged at the top of the speed reducer (5), and a rotarydisc (6) is installed on the output shaft of the speed reducer (5); the elastic sheet elasticity testing device (3) comprises a base (11) and a lifting air cylinder (12); and a pressure applying air cylinder (14), a guide rail B (15) and an elasticity tester (16) which are vertically arranged are fixedly arranged on the left end surface of a sliding plate (13) in sequence from top to bottom. The device has the advantages that the structure is compact, the elastic sheet testing efficiency is improved, the testing precision is improved, and the operation is simple.

Owner:CHENGDU HOMIN TECH

Stainless steel wire strength detection equipment based on elasticity testing mechanism

PendingCN113504120APrevent dumpingGuaranteed accuracyMaterial strength using tensile/compressive forcesClassical mechanicsEngineering

The invention relates to the technical field of stainless steel wires, in particular to stainless steel wire strength detection equipment based on an elastic testing mechanism. The equipment at least comprises a bottom plate and two spring limiting mechanisms, wherein the top edge of the bottom plate is provided with a supporting plate, the end of the supporting plate is provided with a cylinder, the end of a cylinder piston rod is connected with an extrusion plate, and the top center of the bottom plate is provided with a pressure sensor; and the two spring limiting mechanisms are symmetrically arranged, each spring limiting mechanisms comprise limiting arc plates, open grooves are formed in the surfaces of the limiting arc plates, the ends of extrusion plates slide in the open grooves, lifting plates are arranged at the two ends of the limiting arc plates, adjusting lead screws are rotationally arranged in the lifting plates, two symmetrical movable arc plates slide on the outer sides of the limiting arc plates, adjusting plates are arranged at the ends, which are close to the bottom, of the movable arc plates, and the surfaces of the two adjusting plates are in threaded fit connection with the outer walls of the two adjusting lead screws correspondingly. The limiting range can be adjusted according to the size and height of the stainless steel wire of a spring, so that the detection stability is facilitated, and the detection accuracy is improved.

