Automatic screening machine

An automatic screening and racking technology, applied in sorting and other directions, can solve the problems of mixing unqualified products into qualified products, slow speed and low screening accuracy, and achieve the effect of fast screening speed, high screening accuracy and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

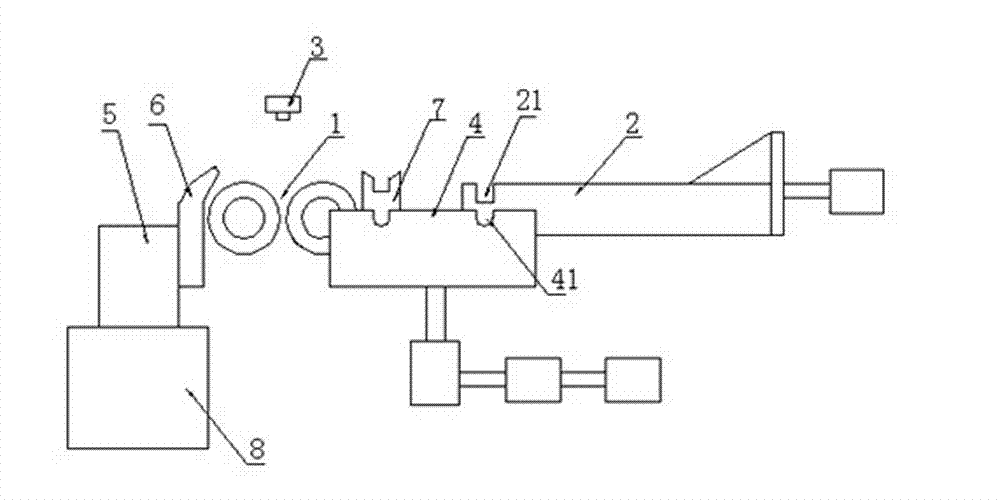

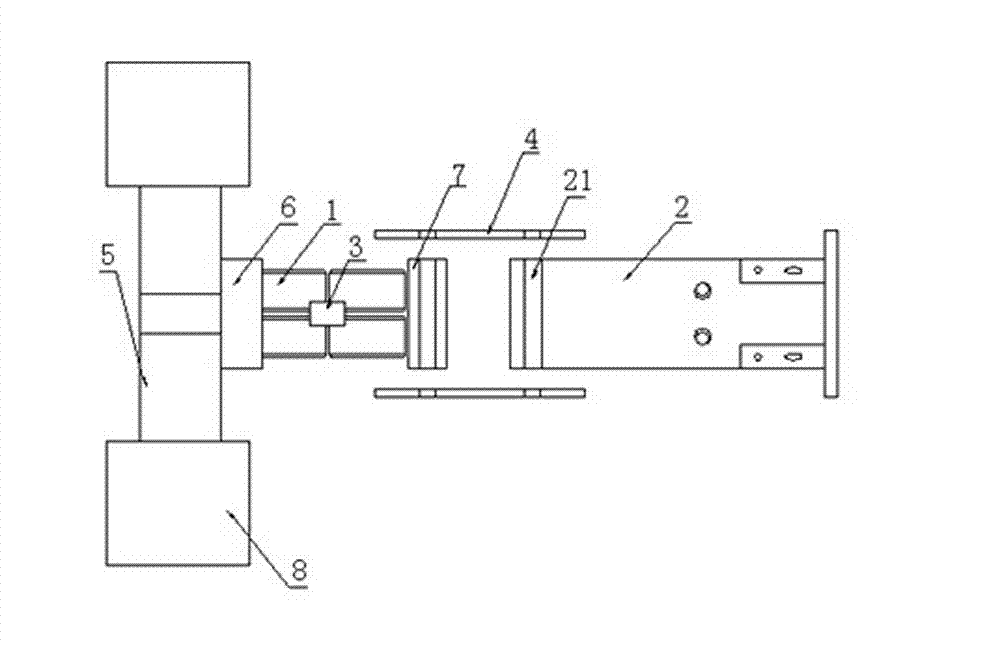

[0015] Embodiment: a kind of automatic screening machine, comprises frame, roller set 1, feeder, screw positioning pushing block 2, imaging device 3, retrieving device 4, receiving device 5, material box 8 and controller, screw positioning pushing block One side of the block 2 is provided with a card slot 21 that can accommodate the screw, and one side of the screw positioning push block 2 is close to the outlet of the feeding channel of the feeder, and the outlet of the feeding channel of the feeder can be aligned with the card on the screw positioning push block 2. The grooves 21 are aligned, the roller set 1 is a pair of rollers rotating in the same direction, the imaging device 3 is located directly above the roller set 1, and the roller set 1 is located in the imaging area of the imaging device 3, and the take-up device 4 can push the screw positioning The screw in the draw-in slot 21 of the block 2 is transported to the middle position of the roller group 1 and the scre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com