Patents

Literature

108results about How to "Fast screening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A system and method for tracking target human trajectory based on face recognition technology

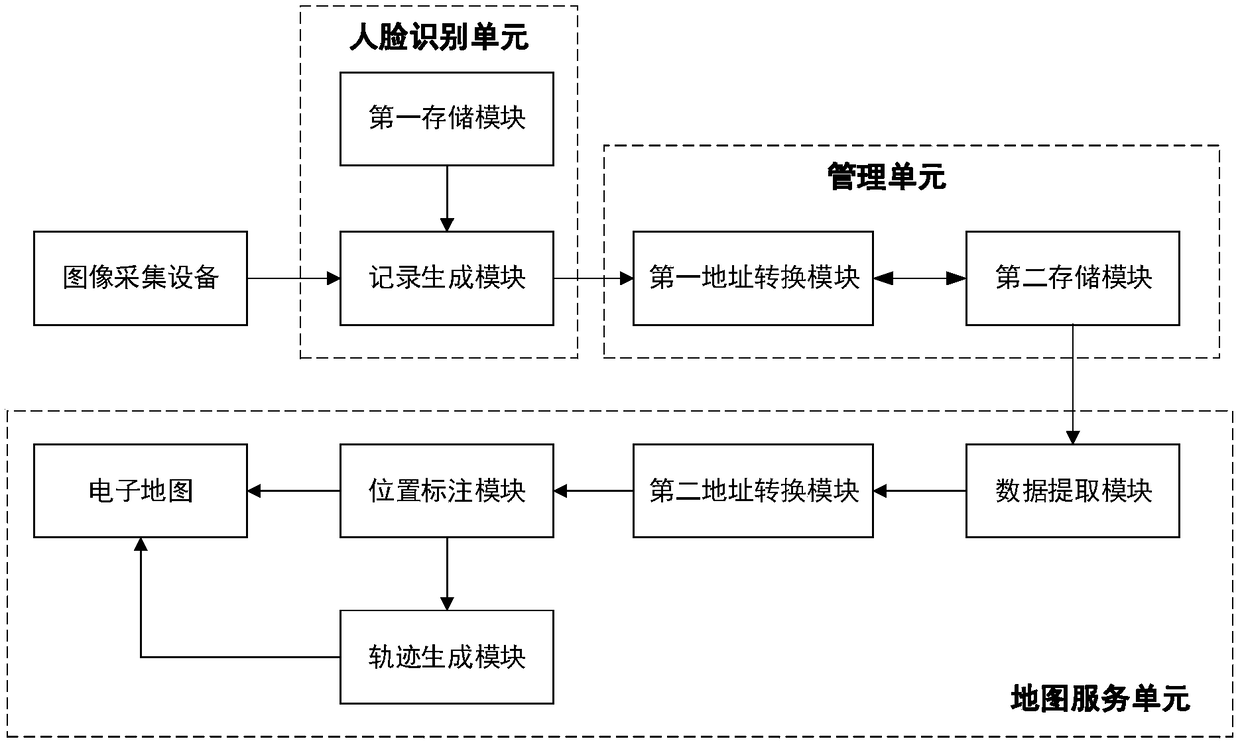

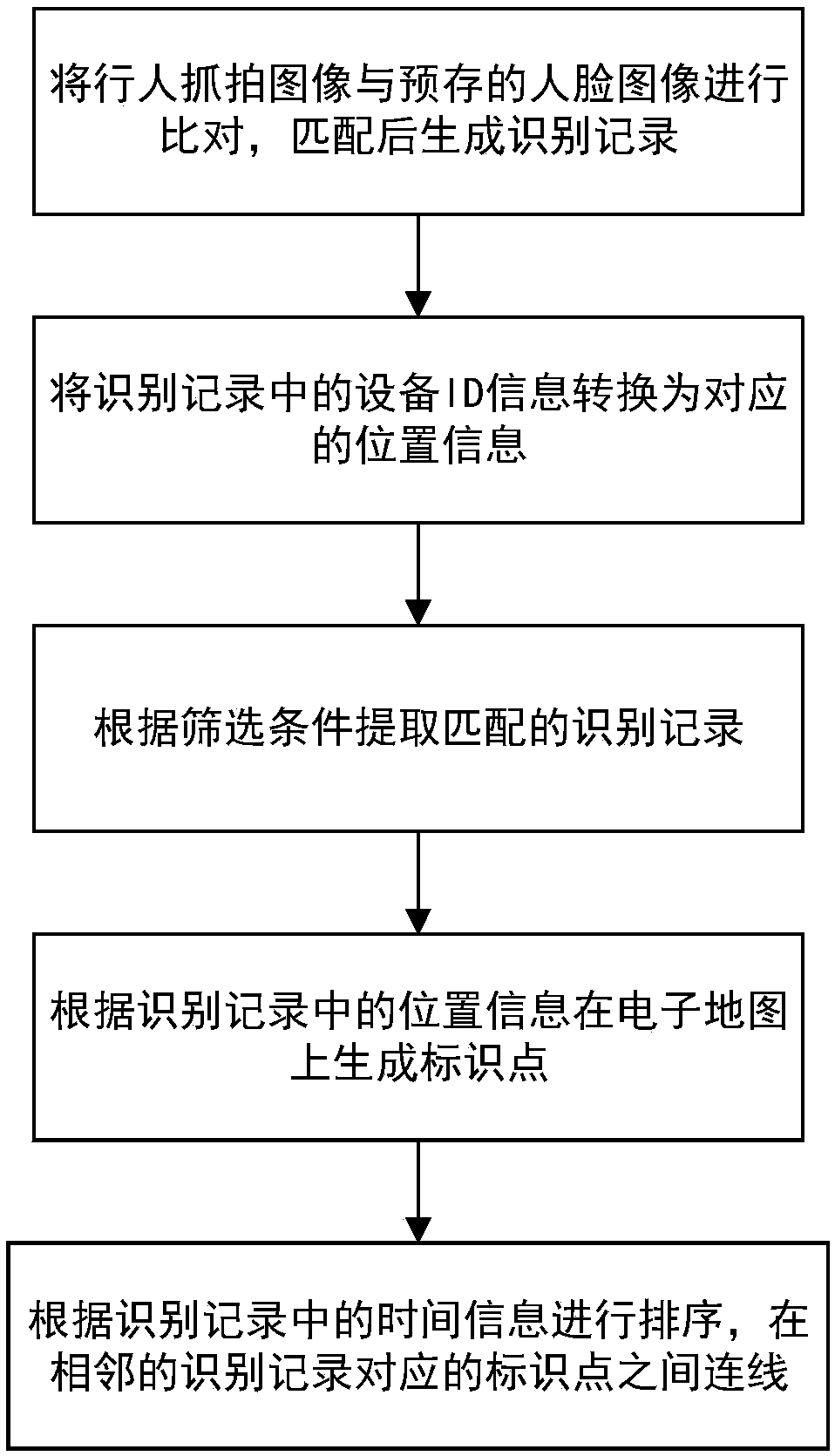

InactiveCN109214276AFast trackRapid positioningCharacter and pattern recognitionTemporal informationManagement unit

The invention belongs to the technical field of video surveillance, and discloses a system and a method for tracking target personnel trajectory based on face recognition technology. The system comprises a face recognition unit, a management unit and a map service unit. A face recognition unit compares a pedestrian snap image generated by an image acquisition device with a face image of a key person stored in advance, and generates a recognition record after matching; a management unit converts the ID information of the image acquisition device in the identification record into corresponding position information; the map service unit extracts matching identification records from the management platform according to an externally inputted screening condition; generating a corresponding identification point on the electronic map according to the position information in the identification record; sorting the identification records according to the time information, connecting lines between the identification points corresponding to the adjacent identification records according to the sorting result to generate a track; the invention can realize the fast tracing and positioning of keypersonnel, greatly shortens the time of manual identification and tracking, and improves the working efficiency.