Owner:安徽珂洁日用品有限公司

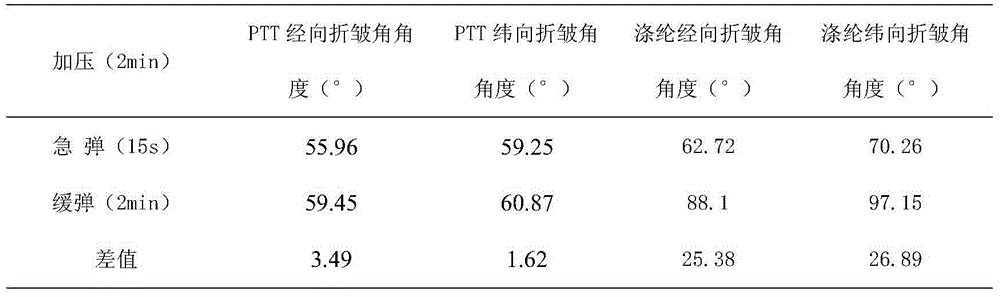

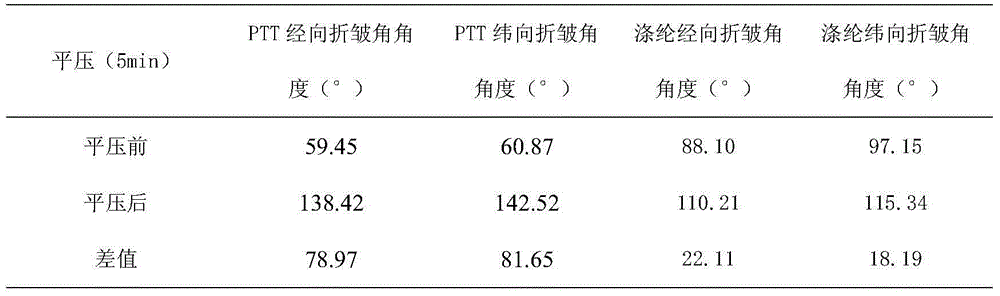

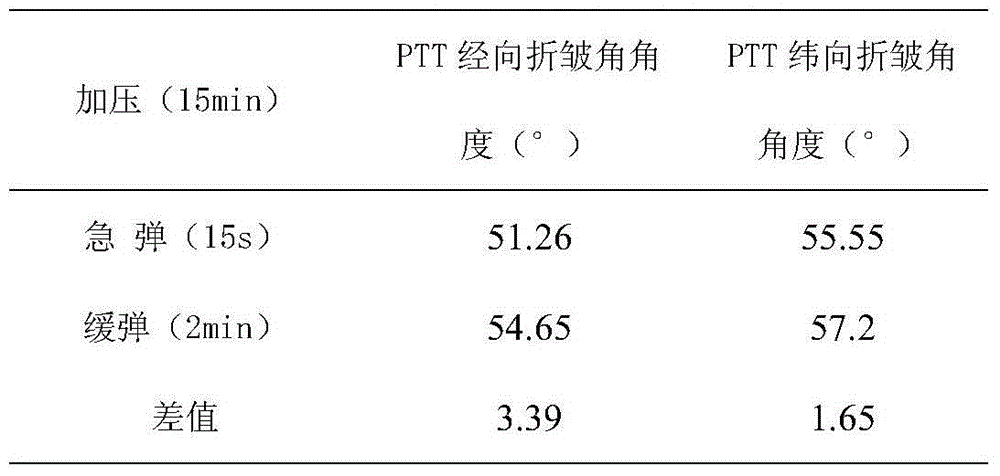

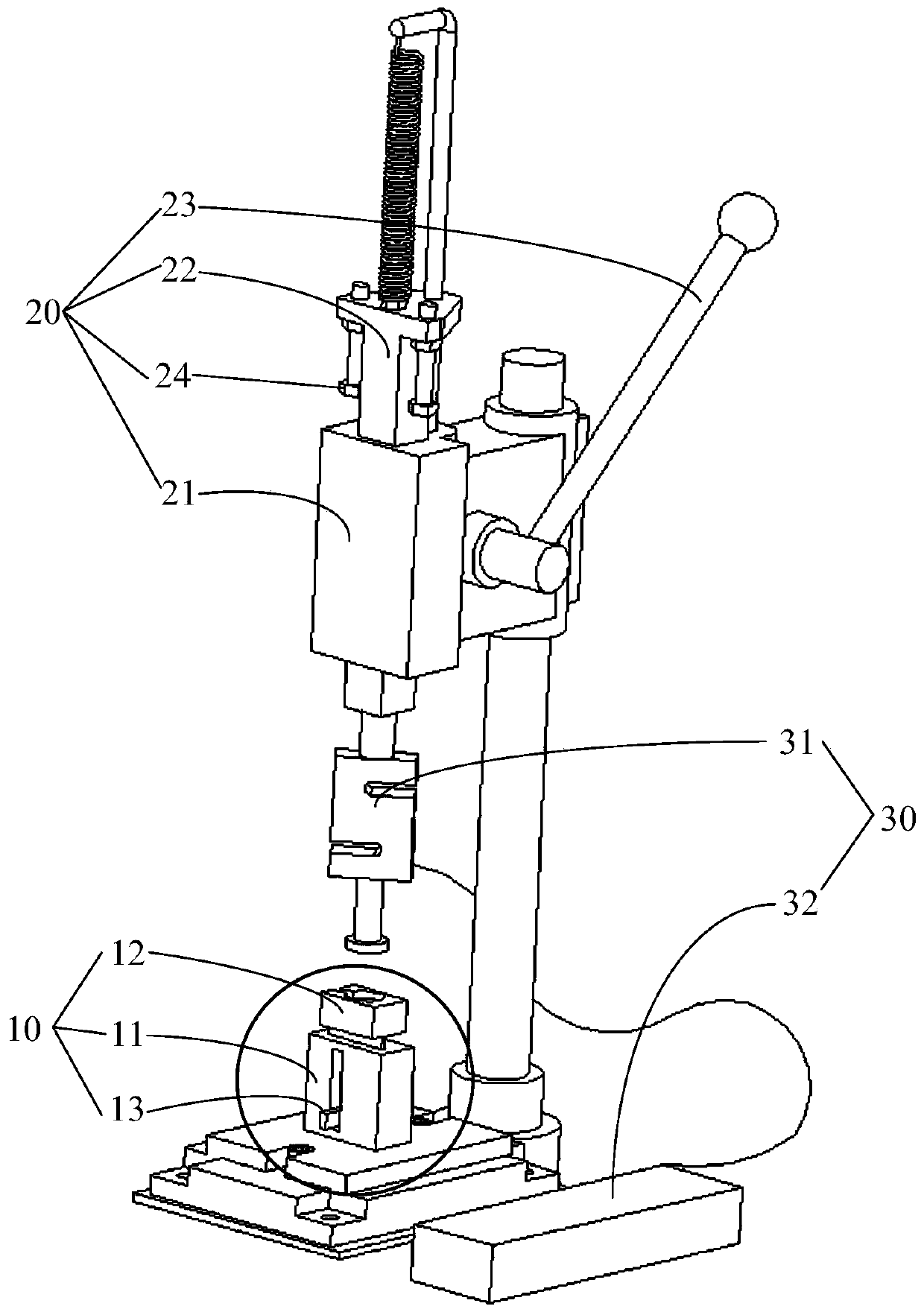

Testing method for memorizing function of PTT fabric

InactiveCN104894833AEffective evaluation of memory functionSimple and fast operationInspecting textilesMaterial strength using repeated/pulsating forcesChinese charactersEngineering

The invention discloses a testing method for the memorizing function of a PTT fabric. The method comprises the steps of shearing the PTT fabric into detecting fabric in shape of a Chinese character Pin according to the testing requirement; folding the side parts of the detecting fabric; pressing the folded part of the detecting fabric through a heavy hammer of a folding elasticity testing instrument for the fabric for a certain period of time; releasing the pressure for 15 seconds; then testing and reading the instantaneous elasticity data through the folding elasticity testing instrument for the fabric; continuously releasing the pressure of the folded part of the detecting fabric; stopping pressing for 2 minutes; then testing and reading slow elasticity data through the folding elasticity testing instrument for the fabric; expanding the folded part of the detecting fabric; then flatly pressing the folded corners of the folded part through the heavy hammer of the folding elasticity testing instrument for the fabric for 5 to 20 minutes; releasing the pressure for 15 seconds; then testing and reading the instantaneous elasticity data through the folding elasticity testing instrument for the fabric. With the adoption of the method, the memorizing function of the PTT fabric can be quantitatively expressed; the operation is simple; the memorizing function of the fabric can be effectively evaluated.

