Patents

Literature

31results about How to "Realize the push effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

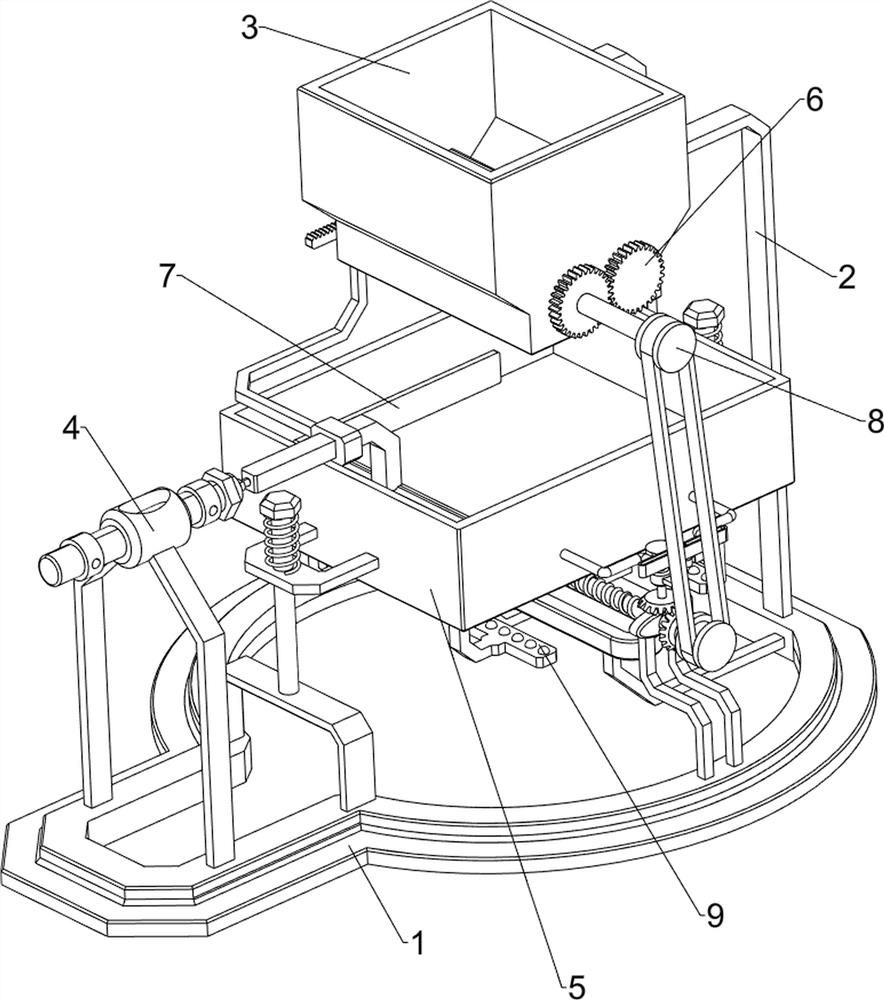

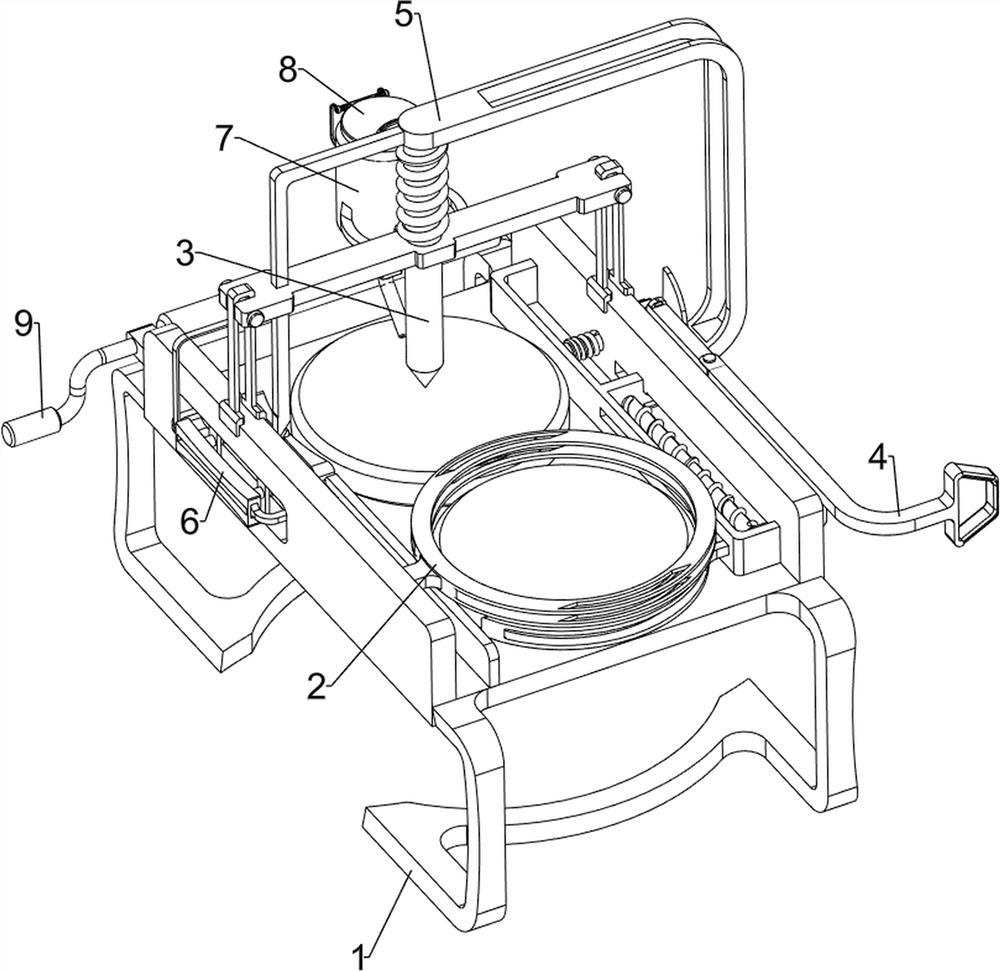

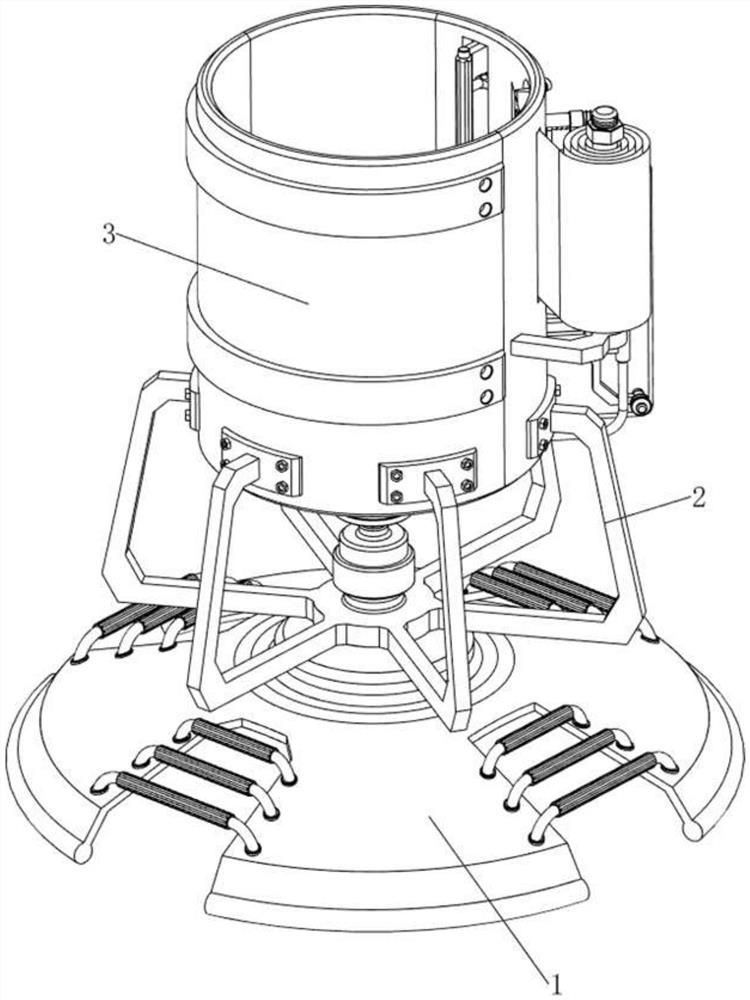

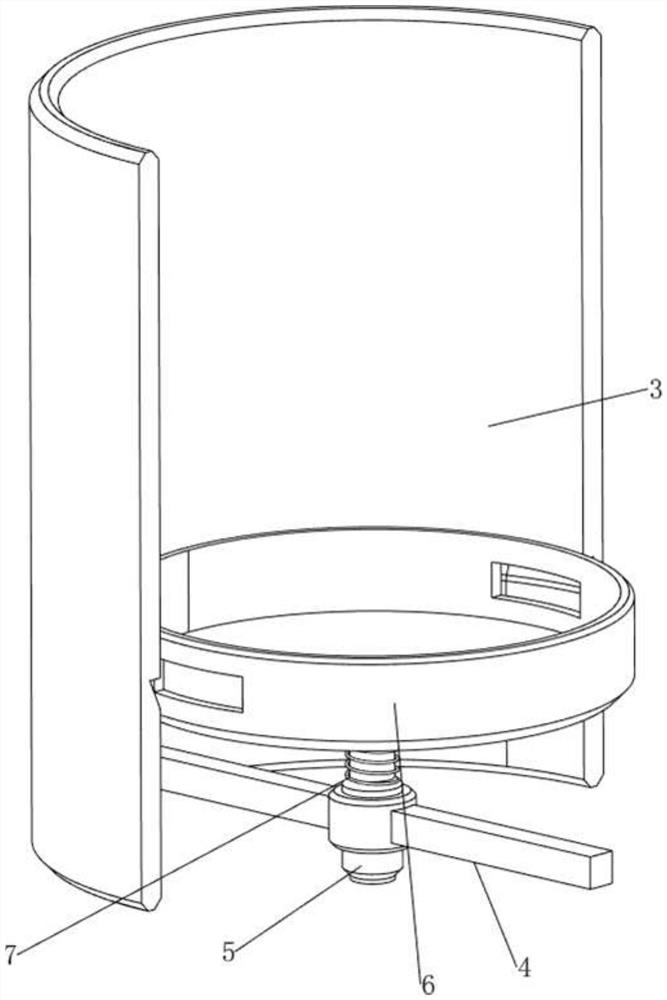

Automatic mixing device for colored glaze production

ActiveCN112844193AWell mixedAchieve broken effectTransportation and packagingRotary stirring mixersGlazeEngineering

The invention relates to a mixing device, and particularly relates to an automatic mixing device for colored glaze production. The automatic mixing device for colored glaze production is good in mixing effect, capable of reducing the labor intensity of workers and easy and understandable to operate. The automatic mixing device for colored glaze production comprises a base, a fixed supporting column, a mixing box body, a discharging box, feeding openings, static crushing cutters, a discharging channel and a filter screen, wherein the fixed supporting column is arranged on the base; the mixing box body is arranged at the top of the fixed supporting column; the discharging box is arranged at the top of the mixing box body; the feeding openings are formed in the two sides of the lower part of the discharging box; three static crushing cutters are rotationally arranged on each of the upper side and the lower side in the mixing box body; the discharging channel is arranged at the bottom of the mixing box body; and the filter screen is arranged between the two sides of the discharging channel. By arranging the crushing mechanism, the colored glaze in the mixing box body is more uniformly mixed through the operation of the crushing mechanism, and the crushing effect is achieved.