Owner:WUHAN HONGXIN TECH SERVICE CO LTD

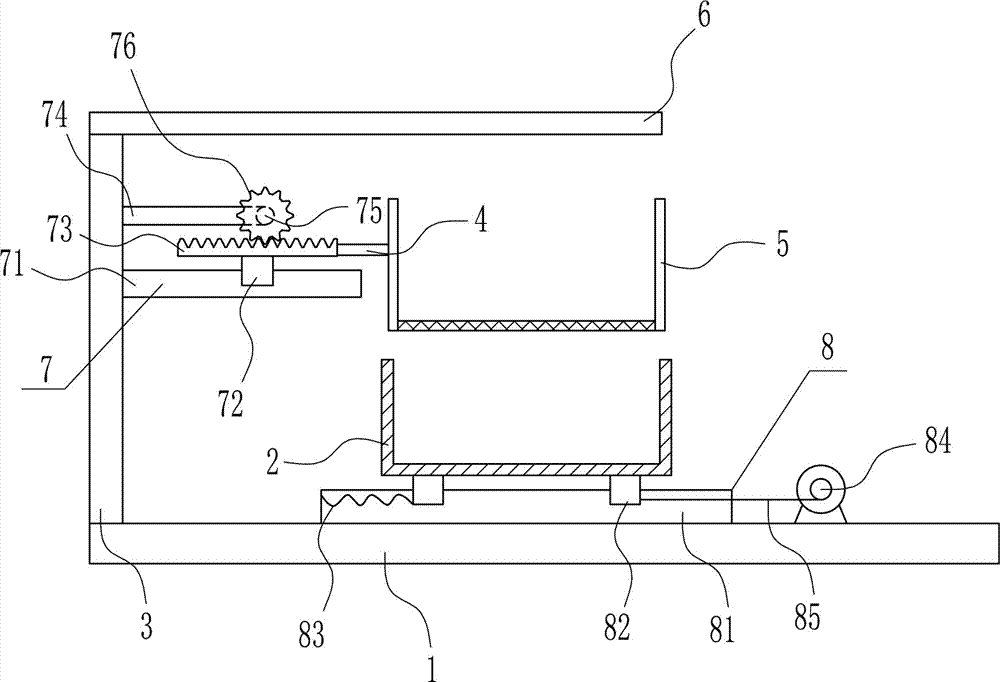

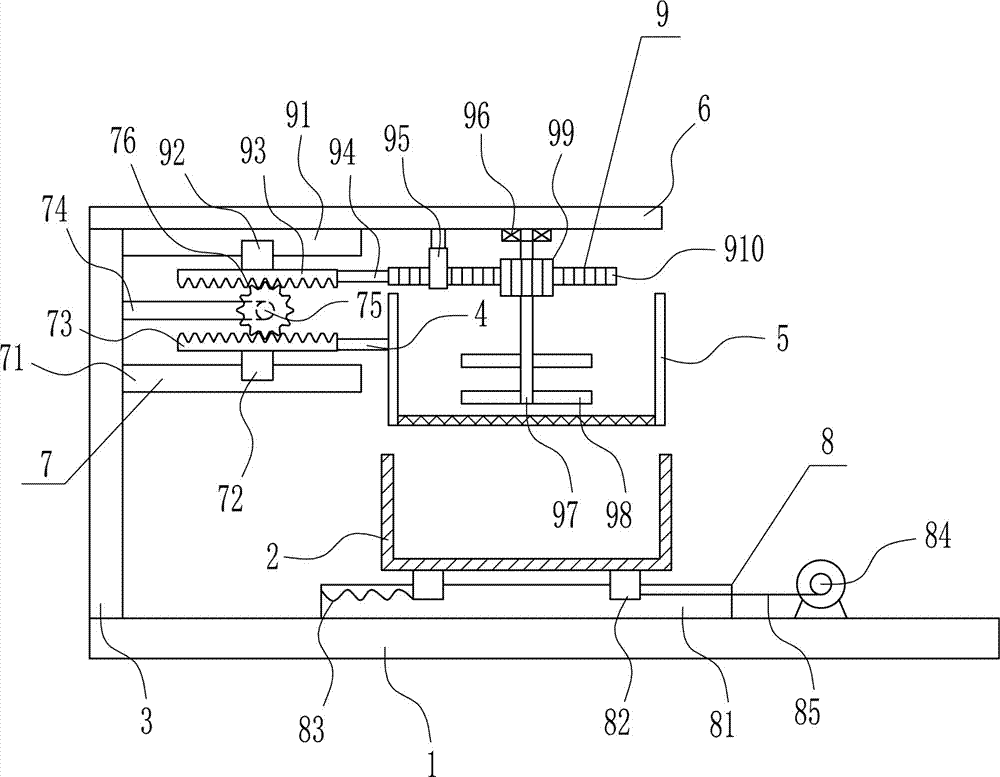

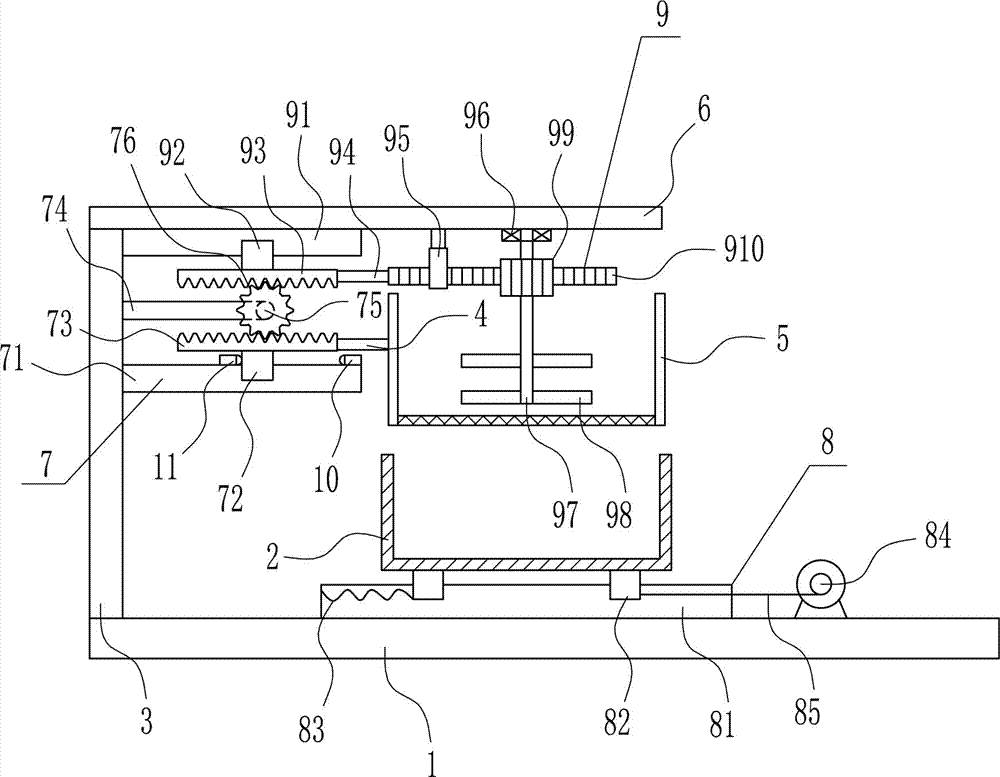

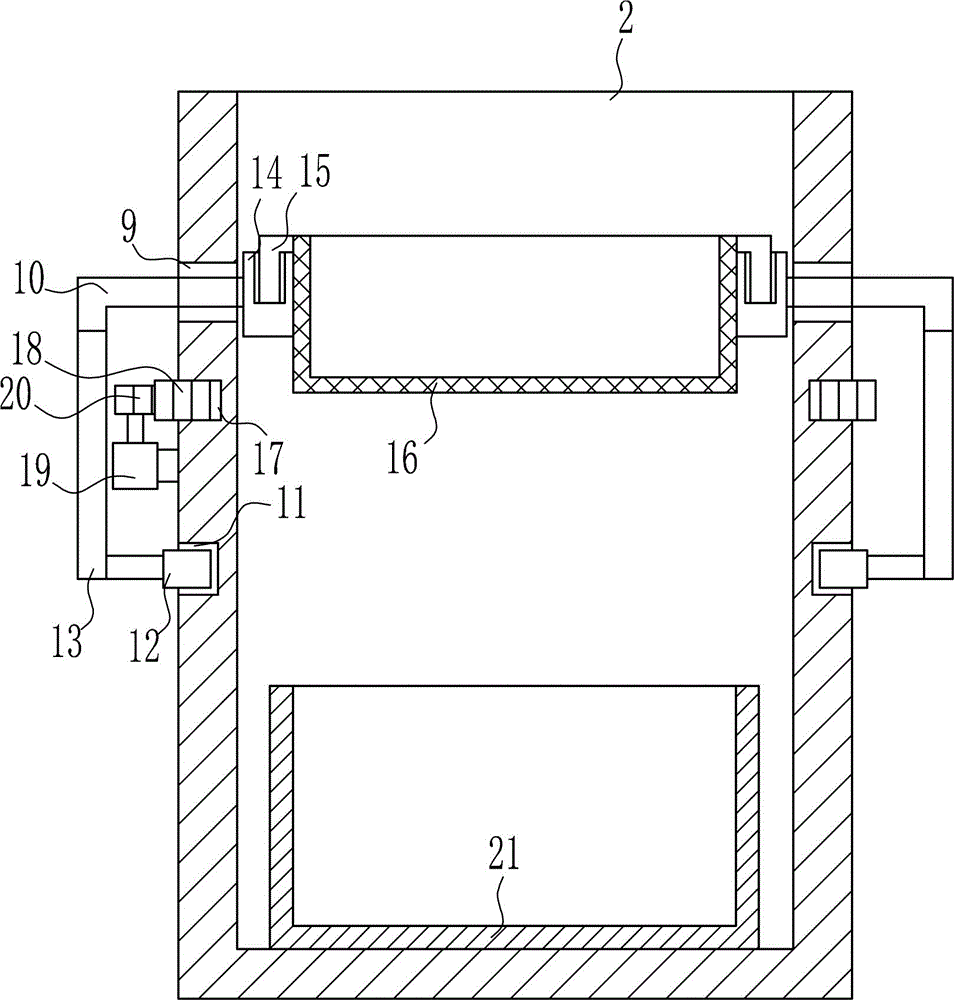

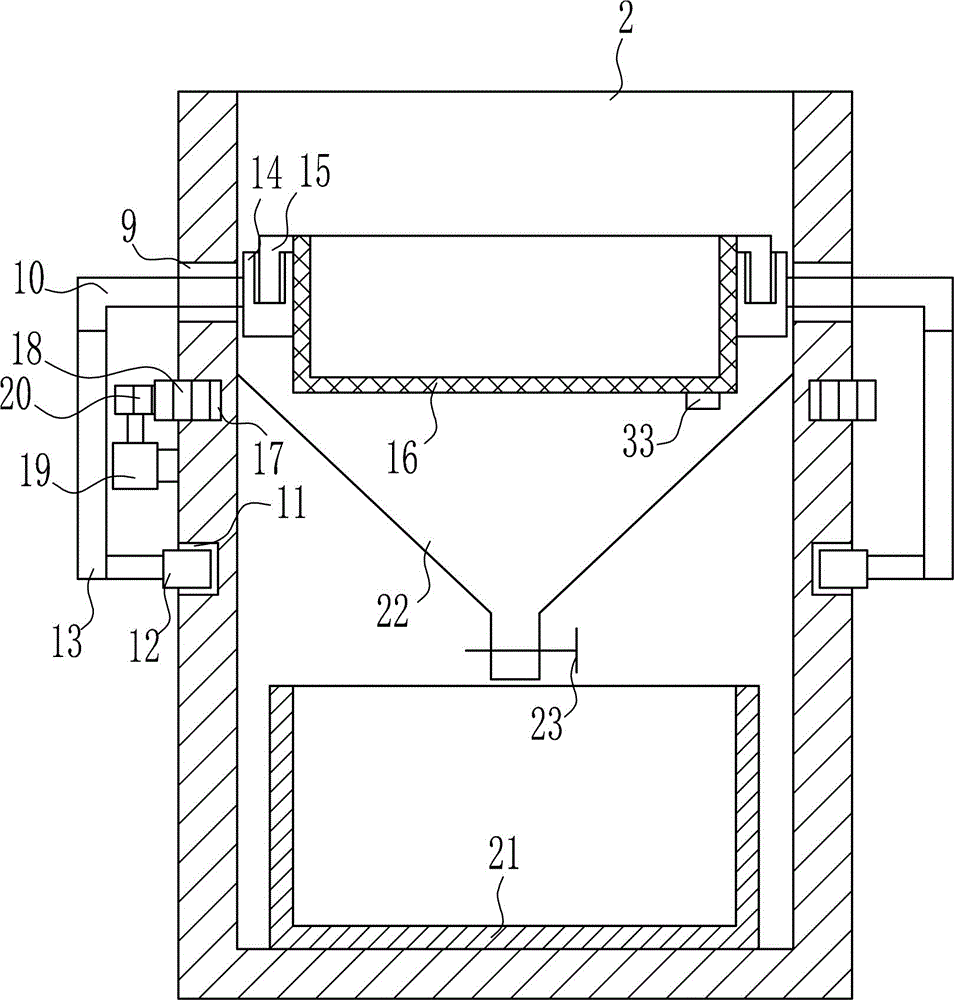

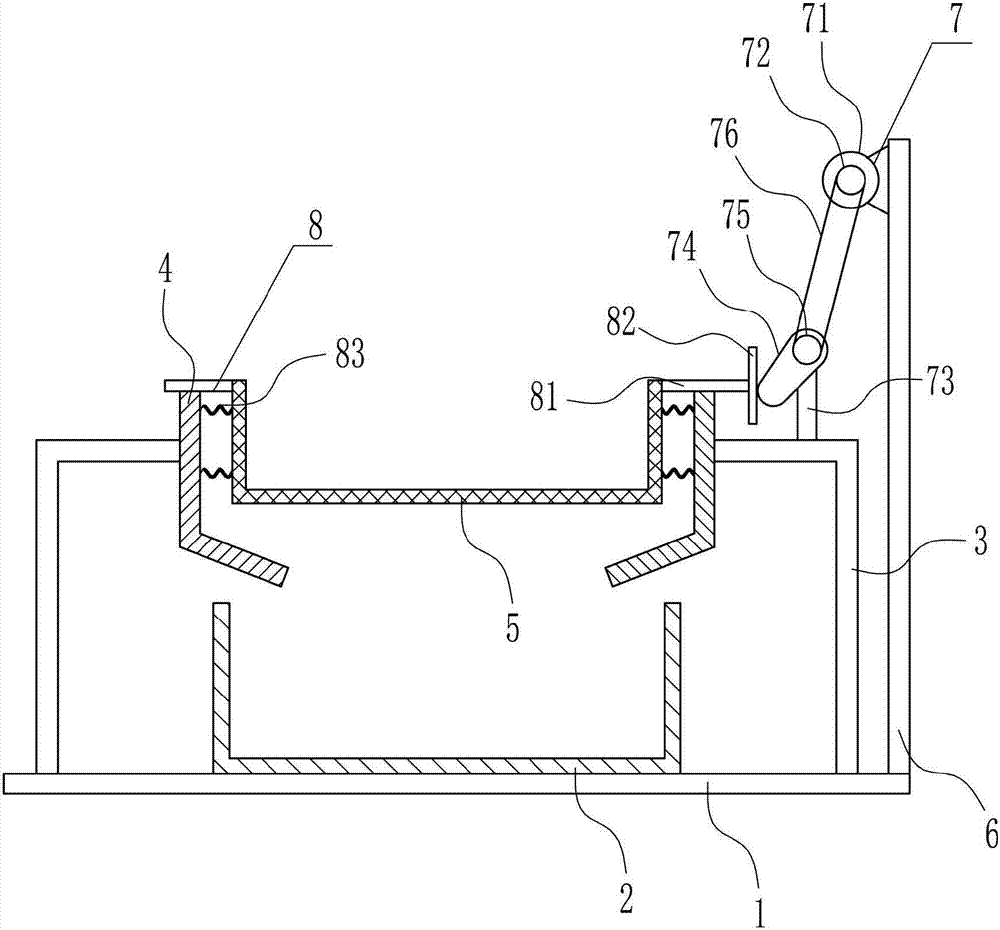

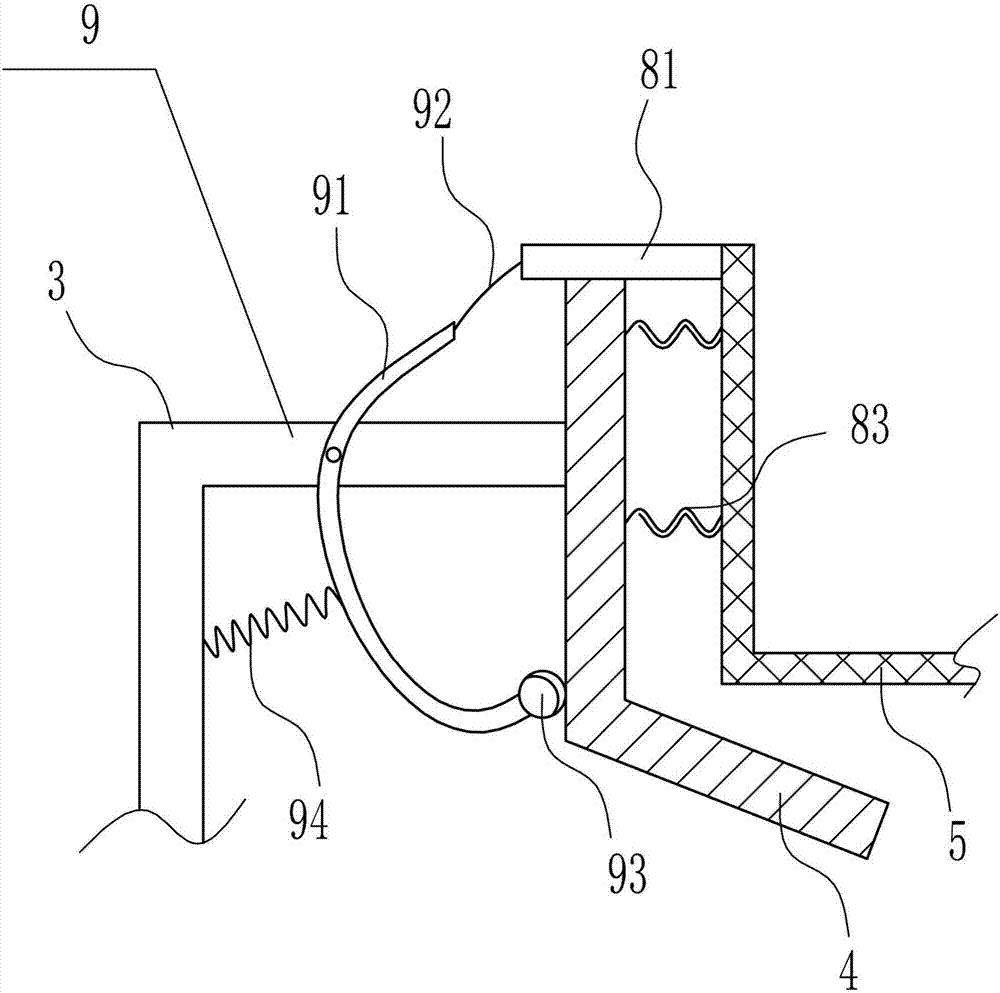

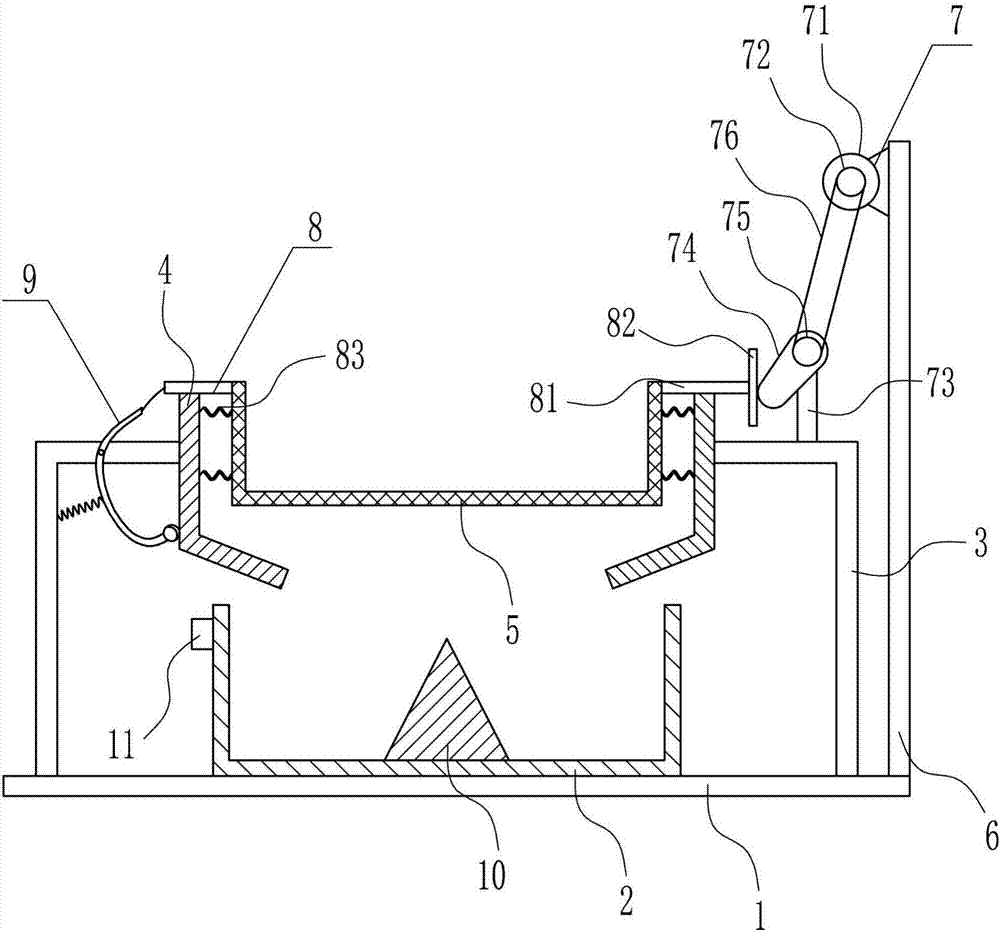

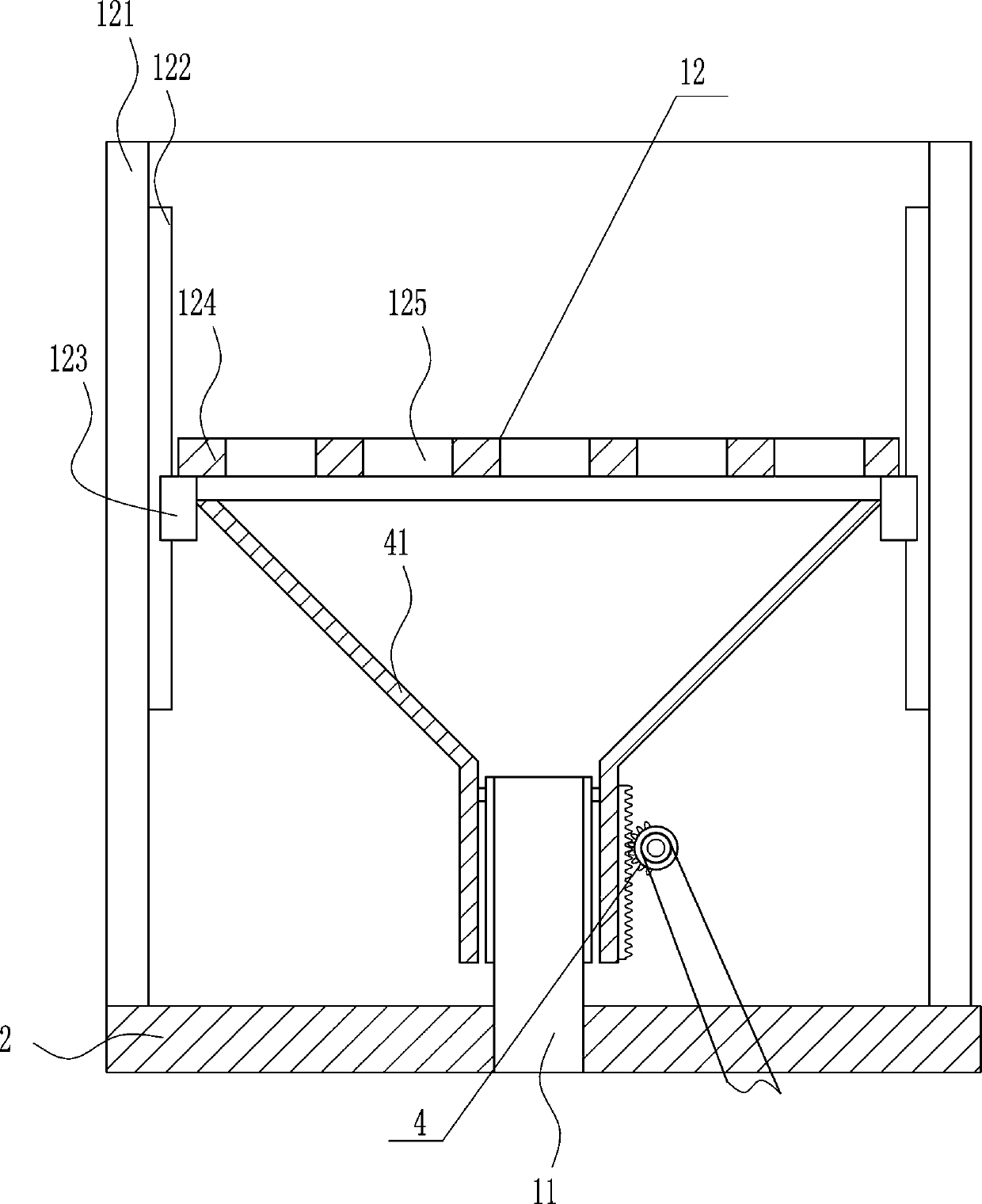

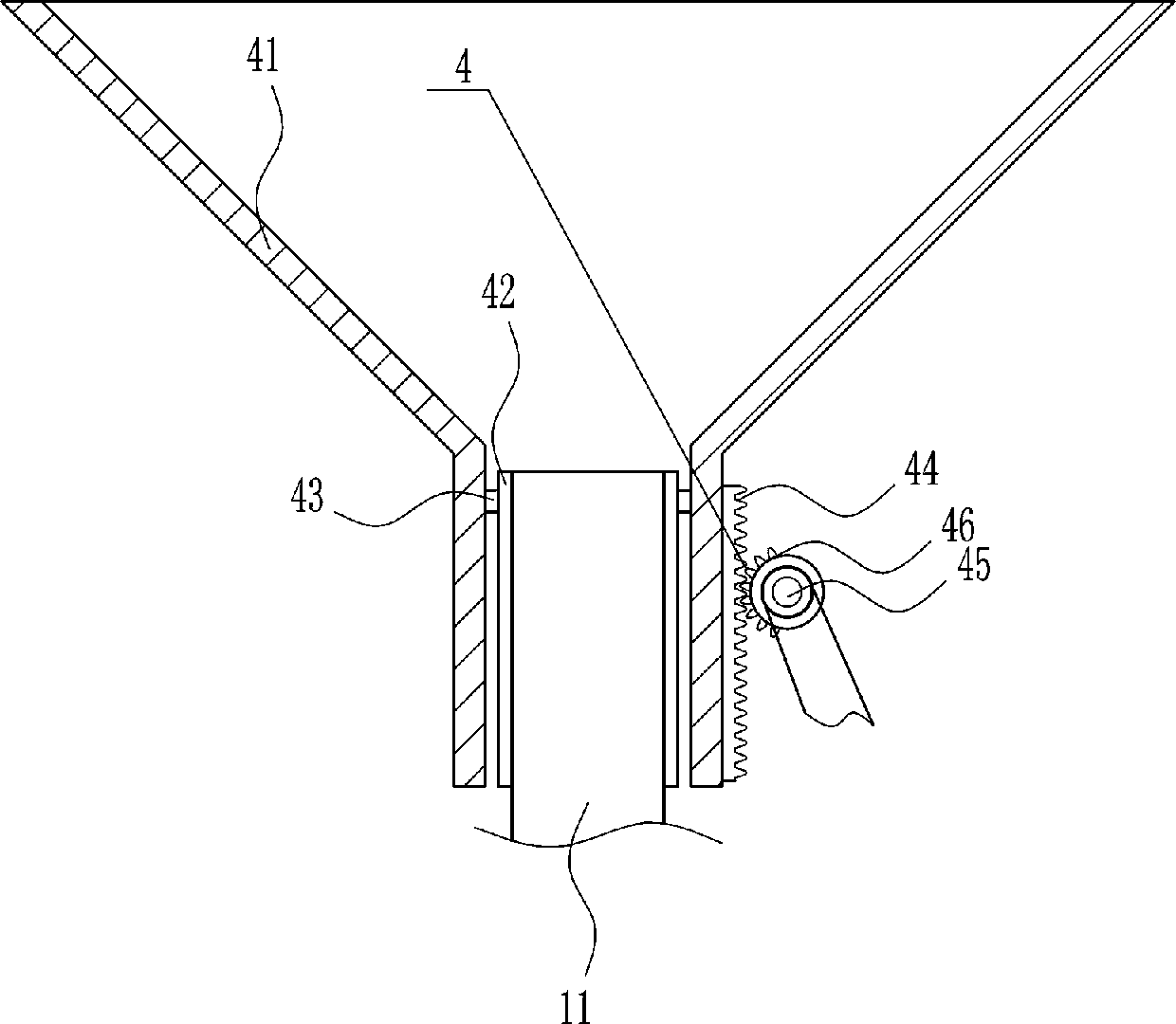

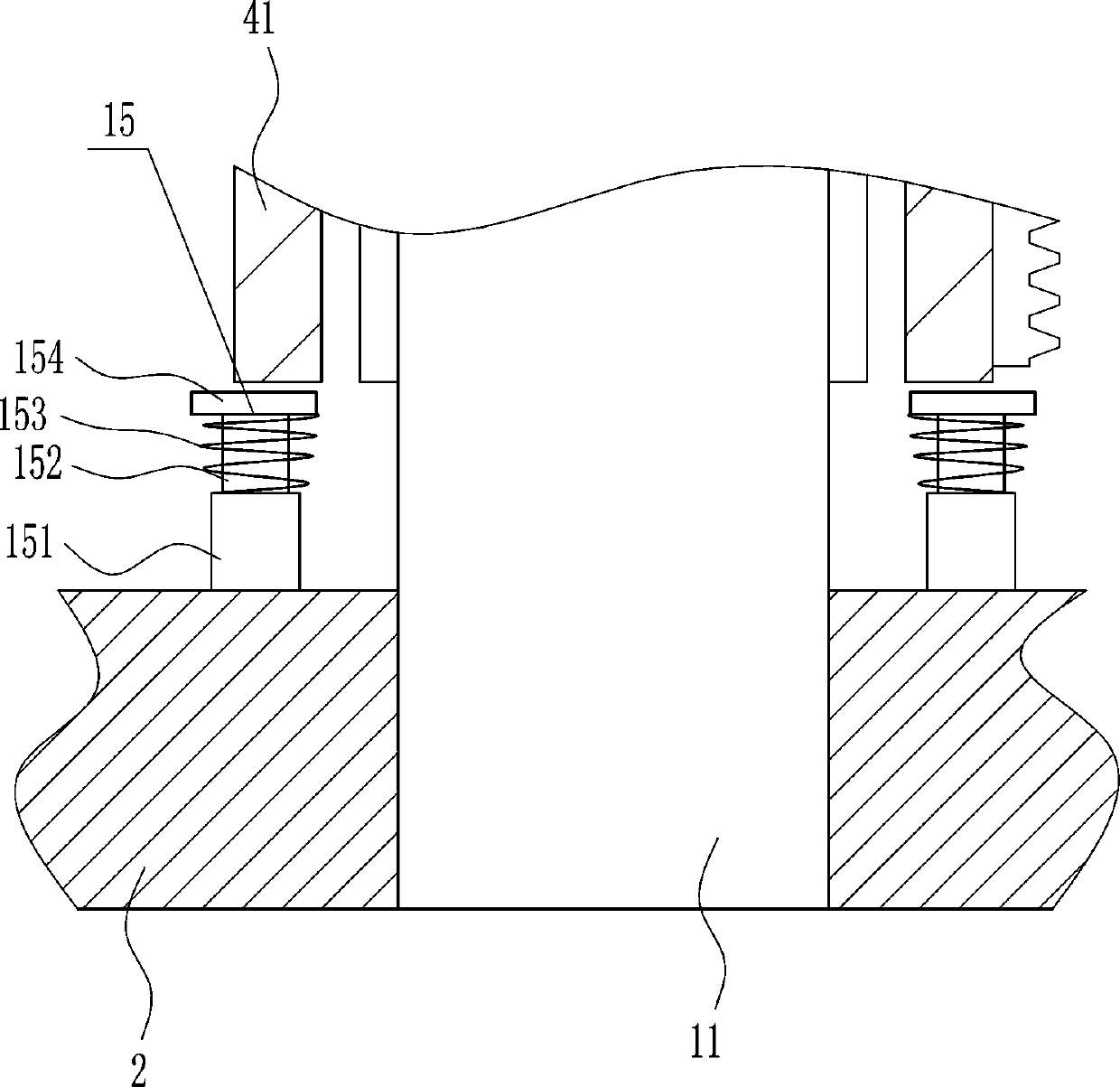

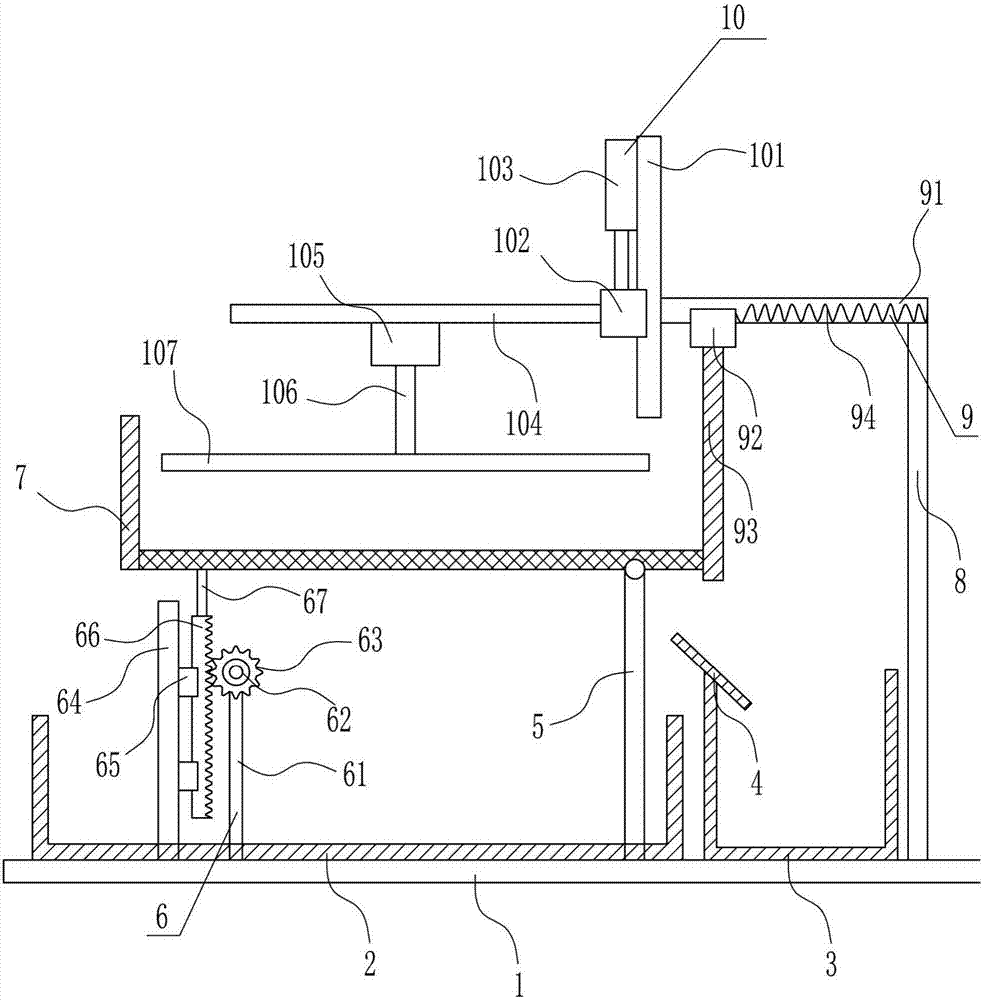

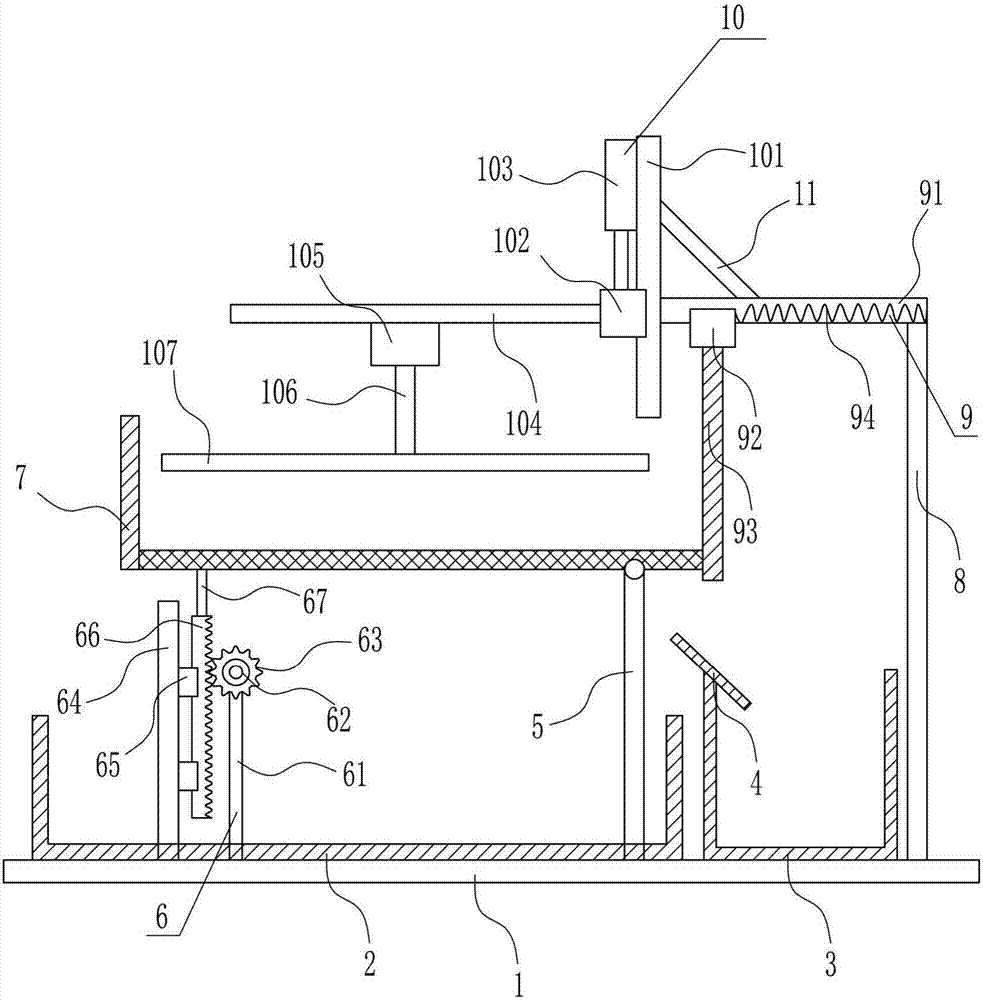

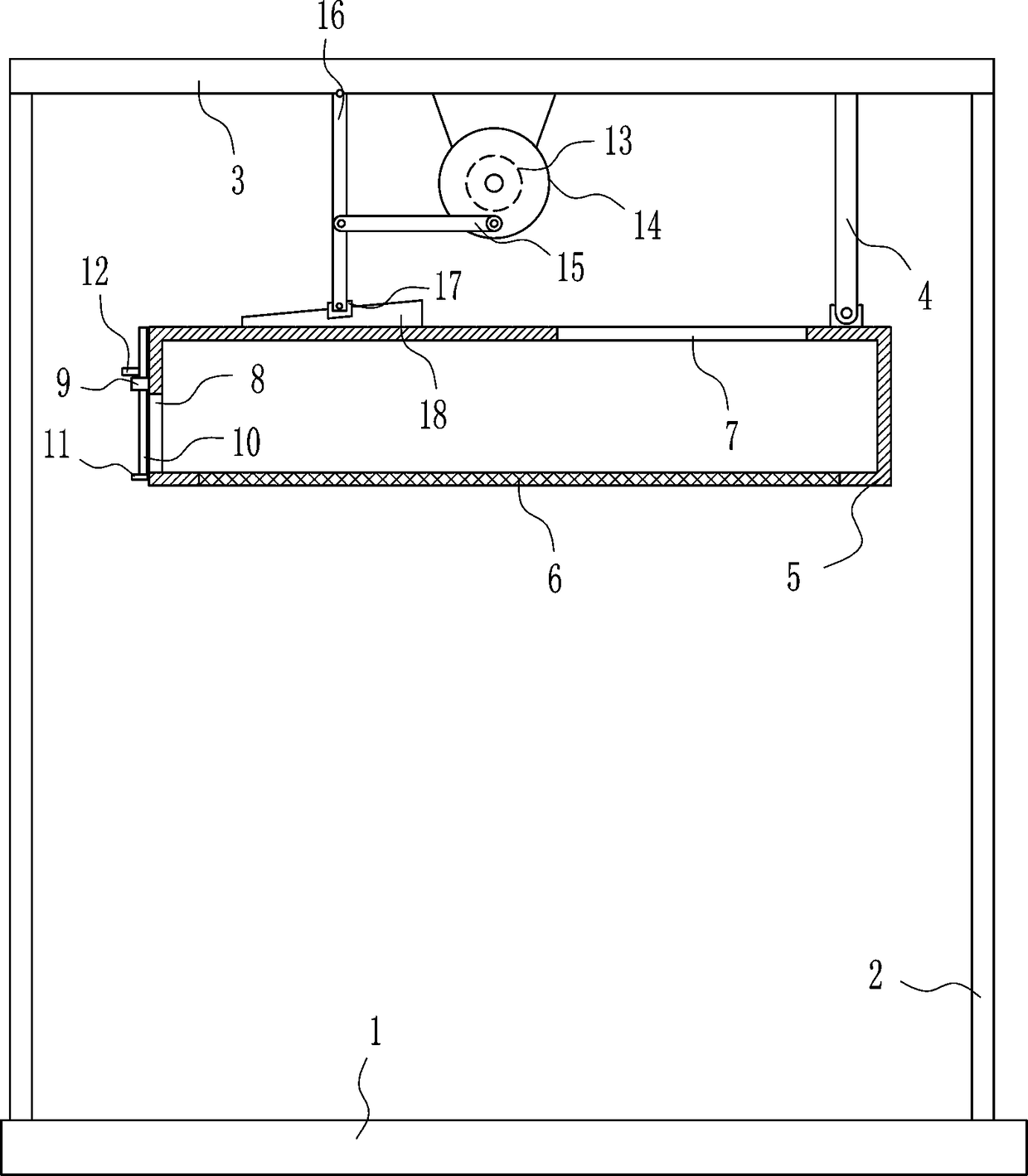

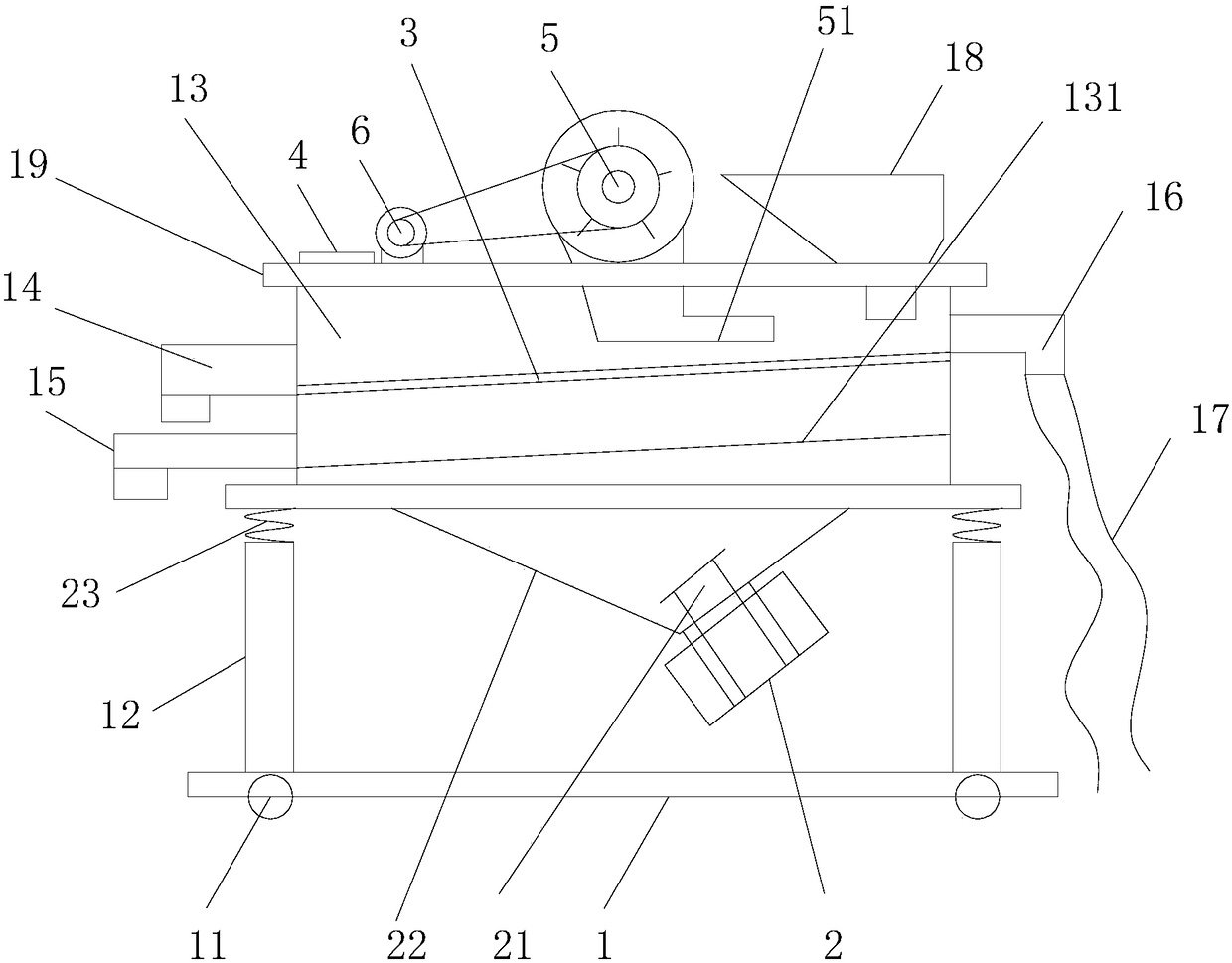

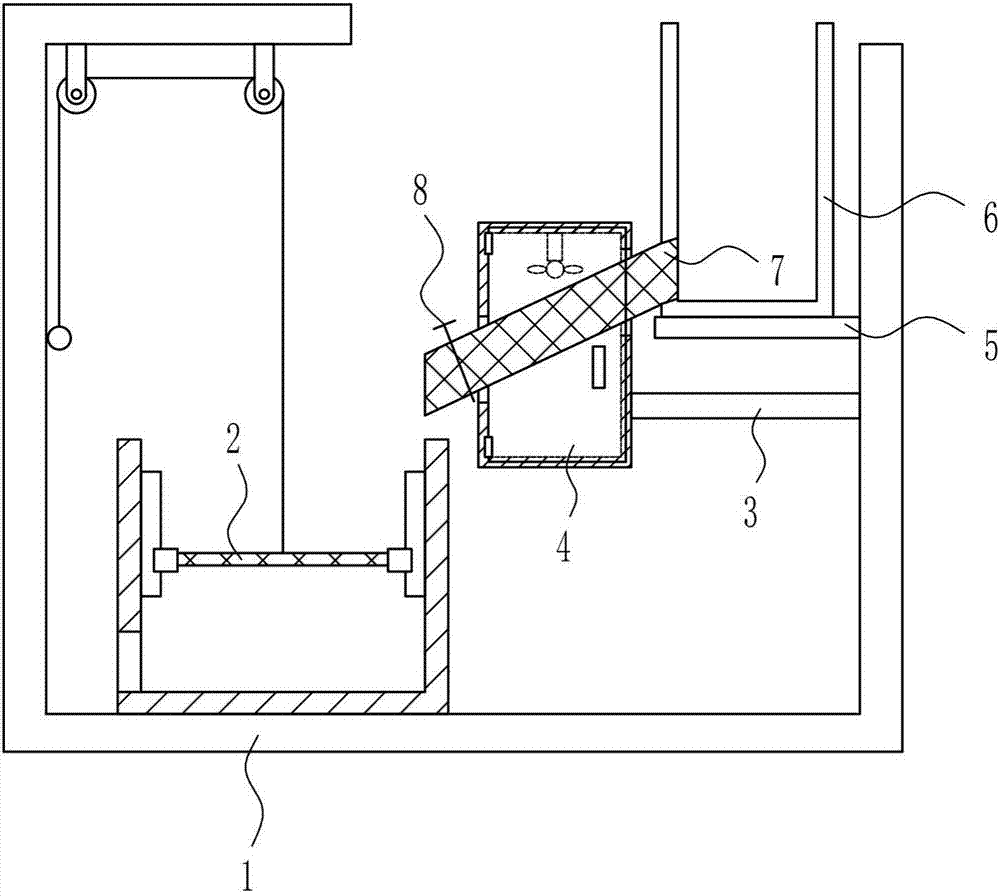

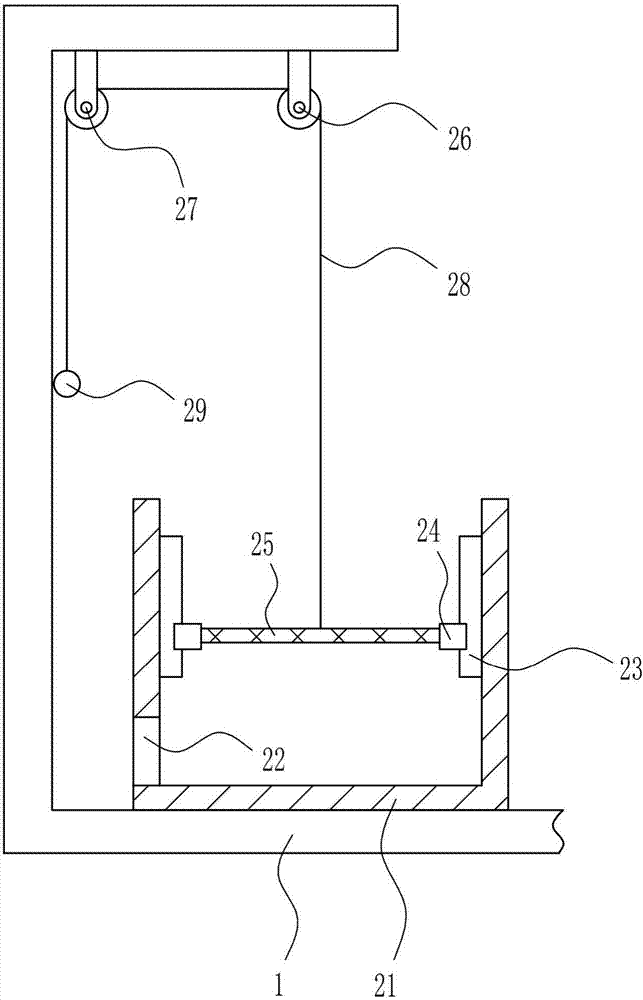

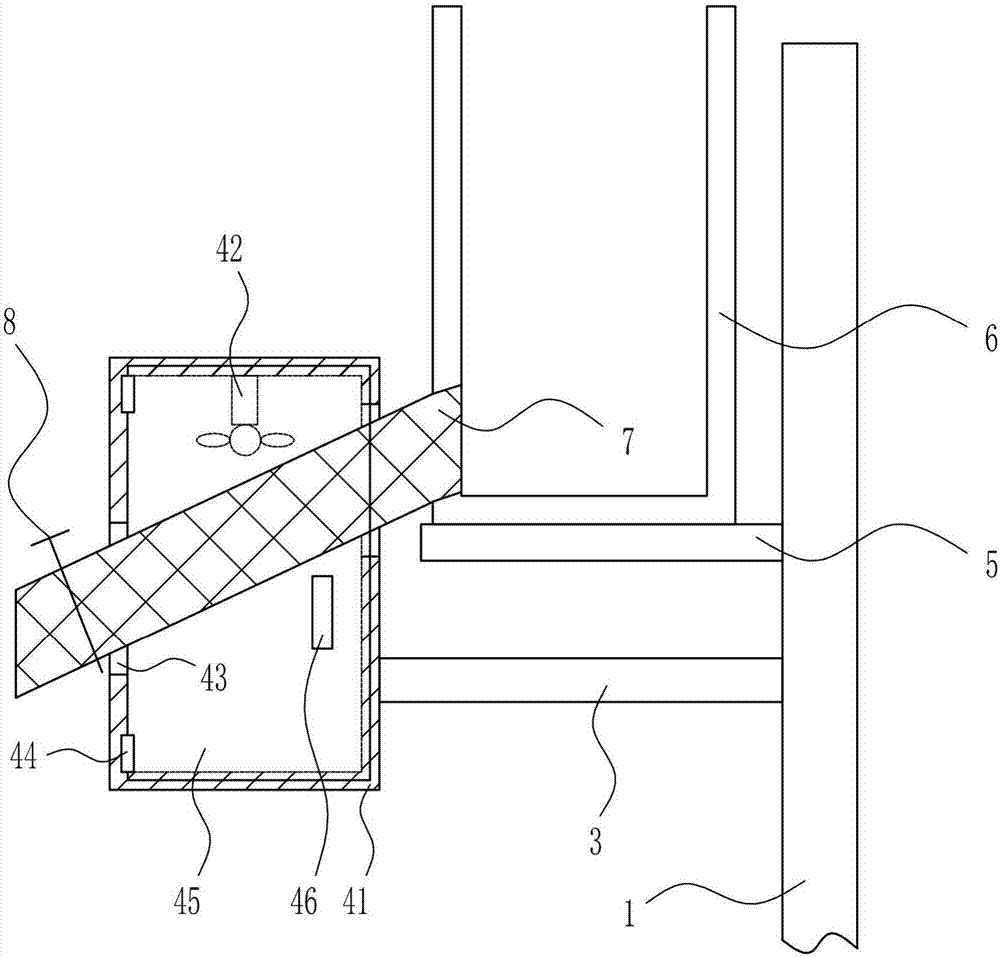

Sand screening equipment for traffic bridge

The invention relates to a screening device, in particular to a sand screening device for traffic bridges. The technical problem to be solved by the present invention is to provide a sand screening device for traffic bridges that saves time and labor, has a fast screening speed, and is not easy to splash out during the screening process, thereby saving sand. In order to solve the above technical problems, the present invention provides such a sand screening equipment for traffic bridges, which includes a bottom plate, a collection frame, a support plate, connecting rods, a screening frame, a top plate, etc.; a second mobile device is arranged in the middle of the top of the bottom plate. The moving part of the second moving device is connected with a collection frame, the left side of the top of the bottom plate is connected with a support plate by means of bolt connection, the top of the support plate is installed with a top plate through bolt connection, and the first mobile device is installed on the upper right side of the support plate . The invention achieves the effects of saving time and labor, fast screening speed, and the sand is not easy to splash out during the screening process, thereby saving sand.

Owner:惠安普科优利网络科技有限公司

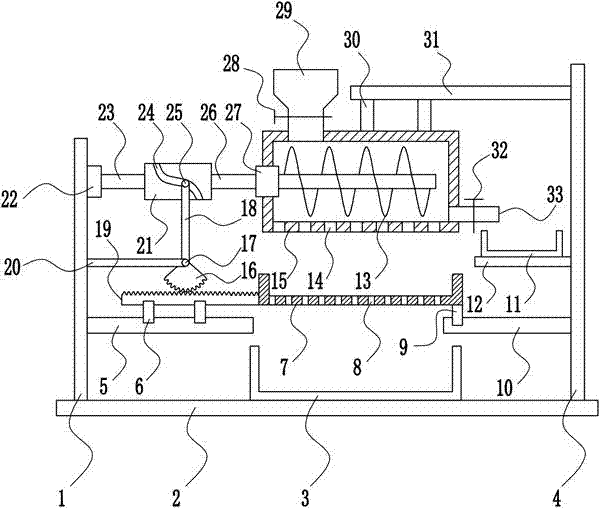

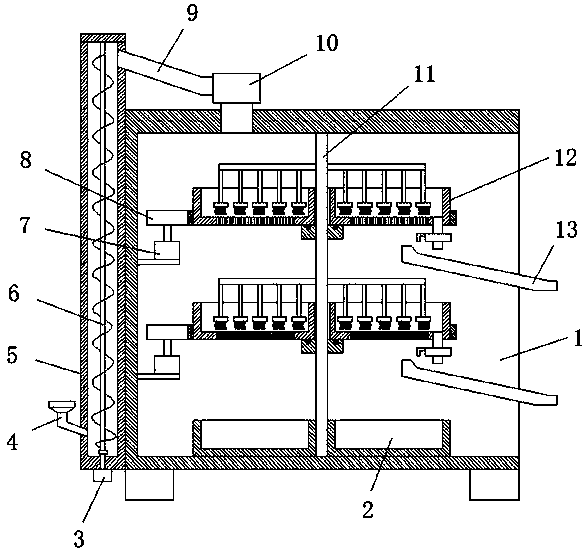

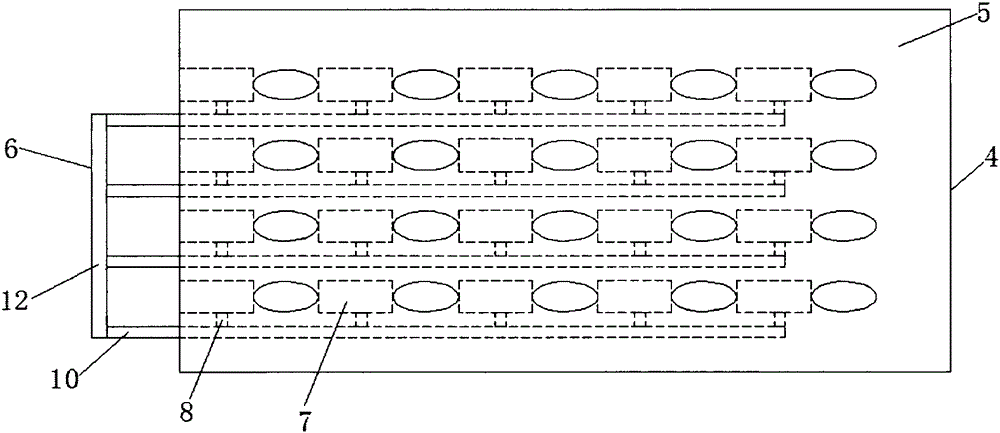

Agricultural mechanical equipment for efficient screening of soybean seeds

