Patents

Literature

68results about How to "Realize the blanking effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

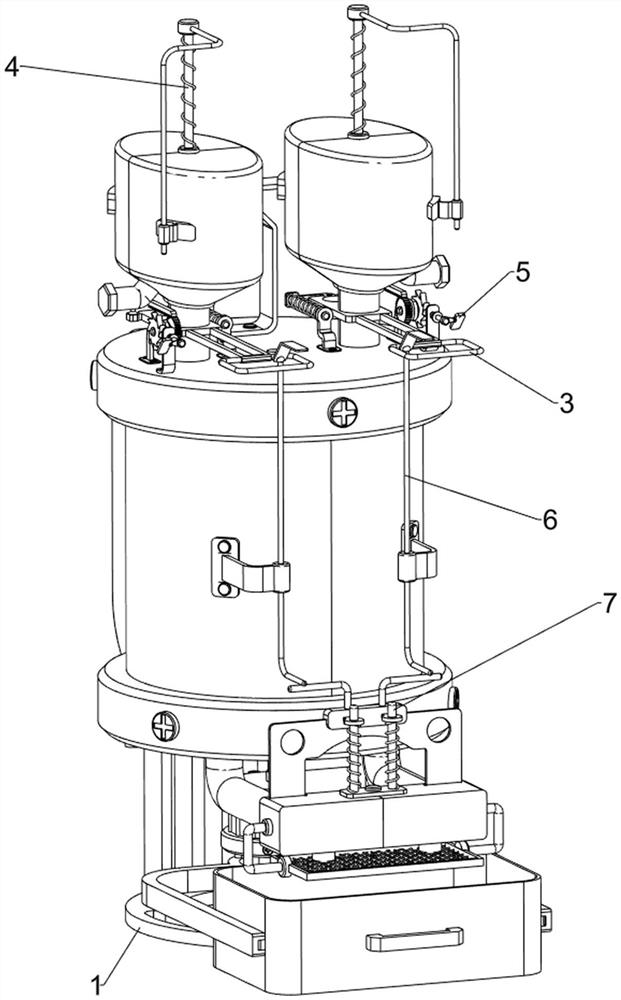

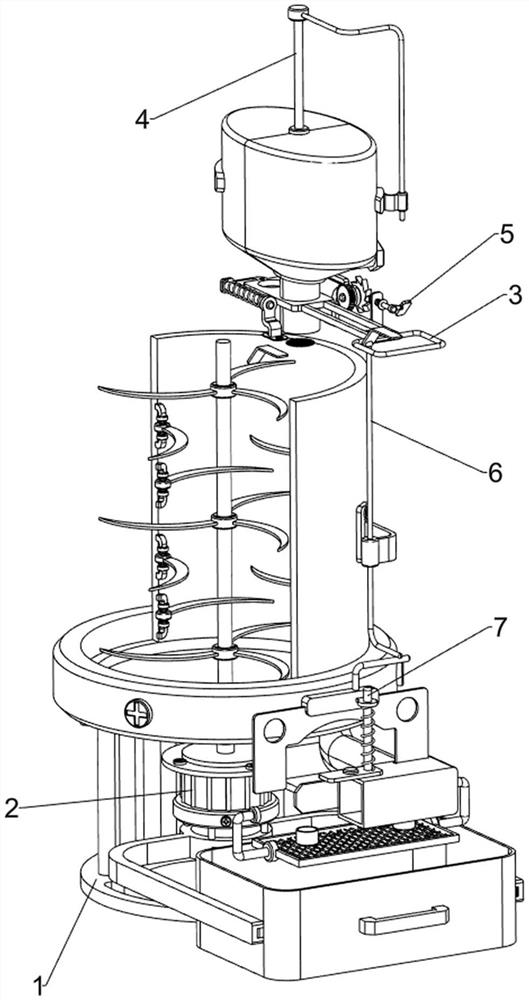

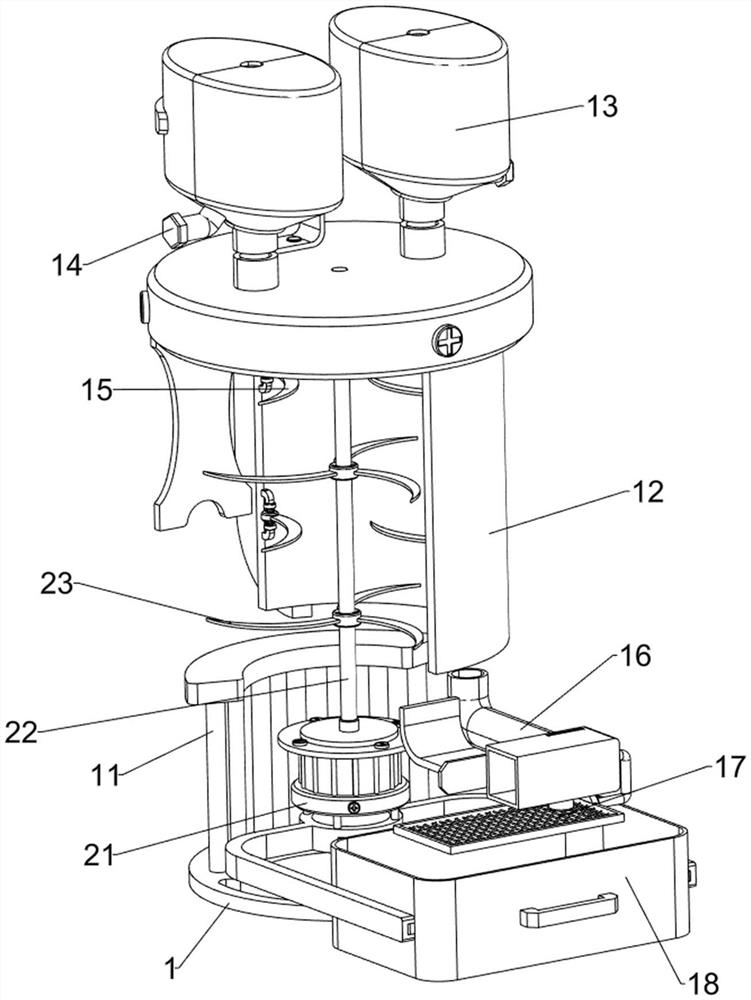

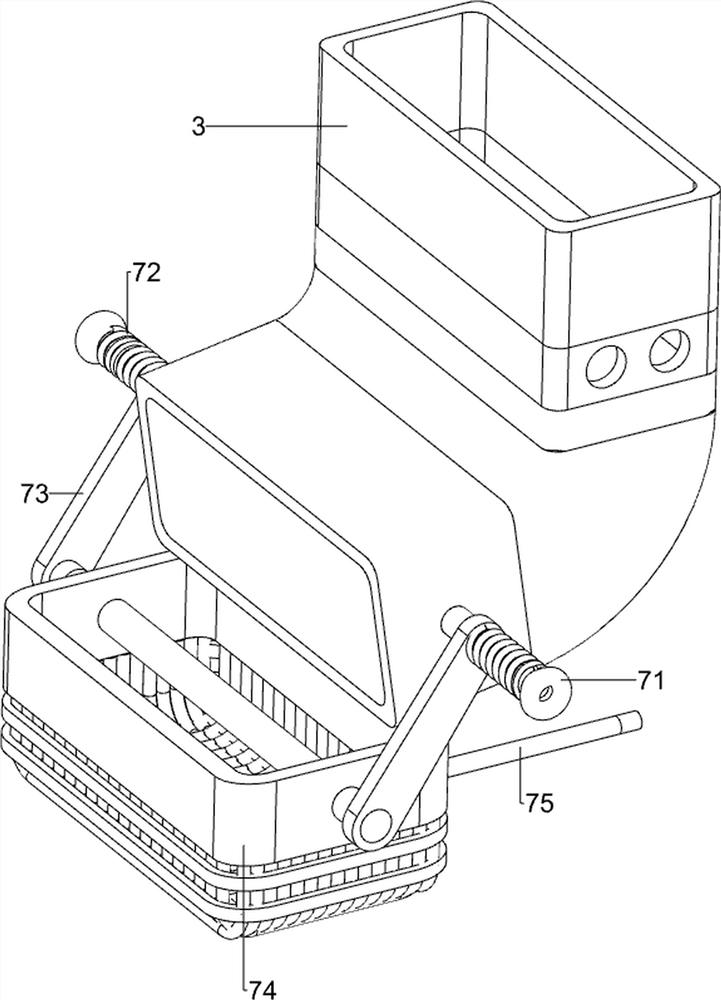

Automatic mixing device for colored glaze production

ActiveCN112844193AWell mixedAchieve broken effectTransportation and packagingRotary stirring mixersGlazeEngineering

The invention relates to a mixing device, and particularly relates to an automatic mixing device for colored glaze production. The automatic mixing device for colored glaze production is good in mixing effect, capable of reducing the labor intensity of workers and easy and understandable to operate. The automatic mixing device for colored glaze production comprises a base, a fixed supporting column, a mixing box body, a discharging box, feeding openings, static crushing cutters, a discharging channel and a filter screen, wherein the fixed supporting column is arranged on the base; the mixing box body is arranged at the top of the fixed supporting column; the discharging box is arranged at the top of the mixing box body; the feeding openings are formed in the two sides of the lower part of the discharging box; three static crushing cutters are rotationally arranged on each of the upper side and the lower side in the mixing box body; the discharging channel is arranged at the bottom of the mixing box body; and the filter screen is arranged between the two sides of the discharging channel. By arranging the crushing mechanism, the colored glaze in the mixing box body is more uniformly mixed through the operation of the crushing mechanism, and the crushing effect is achieved.

Owner:高安常莹新型材料有限公司

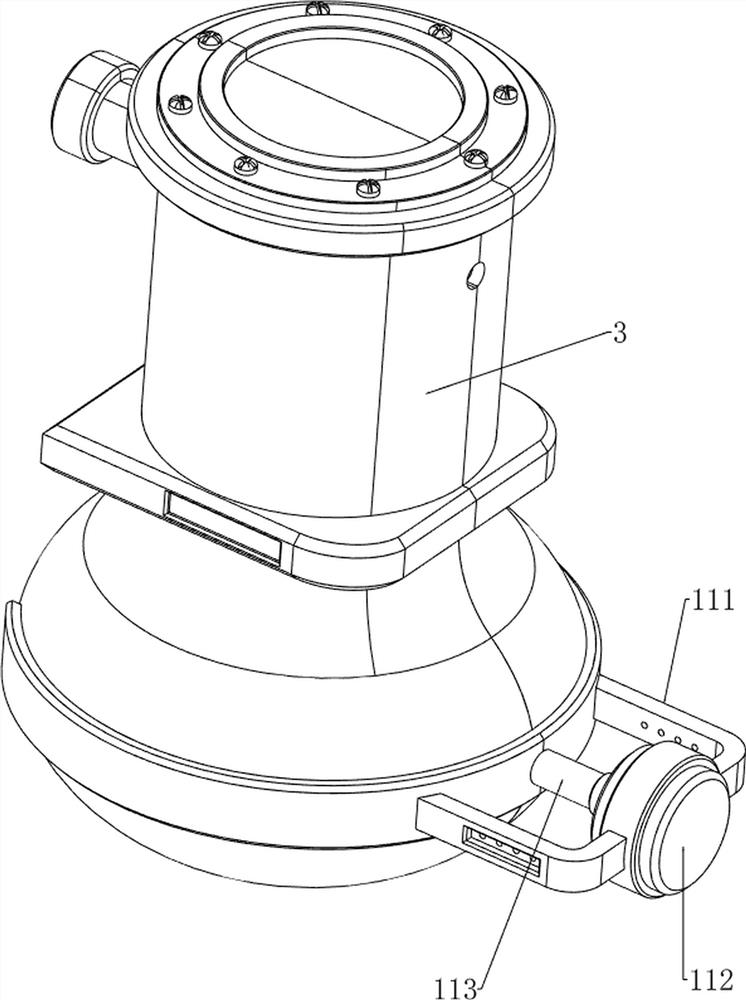

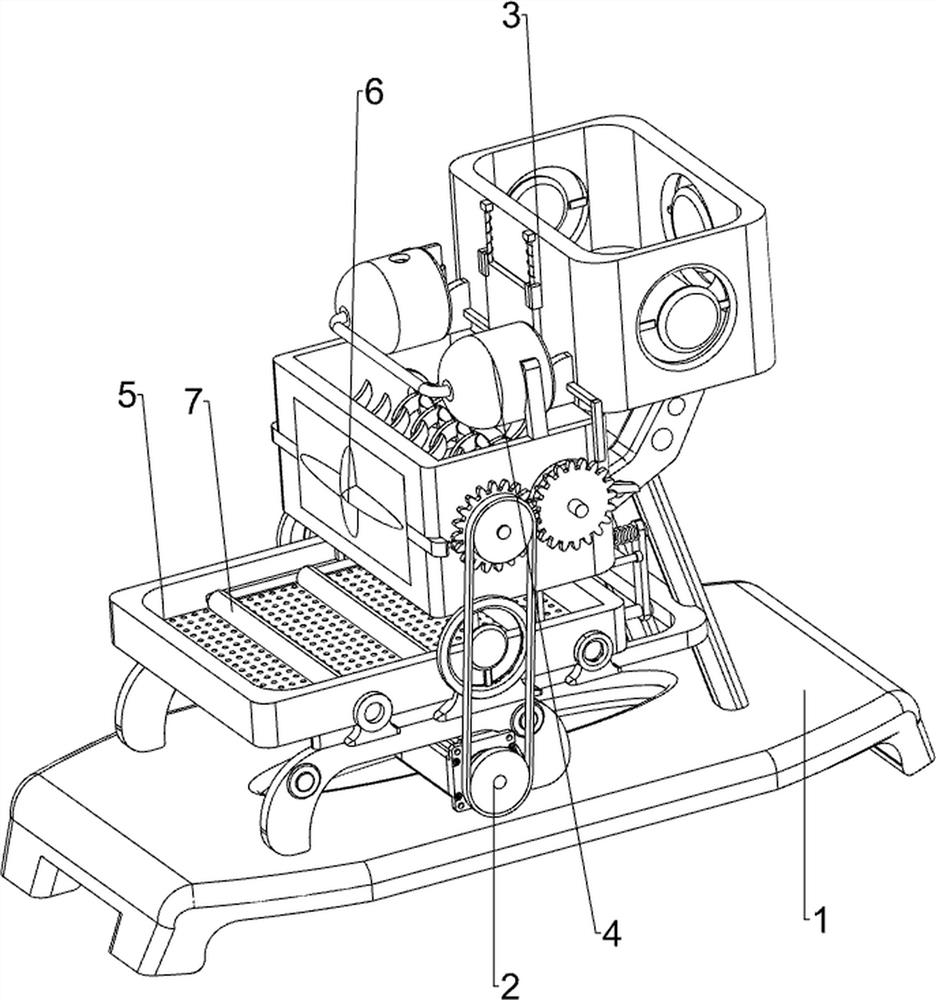

Equipment for centralizedly treating used medical needle tubes

PendingCN113019559AAchieve the crushed effectReduce manual operationsSievingSolid waste disposalBiomedical engineeringGeneral surgery

The invention relates to treatment equipment, in particular to equipment for centralizedly treating used medical needle tubes. The equipment for centralizedly treating the used medical needle tubes can realize automatic crushing, automatic feeding and automatic screening. The equipment for centralizedly treating the used medical needle tubes comprises a first supporting plate, first supporting frames, a fluid frame, a grinding mechanism, a power mechanism, a discharging mechanism, a vibration mechanism and a collecting box; the first supporting frames are arranged on the two sides of the first supporting plate; the fluid frame is connected between the two first supporting frames; the grinding mechanism is arranged on the fluid frame; the power mechanism is arranged between the grinding mechanism and the first supporting plate; the discharging mechanism is arranged on the upper side of the fluid frame; the vibration mechanism is arranged on the lower side of the fluid frame; and the collecting box is arranged on the first supporting plate. According to the equipment, through rotation of a first gear and a second gear, a driving gear rotates, and then a first rotating shaft on the left side rotates, so that grinding devices rotate to grind the needle tubes.

Owner:黄志武

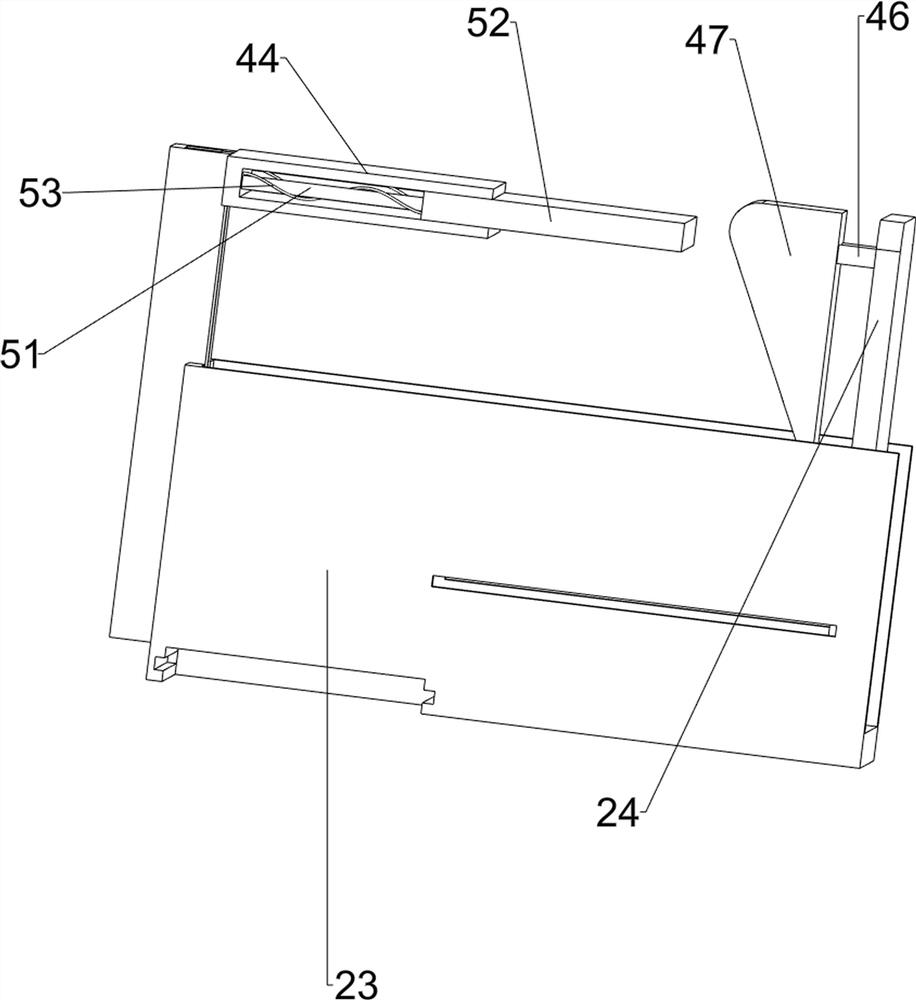

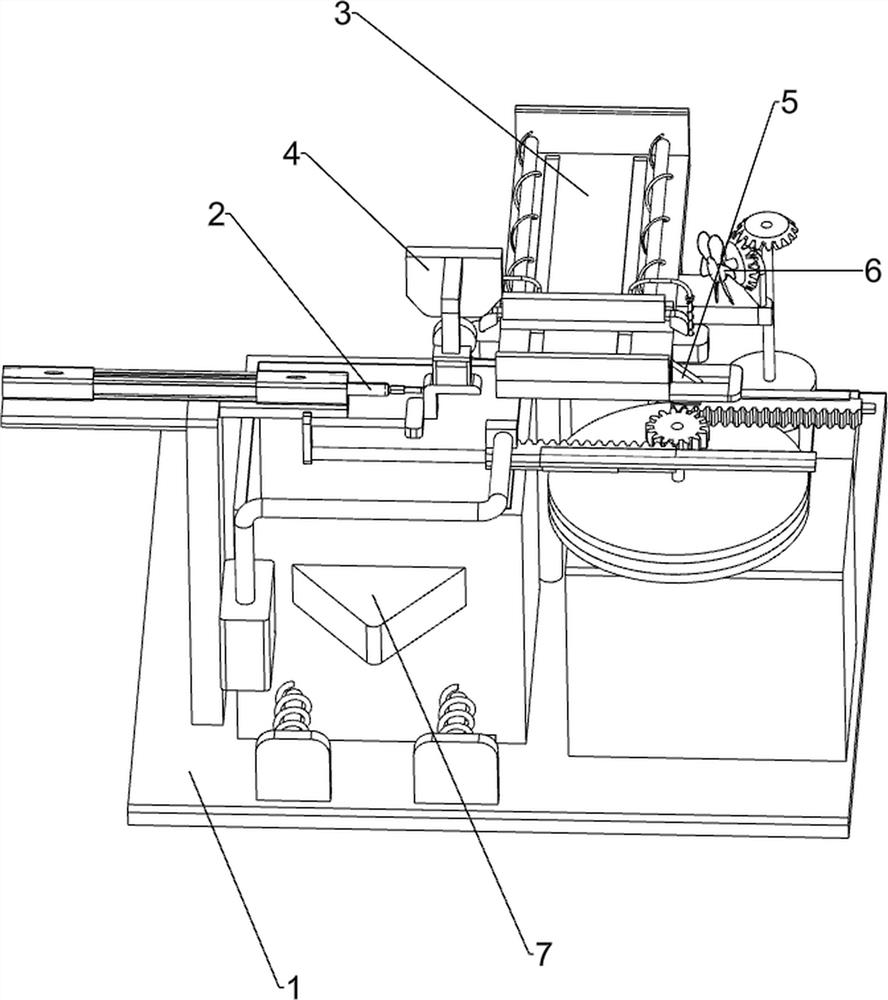

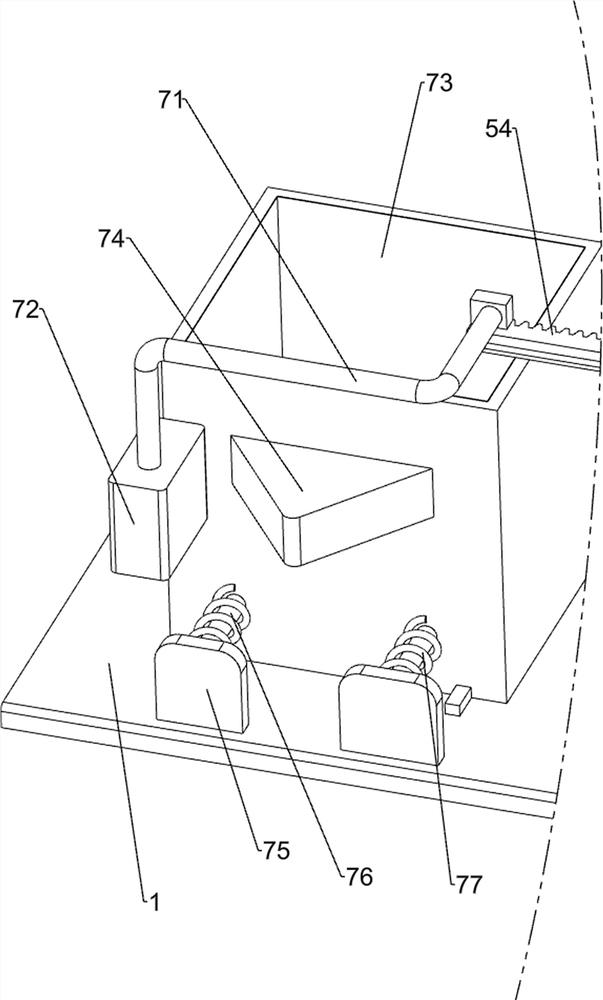

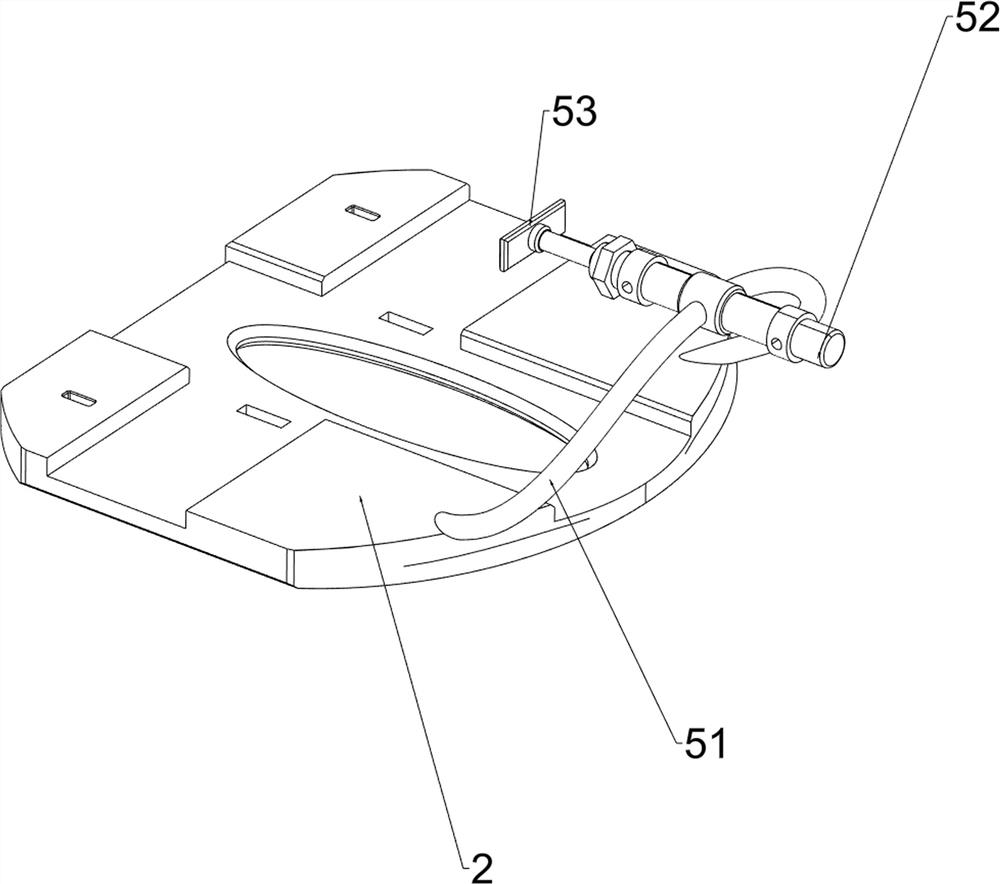

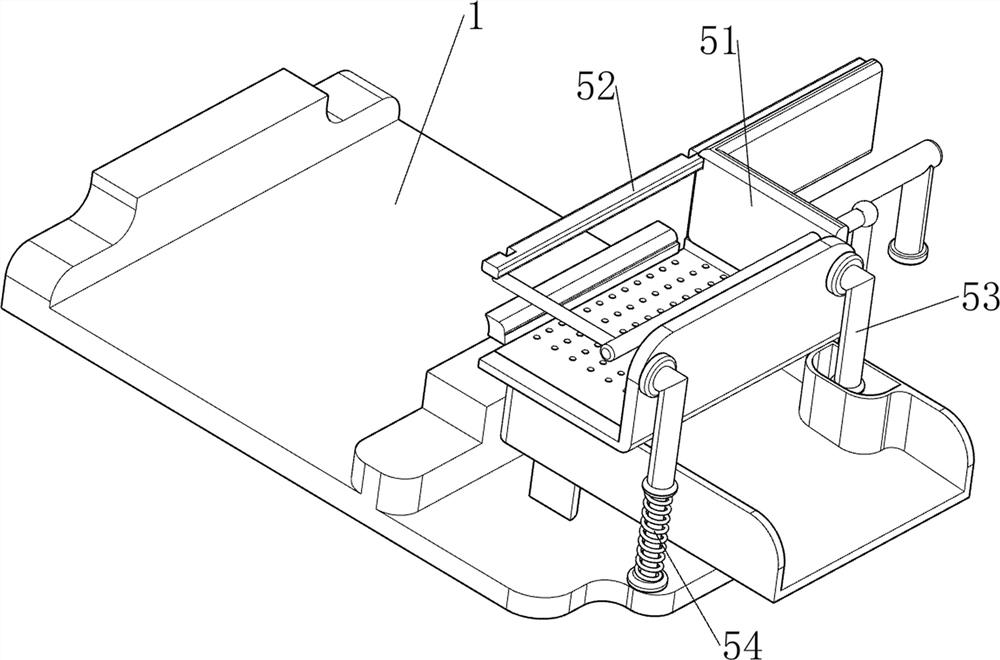

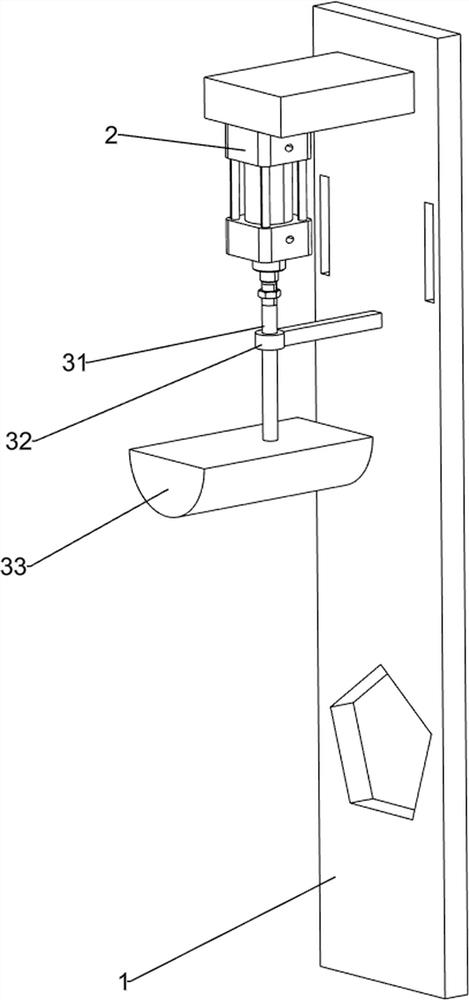

Pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection

PendingCN112477255ARealize the effect of extrusionRealize the blanking effectPressesThermodynamicsEngineering

The invention relates to extrusion forming and recycling equipment, in particular to pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection. The pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection can achieve automatic feeding and discharging and automatic extrusion forming. The pneumatic type waste zip-top can extrusion forming and recycling equipment for environmental protection comprises a base and a discharging mechanism, and a compression mechanism is arranged on the base; and the discharging mechanism is arranged at the lower part of the compression mechanism. An air cylinder extends to push a push rod backwards, so that an extrusion plate is pushed backwards, the extrusion plate pushes a zip-top can backwards, the zip-top can is clamped between the inner wall of the rear side of an extrusion table and the extrusion plate, and the effect of extrusion forming of the zip-top can isachieved. A first handle is manually pulled leftwards, a first baffle is subjected to leftward pulling force to enable a first sliding block to slide leftwards, a first baffle moves leftwards to drivea first fixing block to move leftwards, and the discharging effect of the zip-top can formed through extrusion is achieved.

