Equipment for centralizedly treating used medical needle tubes

A centralized processing and equipment technology, applied in grain processing, solid separation, sieving, etc., can solve the problems of labor-intensive, incapable of needle crushing, poor processing effect, etc., and achieve the effect of reducing manual operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

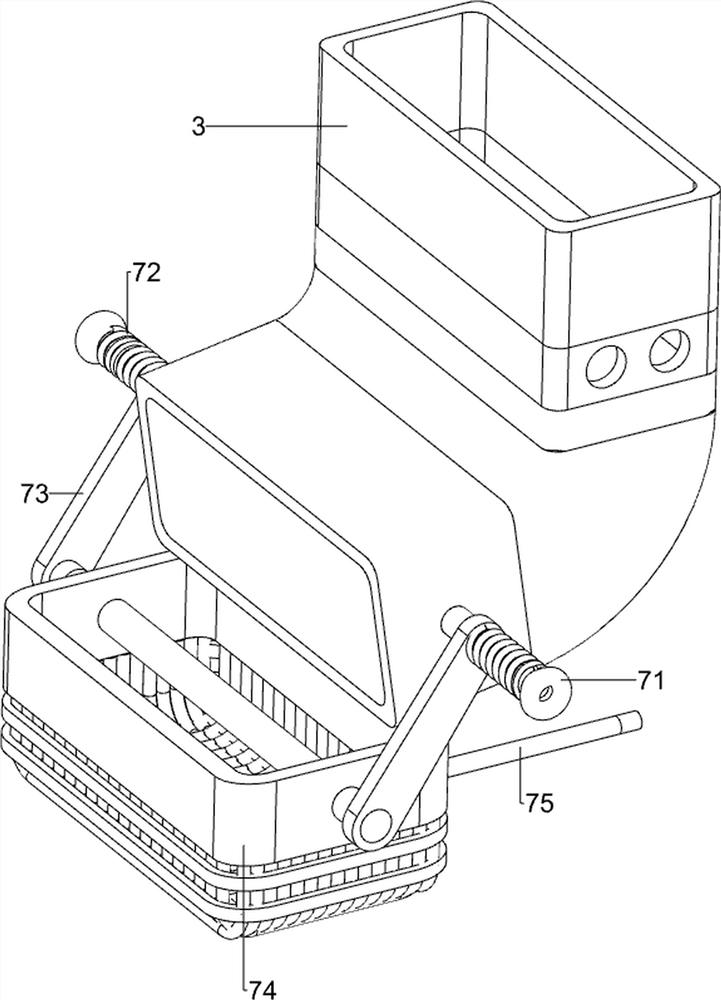

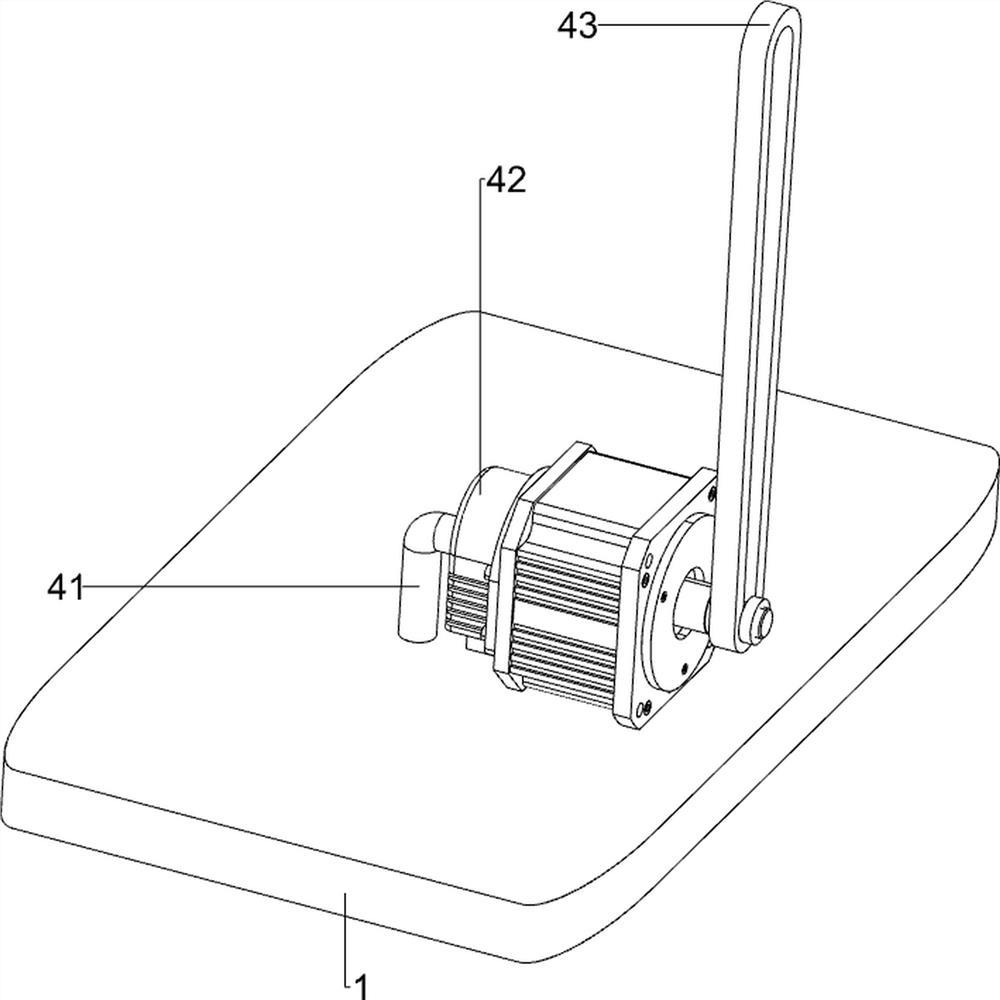

[0061] A centralized treatment device for medical needle tubes after use, such as figure 1 As shown, it includes a first support plate 1, a first support frame 2, a fluid frame 3, a power mechanism 4, a crushing mechanism 5, a feeding mechanism 6, a vibrating mechanism 7 and a collection box 10. The upper right of the first support plate 1 The first support frame 2 is provided on both sides of the front and back of the head, and a fluid frame 3 is connected between the left parts of the two first support frames 2, and a crushing mechanism 5 is arranged on the fluid frame 3, and the crushing mechanism 5 and the first support plate A power mechanism 4 is arranged between 1, a feeding mechanism 6 is arranged on the upper right side of the fluid frame 3, a vibrating mechanism 7 is arranged on the lower side of the fluid frame 3, and a collection box 10 is arranged on the left side of the first support plate 1.

[0062] When people need to process the needle tubes, they can use thi...

Embodiment 2

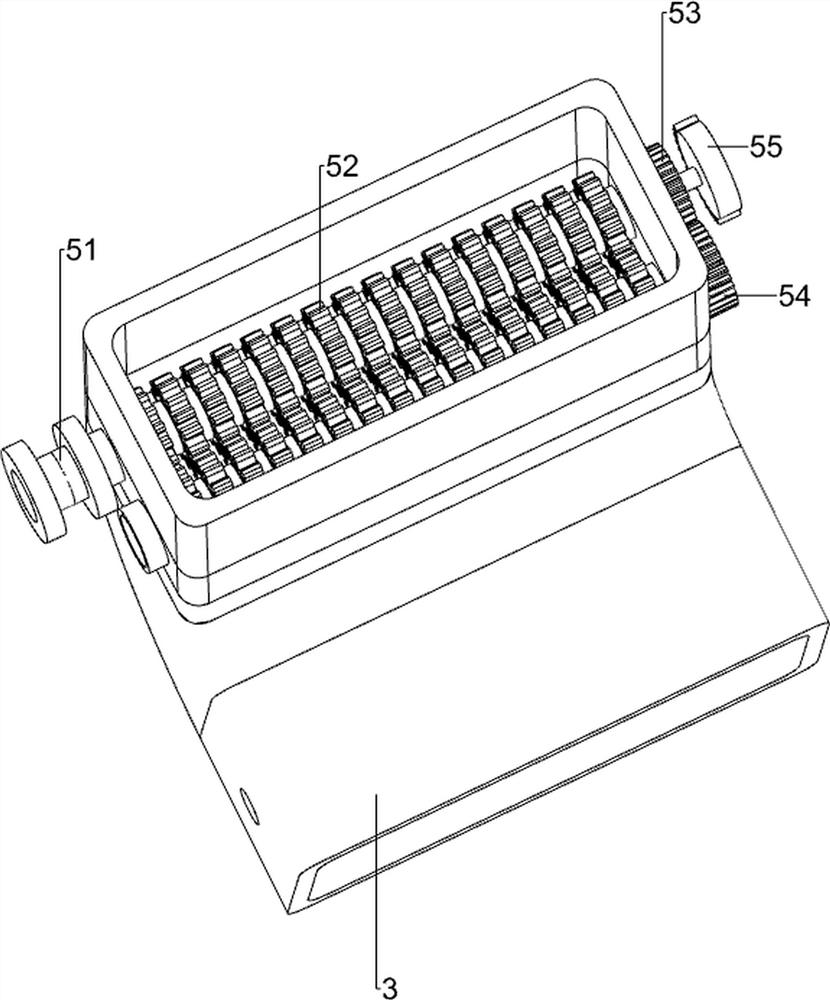