Owner:高安常莹新型材料有限公司

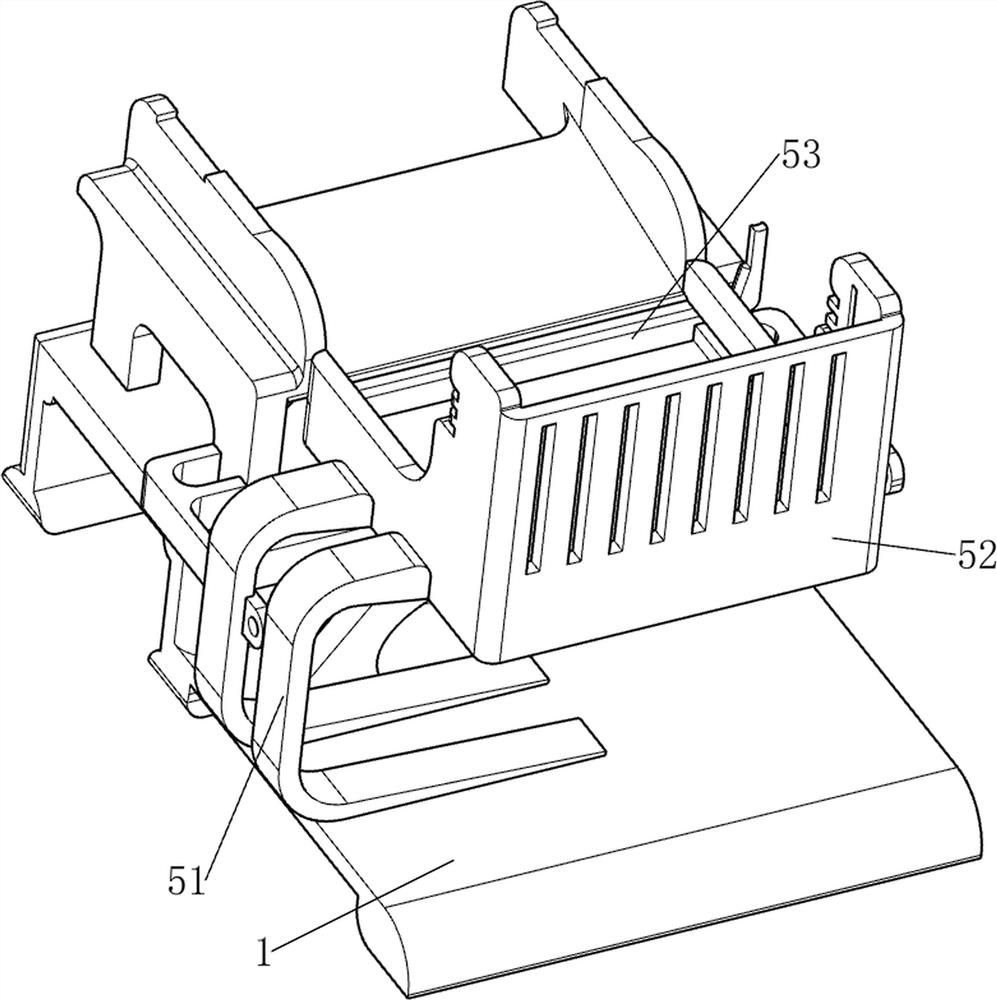

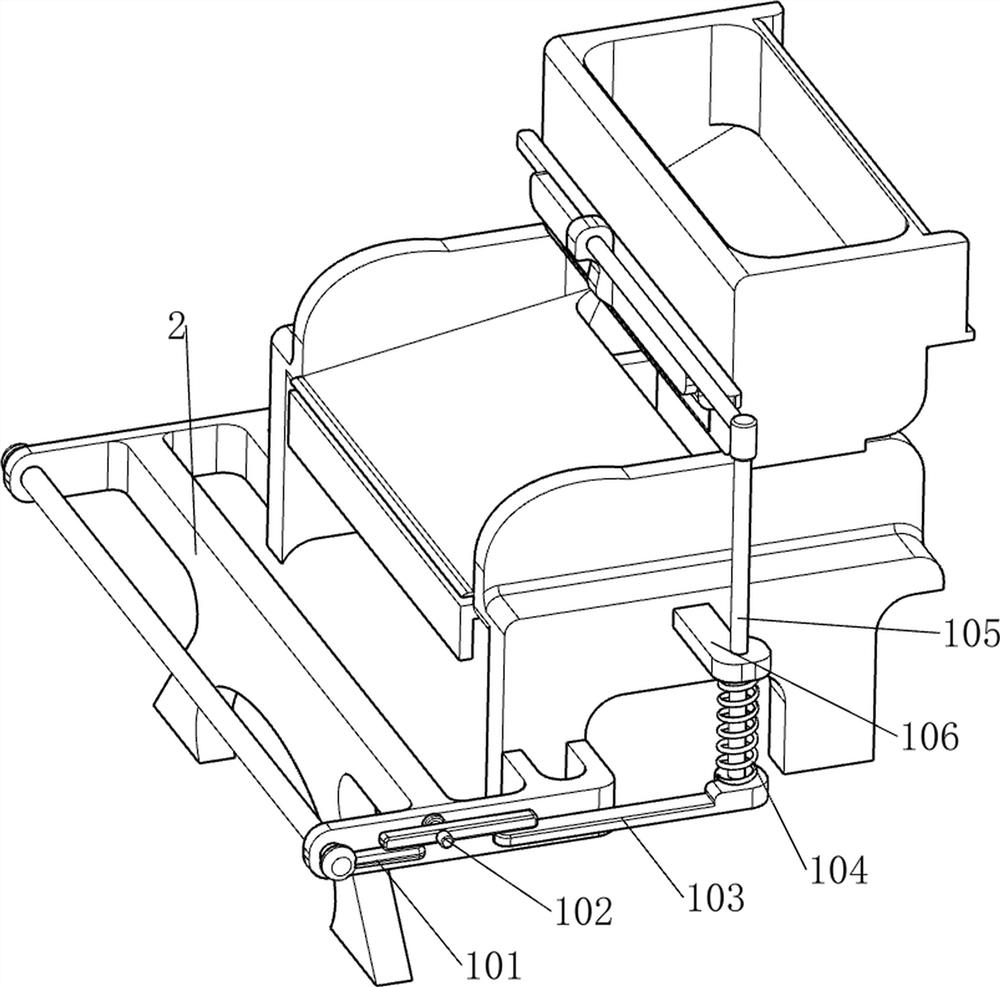

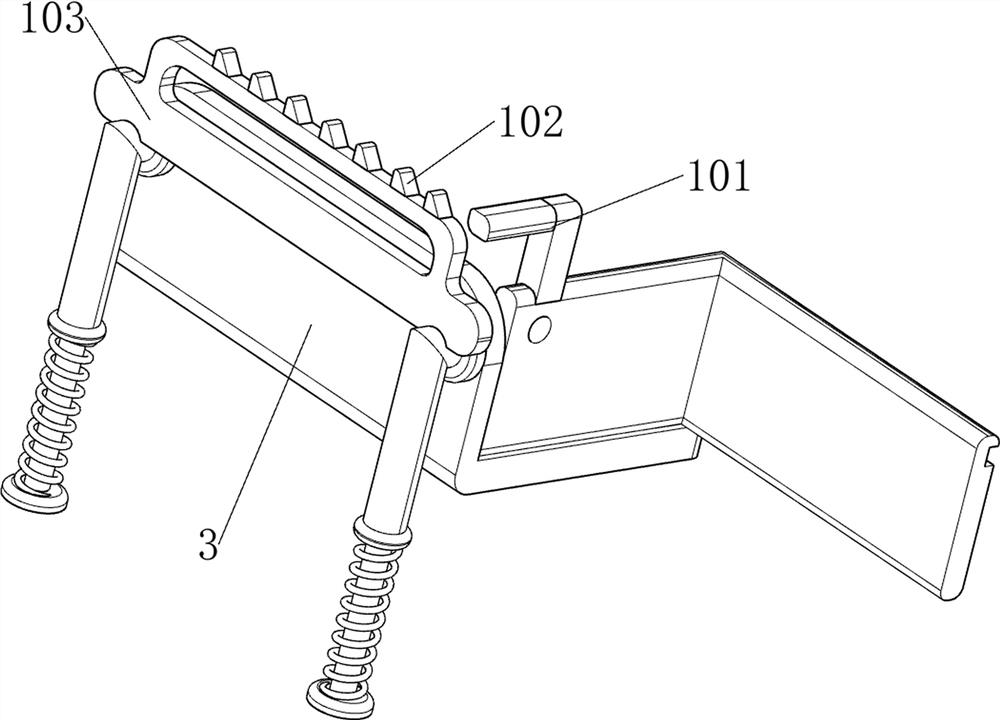

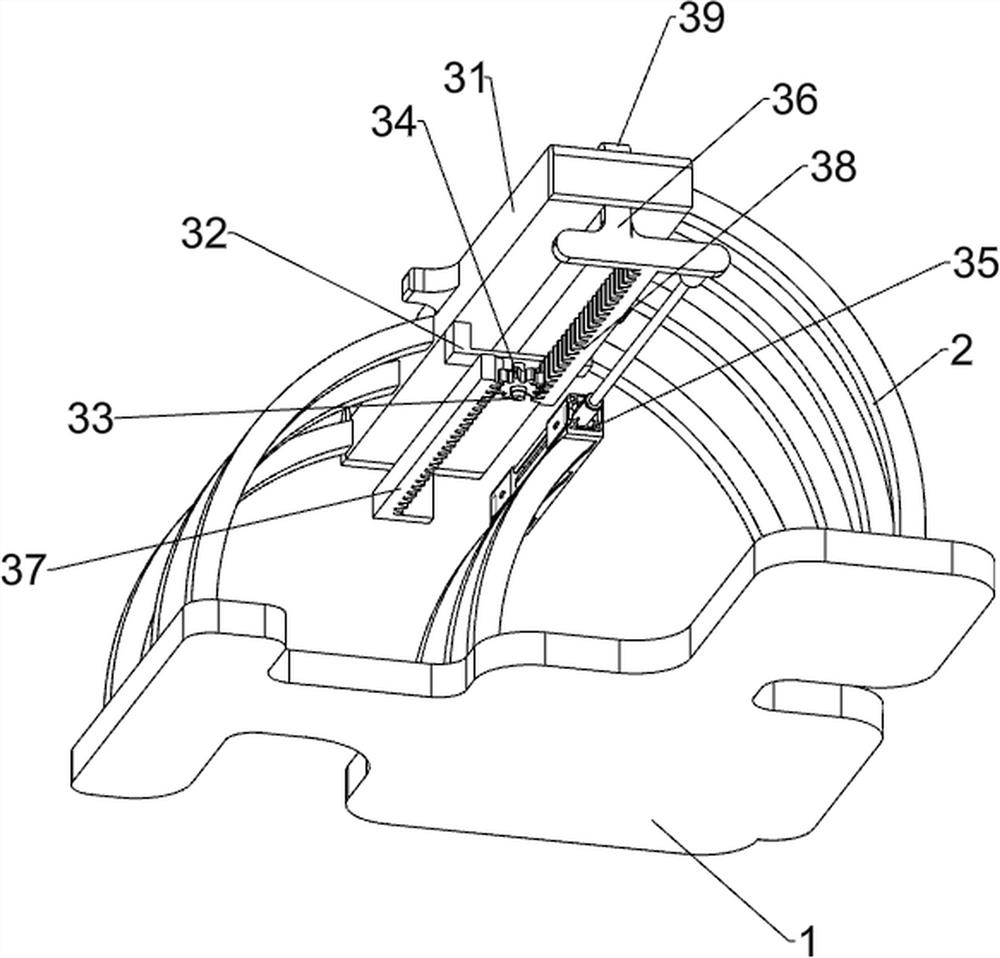

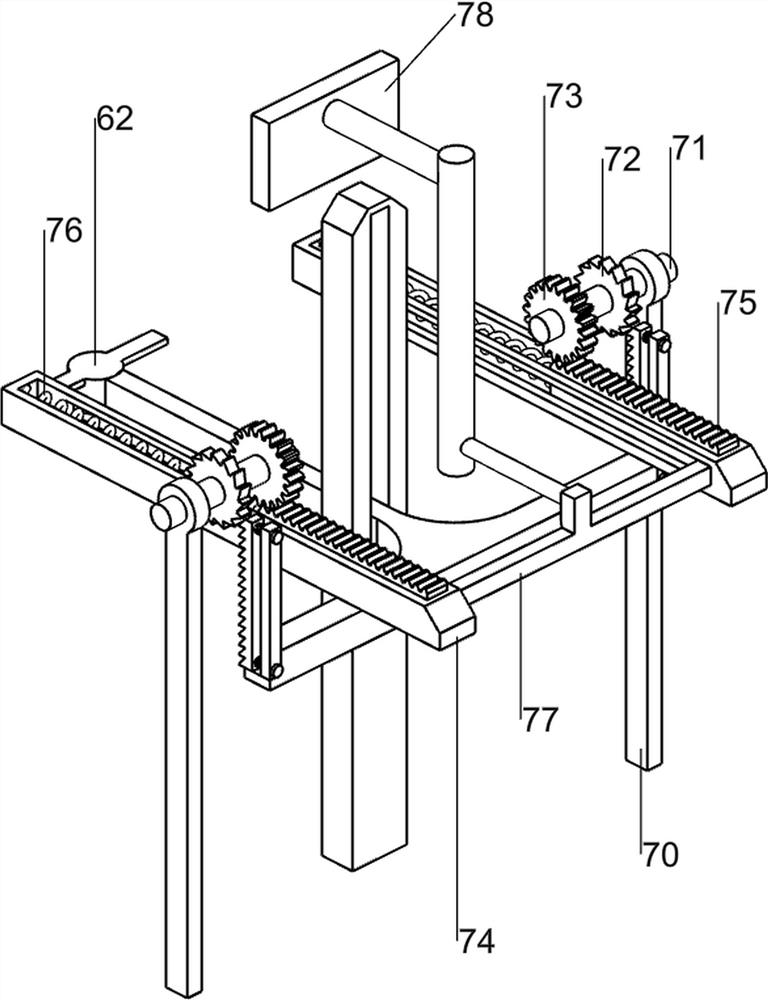

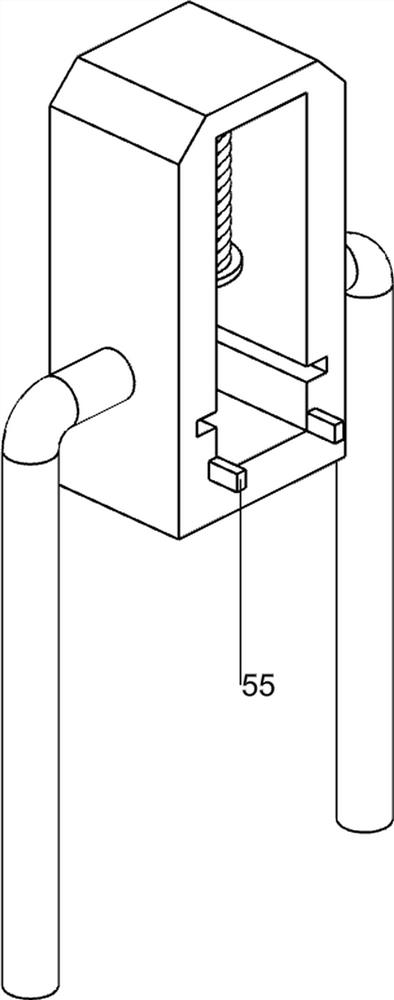

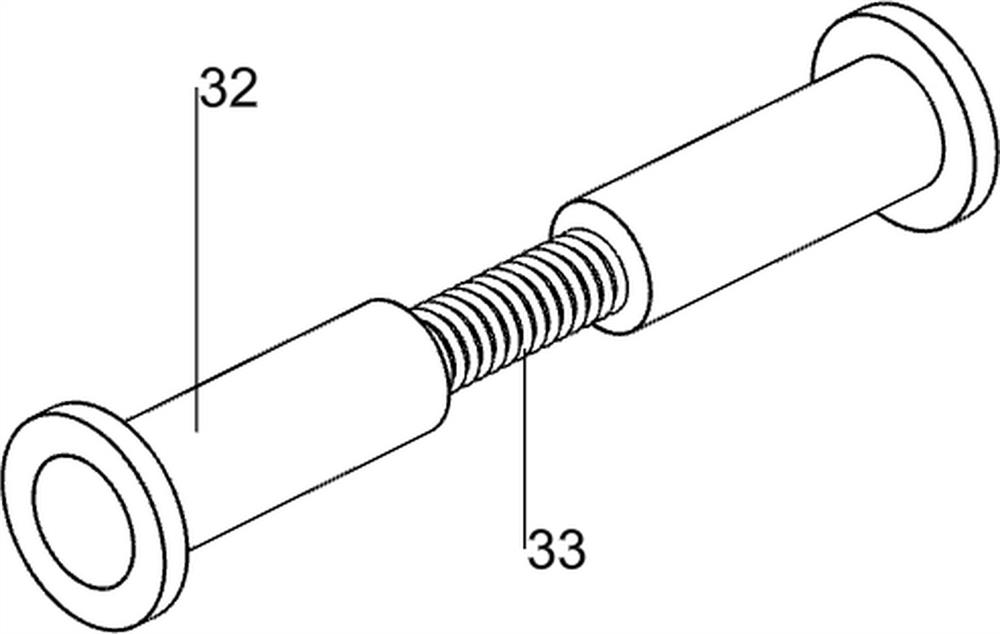

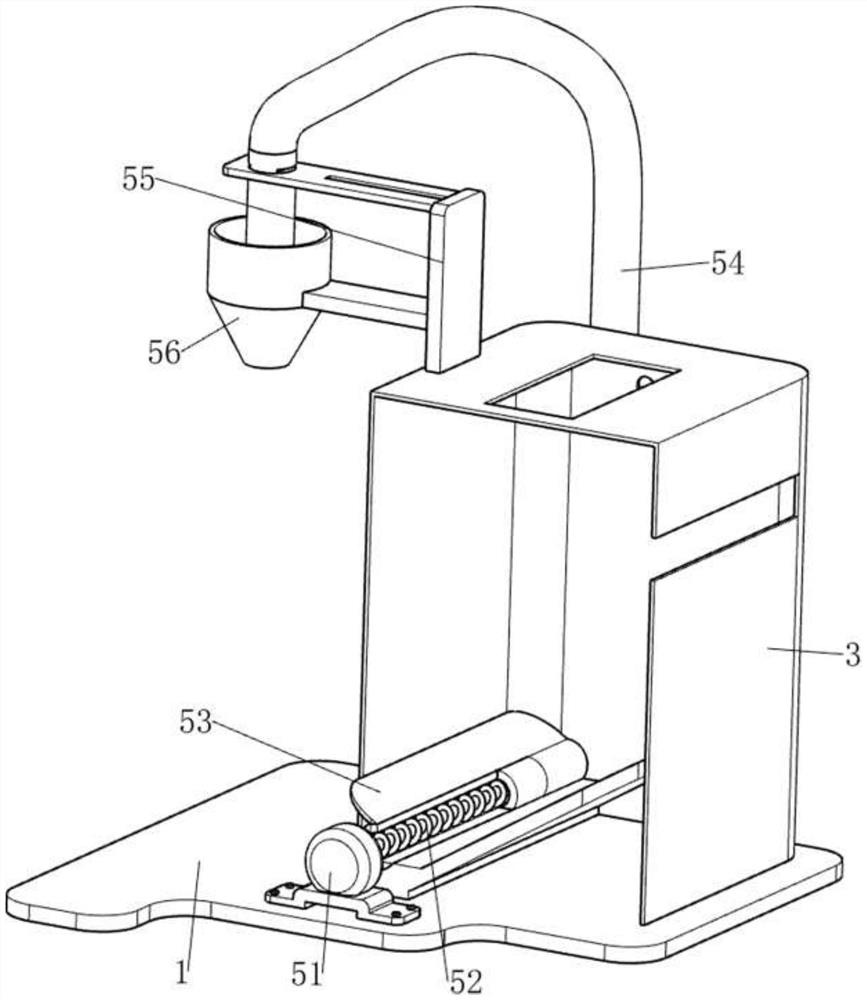

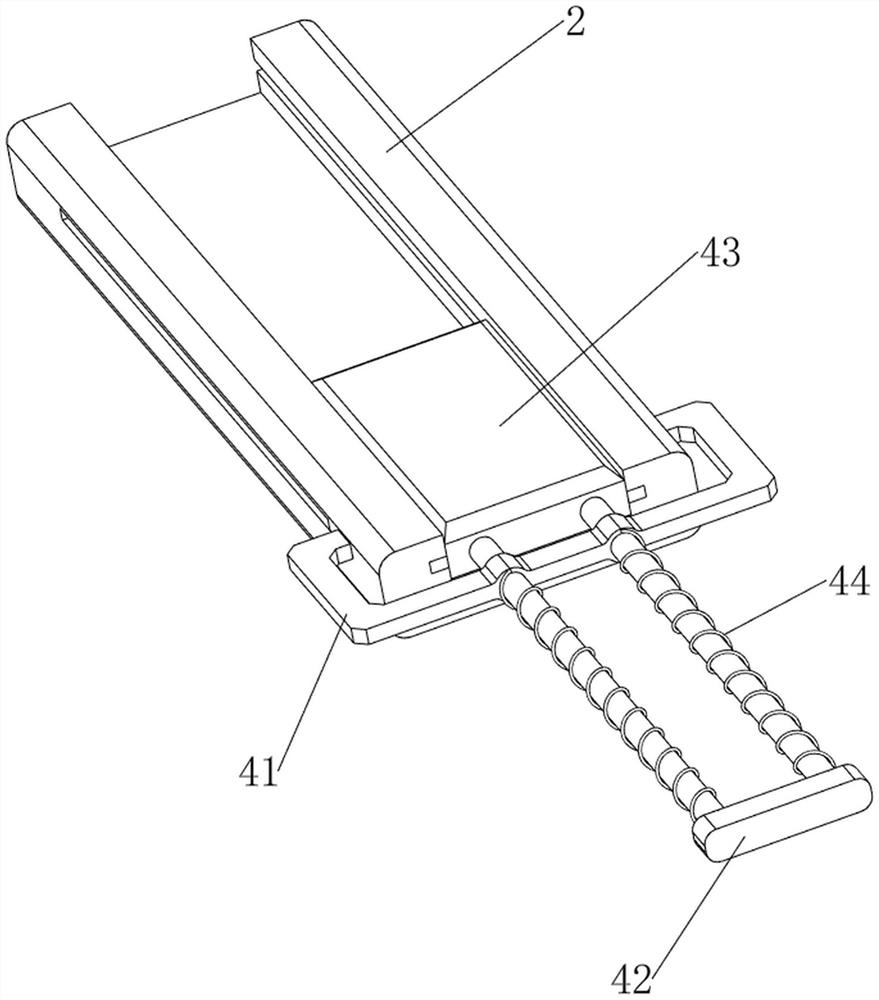

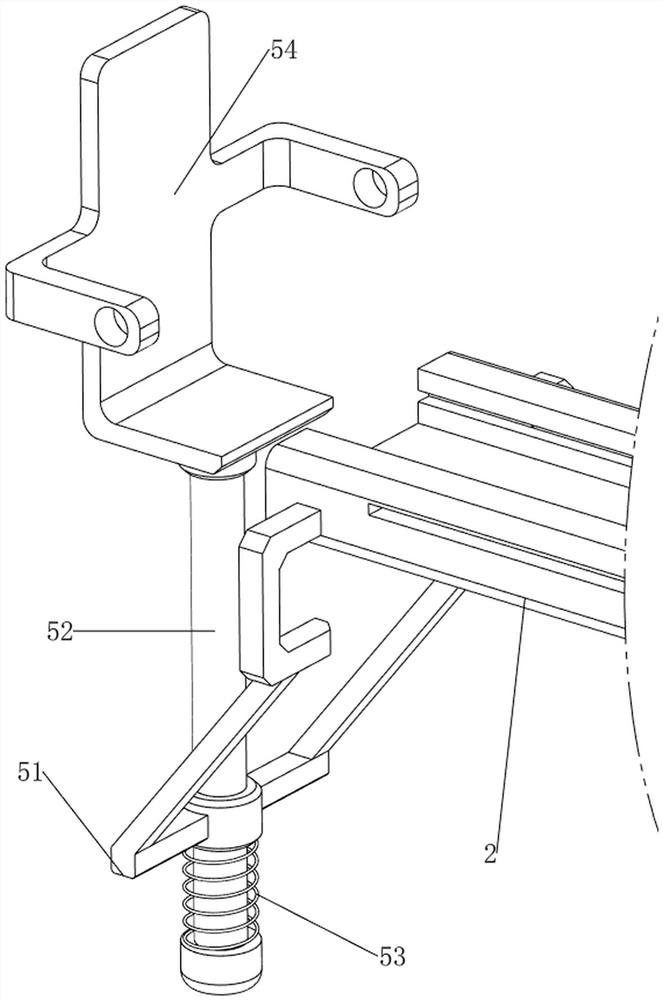

Medical square tablet mashing equipment for pediatric department

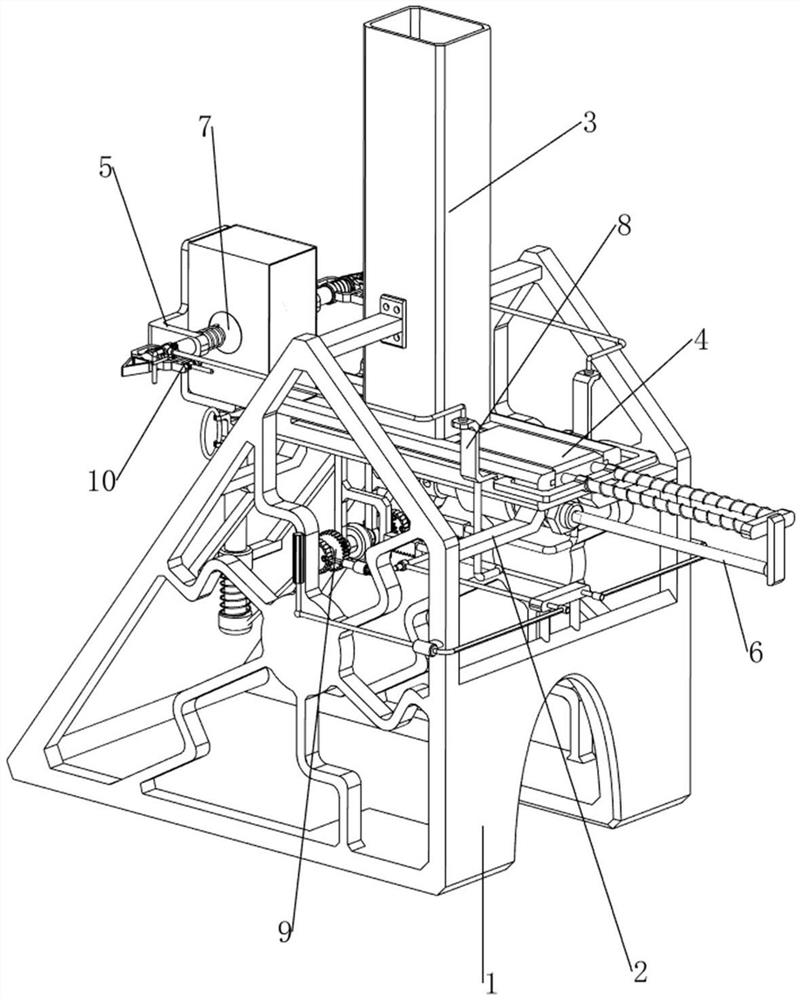

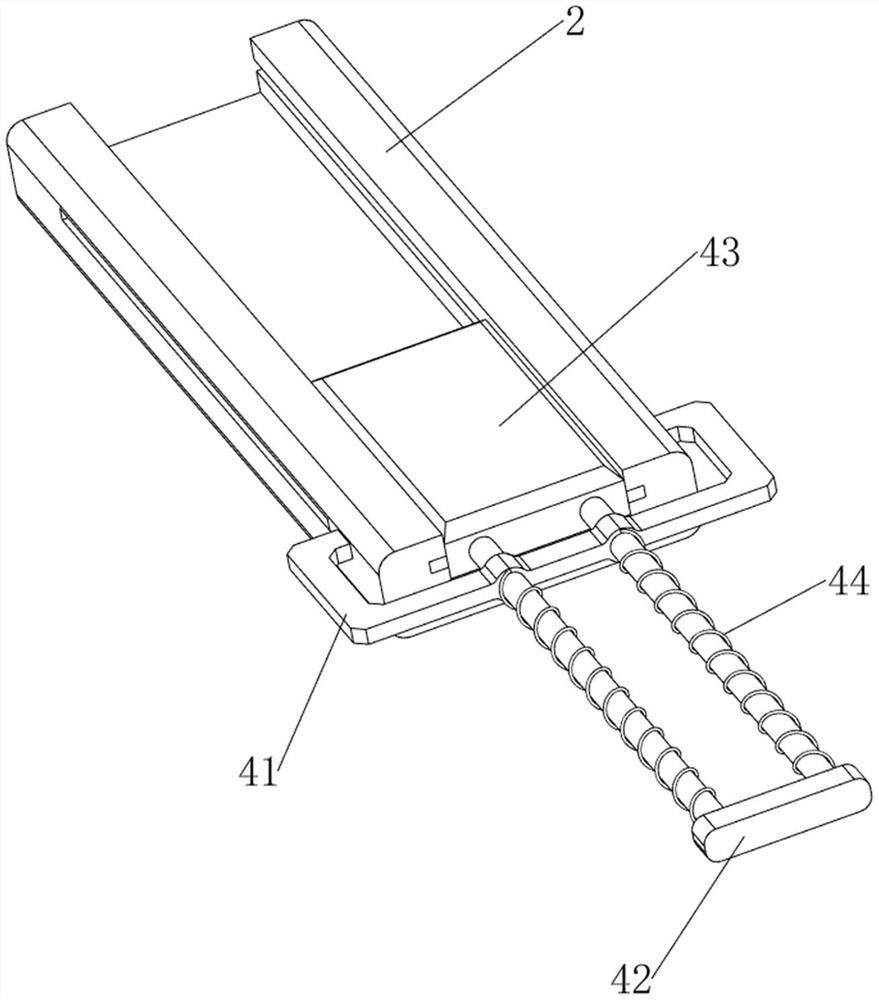

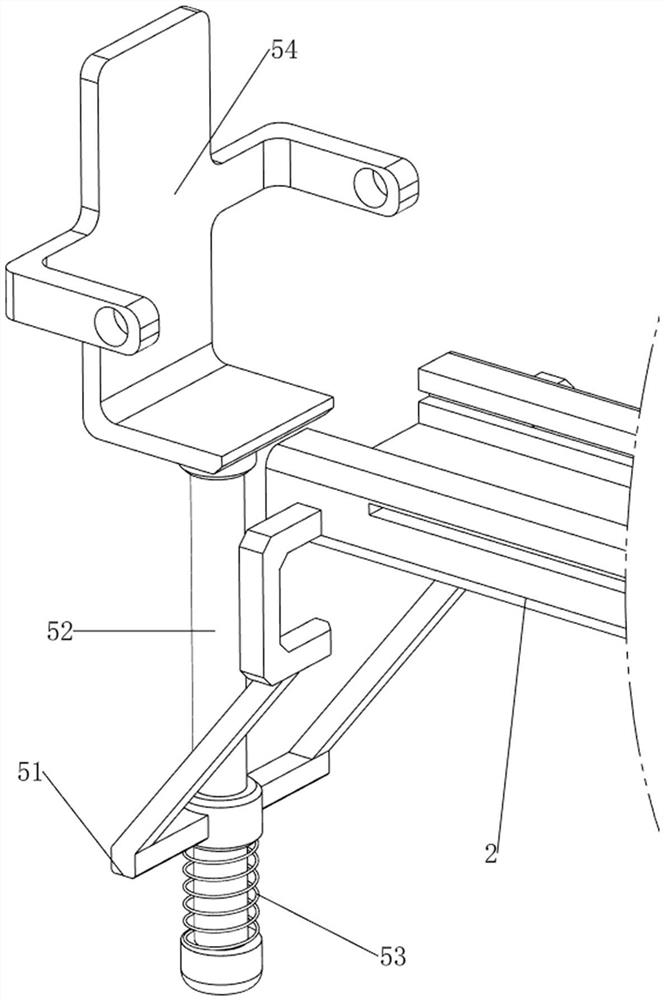

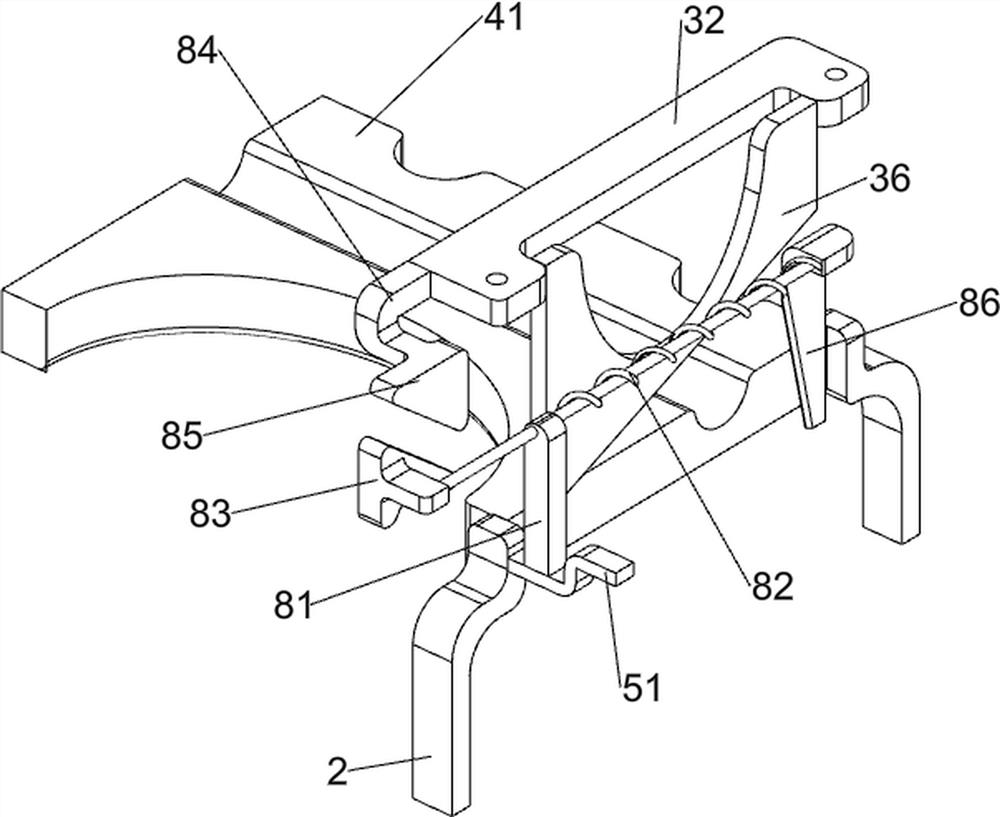

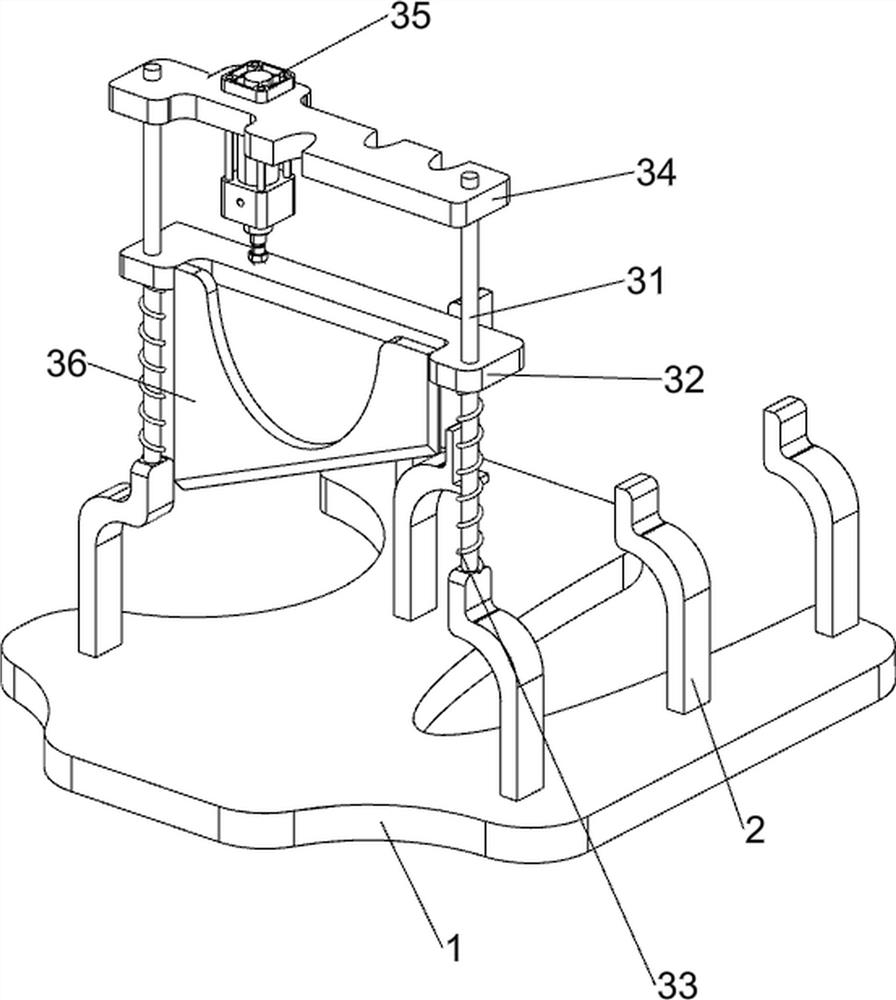

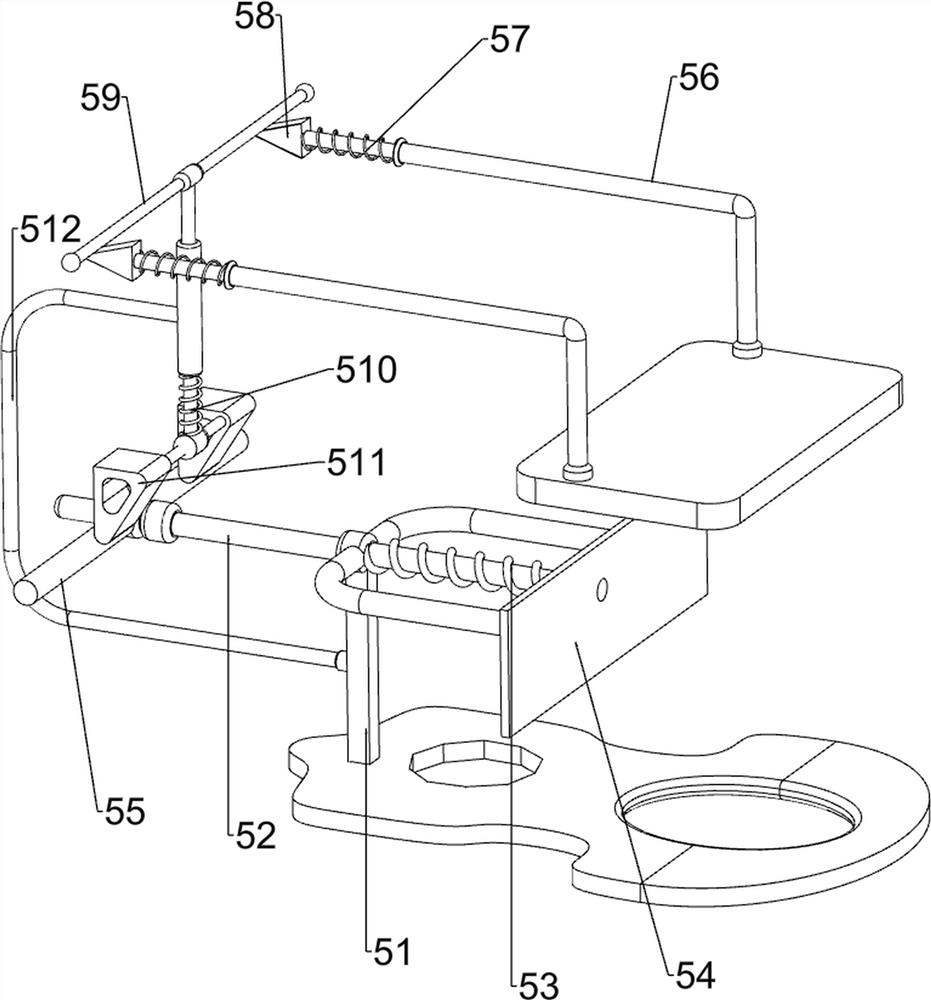

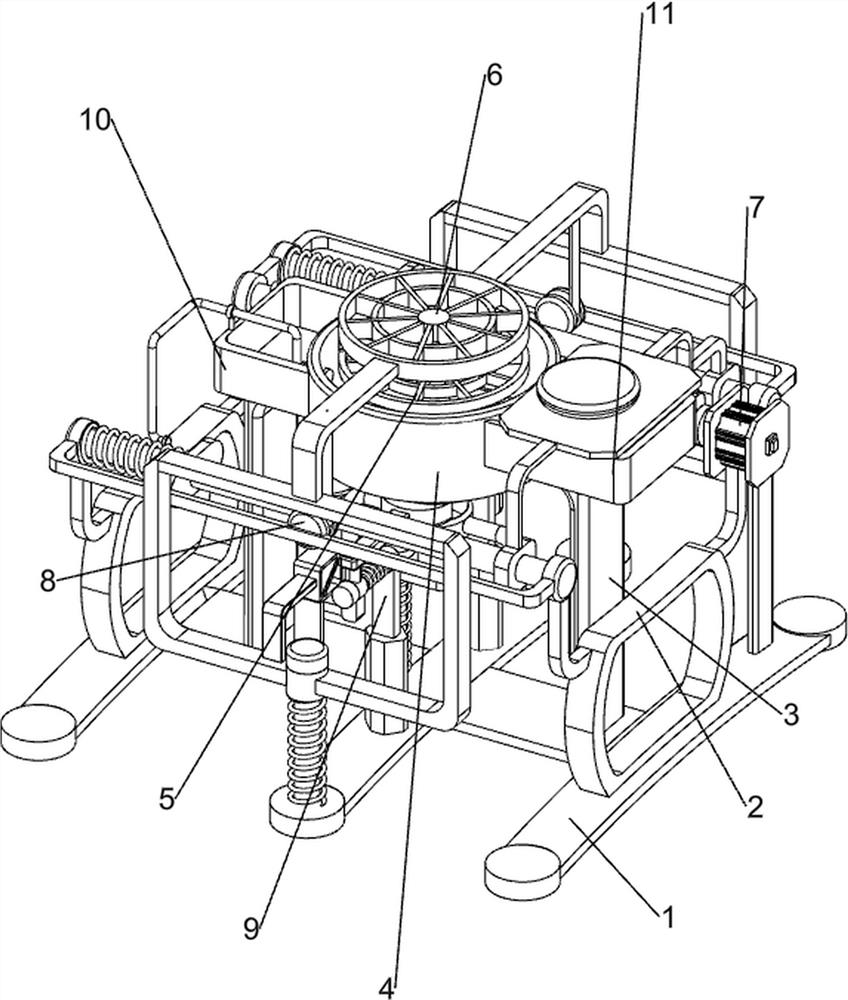

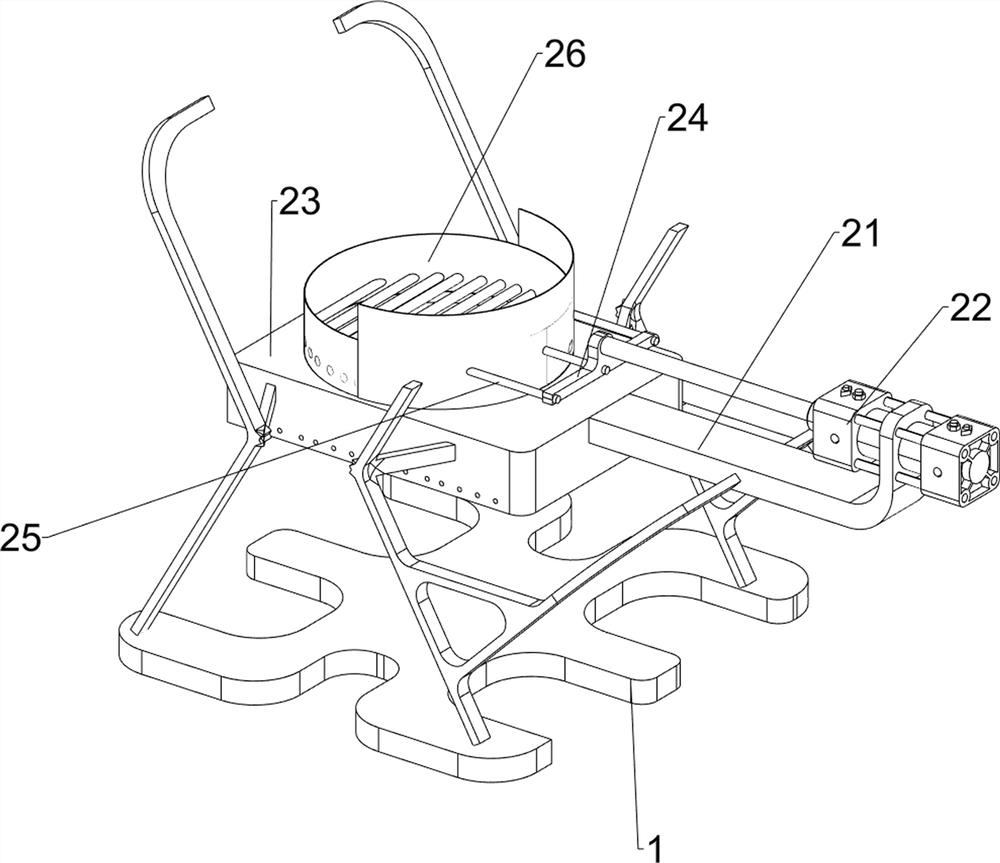

PendingCN113304805ARealize the push effectSave human effortOral administration deviceGrain treatmentsEngineeringSurgery

The invention relates to mashing equipment, in particular to medical square tablet mashing equipment for pediatric department. The medical square tablet mashing equipment for the pediatric department can mash tablets automatically, is good in mashing effect and can mash a large number of tablets. The medical square tablet mashing equipment for the pediatric department comprises a bottom frame, a first supporting block, a second supporting block, a material pushing mechanism, an extruding mechanism and an extrusion block, wherein the first supporting block is arranged on the bottom frame; the second supporting block is arranged between the upper part of the first supporting block and the bottom frame; the material pushing mechanism is arranged between the bottom frame and the first supporting block and between the bottom frame and the second supporting block; the extruding mechanism is arranged on the material pushing mechanism; and the extrusion block is arranged on the material pushing mechanism in a sliding mode, and the extrusion block is fixedly connected with the extrusion mechanism. By arranging the material pushing mechanism, people push the material pushing mechanism to operate, so that the material pushing mechanism can push tablets to the position below the extrusion block, and the material pushing effect is achieved.

Owner:张志嵘

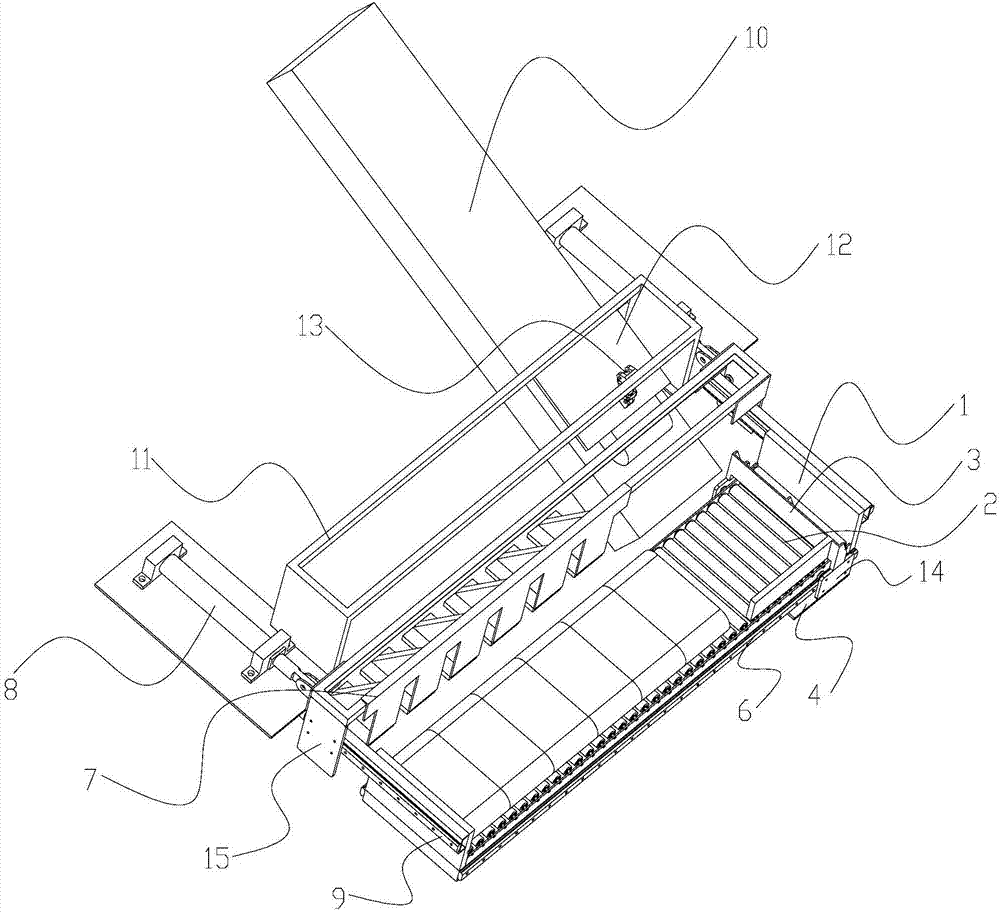

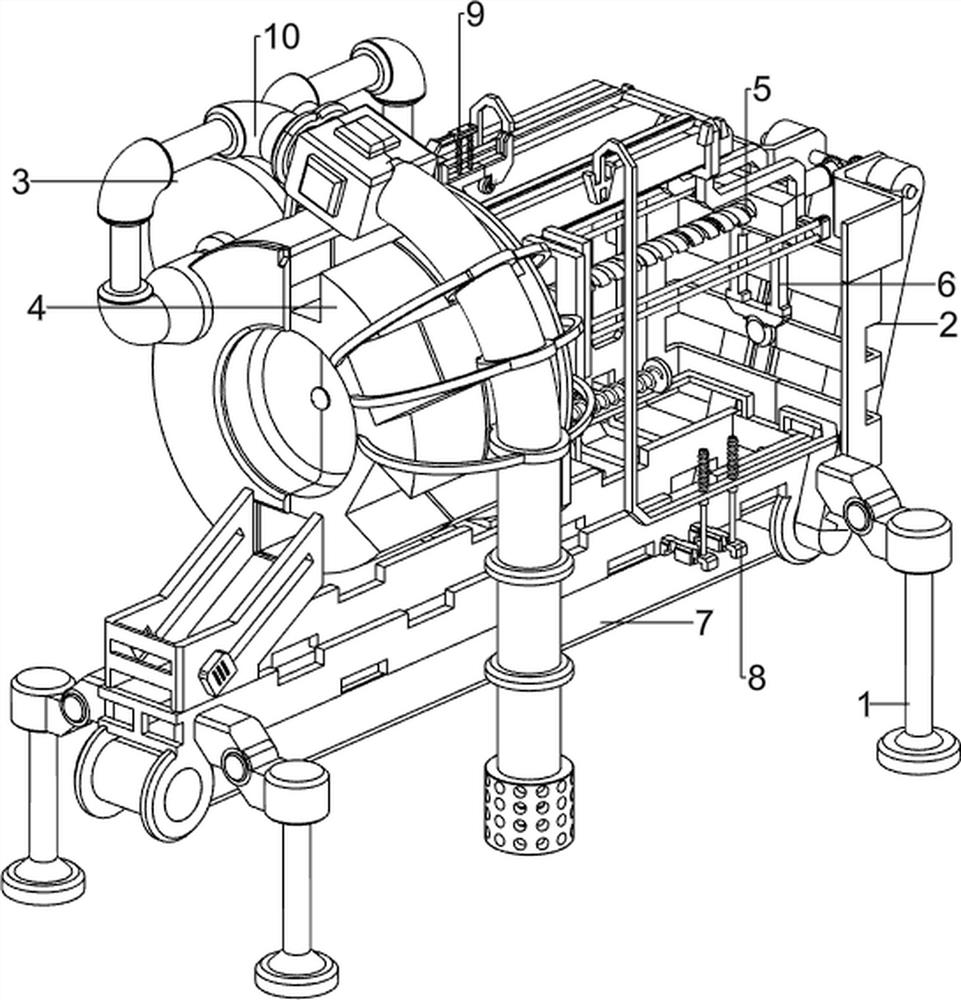

Cement bag transportation buffer machine

InactiveCN107416489ARealize the push effectRealize the limit functionLoading/unloadingConveyor partsEngineeringMechanical engineering