Owner:曾鹏

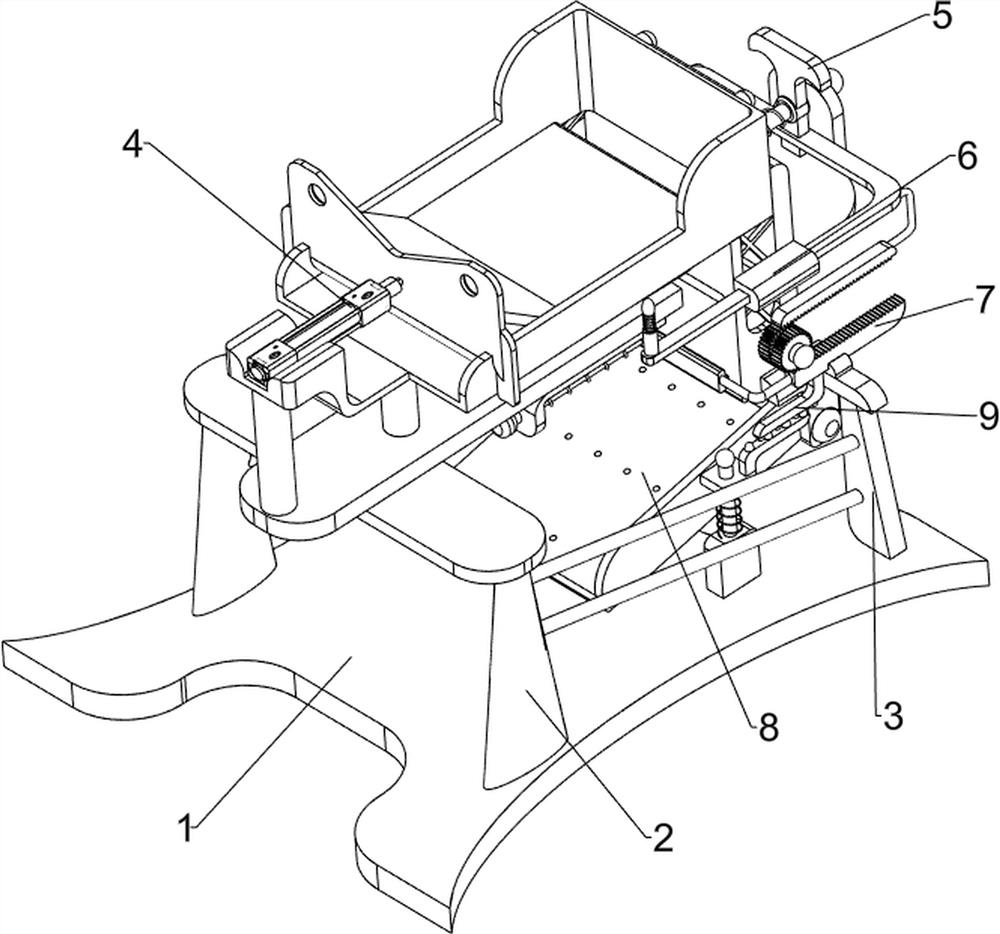

Medical square tablet mashing equipment for pediatric department

PendingCN113304805ARealize the push effectSave human effortOral administration deviceGrain treatmentsEngineeringSurgery

The invention relates to mashing equipment, in particular to medical square tablet mashing equipment for pediatric department. The medical square tablet mashing equipment for the pediatric department can mash tablets automatically, is good in mashing effect and can mash a large number of tablets. The medical square tablet mashing equipment for the pediatric department comprises a bottom frame, a first supporting block, a second supporting block, a material pushing mechanism, an extruding mechanism and an extrusion block, wherein the first supporting block is arranged on the bottom frame; the second supporting block is arranged between the upper part of the first supporting block and the bottom frame; the material pushing mechanism is arranged between the bottom frame and the first supporting block and between the bottom frame and the second supporting block; the extruding mechanism is arranged on the material pushing mechanism; and the extrusion block is arranged on the material pushing mechanism in a sliding mode, and the extrusion block is fixedly connected with the extrusion mechanism. By arranging the material pushing mechanism, people push the material pushing mechanism to operate, so that the material pushing mechanism can push tablets to the position below the extrusion block, and the material pushing effect is achieved.

Owner:张志嵘

Agricultural organic fertilizer dehydration equipment

InactiveCN112484403ARealize extrusion dehydration effectRealize the output effectDrying solid materials without heatStationary filtering element filtersAgricultural scienceAgricultural engineering

The invention relates to a dehydration device, in particular to agricultural organic fertilizer dehydration equipment. The agricultural organic fertilizer dehydration equipment can be used for discharging organic fertilizer for multiple times, automatically discharging and extruding to dehydrate the organic fertilizer. The agricultural organic fertilizer dehydration equipment comprises a rack anda discharging mechanism; an extrusion dehydration mechanism is arranged on the rear side of the rack; and the discharging mechanism is arranged at the upper part of the rear side of the rack. According to the agricultural organic fertilizer dehydration equipment, an air cylinder telescopic rod extends downwards to drive a pressing plate to move downwards to extrude and dehydrate the organic fertilizer, moisture of the organic fertilizer flows out of a filter screen, and the extrusion and dehydration effect is achieved; and an arc-shaped connecting plate moves downwards, a first telescopic assembly in the contraction state is stretched, a discharging opening between the rack and the arc-shaped connecting plate is opened, and the discharging effect is achieved.

Owner:冉乾

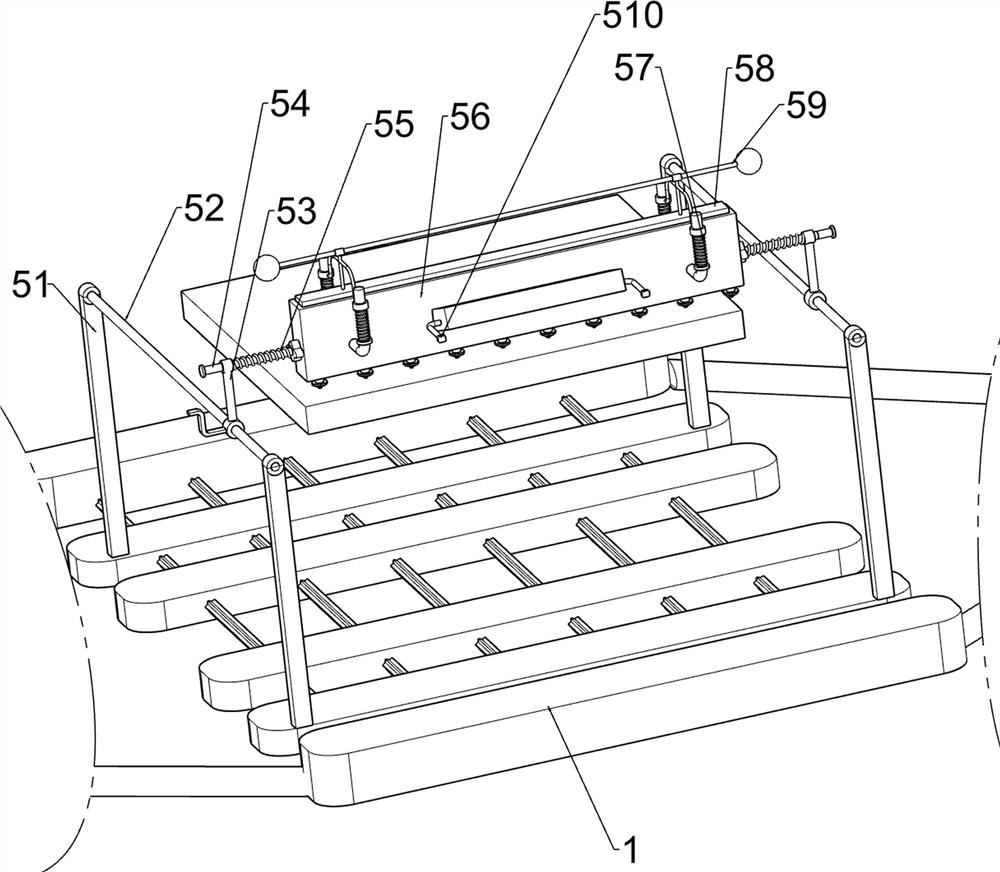

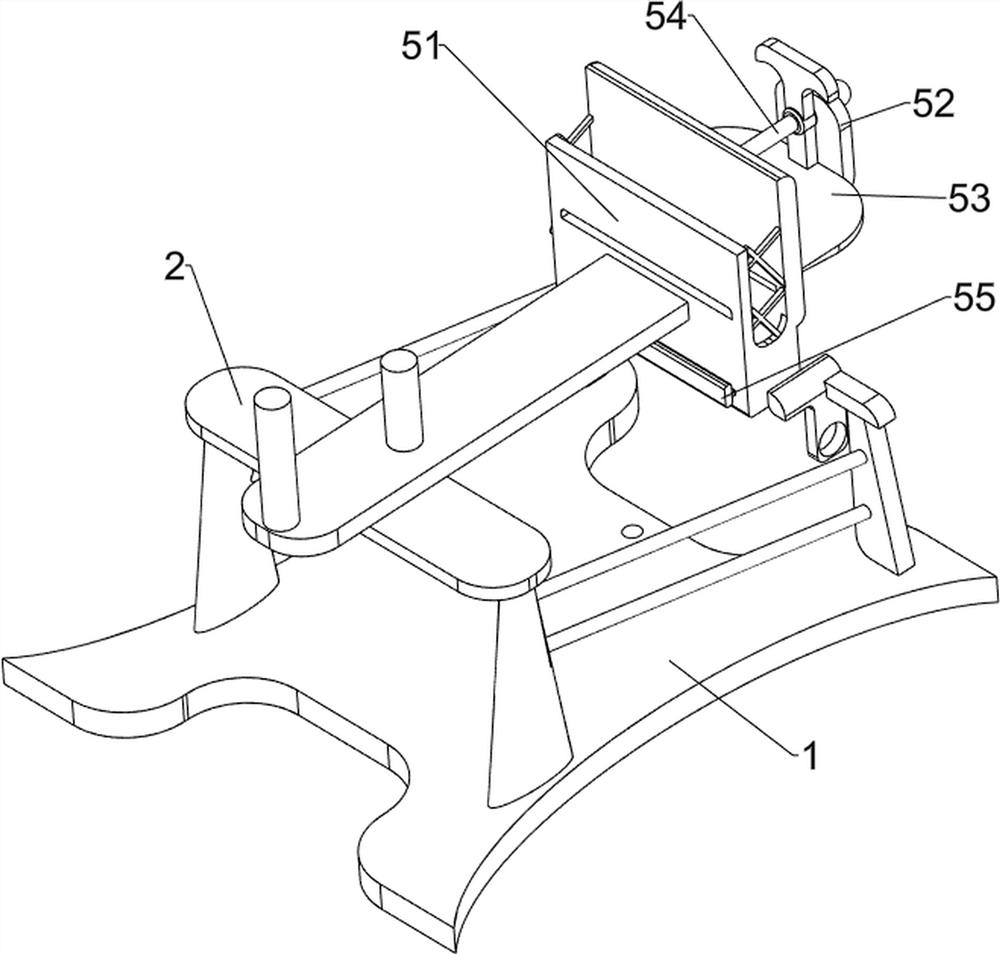

Square wood block slotting equipment for building materials

ActiveCN112265086ARealize the effect of slottingRealize the clamping effectSolid waste managementWood mortising machinesArchitectural engineeringMechanical engineering

Owner:中基安泰(新疆)建设有限公司

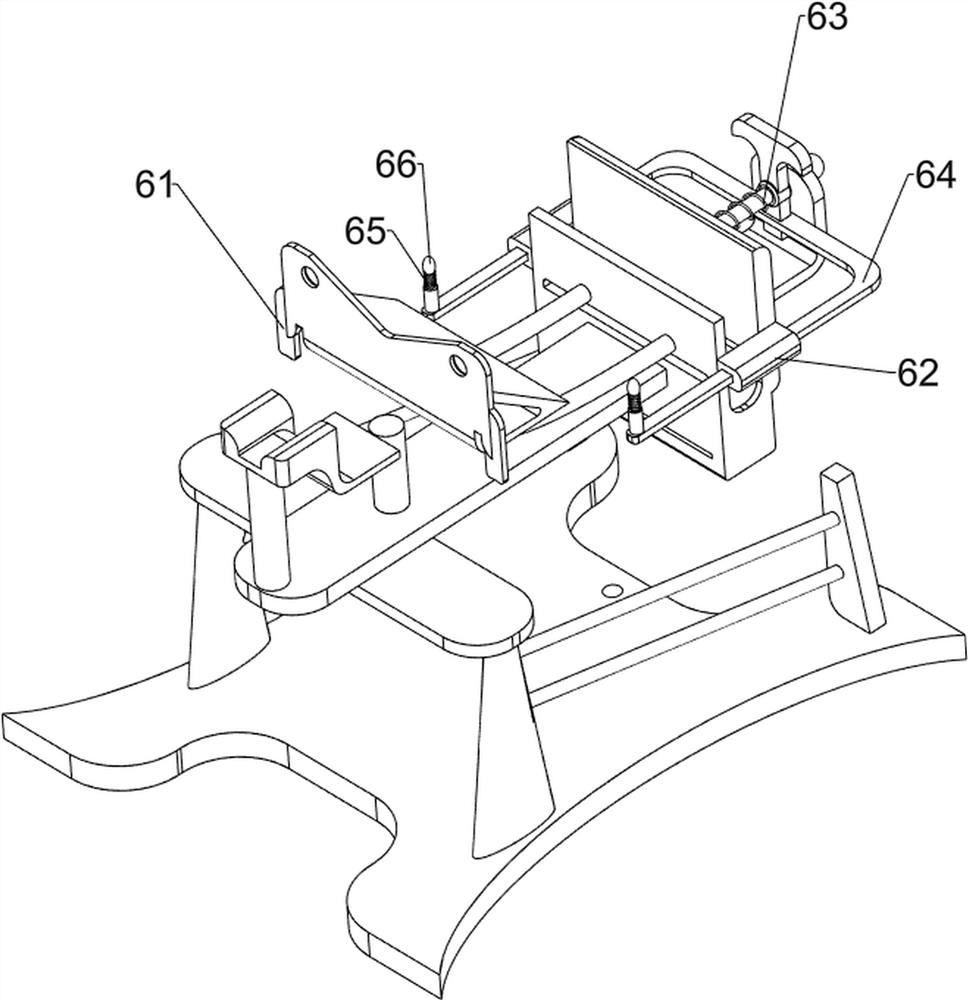

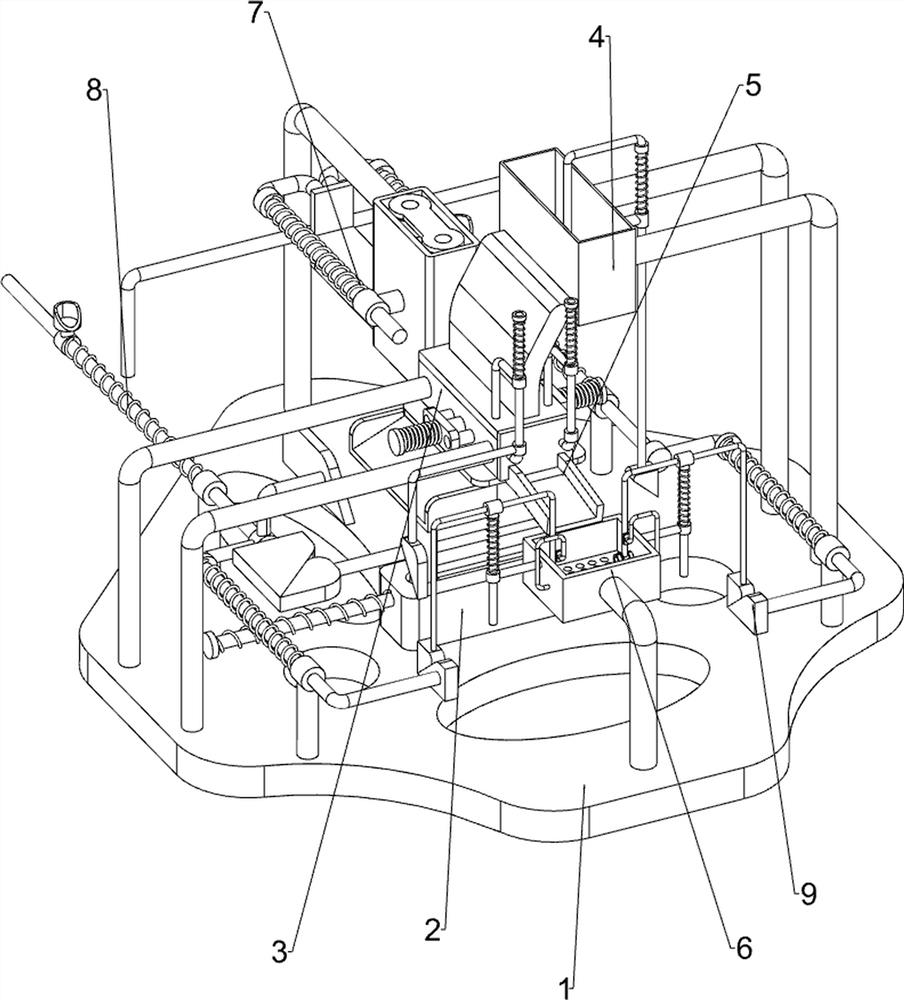

Welding device for high-end equipment manufacturing

PendingCN112743271ARealize the welding effectRealize the driving effectWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention relates to a welding device, in particular to a welding device for high-end equipment manufacturing. The welding device for high-end equipment manufacturing is higher in fixing stability and capable of achieving automatic splicing and automatic welding. The welding device for high-end equipment manufacturing comprises a supporting leg, first supports, a welding mechanism and a pushing mechanism, and a mounting plate is arranged on the supporting leg; each of the left side and the right side of the top of the mounting plate is provided with the two first supports. the welding mechanism is arranged among the four first supports; and the pushing mechanism is arranged on the front side of the top of the mounting plate. A first sliding sleeve is pushed backwards to move backwards, so that an electric welding gun is driven to move backwards, a first spring is stretched, and after the electric welding gun makes contact with two metal plates, the electric welding gun welds the two metal plates, and the welding effect is achieved.

Owner:吴彬

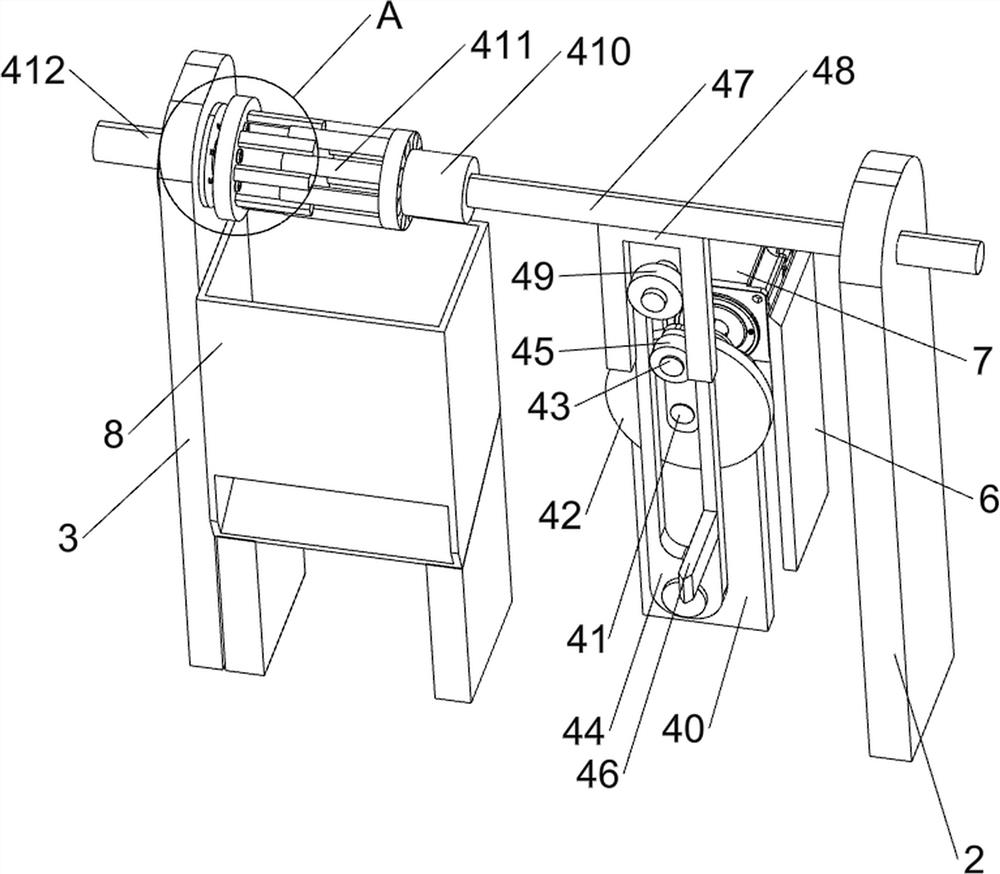

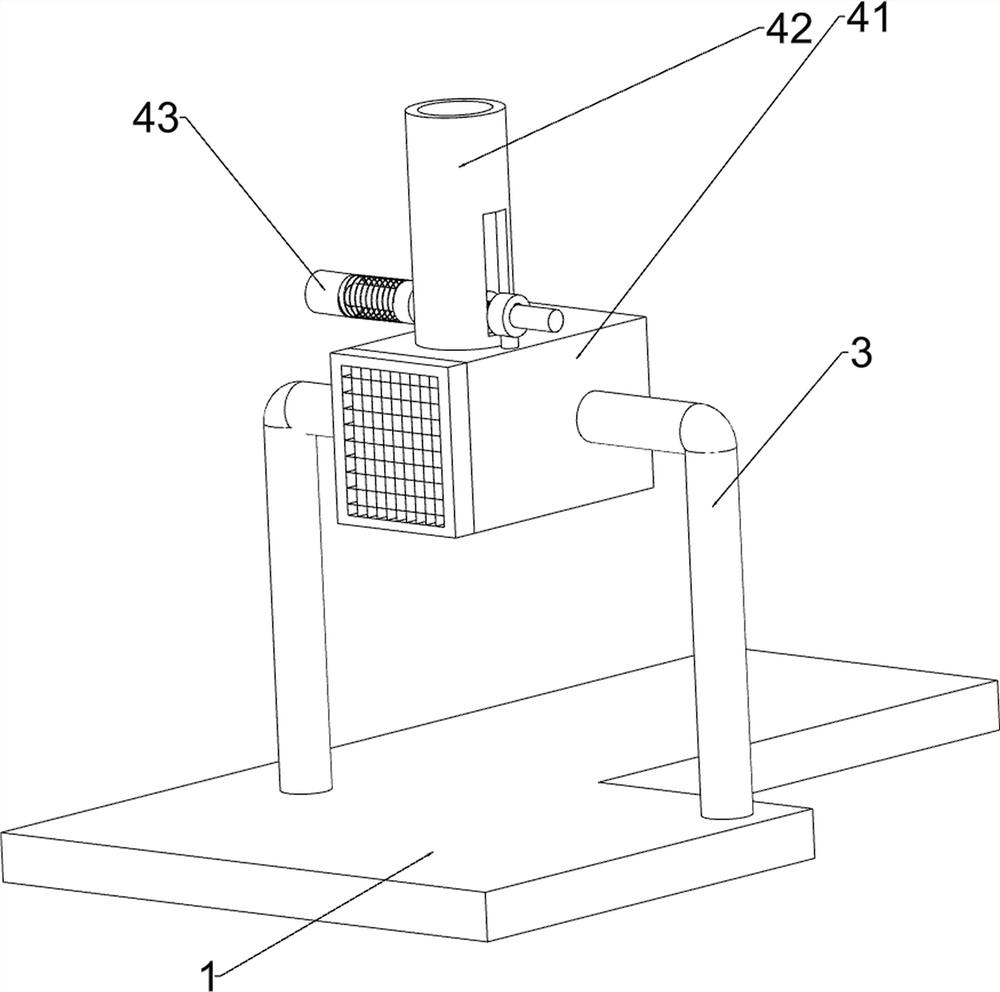

Equipment for separating zip-top can body from cover

PendingCN112091320AQuick cutRealize the blanking effectMetal sawing devicesIndustrial engineeringServo

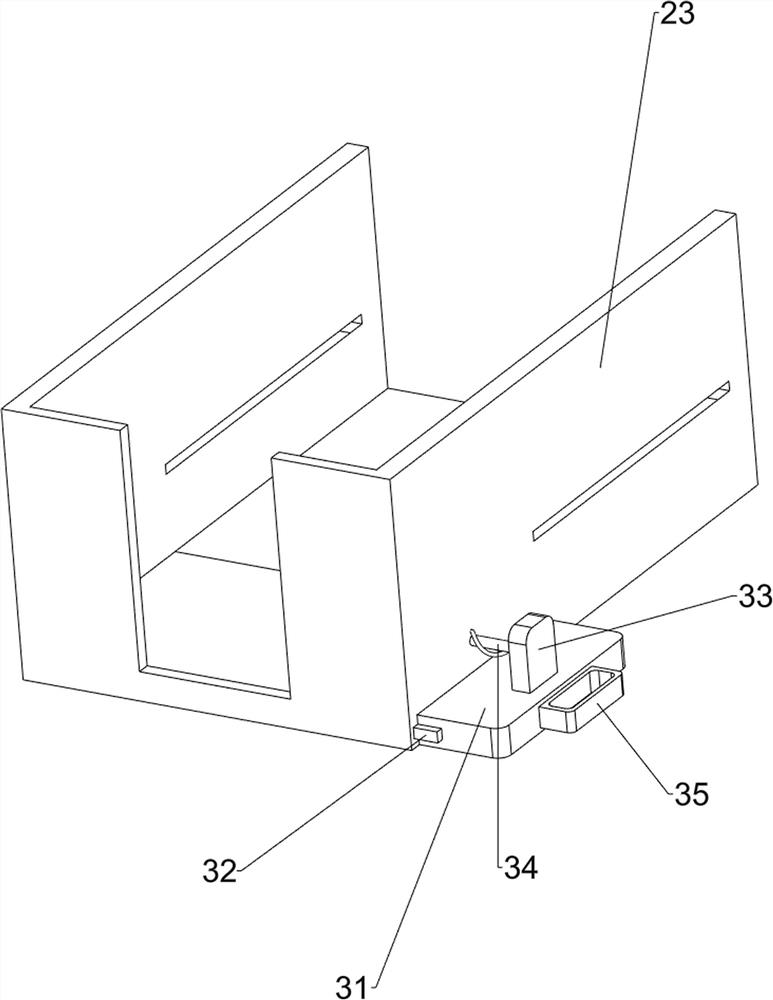

The invention relates to separation equipment, in particular to equipment for separating a zip-top can body from a cover. According to the equipment for separating the zip-top can body from the cover,zip-top cans can be rapidly cut, and automatic feeding can be conducted. The equipment for separating the zip-top can body from the cover comprises a base used for installing the whole equipment, a supporting frame arranged on one side of the upper part of the base, a servo motor arranged on the upper part of the supporting frame, a feeding mechanism arranged on the upper part of the base, and acutting mechanism arranged on the side, away from the supporting frame, of the upper part of the base. The equipment achieves the effects that zip-top cans can be quickly cut, and automatic feeding can be conducted. A saw blade is driven by a first rotating shaft to move up and down, so that the zip-top cans can be quickly cut.

Owner:梁华娇

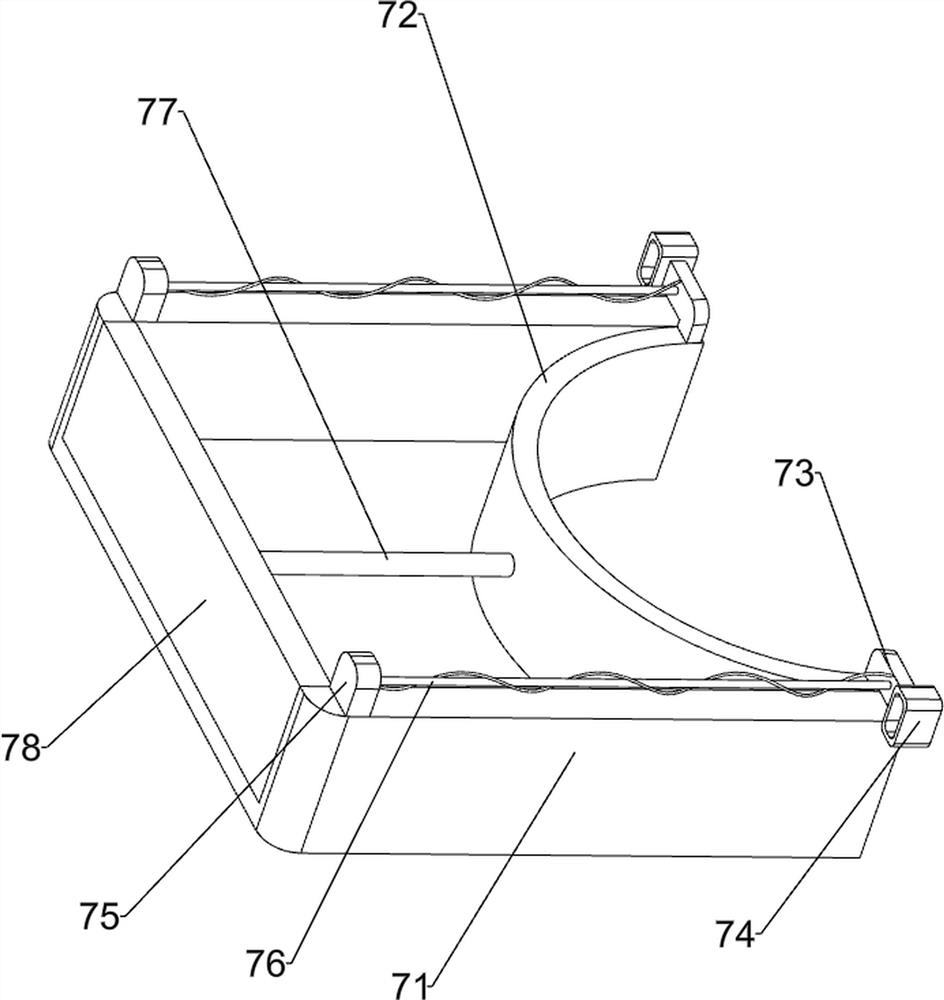

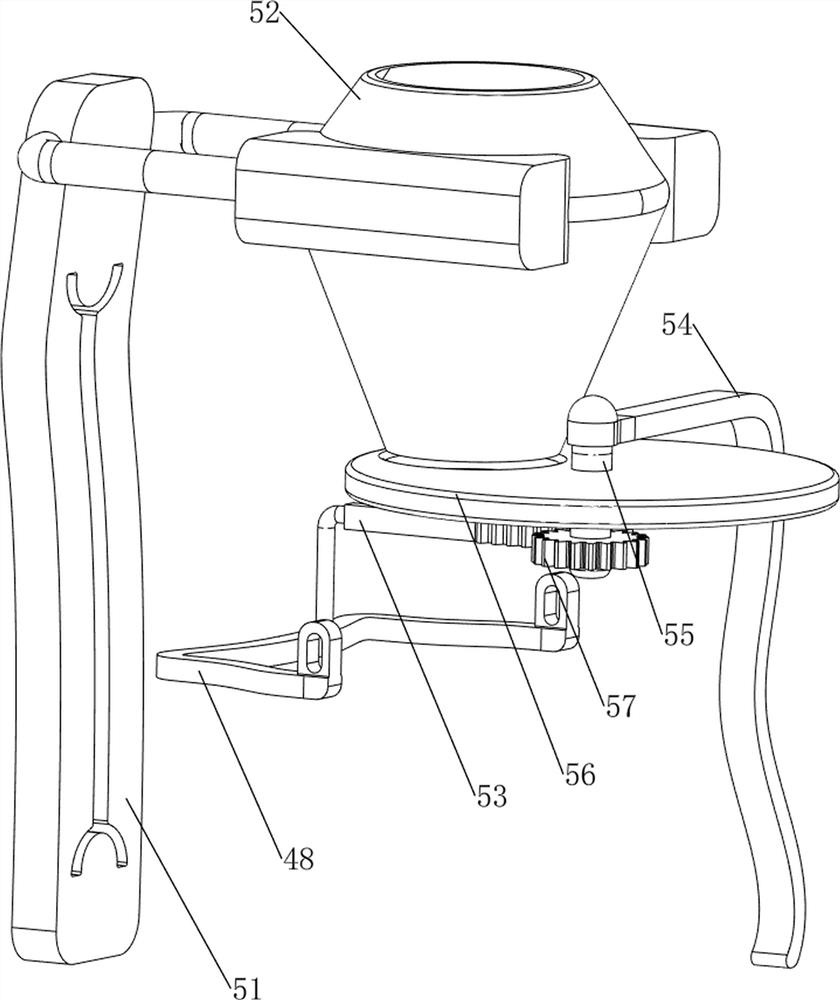

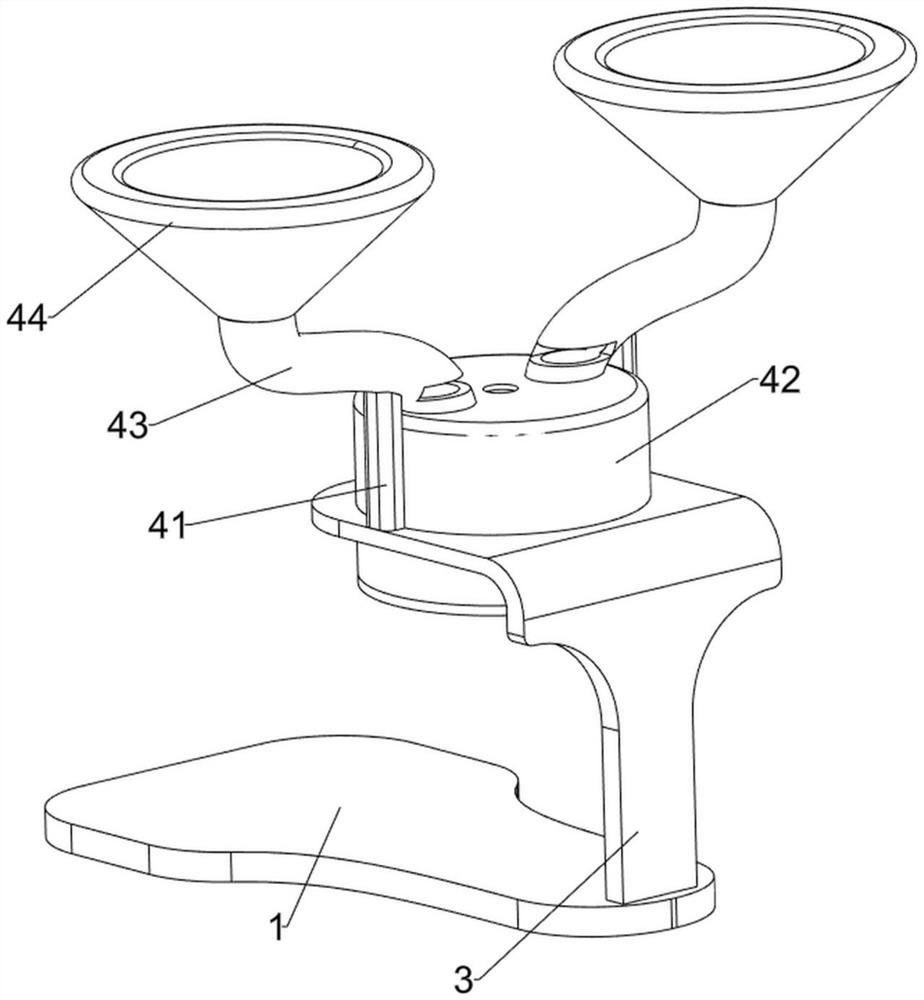

Quick flour subpackaging device for food processing

ActiveCN113044258ARealize the blanking effectRealize the feeding effectWrapper twisting/gatheringSolid materialSpiral bladeElectric machinery

The invention relates to a subpackaging device, in particular to a quick flour subpackaging device for food processing. The quick flour subpackaging device for food processing is convenient to package, easy to operate and wide in applicability. The quick flour subpackaging device for food processing comprises supporting legs and a workbench, and the workbench is arranged among the tops of the four supporting legs. A mounting frame is included and is arranged at the top of the workbench. A first discharging mechanism is included and is arranged at the top of the mounting frame. A second discharging mechanism is included and is arranged on the inner wall of the workbench. According to the quick flour subpackaging device for food processing, an output shaft of the motor rotates to drive a transmission shaft to achieve transmission, so that spiral blades are driven to rotate, the spiral blades can enable flour to fall off onto a bag through a discharging opening, and the discharging effect is achieved. And a torsion spring is reset to drive a second rotating shaft to rotate reversely, so that a rotating disc is driven to swing towards the inner side, people pull out the bags from the workbench intermittently, and the bag discharging effect is achieved.

