Automatic closed loop joint debugging method for telecontrol equipment and regulation and control main station of intelligent substation

An automatic and intelligent substation technology for substations, applied in circuit devices, electrical components, information technology support systems, etc., can solve problems such as high safety risks, low work efficiency, remote miscontrol, etc., to avoid safety risks, improve work efficiency, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

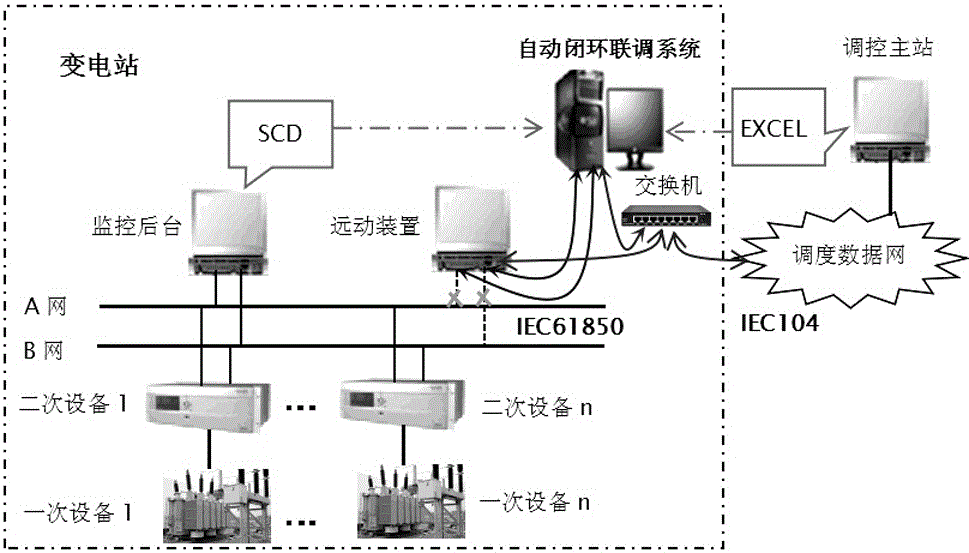

[0026] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

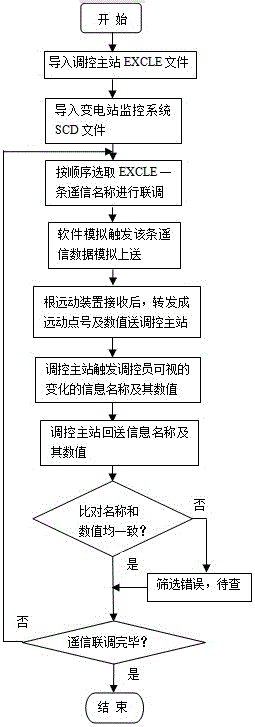

[0027] A method for automatic closed-loop joint debugging of a smart substation telecontrol device and a control master station according to the present invention comprises the following steps,

[0028] S1: Provide a substation automatic closed-loop joint debugging system. The substation automatic closed-loop joint debugging system is connected to the station control layer end of the remote control device, and ensures that the remote control device is disconnected from the A / B network in the station. The automatic closed-loop joint debugging system of the substation The control system also shares the network with the remote control device and the control master station through the switchboard;

[0029] S2: The automatic closed-loop joint commissioning system of the substation imports the EXCEL model file of the control master station and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com