Online testing device for elastic force of bent elastic sheet

An on-line testing and shrapnel technology, applied in the direction of applying stable bending force to test material strength, elasticity, mechanical parts, etc., can solve problems such as reducing the testing efficiency of bending shrapnel, increasing the positioning process, and poor test accuracy. , to achieve the effect of improving test efficiency, improving test accuracy and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

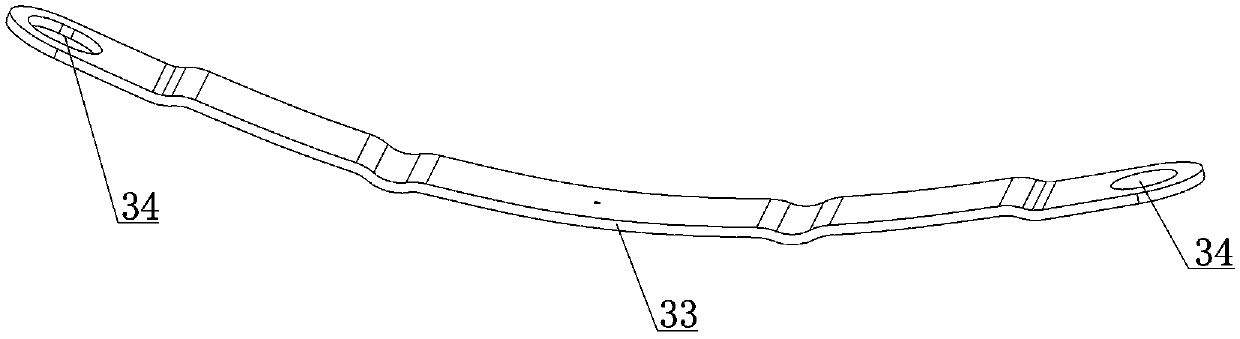

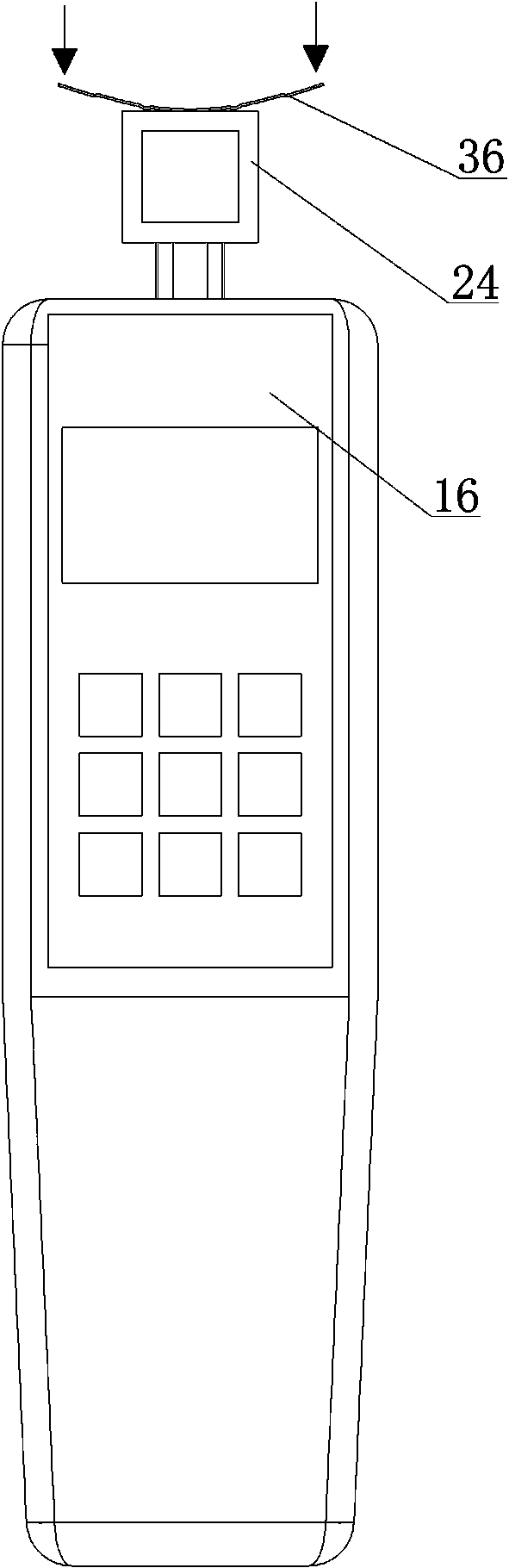

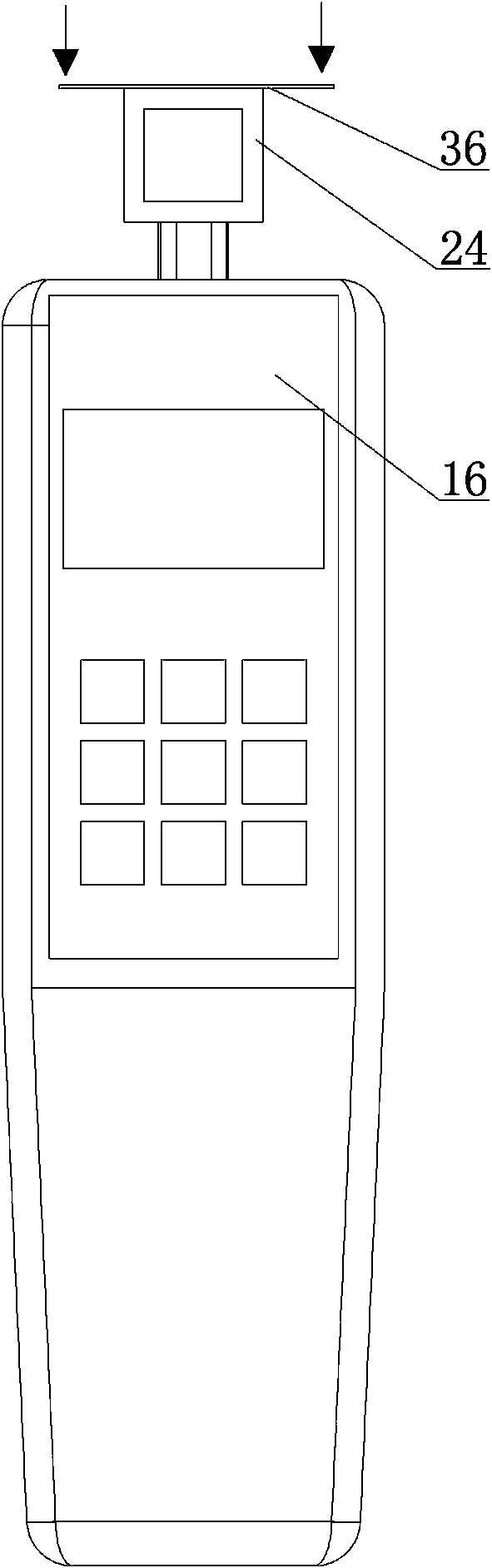

[0032] like Figure 4~14 As shown, an online testing device for the elastic force of curved shrapnel includes a workbench 1 on which a shrapnel transfer device 2 and a shrapnel elasticity testing device 3 are arranged. The shrapnel transfer device 2 includes a device fixed on the workbench 1 The stepper motor 4 and the reducer 5 on the top, the output shaft of the stepper motor 4 is connected with the input shaft of the reducer 5 through a coupling, the top of the reducer 5 is provided with an output shaft, and the output shaft of the reducer 5 is installed with The turntable 6, on the top surface of the turntable 6 and along its circumferential direction, a plurality of shrapnel support assemblies 7 are arranged, the shrapnel support assemblies 7 are evenly distributed on the turntable 6, the shrapn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com