Owner:山东咏禾食品有限公司

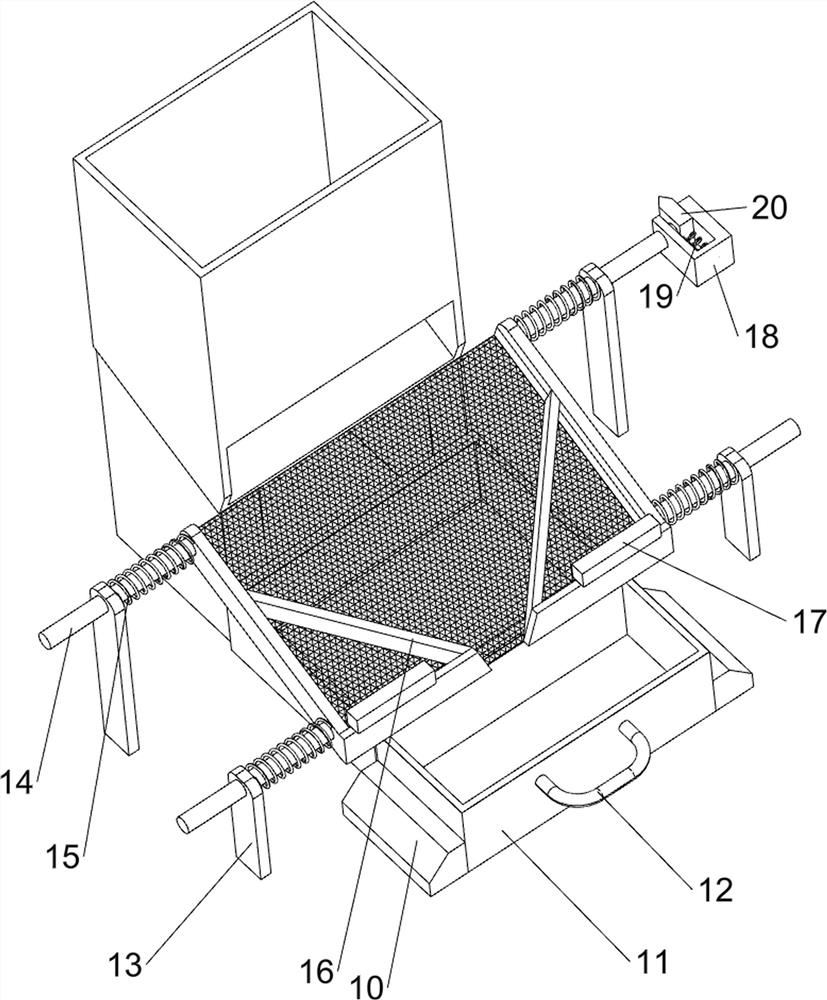

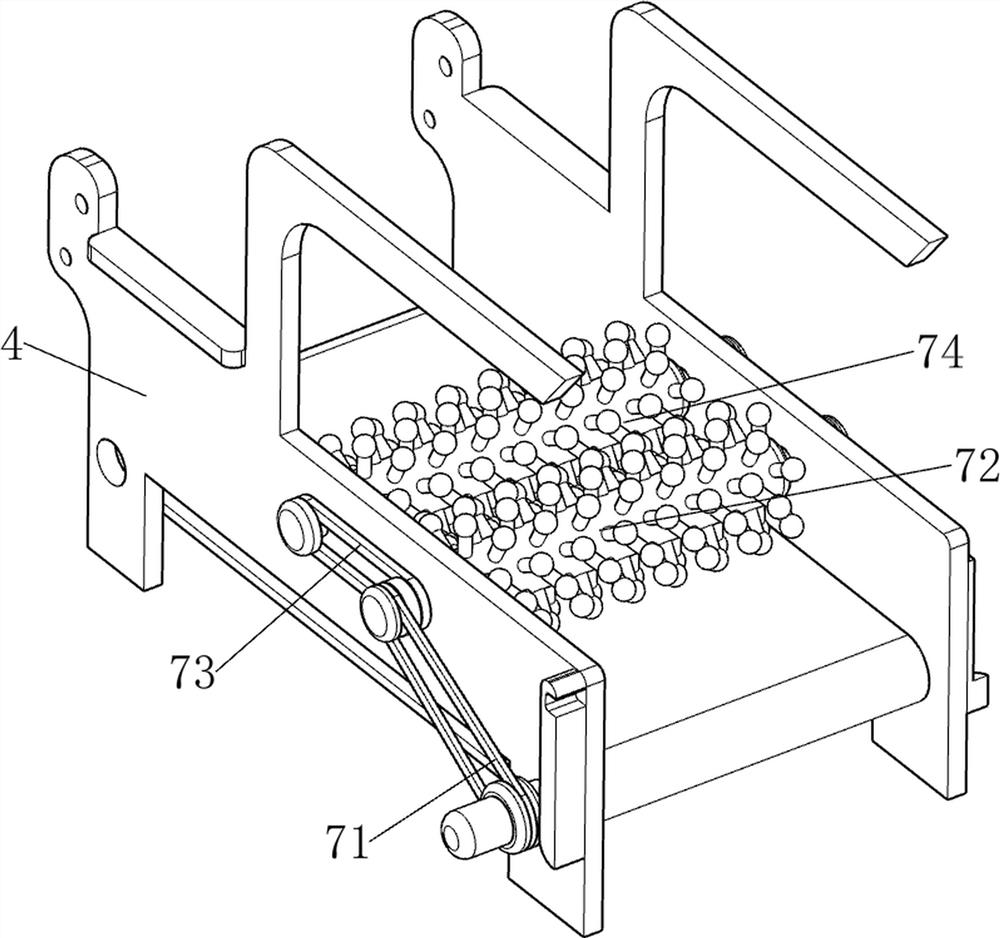

Fine sand screening equipment for building

ActiveCN113070204AFast screeningRealize the blanking effectSievingScreeningArchitectural engineeringMechanical engineering

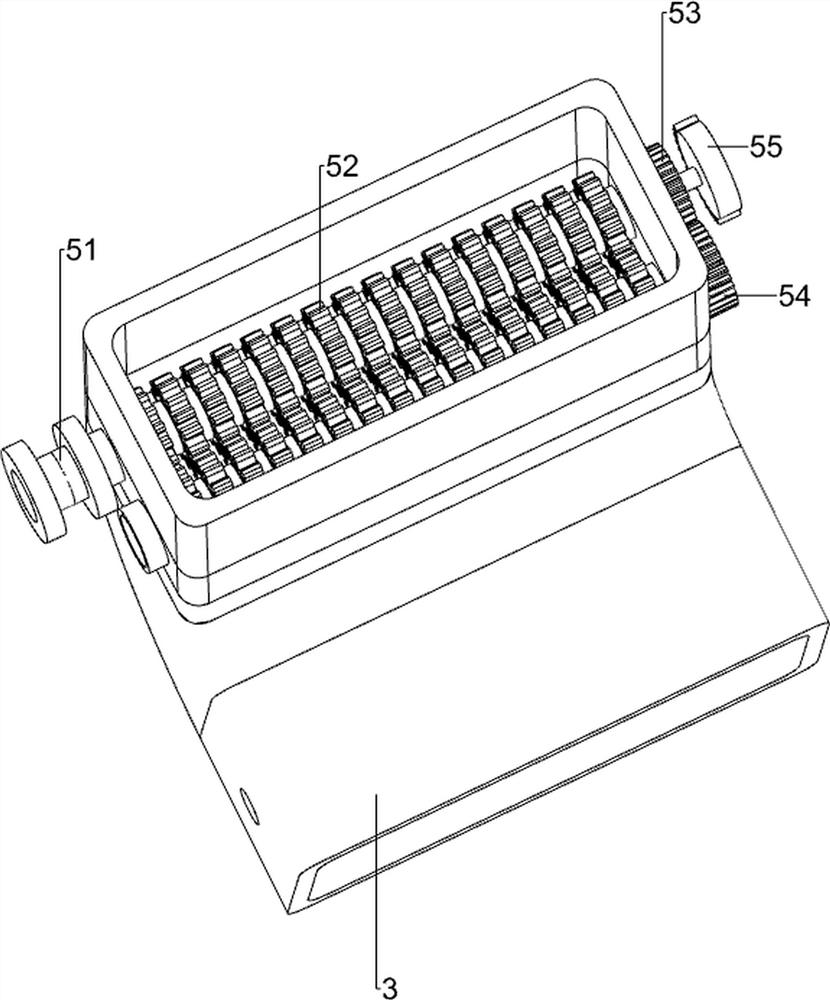

The invention relates to screening equipment, in particular to fine sand screening equipment for construction. The technical problem to be solved is to provide the fine sand screening equipment for the building, which can automatically discharge sand and is relatively high in screening speed. The fine sand screening equipment for construction comprises a bottom plate used for supporting the whole equipment, a base arranged at one side of the upper part of the bottom plate, a cylinder arranged at the upper part of the base, a pushing mechanism arranged at the upper part of the bottom plate, and a discharging mechanism arranged at the side, close to the cylinder, of the upper part of the bottom plate. According to the fine sand screening equipment, the effects that the sand can be automatically discharged, and the screening speed is high are achieved; and stone sand is discharged into a screening frame, the cylinder drives a push rod and the screening frame to move, and therefore the stone sand can be rapidly separated.

Owner:池州市汇成废弃资源综合利用有限公司

Automatic pecan shell opening equipment

PendingCN112089060AAchieve automatic feedingReached can be automatically unloadingHuskingHullingAgricultural engineeringStructural engineering

Owner:钟守云

Screening device for rare earth raw material processing

InactiveCN113877817ARealize the push effectNo manual push requiredSievingGas current separationRaw materialSupport plane

The invention relates to a screening device, in particular to a screening device for rare earth raw material processing. The screening device for rare earth raw material processing is good in screening effect, capable of conducting secondary screening and low in cost. The screening device for rare earth raw material processing comprises a bottom frame, a first discharging frame, a first supporting frame, a first screening frame, a material pushing mechanism and a rotary reciprocating mechanism; the first discharging frame is arranged on the bottom frame; the first supporting frame is arranged on the bottom frame; the first screening frame is arranged on the first supporting frame in a sliding mode; the material pushing mechanism is arranged among the bottom frame, the first screening frame and the first supporting frame; and the rotary reciprocating mechanism is arranged among the bottom frame, the first supporting frame and the material pushing mechanism. According to the screening device, a material pushing frame is manually pushed to move backwards, rare earth is pushed together through the material pushing frame, screening is convenient, and the material pushing effect is achieved.

Owner:叶小刚

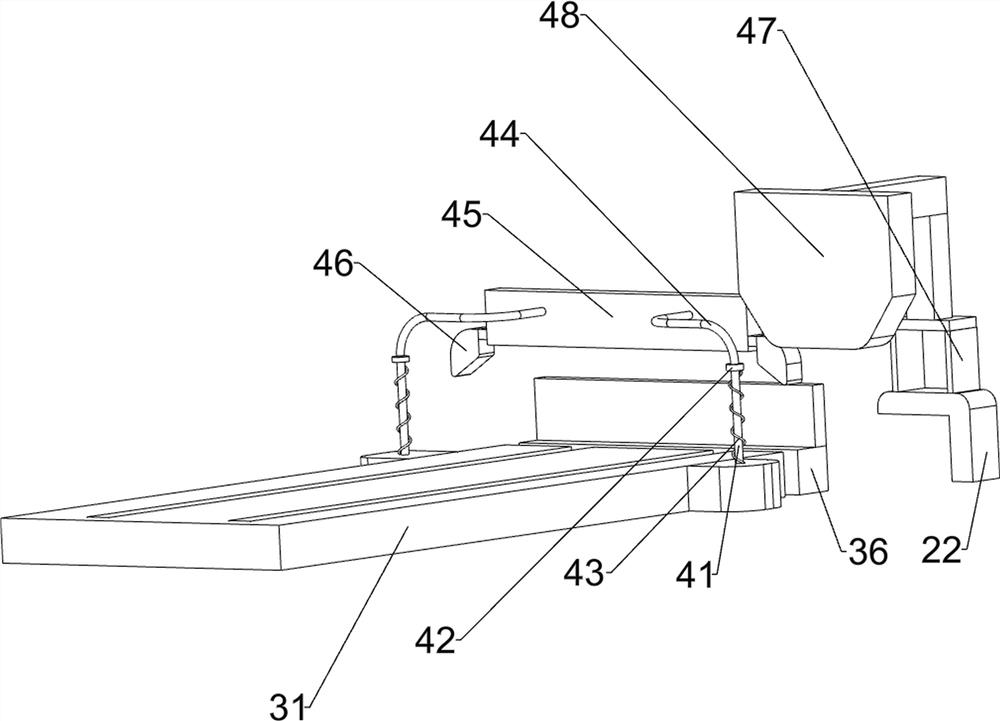

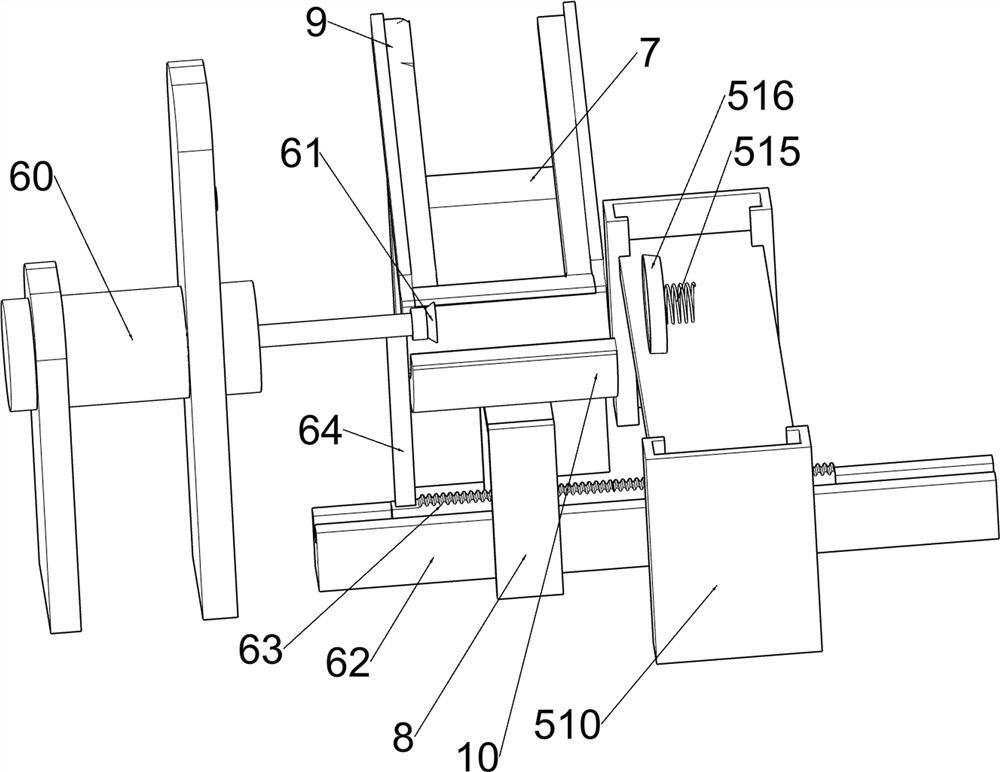

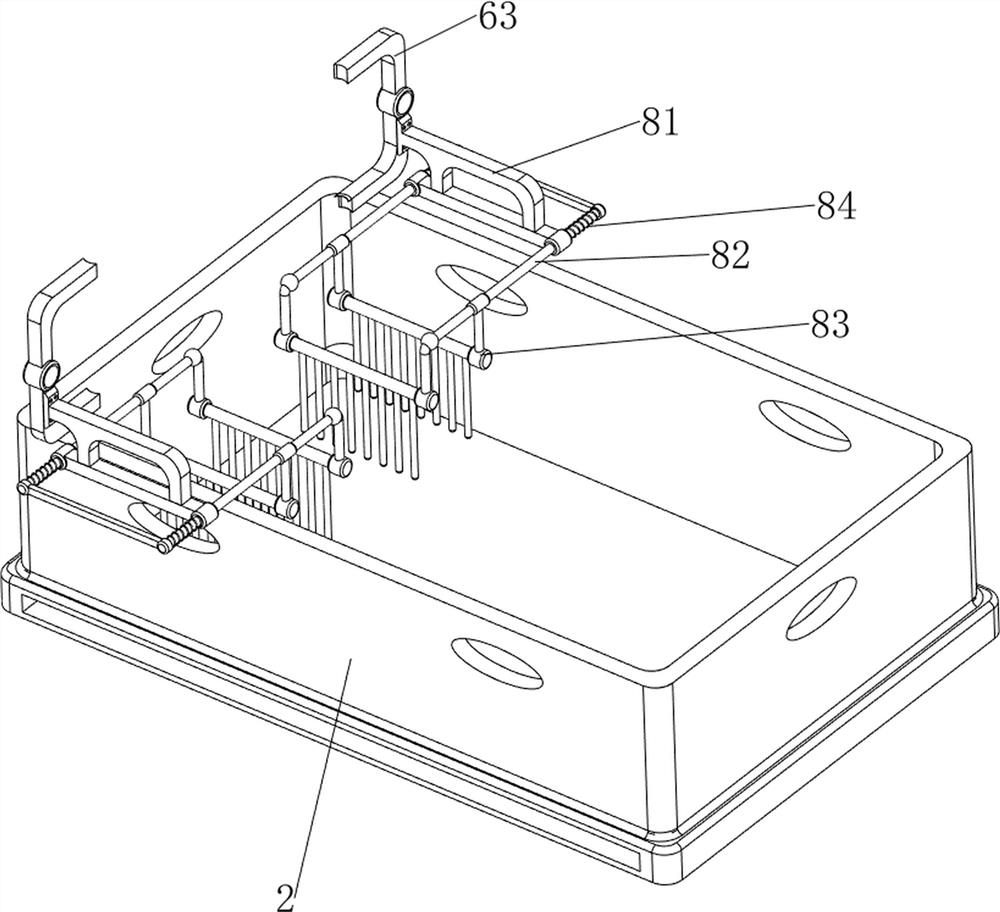

Particle extrusion device for modified starch processing

ActiveCN112497551ARealize the blanking effectStirring effect is evenSievingScreeningEngineeringMechanical engineering

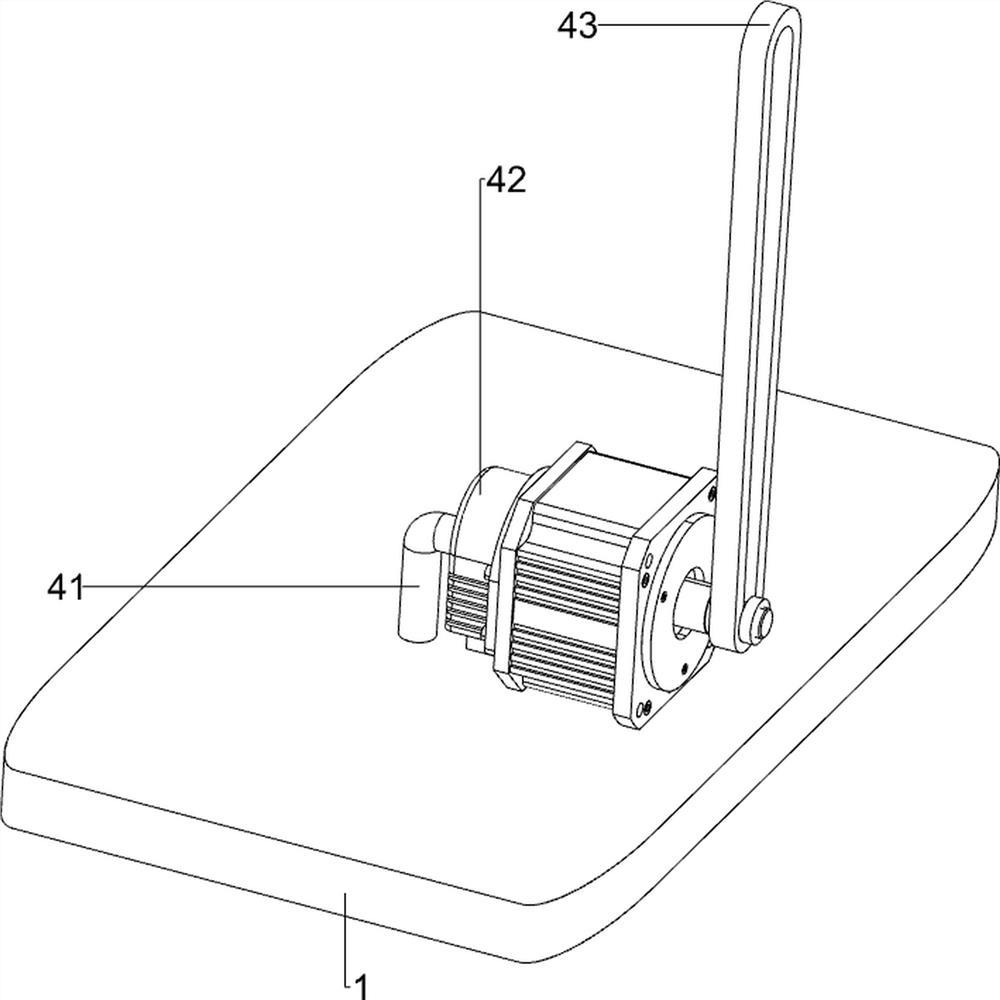

The invention relates to a particle extrusion device, in particular to a particle extrusion device for modified starch processing . The particle extrusion device for modified starch processing provided by the invention is uniform in mixing and good in extrusion effect. The particle extrusion device for modified starch processing comprises a base, a supporting seat, a feeding mechanism, a rotatingmechanism and a reciprocating mechanism. A first supporting column is arranged on the base; the supporting seat is arranged on the base; the feeding mechanism is arranged at the upper part of the supporting seat; the rotating mechanism is arranged on the feeding mechanism; and the reciprocating mechanism is arranged at the lower part of the feeding mechanism, and is connected with the rotating mechanism in a sliding manner. According to the particle extrusion device for modified starch processing provided by the invention, modified starch is discharged through a discharging frame and slides into a stirring box through a discharging pipe, so that the discharging effect is achieved; and by arranging a collecting mechanism, the purified modified starch is collected by the collecting mechanismand is convenient for people to take and use.

Owner:DONGXIANG HEDA IND CO LTD

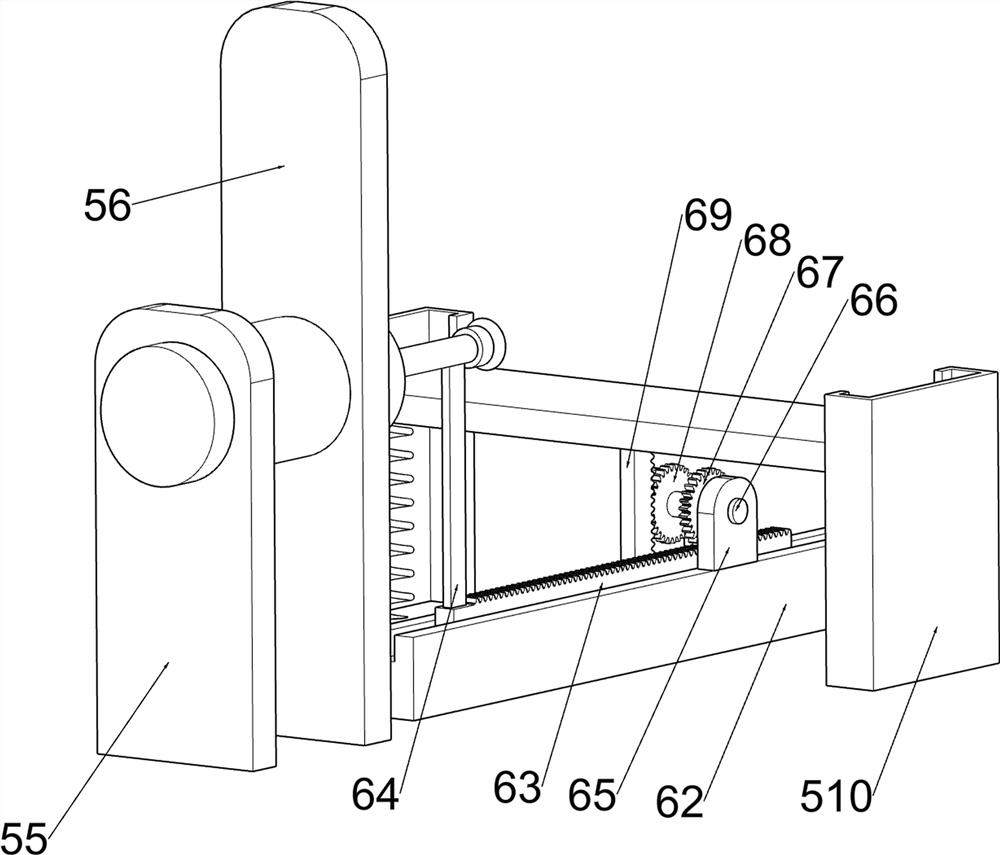

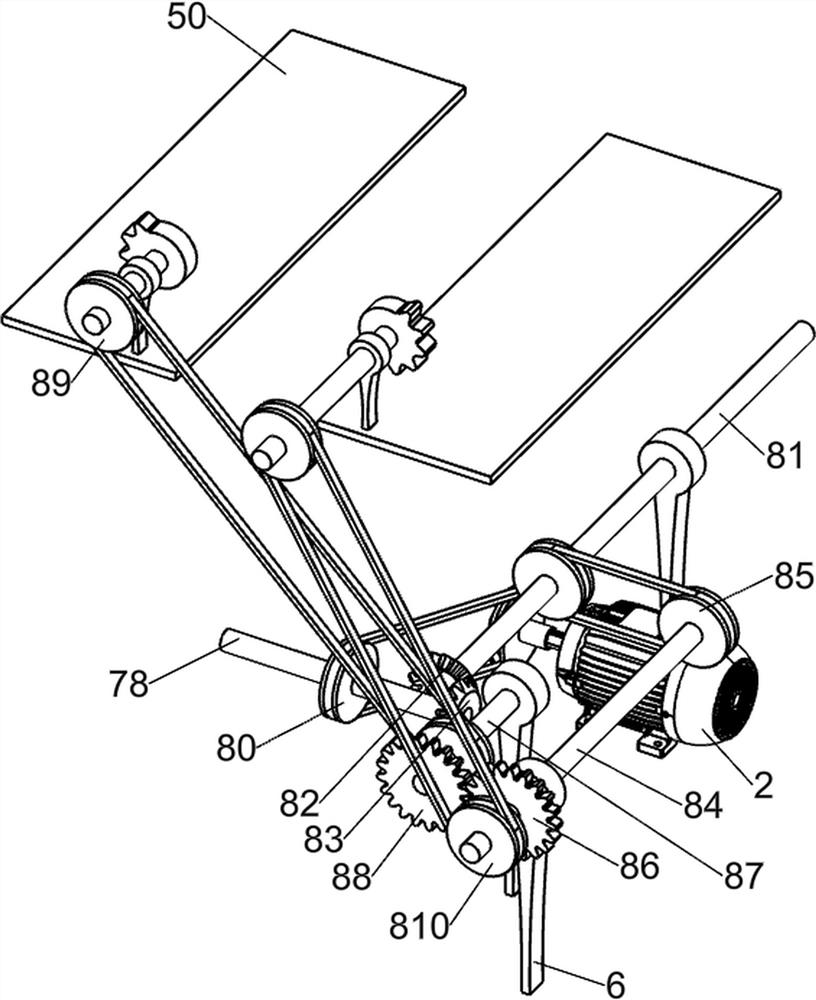

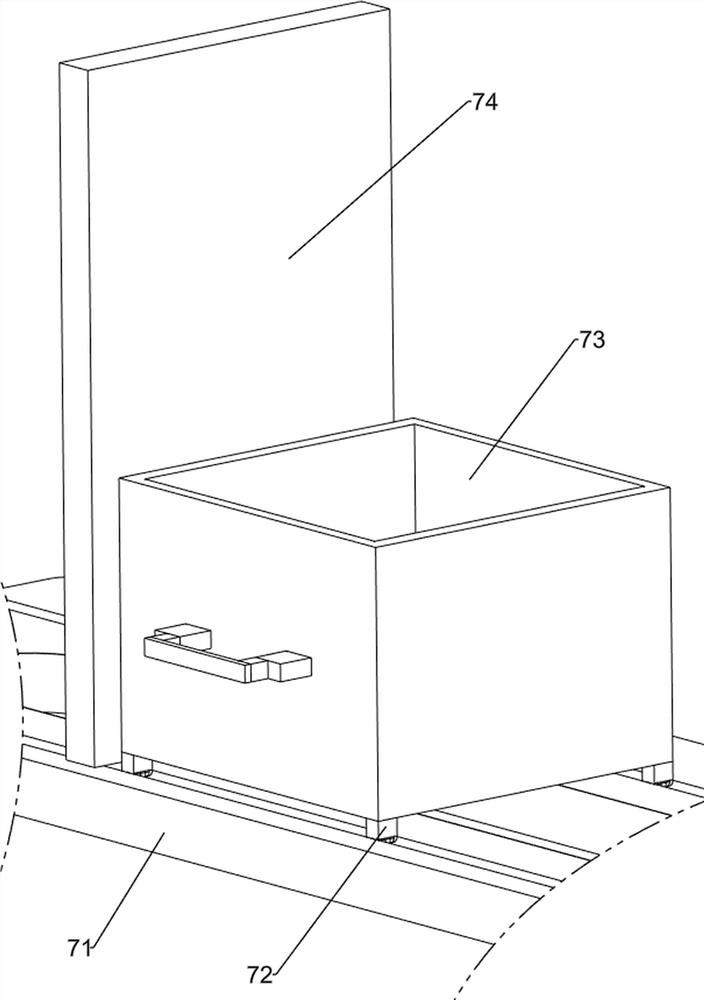

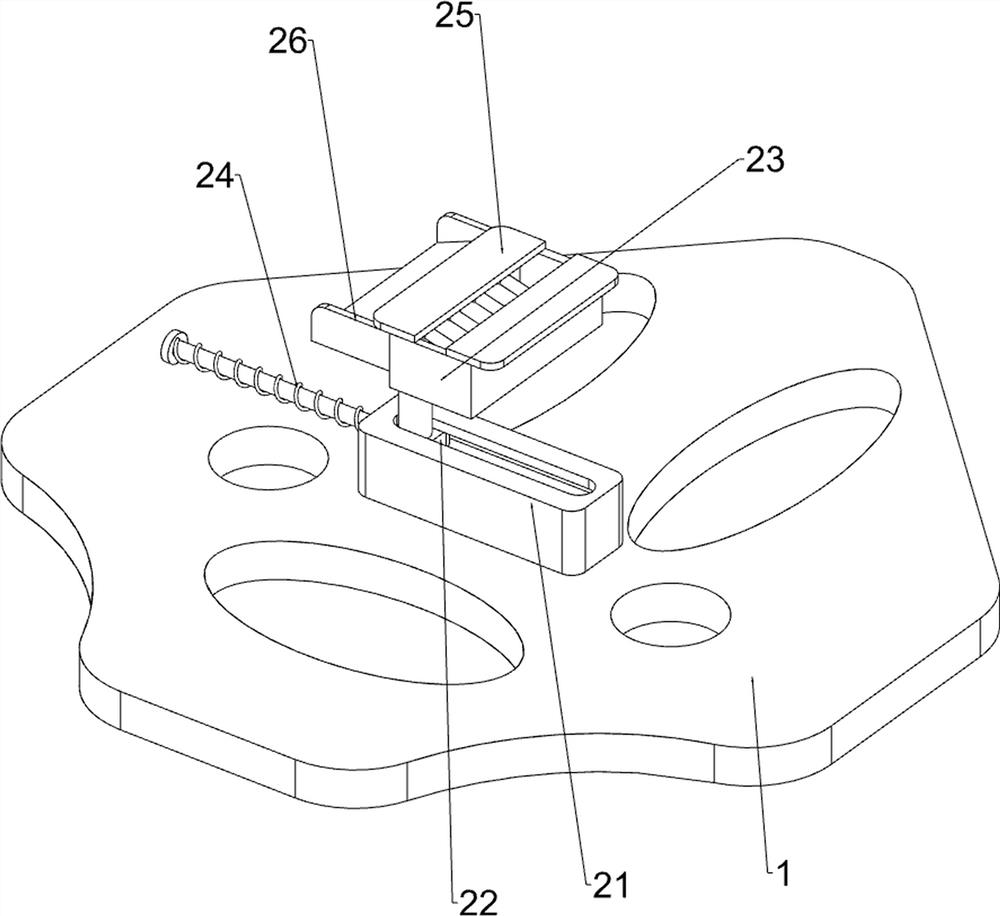

Steel plate surface painting equipment for metal processing

PendingCN112742648ARealize the clamping effectRealize the blanking effectGrinding carriagesSpray boothsSteel platesMetal working

The invention relates to painting equipment, in particular to steel plate surface painting equipment for metal processing. According to the steel plate surface painting equipment for metal processing, discharging is uniform, and automatic painting and automatic stirring painting are achieved. The steel plate surface painting equipment for metal processing comprises a first fixing plate, a collecting box, a clamping mechanism and a discharging mechanism; rails are arranged at the left side and the right side of the first fixing plate; the collecting box is arranged at the upper middle part of the first fixing plate; the clamping mechanism is arranged at the upper part of the collecting box; and the discharging mechanism is arranged on the first fixing plate. According to the steel plate surface painting equipment, by loosening clamping blocks and resetting a first spring, the two clamping blocks are driven to move oppositely, the clamping blocks make contact with a steel plate, the steel plate is clamped by the clamping blocks, and the clamping effect is achieved.