The invention relates to a cement bag transportation buffer machine, comprising: a transportation assembly, a pushing assembly, a horizontal pushing assembly and a downhill conveyor, the transportation assembly includes a transportation frame and several rollers, and several rollers are rotatably arranged on the surface of the transportation frame ; The pushing component is used for pushing longitudinally on the track formed by the roller, and the horizontal pushing component is used for pushing horizontally on the track formed by the roller. The downhill conveyor is arranged on one side of the second push plate and the slope bottom of the downhill conveyor communicates with the track formed by several rollers. First of all, the bagged cement is pushed horizontally to one station through the pushing component, and after each bag of cement is pushed from one station to several stations, the horizontal pushing effect is realized through the horizontal pushing component, and it is pushed to the installation equipment In the process of pushing, the position is limited by the action of the first push plate and the stop plate, and the correction is realized through the gap between the push plates on the second push plate. The process is simple, fast, and efficient. The error rate is low.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

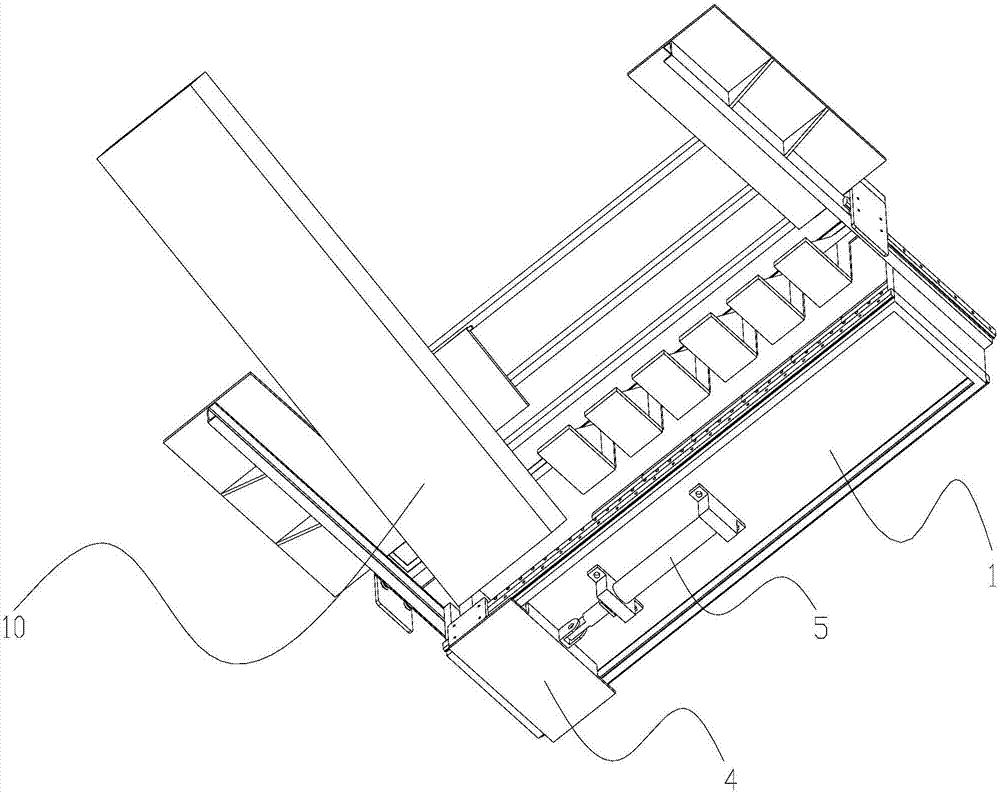

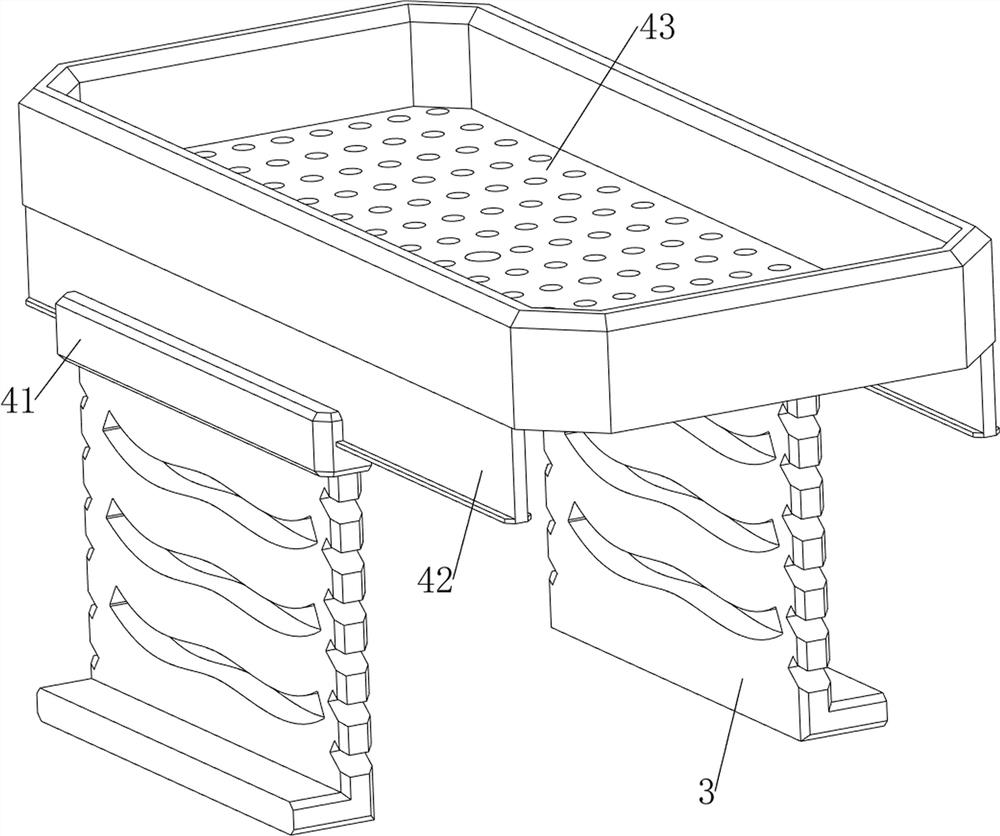

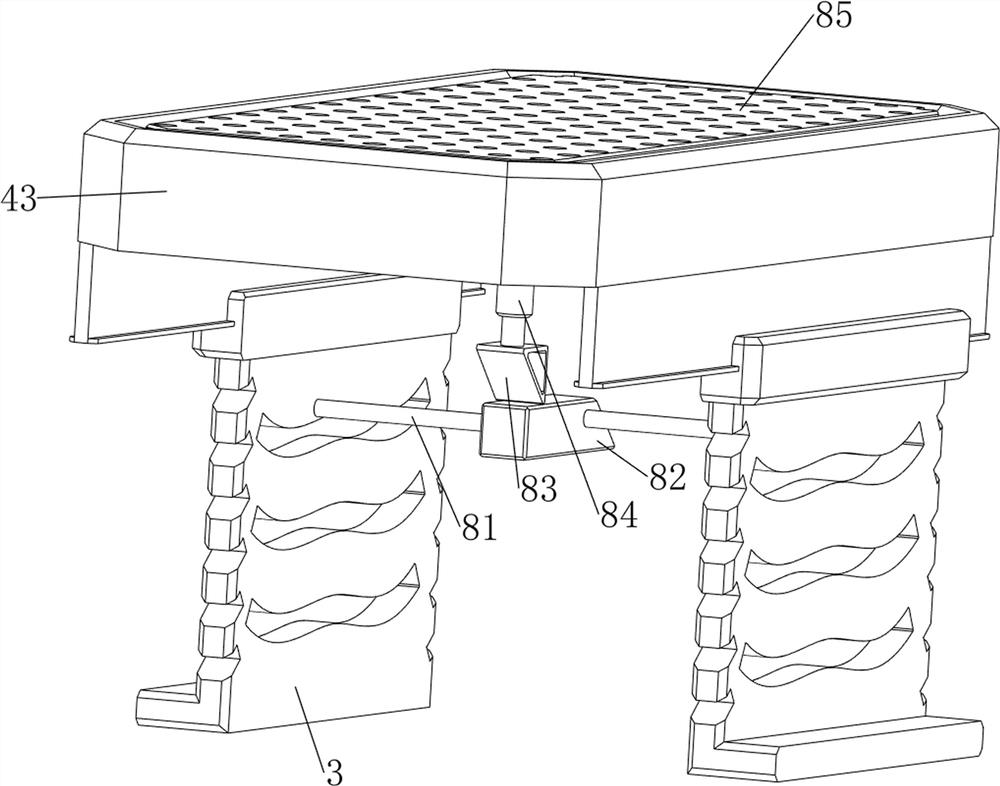

Screening device for rare earth raw material processing

InactiveCN113877817ARealize the push effectNo manual push requiredSievingGas current separationRaw materialSupport plane

The invention relates to a screening device, in particular to a screening device for rare earth raw material processing. The screening device for rare earth raw material processing is good in screening effect, capable of conducting secondary screening and low in cost. The screening device for rare earth raw material processing comprises a bottom frame, a first discharging frame, a first supporting frame, a first screening frame, a material pushing mechanism and a rotary reciprocating mechanism; the first discharging frame is arranged on the bottom frame; the first supporting frame is arranged on the bottom frame; the first screening frame is arranged on the first supporting frame in a sliding mode; the material pushing mechanism is arranged among the bottom frame, the first screening frame and the first supporting frame; and the rotary reciprocating mechanism is arranged among the bottom frame, the first supporting frame and the material pushing mechanism. According to the screening device, a material pushing frame is manually pushed to move backwards, rare earth is pushed together through the material pushing frame, screening is convenient, and the material pushing effect is achieved.

