Elasticity testing socket for low-temperature application

A technology of elasticity testing and low temperature application, applied in the field of sockets, it can solve the problems of easily damaged components and heavy workload, and achieve the effects of good compatibility, convenient application and reliable electrical connection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

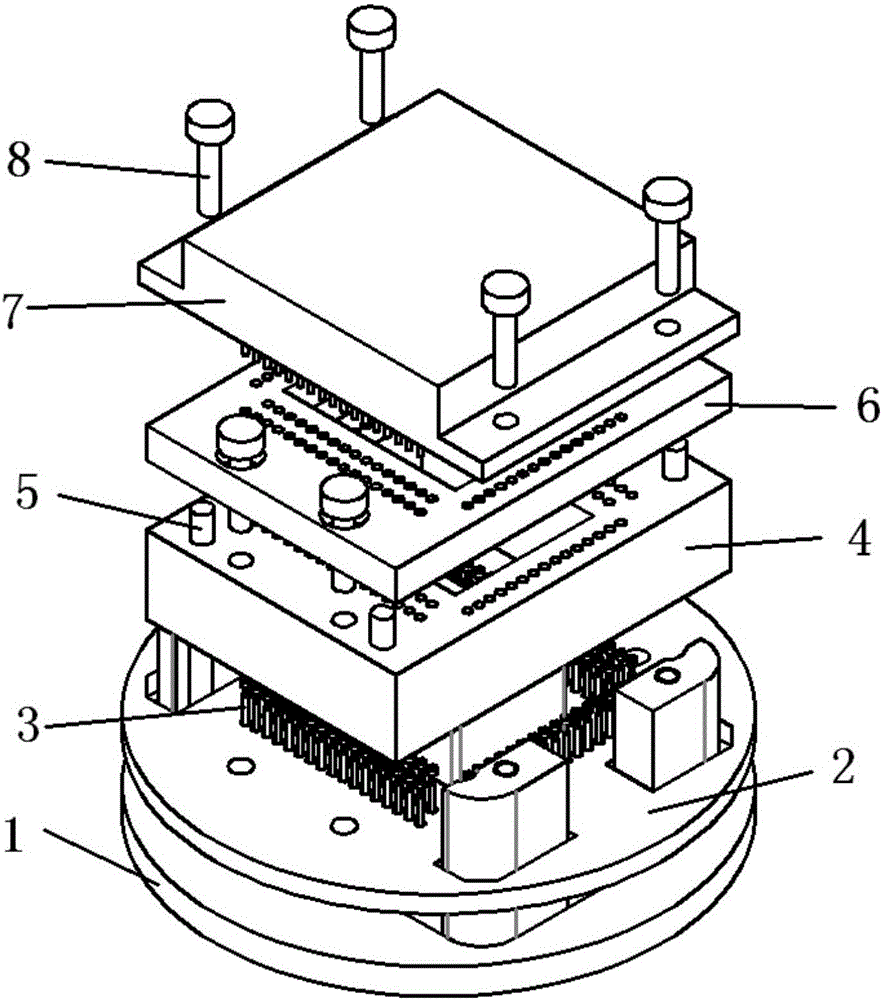

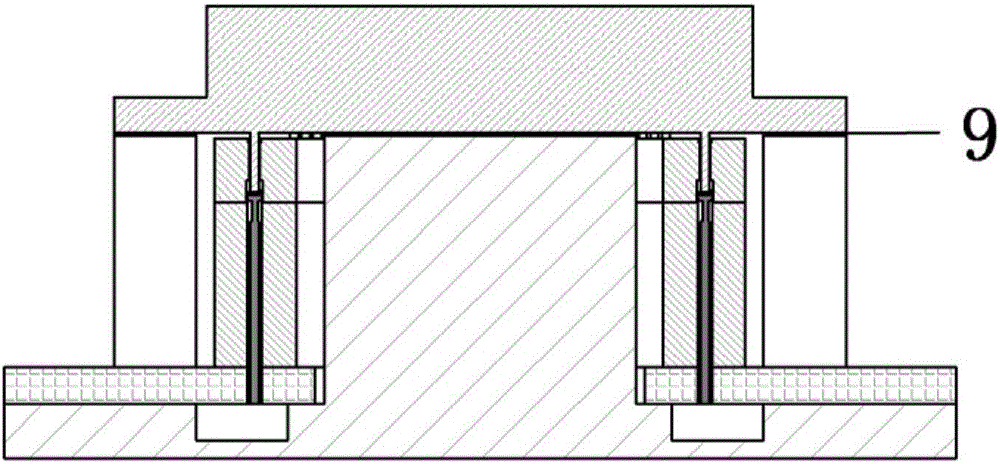

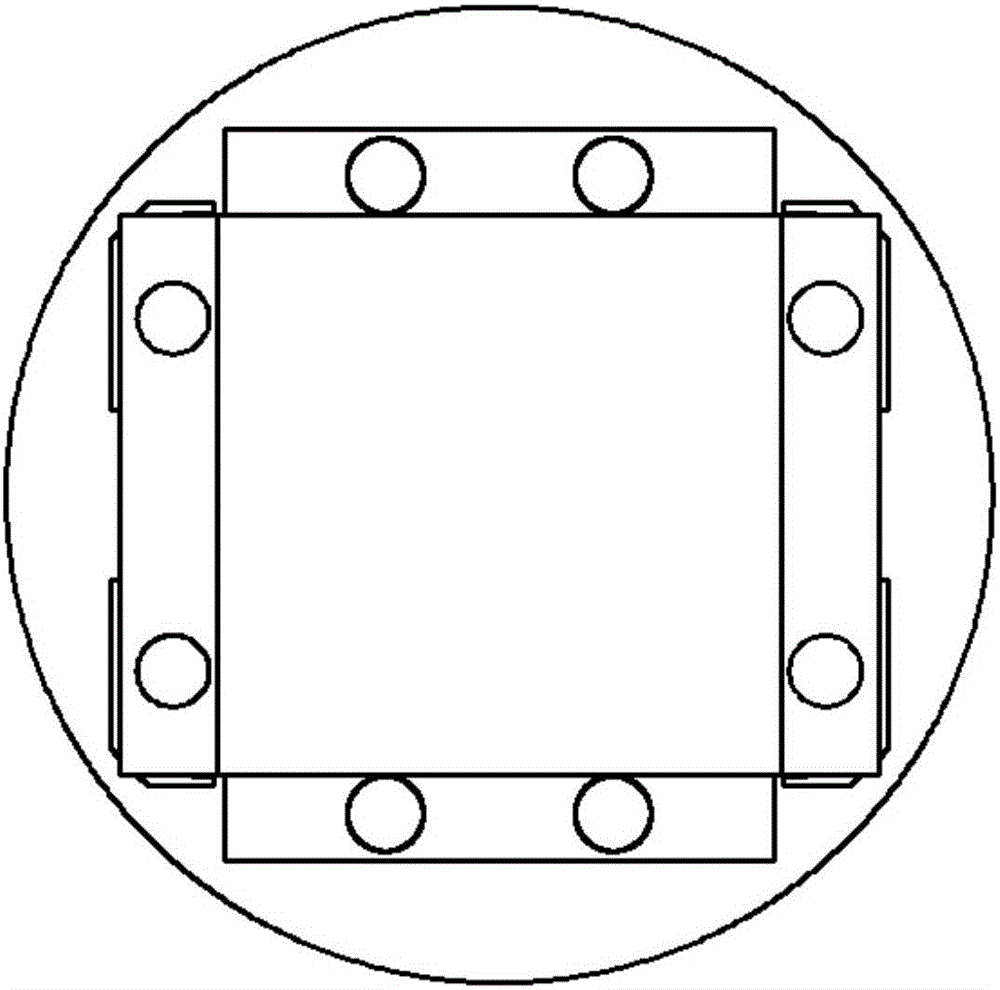

[0012] The invention provides a specific application example of an elastic test socket for low temperature applications, see Figure 1 ~ Figure 4 , including a heat conduction base 1, a PCB circuit board 2, an elastic pin 3, an elastic pin guide plate 4, a positioning pin 5, an assembly pin guide plate 6 and a focal plane assembly 7. The focal plane assembly 7 is a PGA structure with a pin spacing of 1.27 mm, and a mounting flange on the outside, which can be fixed by four screws 8 . The heat conduction base 1 is made of red copper material. The middle of the heat conduction base 1 is a cold platform, and there are 4 component installation pillars around it. The surface of the installation pillars must be on the same plane as the cold platform. Both the elastic needle guide plate 4 and the component needle guide plate 6 are made of polyamide insulating material, and a cavity is provided at the corresponding position of the intermediate cooling platform. The pin is inserted in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com