Owner:周成建

Multistage sieving machine for high-reflectivity powder paint sieve residue measuring

InactiveCN112588578ARealize the rotation effectRealize the collection effectSievingScreeningHigh reflectivityStructural engineering

The invention relates to a sieving machine, in particular to a multistage sieving machine for high-reflectivity powder paint sieve residue measuring. The invention provides the multistage sieving machine for high-reflectivity powder paint sieve residue measuring, which is better in shockproof effect, higher in safety coefficient and more in sieving times. The multistage sieving machine for high-reflectivity powder paint sieve residue measuring comprises a bottom plate, second mounting frames, a sieving mechanism and a pushing-out mechanism, wherein first mounting frames are arranged at left and right sides on the bottom plate; the second mounting frames are arranged on left and right parts of the right side of the bottom plate; the sieving mechanism is connected between the two first mounting frames; and the pushing-out mechanism is arranged on the sieving mechanism. A pushing rod is forwards pushed to drive a scraping plate to move forwards, and a second spring is stretched, so that the scraping plate forwards pushes out the high-reflectivity powder paint on a sieving plate, and then the high-reflectivity powder paint is pushed into a through hole in the sieving plate, and thus, the pushing-out effect is realized.

Owner:九江昌顺新材料有限公司

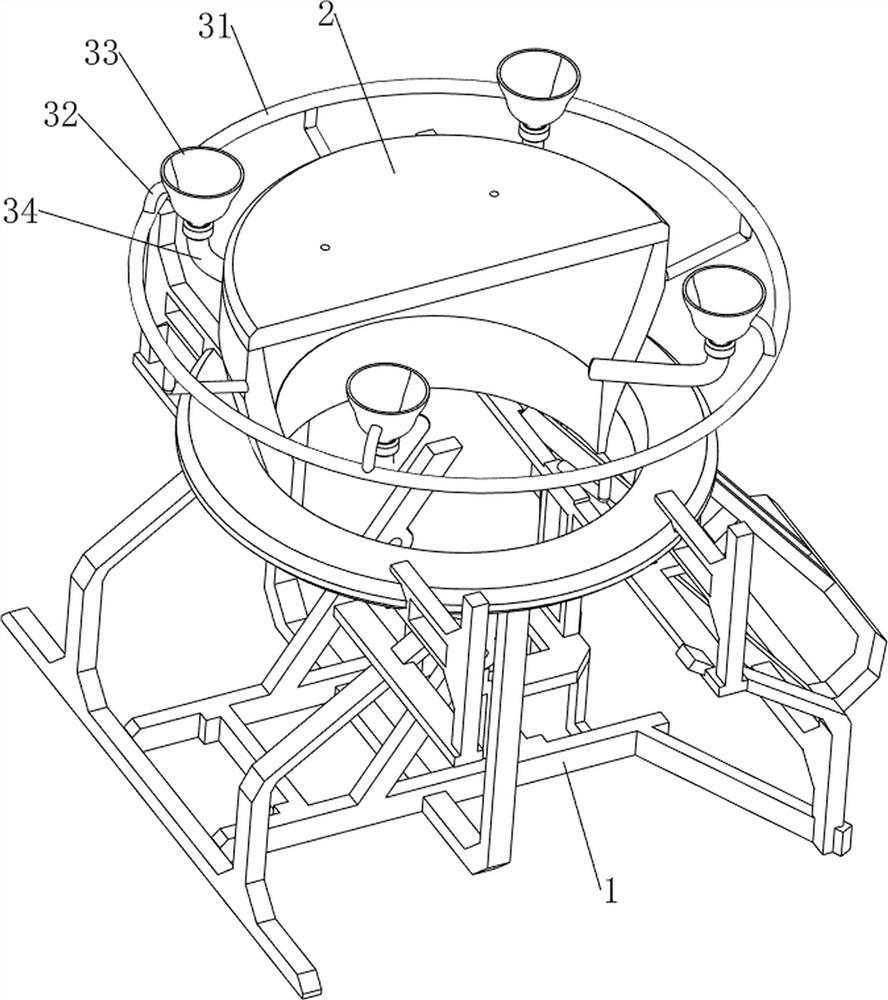

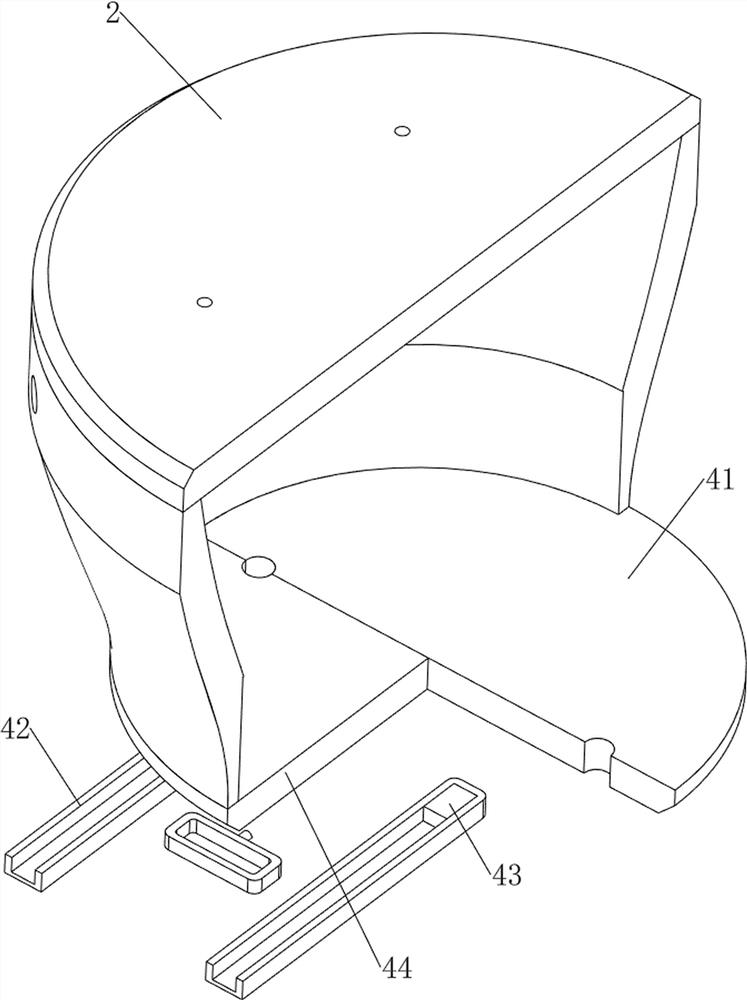

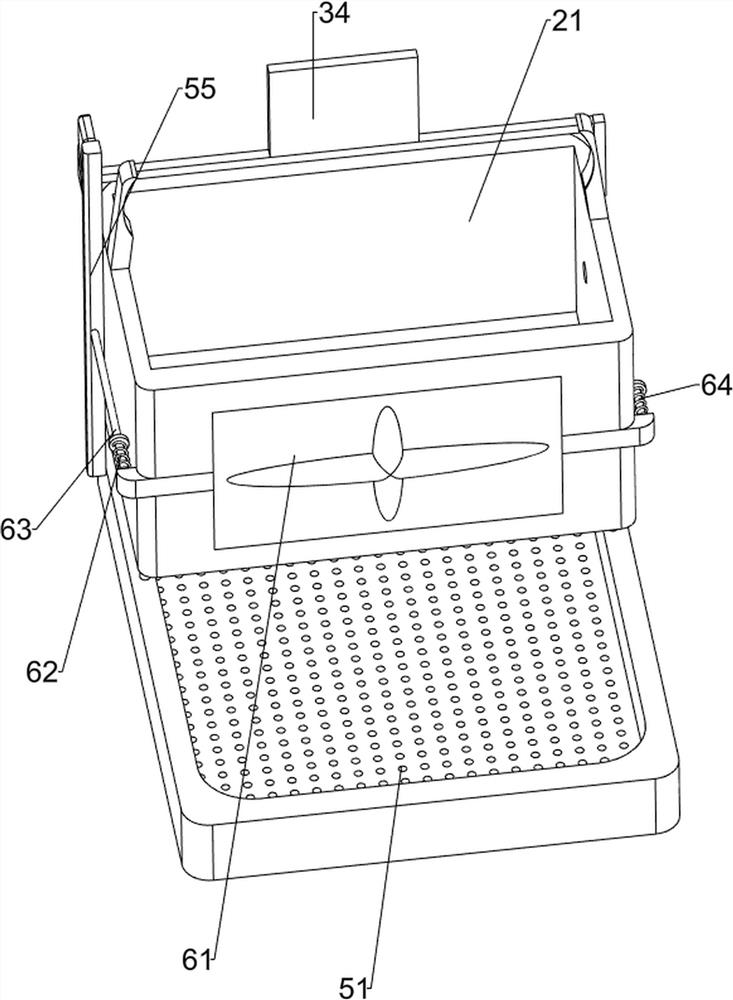

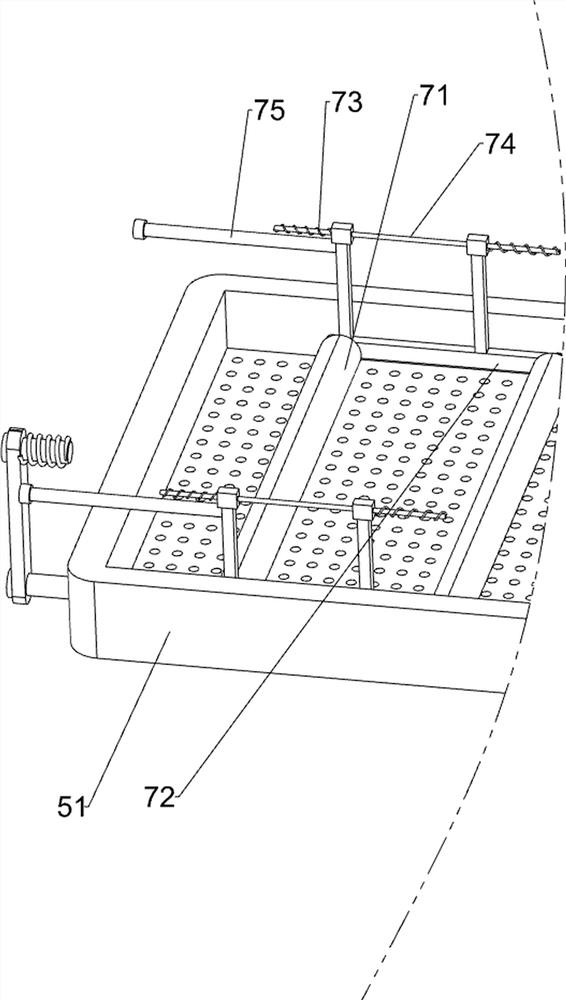

Extraction device for rare earth hydrometallurgy

InactiveCN113637845ARealize the blanking effectExtract pureRotary stirring mixersMixer accessoriesHydrometallurgyVALVE PORT

The invention relates to a separation device, in particular to an extraction device for rare earth hydrometallurgy. The extraction device for rare earth hydrometallurgy, provided by the invention, is relatively uniform in mixing, high in mixing efficiency and simple to operate. The extraction device for rare earth hydrometallurgy comprises a bottom plate and a first support, a first storage box, a feeding frame, a mounting plate, a second support and a first valve; the first support is arranged on the bottom plate; the first storage box is mounted at the top of the first support; the feeding frame is arranged on the upper side of the first storage box; the mounting plate is arranged on the upper portion of the first support, and the mounting plate is connected with the first storage box; the second support is arranged at the bottom of the first storage box; and the first valve is rotationally arranged on the second support. By arranging a material blocking mechanism, when people pull the material blocking mechanism, rare earth and extracting materials flow downwards into the lower side of the first storage box; the rare earth is separated in the first storage box; and then the discharging effect is achieved.

Owner:王鲜

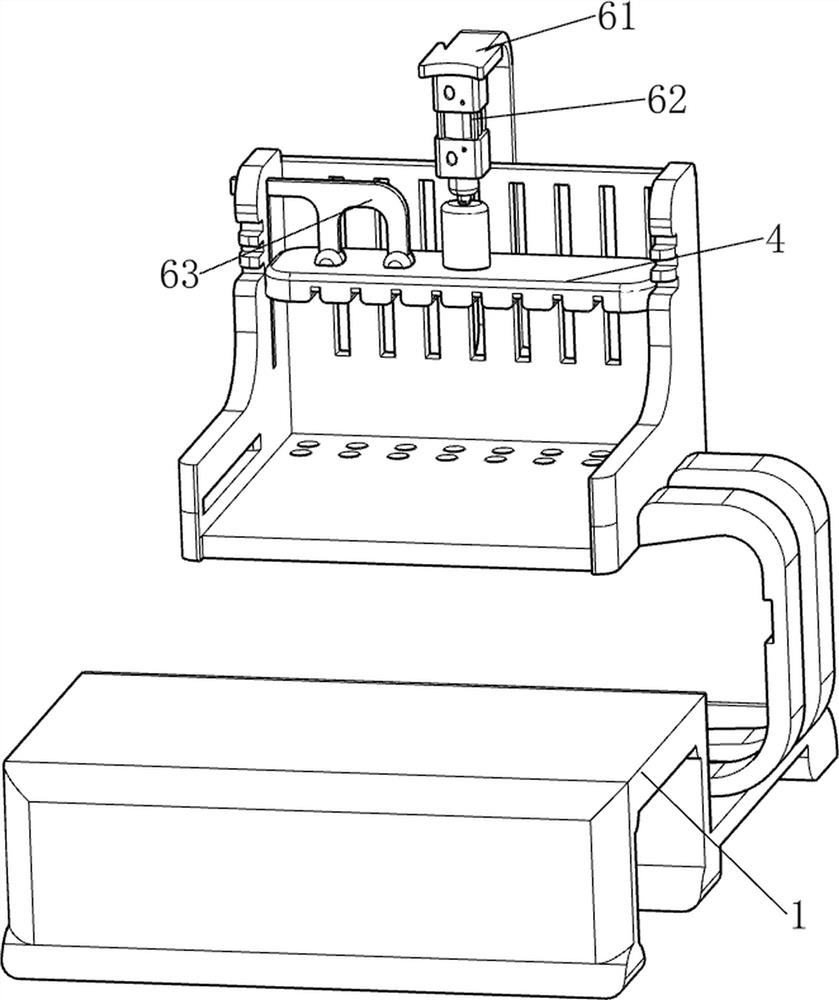

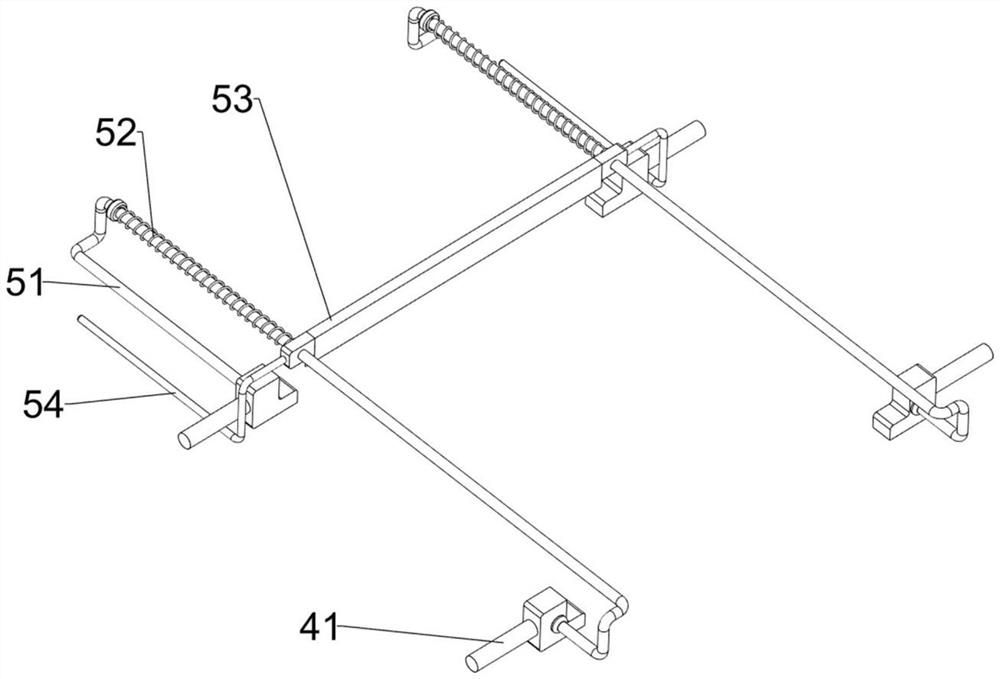

Industrial automatic dicing device for plywood

ActiveCN112743637ARealize the driving effectAchieve cutting effectProfiling/shaping machinesSupport planeManufacturing engineering

The invention relates to a dicing device, in particular to an industrial automatic dicing device for plywood, and aims to provide the industrial automatic dicing device which is used for the plywood and is convenient to operate, complete in cutting surface and relatively high in cutting quality. The industrial automatic dicing device for the plywood comprises a base, first fixing frames, a pushing mechanism and a cutting mechanism; a supporting frame is arranged on the base; the two first fixing frames are arranged on one side of the base and are connected with the supporting frame; the pushing mechanism is arranged at the top of the supporting frame; and the cutting mechanism is arranged between the two first fixing frames. An air cylinder telescopic rod extends backwards and drives a first pushing frame to move backwards, the first pushing frame pushes the plywood backwards, and the pushing effect is achieved.

Owner:临沂汇丰木业有限公司

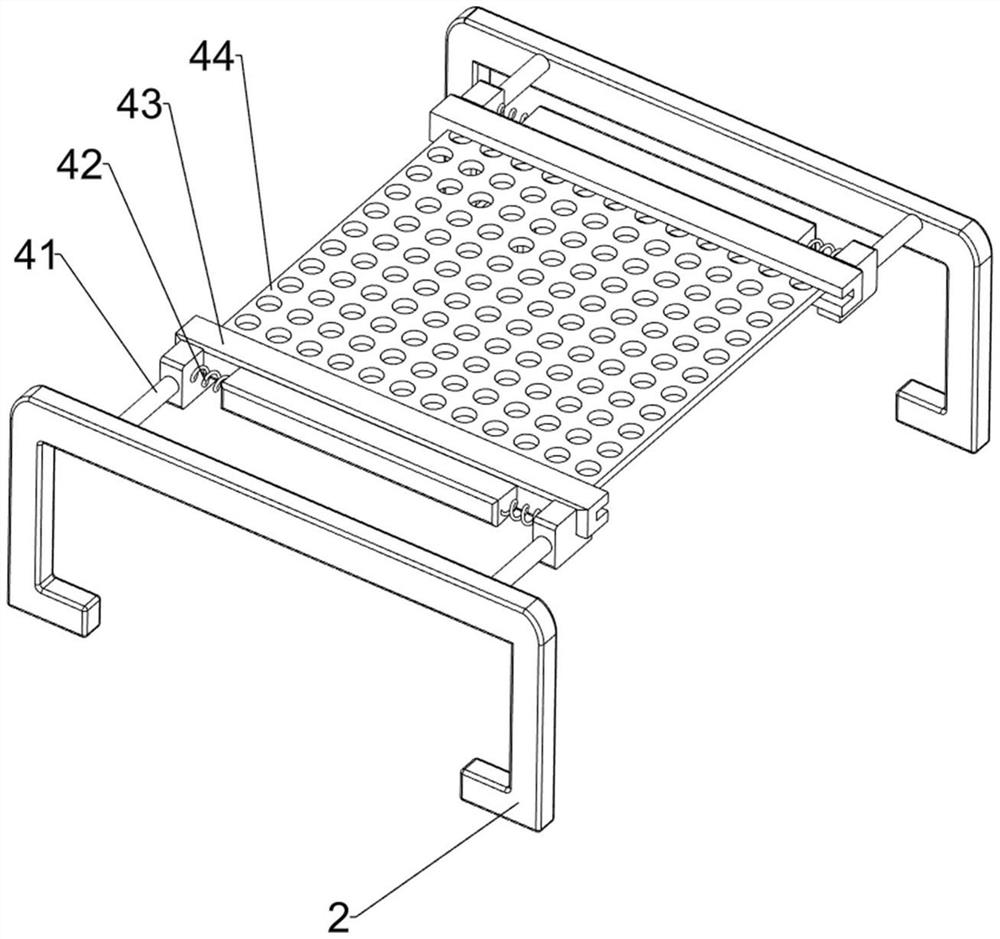

Staining agent uniformly-stirring smearing equipment for clinical laboratory

PendingCN112710521ARealize the effect of sending to the rightPlay a role in carrying chromosomesRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention relates to smearing equipment, in particular to staining agent uniformly-stirring smearing equipment for a clinical laboratory. The staining agent uniform stirring and smearing equipment for the clinical laboratory can improve the chromosome smearing uniformity and simplify the operation steps. The staining agent uniform stirring and smearing equipment for the clinical laboratory comprises: a bottom plate and a mold position frame, wherein the mold position frame is arranged on the bottom plate; a conveying mechanism which is arranged in the middle of the mold position frame; a material carrying table mechanism which is arranged on the conveying mechanism; and a discharging mechanism which is arranged on the upper part of the mold position frame and the material carrying table mechanism. The motor output shaft rotates to drive the first belt wheel assembly to rotate, so that the first transmission roller is driven to rotate, the flat belt is driven to transmit, the second transmission roller rotates along with the flat belt, and the effect of rightward conveying of chromosomes falling into the material carrying table mechanism is achieved.

Owner:聂宝林

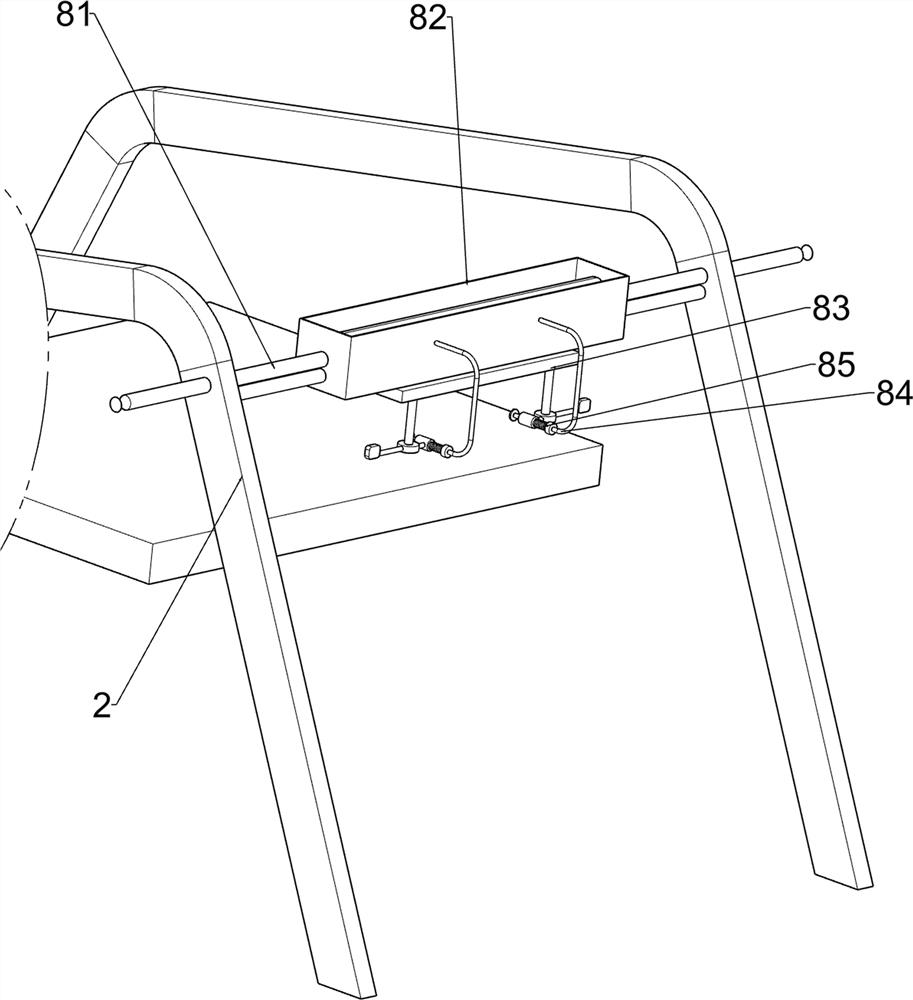

Wood wax oil applying device for wood floor for house decoration

ActiveCN112916291AAchieve fixationRealize the feeding effectLiquid surface applicatorsCoatingsPulp and paper industrySupport plane

The invention relates to a wax oil device, in particular to a wood wax oil applying device for a wood floor for house decoration. The wood wax oil applying device for wood floor for house decoration is few in operation actions, short in consumed time and capable of evenly applying wood wax oil. Th wood wax oil applying device for wood floor for house decoration comprises a base, first supporting frames, a fixing mechanism and a feeding mechanism; sliding rails are arranged on the left side and the right side of the base; the first supporting frames are arranged on the left portion and the right portion of the upper front side of the base; the fixing mechanism is arranged between the rear sides of the two sliding rails; and the feeding mechanism is arranged on the first supporting frames. According to the device, a clamp is pushed towards the outside of the device, a first spring stretches out, a wood floor is placed in the clamp, then the clamp is loosened, and the first spring returns, so that a fixing effect is achieved.

