Mushroom stem penetrating fermentation equipment

A technology for fermentation equipment and mushroom rods, which is applied to the field of mushroom rod penetration fermentation equipment, can solve problems such as insufficient penetration holes, influence on growth of mushrooms, slow penetration speed, etc., and achieve the effect of uniform distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

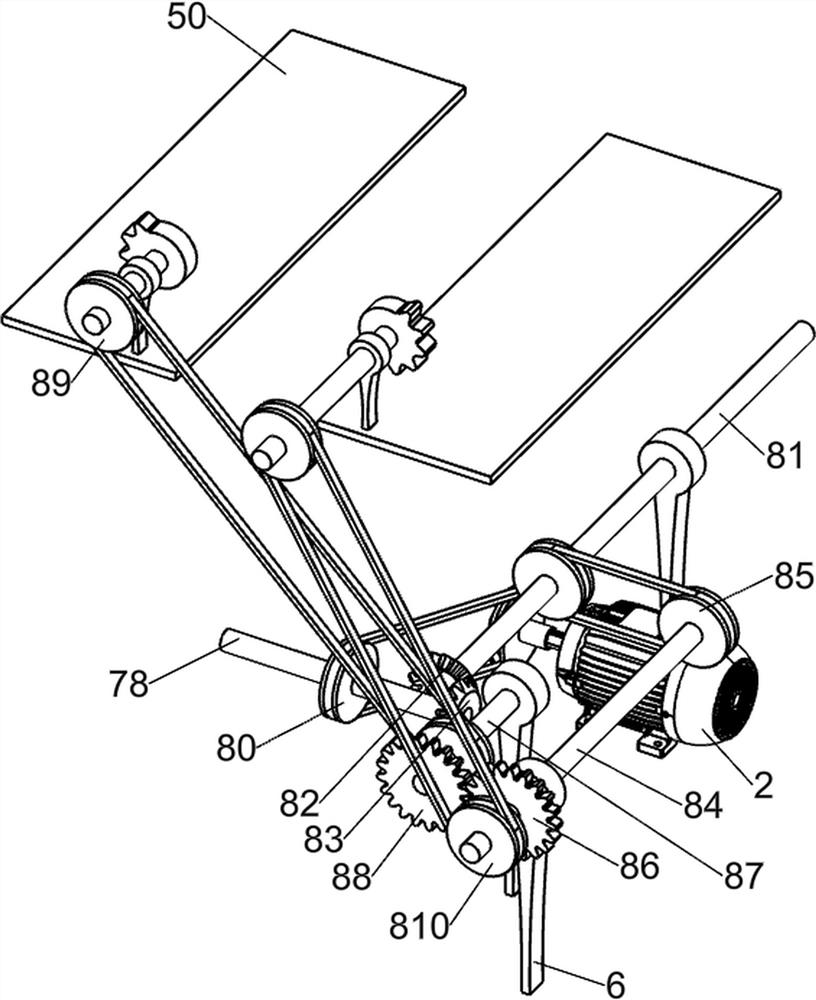

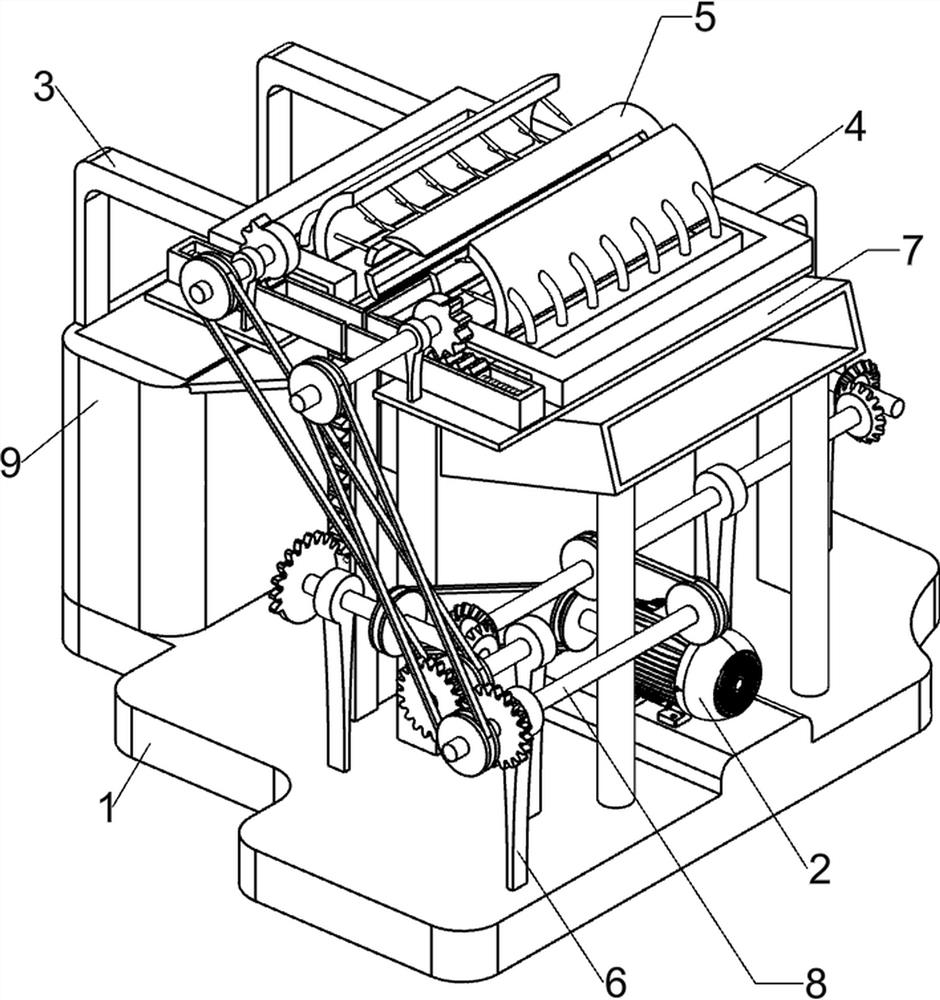

[0025] A kind of mushroom rod penetrating fermentation equipment, such as figure 1 As shown, it includes a base plate 1, a servo motor 2, a first L-shaped rod 3, a second L-shaped rod 4, a piercing mechanism 5, a first bearing seat 6, a loading and unloading mechanism 7 and a driving mechanism 8, and the upper right side of the base plate 1 A servo motor 2 is provided, a first L-shaped rod 3 is arranged symmetrically front and rear on the left side of the upper part of the bottom plate 1, a second L-shaped rod 4 is provided on the rear side of the upper part of the bottom plate 1, a loading and unloading mechanism 7 is arranged in the middle of the upper part of the bottom plate 1, and the bottom plate 1 Three first bearing blocks 6 are arranged on the right front side of the upper part, a piercing mechanism 5 is arranged on the upper part of the loading and unloading mechanism 7, and a driving mechanism 8 is arranged on the right side of the upper part of the bottom plate 1. ...

Embodiment 2

[0028] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 and Figure 5 As shown, the piercing mechanism 5 includes a mounting plate 50, a second bearing seat 51, a second rotating shaft 52, a first slide rail 53, a first missing gear 54, a first rack 55, a first spring 56, and a second slide rail 57, slide block 58, puncture plate 59, curved connecting rod 510 and puncture tube 511, the first L-shaped bar 3 on both sides and loading and unloading mechanism 7 are all provided with mounting plate 50, and the mounting plate 50 tops of both sides are arranged A second bearing seat 51 is provided, and a second rotating shaft 52 is provided in the second bearing seat 51. The second rotating shaft 52 on both sides is provided with a first missing gear 54. A first slide rail 53 is provided, and a first rack 55 is slidably provided in the first slide rail 53, and the first rack 55 meshes with the first missing gear 54. Between the first slide rail 53 and the first ra...

