Elastic force testing machine and point inspection method thereof

A testing machine and elastic force technology, applied in force/torque/power measuring instruments, measuring devices, instruments, etc., can solve the problems of only testing one or a few pogo pins, and the testing efficiency needs to be improved, so as to achieve a novel and practical design Strong, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

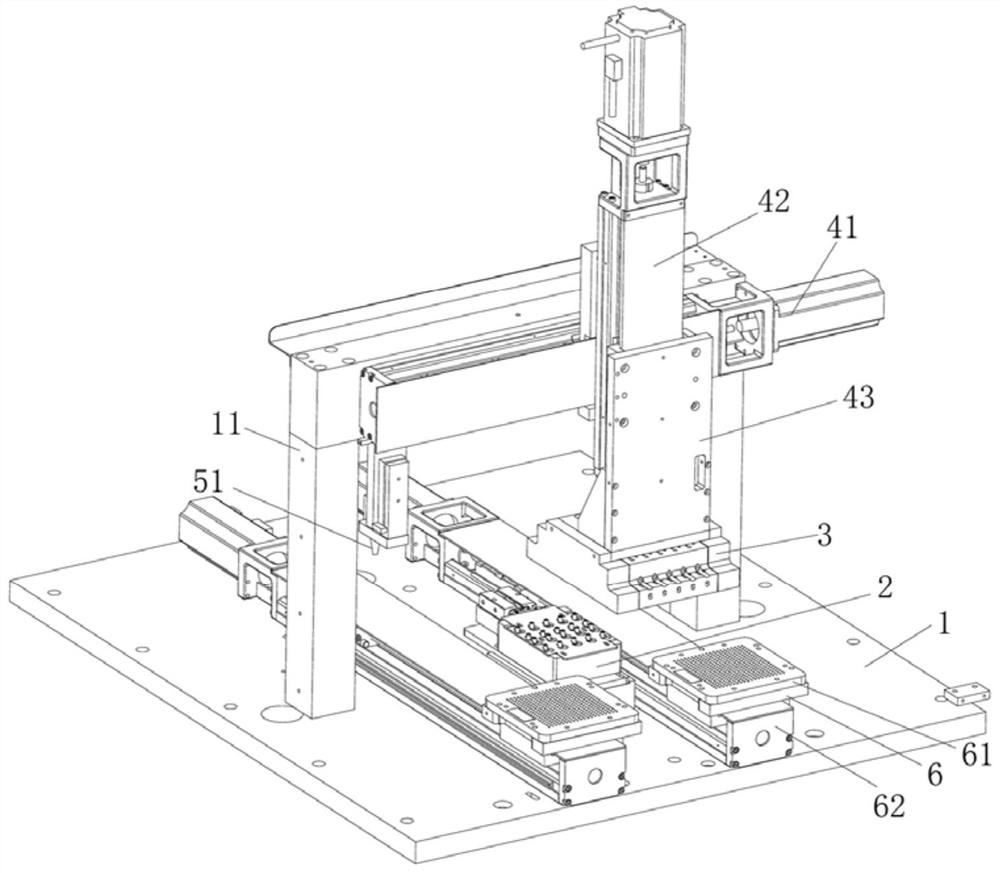

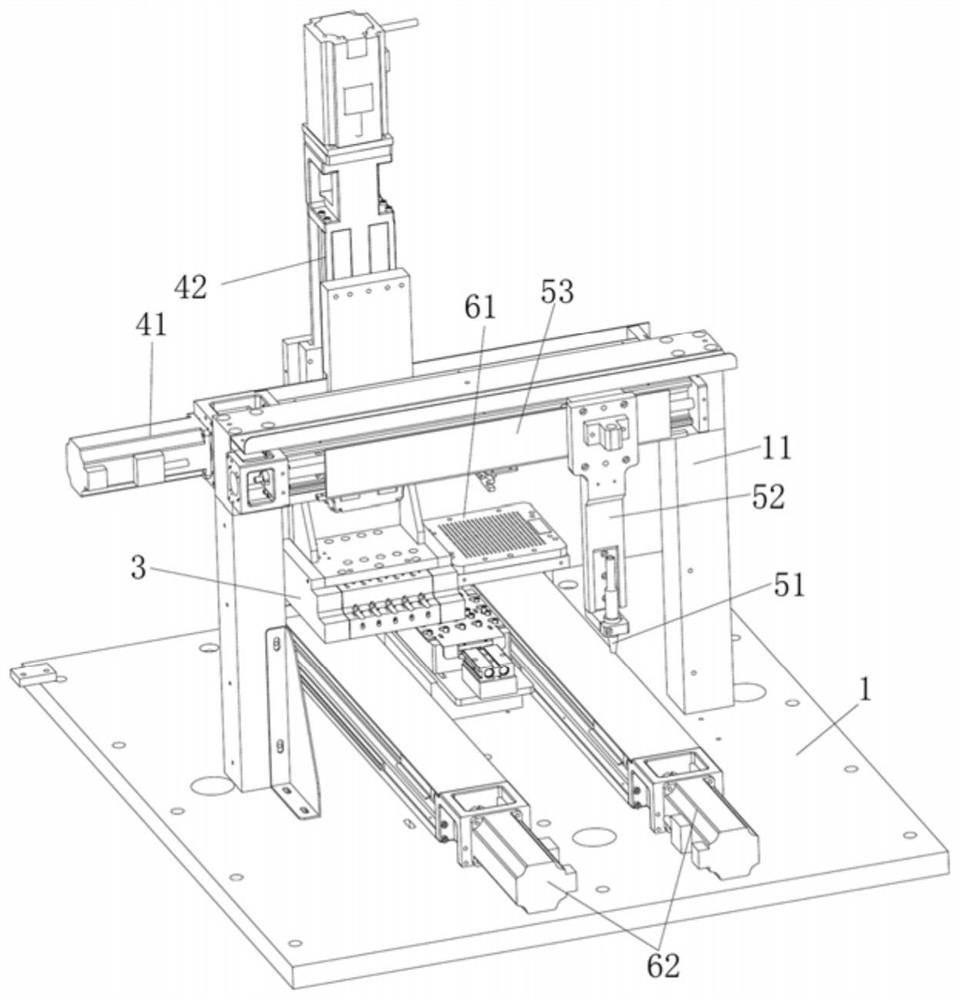

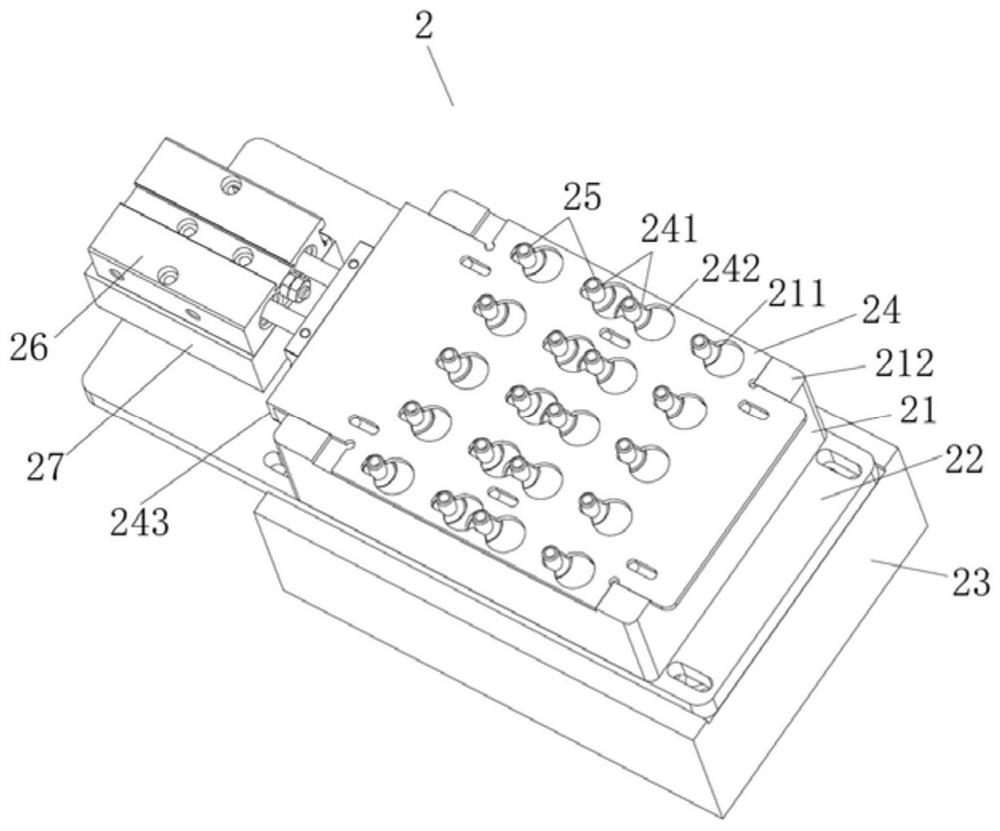

[0038] like Figure 1-6, shown in 8-13, a kind of elastic testing machine, comprises machine platform 1 and the test platform 6 that is arranged on the machine platform 1, storage bin 2, test device 3, moving mechanism, and test platform 6 places the material that carries out elastic force test, The material is a pogo pin, and the elastic force test is driven by the moving mechanism to move between the storage bin 2 and the test bench 6; the test device 3 includes a plurality of induction assemblies 32 distributed in a matrix, and the induction assembly 32 includes a load cell 321 and a probe 322 , the probe 322 is arranged on the sensing end of the load cell 321, and the storage bin 2 is placed with a plurality of weights 25 for point inspection of each load cell 321. The contact part 323 is in contact with the weight 25 during point inspection and puts the weight 25 out of the second contact part 324 of the storage bin 2. The contacts of the first contact part 323 of each lo...

Embodiment 2

[0057] like Figure 7 As shown, the difference from Embodiment 1 is that the second contact portion 324 is a suction cup, the top surface of the body 251 of the weight 25 has a plane 244 for the suction cup to absorb, and the inner diameter of the locking portion 241 is between the diameter of the suction cup and the body of the weight 25. The holes between the diameters of 251; the first contact part 323 is also a non-magnetized contact piece; the weight 25 is sucked by means of a suction cup.

[0058] A check method for the above elastic testing machine, comprising the following steps,

[0059]Step 1, unlocking the weight 25, and driving the movable piece 24 to move through the driving member 26, so that the locking part 241 of the movable piece 24 is moved away from the direction in which the weight 25 is separated from the storage chamber 211;

[0060] Step 2, the test device 3 is reset by the moving mechanism, and the data of each load cell 321 is collected when no-load,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com