Yarn elasticity testing device for spinning

A technology of elastic testing and yarn, which is applied in the field of textile yarn elastic testing device, to achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

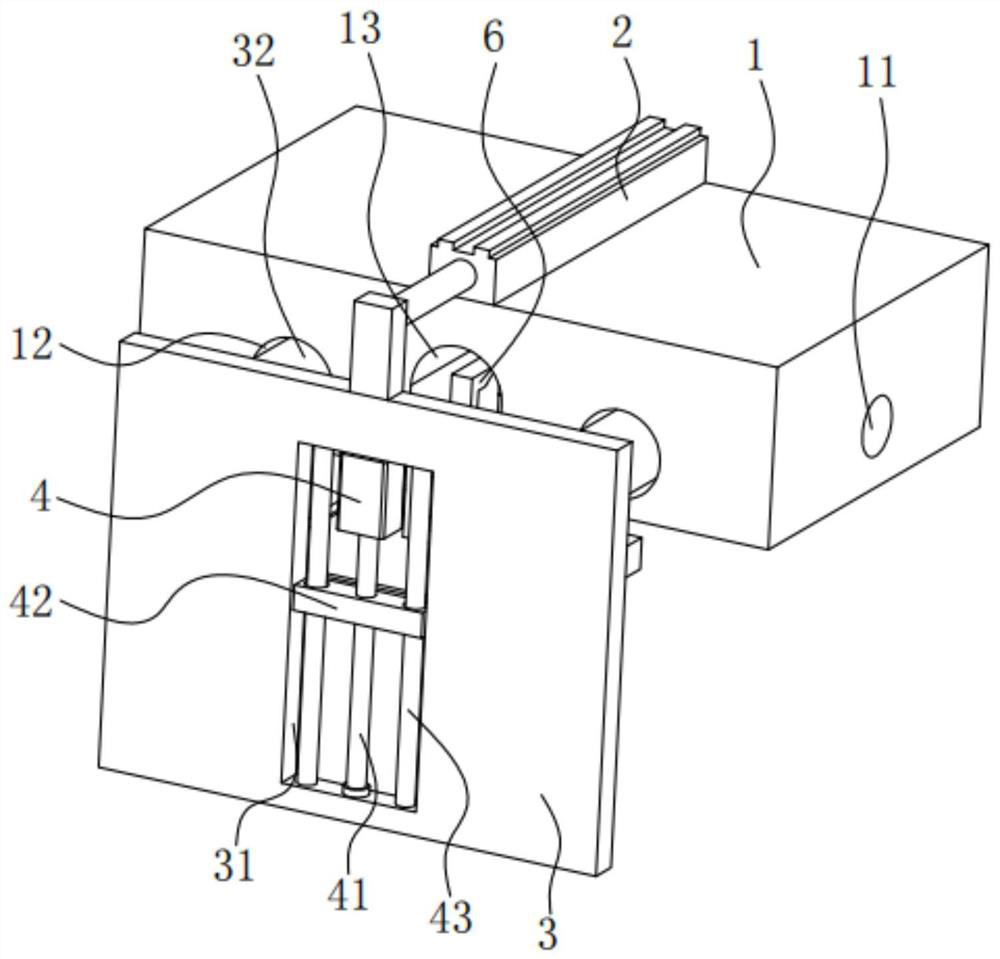

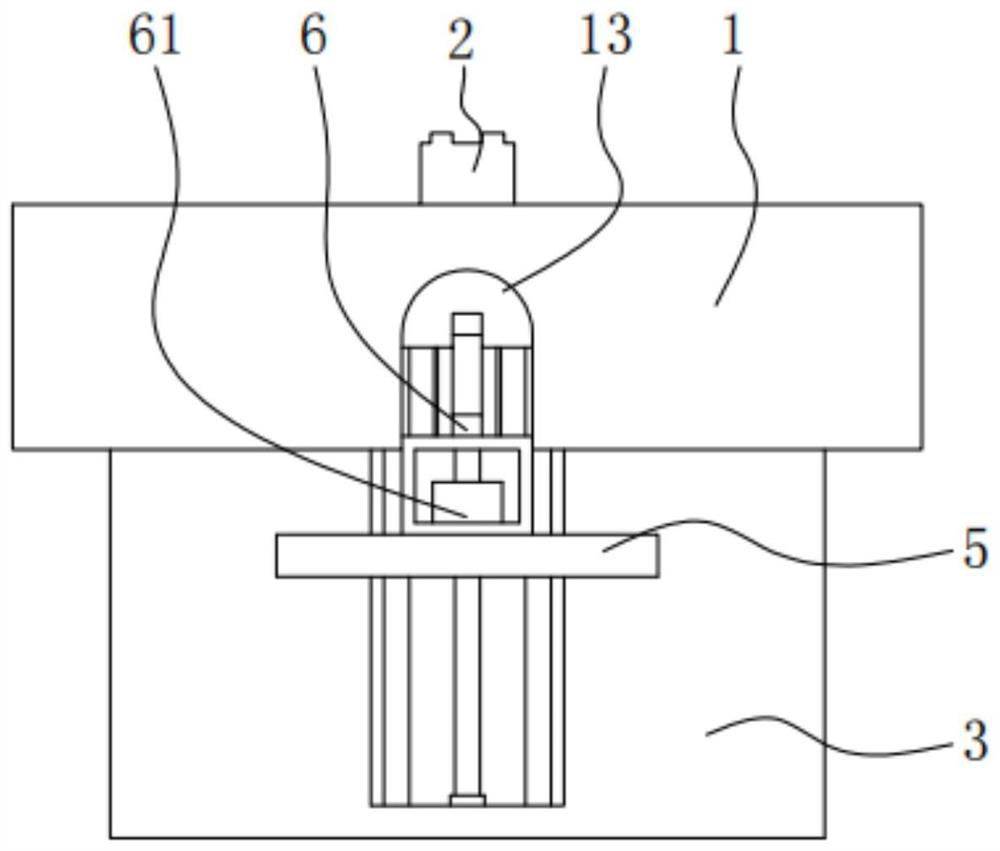

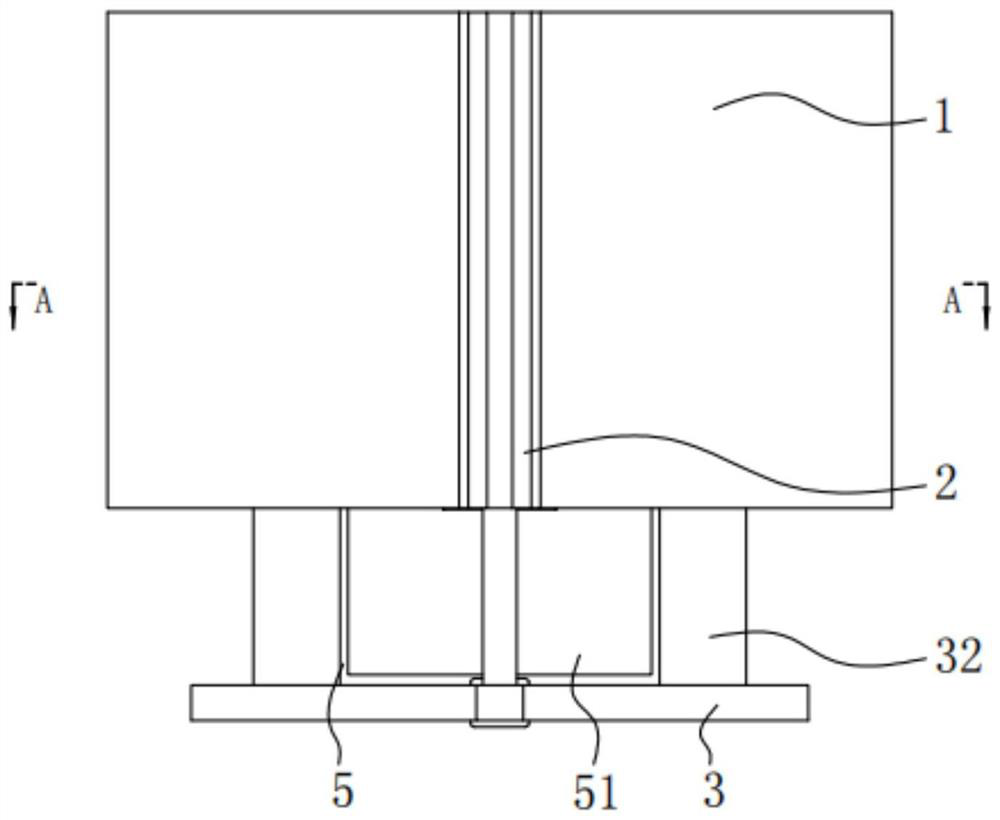

[0041] Please refer to figure 1 , figure 2 , image 3 with Figure 4 ,in, figure 1 A three-dimensional view of the first embodiment of the textile yarn elasticity testing device provided by the present invention; figure 2 for figure 1 The rear view of the whole shown;

[0042] image 3 for figure 1 The top view of the whole shown; Figure 4 for figure 1 Sectional view of part A-A shown.

[0043] A textile yarn elasticity testing device comprises: a mounting frame 1, a threading hole 11 is opened on the mounting frame 1, and a telescopic groove 12 is opened on the front of the mounting frame 1, and an adjusting hole 13 is opened on the mounting frame 1 , and the bottom of the mounting frame 1 is provided with a movable groove 14; the telescopic element 2, the bottom of the telescopic element 2 is fixed on the top of the mounting frame 1; the linkage frame 3, one side of the linkage frame 3 is fixed on the At the output end of the telescopic member 2, the linkage fr...

Embodiment 2

[0080] see Figure 5 with Image 6 , based on the textile yarn elasticity test device provided in the first embodiment of the present application, the second embodiment of the present application proposes another textile yarn elasticity test device. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0081] Specifically, the difference between the textile yarn elasticity testing device provided in the second embodiment of the present application is that the textile yarn elasticity testing device further includes:

[0082] The top of the lifting plate 5 is provided with a support groove 51, the inside of the support groove 51 is fixedly connected with a buffer slide shaft 7, the top of the buffer slide shaft 7 is provided with a movable plate 71, and the bottom of the movable plate 71 is provided with There are pressure sensors 8 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com