Owner:叶小刚

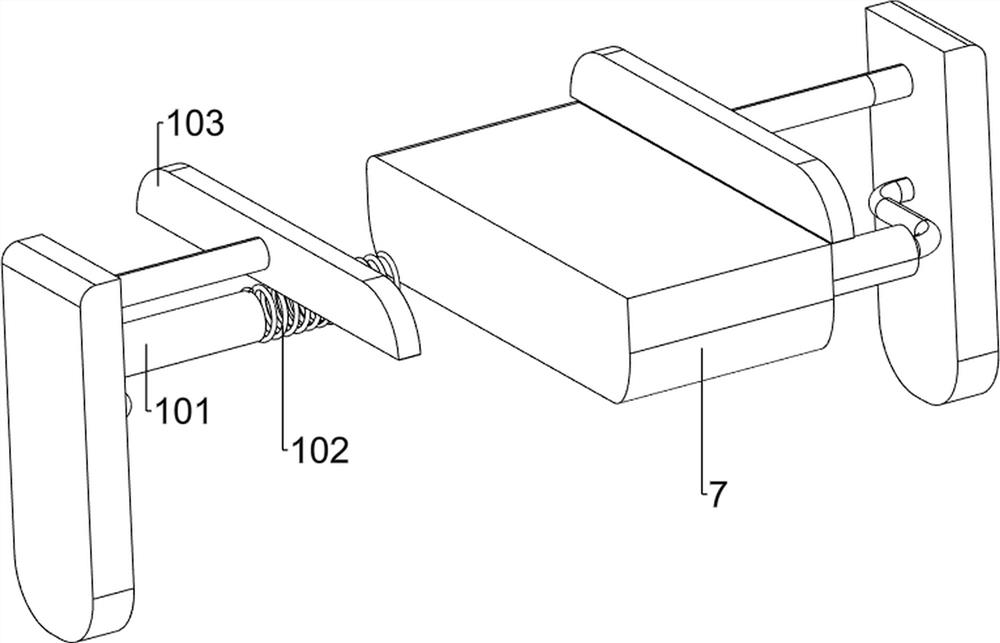

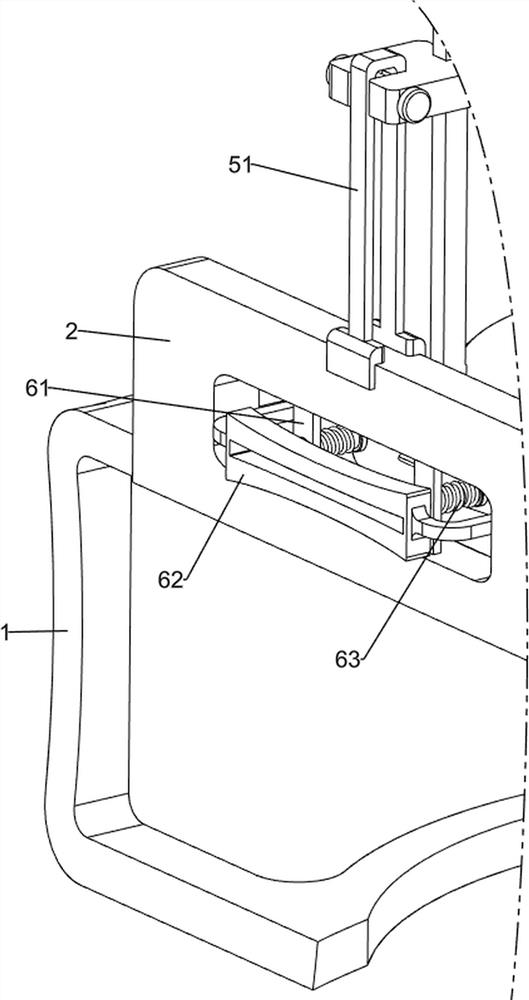

Automatic packaging device for circuit breaker production

ActiveCN112849519AAvoid displacementRealize the push effectPackagingPackaging CaseControl engineering

The invention relates to a packaging device, and particularly relates to an automatic packaging device for circuit breaker production. The automatic packaging device for circuit breaker production can achieve automatic packaging, reduces labor force of workers and is convenient to use. The automatic packaging device for circuit breaker production comprises supporting feet, a sliding rail plate, a discharging frame, a pushing mechanism and a moving mechanism, wherein the sliding rail plate is arranged between the two sides of the supporting feet, the discharging frame is arranged between the two sides of the supporting feet, the pushing mechanism is arranged on the sliding rail plate, and the moving mechanism is arranged on the sliding rail plate. According to the automatic packaging device, a first sliding rod is manually pushed to slide leftwards, a first spring is compressed, and therefore a sliding block is driven to move leftwards, a circuit breaker can be pushed out through the sliding block, and the pushing effect is achieved; and after the circuit breaker is pushed to a packaging box again through the sliding block, people need to push a supporting plate to move downwards again, and therefore a second sliding rod is driven to continue to slide downwards, a second spring continues to reset, and the moving effect is achieved.

Owner:江西双宏科技电气有限公司

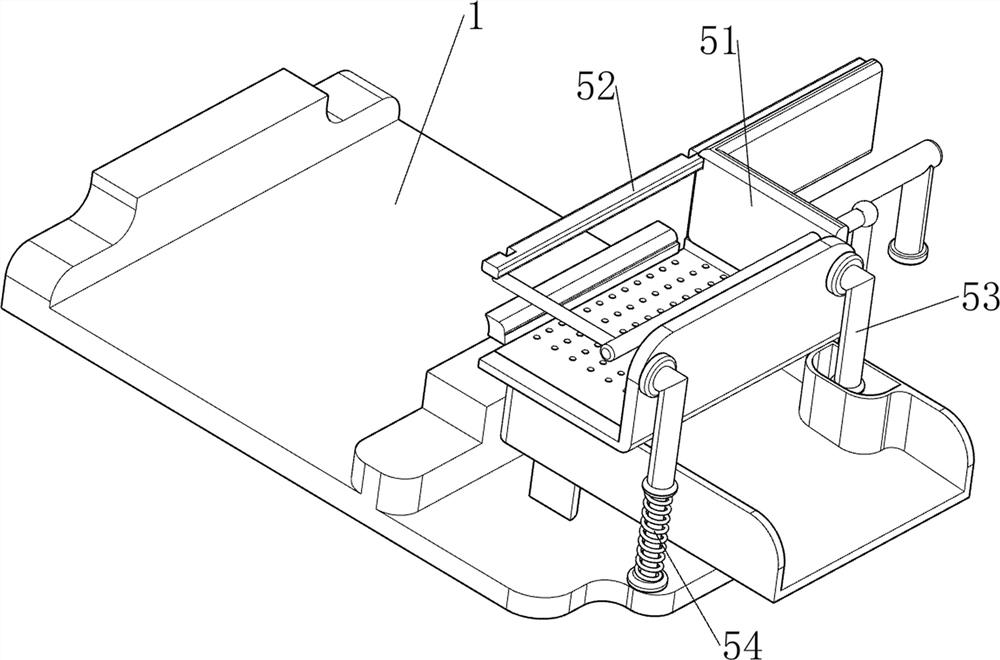

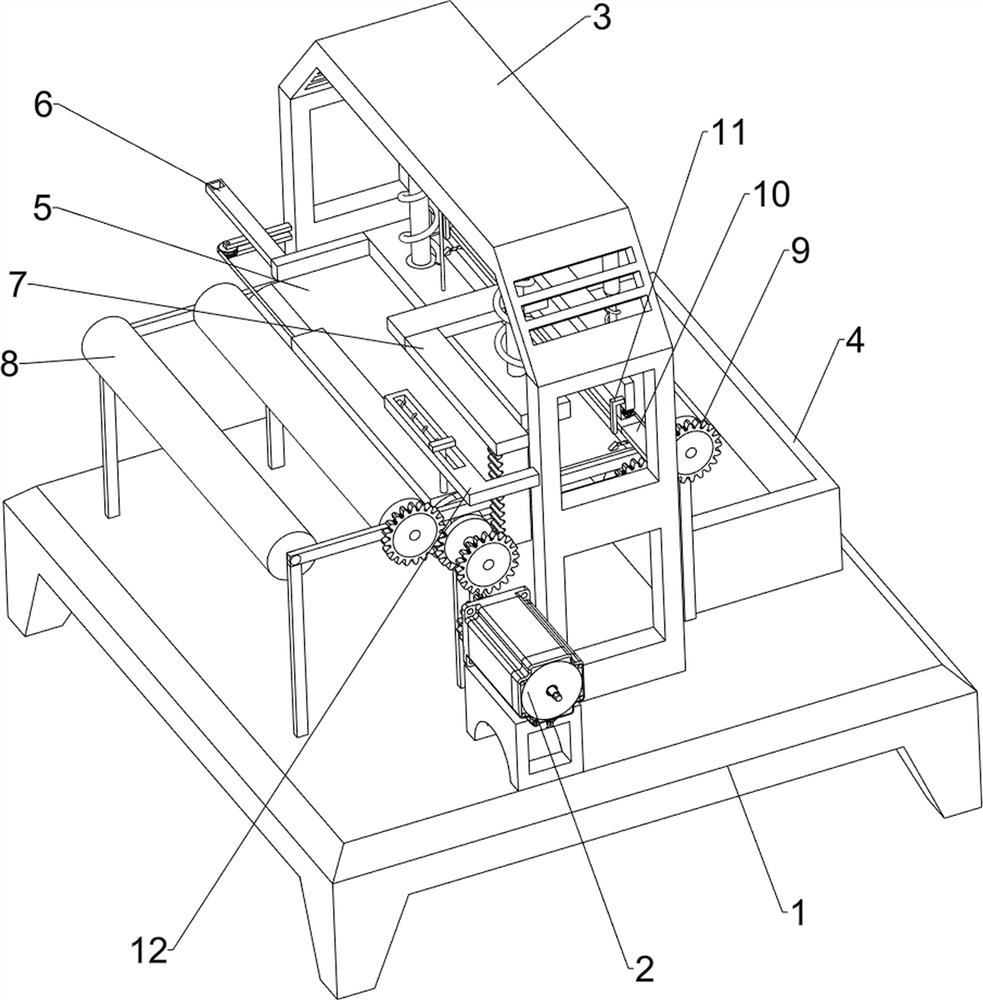

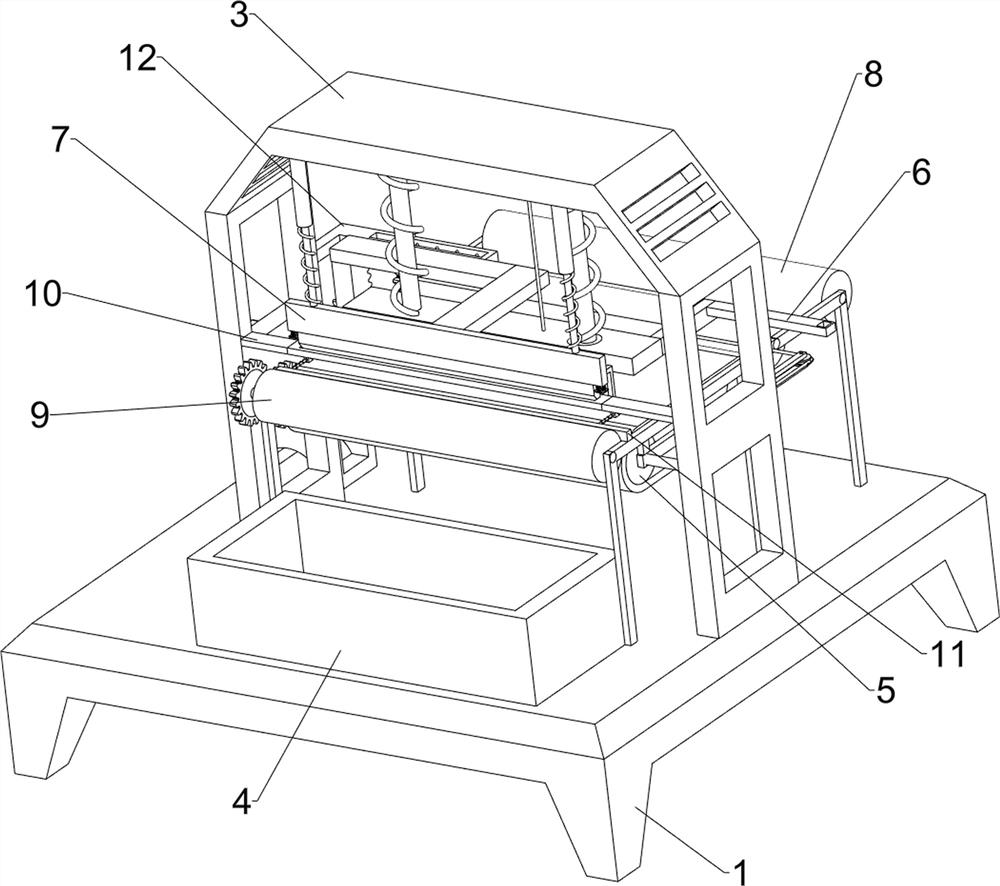

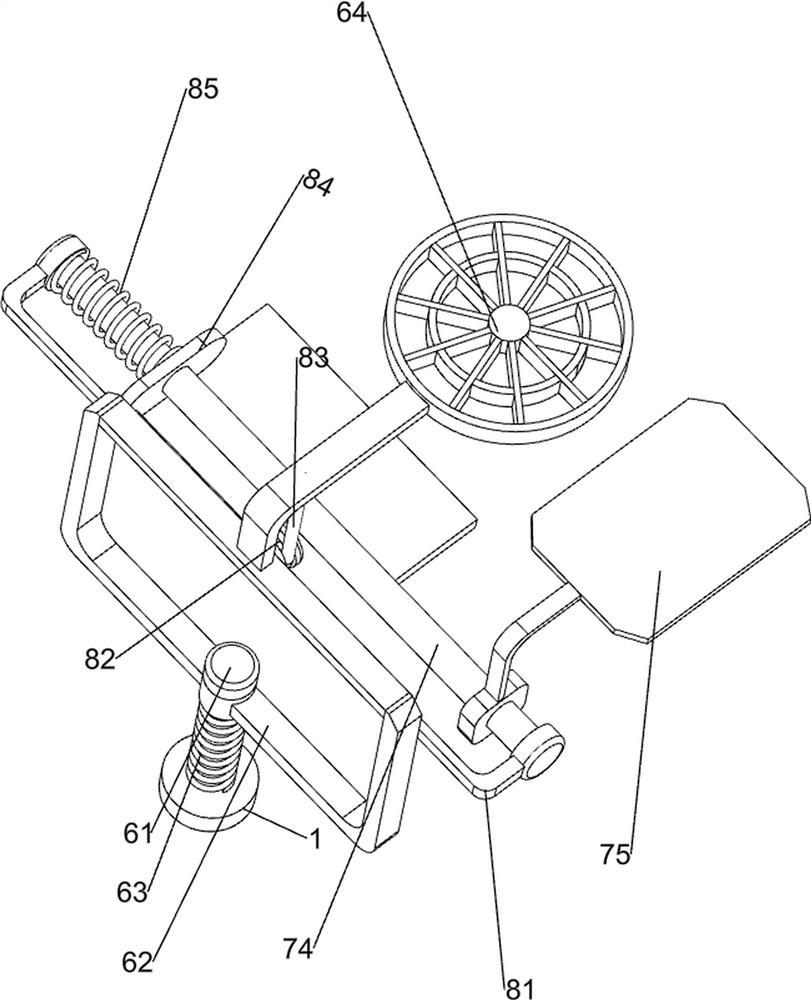

Efficient herbal medicine slicing equipment for Chinese and western medicine combination department

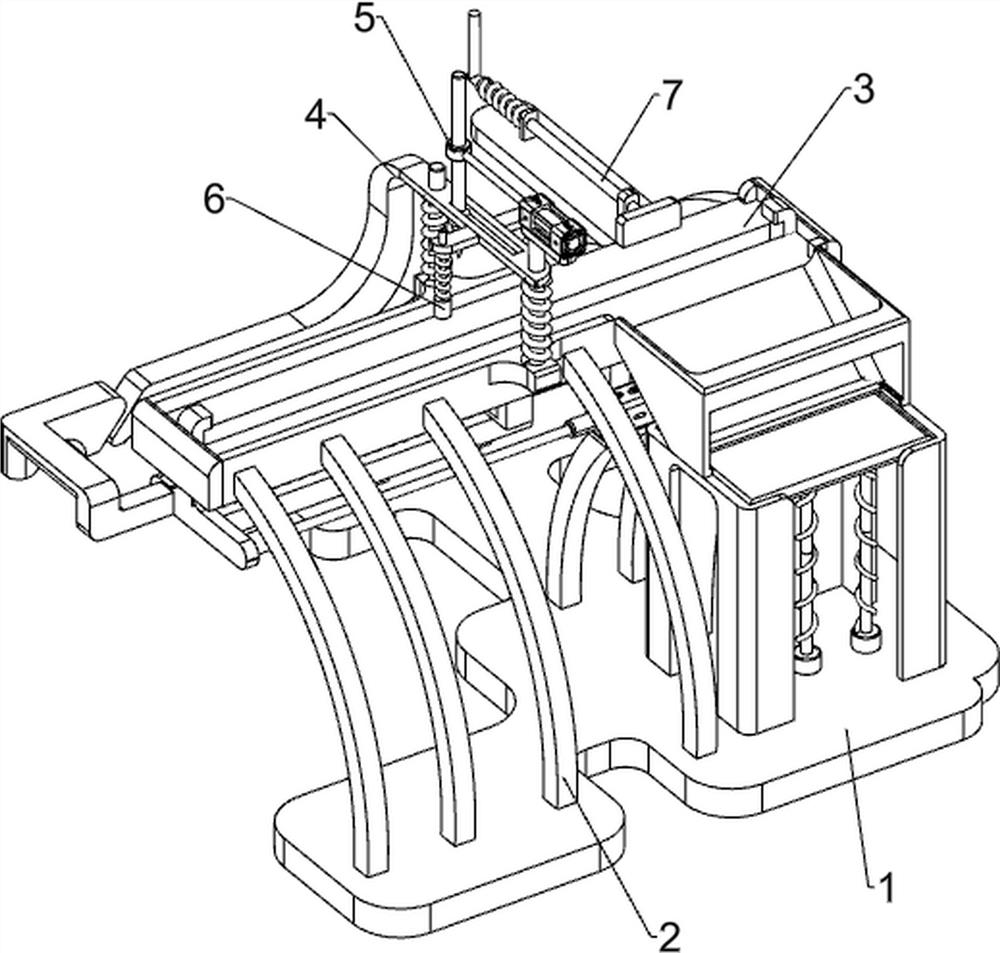

PendingCN112828961ARealize the operationRealize the push effectMetal working apparatusBiomedical engineeringWestern medicine

The invention relates to slicing equipment, and particularly relates to efficient herbal medicine slicing equipment for Chinese and western medicine combination department. The invention provides the efficient herbal medicine slicing equipment for the Chinese and western medicine combination department, and the efficient herbal medicine slicing equipment is capable of automatically clamping, discharging and pushing herbal medicines. The efficient herbal medicine slicing equipment for the Chinese and western medicine combination department comprises a bottom plate, supports, a slicing mechanism and a material pushing mechanism, and the four supports are symmetrically arranged on the two sides of the bottom plate; the slicing mechanism is arranged between the tops of the two supports; and the material pushing mechanism is connected among the upper parts of the six supports. According to the efficient herbal medicine slicing equipment, after the herbal medicines are placed on the material pushing mechanism, an air cylinder is started, an air cylinder telescopic rod drives a lower pressing plate to reciprocate up and down, the lower pressing plate moves downwards to drive a slicing knife to move downwards, and a spring is compressed, so that the herbal medicines are sliced by the slicing knife.

Owner:胡青平

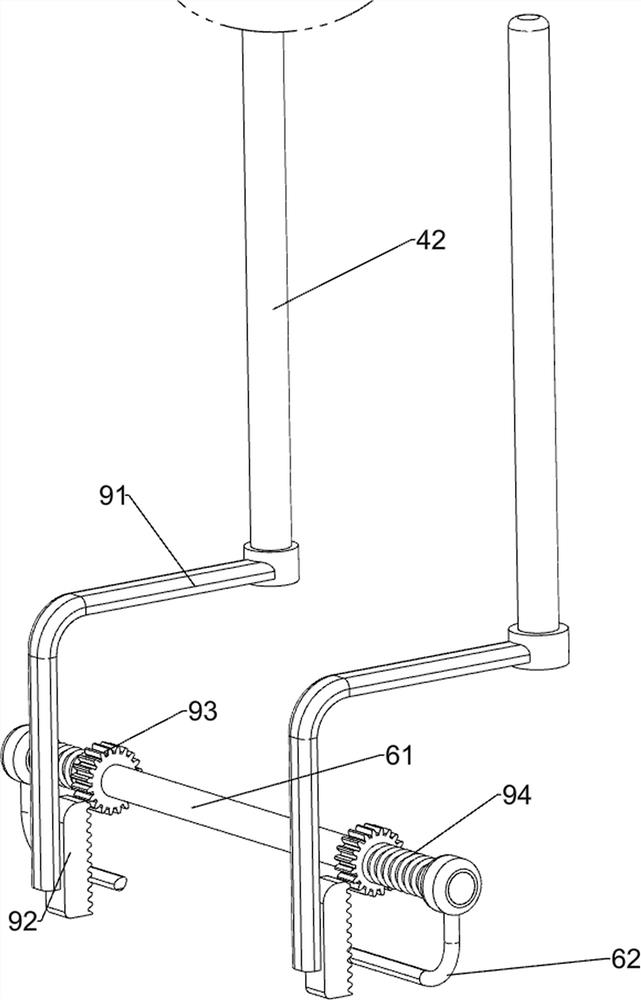

Efficient positioning welding equipment for alloy steel for high-end equipment manufacturing

InactiveCN112658546AAchieve positioningRealize the welding effectWelding/cutting auxillary devicesAuxillary welding devicesGear wheelIndustrial engineering

The invention relates to efficient positioning welding equipment for alloy steel, in particular to efficient positioning welding equipment for alloy steel for high-end equipment manufacturing. The efficient positioning welding equipment for the alloy steel for high-end equipment manufacturing can achieve automatic welding, the quality of welded products is stable, and manpower resources are not wasted. The efficient positioning welding equipment for the alloy steel for high-end equipment manufacturing comprises a bottom plate, supports, a positioning mechanism, a pressing mechanism, a welding mechanism and the like, wherein the supports are arranged on the bottom plate, the positioning mechanism is arranged between the supports, the pressing mechanism is arranged in the middle of the positioning mechanism, and the welding mechanism is arranged at the top of the left front side of the pressing mechanism. According to the equipment, a telescopic rod of a first air cylinder moves leftwards to drive a push plate to move leftwards, so that a second rack is driven to move leftwards, then a straight gear is driven to rotate, the straight gear rotates to drive a first rack to move rightwards, a magnet on the right side can attract the welded alloy steel to the right side of a containing plate, and the positioning effect is achieved.