InactiveCN106903049ASave materialEasy to carryGas current separationAgricultural engineeringMechanical equipment

The invention relates to agricultural mechanical equipment for efficient screening of soybean seeds. The agricultural mechanical equipment comprises a left frame, a bottom plate, a first collecting frame, a right frame, a first sliding rail, a first sliding block, a screening plate, a second sliding block, a second sliding rail, a second collecting box, a fixing plate and the like. The left frame is welded to the left side of the top of the bottom plate, the right frame is welded to the right side of the top of the bottom plate, and the first collecting frame is placed in the middle of the top of the bottom plate. The agricultural mechanical equipment has the beneficial effects that the structure is novel, the screening speed is high, and the soybean seeds are not damaged; and a worker can achieve efficient screening work on the soybean seeds through the equipment, operation is simple, and in addition, time and labor are saved.

Owner:六安市富民农用器材制造有限公司

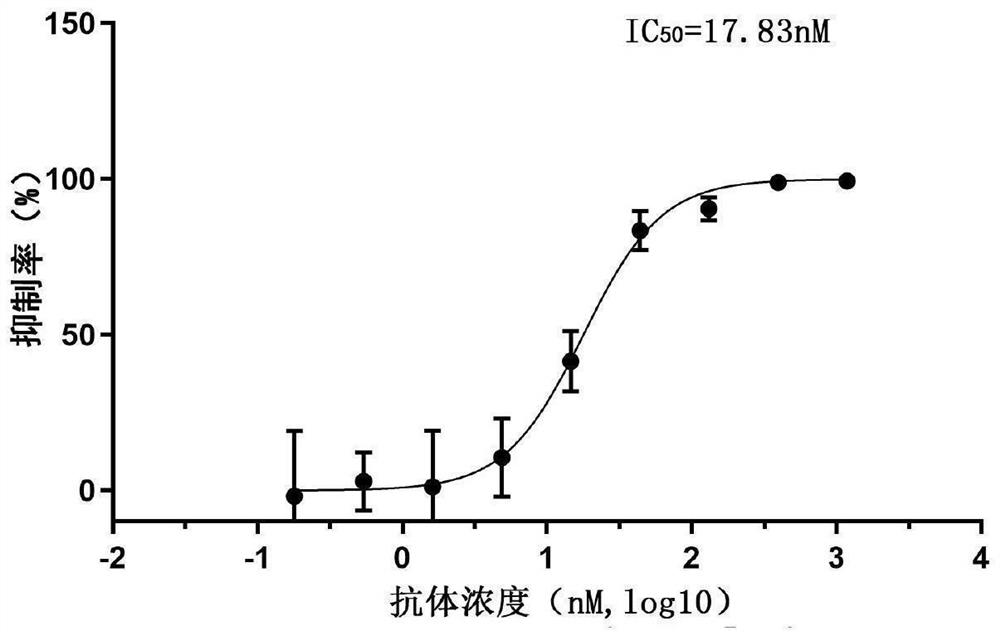

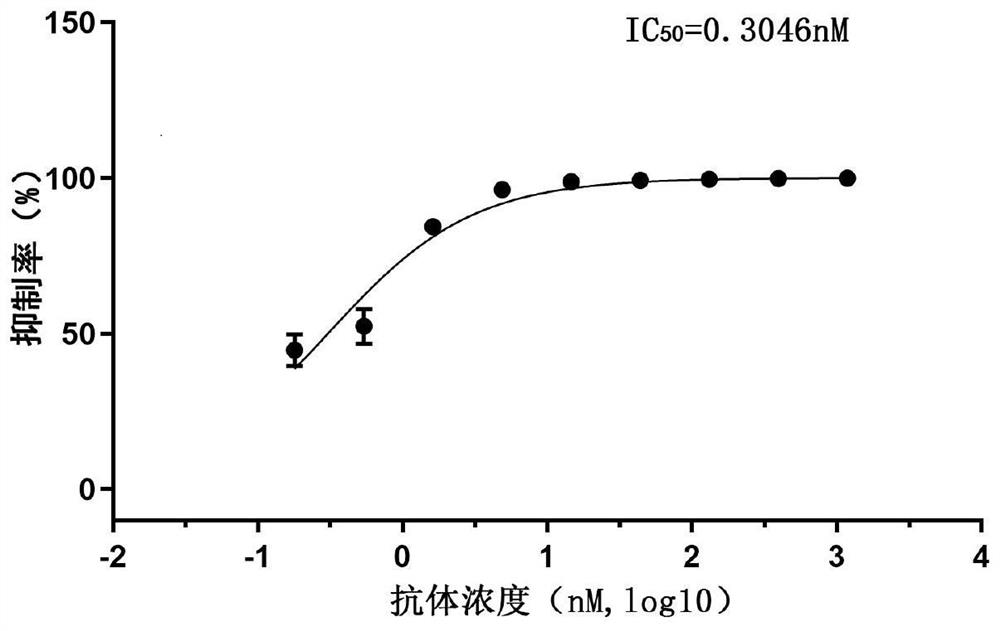

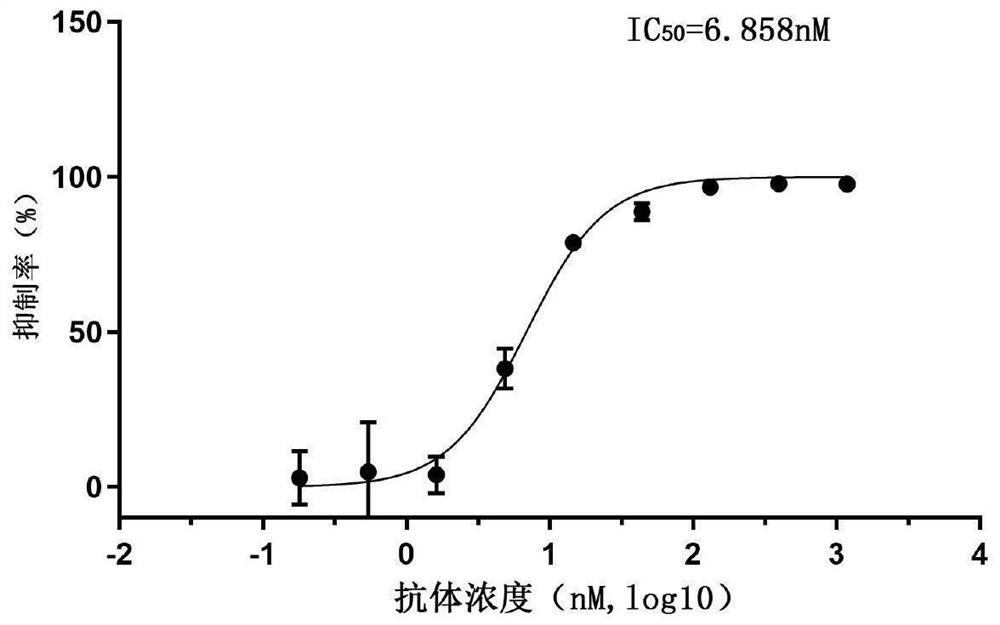

Neutralizing nano antibody for resisting novel coronavirus SARS-CoV-2 and application thereof

ActiveCN113563463AHigh neutralizing activityNot infectiousAntibody mimetics/scaffoldsGenetically modified cellsAntigenBiomedical engineering

The invention discloses a neutralizing nano antibody for resisting novel coronavirus SARS-CoV-2 and application thereof, and belongs to the technical field of biological medicine. Variable regions of the neutralizing nano antibody are provided with three complementary determining regions CDR1, CDR2 and CDR3; and the neutralizing nano antibody is any one of (a1)-(a6). The neutralizing nano antibody for resisting novel coronavirus SARS-CoV-2 provided by the invention can be effectively combined with an RBD antigen, can effectively compete with human ACE2 protein to be combined with the RBD antigen after being fused with a human IgGFc tag, has high neutralizing activity on SARS-CoV-2 pseudotype virus, and has important scientific significance and application prospects for prevention and clinical treatment of diseases caused by the novel coronavirus SARS-CoV-2 and research and development of diagnostic reagents.

