U-shaped spring clamp elasticity test system and elasticity test method

A test system and test method technology, applied in force/torque/power measuring instruments, measuring devices, instruments, etc., can solve problems such as poor batches, influence of material instability factors, and hysteresis, and achieve low processing difficulty, small investment, and The effect of simple tooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Since the current elastic force test for the U-shaped spring clip is basically verified by indirect means, for example, the elastic force of the U-shaped spring clip is verified according to the pull-out force of the magnetic steel after the motor stator is assembled, the strength of the U-shaped spring clip material, etc. However, these verification methods are all lagging behind, and are greatly affected by unstable factors of materials, and have the risk of bad batches. In order to solve the above problems, the present invention provides a U-shaped clip elastic testing system and elastic testing method, which can conveniently and quickly test the elastic value of the U-shaped clip compressed in a specified size.

[0044] A U-shaped spring clamp elastic force testing system and elastic force testing method of the present invention will be further described below in conjunction with the accompanying drawings.

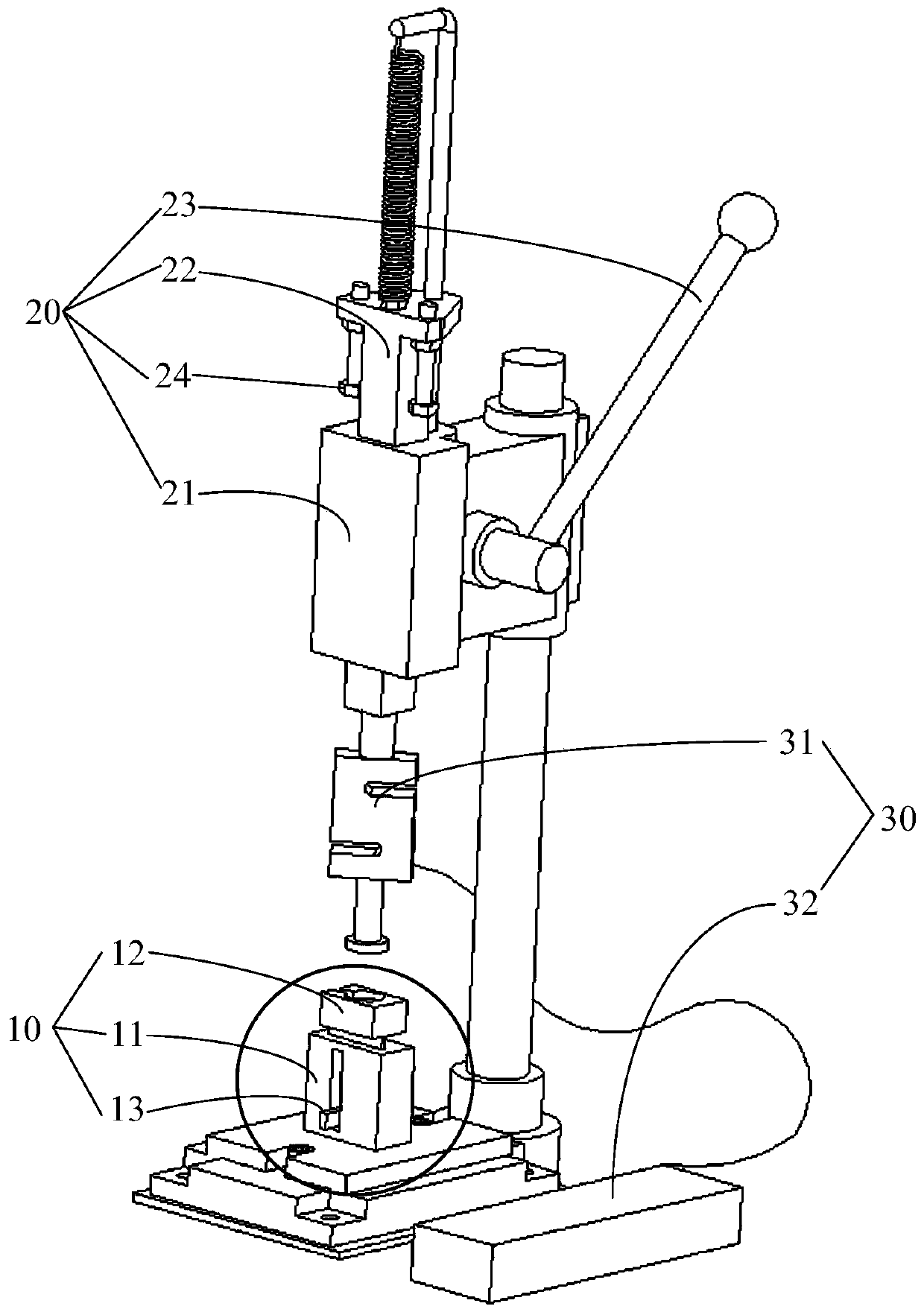

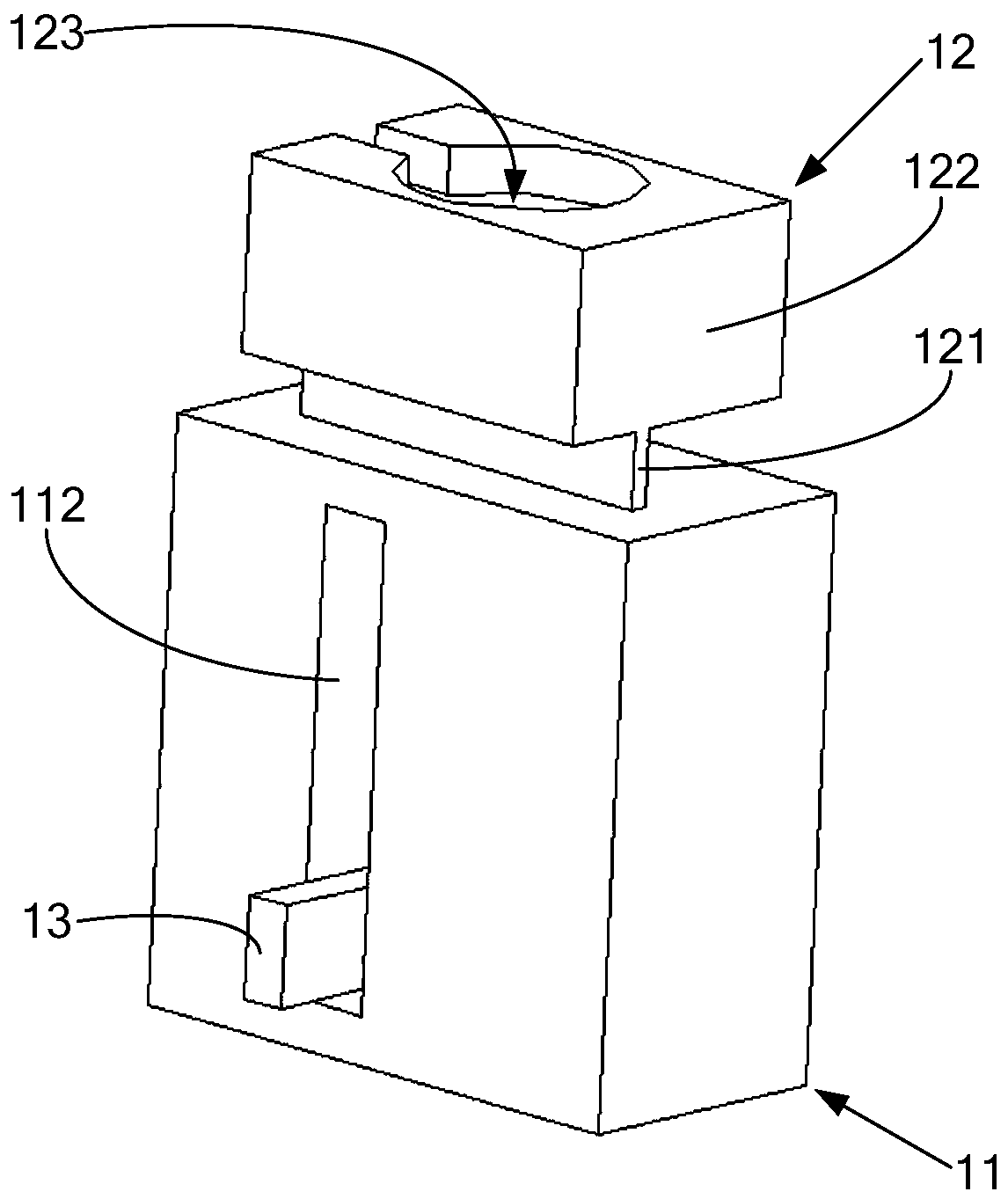

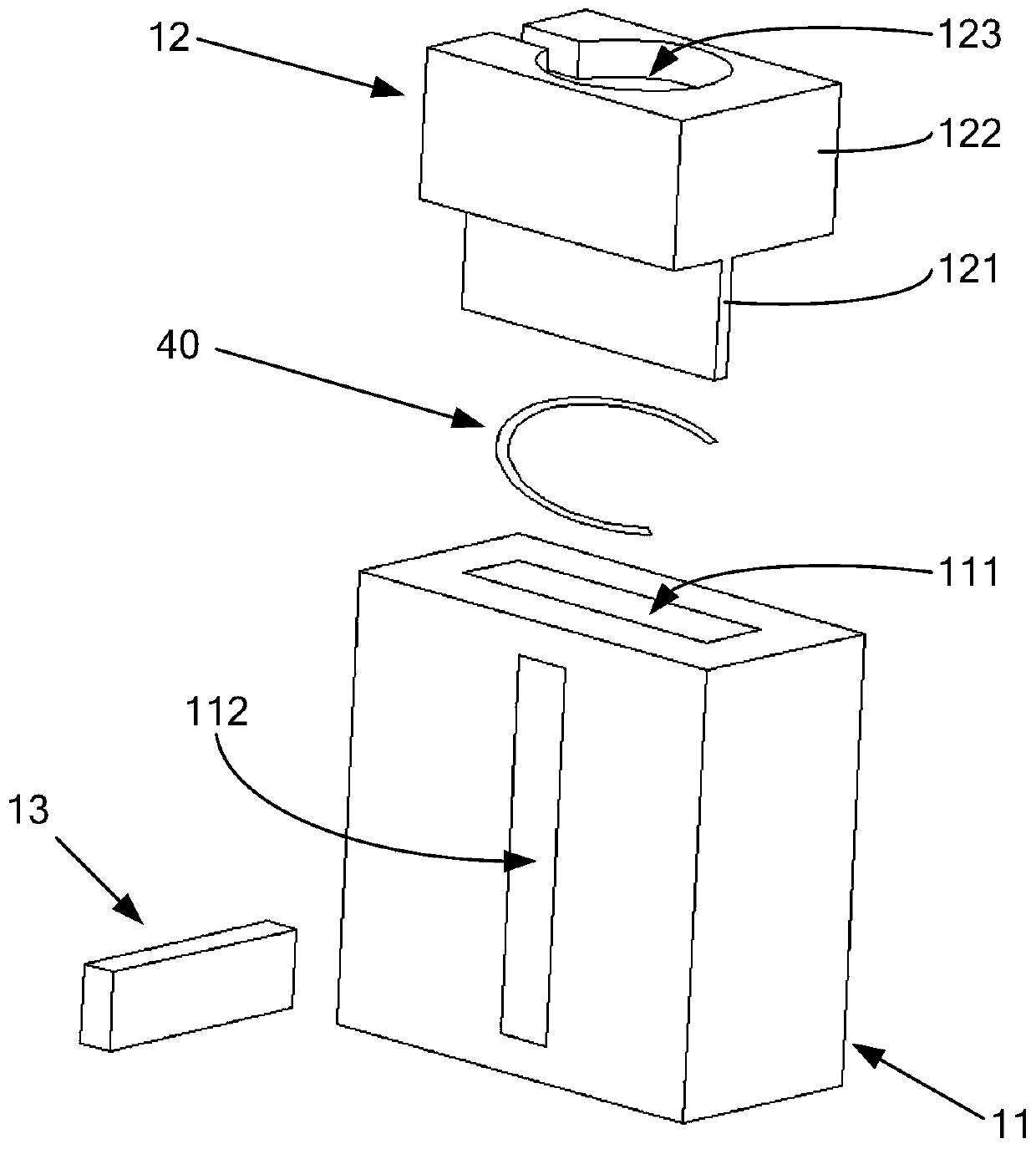

[0045] refer to Figure 1 ~ Figure 3 Shown, a kind of U-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com