Owner:南京俊士通商贸有限公司

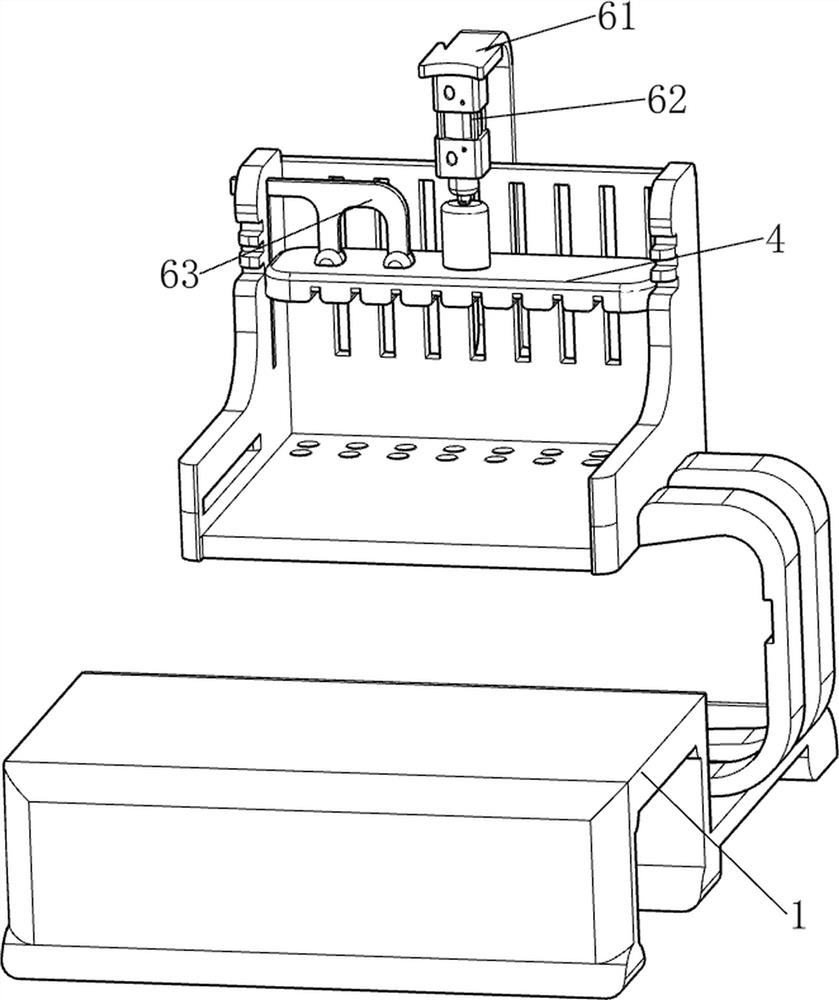

Printing equipment for processing hard toys for children

ActiveCN112373187APrinting realizationSave human effortRotary pressesConveyor partsTextile printerMechanical engineering

The invention relates to printing equipment, in particular to printing equipment for processing hard toys for children. The technical problem to be solved is to provide the printing equipment for processing the hard toys for children, so that automatic printing and feeding and discharging can be achieved. The invention provides the printing equipment for processing the hard toys for children comprises a base, supporting columns, a placing and color supplementing mechanism and a printing mechanism, wherein the supporting columns are arranged on the four sides of the base; the placing and colorsupplementing mechanism is arranged on one side of the base; and the printing mechanism is arranged on the placing and color supplementing mechanism. Through cooperation of the placing and color supplementing mechanism and the printing mechanism, toys can be printed, so that manpower is saved; and through cooperation of a discharging mechanism and a pushing mechanism, the effects of automatic printing and convenient discharging can be achieved, and the working efficiency of people can be improved.

Owner:威利文化产业(河源)有限公司

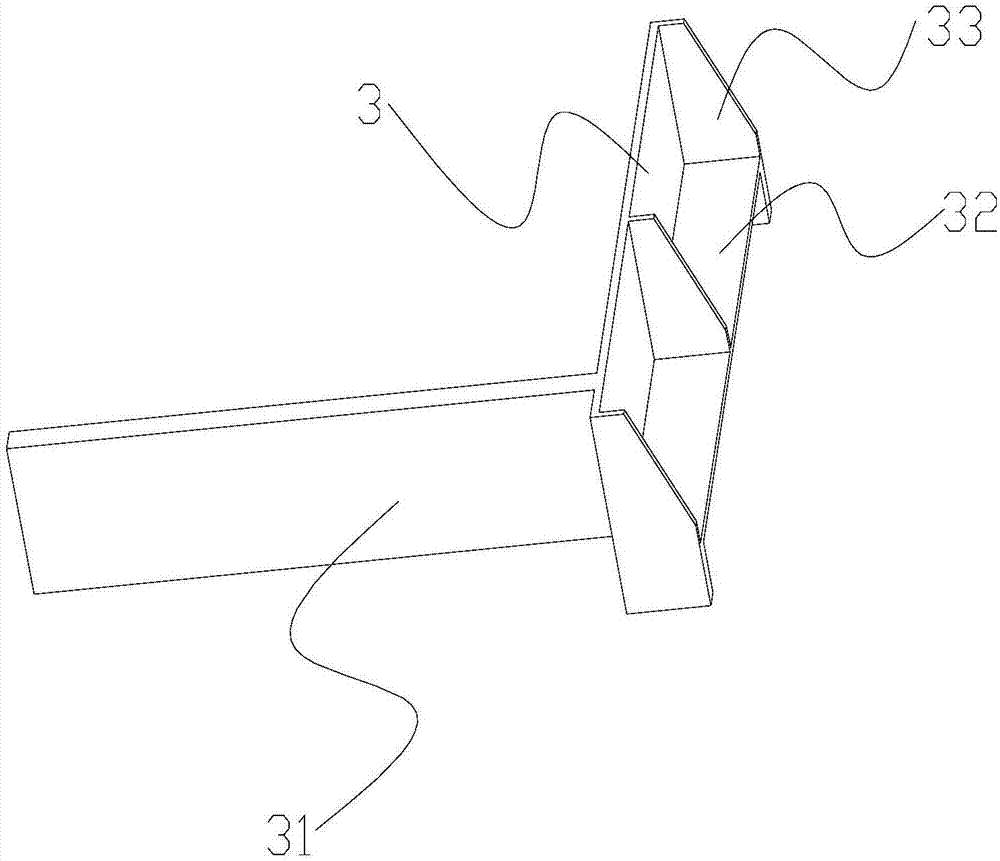

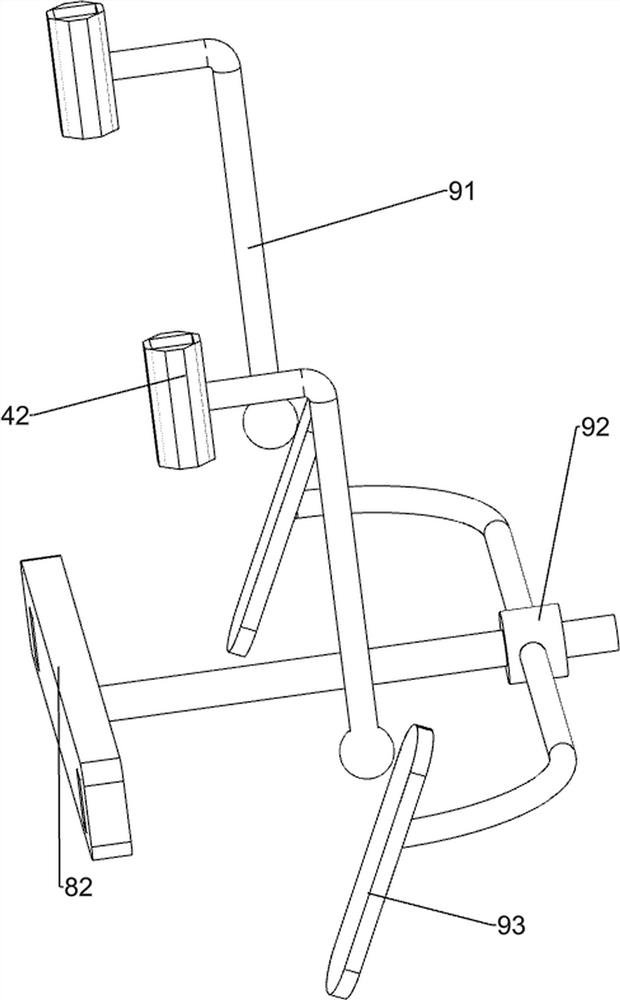

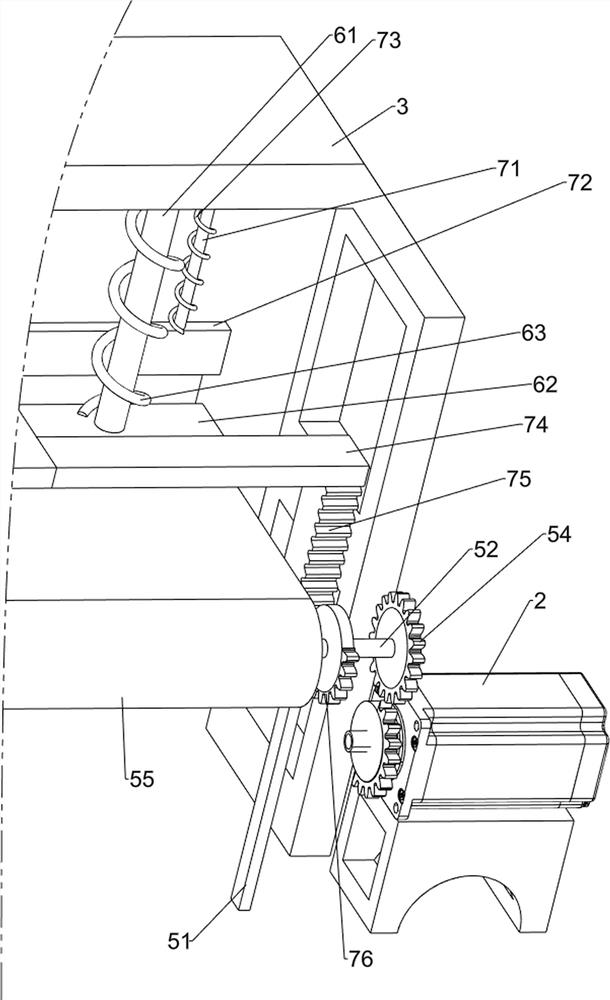

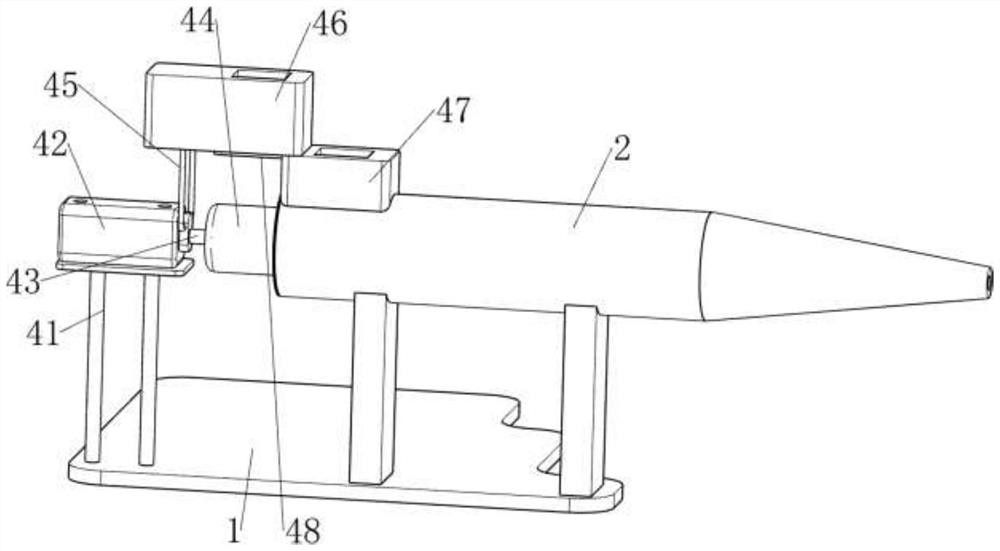

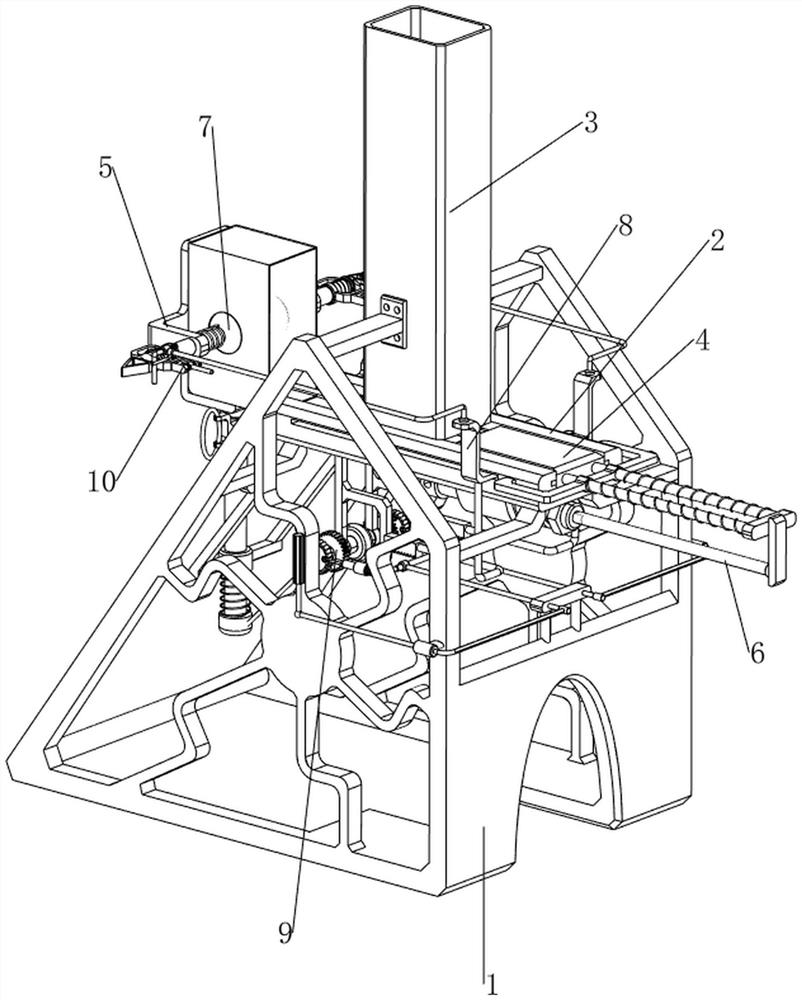

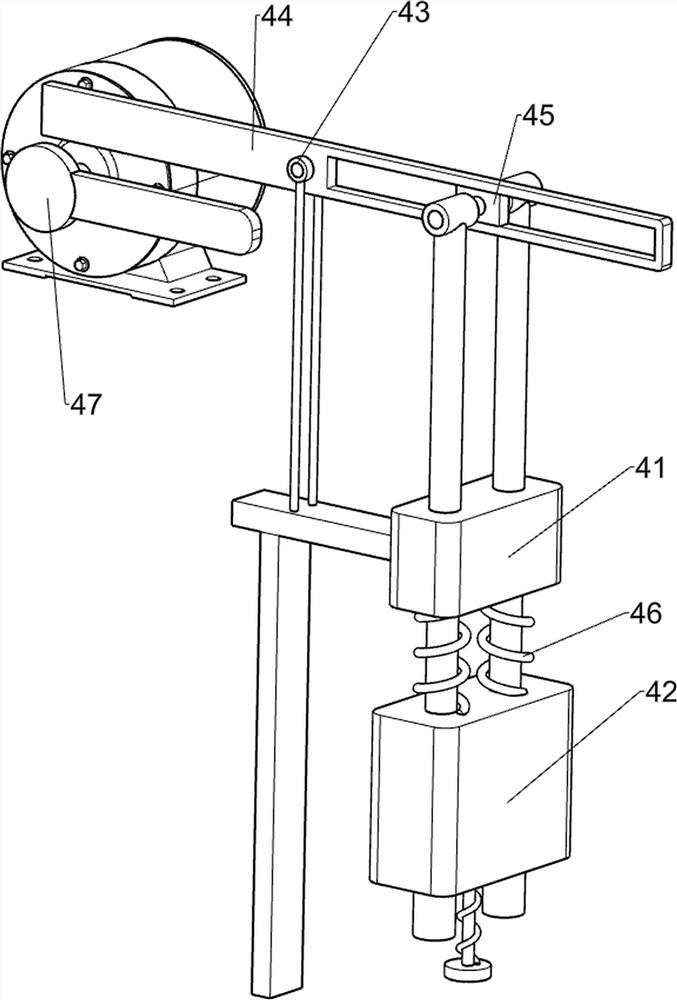

Steel pipe bending equipment for construction site building

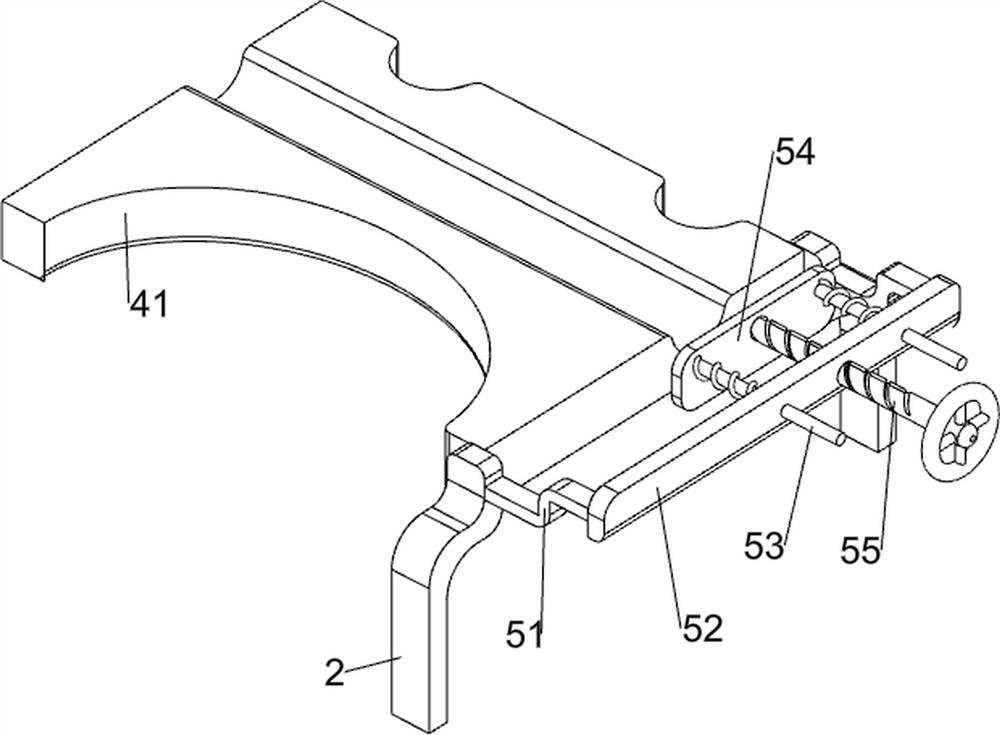

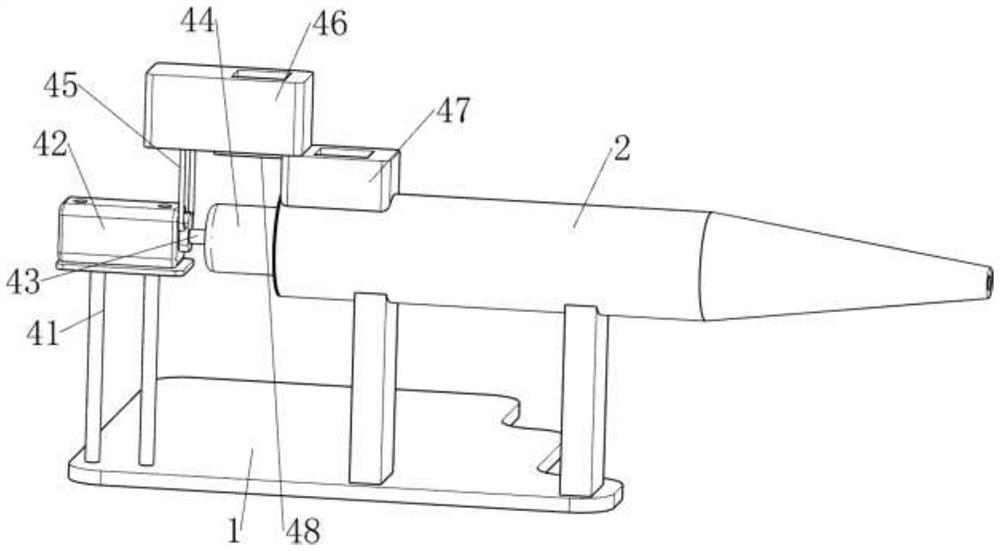

PendingCN112828101ARealize the push effectRealize the bending effectMetal-working feeding devicesPositioning devicesSteel tubeArchitectural engineering

The invention relates to bending equipment, in particular to steel pipe bending equipment for a construction site building. The steel pipe bending equipment for the construction site building achieves automatic feeding, automatic clamping and automatic bending. The steel pipe bending equipment for the construction site building comprises a first supporting plate, first supporting frames, a second supporting plate, third supporting frames, a fixed rod, a discharging frame and a bending mechanism. The two sides of the first supporting late are each symmetrically provided with the two corresponding first supporting frames. The second supporting plate is connected among the tops of the four first supporting frames. The third supporting frames are arranged on the two sides of the second supporting plate. The fixed rod is arranged between the two third supporting frames. The discharging frame is connected to the fixed rod. The bending mechanism is arranged on the fixed rod. According to the steel pipe bending equipment, a pusher is manually pushed rightwards to drive a steel pipe to move rightwards, a second spring is compressed, a first round block rod moves rightwards, the steel pipe is pushed into a clamping mechanism, and the pushing effect is achieved.

Owner:欧志嘉

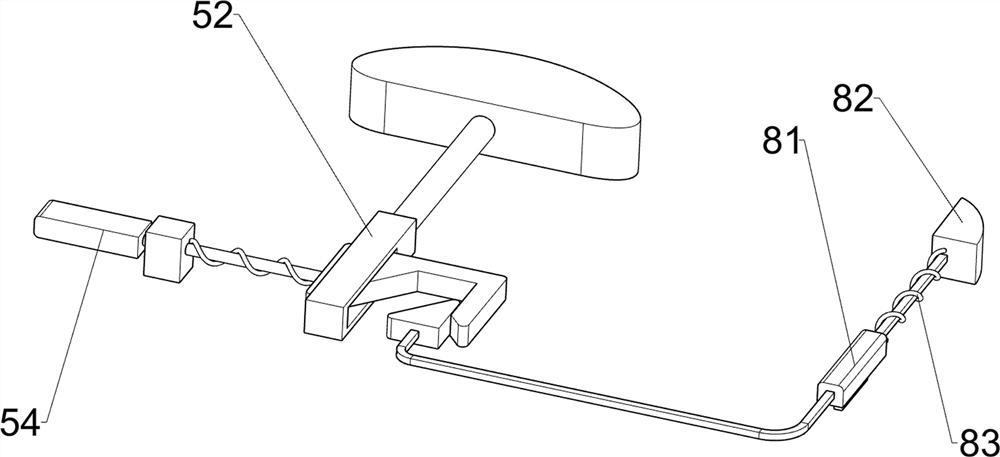

Extrusion type modified starch grinding device

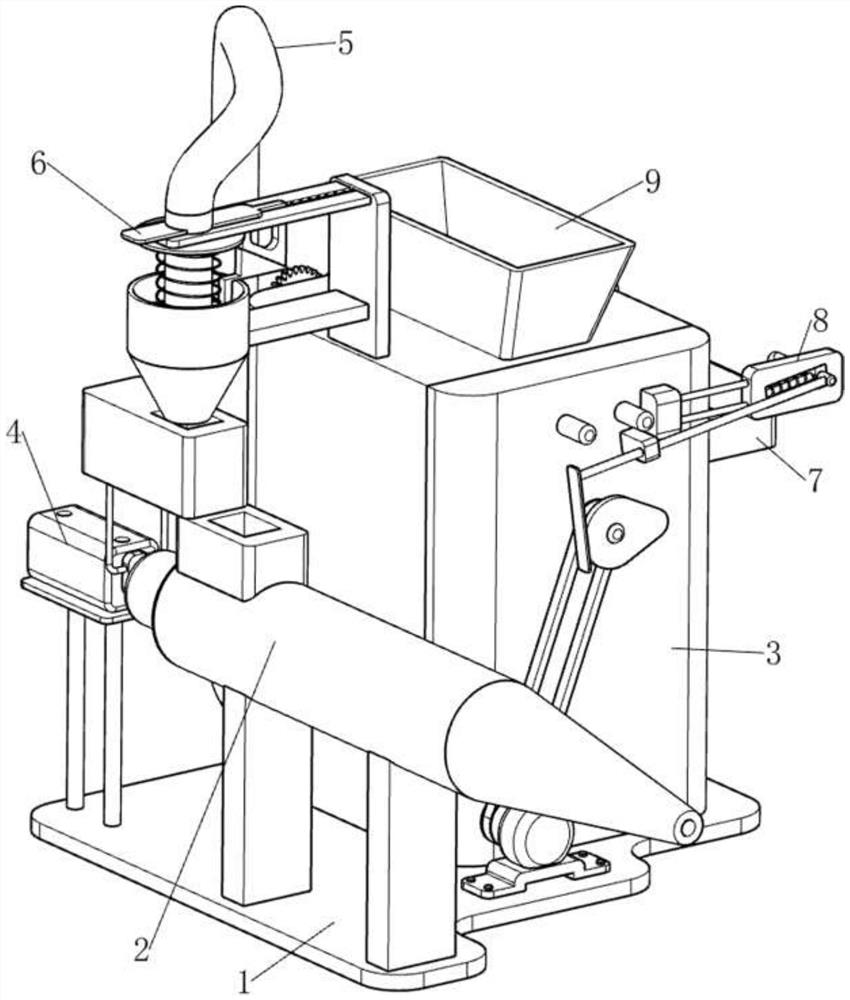

PendingCN113083414ARealize the effect of pressing down and crushingGrind evenlyGrain treatmentsComposite materialManufacturing engineering

The invention relates to a grinding device, in particular to an extrusion type modified starch grinding device. The extrusion type modified starch grinding device can improve the production efficiency and has the function of grinding while extruding. The extrusion type modified starch grinding device comprises a first fixing plate, a first supporting plate, a first discharging frame, a pressing mechanism and a material pushing mechanism; the first fixing plate is provided with the first supporting plate; the first discharging frame is arranged on the first supporting plate; the pressing mechanism is arranged on the first discharging frame; and the material pushing mechanism is arranged on the first fixing plate. According to the extrusion type modified starch grinding device, when first connecting rods are pushed by hands to move downwards, first springs are driven to be stretched, and then a grinding plate is driven to move downwards, so that modified starch in the first discharging frame is extruded and ground, and the effects of pressing and grinding are achieved.