Owner:南京欣三人行网络科技有限公司

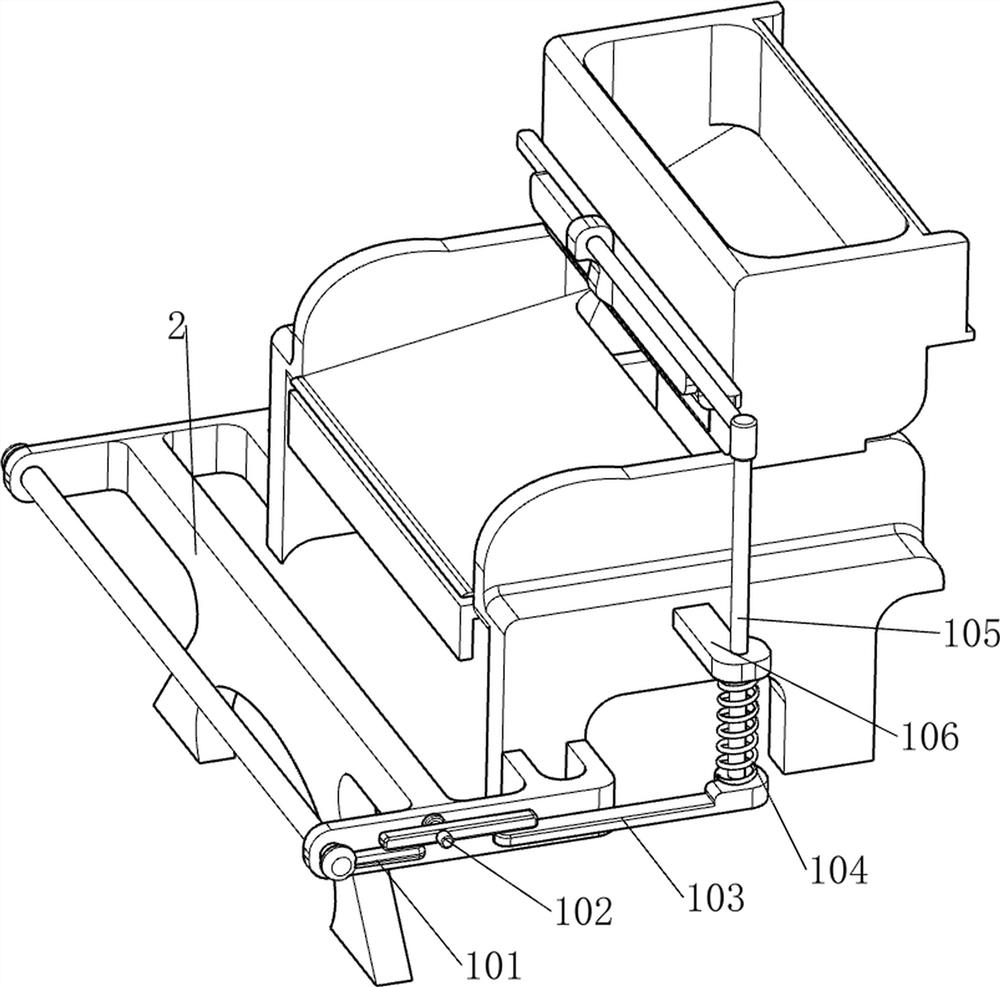

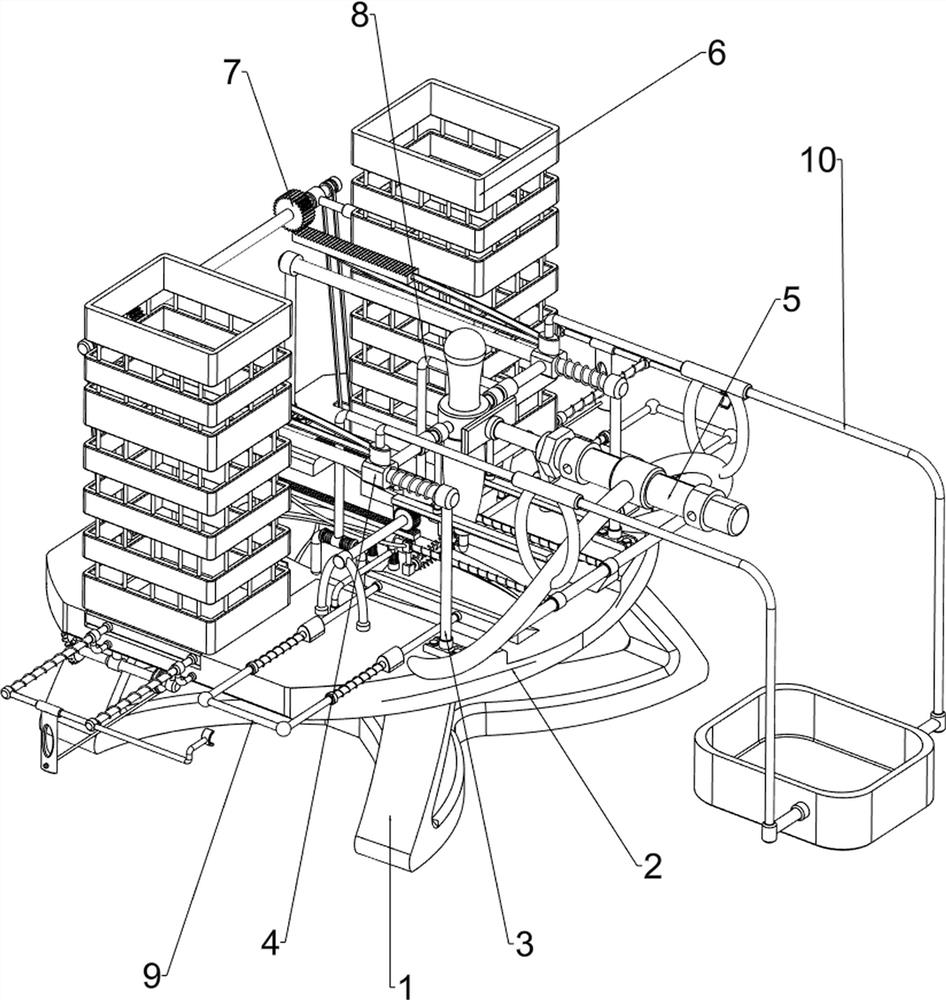

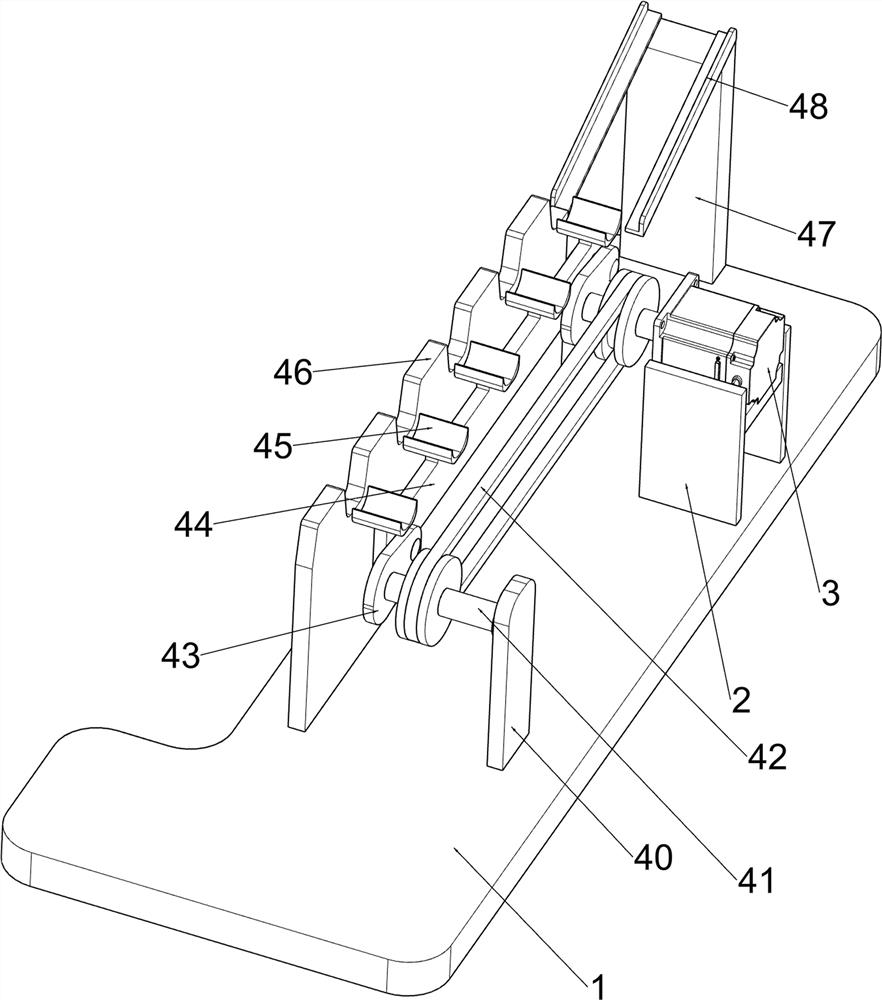

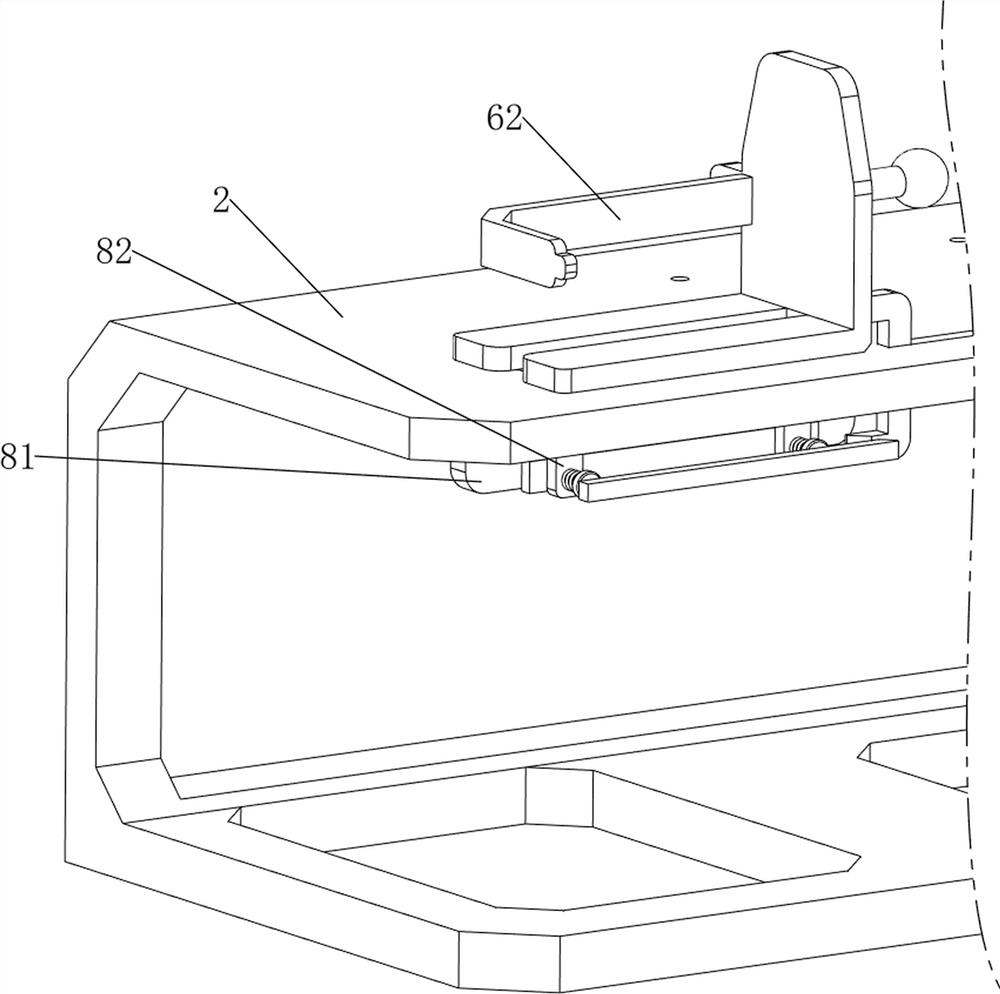

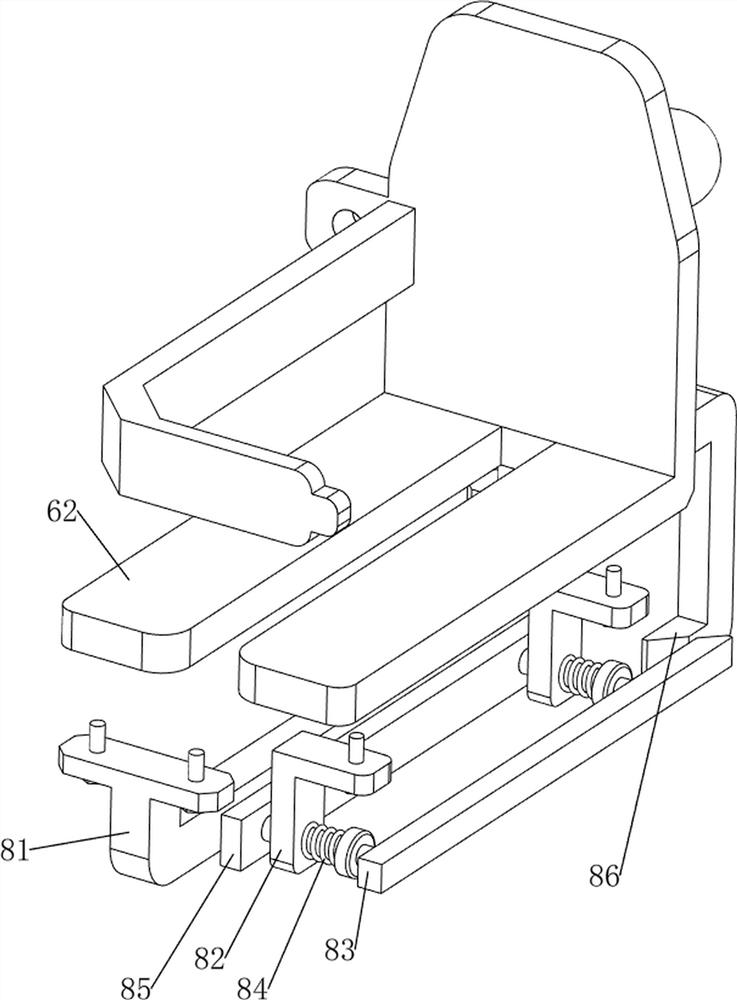

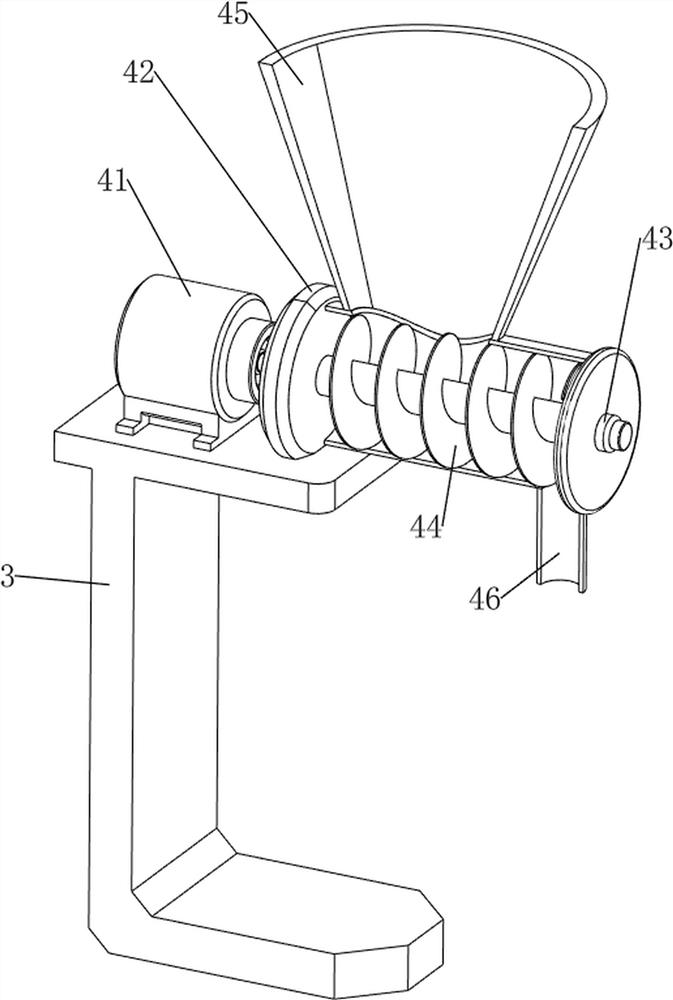

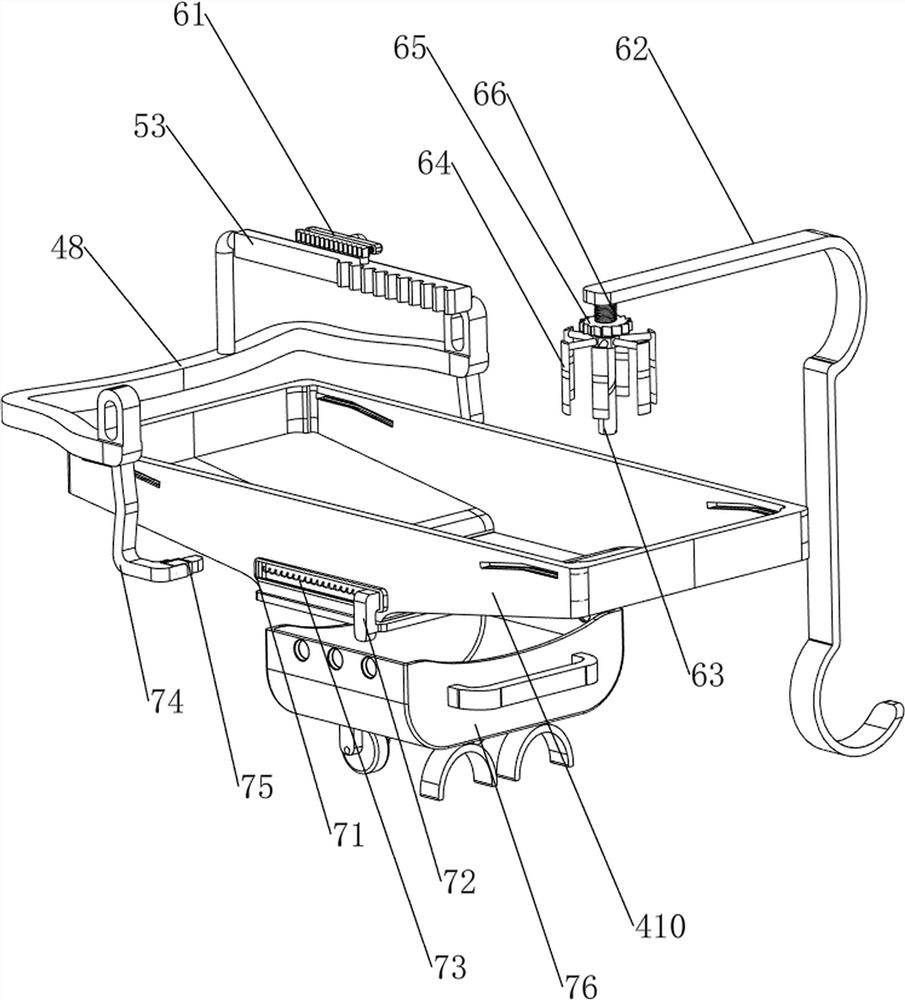

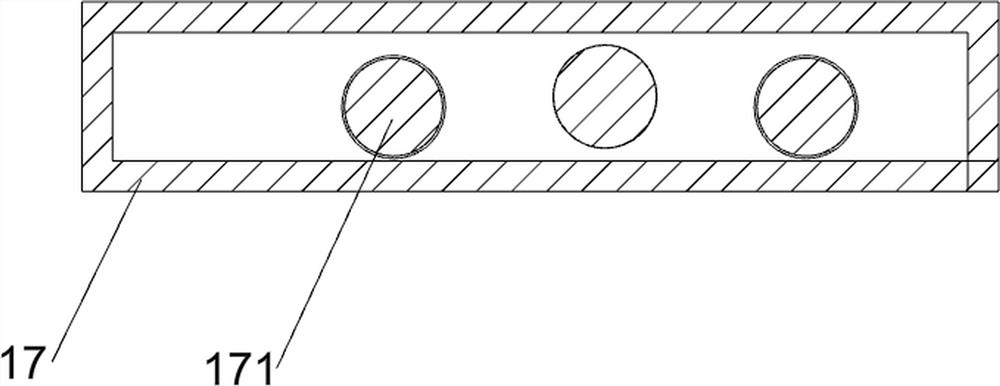

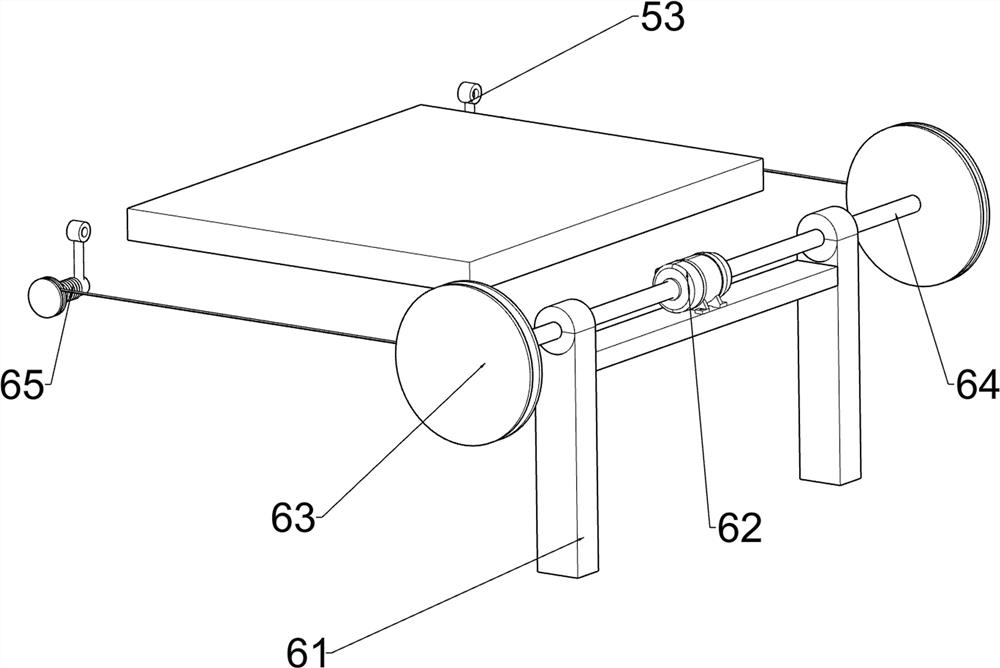

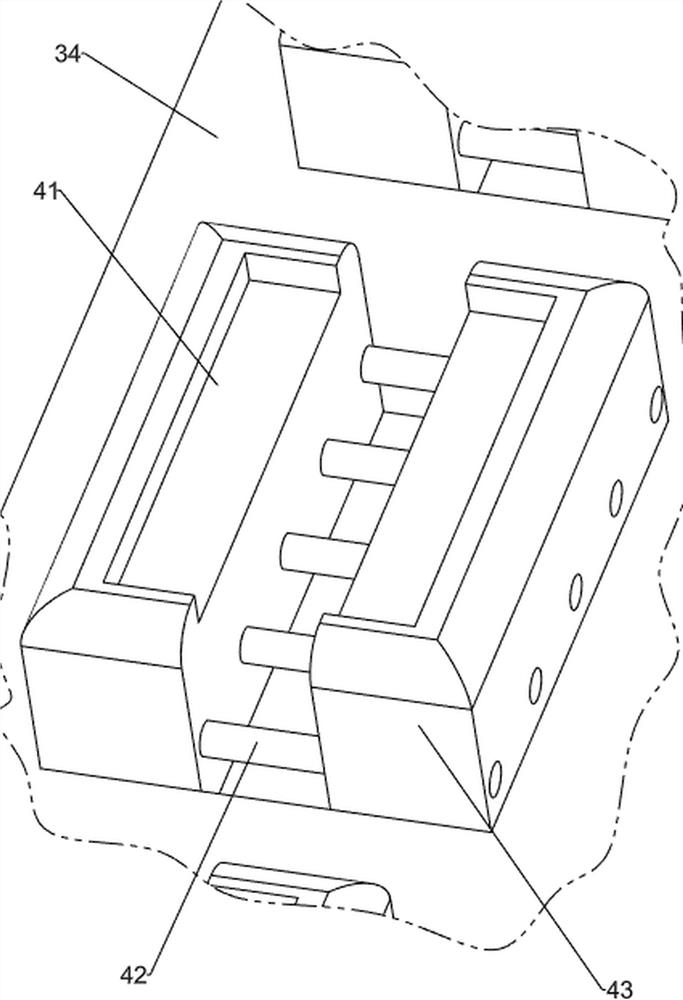

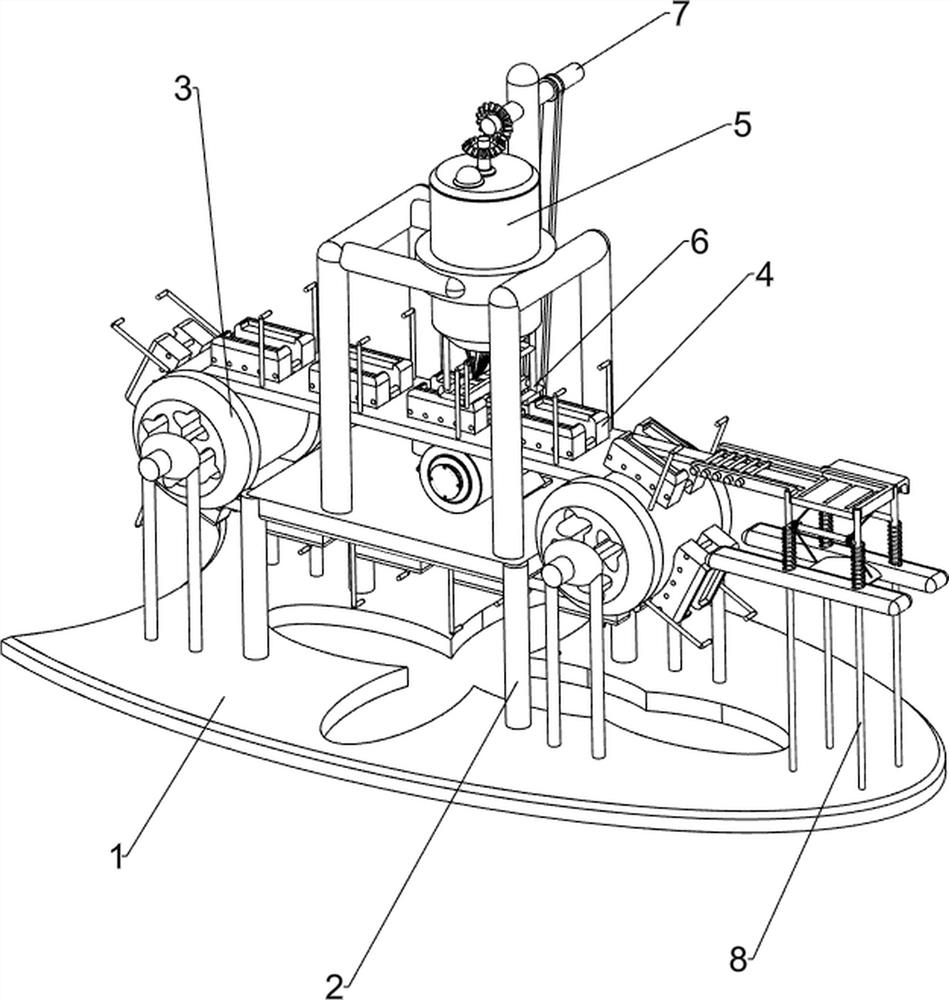

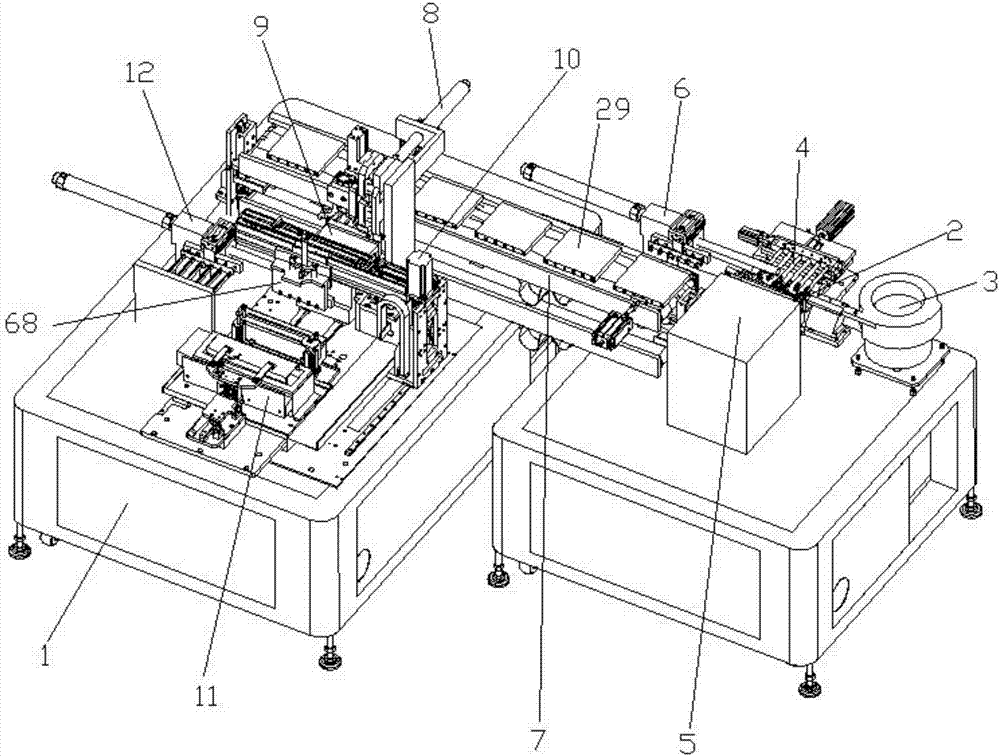

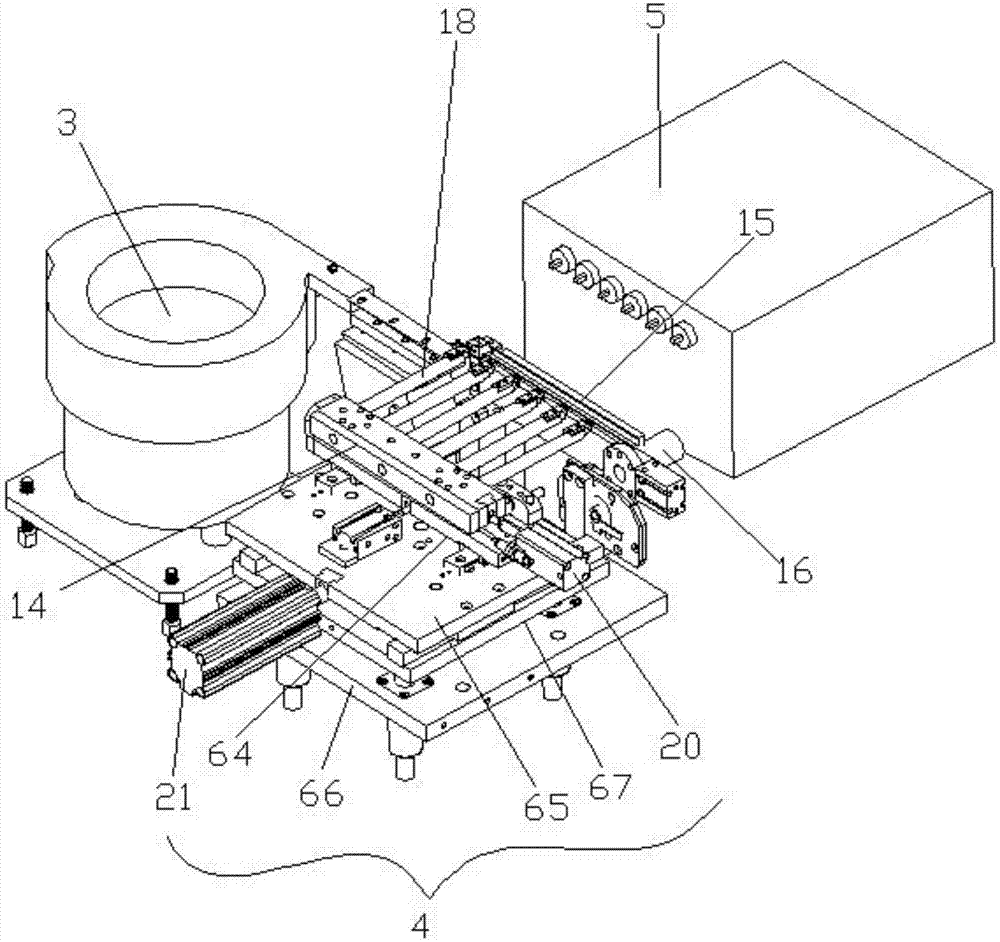

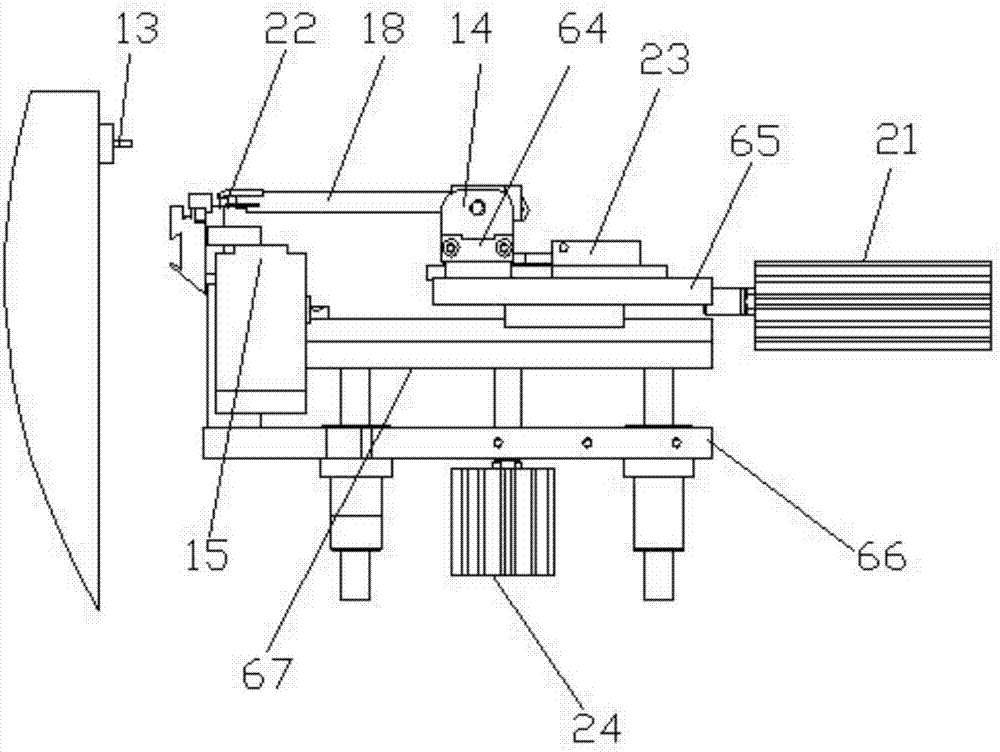

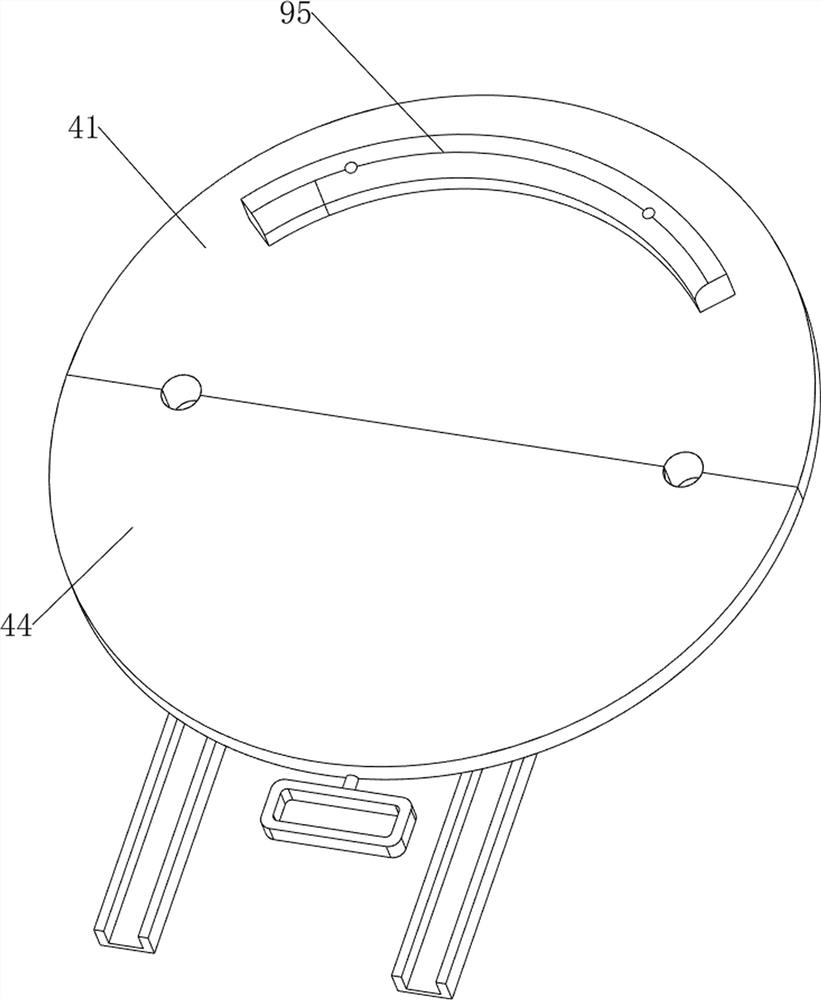

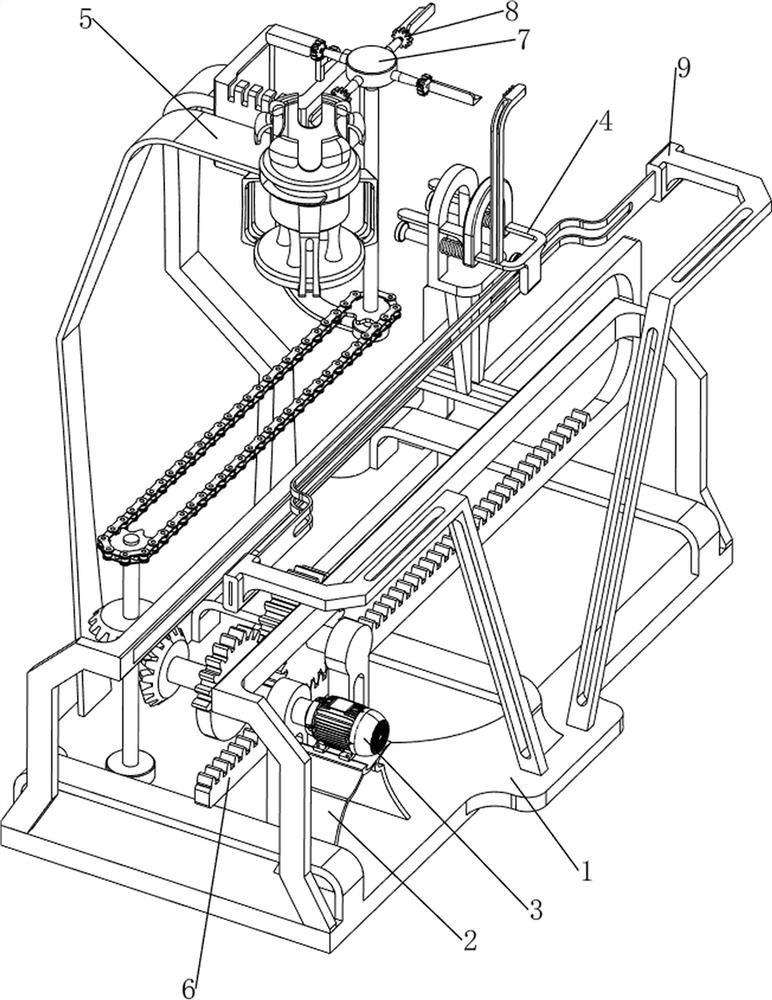

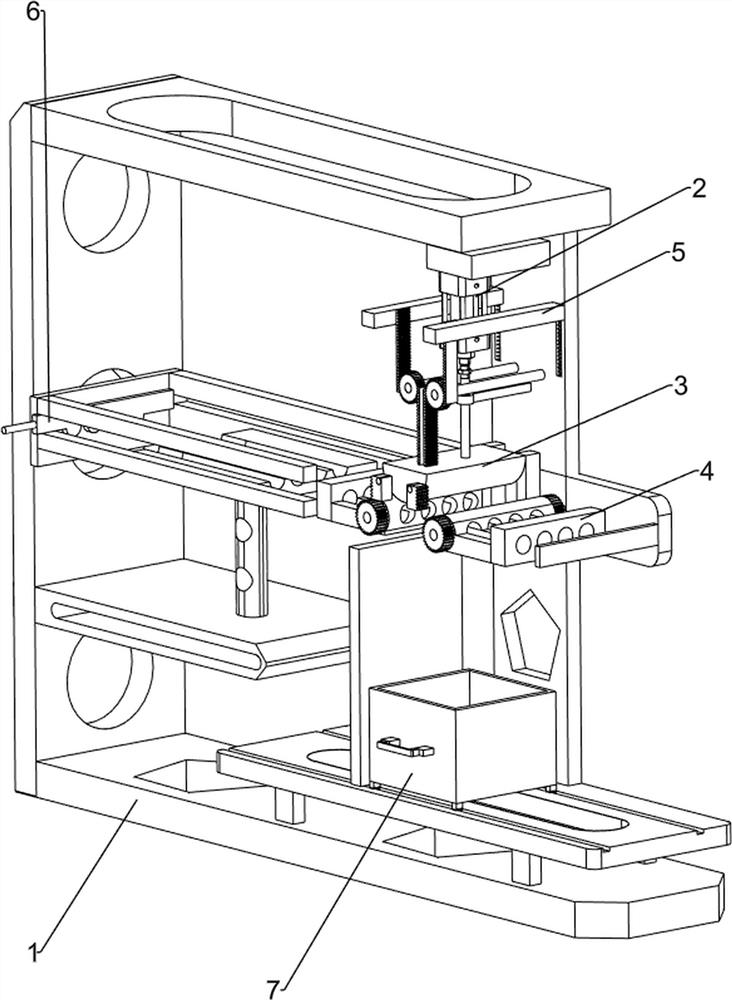

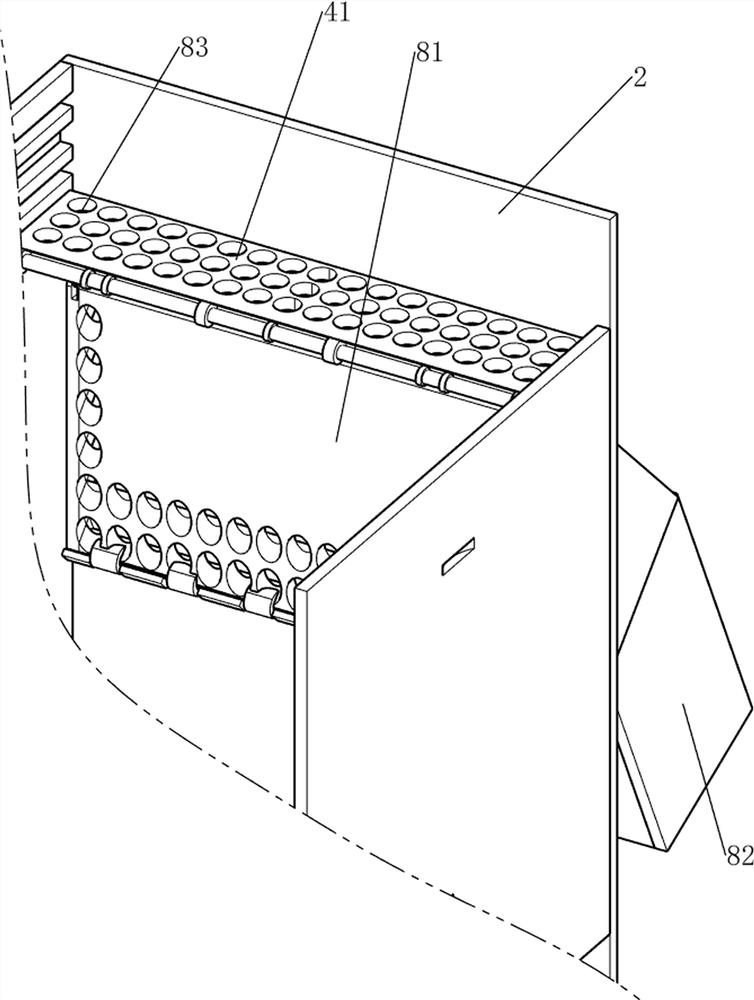

Full automated electronic coil tin dipping machine

ActiveCN107511555AReduce manual labor intensityImprove immersion tin efficiencySolder feeding devicesManipulatorButt joint

The invention discloses a full automated electronic coil tin dipping machine. The full automated electronic coil tin dipping machine comprises a control box. One end of the control box is provided with a vibrating disc. The discharging end of the vibrating disc is provided with a positioning rail. One side of the positioning rail is provided with a butt-joint clamping device. The other side of the positioning rail is provided with a butt-joint box. The upper portion of the butt-joint clamping device is provided with a loading and unloading manipulator. A conveying belt is arranged on the side edge of the loading and unloading manipulator. The conveying belt is provided with a tool bearing plate. The tool bearing plate is internally and evenly provided with material pipes which are used for storing an electronic coil and penetrate through the two end surfaces of the tool bearing plate. The other side of the conveying belt is provided with a material clamping manipulator used for conveying the tool bearing plate. The lower portion of the material clamping manipulator is provided with a material passing device used for conveying the electronic coil in the tool bearing plate to a tin dipping manipulator. The front end of the material passing device is provided with the tin dipping manipulator and a blanking manipulator. The other side of the tin dipping manipulator is provided with a tin dipping device. By means of the full automated electronic coil tin dipping machine, electronic coil fixed-point tin dipping is completed through mechanical full automation controlling, the tin dipping efficiency of the electronic coil is greatly improved, the labor cost is reduced, and the producing efficiency is improved.

