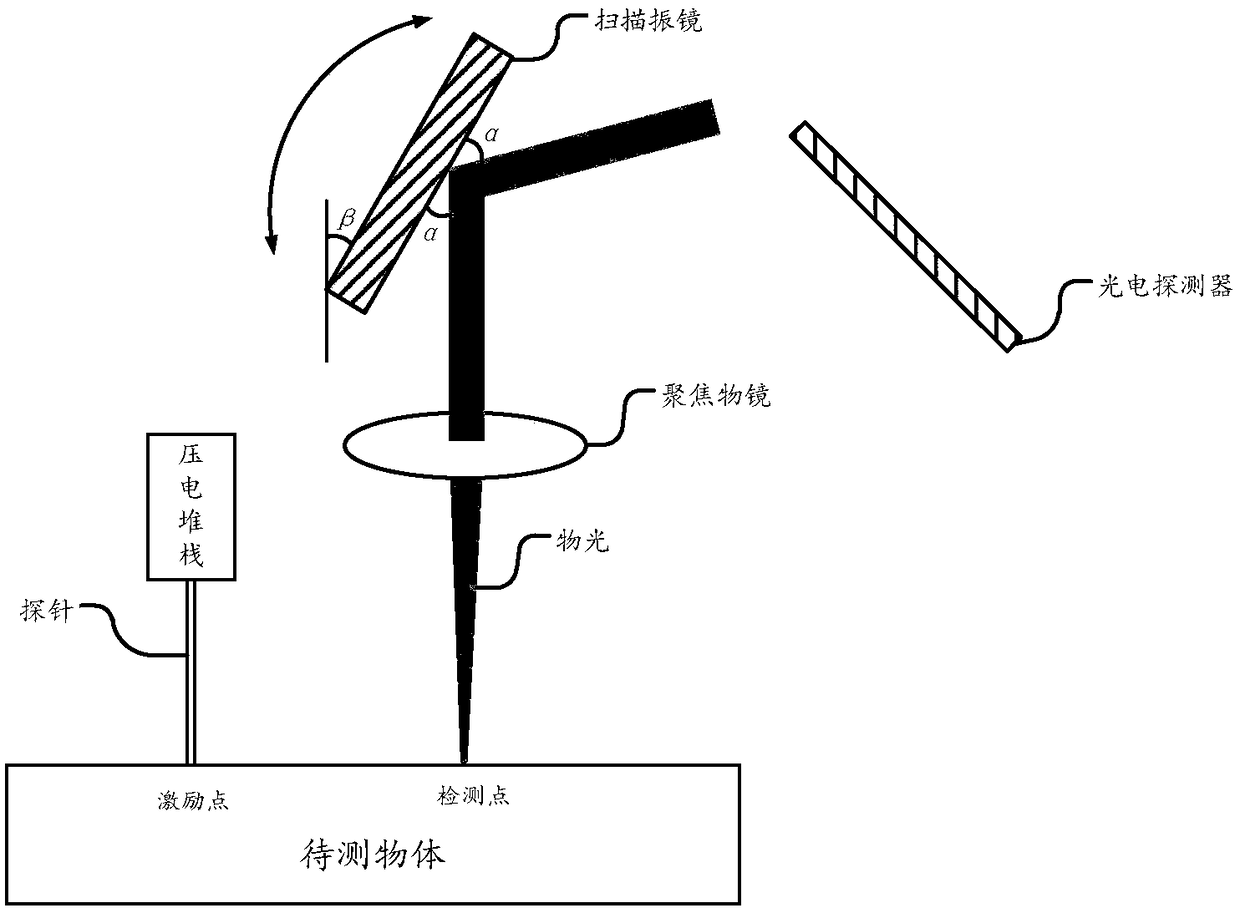

Optical elasticity test method

An elastic testing and optical technology, applied in material analysis, measuring devices, scientific instruments, etc. through optical means, can solve the problems of long processing time, low accuracy, and collecting a large amount of data, and achieve shortened test time and small loading range , the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