[0064] On the basis of Example 1, such as Figure 2-5 As shown, the crushing mechanism 5 includes a first rotating shaft 51, a crushing device 52, a first gear 53, a second gear 54 and a missing gear 55. The left and right sides of the fluid frame 3 are rotatably provided with the first rotating shaft 51, and the second A rotating shaft 51 is evenly provided with a plurality of crushers 52, the front side of the first rotating shaft 51 on the right side is provided with a first gear 53, the front side of the first rotating shaft 51 on the left side is provided with a second gear 54, and the first gear 53 It meshes with the second gear 54 , and the front side of the first rotating shaft 51 on the right is provided with a missing gear 55 .

[0065] After the needle tube in the feeding mechanism 6 falls into the fluid frame 3, people start the power mechanism 4, and the parts of the power mechanism 4 rotate to drive the first rotating shaft 51 on the right to rotate, so that the ...

Embodiment 3

[0073] On the basis of Example 2, such as Figure 6 and Figure 7 As shown, a first auxiliary mechanism 8 is also included. The first auxiliary mechanism 8 includes a fourth support frame 81, a first rack frame 82 and a third spring 83. The front part of the fluid frame 3 is provided with a fourth support frame 81. The fourth support frame 81 is slidably provided with a first rack frame 82, the missing gear 55 and the opener 64 are all matched with the first rack frame 82, and the first rack frame 82 is connected with the fourth support frame 81. There is a third spring 83 wound around the first rack frame 82 .

[0074] When the missing gear 55 rotates and contacts the first rack frame 82, the missing gear 55 drives the first rack frame 82 to move upward, and the third spring 83 is compressed. When the first rack frame 82 moves upward and touches the switch 64, The first rack frame 82 drives the switch 64 to move upward, and the first spring 65 is compressed, so that the nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com