High-efficiency sand screening equipment for construction

A technology for screening equipment and construction, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low efficiency, slow screening speed, labor cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

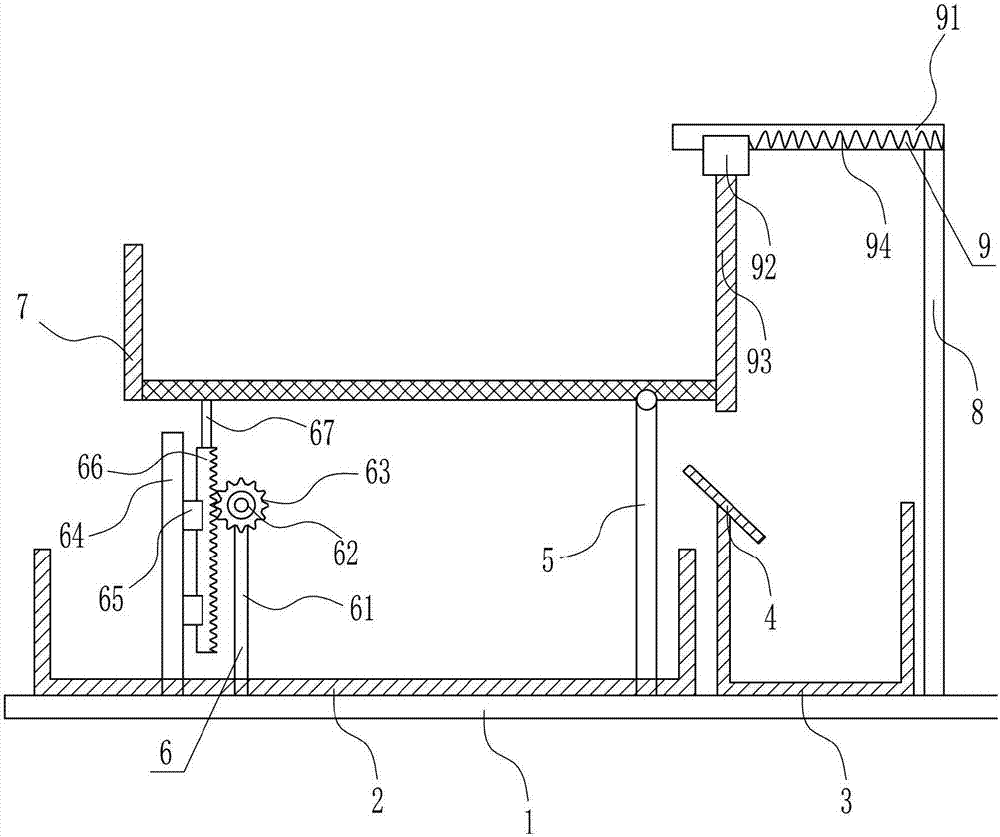

[0021] A kind of high-efficiency sand screening equipment for construction, such as Figure 1-3 As shown, it includes a bottom plate 1, a first collection frame 2, a second collection frame 3, a sloping plate 4, a first vertical bar 5, a pushing device 6, a screening frame 7, a bracket 8 and a material retaining device 9, and the top left of the bottom plate 1 The first collection frame 2 is installed on the side by bolt connection, the second collection frame 3 is installed on the top right side of the bottom plate 1 by bolt connection, and the slant plate 4 is installed on the top left side of the second collection frame 3 by bolt connection , the right side of the top of the bottom plate 1 is equipped with a bracket 8 by means of bolt connection, the bracket 8 is located on the right side of the second collection frame 3, and the top of the bracket 8 is provided with a stopper 9, and the stopper 9 includes a second slide rail 91, a second Two sliders 92, material blocking p...