Owner:SHAOXING UNIVERSITY

U-shaped spring clamp elasticity test system and elasticity test method

PendingCN111458063AEasy to installEasy to operateApparatus for force/torque/work measurementTransverse grooveStructural engineering

The invention relates to a U-shaped spring clamp elasticity test system and an elasticity test method. The U-shaped spring clamp elasticity test system comprises: a testing tool, wherein the testing tool comprises a pressing block used for applying pressure to a U-shaped clamp, a cushion block used for positioning the deformation size of the U-shaped clamp and a containing table, the containing table is provided with a transverse groove used for containing the U-shaped clamp and allowing the pressing block to be inserted and a vertical groove allowing the cushion block to be inserted into theopening of the U-shaped clamp, and the transverse groove and the vertical groove are communicated in a crossed mode; a manual pressing machine which is used for applying pressure to the pressing block; and a detection assembly which is connected to the manual pressing machine and is used for detecting the elastic force of the U-shaped clamp. The U-shaped spring clamp elasticity test system is convenient to install, easy to operate, capable of utilizing existing equipment, simple in tool, small in machining difficulty and small in investment; and when the U-shaped spring clamp elasticity test system is used for elasticity testing, the elasticity value of the U-shaped spring clamp compressed under the specified size can be rapidly tested.