Owner:INST OF PATHOGEN BIOLOGY CHINESE ACADEMY OF MEDICAL SCI

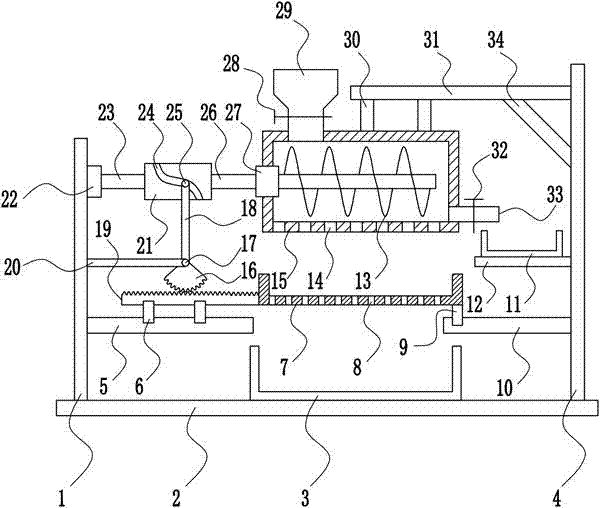

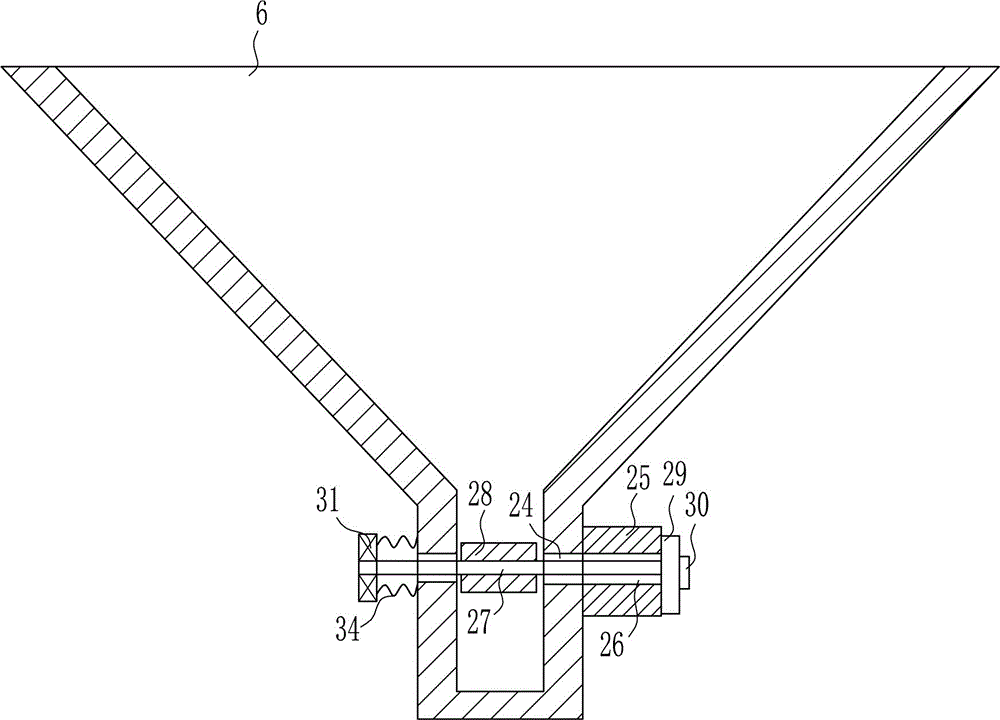

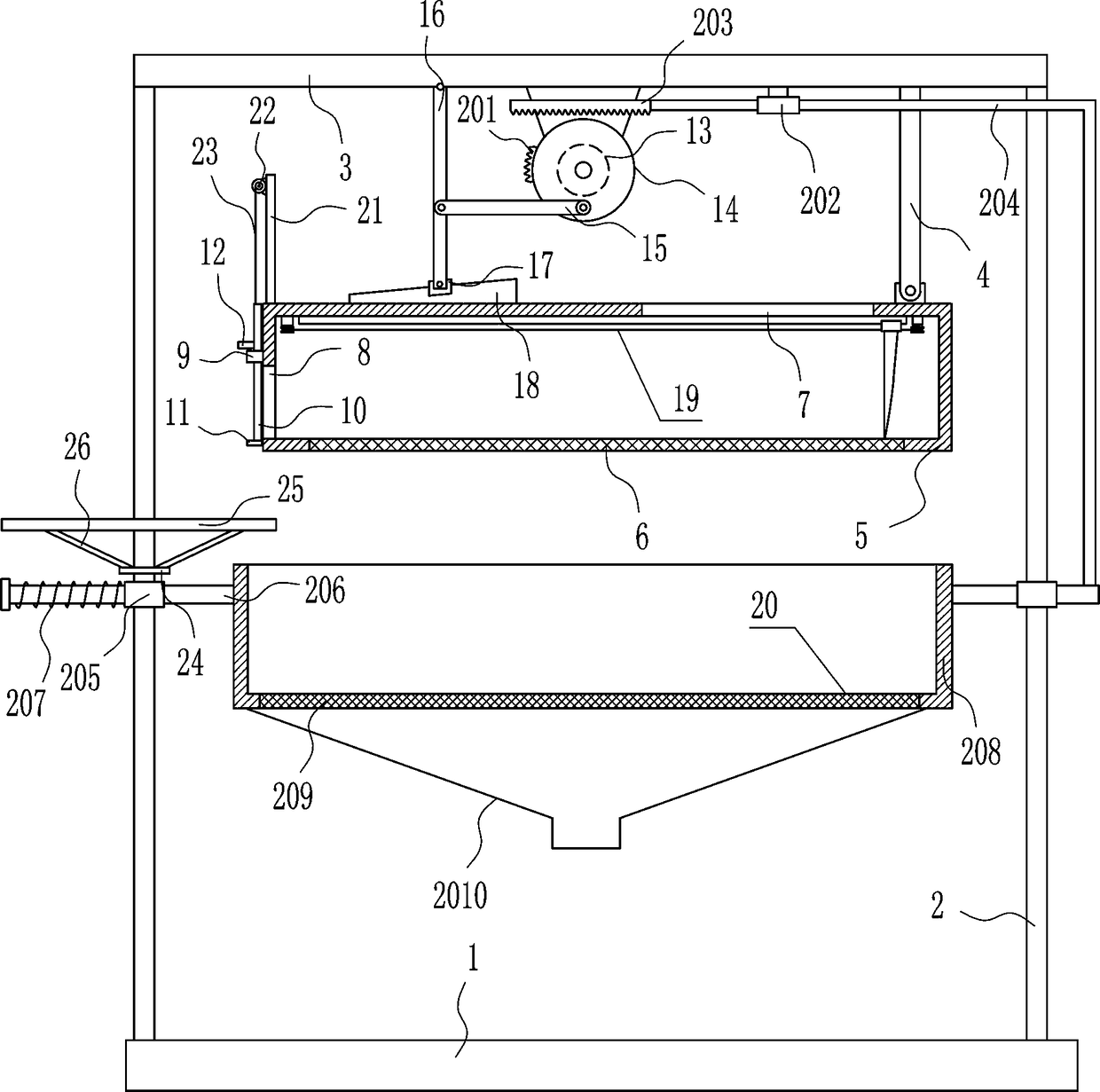

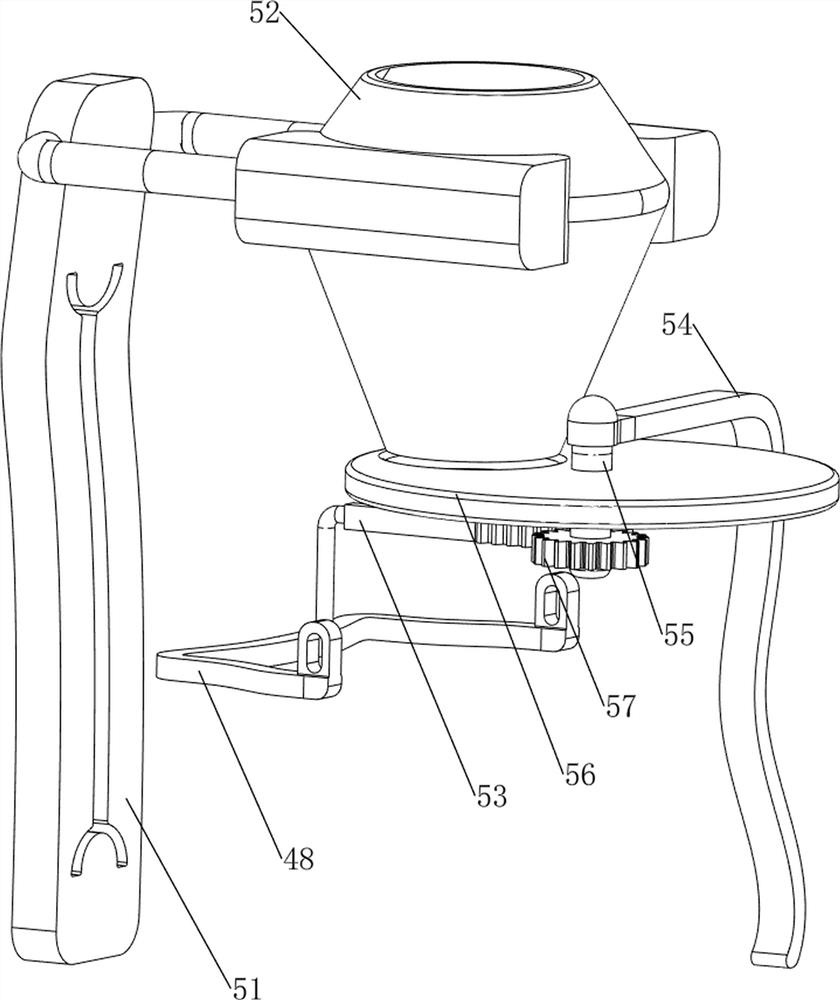

Rare earth macadam screening device for recovering rare earth wastes

ActiveCN106733608AAvoid stayingPrevent leftover rare earth waste from falling intoSievingScreeningScreening effectRare earth

The invention relates to a rare earth macadam screening device and particularly relates to a rare earth macadam screening device for recovering rare earth wastes. The technical problem to be solved by the invention is to provide a rare earth macadam screening device for recovering rare earth wastes, and the rare earth macadam screening device is good in screening effect, high in screening speed, capable of adjusting the charging flow of a charging hopper, high in utilization ratio and capable of reducing economic loss and saving resources. In order to solve the technical problem, the invention provides such a rare earth macadam screening device for recovering rare earth wastes; the rare earth macadam screening device comprises a bottom plate, a screening barrel, a side plate, a vertical moving device, a first supporting rod, a first charging hopper, a box door, a first connecting rod, a slide block, a second connecting rod, a U-shaped magnet and the like; and the middle of the top of the bottom plate is provided with the screening barrel. According to the rare earth macadam screening device for recovering rare earth wastes, provided by the invention, the rare earth wastes in an iron screening plate are screened by rotating the iron screening plate.

Owner:江苏诺德环保工程有限公司

Screening device for activated carbon processing

PendingCN108311388AEasy to filterEasy transferSievingGas current separationActivated carbonEngineering

The invention discloses a screening device for activated carbon processing. The screening device comprises a shell, and the shell is of a cylindrical structure with an opening in the side edge, a fixing shaft is arranged in the shell, a fixing base fixedly sleeves the fixing shaft, an annular sliding groove is formed in the top of the fixing base, a first catch tray movably sleeves the fixing shaft and is located above the fixing base, an annular sliding block is fixed to the bottom of the first catch tray and is arranged in the sliding groove in the top of the fixing base in a sliding mode, amounting hole is formed in the bottom of the first catch tray, a screen is arranged in the mounting hole, a gear ring is arranged at the side edge of the first catch tray, the bottom of the first catch tray communicates with a material taking pipe, and a shut-off valve is arranged at the pipe section of the material taking pipe. According to the screening device, activated carbon with multiple particle sizes can be conveniently screened in a large scale, the screening speed is high, material conveying is convenient, the operation is very simple, the structure is novel, and the practicabilityis good.

Owner:贵州森环活性炭有限公司

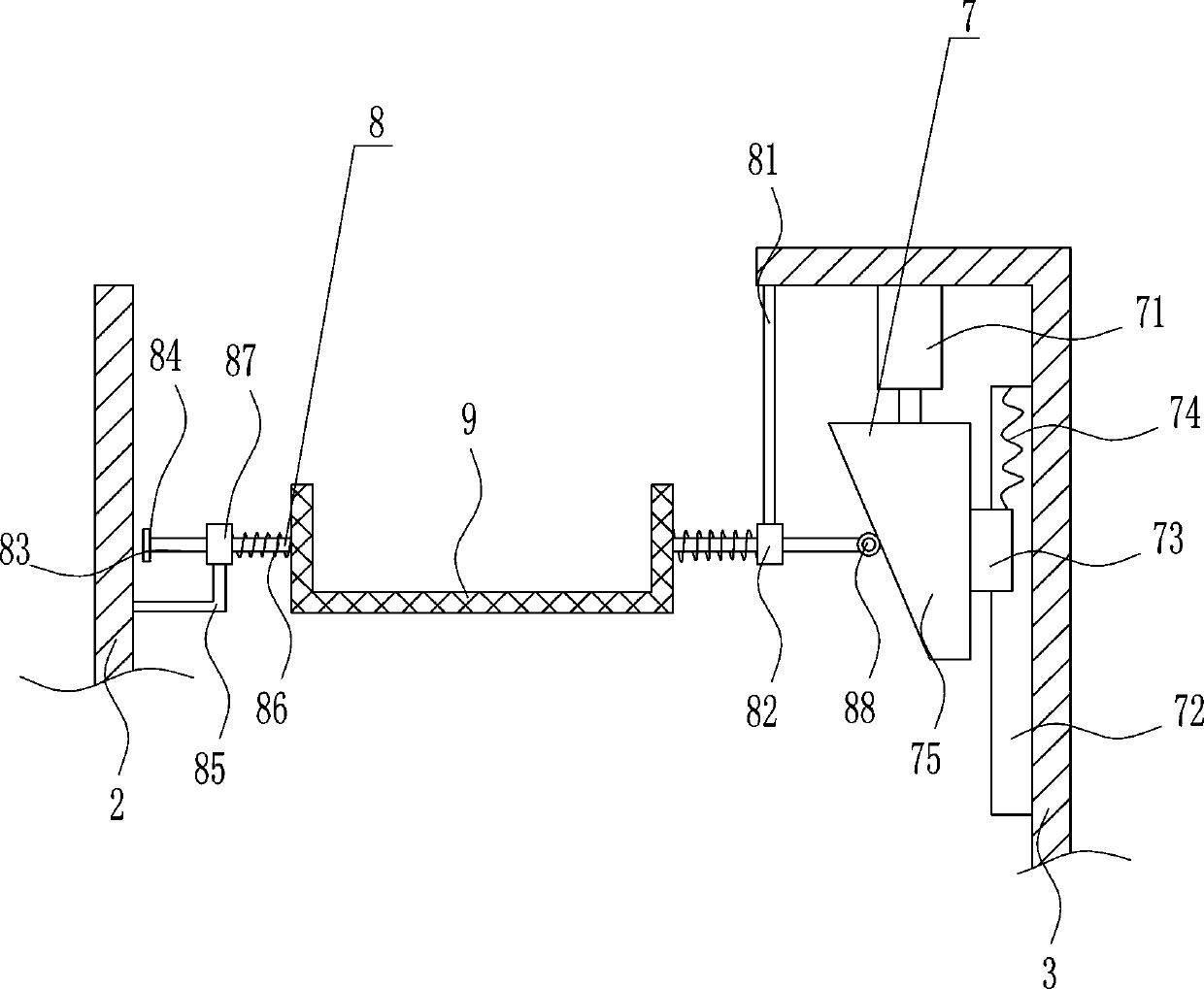

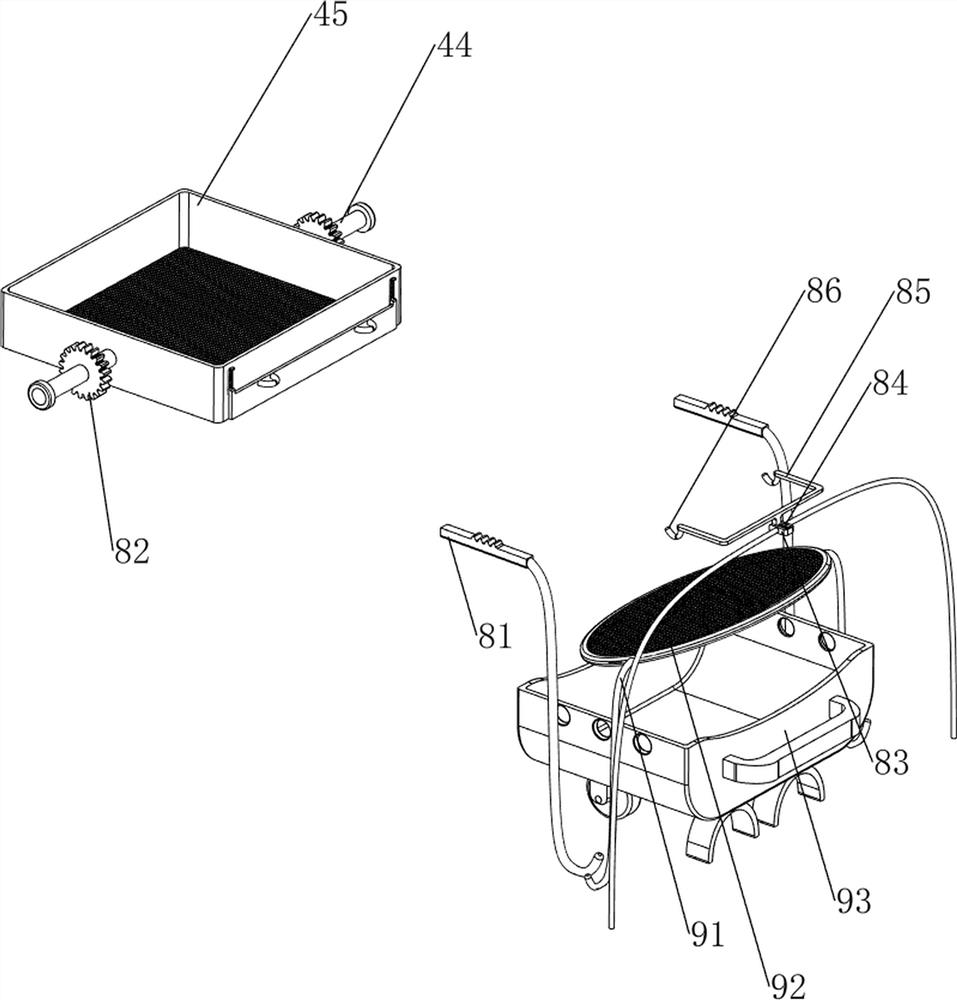

Agricultural Chinese chestnut screening device

InactiveCN107649369ADoes not affect later useEasy to filterSievingScreeningAgricultural engineeringAgriculture

The invention relates to a screening device, in particular to an agricultural Chinese chestnut screening device. According to the agricultural Chinese chestnut screening device, the screening speed and the working efficiency are high, and Chinese chestnut is not damaged due to easily falling of Chinese chestnuts in the screening process. The agricultural Chinese chestnut screening device comprisessupporting legs, a bottom plate, a supporting rod and the like. The supporting legs are symmetrically mounted on the two left side and the right side of the bottom of the bottom plate, a dischargingpipe is connected to the middle of the bottom plate in an embedded mode, and the supporting rod is mounted on the right side of the top of the bottom plate; and a feeding device is arranged between the top end of the supporting rod and the upper part of the discharging pipe, and the feeding device communicates with the interior of the discharging pipe. According to the agricultural Chinese chestnut screening device, the Chinese chestnuts can be primarily screened through a placing device, so that further screening of the Chinese chestnuts by a moving plate is facilitated, the screening effectis good, and the effects that the screening speed is high, the working efficiency is high, and the Chinese chestnuts are not damaged due to easily falling of the Chinese chestnuts are achieved.

