POGOPIN probe elasticity test equipment

A technology of elastic testing and probe, which is applied in the field of POGOPIN probe elastic testing equipment, can solve the problems of wasting a lot of time and effort, and achieve the effect of convenient placement or taking, and convenient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

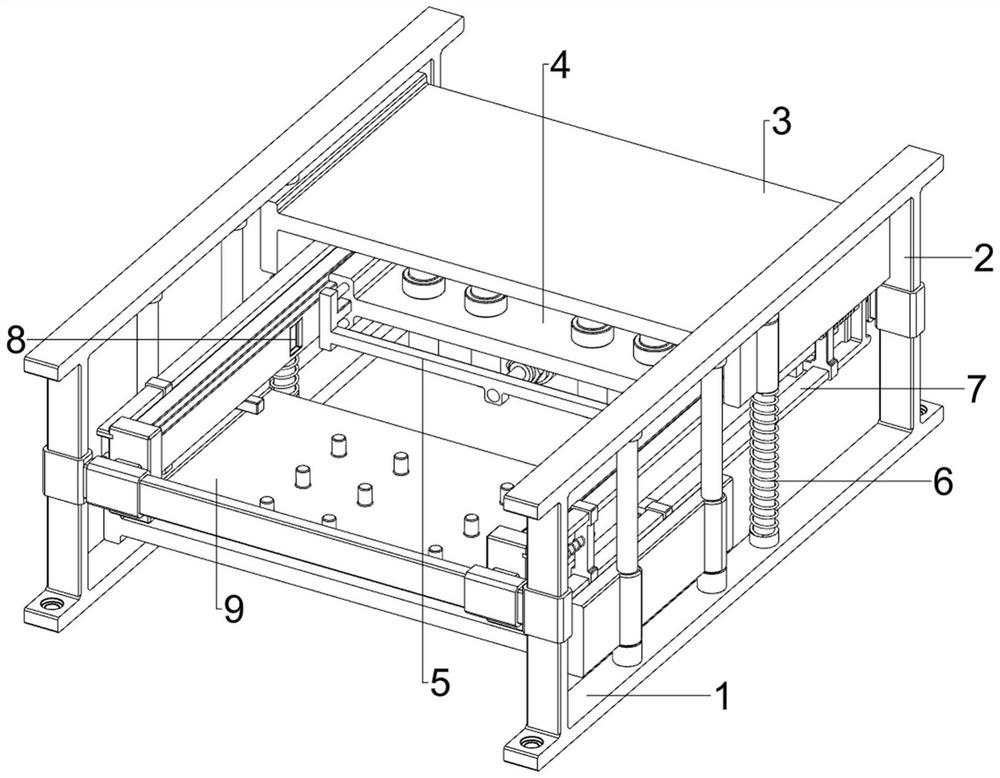

[0035] A kind of POGOPIN probe elasticity testing equipment, refer to Figure 1-Figure 10 , including a base 1, a fixed frame 2, a pressure plate 3, a placement mechanism 4, a displacement mechanism 5, an extrusion mechanism 6 and a limit mechanism 7, the tops of the base 1 on the left and right sides are welded with a fixed frame 2, and the middle part of the fixed frame 2 There is a placement mechanism 4 between them, a displacement mechanism 5 is arranged on the placement mechanism 4, an extruding mechanism 6 is arranged on the top of the base 1, and a pressing plate 3 is arranged on the extruding mechanism 6, and the POGOPIN probe can be moved when the pressing plate 3 moves downward. Squeeze, place mechanism 4 is provided with limit mechanism 7.