Owner:吁红

Steel plate bending resistance detection device for construction sites

PendingCN113075054ARealize the effect of bending detectionRealize the feeding effectMaterial strength using steady bending forcesClassical mechanicsStructural engineering

Owner:赵毅明

Light transmission device punching equipment for vehicle-mounted microscope

ActiveCN112828999ARealize the push effectRealize the effect of opening and closingMetal working apparatusIn vehicleEngineering

The invention relates to punching equipment, in particular to light transmission device punching equipment for a vehicle-mounted microscope. According to the light-transmitting device punching equipment for the vehicle-mounted microscope, automatic punching is achieved, manual punching errors are reduced, and operation is convenient. The light transmission device punching equipment for the vehicle-mounted microscope comprises a first supporting plate, first supporting frames arranged on the first supporting plate, a second supporting plate arranged between the tops of the first supporting frames, second supporting frames arranged at the tops of the two sides of the middle of the second supporting plate, and a discharging frame arranged between the second supporting frames at the two sides. According to the light transmission device punching equipment, a first long block frame is manually pushed to move rightwards, so that a pusher is driven to move rightwards, a first spring is compressed, the pusher moves rightwards to push out a light transmission device, and the material pushing effect is achieved.

Owner:上饶市鑫锐光电有限公司

Automatic stamping mechanism for stainless steel cover machining

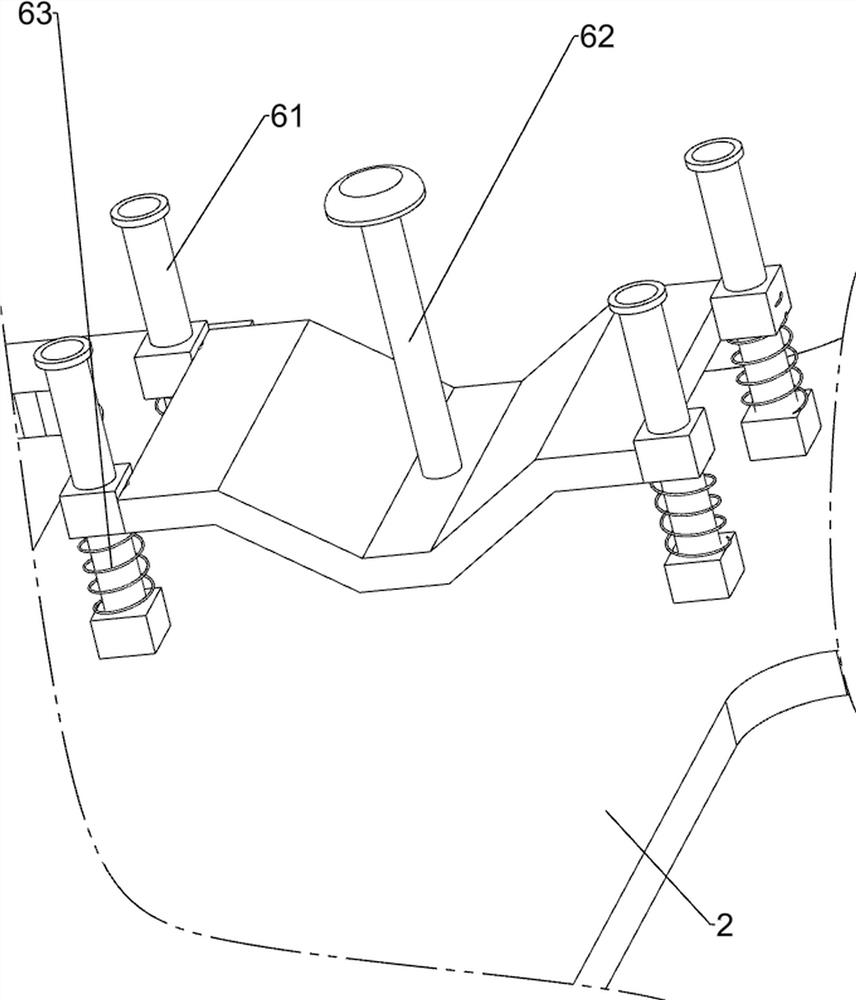

PendingCN113183647ARealize the push effectRealize the effect of automatic upward liftingStampingStampingStructural engineering

The invention relates to an automatic stamping mechanism, in particular to an automatic stamping mechanism for stainless steel cover machining. The invention provides the automatic stamping mechanism for stainless steel cover machining which improves the stamping accuracy and the stamping effect and can automatically feed and discharge and automatically stamp. The automatic stamping mechanism for stainless steel cover machining comprises supports, a workbench, stop levers, a stamping mechanism and a pushing mechanism; the workbench is connected to a position among the top ends of the four supports; the stop levers are symmetrically arranged at the top of the workbench; the stamping mechanism is arranged at the top of the workbench; and the pushing mechanism is arranged on the workbench. According to the automatic stamping mechanism for stainless steel cover machining, the pushing mechanism is arranged, people push the pushing mechanism forwards, a stainless steel cover is pushed to a position between the stop rods, and therefore the stainless steel cover pushing effect is achieved.

Owner:叶胡海

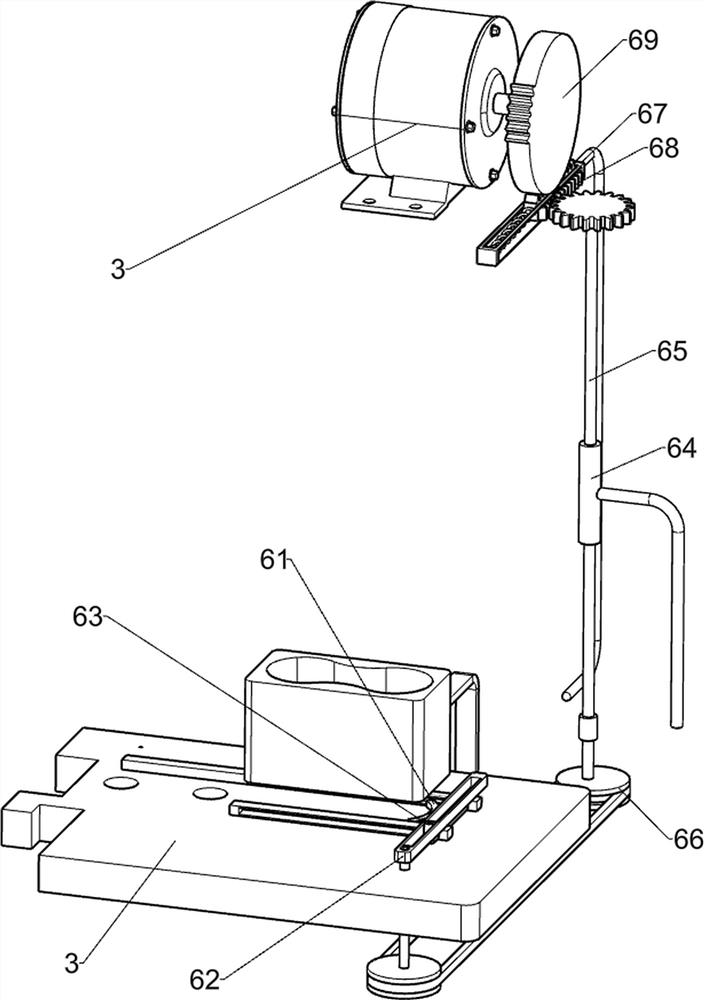

Automatic material digging equipment for workshop processing

ActiveCN112958843ARealize the push effectRealize the effect of diggingPositioning apparatusMetal working apparatusMachiningIndustrial engineering

The invention relates to material digging equipment, in particular to automatic material digging equipment for workshop processing. According to the automatic material digging equipment for workshop machining, materials can be automatically dug out, hands are not hurt, and the labor intensity of workers is reduced. Automatic material digging equipment for workshop machining comprises: a first supporting plate and first supporting frames, wherein the first supporting frames are symmetrically arranged on the first supporting plate; telescopic sleeves which are arranged on the first supporting plate, wherein the inner sides of the telescopic sleeves are connected to the outer sides of the first supporting frames; fixed connecting frames which are symmetrically arranged between the telescopic sleeves on the two sides; a second supporting plate which is arranged between the fixed connecting frames on the two sides; and second supporting frames which are arranged in the middles of the bottoms of the second supporting plates. A pusher is manually pushed to move backwards, and a first spring is compressed, so that a first cylindrical rod is driven to move backwards, and an iron block is pushed to a third supporting plate to achieve the pushing effect.

Owner:SHENZHEN JINGCHUANGHONG TECH

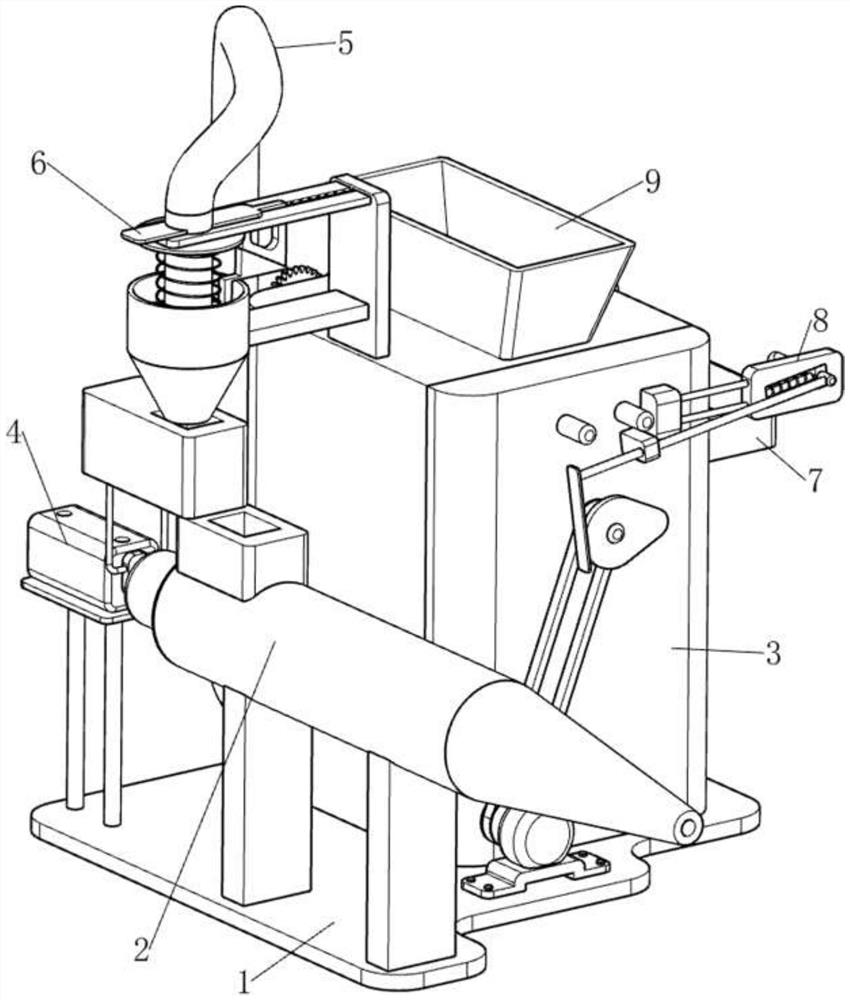

Automatic discharging and grinding device for refined wheat flour

PendingCN112973856ATo achieve the effect of advancingTo achieve the effect of shakingGrain treatmentsControl engineeringAgricultural engineering

The invention relates to a grinding device, in particular to an automatic discharging and grinding device for refined wheat flour. The invention provides the automatic discharging and grinding device for the refined wheat flour, so that automatic grinding is achieved, the grinding speed is relatively high, and the labor intensity of workers is reduced. The automatic discharging and grinding device for the refined wheat flour comprises a base, a first support, a discharging box, a propelling mechanism, a shaking mechanism and a grinding mechanism, wherein the first support is arranged on the base; the discharging box is arranged on the upper side of the first support; the propelling mechanism is arranged on the base; the shaking mechanism is arranged between the two sides of the base; and the grinding mechanism is arranged between the discharging box and the propelling mechanism. According to the automatic discharging and grinding device for the refined wheat flour provided by the invention, a first push rod drives the grinding mechanism to move rightwards and rotate, and wheat flour is ground, so that a propelling effect is achieved; and a shaking box moves up and down, so that the shaking box shakes, the flour is shaken, and a shaking effect is achieved.

Owner:王仕长

Flour cake screening and removing device

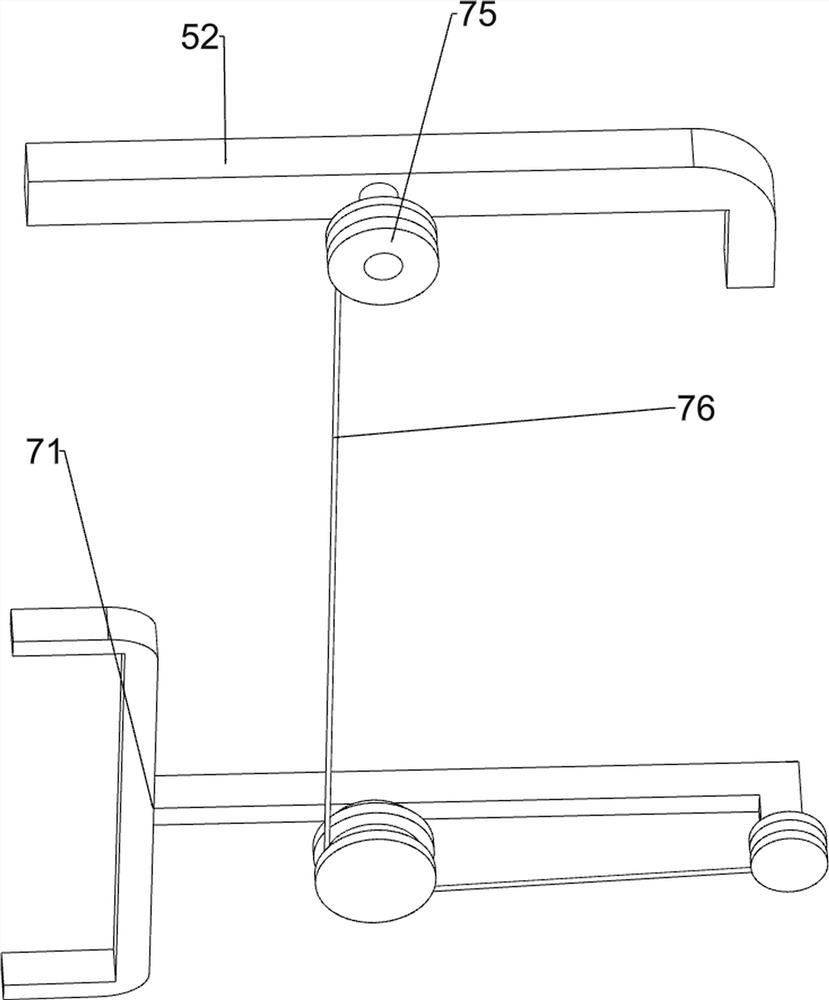

ActiveCN113305007ATo achieve the effect of filtering flourRealize the output effectSievingGas current separationAgricultural engineeringStructural engineering

The invention relates to a removing device, in particular to a flour cake screening and removing device, and provides the flour cake screening and removing device which is good in screening effect and capable of shortening the labor time of workers and reducing the labor expenditure of the workers. The flour cake screening and removing device comprises first fixing frames, second fixing frames, third fixing frames, a filtering mechanism, a discharging mechanism and pushing mechanisms; the two first fixing frames are arranged between the second fixing frames on the two sides; the third fixing frames are symmetrically arranged on the inner walls of the two first fixing frames; the filtering mechanism is arranged between the tops of the third fixing frames on the two sides; the discharging mechanism is arranged between the two first fixing frames; and the pushing mechanisms are arranged on the two first fixing frames. Through arrangement of the filtering mechanism, a worker pushes the filtering mechanism to move left and right to filter and screen caked flour, and the effect of filtering the flour is achieved.

Owner:宝鸡周原贡品农业科技有限公司

A kind of paper printing equipment for advertising media

ActiveCN112428683BRealize the effect of sending to the rightRealize automatic pressing downRotary pressesPile receiversPrinting pressIndustrial engineering

The invention relates to a paper printing device, in particular to a paper printing device for advertising media. The invention provides a paper printing device for advertising media, which can remove stains on paper, automatically load and unload paper, and self-cut. A paper printing equipment for advertising media, comprising: a bottom plate, on which a servo motor is installed; a support frame, on which the middle of the bottom plate is provided with a support frame; a collection box, on which the bottom plate is provided with a collection box; The mechanism, the output shaft of the servo motor and the support frame are all connected with the moving mechanism; the printing mechanism, the inner wall of the top of the support frame is provided with a printing mechanism. The invention drives the intermittent gear group to rotate through the rotation of the output shaft of the servo motor, thereby driving the first rotating shaft to rotate intermittently, and the rotation of the first rotating shaft drives the transmission assembly transmission and the rotation of the second rotating shaft to realize the effect of intermittently conveying the paper to the right.

Owner:日照天晨文化传媒有限公司

An injection molding machine filling equipment

ActiveCN112848090BRealize the effect of fillerRealize the effect of automatic feedingPlastic recyclingProcess engineeringInjection molding machine

The invention relates to a filler device, in particular to a filler device of an injection molding machine. The present invention provides an injection molding machine filling equipment capable of automatic feeding, better filling effect and simple use. The technical embodiment of the present invention is: an injection molding machine filling equipment, comprising: a bottom plate and a melting device, the bottom plate is provided with a melting device; a storage bin, a storage bin is provided on the bottom plate; a filler assembly, between the bottom plate and the melting device There is a packing assembly; an automatic feeding assembly, and an automatic feeding assembly is arranged between the storage bin and the bottom plate. In the present invention, a filler assembly is provided, and the operation of the filler assembly can push the plastic into the melting device for melting, and push it into the injection molding machine to achieve the effect of filler; The plastic in the bin is pushed into the packing assembly, without manual intermittent packing, and the effect of automatic feeding is realized.

Owner:金华市艺晟工具有限公司

Partition plate high-precision grooving equipment for building decoration

ActiveCN114347184ARealize the push effectAchieve the effect of automatic downward pressure slottingProfiling/shaping machinesBark-zones/chip/dust/waste removalStructural engineeringBuilding renovation