Owner:太仓新兰电子有限公司

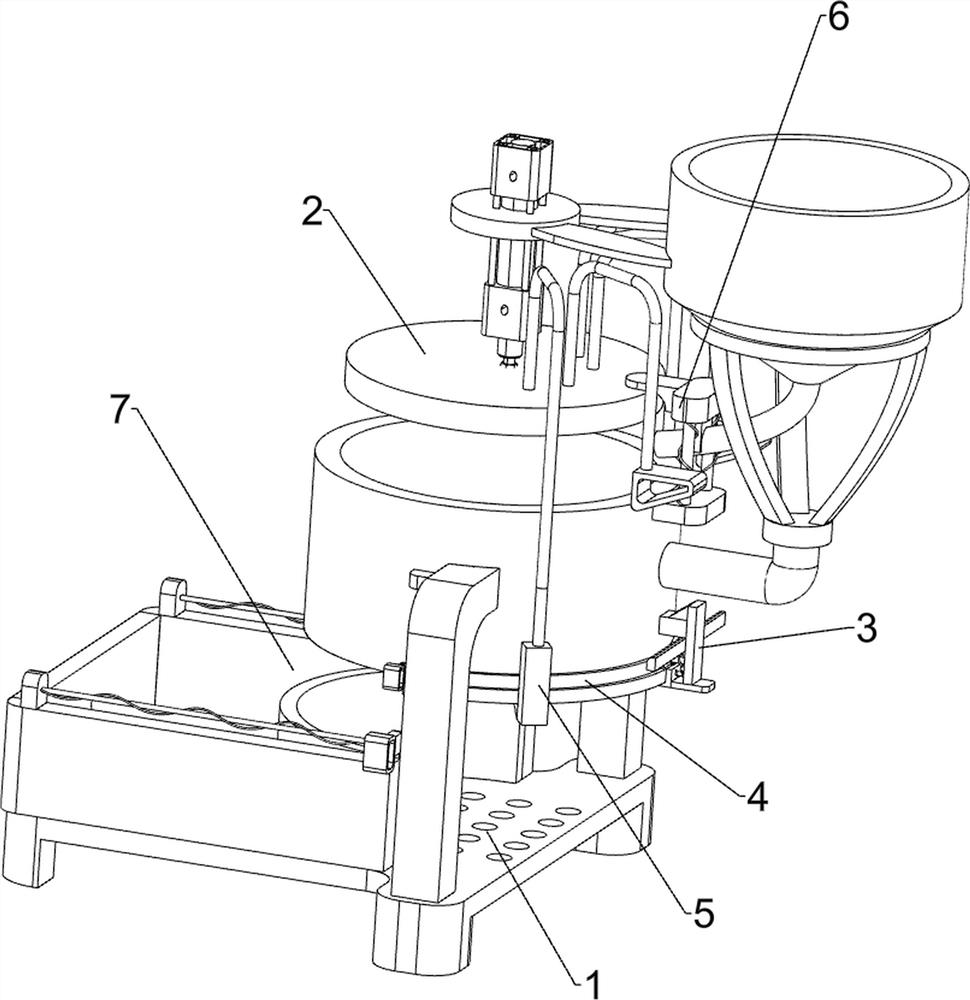

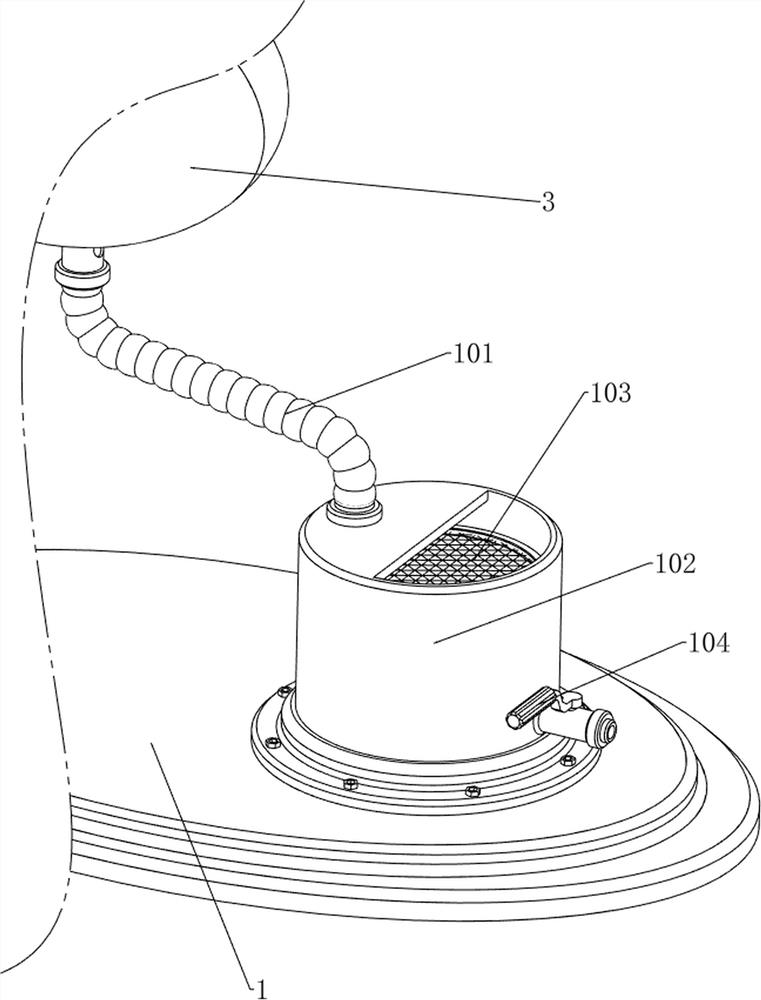

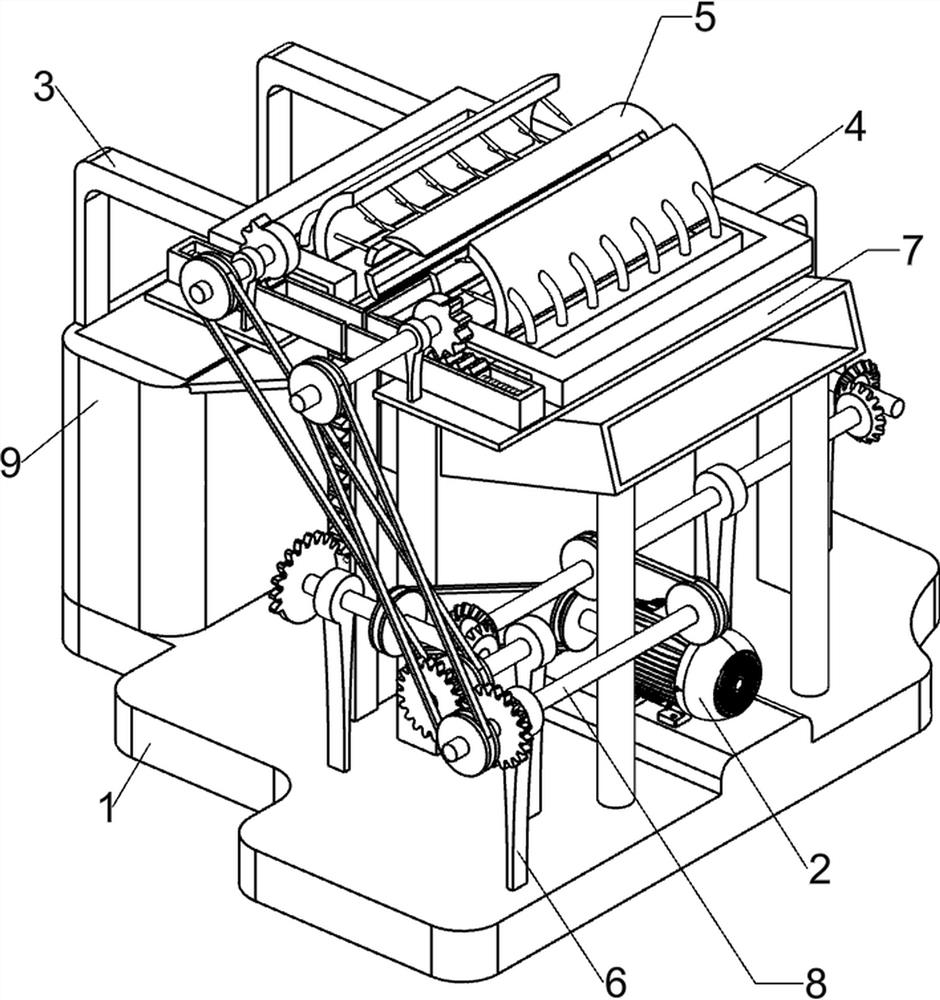

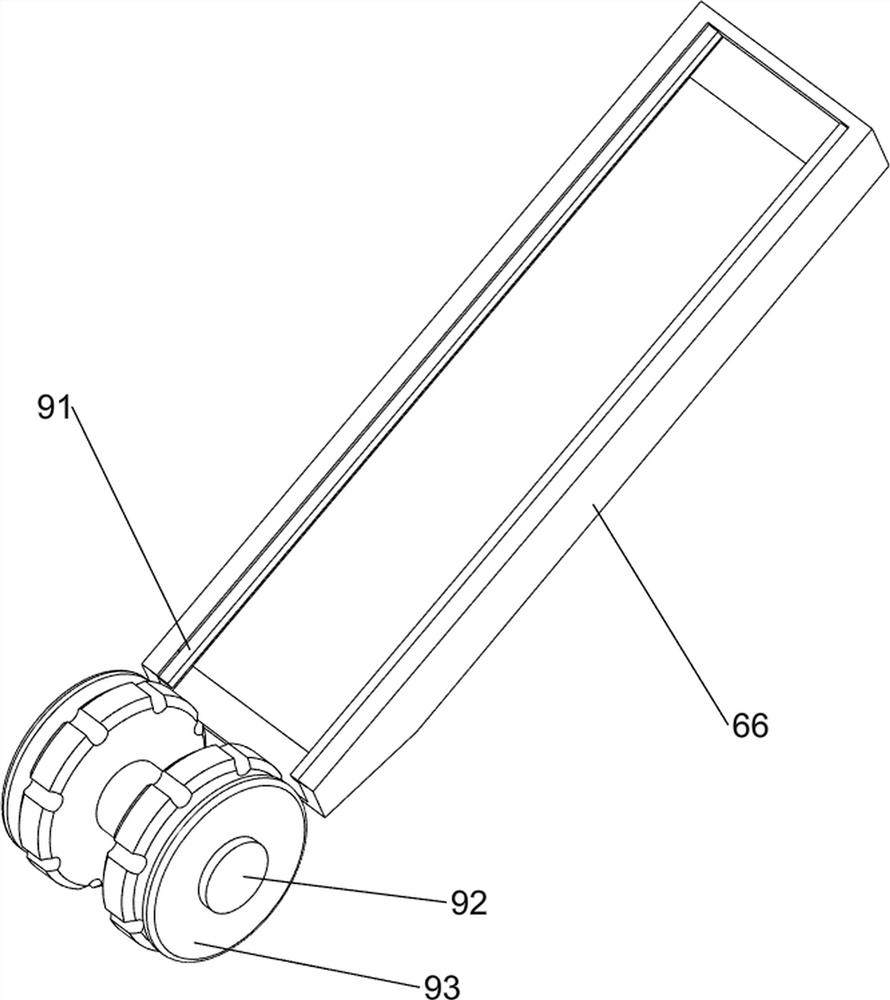

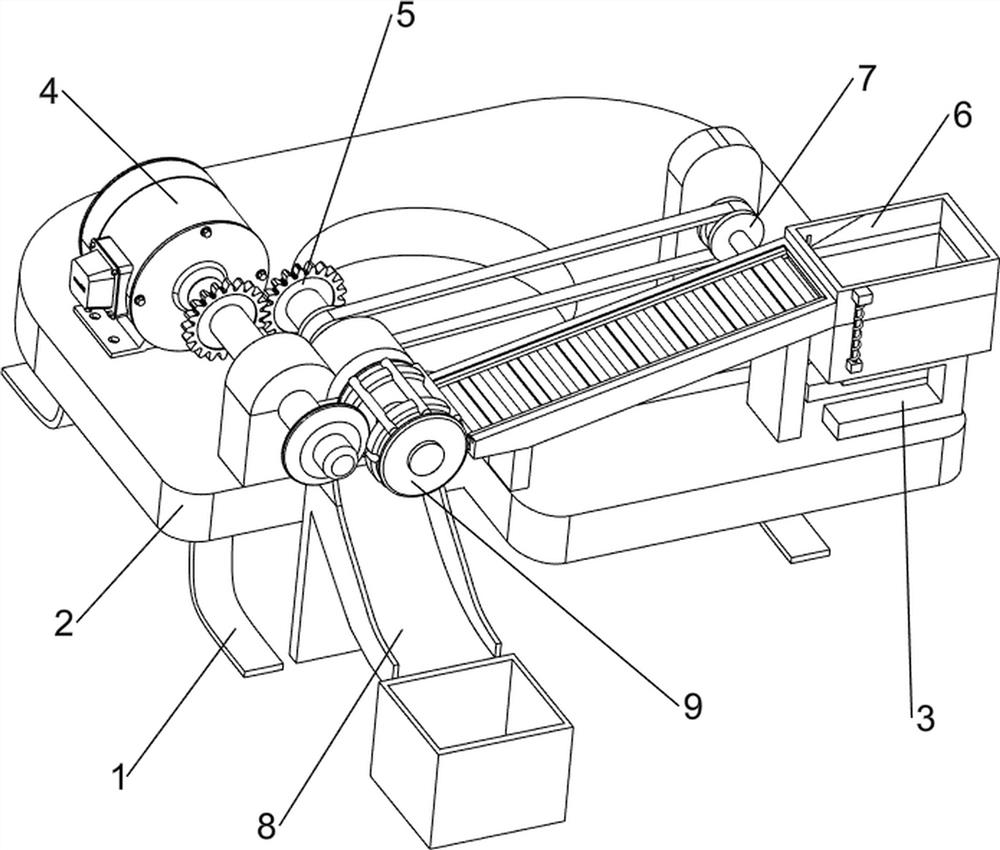

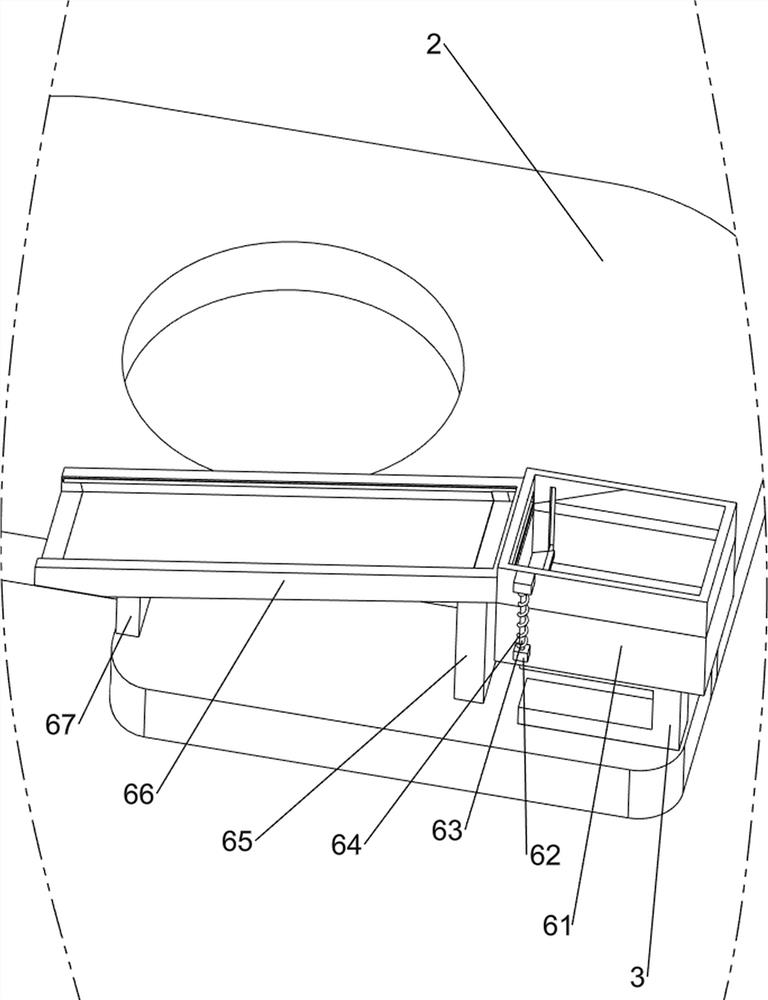

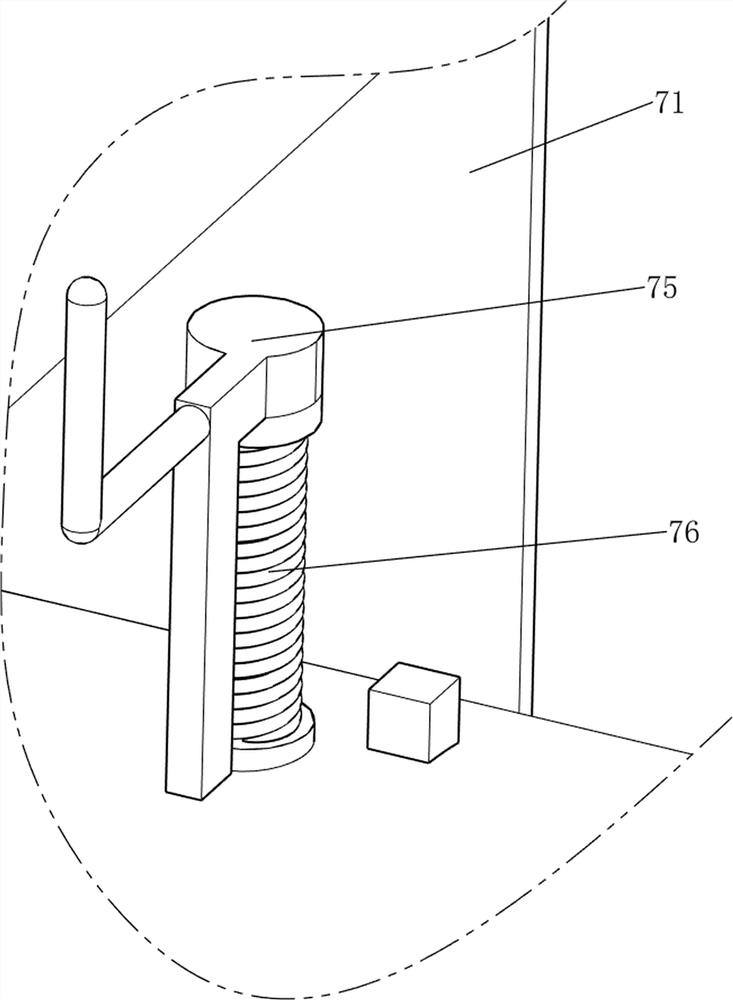

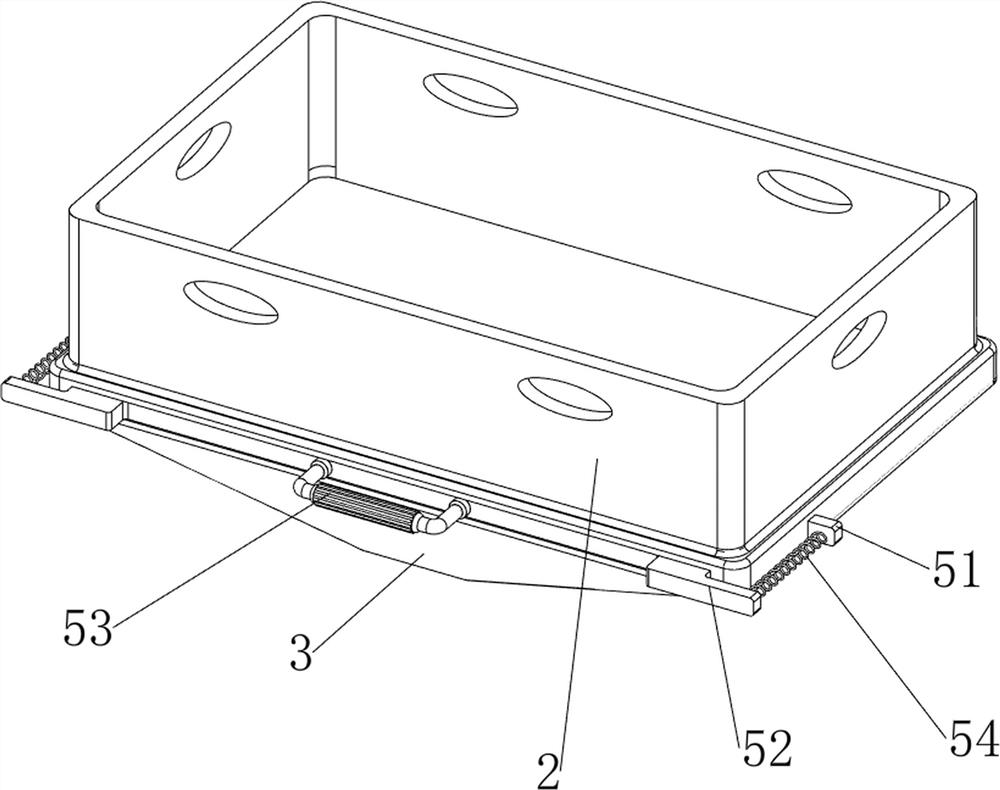

Lifting type crushing equipment for flour processing

PendingCN113351307ARealize the effect of guiding materialRealize the blanking effectGrain treatmentsStructural engineeringManufacturing engineering

The invention relates to crushing equipment, and particularly relates to lifting type crushing equipment for flour processing. The lifting type crushing equipment for flour processing is good in crushing effect, low in cost and wide in applicability. The lifting type crushing equipment for flour processing comprises a supporting frame, a processing barrel, a material guiding mechanism, a discharging mechanism and a crushing mechanism, and the processing barrel is arranged on the supporting frame; the material guiding mechanism is arranged on the outer wall of the upper side of the processing barrel; the discharging mechanism is arranged between the bottom of the processing barrel and the supporting frame; and the crushing mechanism is arranged on the discharging mechanism. According to the lifting type crushing equipment for flour processing, through the arrangement of the material guiding mechanism, people pour flour into a material guiding hopper, so that the flour flows to a material guiding pipe through the material guiding hopper and falls into the discharging mechanism from the material guiding pipe, and the material guiding effect is achieved; and through the arrangement of the discharging mechanism, people pull a moving plate to move leftwards so as to drive a sliding block to slide leftwards, the moving plate moves leftwards so that flour can fall into a collecting frame below, and the discharging effect is achieved.