Owner:深圳诺智研机械研究设计有限公司

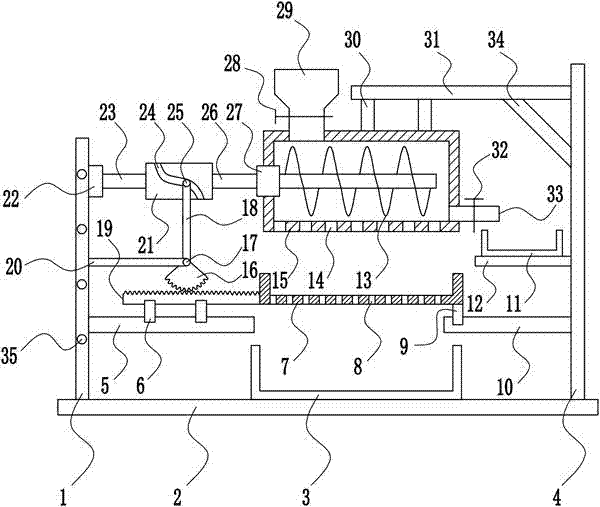

High-efficiency sand screening equipment for construction

Owner:江苏苏南建筑安装工程有限公司

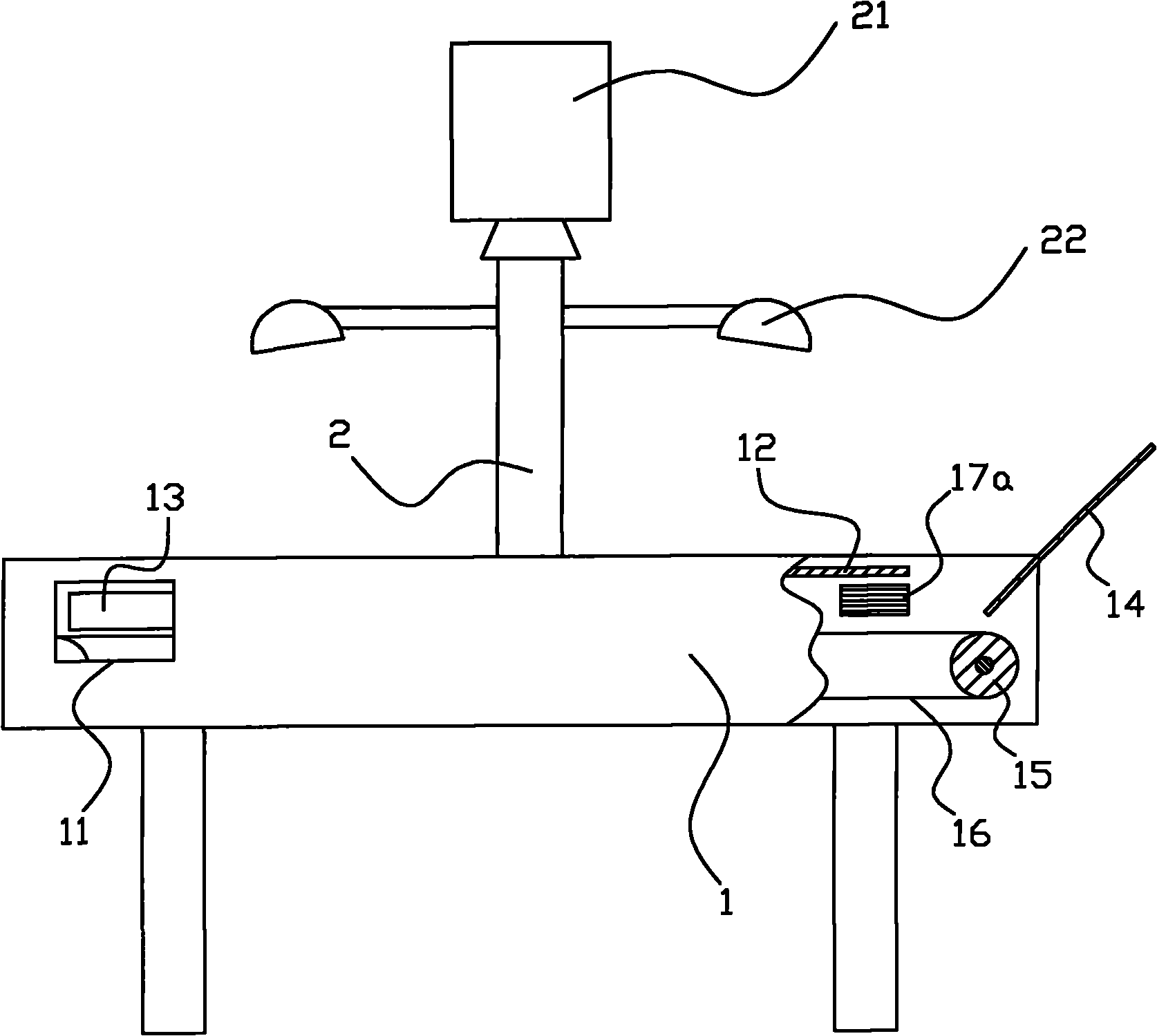

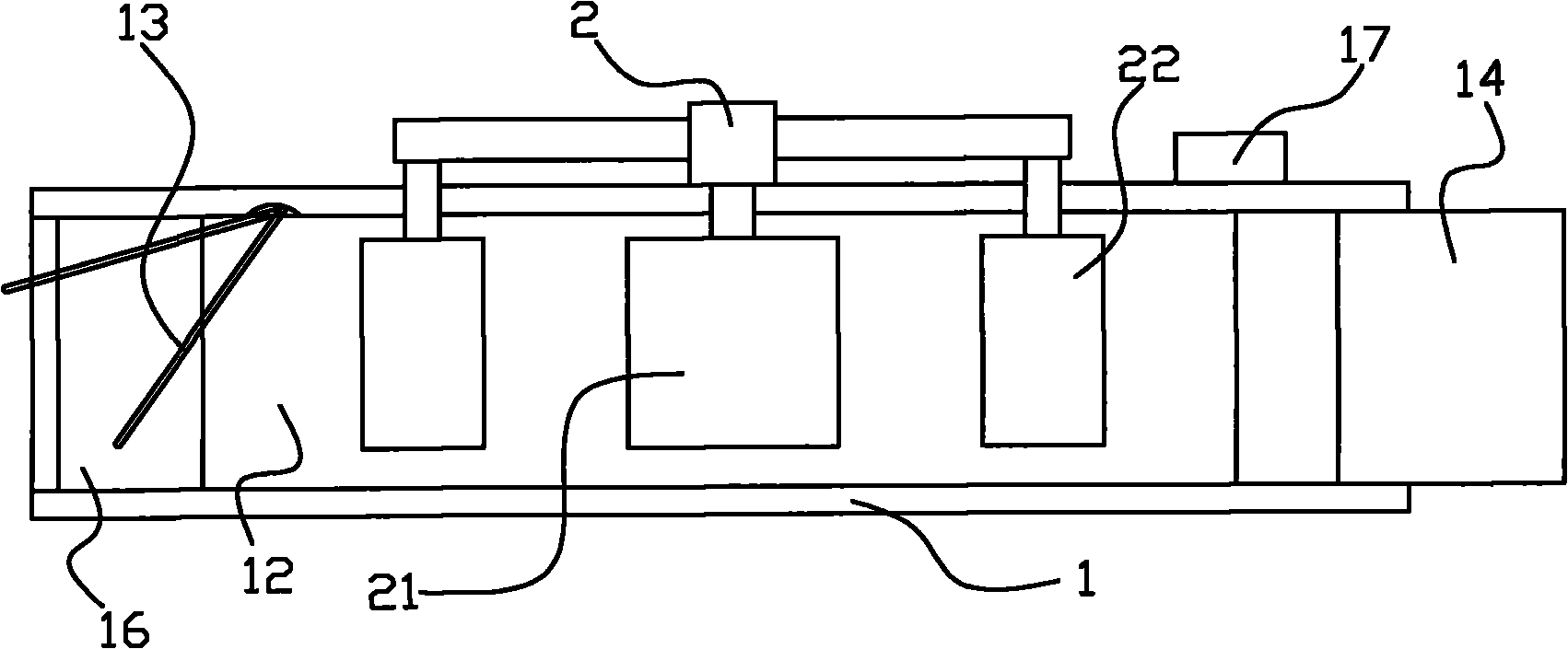

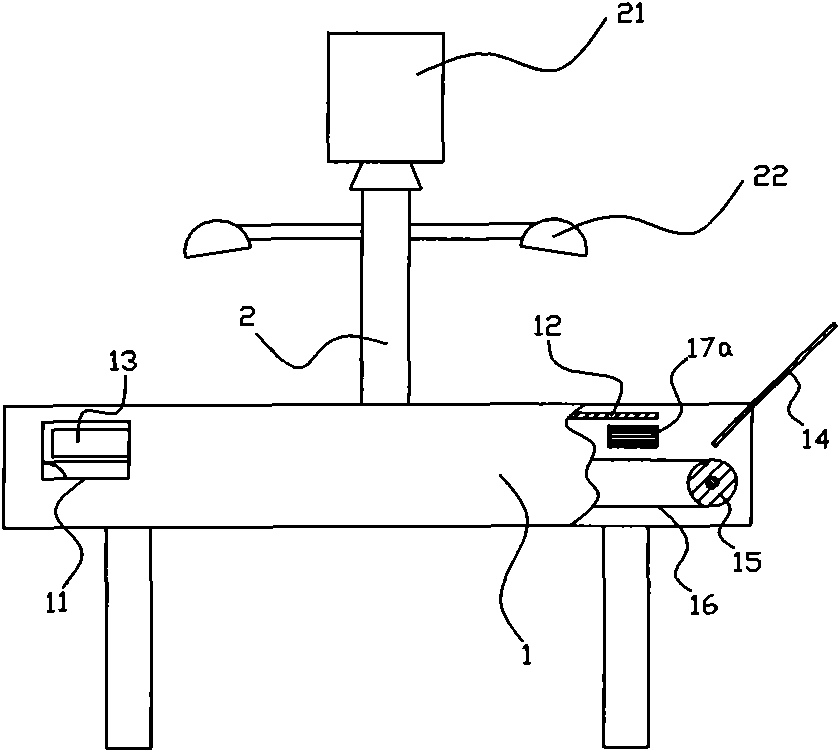

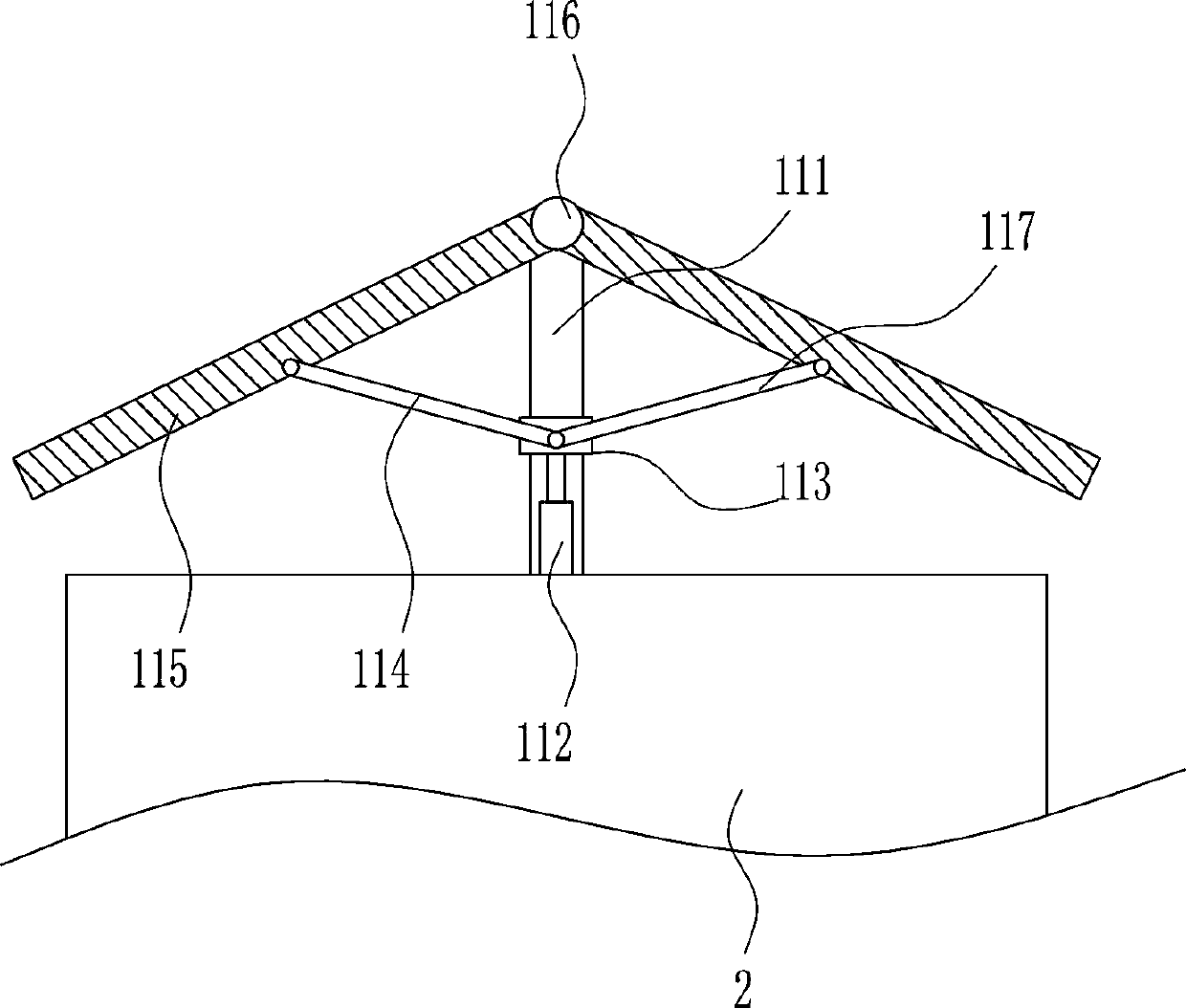

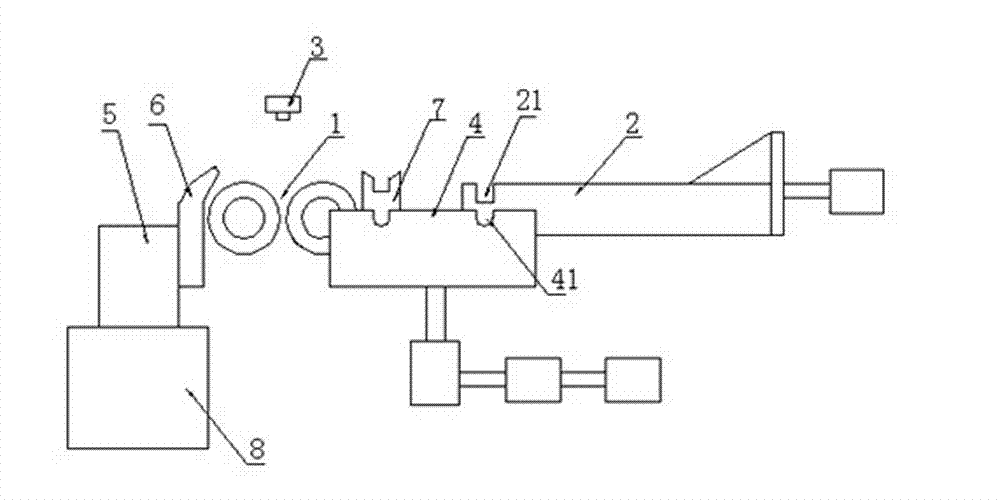

Method and special device for rapidly identifying wild large yellow croaker

InactiveCN102087098AReduce the temperatureReduce stressUsing optical meansBody heightDiffuse reflection

The invention discloses a method for rapidly identifying a wild yellow croaker, comprising the steps of measuring eye diameter, head length, body height, body length, lip length, head length, caudal peduncle height and caudal peduncle length and screening out the wild yellow croaker according to a screening standard, wherein the ratios of the eye diameter to the head length, the body height to the body length, the lip length to the head length and the caudal peduncle height to the caudal peduncle length are calculated. The invention also discloses a special device with the method, comprising a machine base provided with a conveyer belt, wherein the upper edge of the machine base is provided with a glass plate so that the conveyer belt, the machine base and the glass plate form a tube body cavity the upper side of which is transparent; a support is arranged at the middle part of the side of the machine base and is provided with a video camera; the support is also provided with a diffuse reflection light; the machine base near the discharging end of the conveyer belt is provided with sorting holes; a sorting device is arranged near the discharging end of the conveyer belt; and the sorting device and the video camera are connected with a control computer. The special device has the advantages of high sorting efficiency, accuracy in sorting and less harm to the croaker body.

Owner:ZHEJIANG OCEAN UNIV

Rare earth gravel screening device for rare earth waste recycling

ActiveCN107739853AAvoid getting wetImpact screeningProcess efficiency improvementRare earthMaterials science

The invention relates to a rare earth gravel screening device, in particular to the rare earth gravel screening device for rare earth waste recycling. The invention aims to solve the technical problemof providing a rare earth gravel screening device for rare earth waste recycling convenient to screen rare earth gravel, fast in screening speed, high in screening efficiency and convenient to move.The rare earth gravel screening device for rare earth waste recycling includes a base plate, a left supporting plate, a right supporting plate, a collecting box, a first supporting rod, a collecting hopper and the like. The left side of the top of the base plate is provided with the left supporting plate and the right side of the top of the base plate is provided with the right supporting plate. The middle of the top of the base plate is provided with the collecting box. The middle of the right side surface of the left supporting plate is provided with the first supporting rod and the right end of the first supporting rod is connected with the collecting hopper. According to the rare earth gravel screening device for rare earth waste recycling, the effects that rare earth gravel screeningis convenient, the screening speed is rapid, screening efficiency is high and movement is convenient are achieved.

Owner:南通海睿知新信息科技有限公司

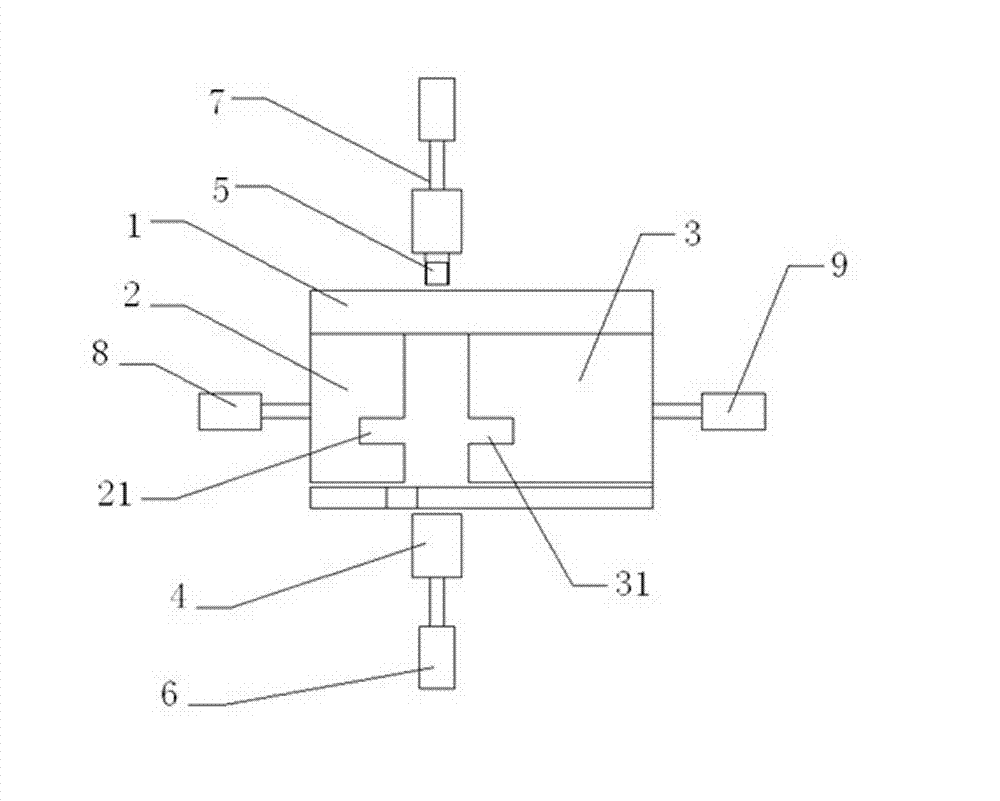

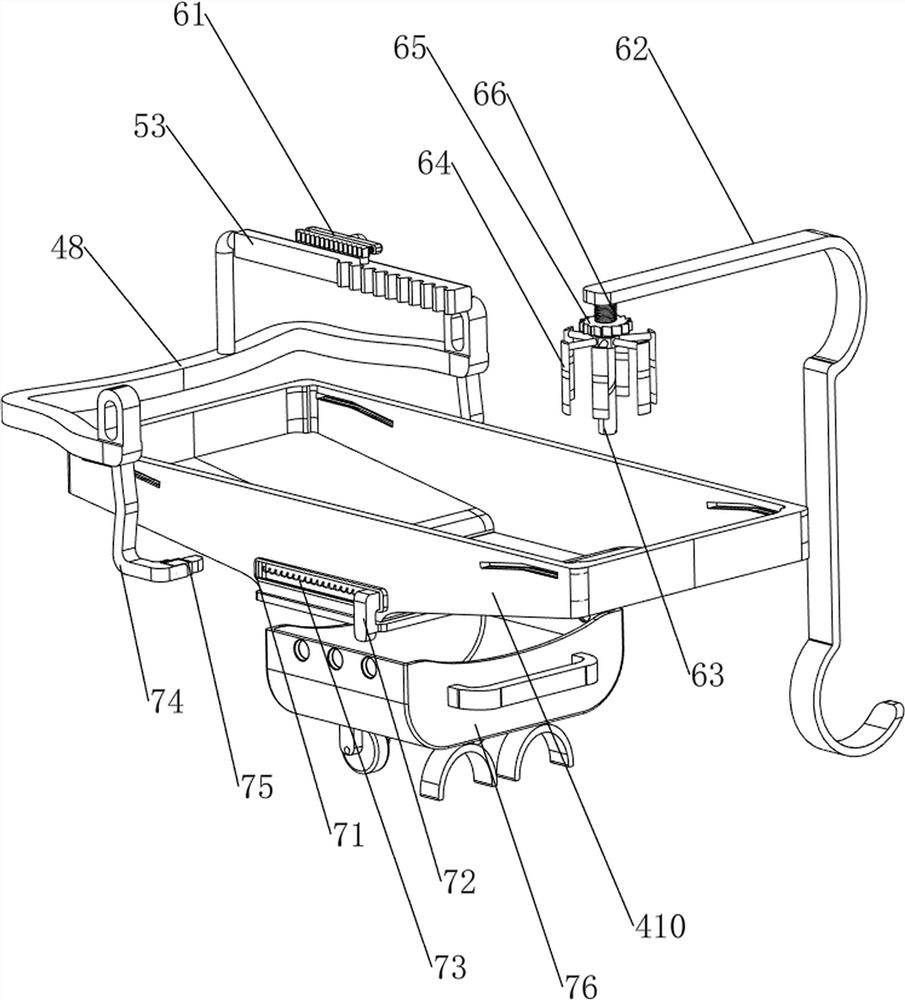

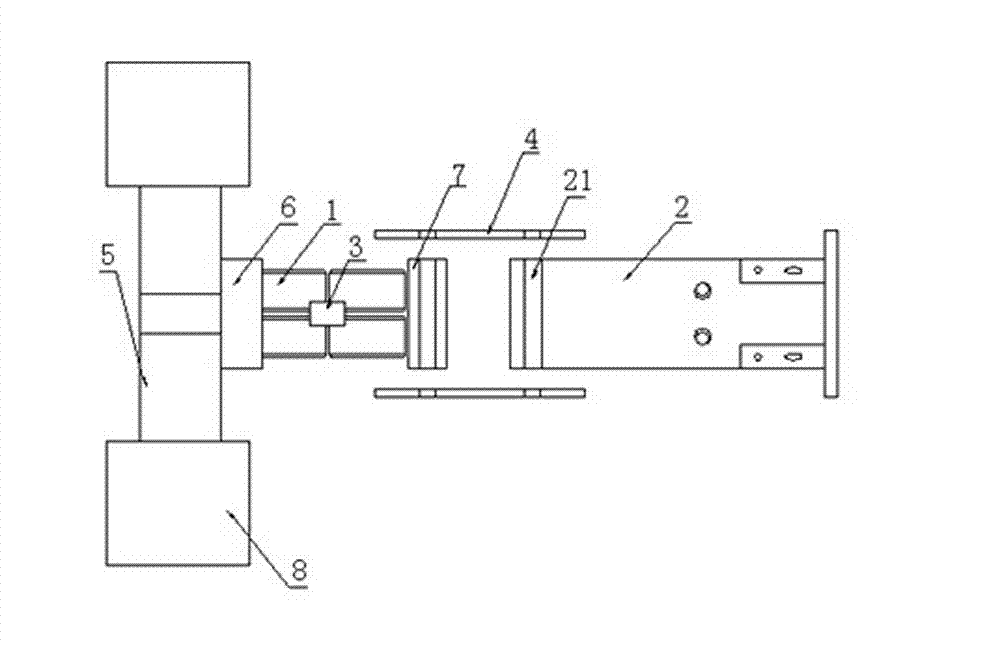

Threaded screening machine

The invention discloses a threaded screening machine. A first inner groove and a second inner groove are formed in the opposite side walls of a first positioning block and a second positioning block which can be capable of sliding to each other, on a rack, and are matched with the circumferential outer side walls of nuts; a discharging hole of a feeder is formed right above a position between the first positioning block and the second positioning block; a pushing block and a gauge are positioned on both axial sides of the first inner groove and the second inner groove respectively, and are collinear with the axis of an assembly of the first inner groove and the second inner groove; the gauge can rotate in the circumferential direction and can be slidably positioned on the rack in the axial direction; the pushing block can slide in the axial direction and can be locked and positioned on the rack in the circumferential direction; a first power device, a second power device, a third power device and a fourth power device can drive the pushing block, the gauge, the first positioning block and the second positioning block to move; a controller is used for controlling the motions of the first power device, the second power device, the third power device and the fourth power device respectively. The threaded screening machine is high in screening speed, high in production efficiency, high in screening accuracy and low in labor intensity; an operator only needs to operate screening equipment to take an unqualified product out.

Owner:DAJINHE FASTENER KUNSHAN

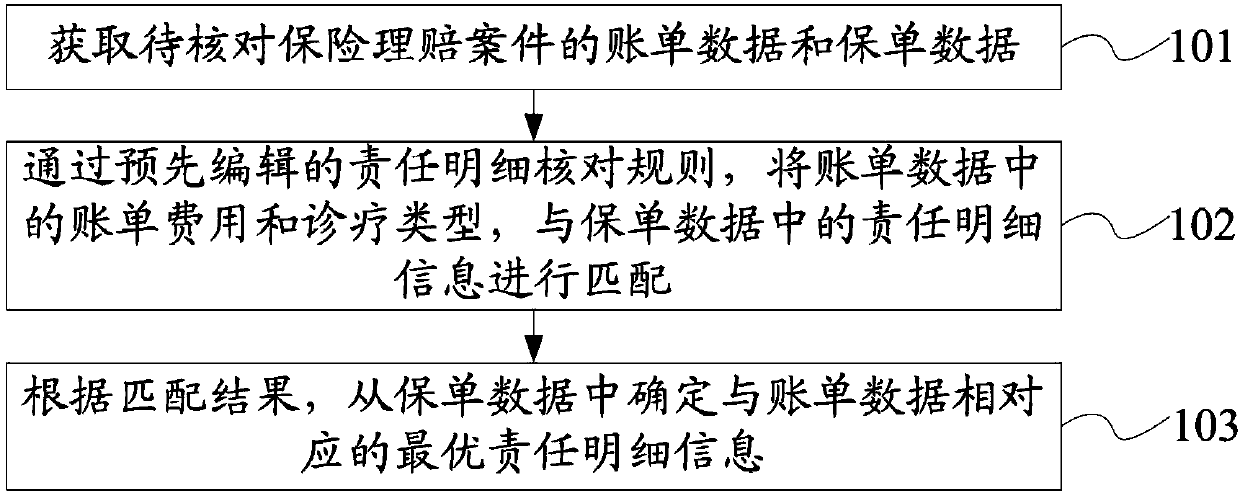

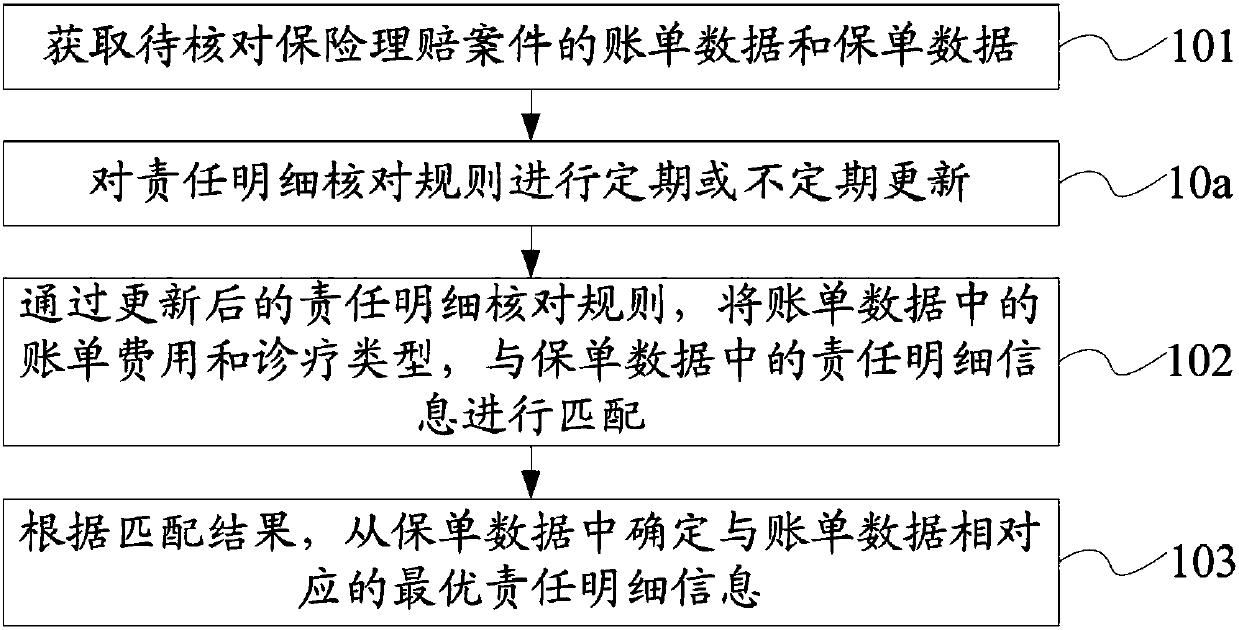

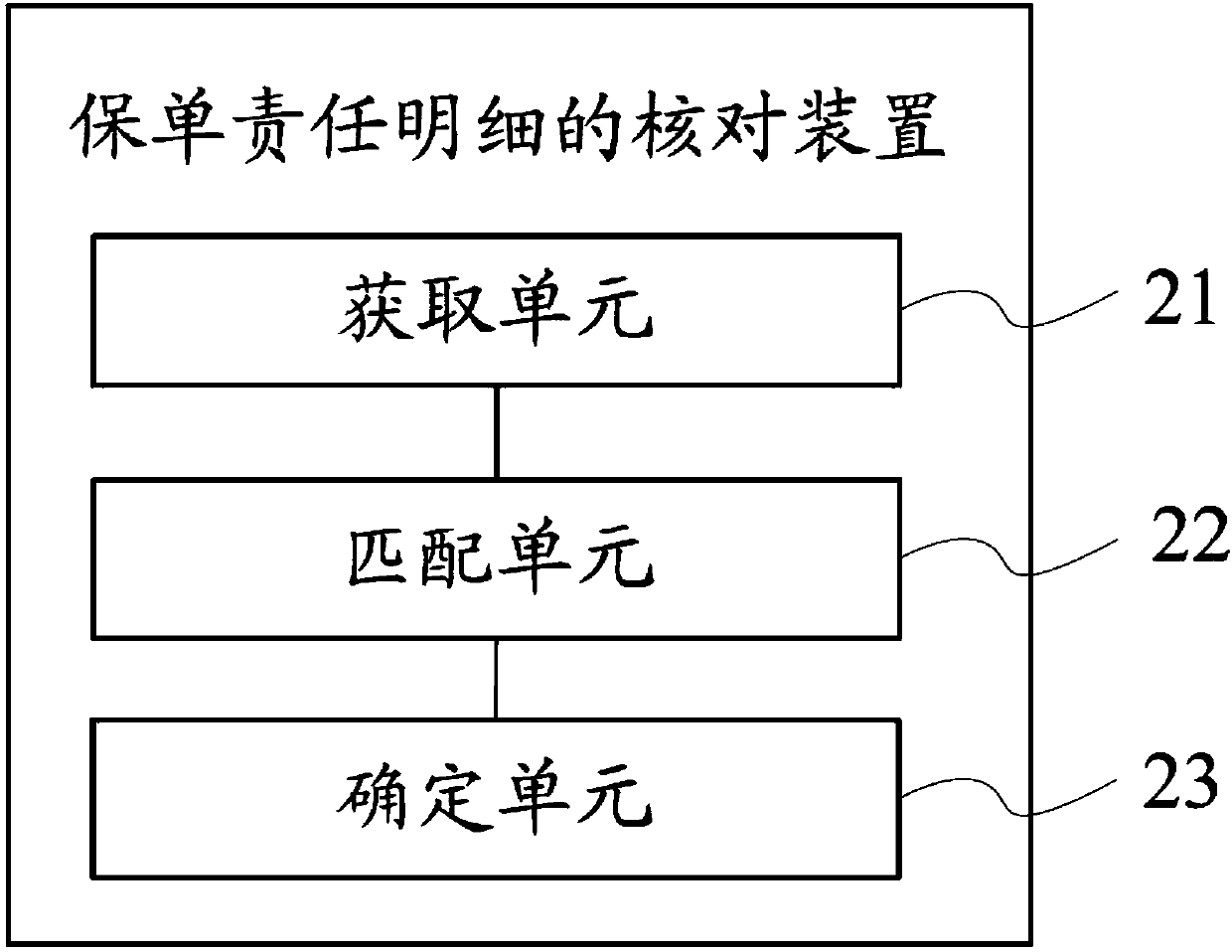

Insurance policy responsibility detail checking method and device

The invention discloses an insurance policy responsibility detail checking method and device. The method comprises the steps that the bill data and the insurance policy data of an insurance claim caseto be checked are acquired; the bill cost and the diagnosis and treatment type in the bill data are matched with the responsibility detail information in the insurance policy data through the pre-edited responsibility detail checking rules; and the optimal responsibility detail information corresponding to the bill data are determined from the insurance policy data according to the matching result. With application of the scheme, the optimal responsibility detail information can be automatically selected out of multiple responsibility detail information of the corresponding insurance policy data according to the bill data of the insurance claim case to be checked in a screening way. The whole automatic screening process is automatically performed without manual participation, and the screening process has fast speed and high accuracy so that a lot of manpower resources can be saved, the error rate can also be effectively reduced and the timeliness and the accuracy of the insurance policy responsibility detail checking process can be enhanced.