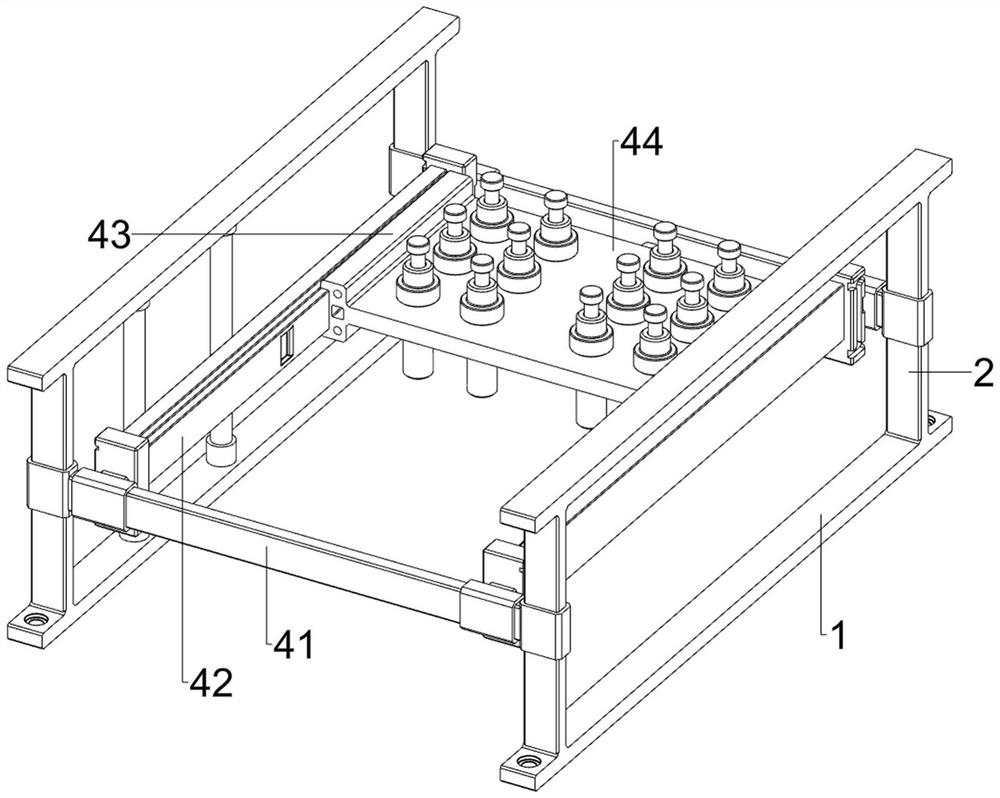

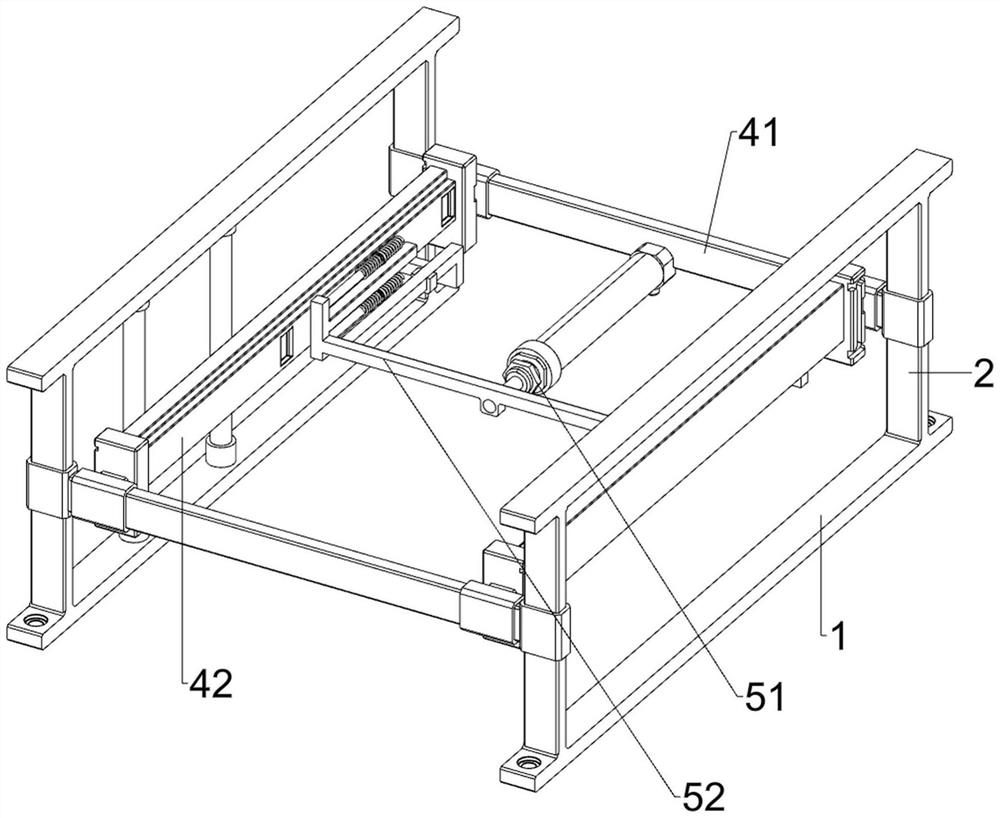

[0036] refer to figure 1 and figure 2 , the placement mechanism 4 includes a fixed rod 41, a slide rail 42, a sliding block 43 and a placement plate 44, a fixed rod 41 is welded symmetrically front and back between the middle...

Embodiment 2

[0042] On the basis of embodiment 1, refer to figure 1 , Figure 11 , Figure 12 and Figure 13 , also includes a stabilizing mechanism 8, the stabilizing mechanism 8 includes a block 82 and a fifth spring 83, the inner middle part of the slide rail 42 is provided with a card slot 81, and the left and right sides of the rear part of the placement plate 44 are all slidably provided with a card. Block 82, the block 82 is connected with the adjacent first guide sleeve 63 slidingly, when the block 82 moves to the outside, it can block the slot 81, thereby stably placing the position of the plate 44, the inside of the block 82 and the placement Fifth springs 83 are provided between the plates 44 .

[0043] Initially, the fifth spring 83 is in a compressed state. When the placing plate 44 moves forward, it drives the block 82 to move forward. The outside movement makes the blocks 82 all be stuck in the slots 81, thereby stabilizing the position of the placement plate 44, making ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com