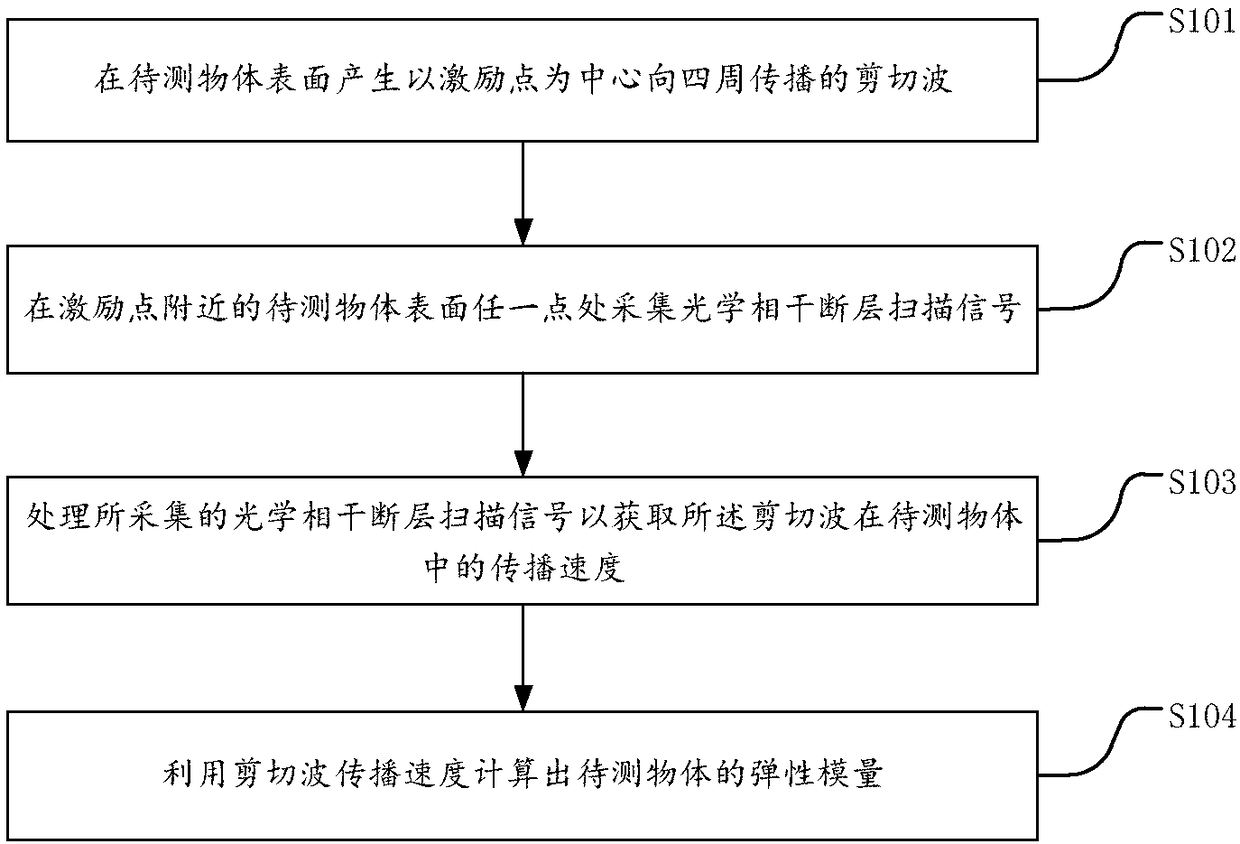

Method used

Image

Examples

Embodiment 1

[0036] Embodiment A pair of test of the elastic modulus of biological tissue analog body