Owner:上海博邦汽车技术有限公司

Elastic force testing machine and point inspection method thereof

PendingCN113049163AIncrease distribution densityImprove efficiencyApparatus for force/torque/work measurementEngineeringMachine

The invention relates to an elastic force testing machine and a point inspection method thereof. The elastic force testing machine comprises a machine table, and a testing table, a storage bin, a testing device and a moving mechanism which are arranged on the machine table, the testing table is used for placing a material for elastic force testing, and the elastic force testing is driven by the moving mechanism to move between the storage bin and the testing table; the testing device comprises a plurality of sensing assemblies distributed in a matrix, each sensing assembly comprises a force measuring sensor and a probe, the probe is arranged at the sensing end of the force measuring sensor, a plurality of weights used for point inspection of the force measuring sensors are placed in the storage bin, the probe is provided with a first contact part which is in contact with the material during elasticity testing and a second contact part which is in contact with the weights and is used for lifting the weights out of the storage bin during point inspection. According to the invention, point inspection and testing are separately contacted through the first contact part which cannot be magnetized and the second contact part which can be magnetized or has magnetism on the probe, so that point inspection of all force sensors on the machine table can be completed at one time, and complicated manual weight hanging and manual data confirmation are avoided.

Owner:东莞市川富电子有限公司

Yarn elasticity testing device for spinning

PendingCN113899620AGuaranteed stabilityElasticity testing facilitatesMaterial strength using tensile/compressive forcesYarnSpinning

The invention provides a yarn elasticity testing device for spinning. The yarn elasticity testing device for spinning comprises a mounting rack, wherein the mounting rack is provided with a threading hole, the front surface of the mounting rack is provided with a telescopic groove, the mounting rack is provided with an adjusting hole, and the bottom of the mounting rack is provided with a movable groove; and an elastic piece, wherein the bottom of the telescopic piece is fixed to the top of the mounting frame. According to the invention, the yarn transversely penetrating through the interior of the threading hole is horizontally arranged, and the symmetrically distributed movable pressing shafts can stably press and limit the two sides of a testing point during testing, so that the stability of the yarn during testing is kept; and during testing, hanging and mounting of the automatic detection equipment are completed through the lifting structure, manual operation is not allowed, and after testing is completed, only the hook frame needs to be automatically separated and reset, so that automatic elasticity testing is conveniently carried out on limiting in the machining process.

Owner:颍上鑫鸿纺织科技有限公司

Elasticity testing socket for low-temperature application

InactiveCN105136312ASo as not to damageSmall vertical projected areaRadiation pyrometryHigh densityHeat transmission

Provided is an elasticity testing socket for low-temperature application. The elasticity testing socket includes a heat conduction pedestal, a PCB circuit board, an elasticity thrusting needle, an elasticity needle guide plate and an assembly needle guide plate, and other parts. The elasticity needle guide plate and the assembly needle guide plate achieve precise alignment via a positioning pin. A pin of a focal plane assembly inserts the assembly needle guide plate and subsequently is in contact with the elasticity thrusting needle which is installed inside the elasticity needle guide plate. The elasticity thrusting needle is connected to the PCB circuit board at the bottom. Upon the testing of the testing socket, the focal plane assembly is secured to the heat conduction pedestal via a locking mechanism such as a screw. Soft metal is arranged between the heat conduction pedestal and the assembly for heat transmission. Under the action of elastic force of a spring, the needle pin of the focal plane assembly and the elasticity thrusting needle maintain a certain contact force without damage to the needle pin. The testing socket is compact in structure and easy to manufacture, can implement cooling of the focal plane assembly via the heat conduction pedestal, and is applicable to refrigeration testing of the high-density needle pin assembly.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Film elasticity testing device

ActiveCN109655189AImplement automatic detection of elastic dataIncrease productivityApparatus for force/torque/work measurementMechanical engineeringLateral move

The invention provides a film elasticity testing device. The film elasticity testing device comprises a rack, wherein the upper portion of the rack is provided with a control panel, a substrate is arranged under the control panel, the substrate is provided with a vertical moving device, the vertical moving device comprises a servo motor, a first screw mechanism and a force measuring device, a pressure detecting thimble is connected below the force measuring device, a bottom plate is welded to the bottom of the rack, a lateral moving device is arranged laterally on the bottom plate, a longitudinal moving device is arranged longitudinally on the bottom plate, and the longitudinal moving device is provided with a product fixing rack. The film elasticity testing device has the advantages thatthe automatic detection of elasticity data of film is achieved, the test precision is accurate, adaptable adjustment can be performed on a film production formula according to test results, and the film production efficiency is improved.