Owner:PING AN TECH (SHENZHEN) CO LTD

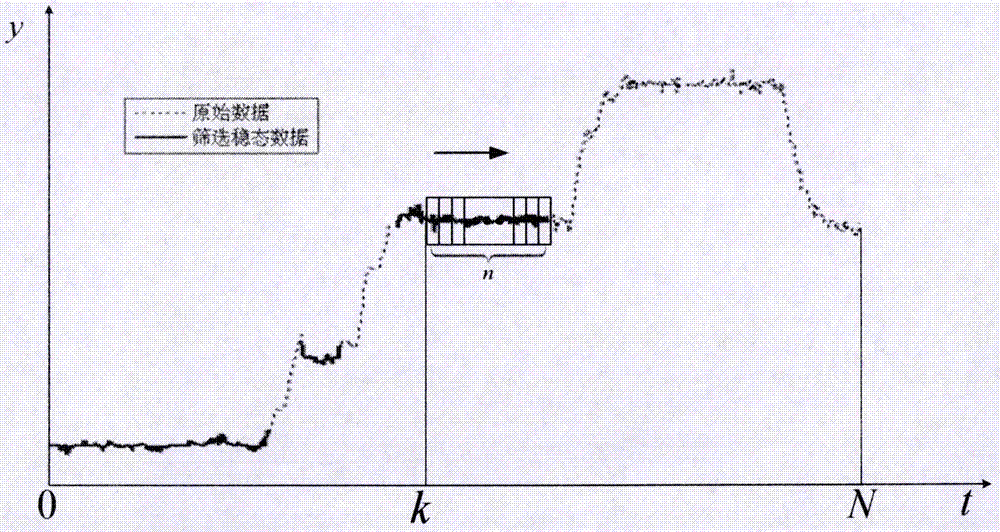

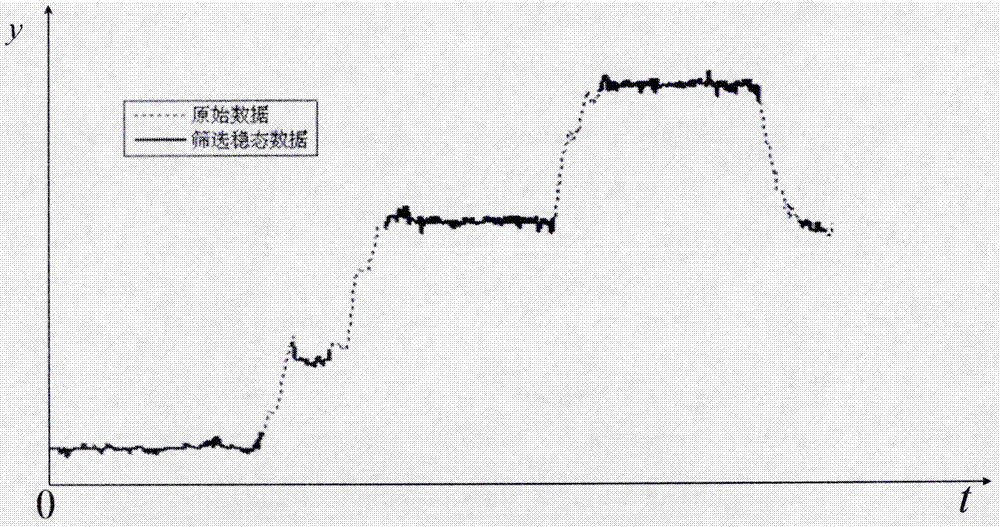

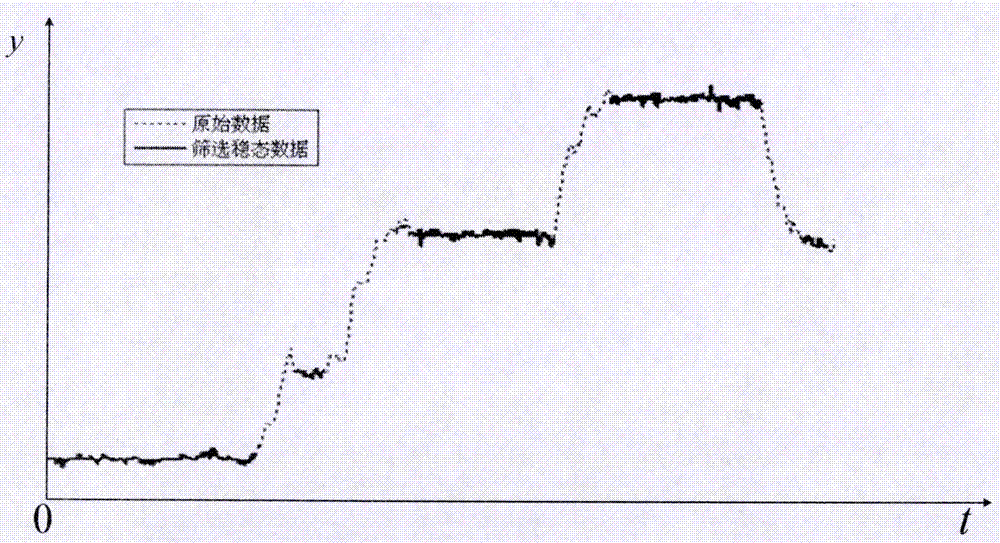

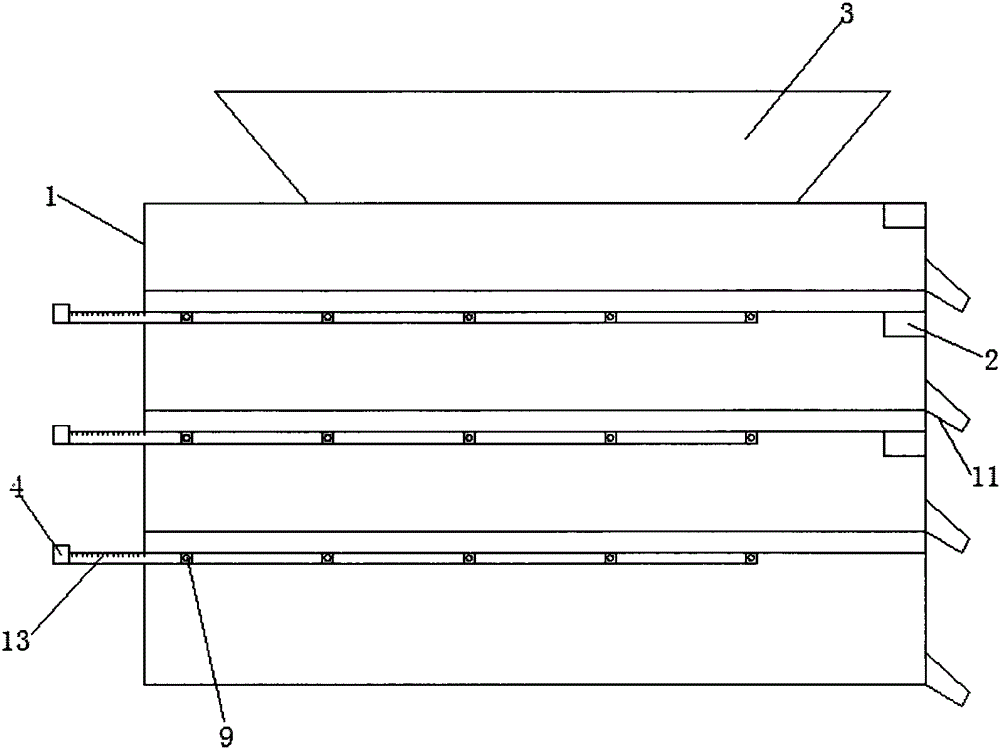

Method for quickly screening steady-state condition data in large-scale process data

ActiveCN106997391ASmall amount of calculationCalculation method is simpleSpecial data processing applicationsMetadata based other databases retrievalData segmentSlide window

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

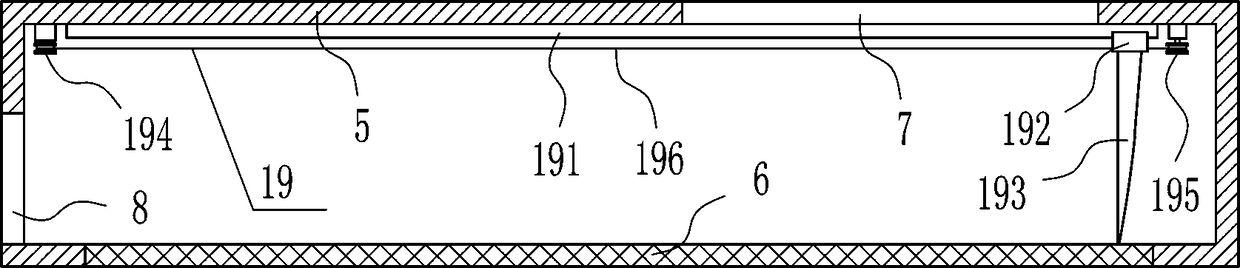

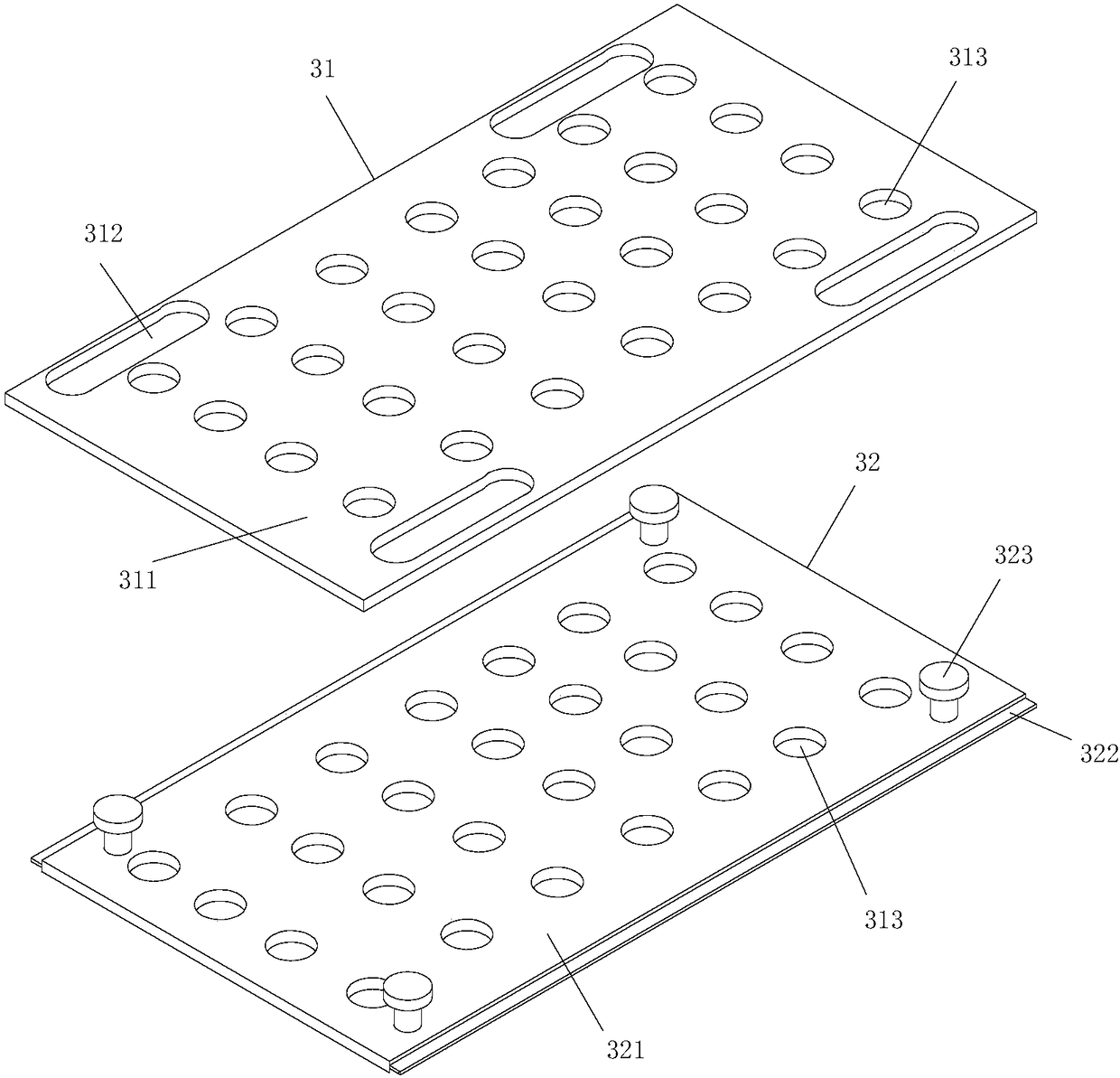

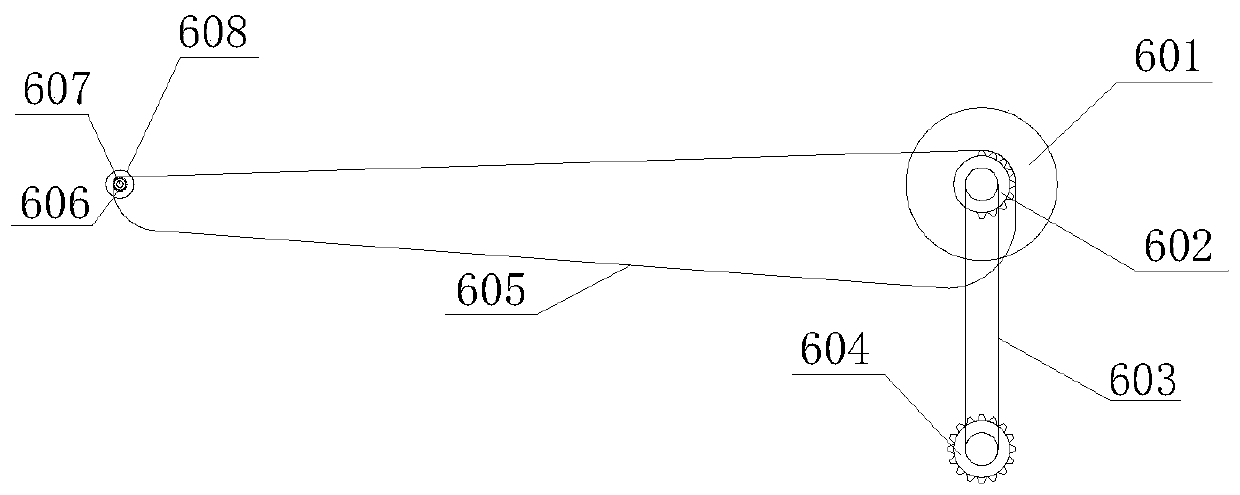

Length-adjustable type screening device of granulator

InactiveCN105128171ASimple structureSpeed up screeningSievingScreeningAgricultural engineeringHole size

The invention discloses a length-adjustable type screening device of a granulator. The length-adjustable type screening device comprises a tank body, wherein a vibrator is arranged at one side of the inner wall of the tank body; the top of the tank body communicates with a feeding hole; a length-adjustable type screening plate is arranged in the tank body; the length-adjustable type screening plate comprises a screen plate; the bottom of the screen plate is movably connected with a baffle rack; a baffle block is arranged on the baffle rack; a convex block is arranged on the baffle block; the baffle block is fixedly connected with a connecting rod through the convex block and a nut; one end of the connecting rod is fixedly connected with a straight rod; and a discharge hole is formed in one side of the tank body. According to the length-adjustable type screening device, the length-adjustable type screening plate which comprises the screen plate and the baffle rack is arranged, so that size of screen holes in the screen plate is regulated by sliding the baffle rack, and therefore, people can screen plastic particles with different lengths. The length-adjustable type screening device is simple in structure, convenient for people to use, and convenient for people to regulate the size of the screen holes by arranging scale marks on the connecting rod.

Owner:SUZHOU POLYKING COMPOSITE

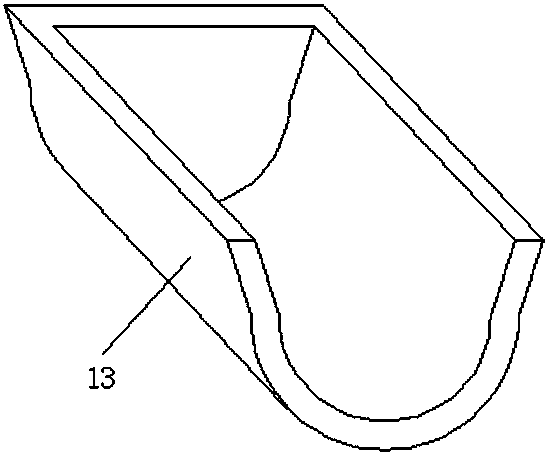

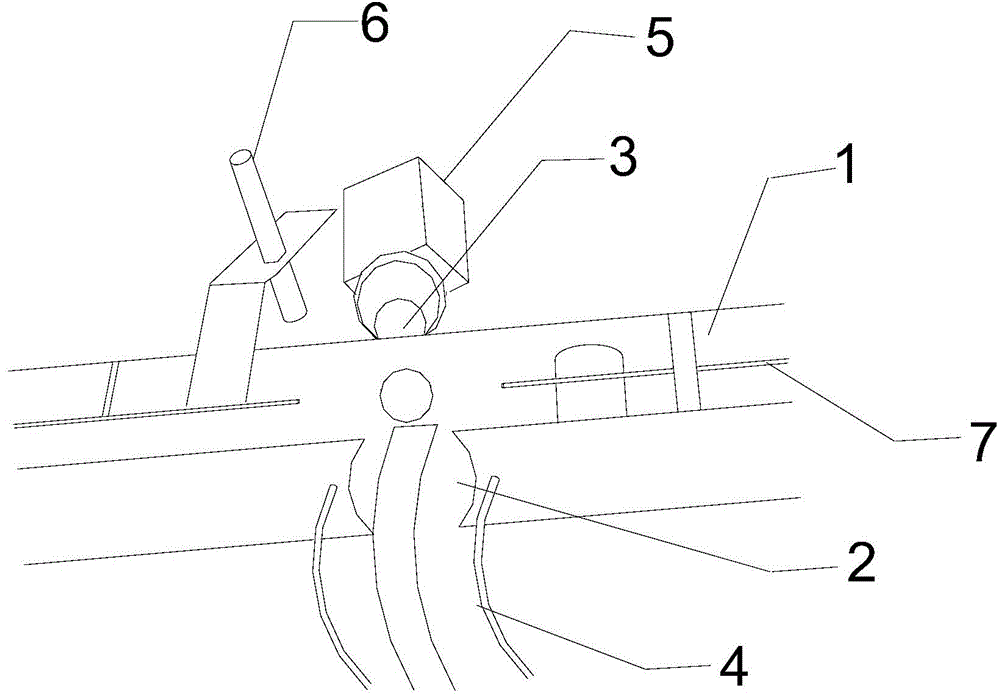

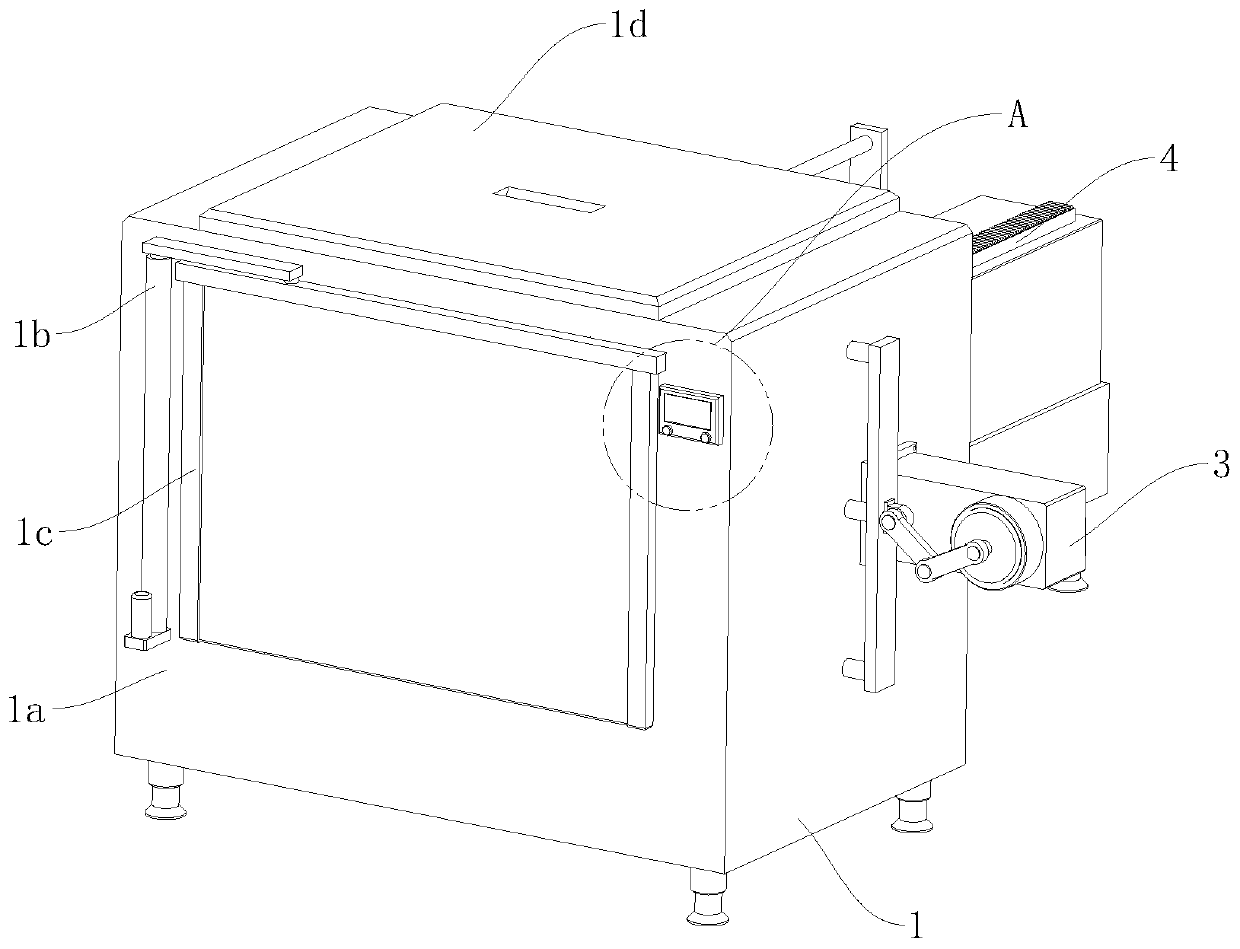

Screening apparatus of bottle cap hoop

Disclosed in the invention is a screening apparatus of a bottle cap hoop. A circular-truncated-cone-shaped cavity is formed in the bottle cap hoop. The screening apparatus comprises a working groove (1), a detection head (3), and a guiding rail (4). The bottle cap hoop is located in the working groove (1) and the axial direction of the bottle cap hoop is perpendicular to the length direction of the working groove (1), so that the bottle cap hoop can roll in the working groove (1). A guiding hole and a turning port (2) are respectively formed in side walls at the tow ends of the working groove (1); and the guiding hole and the turning port (2) are symmetric at the length direction of the working groove (1). One end of the guiding rail (4) is arranged at the outer edge of the turning port (2); and the detection head (3) having a cylindrical structure can extend into the working groove (1) through the guiding hole. With the screening apparatus, bottle cap hoops in a chaotic mode can be screened effectively.

Owner:WUHU BLUE SKY ENG PLASTIC CO LTD

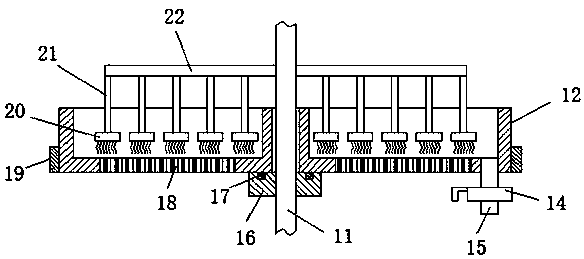

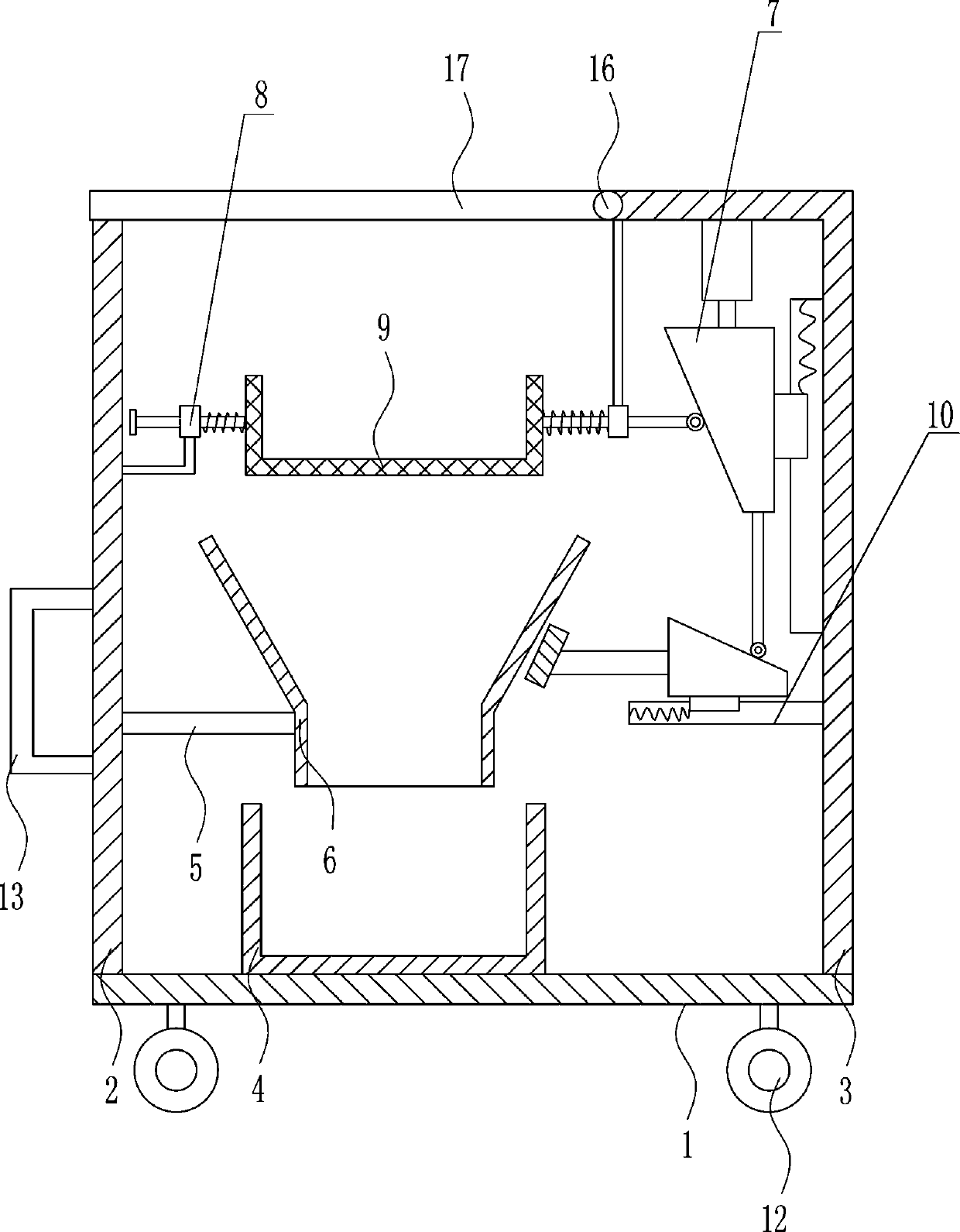

Agricultural soybean grading and screening equipment

InactiveCN108526012AImprove filtering effectFast screeningSievingGas current separationAgricultural engineeringAgriculture

The invention relates to screening equipment, in particular to agricultural soybean grading and screening equipment. The invention aims to provide the agricultural soybean grading and screening equipment which is good in screening effect and high in screening rate, and different sizes of soybeans cannot be screened out together. In order to solve the technical problem, the agricultural soybean grading and screening equipment provided by the invention comprises a base plate, supporting rods, a top plate, a vertical rod, a screening box, a first screen plate, a first guide sleeve, a baffle plate, a first limiting block, a second limiting block, a motor and the like, wherein the supporting rods are symmetrically mounted on the left side and the right side of the top of the base plate; the topplate is mounted between the tops of the supporting rods on the left side and the right side; the vertical rod is mounted on the right side of the bottom of the top plate; the screening box is mounted at the bottom of the vertical rod rotatably. According to the agricultural soybean grading and screening equipment, through a secondary screening device, the soybeans can be further screened, the soybean screening effect is better, and the effects that the screening effect is good, the screening rate is high, and the different sizes of soybeans cannot be screened out together are achieved.