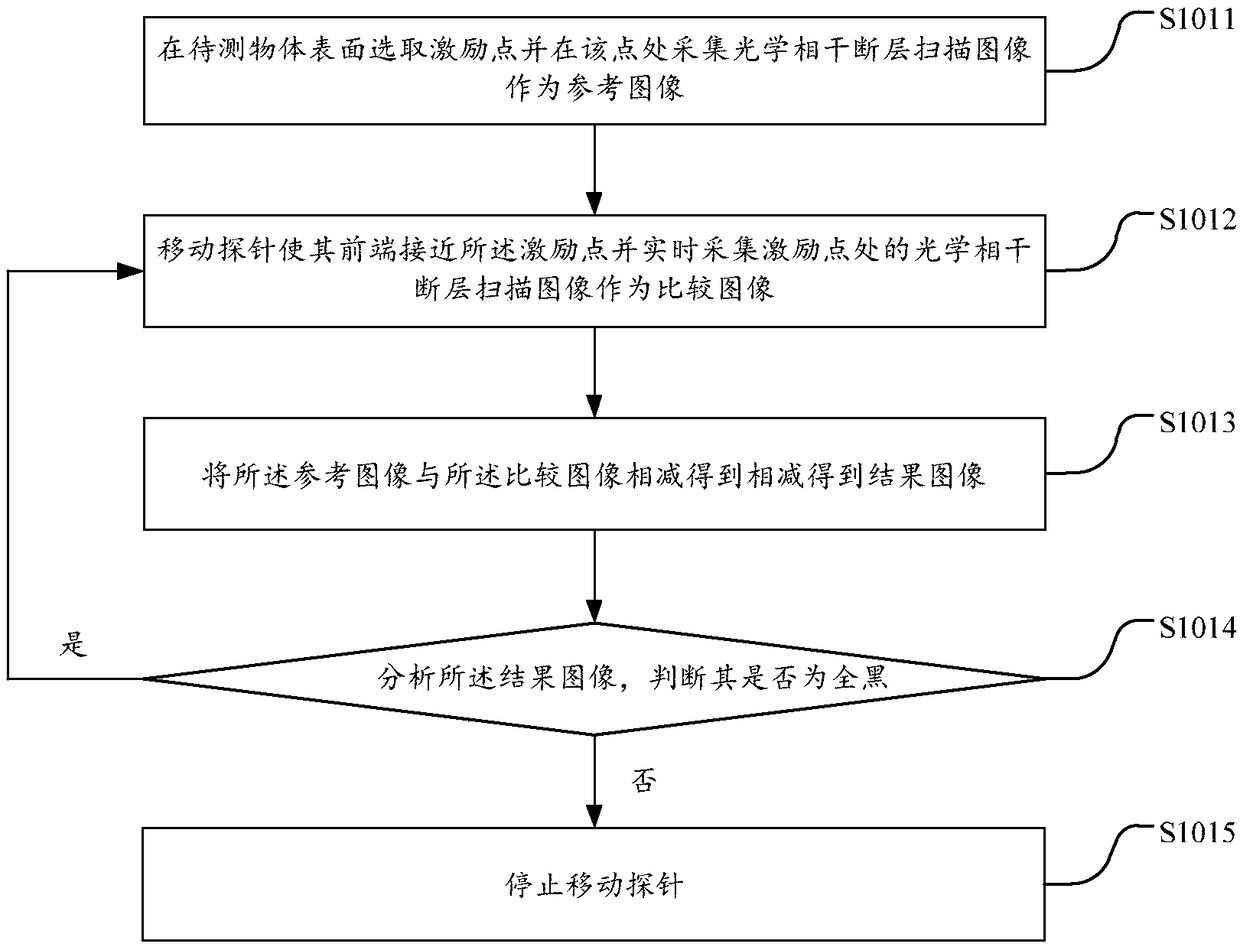

[0037] In order to ensure that the probe does not cause damage to the surface of the object to be measured during the operation, it is necessary to adjust the probe to make it perpendicular to the surface of the object to be measured before the shear wave velocity test and make the front end of the probe touch the surface of the object to be measured without acting on the surface of the object to be measured. The surface of the object, that is to say, make the tip of the probe just touch the surface of the object to be measured. Such as image 3As shown, the method of subtracting the optical coherence tomography images can be used to judge whether the probe has just touched the surface of the object to be measured: the image at the excitation point when the probe is not in contact with the surface of the object to be measured is collected by optical coherence tomography As a reference i...

Embodiment 2

[0049] Embodiment two is to the test of the modulus of elasticity of the isolated chicken liver sample

[0050] Select the excitation point on the surface of the isolated chicken liver sample as the first excitation point, and select a detection point within 10 mm from the surface of the excitation point, and the distance between the detection point and the excitation point does not need to be measured. After the probe is set at the initial position, the position of the probe is adjusted through the three-dimensional mobile stage combined with the real-time image of the above-mentioned optical coherence tomography, so that the probe is perpendicular to the surface of the chicken liver and the front end of the probe is aligned with the isolated chicken liver sample to be tested The surface is just in contact, and the setting of the contact between the probe and the isolated chicken liver sample adopts the method of real-time subtraction of the optical coherence tomography image,...

Embodiment 3

[0056] Embodiment 3 In vivo skin elastic modulus test of human body

[0057] In this embodiment, the finger pulp skin test is described. Firstly, the probe tip is placed in the area to be tested on the finger pulp, and the probe tip is adjusted to maintain slight contact with the finger pulp skin at the excitation point through a three-dimensional moving table. Then focus the optical coherence tomography object light beam on any point within 10 mm from the excitation point on the surface of the finger as the first detection point. 1ms in advance so that the shear wave information can be collected. After the probe is set to be in proper contact with the skin of the finger pulp, the piezoelectric stack is started to load the shear wave on the skin of the finger pulp through the probe; after the optical coherence tomography signal is collected at the first detection point, the control such as figure 1 The scanning galvanometer shown is rotated to move the optical coherence tomog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com