Owner:中山市鼎诚盛新材料有限公司

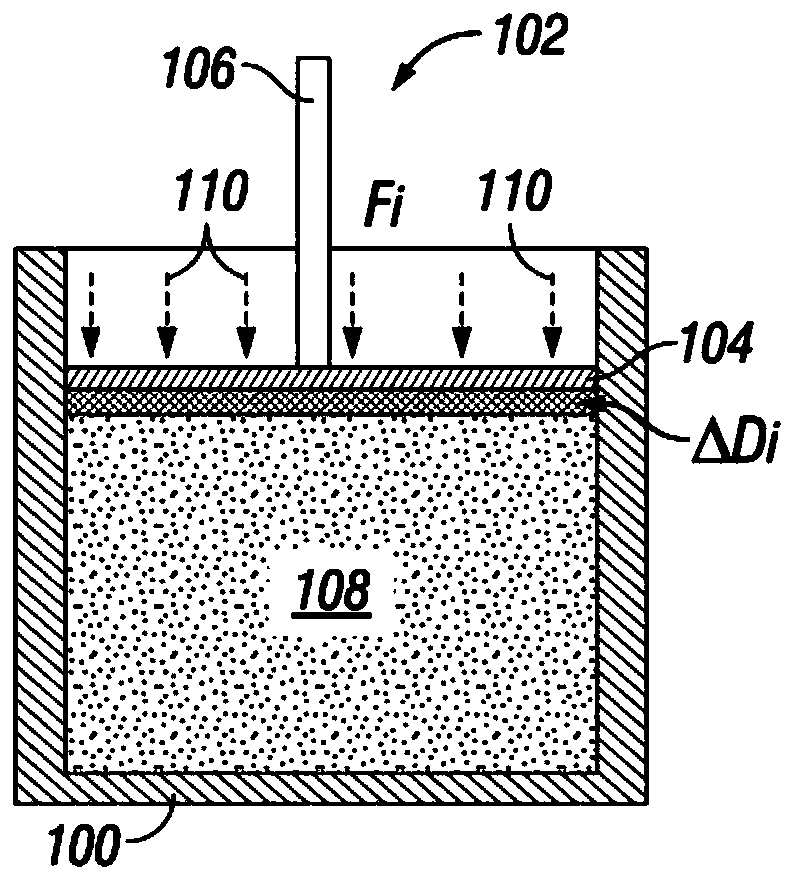

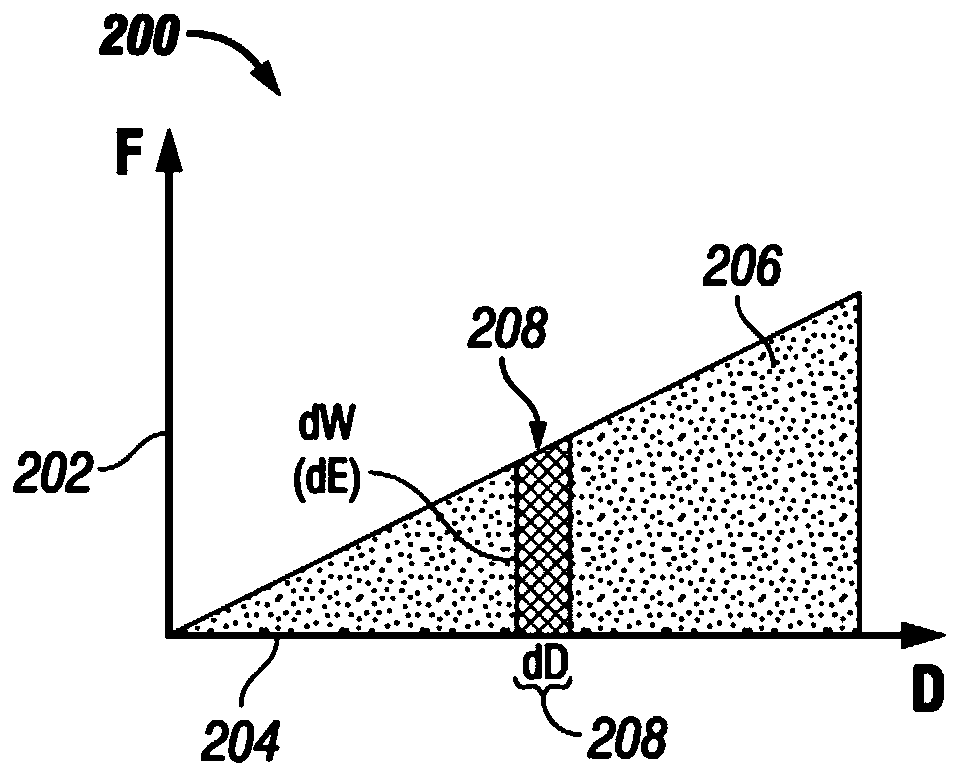

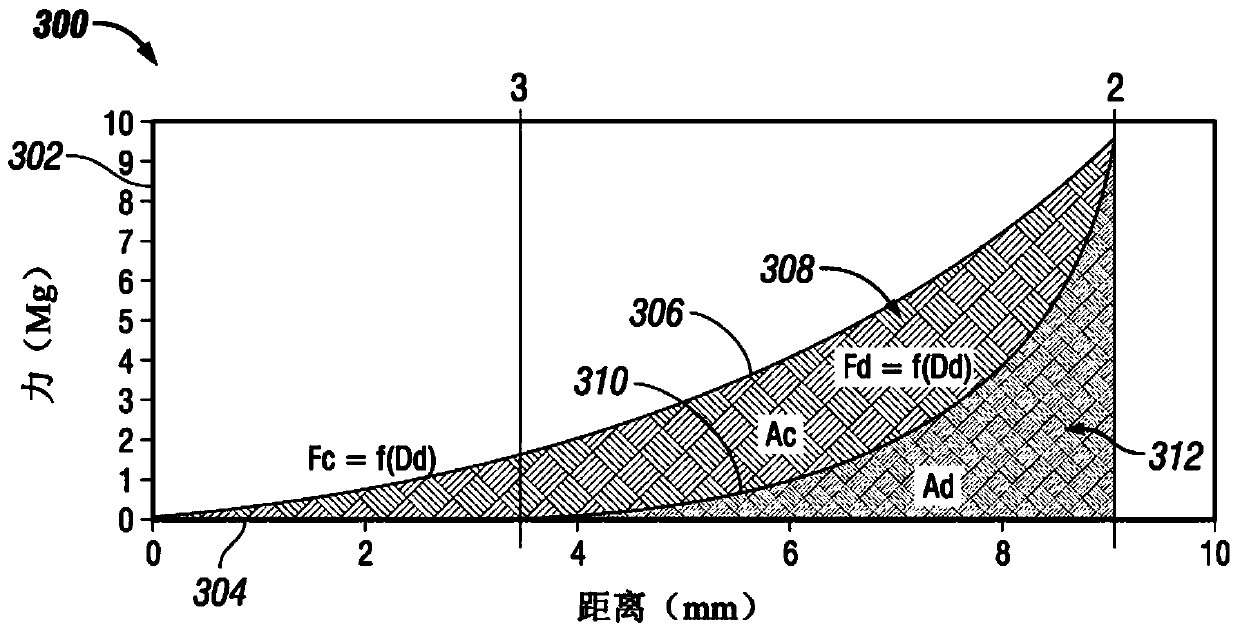

Strain energy-based method and apparatus to determine the coefficient of resilience of lost circulation materials

InactiveCN111556960AFlow propertiesMaterial strength using tensile/compressive forcesStrain energyMechanical engineering

A portable resilience testing apparatus for lost circulation materials (LCMs) is provided. The portable resilience testing apparatus includes a test cell and a probe that moves and applies a force toa sample of LCM contained in the test cell. The portable resilience testing apparatus may be used to perform a compression cycle and decompression cycle on the LCM sample. A coefficient of resilienceof the LCM sample is determined from the desorbed strain energy released during the decompression and the absorbed strain energy stored during the compression cycle. A method of determining the coefficient of resilience is also provided.

Owner:SAUDI ARABIAN OIL CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com