Owner:谢思媛

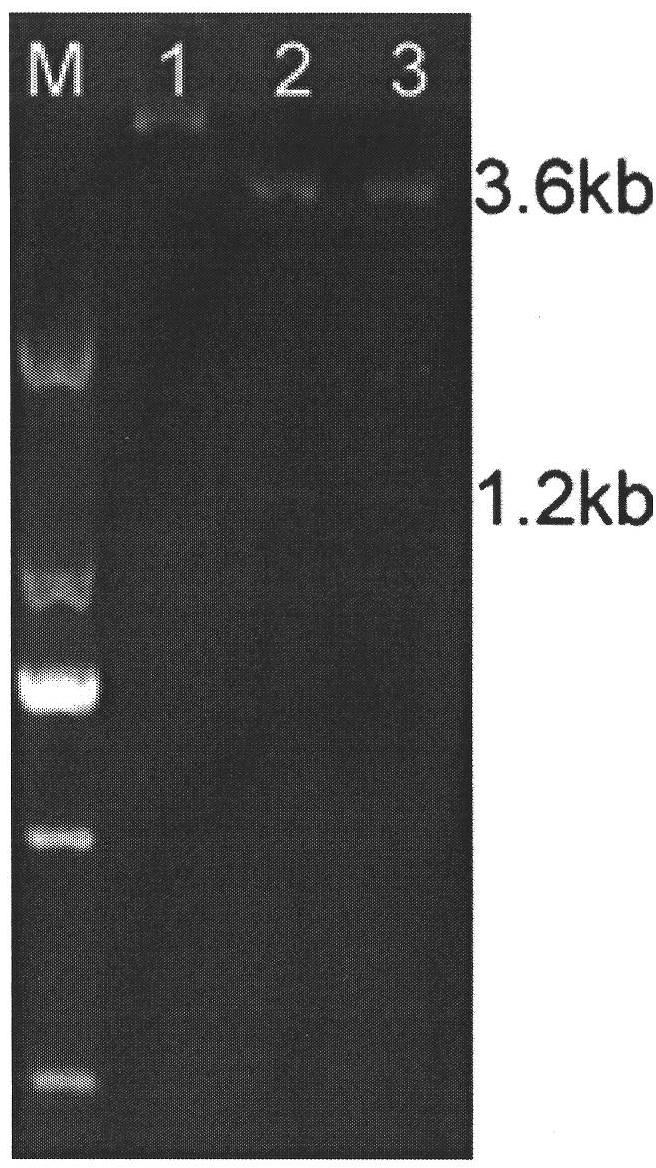

Influenza virus H1N1 subtype neuraminidase as well as gene, inhibitor screening model and application thereof

InactiveCN102586295ABiologically activeHigh secretion and expression efficiencyFungiHydrolasesPichia pastorisHigh-Throughput Screening Methods

The invention provides influenza A-type influenza virus neuraminidase (NA), a gene and a preparation method thereof as well as a construction method of a screening model of an influenza virus neuraminidase inhibitor. Particularly, influenza A-type influenza virus H1N1 subtype neuraminidase is secretly expressed by pichia pastoris to obtain the neuraminidase with biological activity, and particularly, the truncated neuraminidases of 82 amino acids at N end of an NA full-length sequence is removed, so that an operation process of the NA prepared by totivirus, which is complicated, consumes time and has a safety problem, is avoided. According to the invention, the A-type influenza virus H1N1 subtype neuraminidase inhibitor screening model is also constructed by utilizing the neuraminidase; and the influenza virus H1N1 subtype neuraminidase has the advantages of definite mechanism of drug action, less material consumption, quick screening speed, high sensitivity, easy realization of high throughput screening and the like.

Owner:SHANGHAI INST OF PHARMA IND

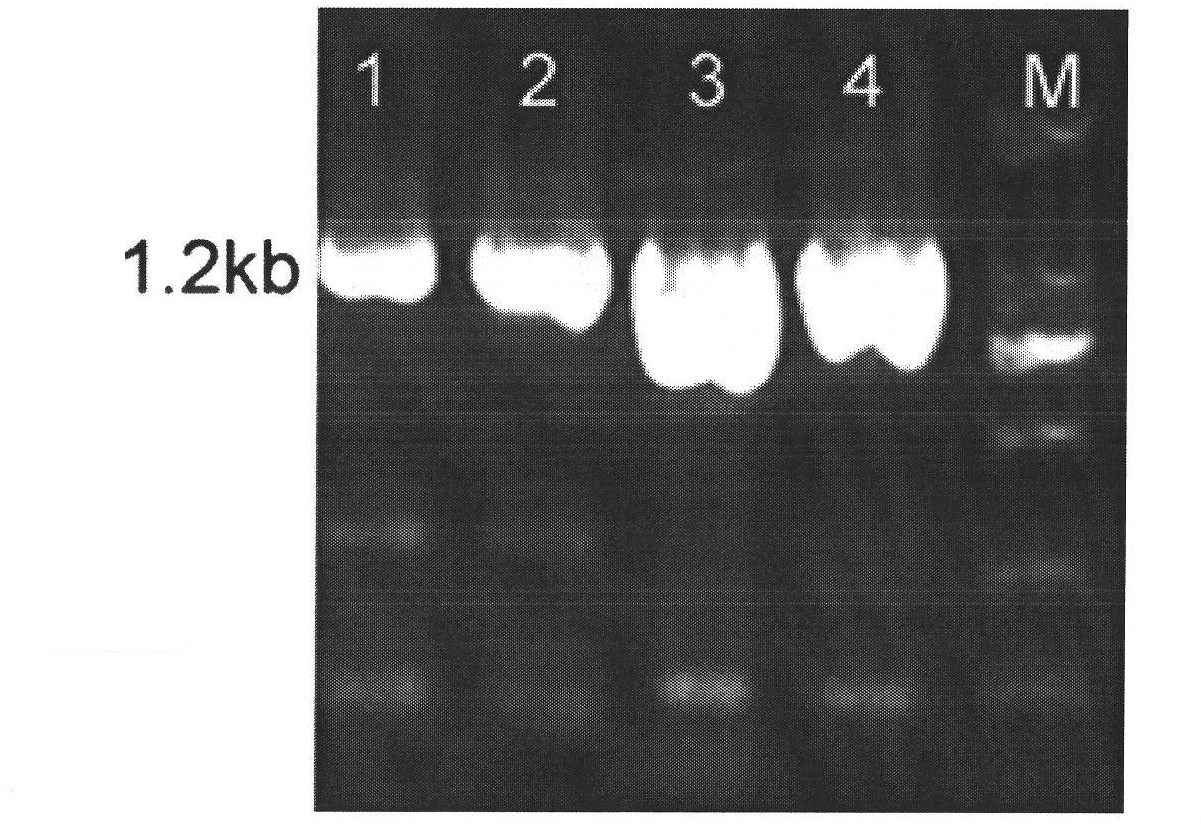

Method for screening transgenic rape using chanamyn seed soaking method

InactiveCN101236197AImprove accuracyLess prone to false positivesBiological testingKanamycinTransgene

The invention discloses a method of screening transgene cole through dipping seeds into kanamycin solution. The cole seeds having undergone transgene processing are dipped into the 0.18-0.30 percent kanamycin solution for processing for 12-24 hours and then are sowed in the soil which does not contain kanamycin, and the green seedlings growing normally are screened as the transgene plants after 2-3 days. The method of screening transgene cole is applicable to screening of a large amount of transgene cole seeds with simplicity, quickness, high efficiency, and reliability.

Owner:SICHUAN AGRI UNIV

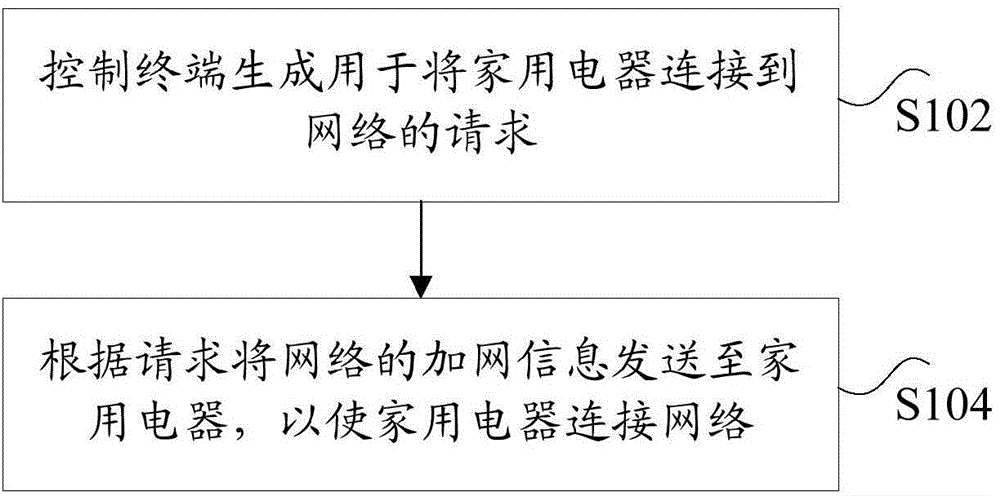

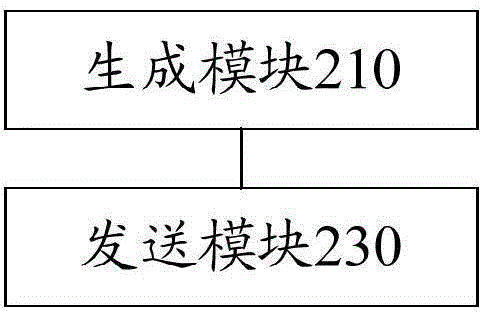

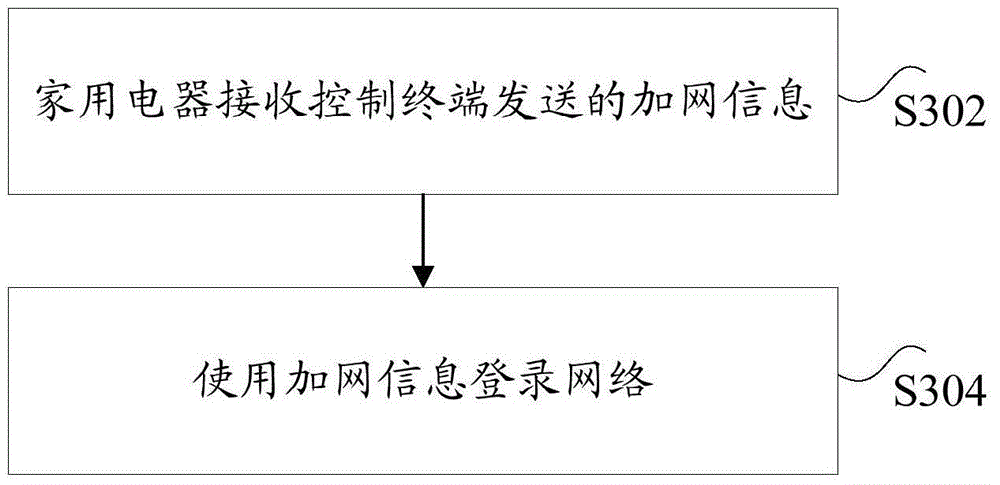

Network access control method, network access control device and network access control system for household appliances

ActiveCN104793508AFast screeningImprove operational efficiencyComputer controlProgramme total factory controlNetwork Access ControlComputer security

The invention discloses a network access control method, a network access control device and a network access control system for household appliances. The method includes generating requests for enabling the household appliances to access to a network by a control terminal, and sending network access information of the network to the household appliances according to the requests to enable the household appliances to access to the network. By the network access control method, the network access control device and the network access control system, the technical problem of low operation efficiency in access of the household appliances to the designated network in the prior art is solved, and operation efficiency in access of the household appliances to the designated network is improved.

Owner:GREE ELECTRIC APPLIANCES INC

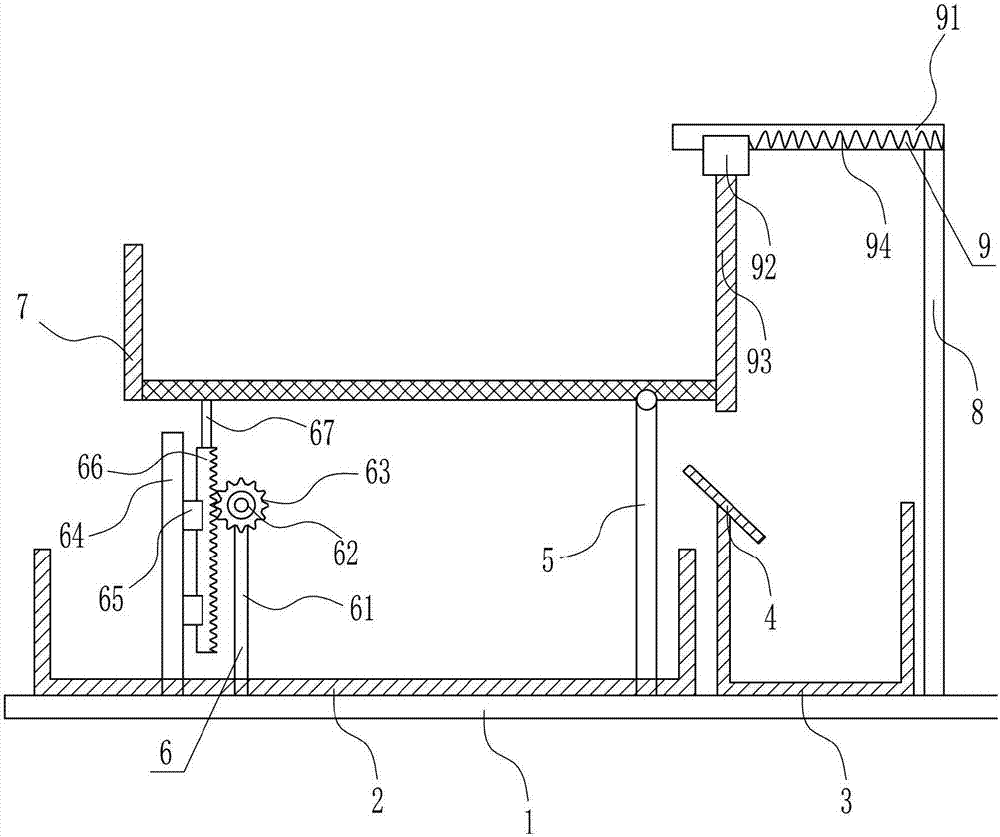

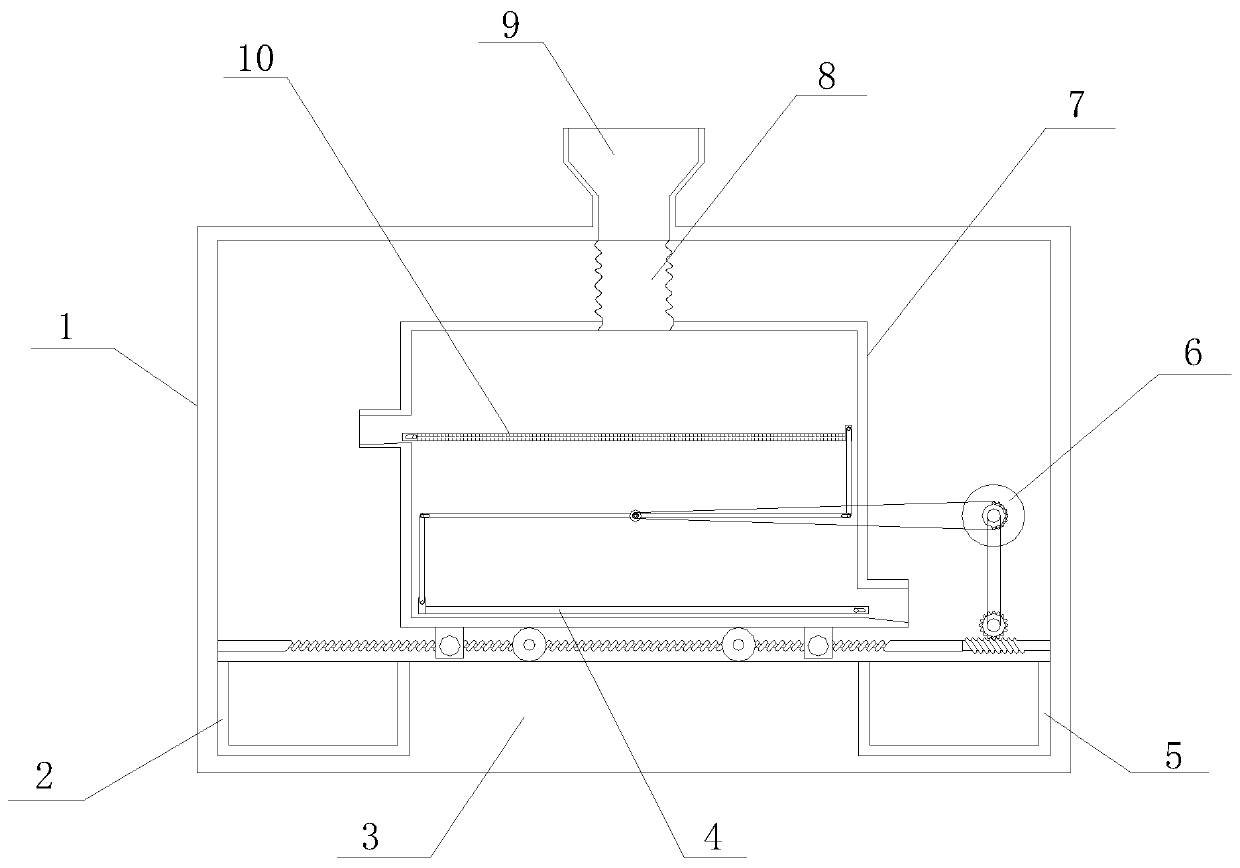

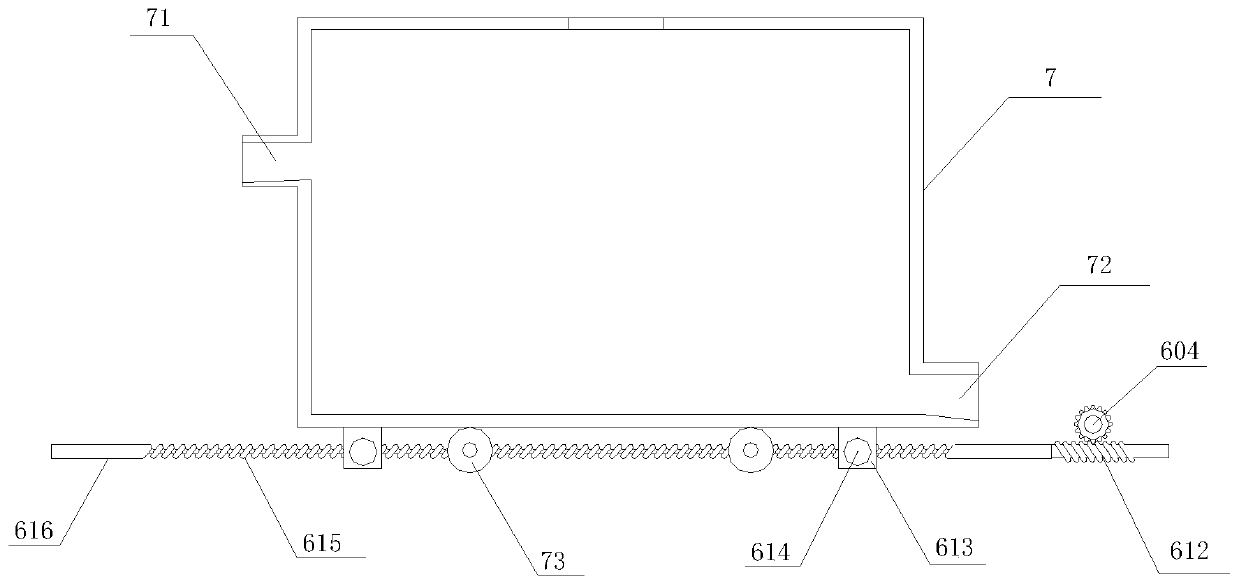

Dry sand grading and screening device

The invention relates to the technical field of screening device, and particularly relates to a dry sand grading and screening device. The dry sand grading and screening device comprises a screening box, and further comprises a controller, a screening mechanism and a discharging mechanism, wherein the screening mechanism comprises a first push plate, a pushing assembly and a filtering assembly; the discharging mechanism comprises a second push plate and a sliding assembly; and the pushing assembly, the filtering assembly and the sliding assembly are all electrically connected with the controller. According to the dry sand grading and screening device, an existing screening mode in the horizontal direction is changed into a screening mode in the vertical direction, meanwhile, filtering holes of different sizes are utilized in the screening process, dry sand is screened layer by layer, the screening speed of the dry sand grading and screening device is higher than that in the prior art,the screening steps are simpler, the screening efficiency of the dry sand is obviously improved, then the yield is increased, and the enterprise income is increased; and meanwhile, the dry sand can bescreened into large, medium and small particles and collected separately, the screening effect is improved, and meanwhile workers can take the dry sand conveniently.

Owner:安徽金砖建筑节能材料有限公司

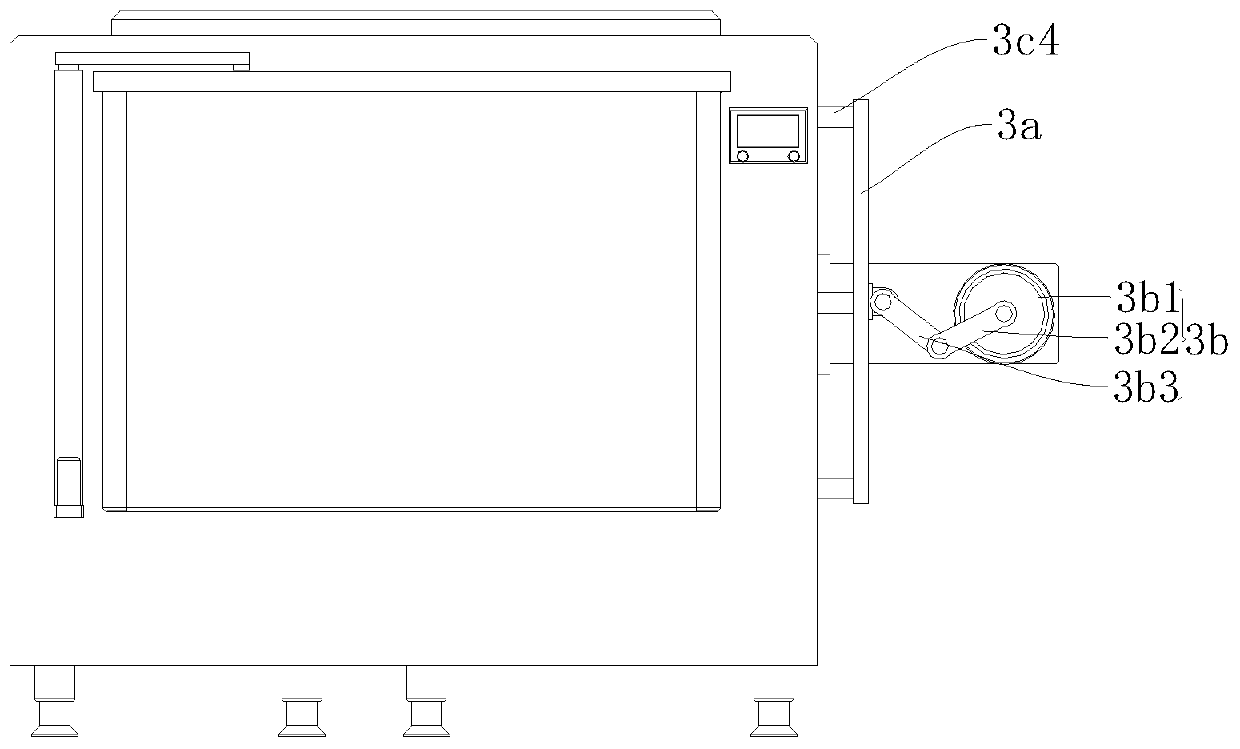

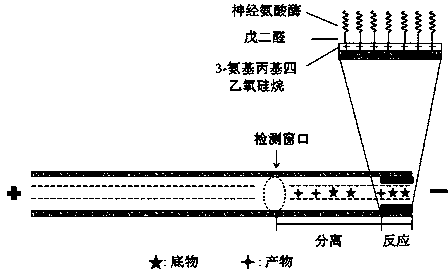

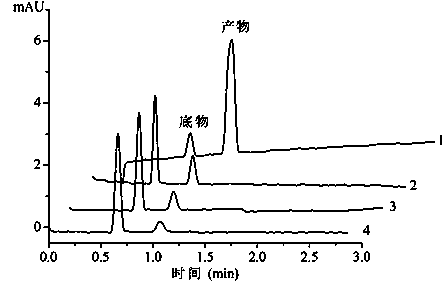

Preparation method of in-capillary immobilized enzyme microreactor

InactiveCN103627634ASimple stepsEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsNeuraminidasePhysical chemistry

The invention provides a preparation method of an in-capillary immobilized enzyme microreactor. A glutaraldehyde bonding method is used for fixing neuraminidase at the outlet end of a capillary. According to the method, the glutaraldehyde bonding method is used for fixing the neuraminidase on the inner wall of the capillary for the first time, and the immobilized enzyme microreactor can be continuously used for more than 1 month; remarkable reduction of the activity of the neuraminidase is avoided, and the stability of the neuraminidase is greatly enhanced, so that the using amount of the neuraminidase is reduced to a great extent; the enzyme microreactor is fixed at the outlet end of the capillary during separation, so that the effective length of sample separation is decreased, and the separation efficiency is greatly improved; the preparation method comprises simple steps, is convenient to operate and high in screening speed, and can be widely applied to the screening of neuraminidase inhibitor.

