Vibration screening mechanism for plastic particle machine

A technology of vibration screening and plastic granules, applied in the field of screening machines, can solve the problems such as the inability to adjust the screening size according to the needs, the mixing of dust and debris, and the inability to remove the dust and debris of plastic particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

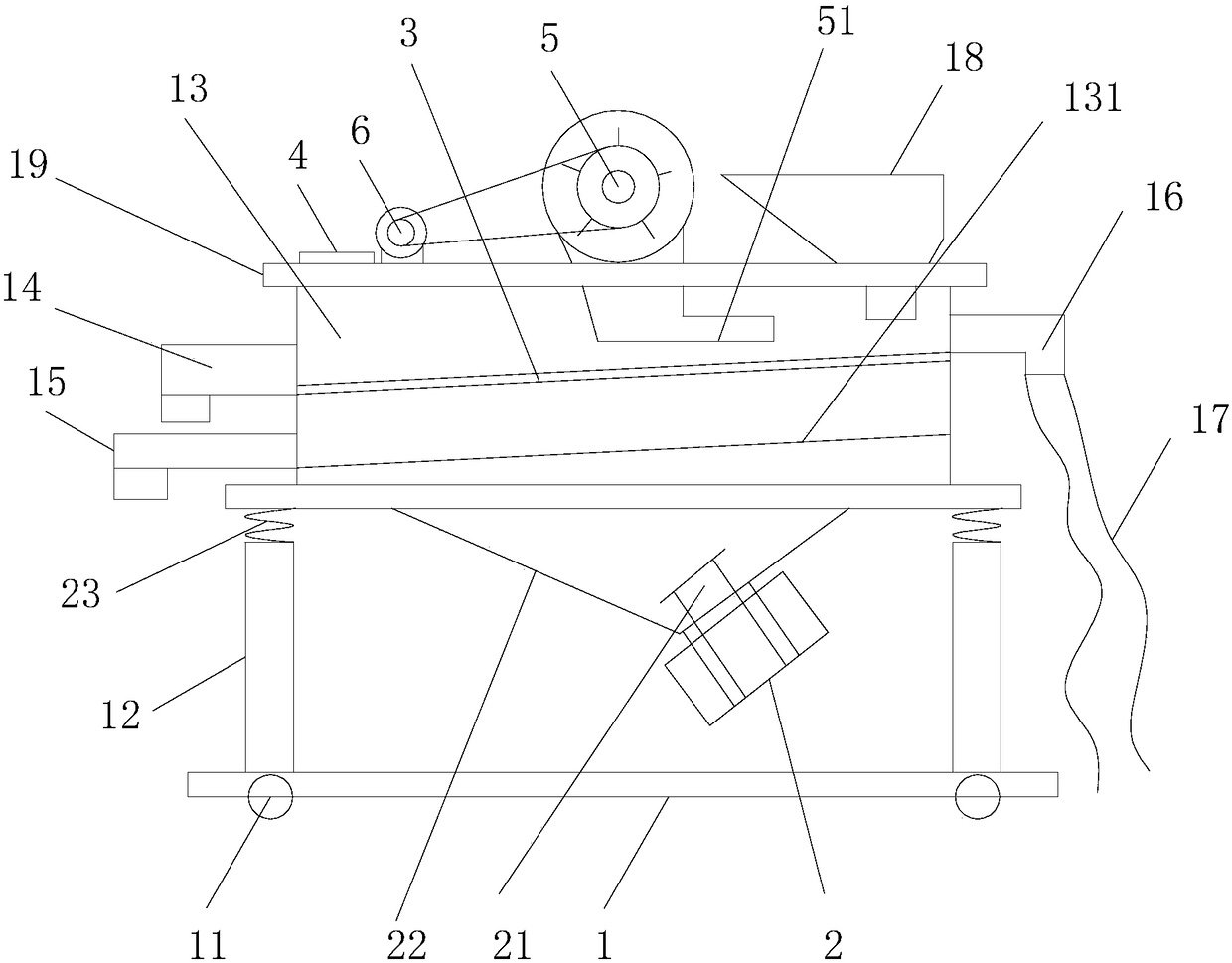

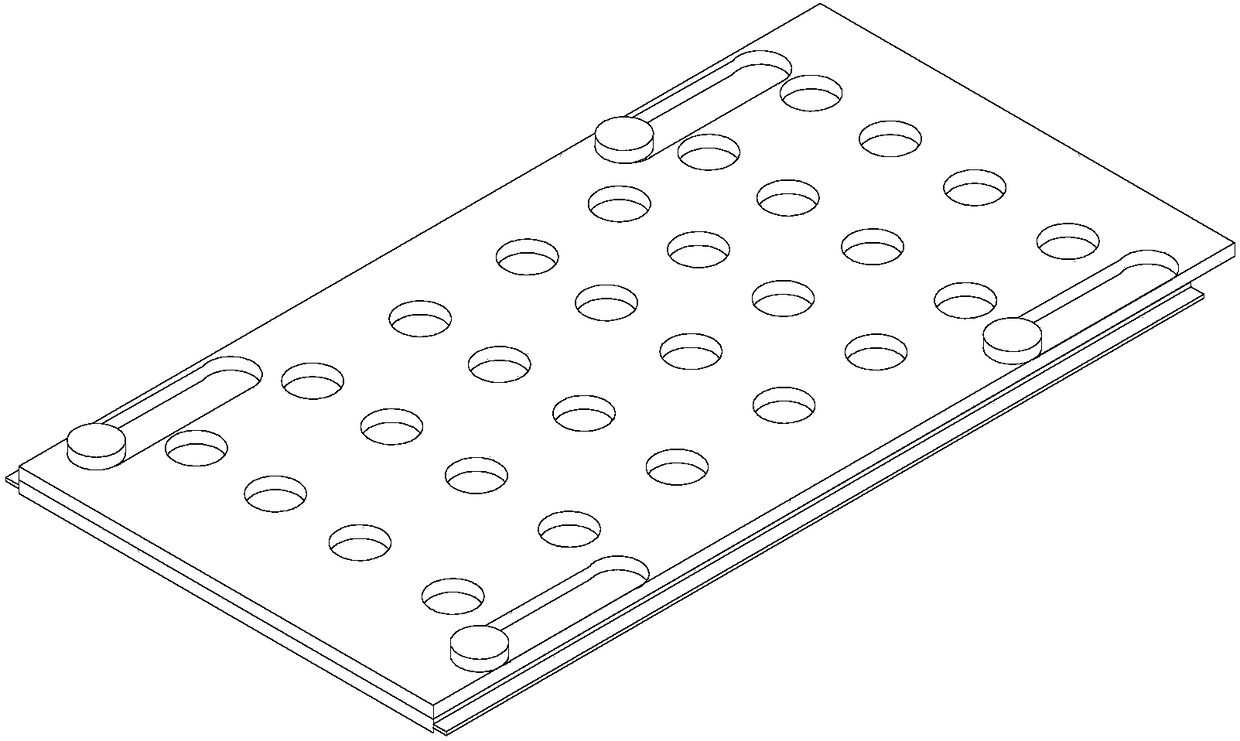

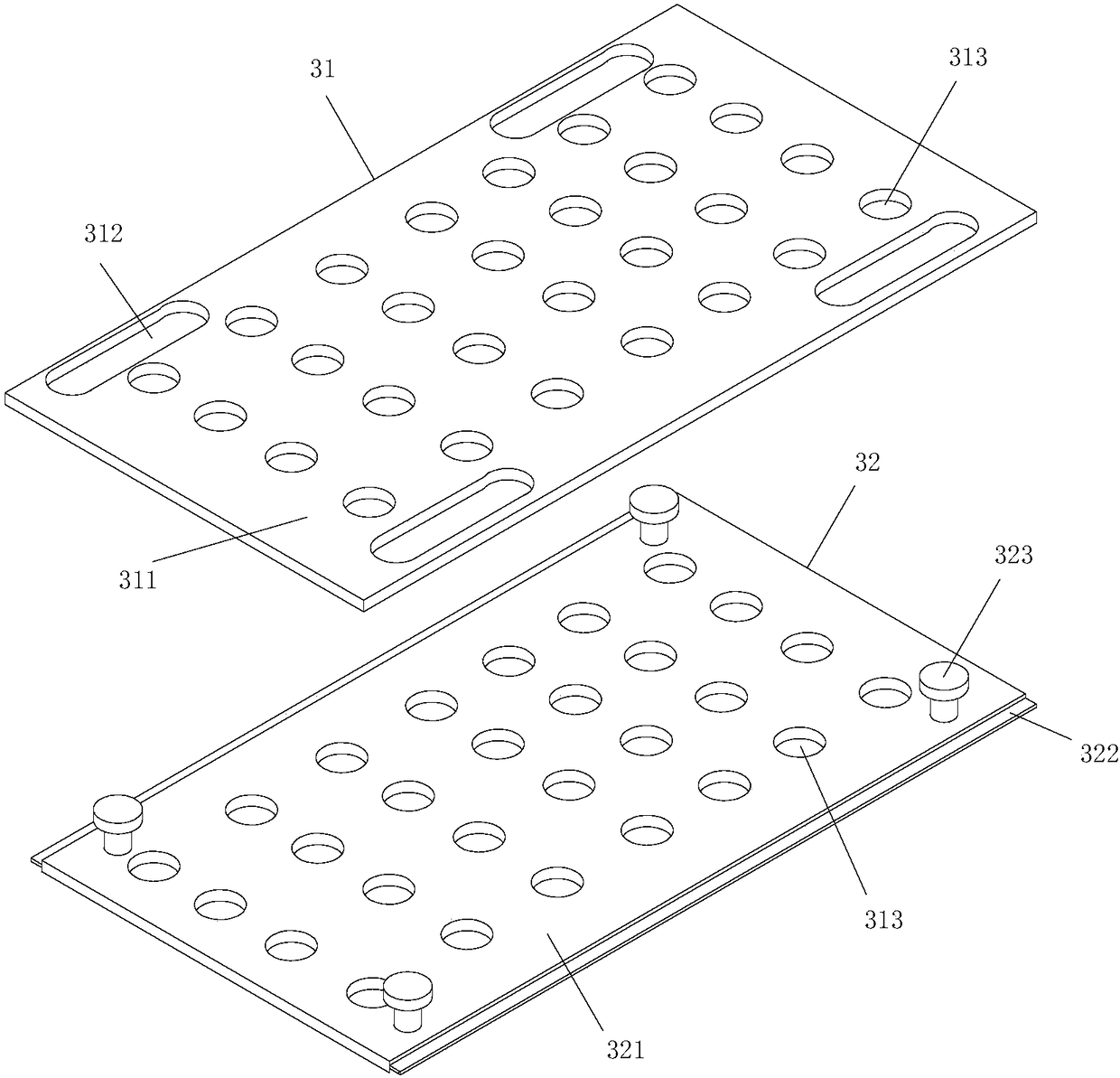

[0021] Such as figure 1 , figure 2 with image 3 As shown, a vibratory screening mechanism for a plastic granulator in this embodiment includes a base 1, a column 12 disposed on the base 1 and a screening box 13 located on the column 12, between the column 12 and the screening box 13 A spring 23 is arranged between them, a force transmission plate 22 is provided at the bottom of the screening box 13, and a vibration motor 2 is installed at the bottom of the force transmission plate 22. The upper end of the screening box 13 is provided with a screening box cover 19, and on the screening box cover 19 An observation window 4 is provided, a blower 5 and a feed port 18 are provided on the screening box 13, and a sieve plate 3 is provided obliquely inside the screening box 13. The sieve plate 3 has two layers in total, and the sieve plate 3 is divided into the first screen plate 31 and the second sieve plate 32 located at the bottom of the first sieve plate 31, the first sieve pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com