Film elasticity testing device

A technology of testing devices and force measuring devices, which is applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve problems such as delayed production efficiency, large errors, and products that cannot meet the requirements of merchants, so as to improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

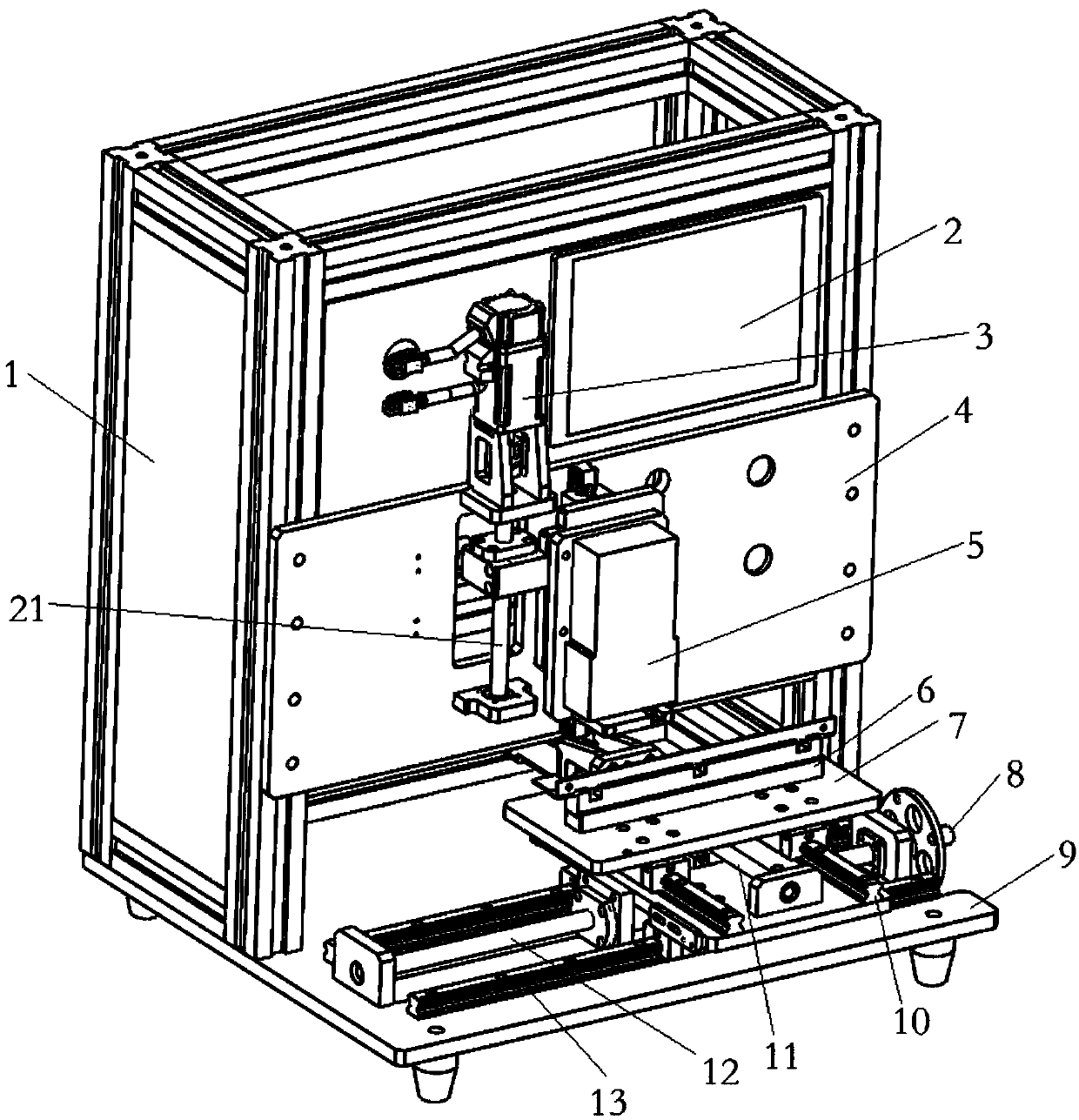

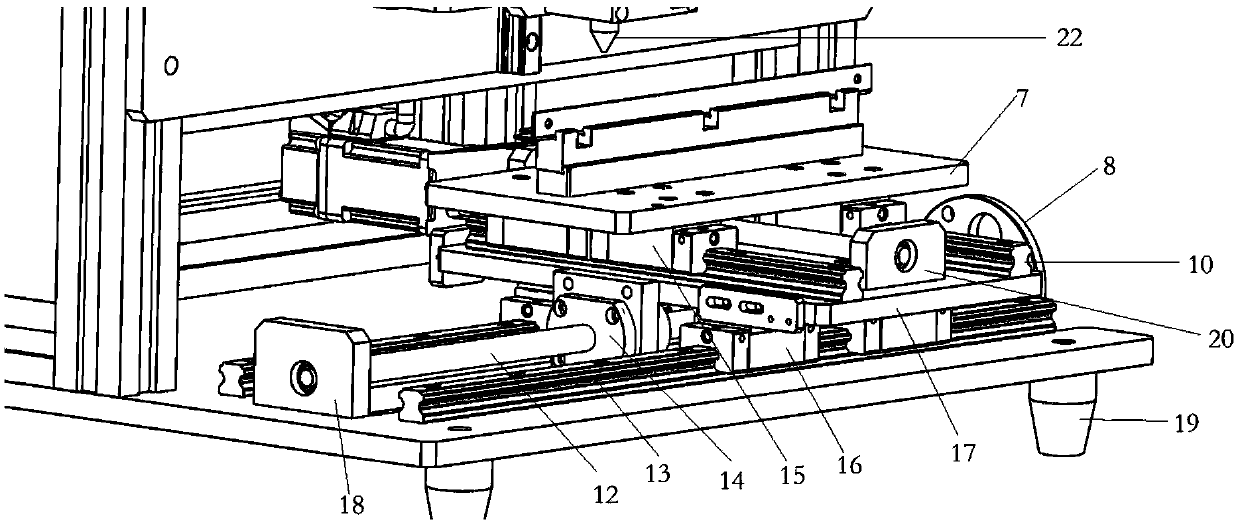

[0016] Embodiment: a kind of film elasticity testing device.

[0017] A film elasticity testing device, comprising a frame 1, a control panel 2 is arranged on the top of the frame 1, a substrate 4 is arranged below the control panel 2, a device for moving up and down is arranged on the substrate 4, and the moving up and down The device includes a servo motor 3, a first screw mechanism 21 and a force measuring device 5, the servo motor 3 is connected to the first screw mechanism 21, and the force measuring device 5 is connected with the first screw mechanism by moving up and down blocks, so A pressure test thimble 22 is connected below the force measuring device 5, and a bottom plate 9 is welded on the bottom of the frame 1. A left and right moving device is arranged on the bottom plate 9 horizontally, and a front and rear moving device is arranged longitudinally. The front and rear moving device is provided with a product Fixture 6. The left and right moving device comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com