Owner:温秋英

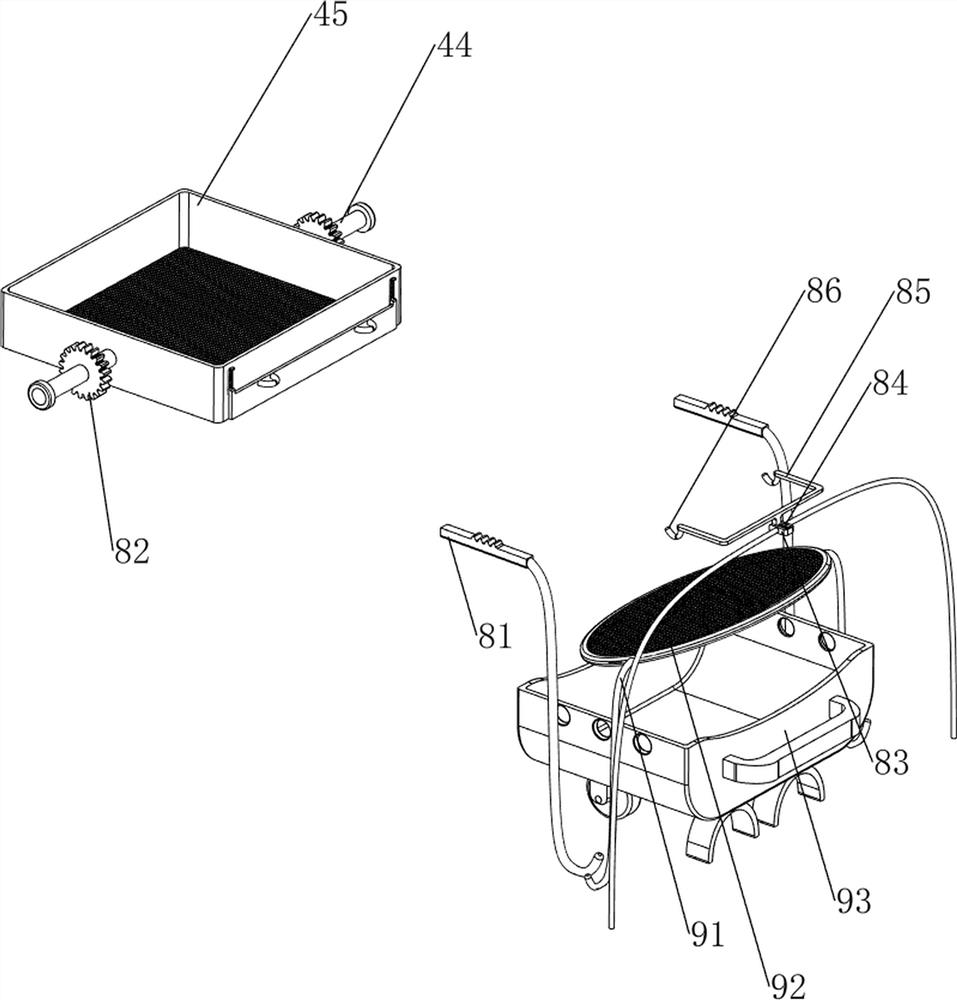

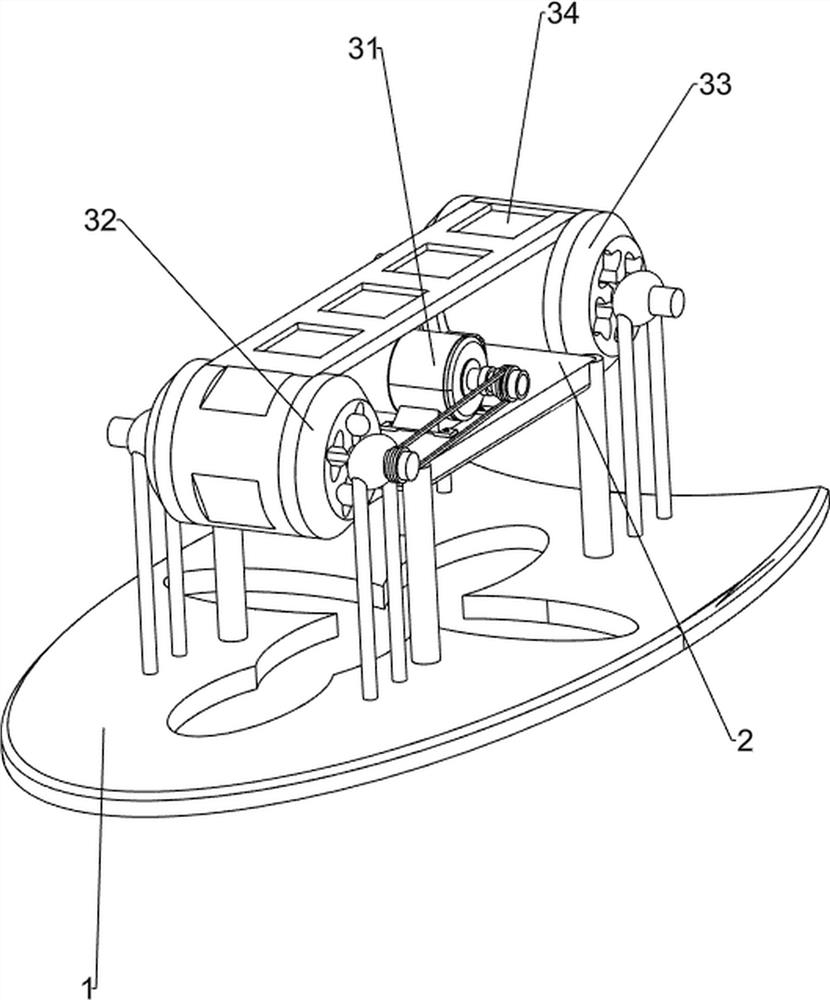

Potato starch rapid forming equipment for food processing

PendingCN113368995AAchieving a shattering effectRealize the blanking effectSievingScreeningAgricultural sciencePotato starch

The invention relates to forming equipment, in particular to potato starch rapid forming equipment for food processing. The invention provides the potato starch rapid forming equipment for the food processing which is automation in roll, reduction in labor cost and high in powder output. The potato starch rapid forming equipment for the food processing comprises a supporting frame and a smashing mechanism and a first discharging mechanism. The smashing mechanism is arranged in the middle of the supporting frame; the first discharging mechanism is arranged on the upper side of the supporting frame. According to the potato starch rapid forming equipment for the food processing, a straight gear set drives a smashing shaft on the right side to rotate, the smashing shafts on the two sides rotate to smash potato crops, the potato crops are smashed into potato powder, and the smashing effect is achieved; a shifting block rotates to drive a first connecting rod to move upwards, so that a first baffle is driven to move upwards, a first elastic assembly is contracted, then a discharging port of a material box is opened, and due to the fact that the bottom of the material box is inclined, the potato crops can automatically fall into a smashing box, and the discharging effect is achieved.

Owner:万细凤

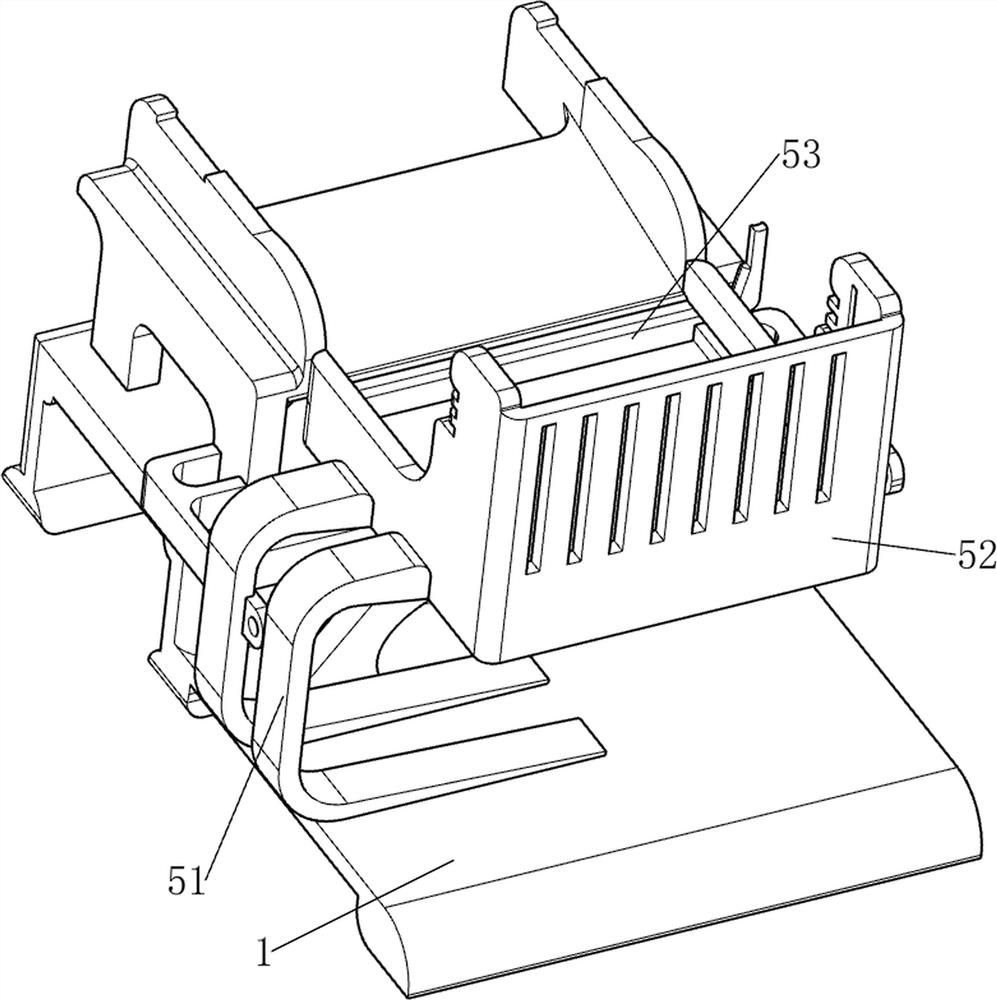

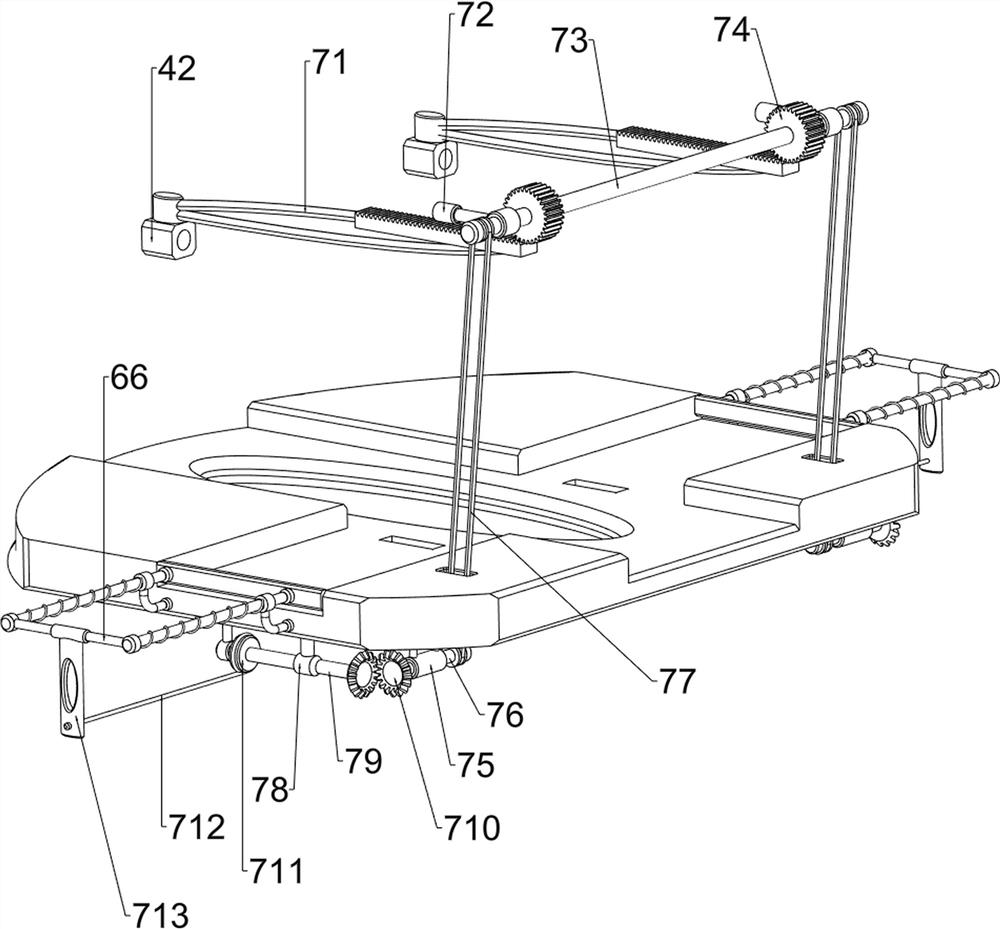

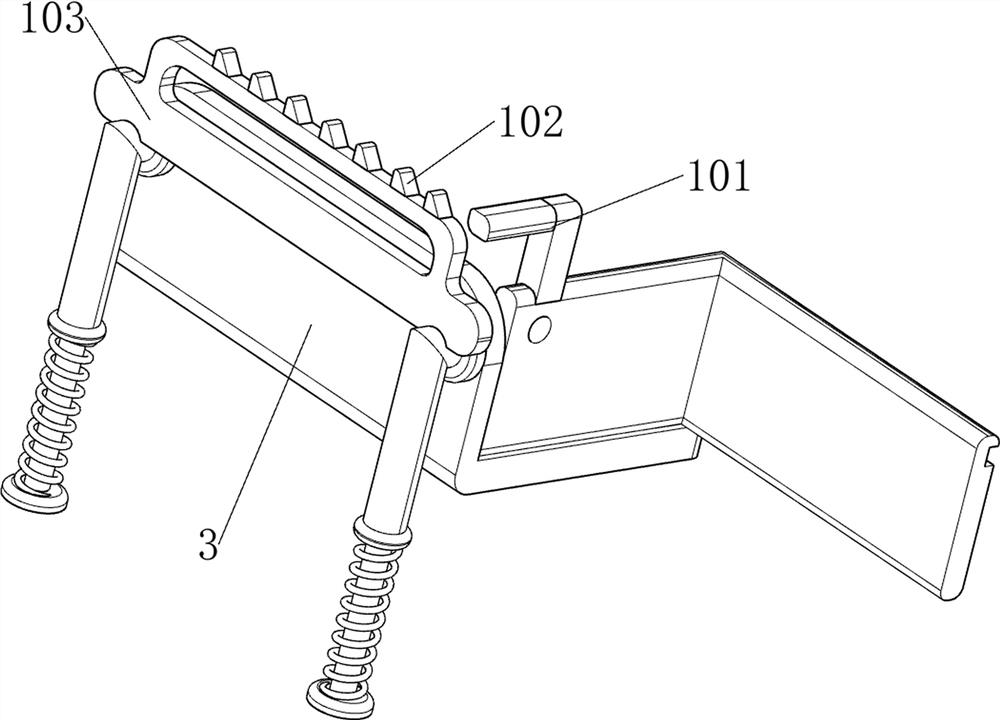

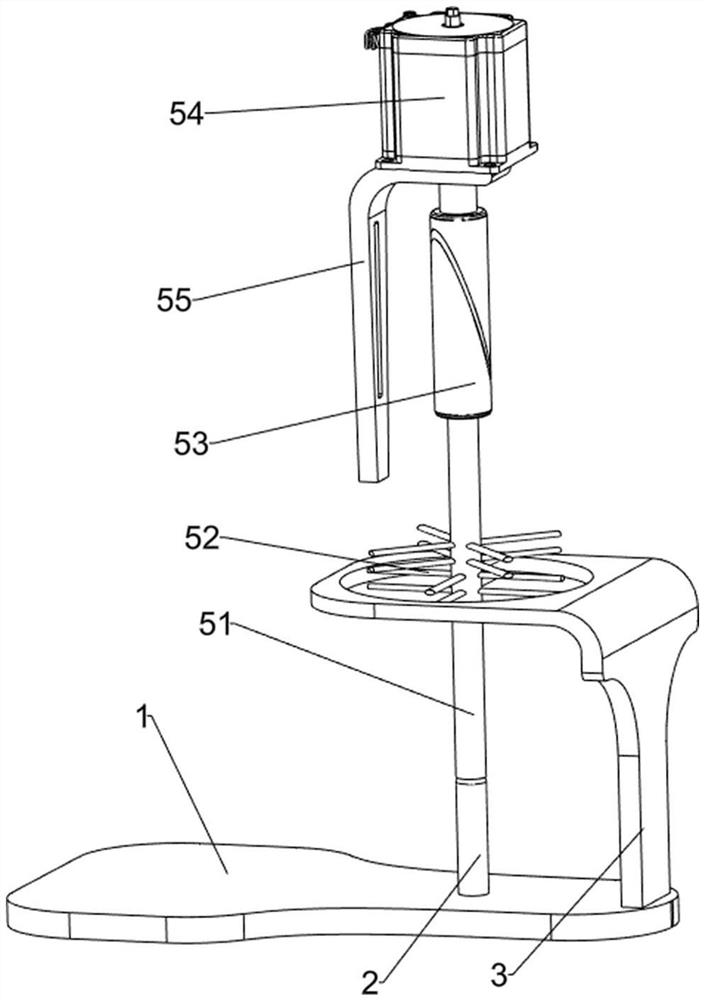

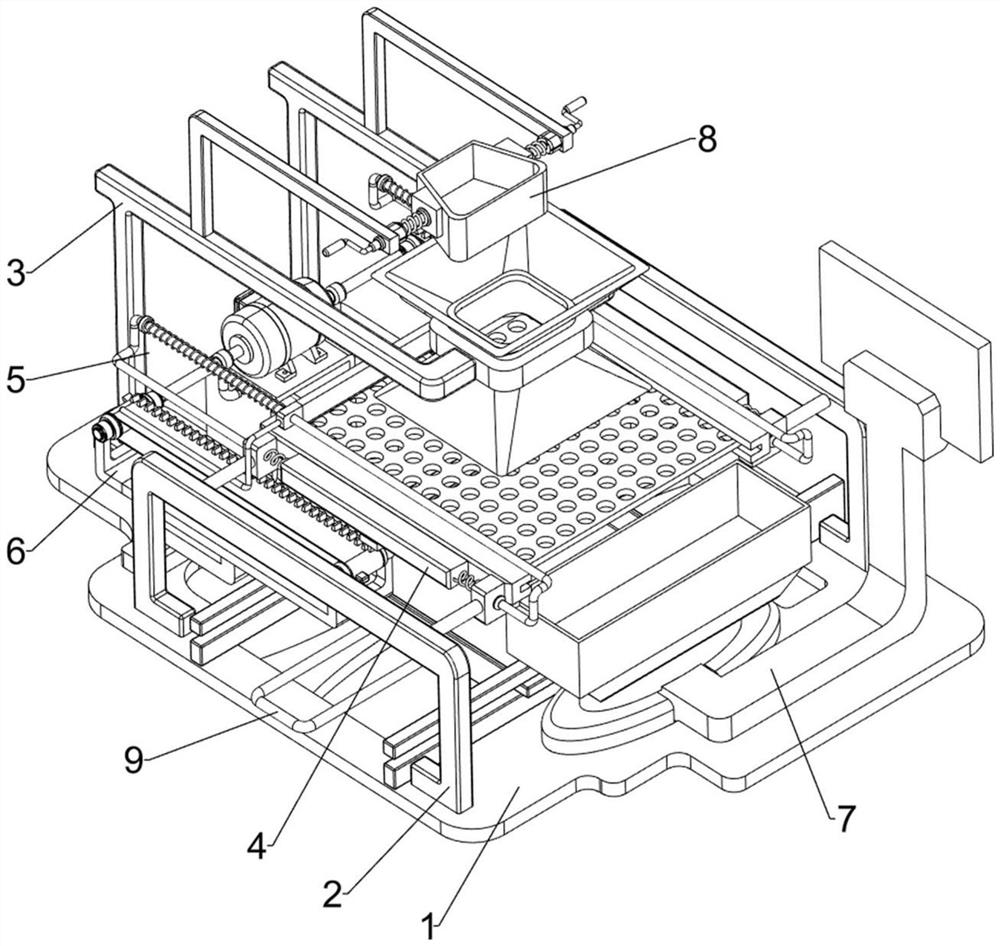

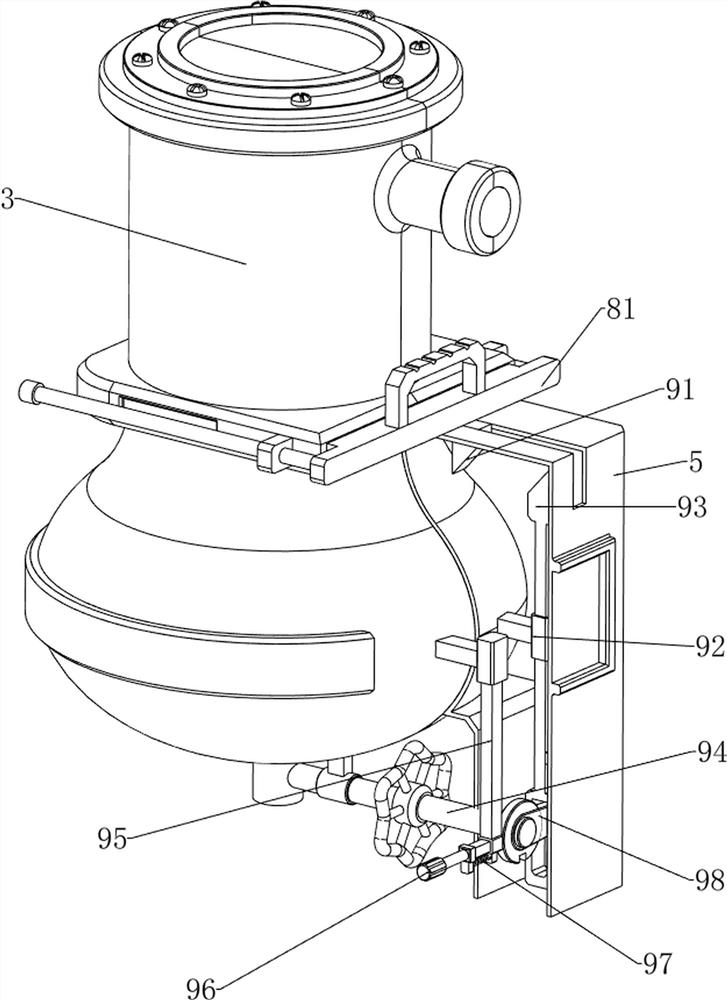

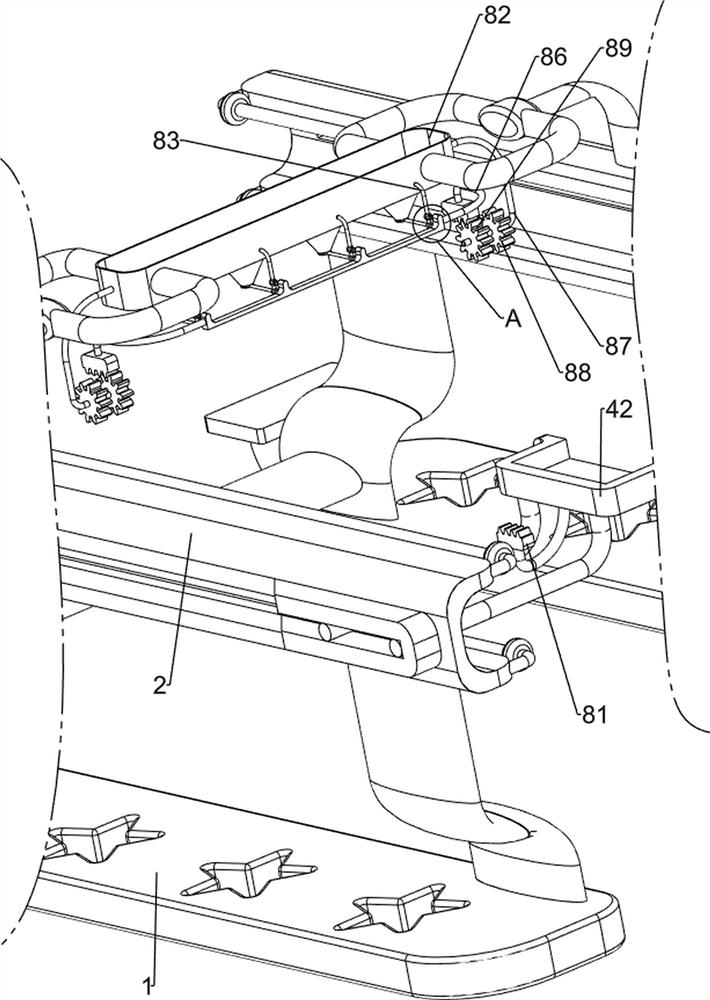

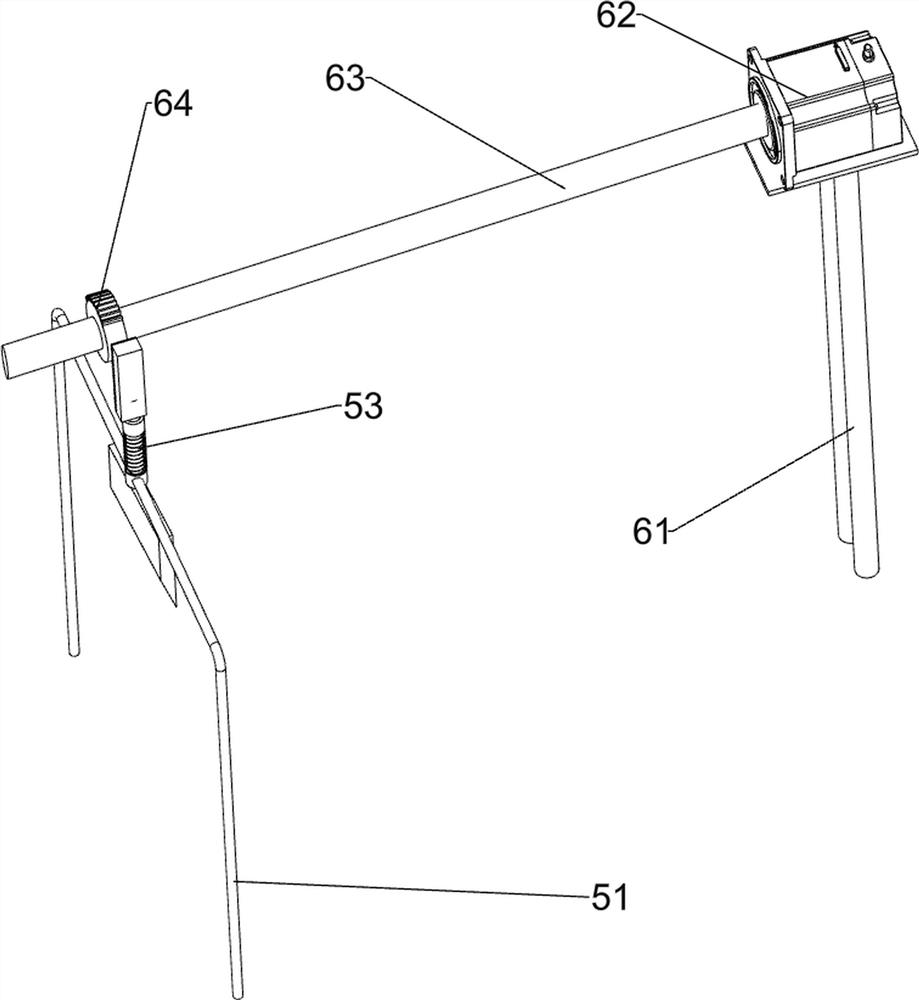

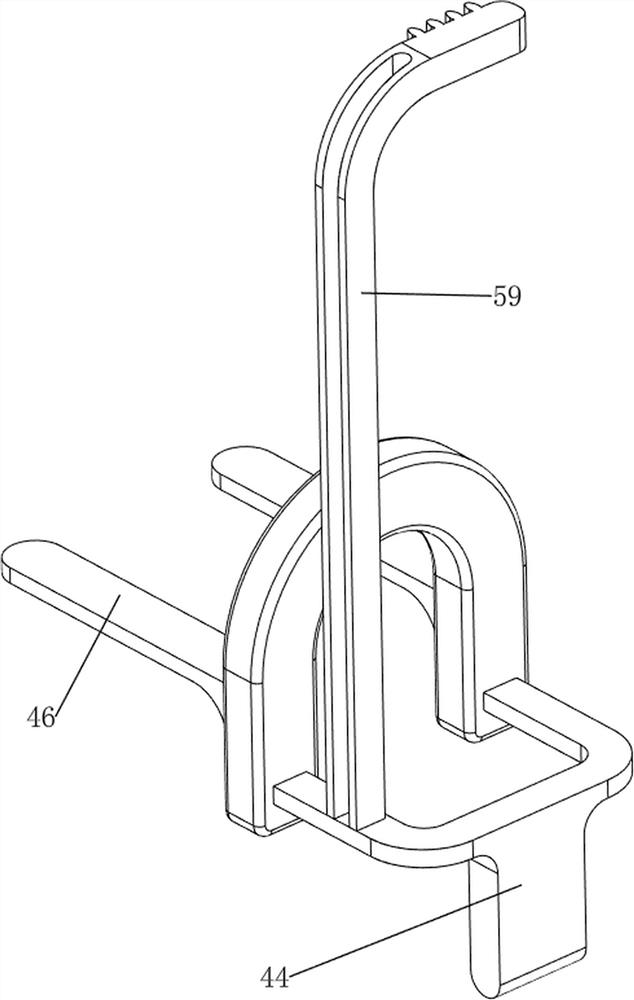

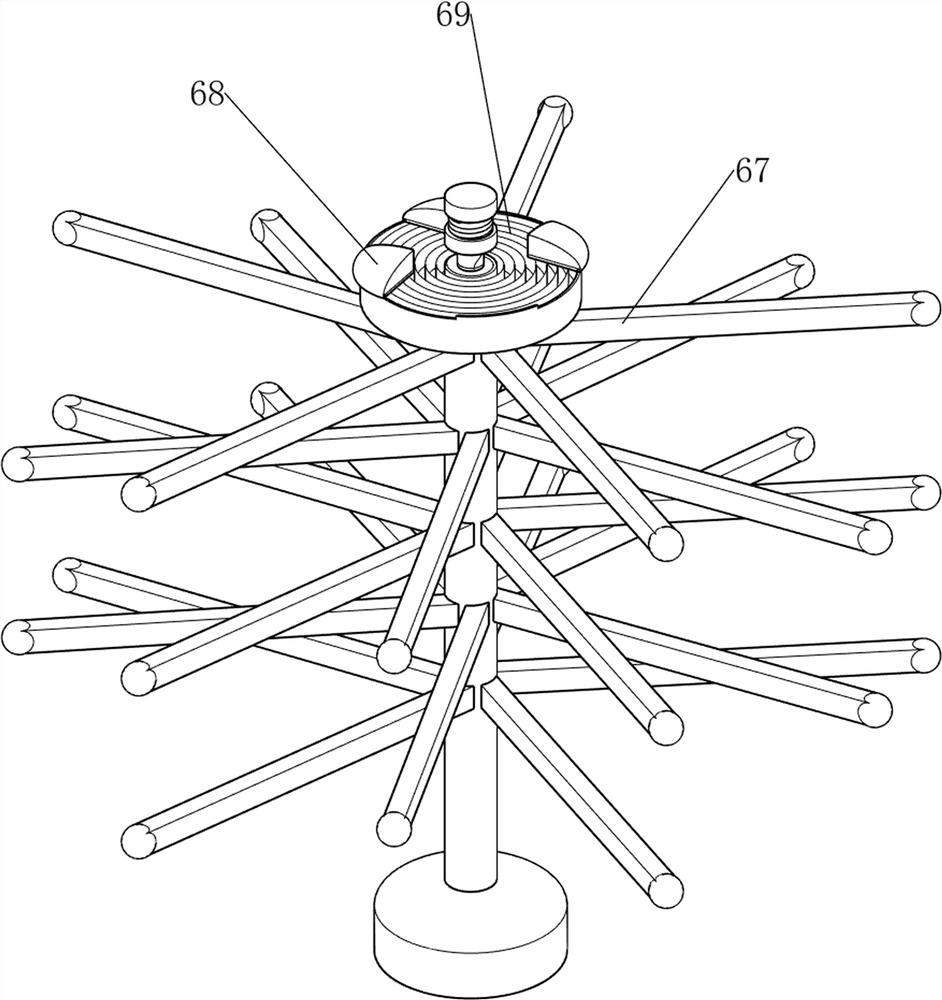

Mushroom stem penetrating fermentation equipment

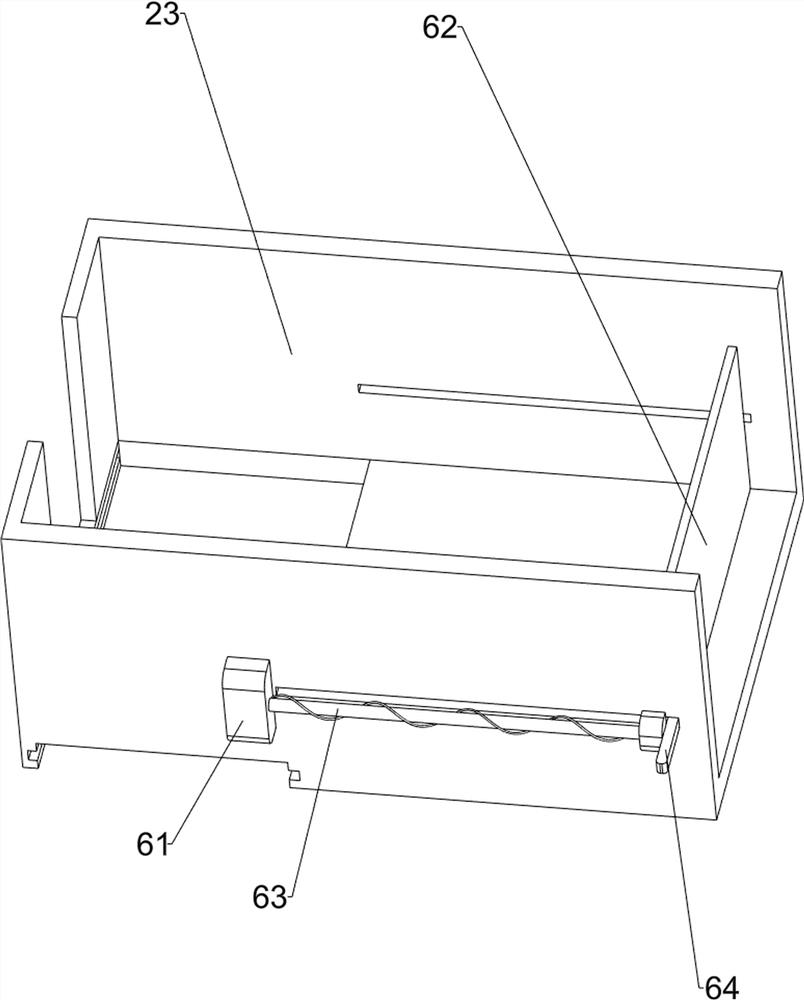

ActiveCN112056151AFast penetrationRealize the blanking effectBio-organic fraction processingCultivating equipmentsBiotechnologyMushroom

The invention relates to penetrating fermentation equipment, in particular to mushroom stem penetrating fermentation equipment. According to the mushroom stem penetrating fermentation equipment, mushroom stems can be rapidly penetrated, and penetrating holes are uniform and tidy. The mushroom stem penetrating fermentation equipment comprises a bottom plate, a servo motor, first L-shaped rods and asecond L-shaped rod, wherein the whole mushroom stem penetrating fermentation equipment is arranged on the bottom plate; the servo motor is arranged on one side of the upper part of the bottom plate;the first L-shaped rods are symmetrically arranged on the other side of the upper part of the bottom plate; and the second L-shaped rod is arranged on the upper part of the bottom plate. The effectsthat the mushroom stems can be rapidly penetrated, and the penetrating holes are uniform and tidy are achieved; after mushrooms are moved to the positions in puncture cylinders, the mushrooms are moved through puncture plates on the two sides, so that the mushroom stems can be rapidly punched, and due to the fact that thorns on the puncture plates are evenly distributed, the effect of even punching can be achieved.

