Experimental equipment for shield tail brush

A technology of experimental equipment and shield tail brush, which is applied to mining equipment, earthwork drilling, tunnels, etc., to achieve the effect of convenient data analysis and simple operation

Active Publication Date: 2013-12-11

CHINA RAILWAY TUNNEL GROUP CO LTD

View PDF4 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] At present, there are many manufacturers producing shield tail brushes in China, but there is no equipment in the industry to test the performance of shield tail brushes. When testing the wear-resistant and elastic equipment that determines the sealing performance of the shield tail brush, it is only based on intuition, and it is inevitable to purchase inferior products, which will bury safety hazards for construction and production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

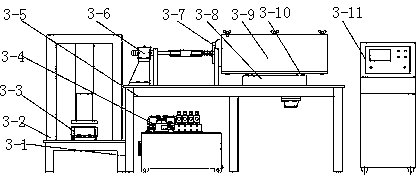

The invention belongs to the technical field of the shield tail brush performance detection and mainly relates to experimental equipment for a shield tail brush. The experimental equipment comprises a hydraulic pump station (3-4), an abrasive resistance testing mechanism (3-5), an elastic testing mechanism (3-2) and a PLC (Programmable Logic Controller) (3-11), wherein the abrasive resistance testing mechanism (3-5) comprises an experiment bench (3-1), a hydraulic motor (4-9), a hydraulic motor output gear (4-4), a pivoting support (3-8), a concrete brush table (3-9) and a lead screw-nut mechanism (3-6); the elastic testing mechanism (3-2) comprises a shield tail brush fixing device (10-1), a portal frame (10-6), a telescopic outer sleeve (10-5), a telescopic inner sleeve (10-4), an oil cylinder (10-7) and a pressing plate (10-3). The experimental equipment for the shield tail brush realizes testing on the performance of the shield tail brush products and prevents security risks caused by improper selection of the products.

Description

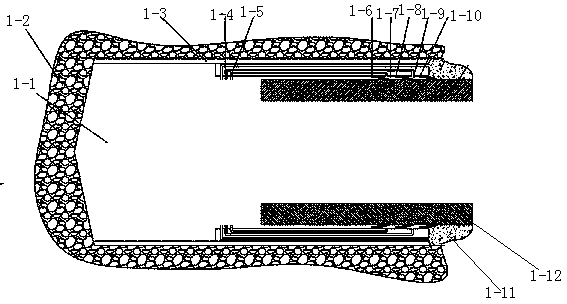

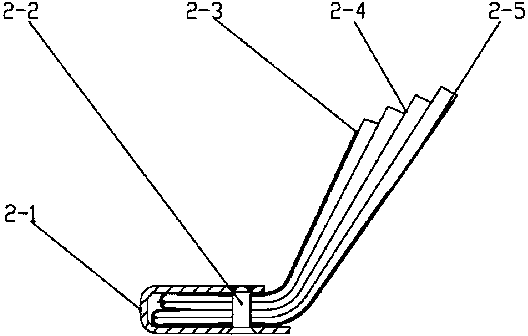

technical field [0001] The invention belongs to the technical field of shield tail brush performance detection, and mainly relates to shield tail brush experimental equipment. Background technique [0002] like figure 1 The shield machine 1-1 shown is a kind of tunnel tunnel excavation construction in soft soil, which has a metal shell 1-3, and the whole machine and auxiliary equipment are installed in the shell, and the soil body 1-2 is excavated under its cover. It is a tunnel construction machine that can form the tunnel at one time, such as , earth muck transportation, complete machine propulsion, and concrete segment 1-11 installation. In order to prevent groundwater, outer soil, lining back grouting 1-11, etc. from flowing into the tunnel, usually three shield tail brushes are circularly welded at the tail of the shield machine, namely shield tail brush Ⅰ1-6, shield tail brush Ⅱ1-8, shield tail brush Brush III 1-10 forms two cavities, namely cavity I1-7 and cavity ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21D9/06

Inventor 李剑雄赵新合刘金祥康宝生董丹阳常孔磊

Owner CHINA RAILWAY TUNNEL GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com