Steel plate surface painting equipment for metal processing

A technology for metal processing, steel plate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

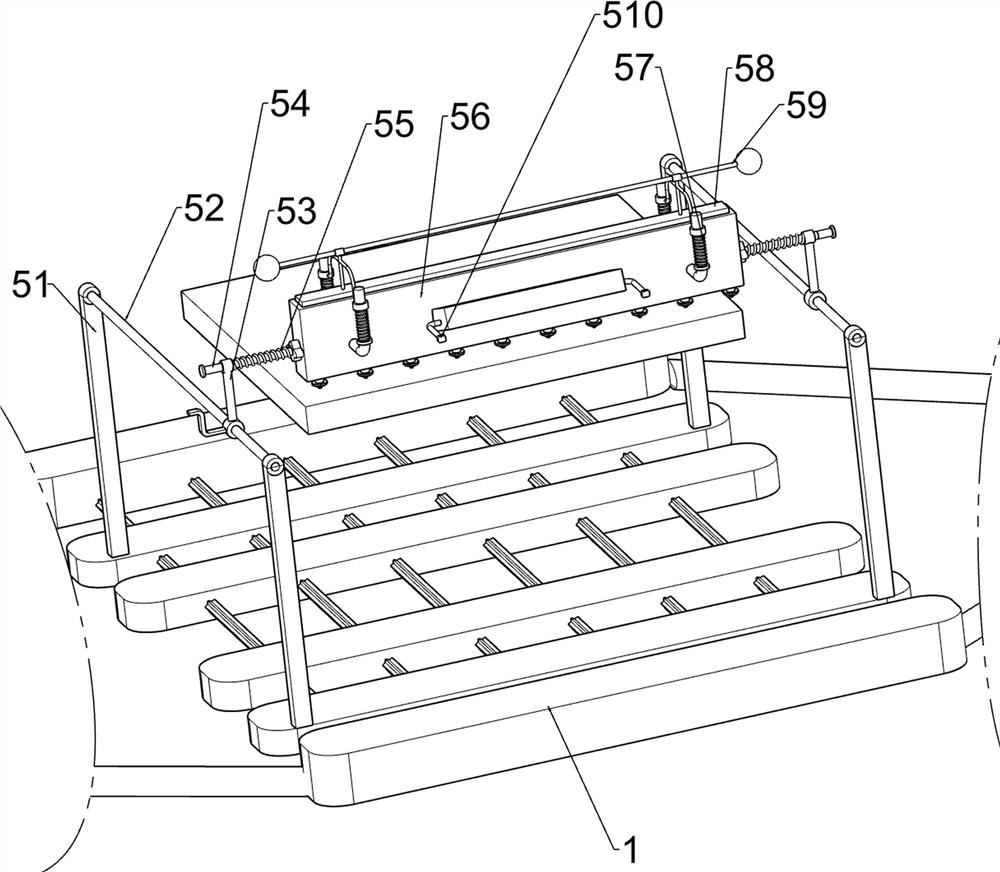

[0067] A steel plate surface painting equipment for metal processing, such as figure 1 As shown, it includes a first fixed plate 1, a track 2, a collection box 3, a clamping mechanism 4 and a blanking mechanism 5, the left and right sides of the first fixed plate 1 are provided with tracks 2, and the upper middle part of the first fixed plate 1 A collection box 3 is provided, a clamping mechanism 4 is provided on the upper part of the collection box 3, and a feeding mechanism 5 is provided on the first fixed plate 1 .

[0068] When people want to paint the steel plate, they can use this steel plate surface painting equipment for metal processing. First, the user places the steel plate in the clamping mechanism 4, and the steel plate is clamped by the clamping mechanism 4. The user then pours the paint into the blanking mechanism 5, so that the paint is sprayed out through the blanking mechanism 5, and the user moves the blanking mechanism 5 backwards, and the blanking mechanis...