Owner:江西华香食品有限公司

Industrial device for processing potatoes into blocks

InactiveCN112809784ARealize the blanking effectAchieve cutting effectMetal working apparatusEngineeringMechanical engineering

The invention relates to an industrial device for processing blocks, in particular to an industrial device for processing potatoes into blocks. The industrial device for processing the potatoes into the blocks is high in block cutting efficiency, short in consumed time and uniform in block cutting size. The industrial device for processing the potatoes into the blocks comprises a fixed plate, first supporting rods, second supporting rods, a discharging mechanism, a cutting mechanism and the like. The first supporting rods are arranged at the top of the front side of the fixed plate, the second supporting rods are arranged at the left side and the right side of the top of the fixed plate, the discharging mechanism is arranged between the two second supporting rods, and the cutting mechanism is arranged on the fixed plate. According to the industrial device, the potatoes are put into a containing barrel and then enter a first collecting frame through the containing barrel, after a certain number of potatoes are put in, a user pushes a clamping part to clamp the potatoes located on the lower portion of the containing barrel, and therefore the discharging effect is achieved.

Owner:葛友新

Automatic plastic equipment for garden shear handle for garden pruning

PendingCN113334656ARealize the blanking effectDomestic articlesPlastic materialsStructural engineering

The invention relates to plastic equipment, in particular to automatic plastic equipment for a garden shear handle for garden pruning, and aims to solve the technical problem about how to provide the automatic plastic equipment which is used for the garden shear handle for garden pruning, can automatically discharge a mold and can automatically scrape off redundant plastic raw materials on the mold. The automatic plastic equipment for the garden shear handle for garden pruning comprises a bottom plate used for supporting the whole equipment, a supporting frame arranged on one side of the upper part of the bottom plate, a motor arranged at the upper part of the supporting frame, and a clamping mechanism arranged at the upper part of the bottom plate. According to the equipment, the effects that the mold can be automatically discharged, and the redundant plastic raw materials on the mold can be automatically scraped off are achieved; the plastic raw materials of the shear handle are placed in a storage box, a first rack meshes with a first straight gear, a discharging pipe and a baffle are made to rotate, and therefore the effect of automatically discharging the mold can be achieved.

Owner:钟今瀛

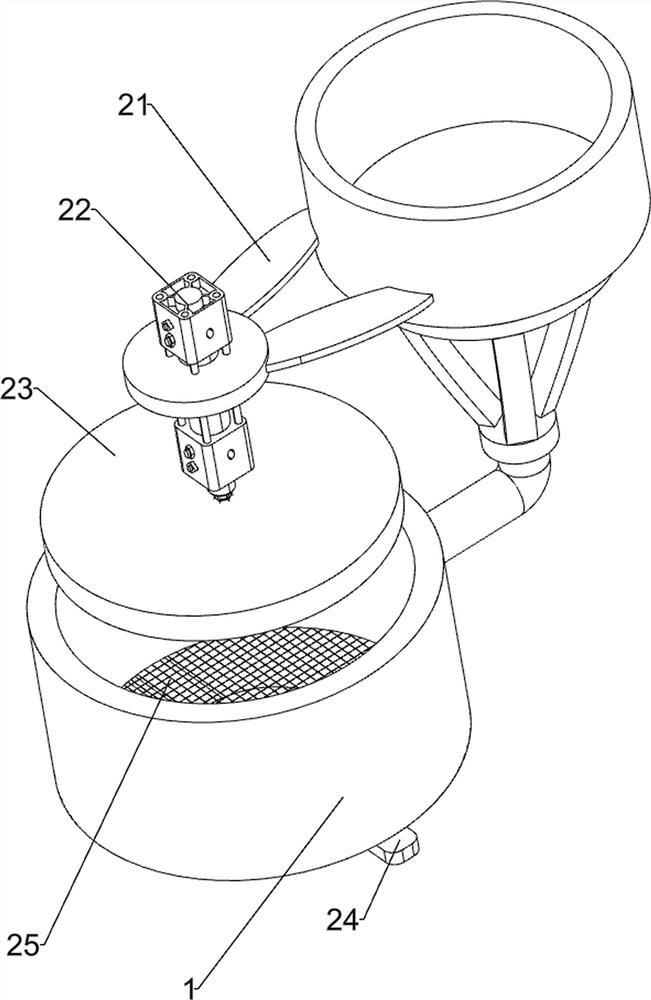

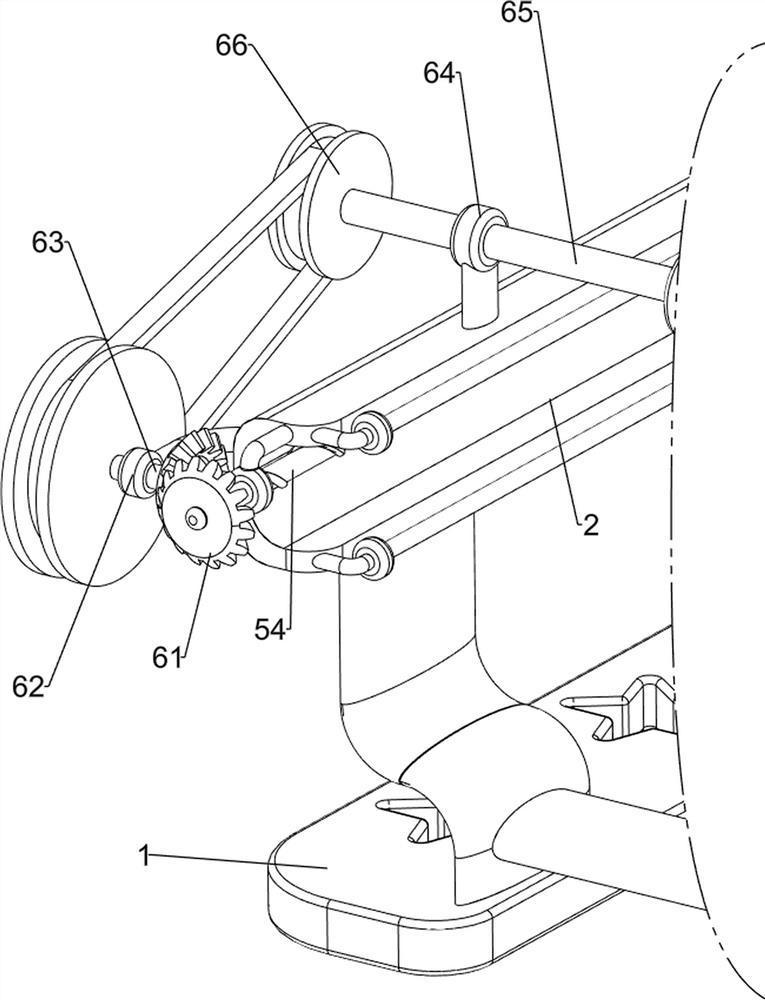

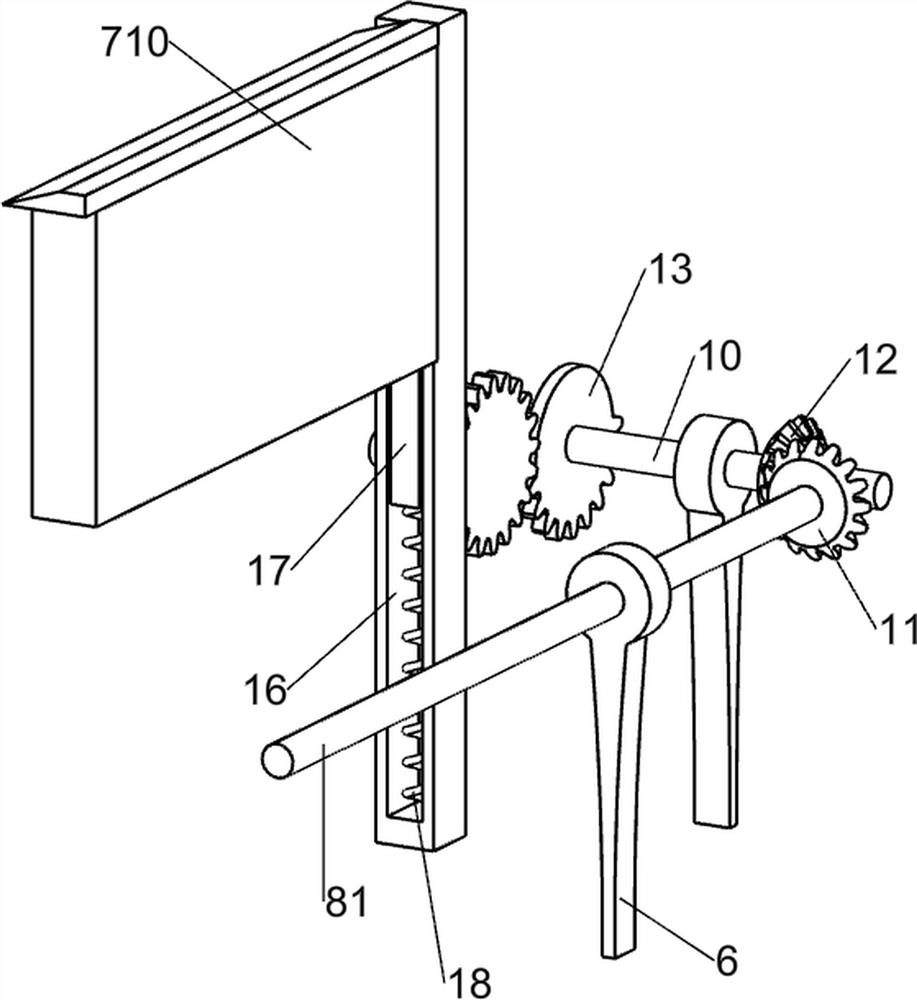

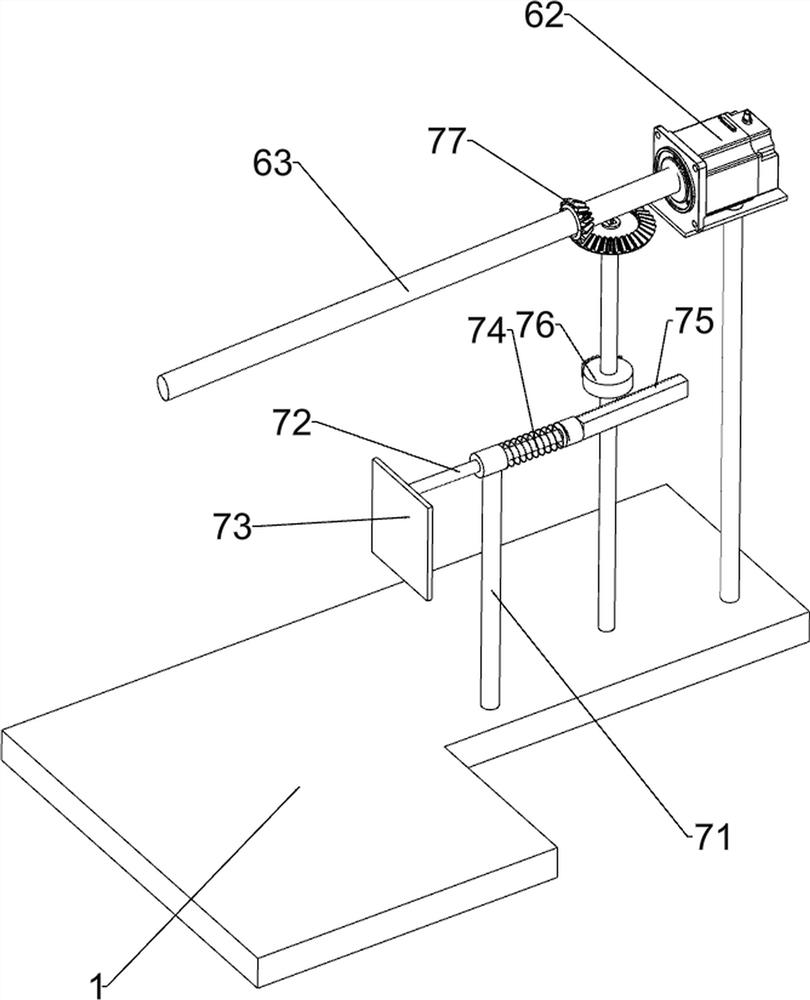

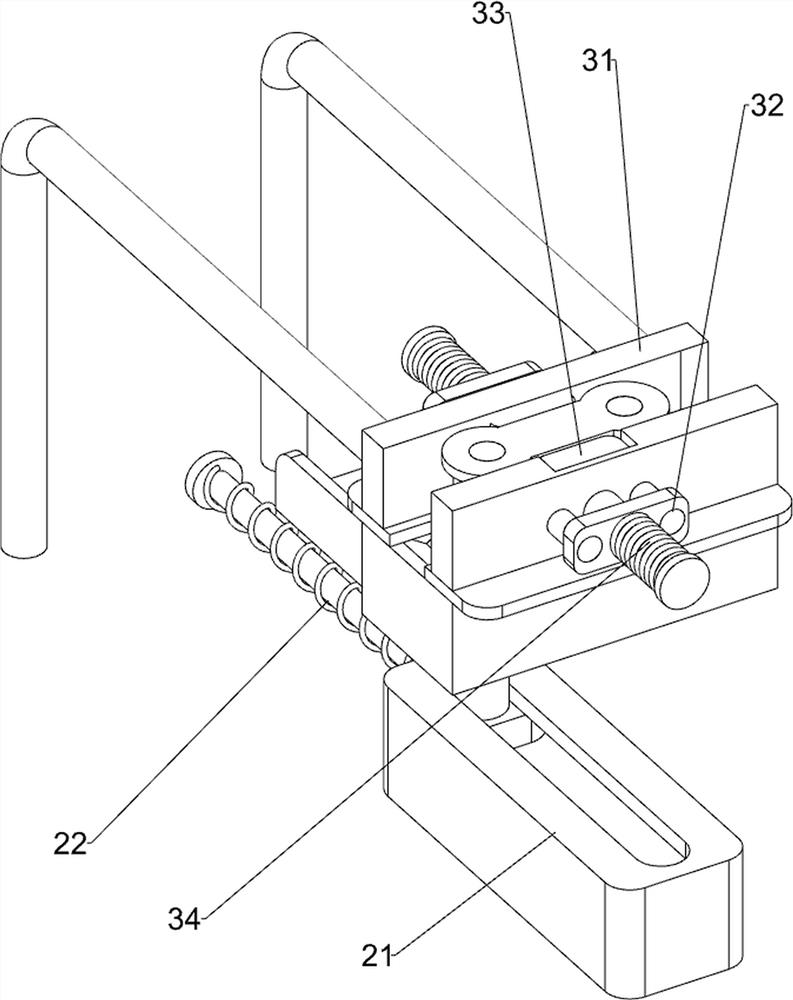

Industrial steel pipe bending device

ActiveCN112872130ARealize the effect of pressing downRealize the bending effectMetal-working feeding devicesPositioning devicesGear wheelClassical mechanics

The invention relates to a bending device, in particular to an industrial steel pipe bending device. The invention provides the industrial steel pipe bending device which can achieve automatic discharging and automatic collecting and is convenient to operate. The industrial steel pipe bending device comprises a first supporting frame, an air cylinder, a downward pressing mechanism, a bending mechanism and the like; and the air cylinder is installed on the upper side of the right portion of the first supporting frame, the downward pressing mechanism is arranged between the upper side of the right portion of the first supporting frame and the air cylinder, and the bending mechanism is arranged between the middle of the right portion of the first supporting frame and the downward pressing mechanism. According to the industrial steel pipe bending device, a telescopic rod of the air cylinder moves downwards to drive a first supporting column to move downwards, so that a U-shaped hammer is driven to move downwards to press a steel pipe downwards, thereby achieving the pressing effect; and a first rack moves downwards to drive a first straight gear on the front side to rotate, so that first rotating shafts are driven to rotate, then first fixing frames are driven to turn inwards to bend the steel pipe, and the bending effect is achieved.

Owner:安徽泓鞍机械制造有限公司

Rapid cooling and quenching device for chain production

ActiveCN112695181ARealize the sliding burning effectRealize the clamping effectFurnace typesProcess efficiency improvementEngineeringChain link

The invention relates to a quenching device, in particular to a rapid cooling and quenching device for chain production. The rapid cooling and quenching device for chain production is easy and convenient to operate, high in quenching efficiency and capable of improving the quenching quality. The rapid cooling and quenching device for chain production comprises a base, wherein a sliding type material burning mechanism is arranged in the middle of the base; and a bearing clamping mechanism which is arranged on the right side of the base. Fuel is put into a burning furnace and ignited, then a user can push a fixed sliding block leftwards, a first spring is compressed, and therefore the burning furnace is driven to move leftwards; and through opposite movement of clamping blocks, a chain in a fixing frame is clamped, and the clamping effect is achieved.

Owner:杭州源景链传动有限公司

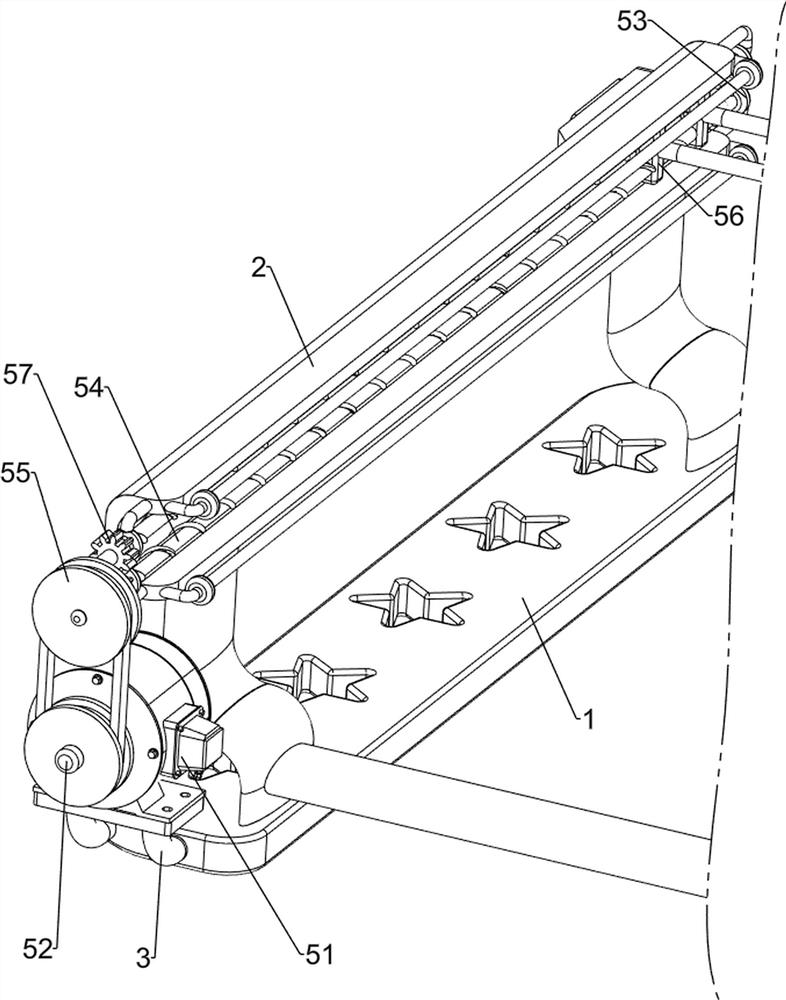

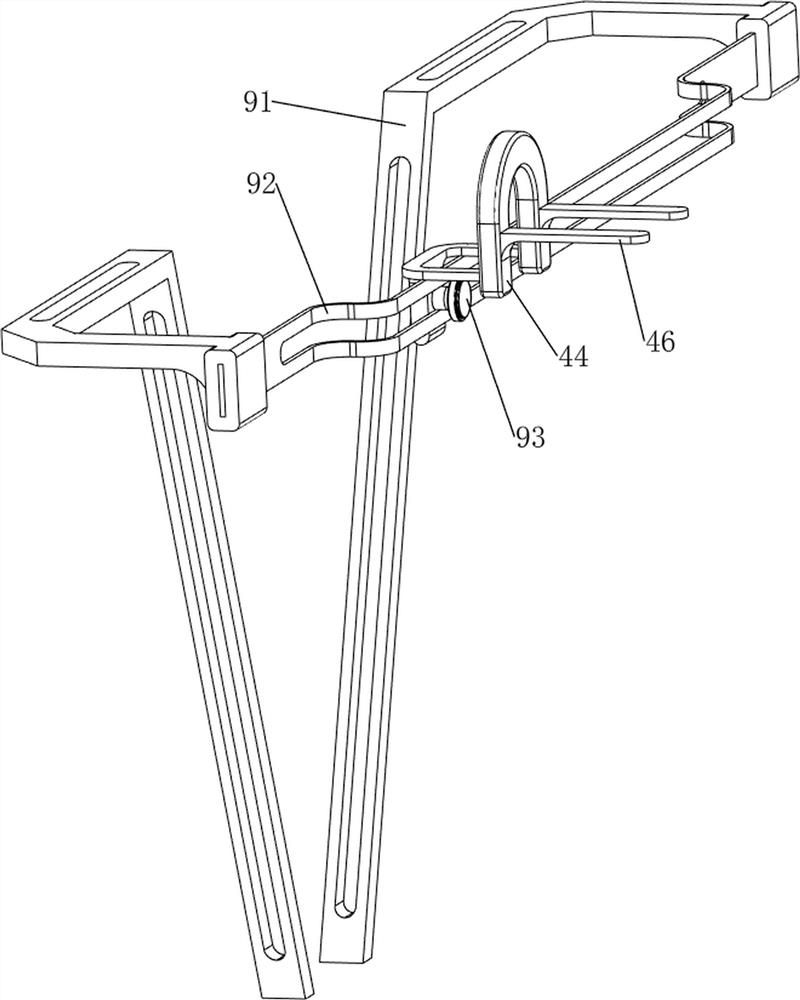

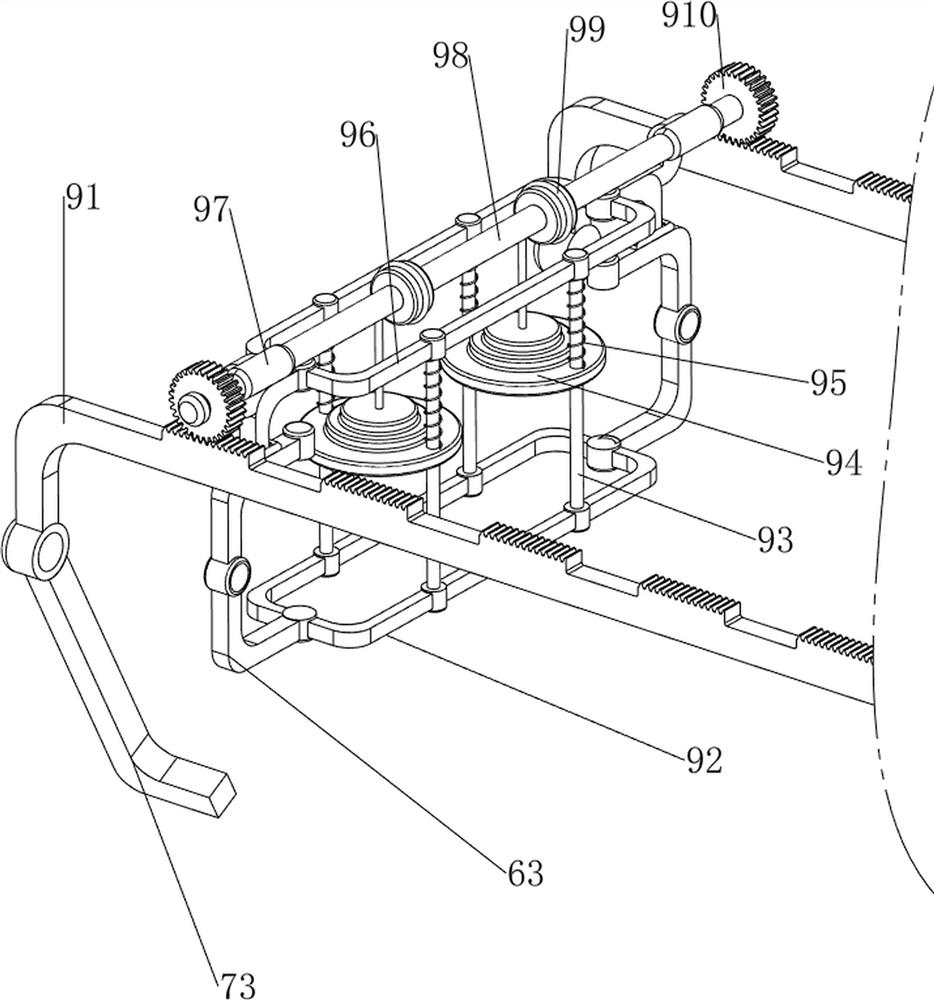

Arch-shaped toothed nail forming device for rice and wheat thresher roller

PendingCN112719131ARealize the bending effectRealize the feeding effectSaving energy measuresAgricultural engineeringElectric machinery

The invention relates to an arch-shaped toothed nail forming device, in particular to an arch-shaped toothed nail forming device for a rice and wheat thresher roller. The arch-shaped toothed nail forming device for the rice and wheat thresher roller is high in working efficiency, high in machining precision and capable of achieving bending of a plurality of toothed nails. The arch-shaped toothed nail forming device for the rice and wheat thresher roller comprises foot stands, a workbench, an installation frame, a bending mechanism, a feeding mechanism and the like, wherein four foot stands are evenly arranged at the bottom of the workbench, two mounting frames are arranged at the top of the right side of the workbench, the bending mechanism is arranged at the top of the left side of the workbench, and the feeding mechanism is arranged at the top of the left side of the workbench. According to the device, a motor output shaft drives a first transmission shaft to rotate so as to drive an extrusion roller to rotate, a user puts a manual toothed nail on the extrusion roller, and the extrusion roller bends the toothed nail.

Owner:安徽环宇米业股份有限公司

Roof wastewater treatment device for building

InactiveCN113769450AAchieve stirring effectRealize the effect of secondary filteringRotary stirring mixersStationary filtering element filtersArchitectural engineeringWater flow

The invention relates to a wastewater treatment device, in particular to a roof wastewater treatment device for a building. The roof wastewater treatment device for the building is suitable for common families, low in manufacturing cost and convenient and fast to install. The roof wastewater treatment device for the building comprises a supporting frame, an enclosure frame, a water receiving opening, a main filter plate, auxiliary filter plates and small rotating plates; the enclosure frame is arranged on the supporting frame; the water receiving opening is formed in the top of the enclosure frame; the main filter plate is arranged on the upper side in the enclosure frame; the auxiliary filter plates are rotationally arranged on the two sides of the main filter plate; and the two small rotating plates are rotationally arranged on the lower side of the interior of the enclosure frame. By arranging a primary mechanism, the main filter plate and the auxiliary filter plates, waste water flowing down from the water receiving opening can be filtered, then people start the primary mechanism to operate, impurities left on the main filter plate can be pushed out, and therefore primary filtering can be conducted.

Owner:赣州申子贸易有限公司

Drying device for recycling low-grade rare earth waste

PendingCN114111287ARealize the blanking effectAchieve stirring effectDrying gas arrangementsDrying chambers/containersWaste materialEnvironmental engineering

The invention relates to a drying device, in particular to a drying device for recycling low-grade rare earth waste. The drying device for recycling the low-grade rare earth waste is good in drying effect, convenient to operate and low in manufacturing cost. A drying device for recycling low-grade rare earth waste comprises supporting legs and a discharging frame, and the discharging frame is arranged on the supporting legs. The discharging frame is arranged between the supporting legs and the bottom of the discharging frame; the hot-air blowers are arranged on the material placing frame, and the number of the hot-air blowers is six; the discharging mechanism is arranged on the lower side of the discharging frame; and the stirring mechanism is arranged on the upper side of the discharging frame. According to the rare earth drying device, people hold a hand pull rod and move the hand pull rod forwards, so that a baffle is driven to move forwards, a first spring is stretched, a discharging opening of a discharging frame is opened, dried rare earth can fall down along the radian of a discharging frame, and the discharging effect is achieved.

Owner:曾令繁

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com