Embodiment 2

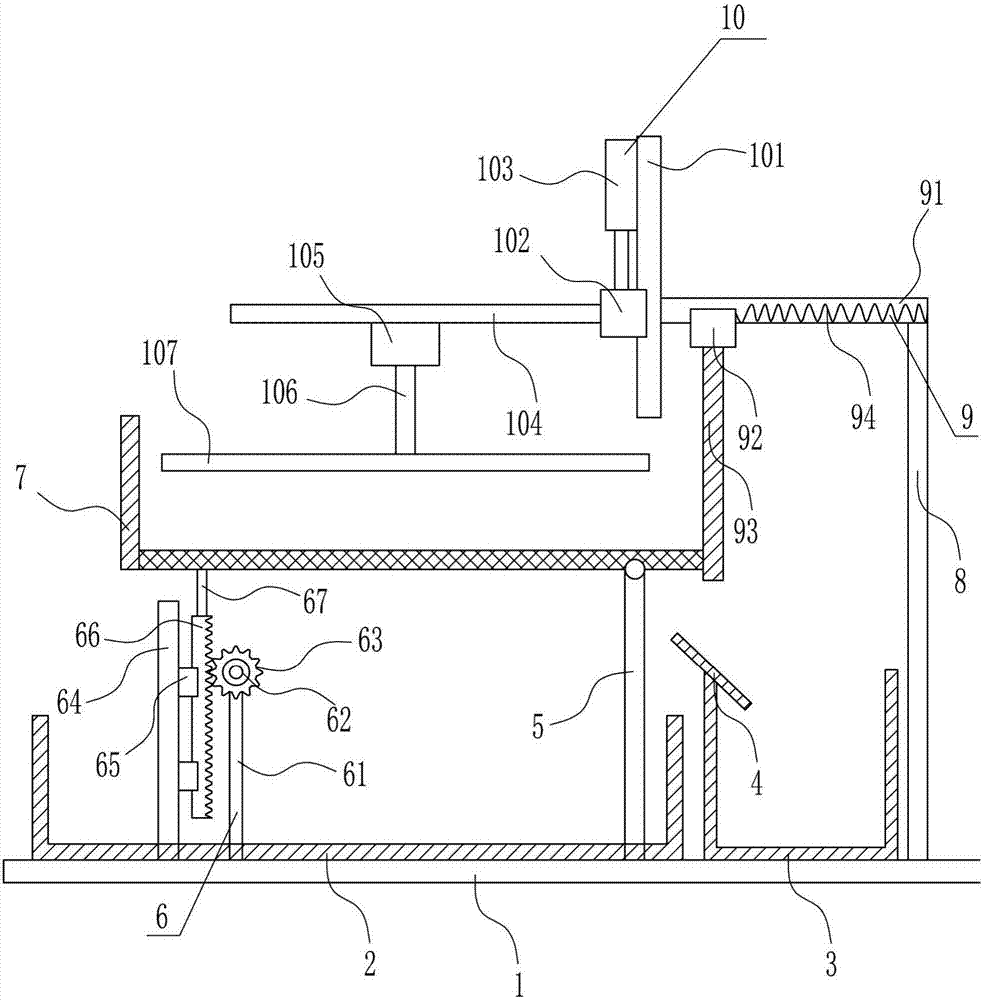

[0023] A kind of high-efficiency sand screening equipment for construction, such as Figure 1-3As shown, it includes a bottom plate 1, a first collection frame 2, a second collection frame 3, a sloping plate 4, a first vertical bar 5, a pushing device 6, a screening frame 7, a bracket 8 and a material retaining device 9, and the top left of the bottom plate 1 The first collection frame 2 is installed on the side by bolt connection, the second collection frame 3 is installed on the top right side of the bottom plate 1 by bolt connection, and the slant plate 4 is installed on the top left side of the second collection frame 3 by bolt connection , the right side of the top of the bottom plate 1 is equipped with a bracket 8 by means of bolt connection, the bracket 8 is located on the right side of the second collection frame 3, and the top of the bracket 8 is provided with a stopper 9, and the stopper 9 includes a second slide rail 91, a second Two sliders 92, material blocking pl...