Embodiment 2

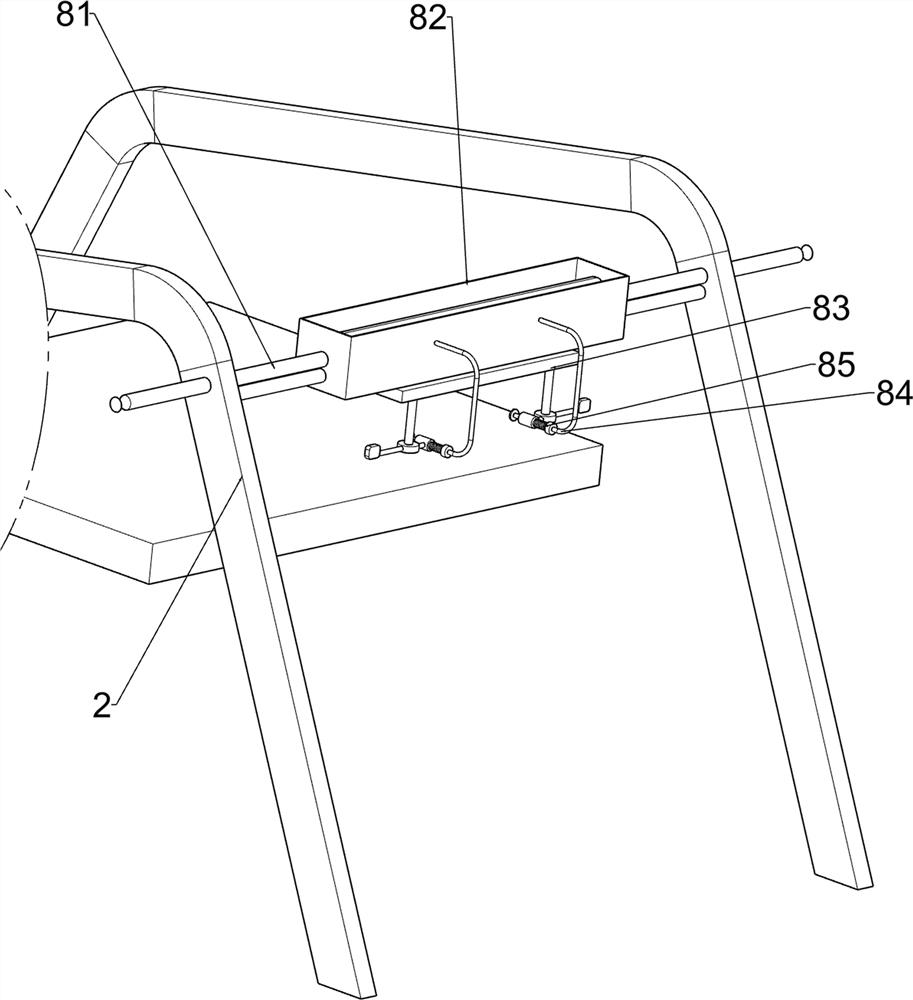

[0070] On the basis of Example 1, such as figure 2 and image 3 As shown, the clamping mechanism 4 includes a first U-shaped bar 41, a clamping block 42, a first bar 43 and a first spring 44, and four first U-shaped bars 41 are arranged on the top of the collection box 3, and the same side A first rod 43 is provided between the two first U-shaped rods 41, and a clamping block 42 is slidably connected between the two first rods 43. The number of clamping blocks 42 is two, and the two first A first spring 44 is wound around each rod member 43 , and both ends of the first spring 44 are connected to the clamping block 42 .

[0071] The user pushes the two clamping blocks 42 in reverse, so that the two clamping blocks 42 move in the opposite direction, the first spring 44 stretches, and the two clamping blocks 42 are separated from each other, and the user places the steel plate between the two clamping blocks. Between the blocks 42, the clamping block 42 is loosened, and the fi...

Embodiment 3

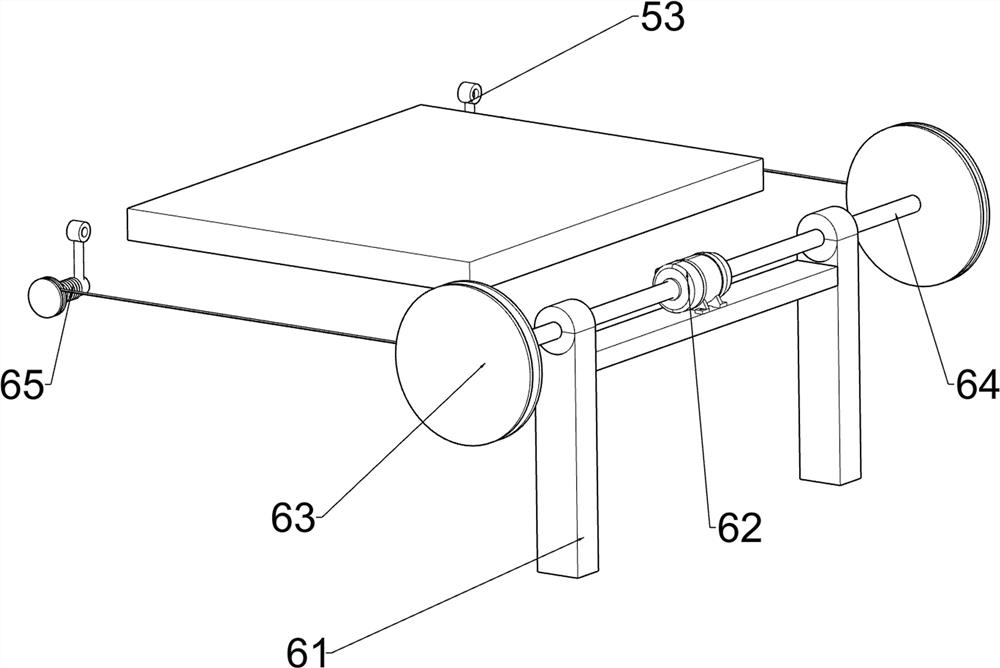

[0075] On the basis of Example 2, such as Figure 4-Figure 7 As shown, a pulling mechanism 6 is also included, the upper and rear side of the first fixed plate 1 is provided with a pulling mechanism 6, and the pulling mechanism 6 includes a second support rod 61, a motor 62, a reel assembly 63, a first rotating shaft 64 and a second Four springs 65, the rear side on the first fixed plate 1 is provided with a second support rod 61, a motor 62 is installed in the middle of the second support rod 61 tops, and the output shafts of the two motors 62 are connected with the first rotating shaft 64, the first rotating shaft 64 It is rotatably connected with the second support rod 61, and a reel assembly 63 is connected between the first sliding sleeve 53 and the first rotating shaft 64. There are two reel assemblies 63, and the reel assembly 63 and the first sliding sleeve 53 is connected with a fourth spring 65, and the number of the fourth spring 65 is two.

[0076] The user starts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com