Owner:WUHAN UNIV

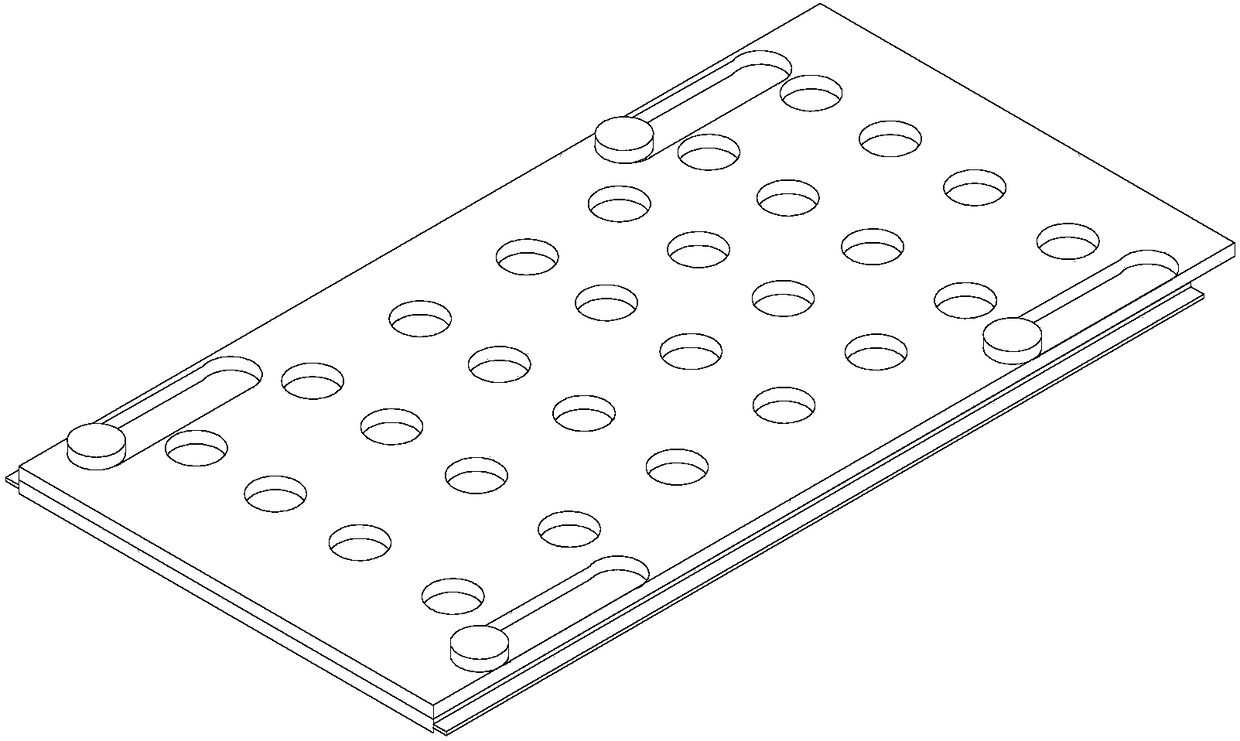

Vibration screening mechanism for plastic particle machine

The invention provides a vibration screening mechanism for a plastic particle machine, and relates to the technical field of screening machines. The vibration screening mechanism comprises a base, stand columns and a screening box. Springs are arranged between the stand columns and the screening box. A force transmitting plate is arranged at the bottom of the screening box, and a vibration motor is arranged at the bottom of the force transmitting plate. A screening box cover is arranged at the upper end of the screening box and provided with an observation window. The screening box is providedwith an air blower and a feeding port. A sieve plate is obliquely arranged in the screening box and divided into a first sieve plate body and a second sieve plate body. The first sieve plate body comprises a main sieve plate body and sieve holes, and U-shaped sliding grooves are formed in the two sides of the first sieve plate body. The second sieve plate body comprises a second main sieve platebody, bosses arranged at the two side ends and sieve holes. Grooves corresponding to the bosses in position are formed in the inner side wall of the screening box. Rivet shafts are arranged on the second main sieve plate body, and each of the two ends of the sieve plate is provided with an outlet. According to the vibration screening mechanism, the screening size can be adjusted according to needs, dust and impurities mixed in plastic particles can be rapidly removed, the surrounding environment is not influenced, the screening speed is high, and efficiency is high.

Owner:中硅融德(天津)科技有限公司

Fine sand screening equipment for building

ActiveCN113070204AFast screeningRealize the blanking effectSievingScreeningArchitectural engineeringMechanical engineering

The invention relates to screening equipment, in particular to fine sand screening equipment for construction. The technical problem to be solved is to provide the fine sand screening equipment for the building, which can automatically discharge sand and is relatively high in screening speed. The fine sand screening equipment for construction comprises a bottom plate used for supporting the whole equipment, a base arranged at one side of the upper part of the bottom plate, a cylinder arranged at the upper part of the base, a pushing mechanism arranged at the upper part of the bottom plate, and a discharging mechanism arranged at the side, close to the cylinder, of the upper part of the bottom plate. According to the fine sand screening equipment, the effects that the sand can be automatically discharged, and the screening speed is high are achieved; and stone sand is discharged into a screening frame, the cylinder drives a push rod and the screening frame to move, and therefore the stone sand can be rapidly separated.

Owner:池州市汇成废弃资源综合利用有限公司

Automatic screening machine

The invention discloses an automatic screening machine. The automatic screening machine is characterized in that one side of a screw positioning push block is provided with a clamping groove for containing screws, one side surface of the screw positioning push block closely props against a feeding channel outlet of a feeder, and the feeding channel outlet of the feeder is capable of aligning with the clamping groove of the screw positioning push block; an idler wheel group comprises a pair of idler wheels which are rotated in the same direction, an imaging device is positioned right above the idler wheel group, and the idler wheel group is positioned in an imaging region of the imaging device; a material taking device is capable of conveying the screws in the clamping groove of the screw positioning push block to the middle position of the idler wheel group and conveying the screws of the middle position of the idler wheel group to the material receiving device, and the material taking device can be positioned on a rack in a rotating manner; material boxes are respectively arranged below the two sides, which are perpendicular to a revolving shaft, of the imaging device transmits information to a controller, and the controller controls the movements of the material receiving device, the material taking device and the screw positioning push block. The automatic screening machine provided by the invention has the advantages that the structure is simple, the screening speed is rapid, and the screening accuracy rate is high.

Owner:DAJINHE FASTENER KUNSHAN

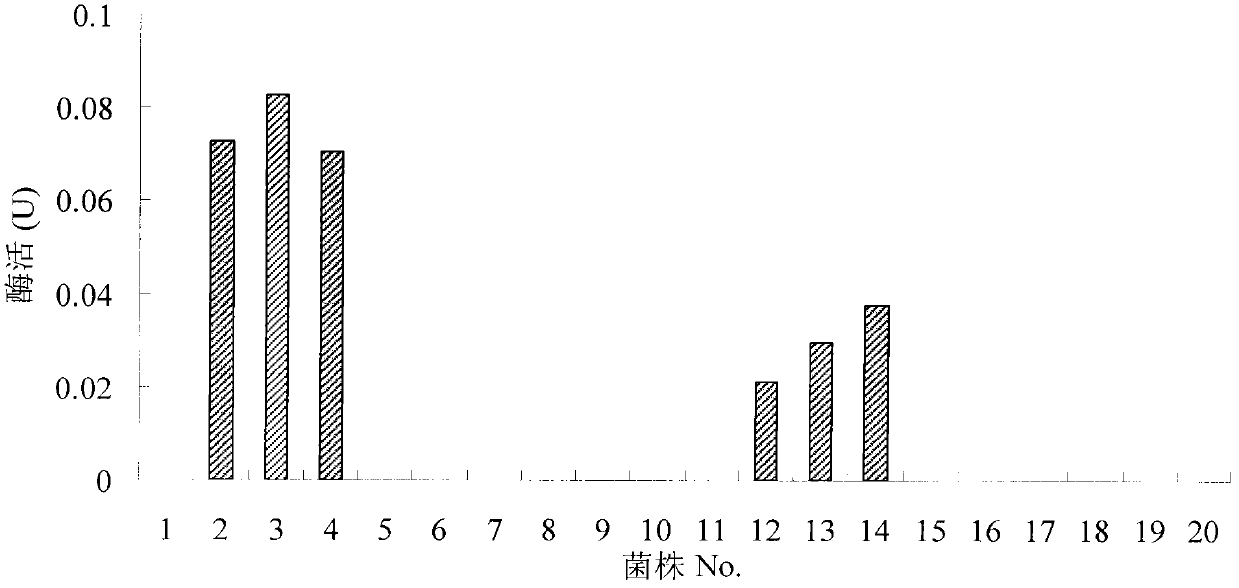

Method for rapid screening of microbial mediums

InactiveCN102747131AReduce screening costsImprove accuracyMicrobiological testing/measurementColor/spectral properties measurementsMicroorganismMicrobiology

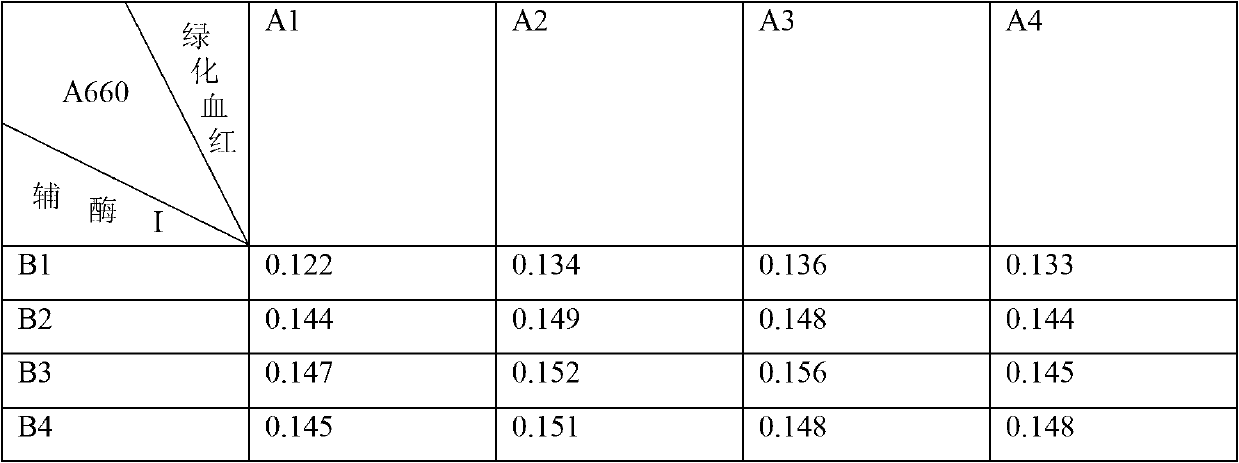

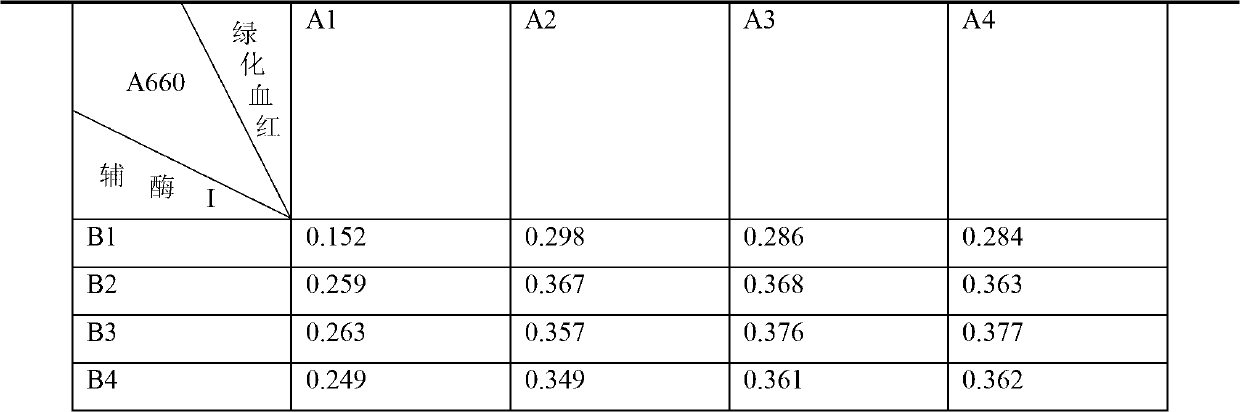

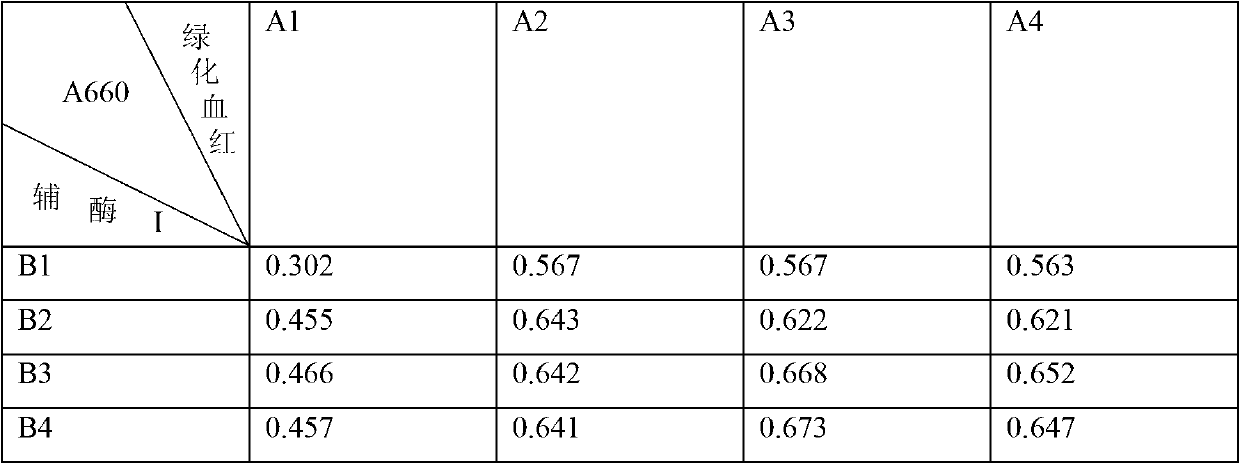

The invention discloses a method for rapid screening of microbial mediums. The method comprises the following steps: preparing bacterium suspension and mediums to be screened; pipetting the mediums to a microplate; pipetting the bacterium suspension to the microplate to inoculate the bacterium suspension to the mediums; sealing the microplate and carrying out shake cultivation for 8 to 10 h; detecting the light absorption value OD of fermentation broth in each micropore by using a microplate reader at an interval of 1 to 2 h; and drawing a growth curve, carrying out comparison and completing screening. The beneficial effects of the invention are as follows: the bacterium suspension of strains to be detected and the differently formulated mediums to be screened are respectively added into each micropore of the microplate for simultaneous fermentation and culture so as to realize the advantages of simple screening steps, convenient operation, a highly accurate thalli growth curve, highly reliable screening results and a fast screening speed, workload of workers is mitigated, cost for screening mediums is reduced, and the method is applicable to a great number of screening experiments of mediums.

Owner:CHENGDU OLYMVAX BIOPHARM

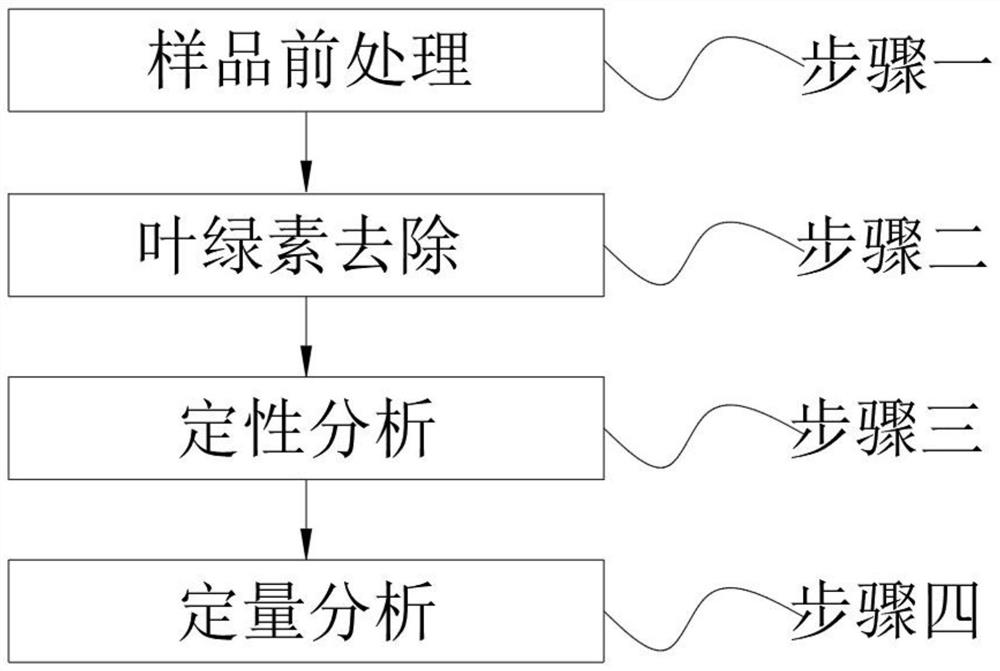

Method for rapidly screening farm chemical residues in vegetables

The invention discloses a method for rapidly screening farm chemical residues in vegetables. The method comprises the following steps: step 1, sample pretreatment; step 2, chlorophyll removal; step 3, qualitative analysis; step 4, quantitative analysis. In the first step, firstly, vegetable leaves of leaf vegetables are cut into pieces and put into a homogenizer to be ground uniformly, and part of pulp with skins of solanaceous vegetables, bulbs, brassica vegetables, melons and legume vegetables is put into the homogenizer to be ground uniformly, so that a sample is prepared. The method is safe and reliable, the screening method is high in screening speed and convenient to use, chlorophyll can be conveniently removed before screening by adding the step of removing chlorophyll in vegetables, sensitivity is improved, screening is convenient, and by using the screening method, 83 farm chemicals with high toxicity, common use and high residual risk and metabolite parameters thereof can be conveniently screened out, the types of the farm chemicals capable of being screened out are more comprehensive, and the method is convenient to popularize and use.

Owner:耿春辉 +1

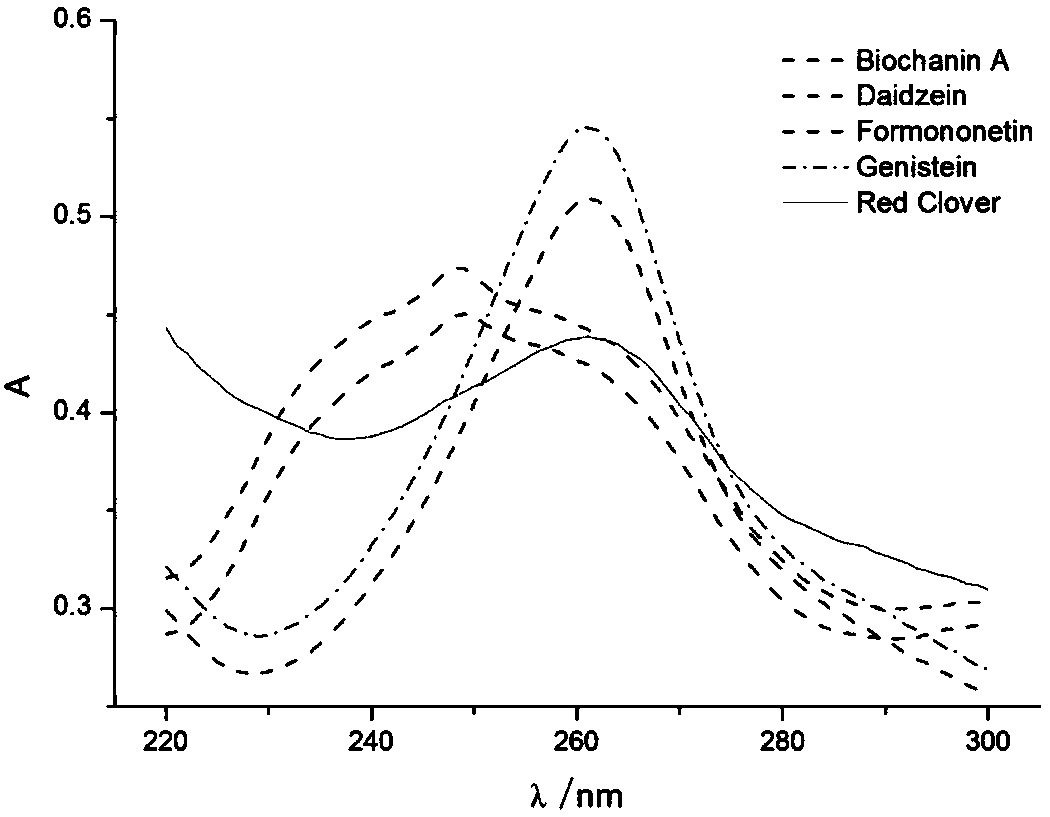

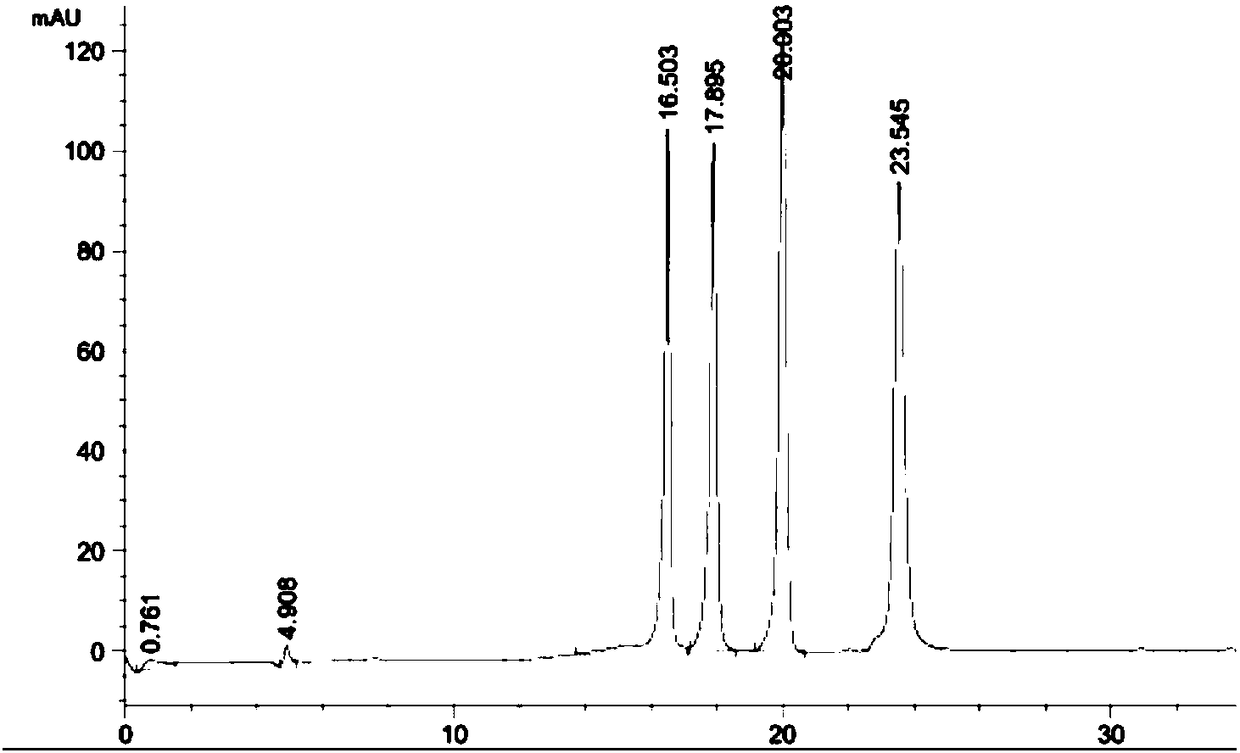

Method of quickly screening standard substance used in quantitative detection of trifolium pratense isoflavone

Trifolium pratense isoflavone is an important phytoestrogen, has an important clinical medicinal value, is an important biochemical ingredient of a plant to cope with adversity stress, and is closelyrelated to various factors such as an environment, a growth cycle and plant after-treatment. Accurate quantitation of isoflavone is a critical foundation of research and applications; however, standard substances used for a quantitation process of trifolium pratense isoflavone are inconsistent at present; relevant studies on errors arising from the inconsistent standard substances are absent. Theinvention discloses a method which adopts 2-4 compounds for thin-layer chromatography calibration of a plant sample on a basis of summarized ultraviolet absorption rules of major compounds of trifolium pratense isoflavone so as to quickly screen the standard substances used in the plant sample to be determined. Via verification by high performance liquid chromatography, the method is scientific and reliable, simple, mature and reliable in technology, low in detection cost, and easy to realize outside a laboratory, saves time and labor, and has low requirements on a detection environment, goodextensibility and huge application and development prospects.

Owner:LANZHOU UNIVERSITY

Screening equipment for soybean processing

The invention relates to screening equipment, in particular to screening equipment for soybean processing. According to the screening equipment for soybean processing, the screening speed is high, and labor force is saved. The screening equipment for soybean processing comprises a mounting frame, a screening device, a connecting rod, a dust removing device, a placing plate, a second frame body and the like. The screening device is arranged on the left portion in the mounting frame. The connecting rod is arranged in the middle of the right wall in the mounting frame. The dust removing device is arranged on the left side of the connecting rod. The placing plate is arranged on the upper portion of the right wall in the mounting frame. The second frame body is arranged on the top of the placing plate. A mesh pipe is arranged on the lower portion of the left wall of the second frame body and penetrates through the dust removing device. A valve is arranged on the left portion of the mesh pipe. Soybeans are subjected to dust removing processing through the dust removing device, impurities and dust in the soybeans are processed, then the soybeans with different sizes are separated through the screening device, and the screening speed is high.

Owner:马爱华

Diamond screening device for producing drawing die

The invention relates to a diamond screening device for producing a drawing die. The diamond screening device comprises a screening box, a first material collecting groove, a first screen mesh, a second material collecting groove, a material receiving groove, a second screen mesh, a motor, a sliding block, a ball nut pair, a screw rod and a transmission shaft, wherein the first collecting groove and the second collecting groove are symmetrically arranged at the bottom end face of the interior of the screening box, the second screen mesh is rotationally connected to the middle of the interior of the material receiving groove, the first screen mesh is rotationally connected to the bottom end of the material receiving groove, a turbine is rotationally connected in the screening box, the turbine is in transmission connection with the output end of the motor through a driving belt, a worm and a transmission shaft are coaxially and rotationally connected in the screening box, the screw rod is fixedly connected with the transmission shaft, the sliding block is fixedly arranged at the bottom end surface of the material receiving groove, the sliding block is in sliding connection with the interior of the screening box, and the ball nut pair is arranged on the outer side of the screw rod in a sleeving mode. The device has the advantages that the structure is excellent, the design is reasonable, the operation is simple and convenient, the screening efficiency is high, the screening effect is good, the screening speed is high, equipment compatibility is high, the application prospect is wide, and the creativity is high.

Owner:天长市恒鑫机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com