Embodiment 3

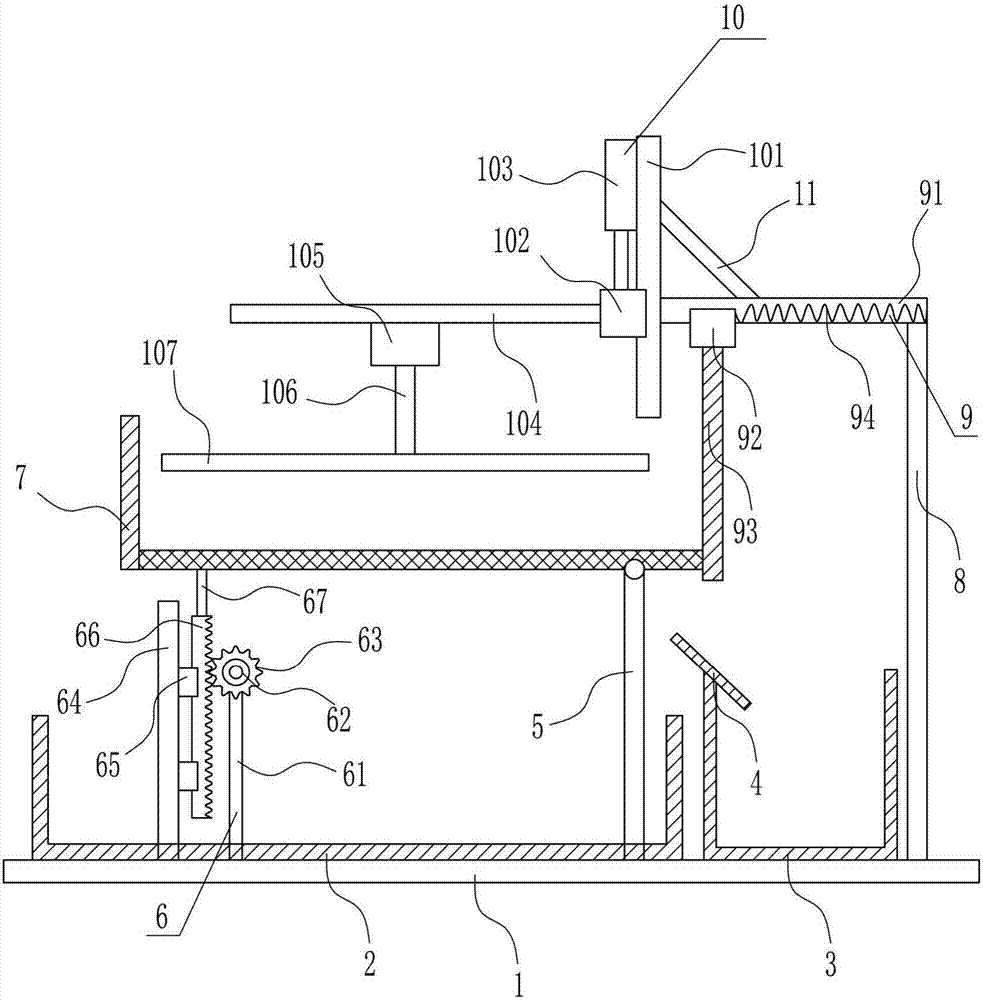

[0026] A kind of high-efficiency sand screening equipment for construction, such as Figure 1-3 As shown, it includes a bottom plate 1, a first collection frame 2, a second collection frame 3, a sloping plate 4, a first vertical bar 5, a pushing device 6, a screening frame 7, a bracket 8 and a material retaining device 9, and the top left of the bottom plate 1 The first collection frame 2 is installed on the side by bolt connection, the second collection frame 3 is installed on the top right side of the bottom plate 1 by bolt connection, and the slant plate 4 is installed on the top left side of the second collection frame 3 by bolt connection , the right side of the top of the bottom plate 1 is equipped with a bracket 8 by means of bolt connection, the bracket 8 is located on the right side of the second collection frame 3, and the top of the bracket 8 is provided with a stopper 9, and the stopper 9 includes a second slide rail 91, a second Two sliders 92, material blocking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com