Embodiment 3

[0035] On the basis of Example 2, such as figure 1 , Figure 6 and Figure 7 As shown, a blanking box 9 is also included, and the left side of the bottom plate 1 is provided with a blanking box 9.

[0036] When the baffle plate 712 moves downward and no longer blocks the mushroom rod, the mushroom rod that has been punctured will fall downwards in the lower material box 9, and when the mushroom rod in the lower material box 9 reaches a certain amount, the user can take it out The mushroom bar in the feeding box 9.

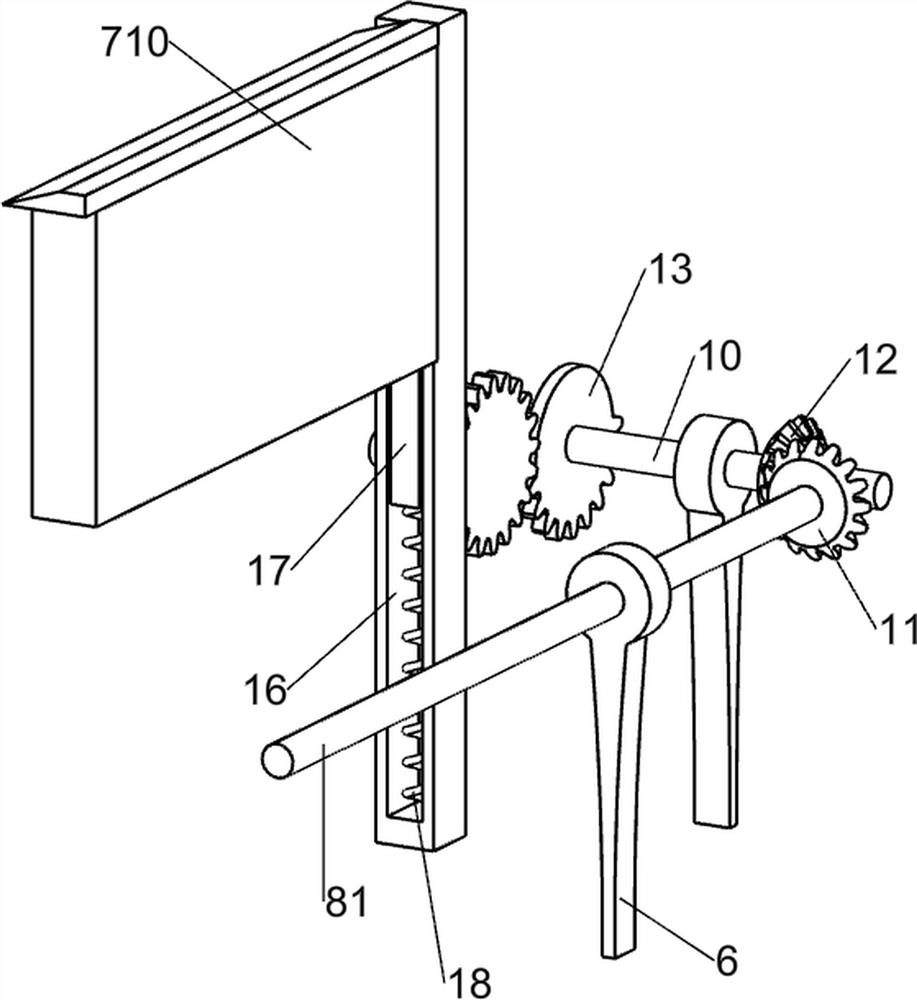

[0037] Also include the first rotating rod 10, the third bevel gear 11, the fourth bevel gear 12, the third missing gear 13, the second rotating rod 14, the third gear 15, the fourth slide rail 16, the third rack 17, The third spring 18 and the fourth bearing seat 19, two fourth bearing seats 19 are provided on the rear side of the bottom plate 1 top, and the fourth bearing seat 19 on the right side is provided with the first rotating rod 10 in a rotating manner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com