Owner:江西天承建设有限公司

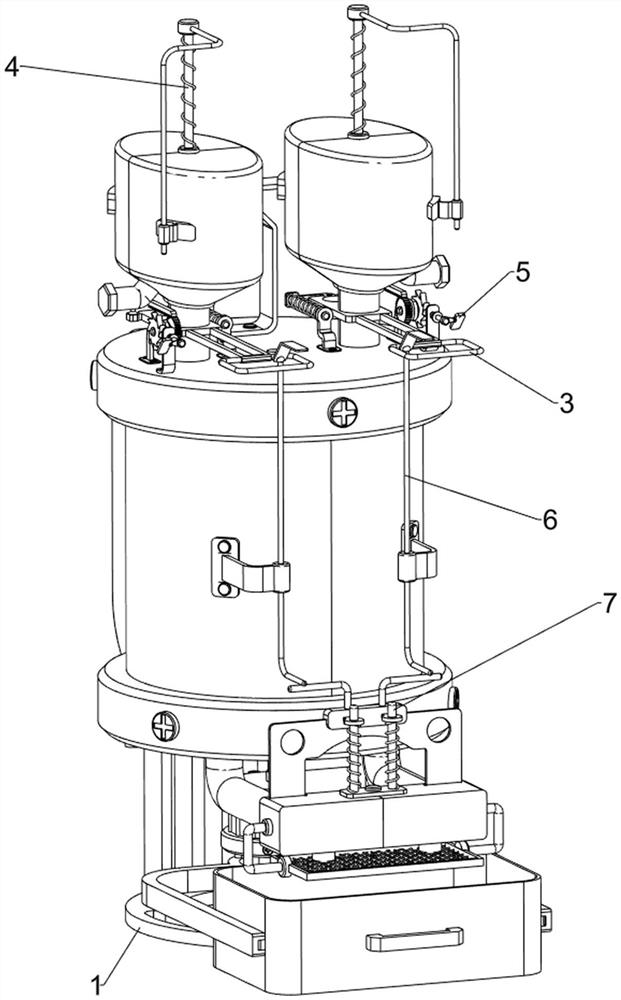

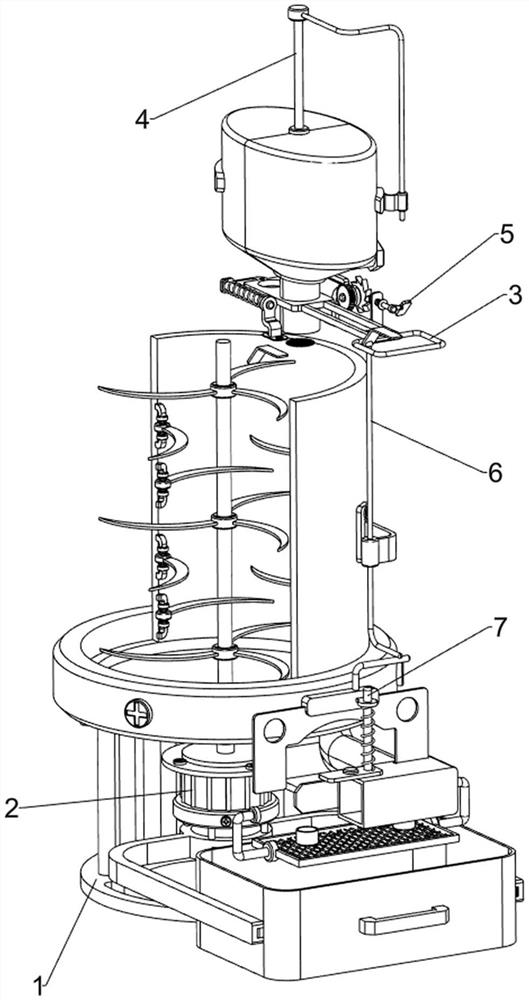

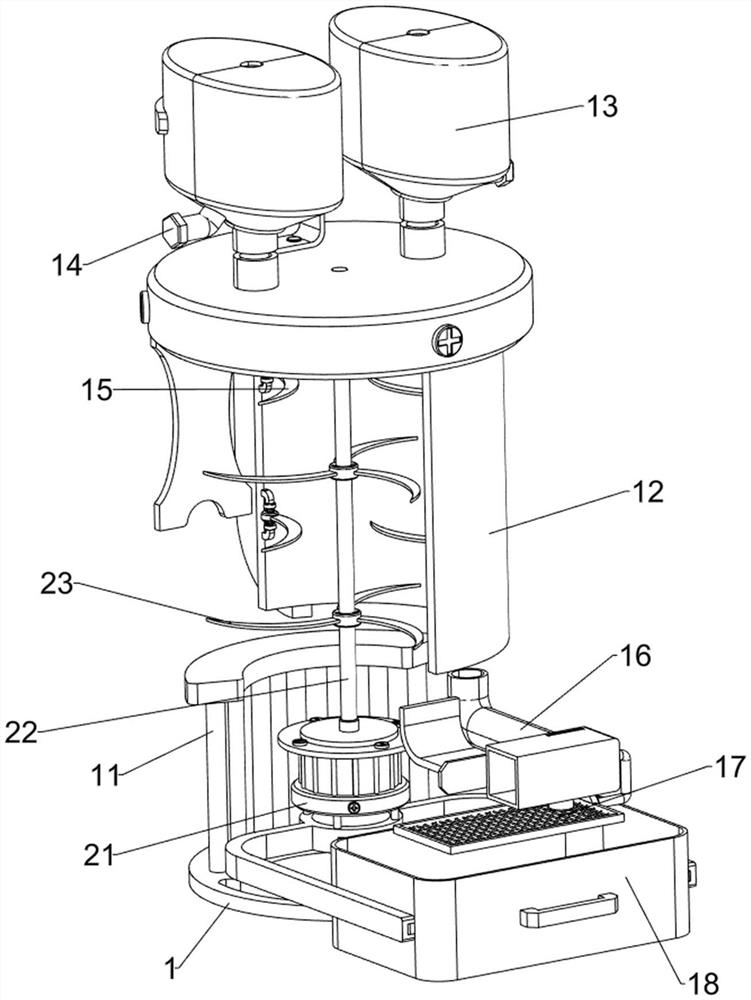

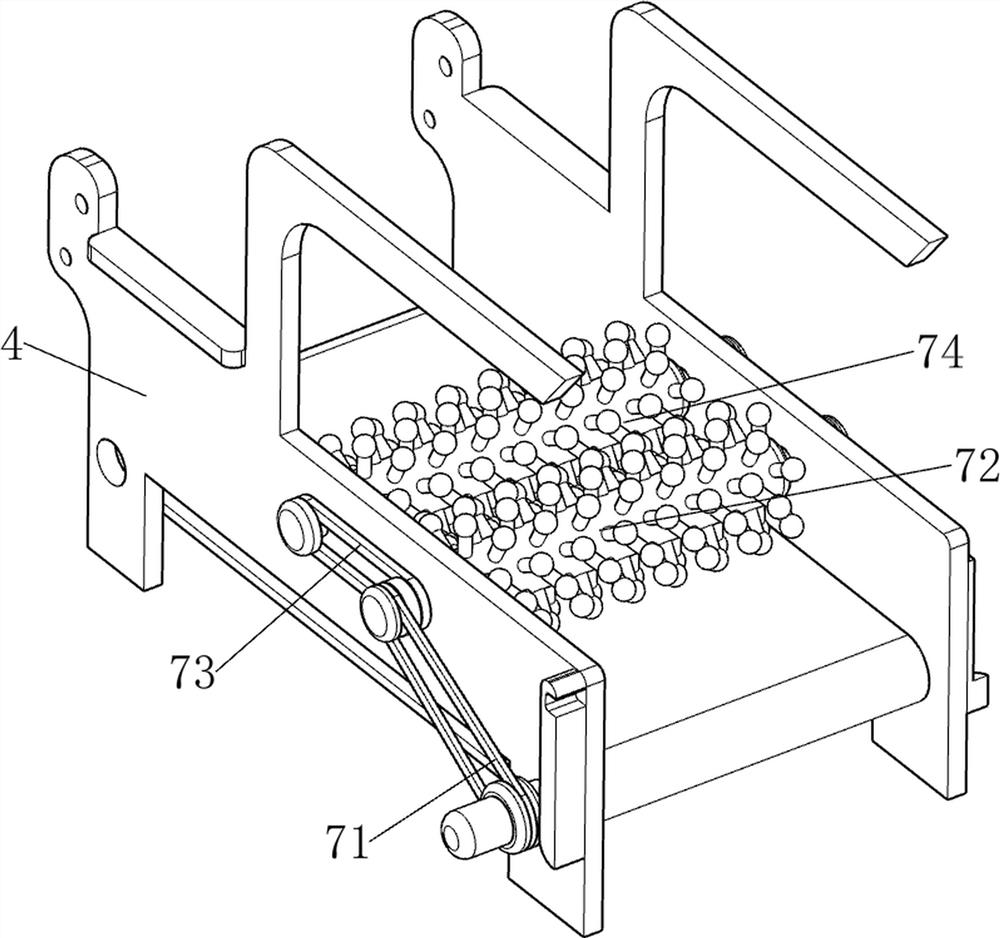

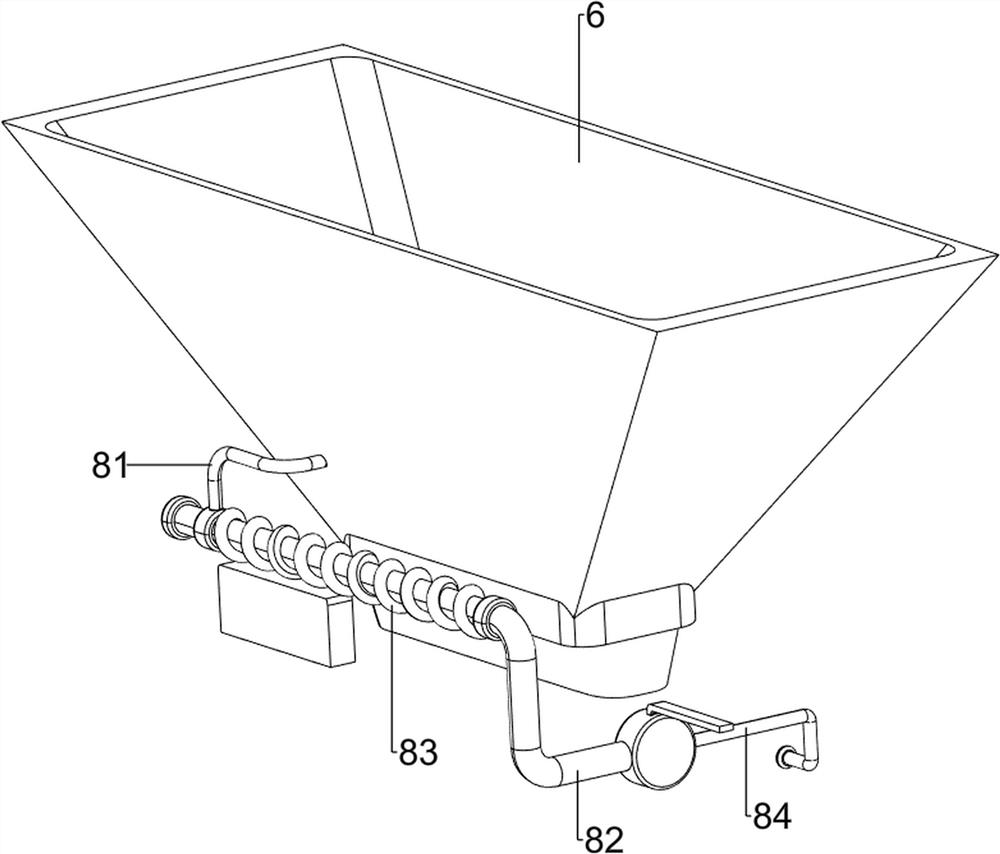

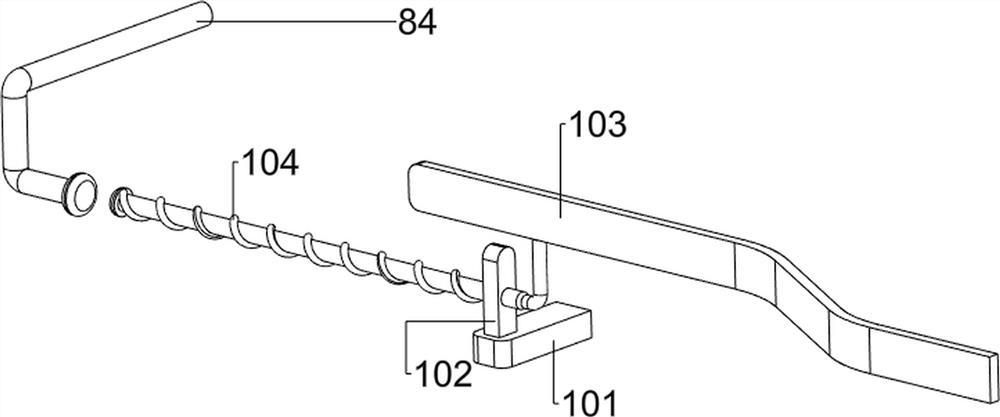

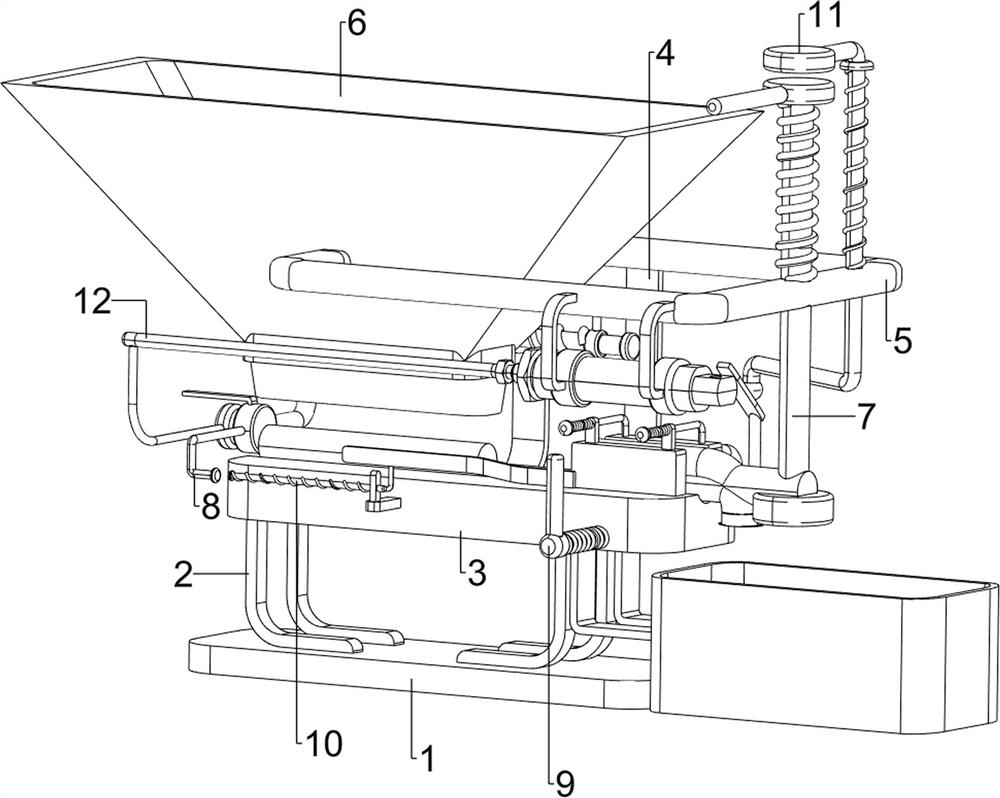

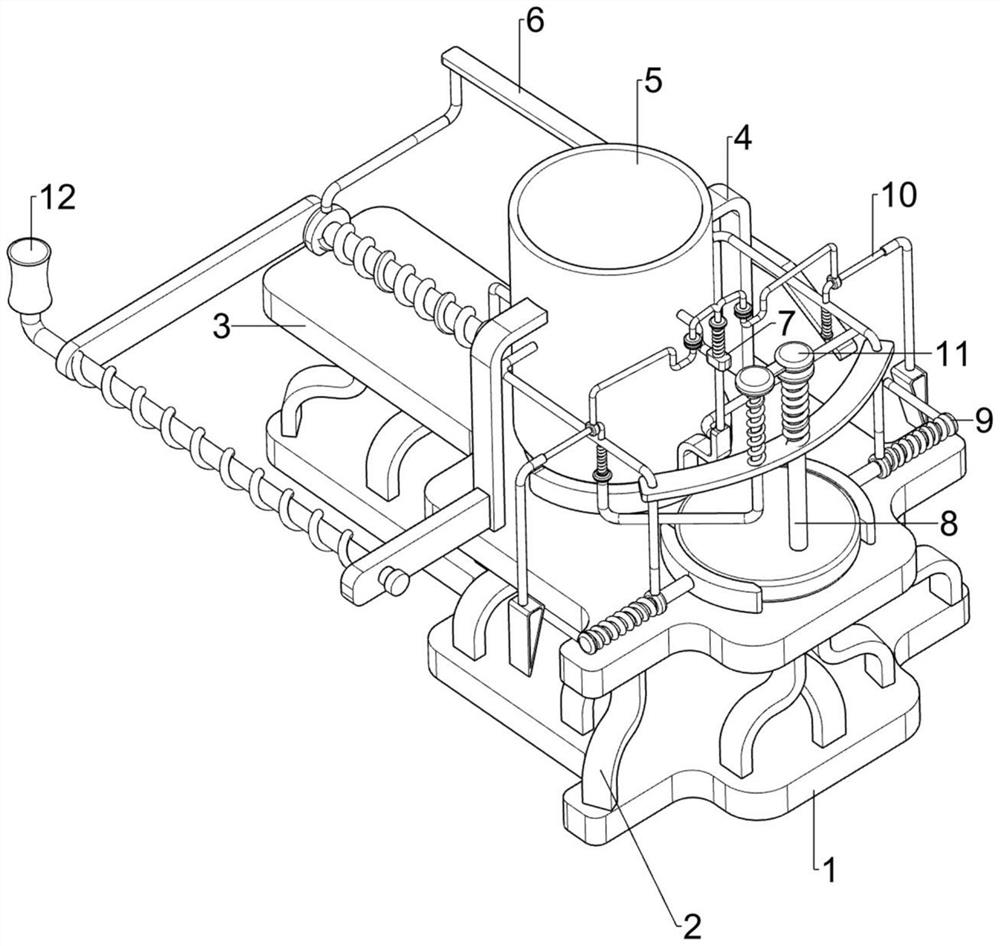

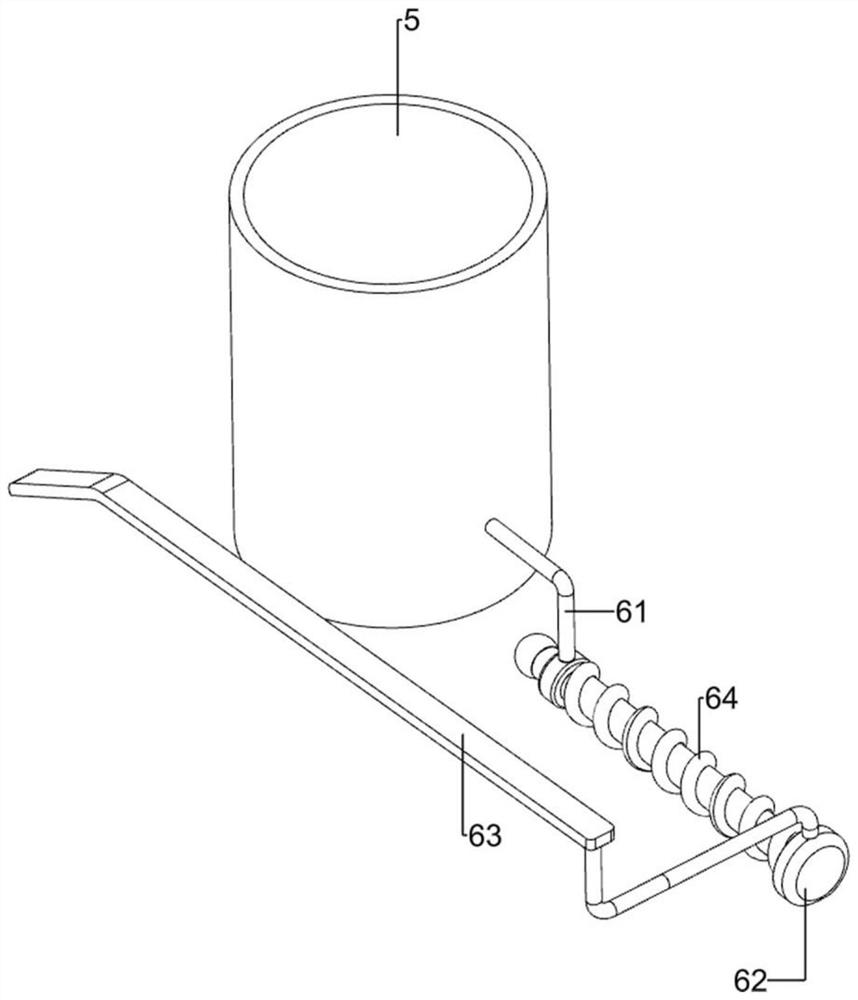

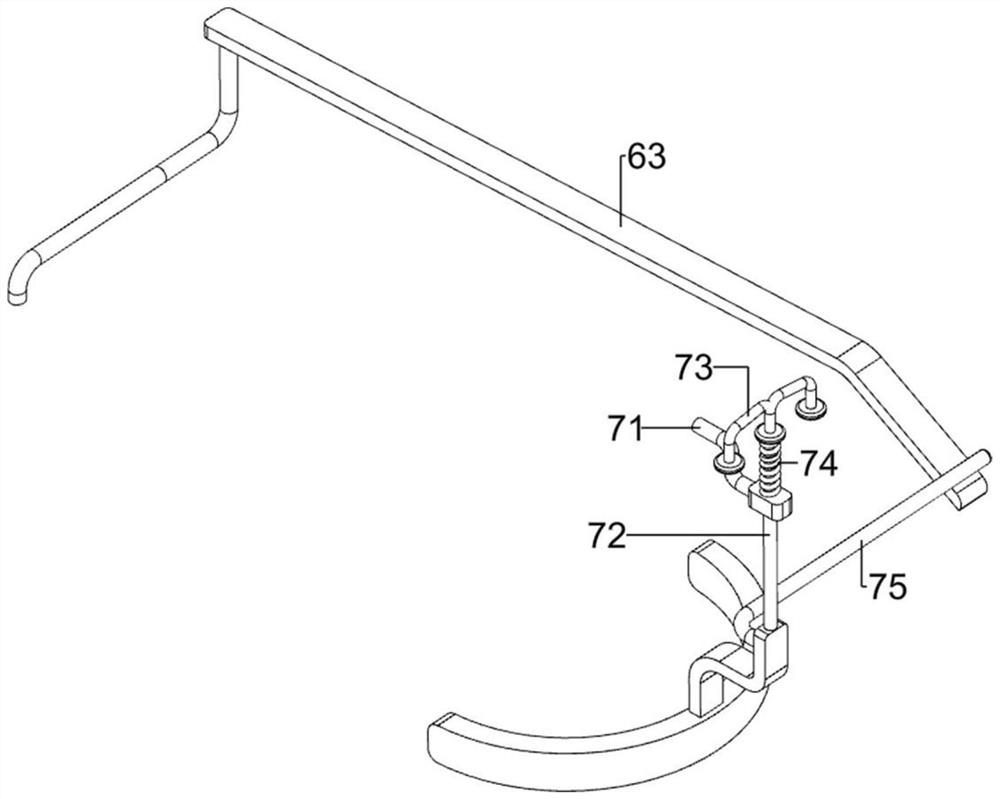

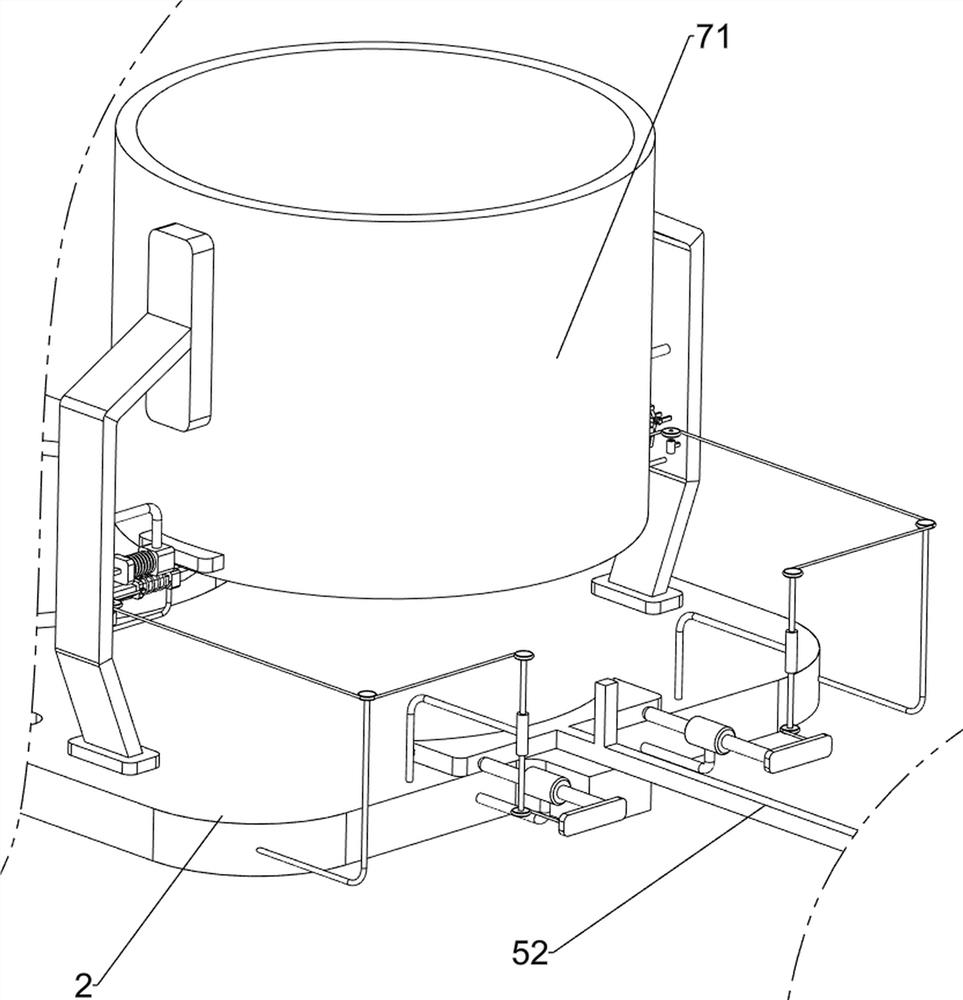

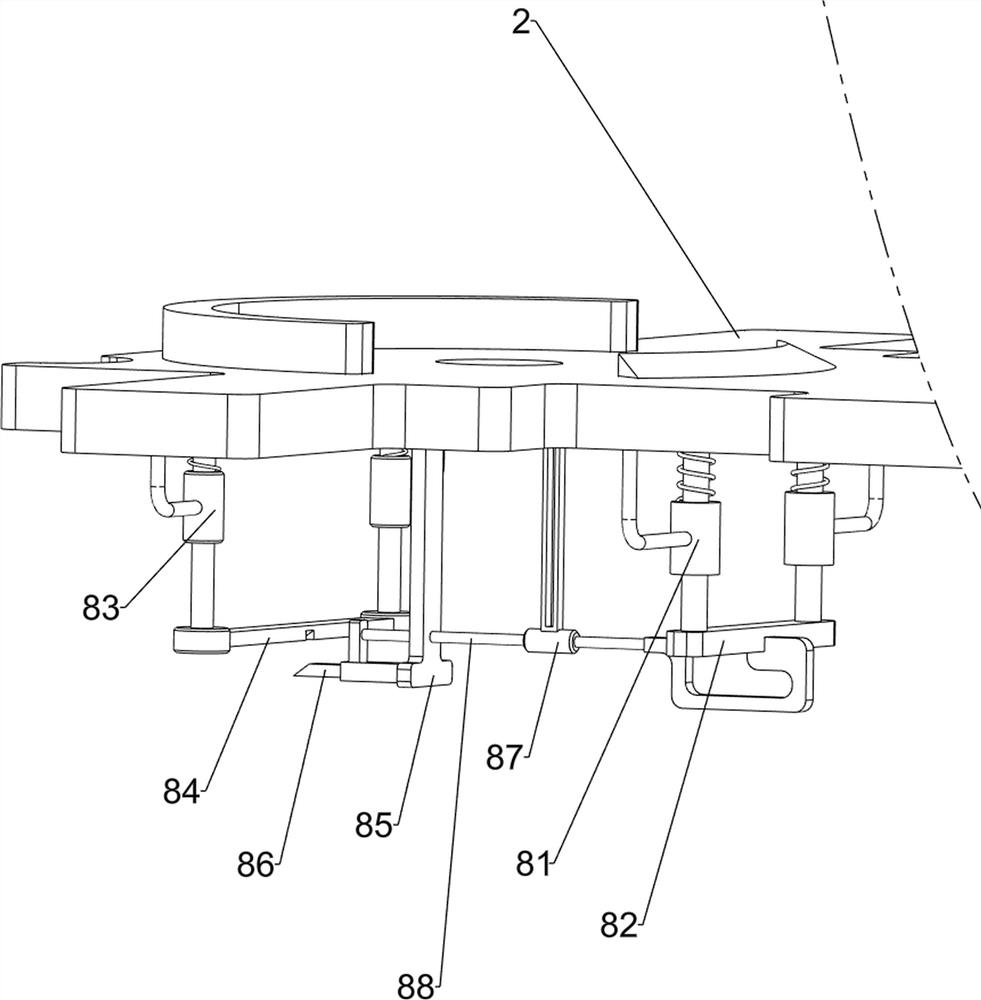

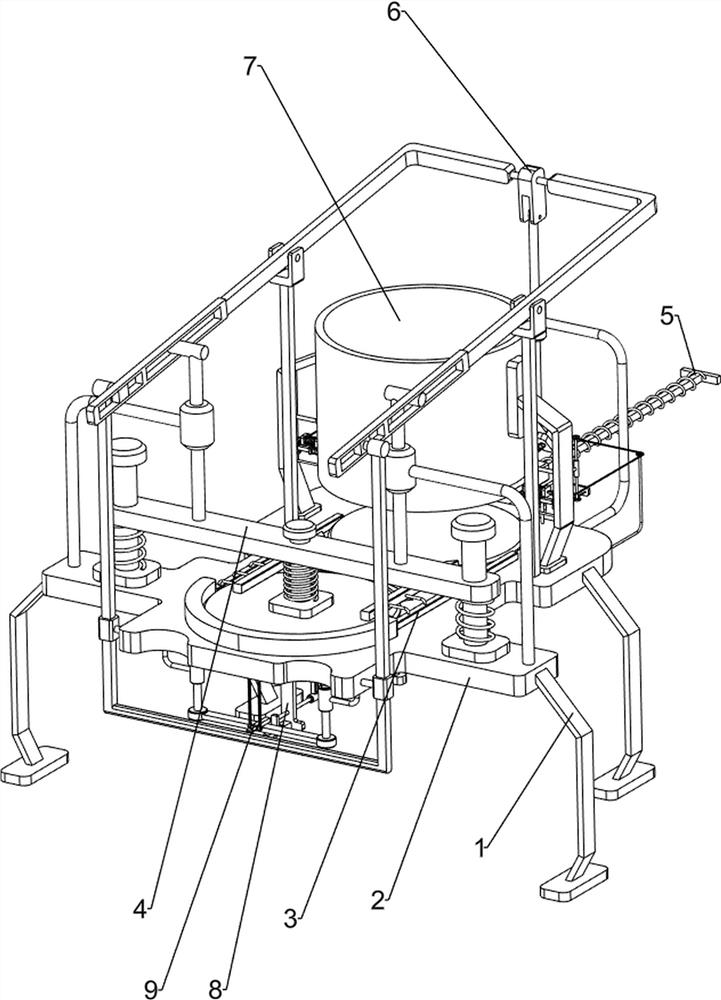

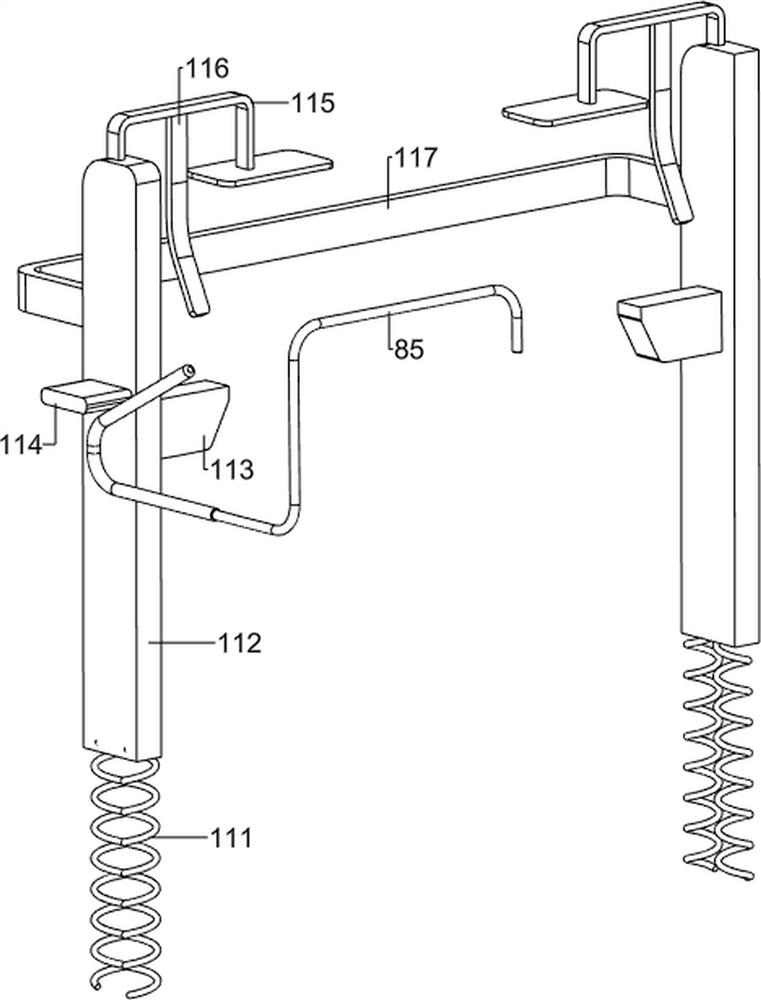

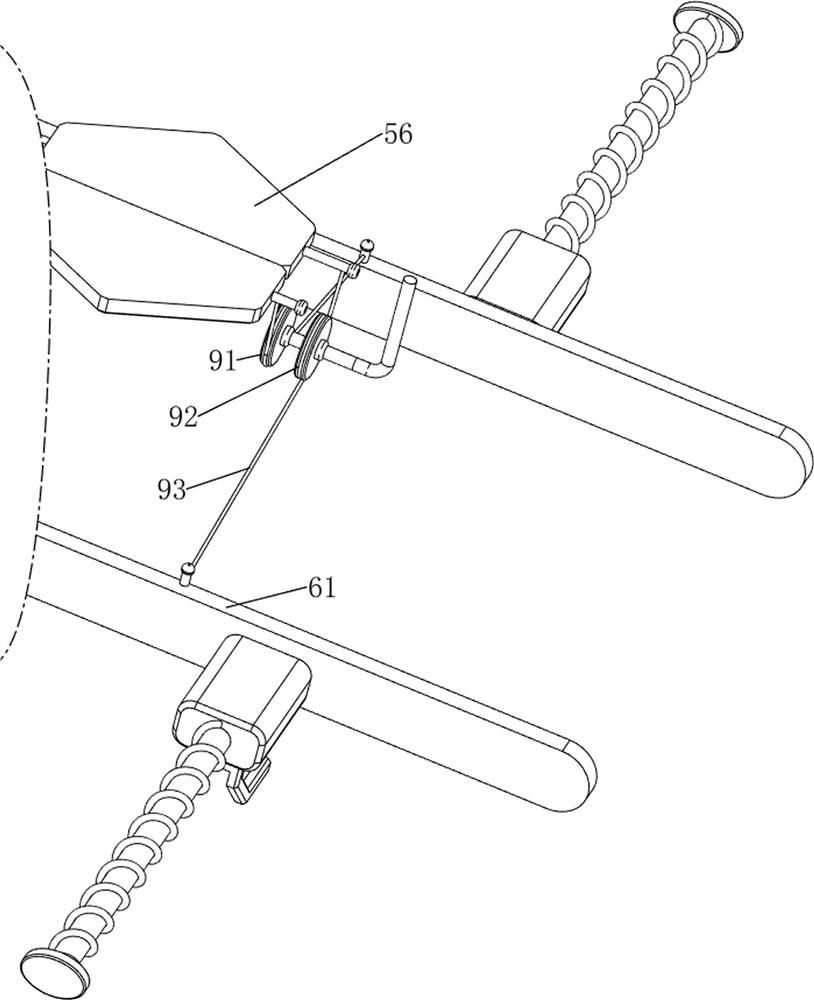

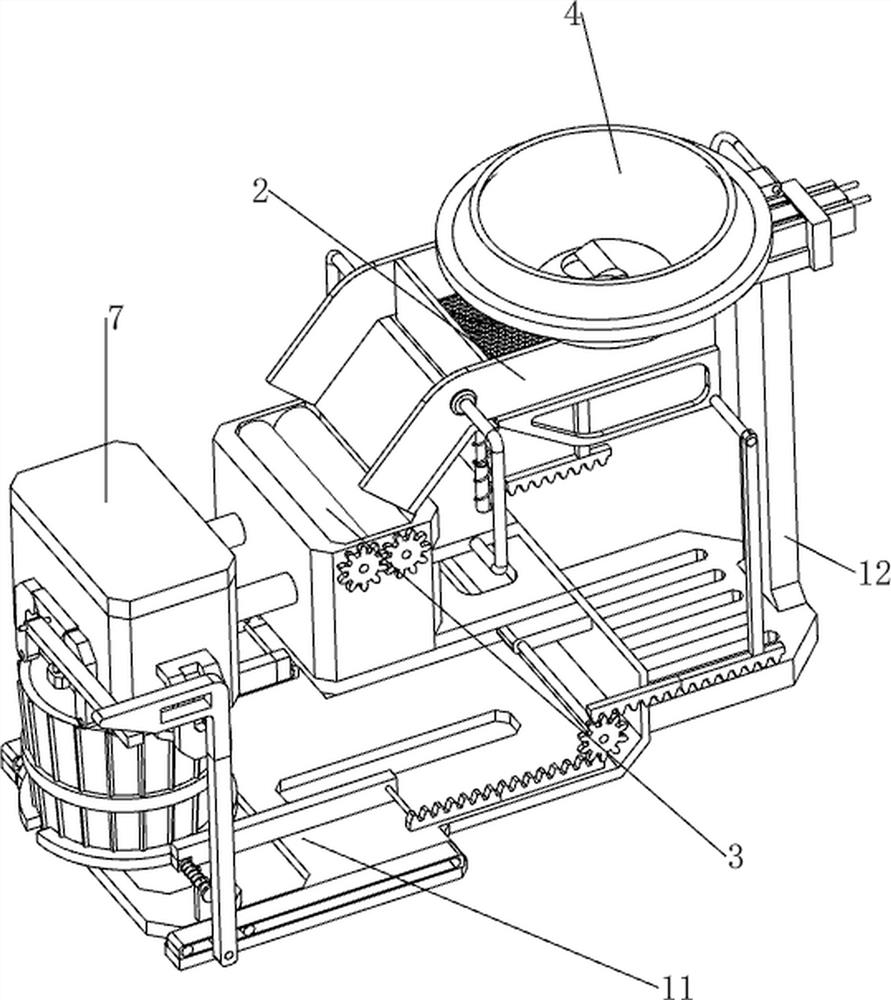

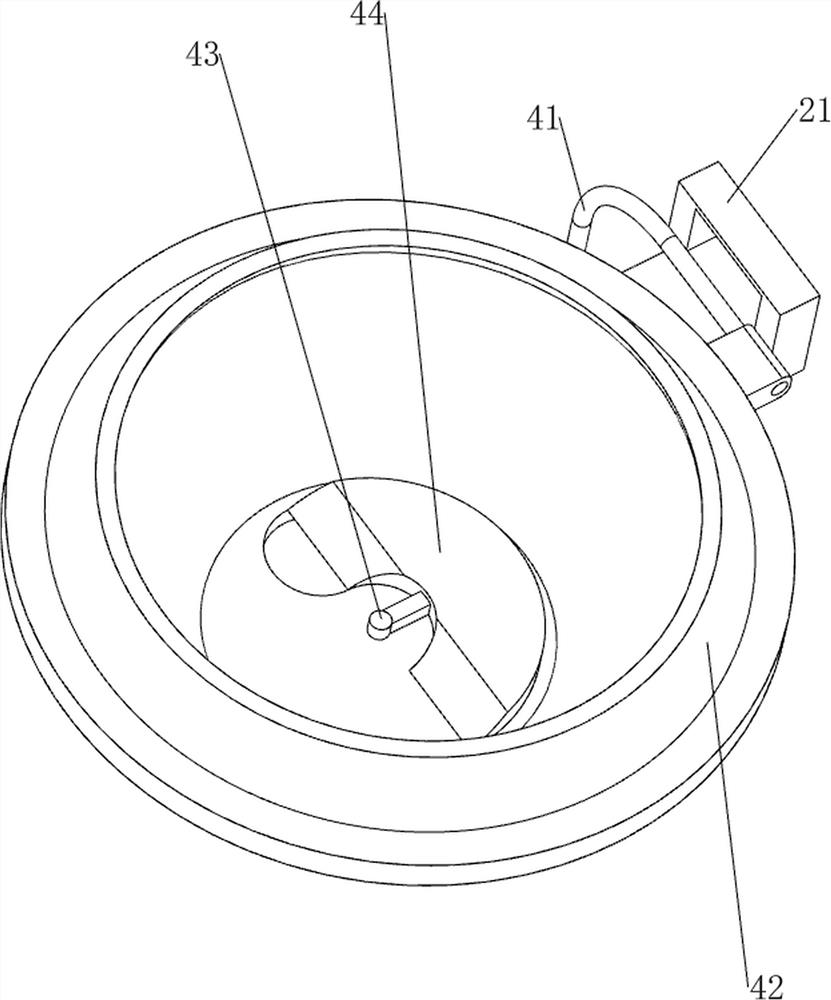

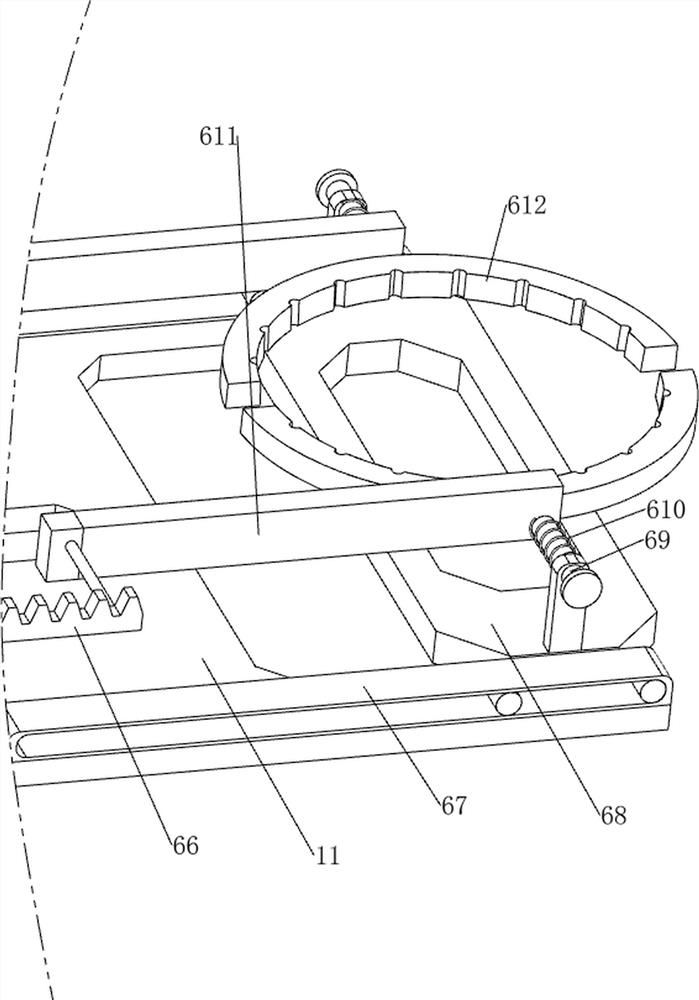

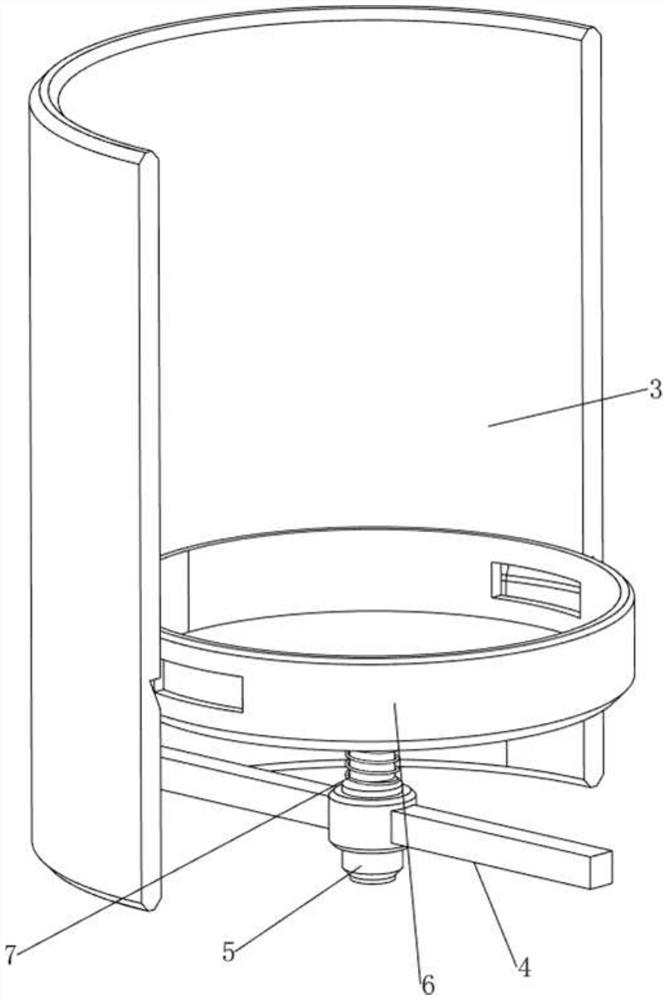

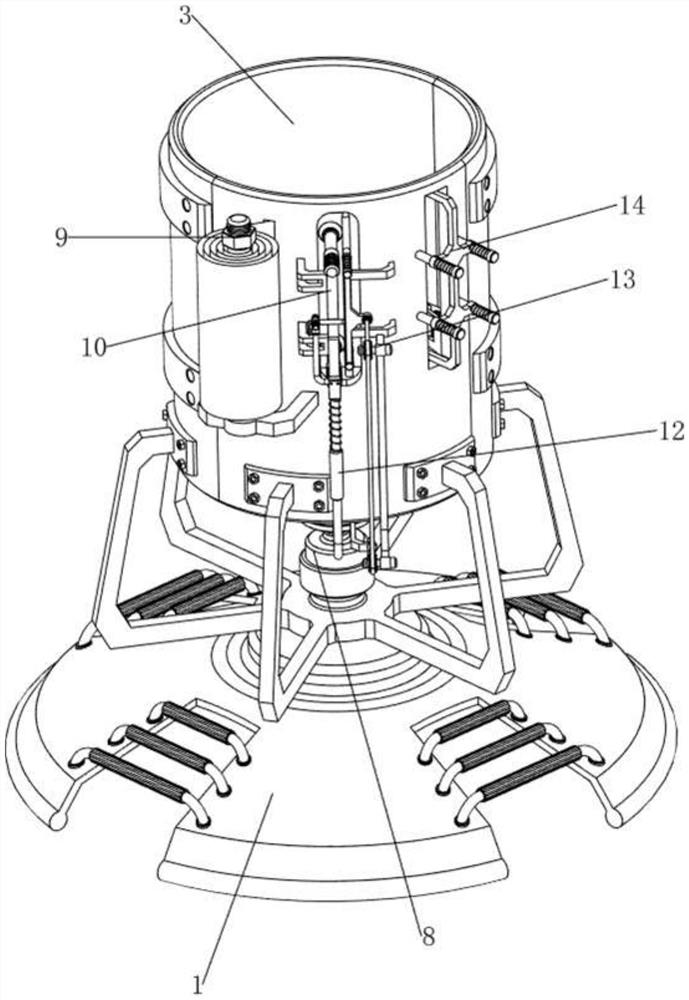

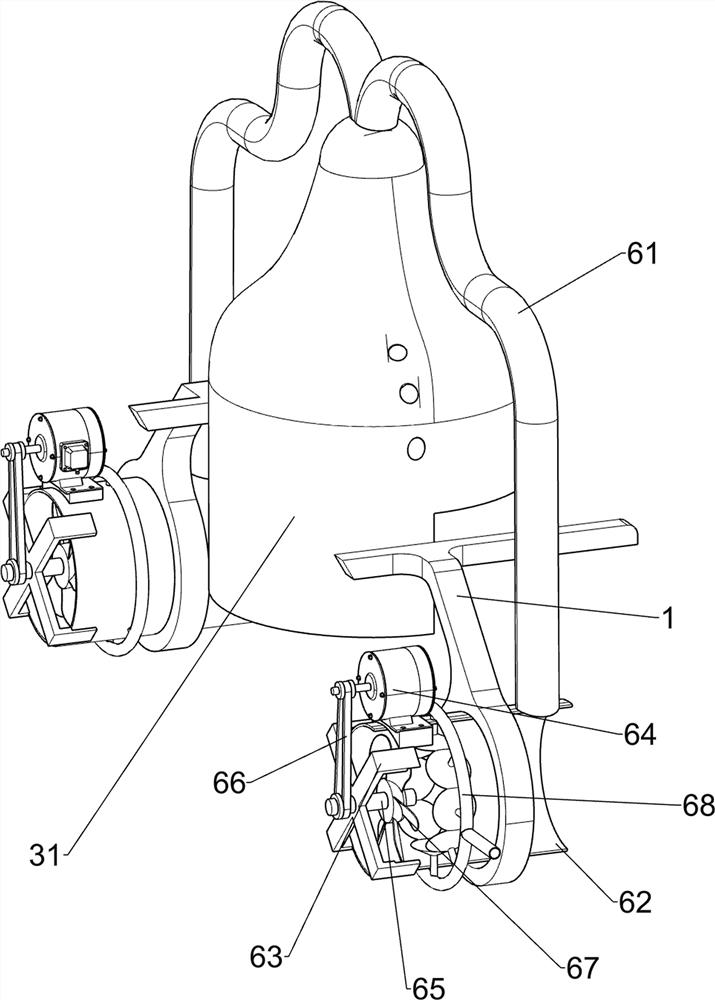

Household wine brewing equipment

PendingCN113373012ARealize the push effectNo manual operationWine preparationProcess engineeringGrape wine

The invention relates to brewing equipment, in particular to household wine brewing equipment. The invention provides the household wine brewing equipment which is used for household wine brewing and automatic wine brewing and is convenient to operate. The household wine brewing equipment comprises a bottom frame, a supporting frame, a material pushing mechanism and a crushing mechanism, wherein the supporting frame is arranged on the bottom frame; the material pushing mechanism is arranged between the top of the supporting frame and the bottom frame; and the crushing mechanism is arranged on the bottom frame. By arranging the material pushing mechanism, the material pushing mechanism is started to operate, grapes can be pushed out, and the material pushing effect is achieved; the crushing mechanism is arranged, the crushing mechanism rotates to crush grapes into juice, manual operation is not needed, time is saved, and the crushing effect is achieved; and through cooperation of a cleaning mechanism and a discharging mechanism, the cleaning mechanism operates to enable the discharging mechanism to operate, grapes can be automatically cleaned and intermittently discharged, and the cleaning and discharging effects are achieved.

Owner:刘良会

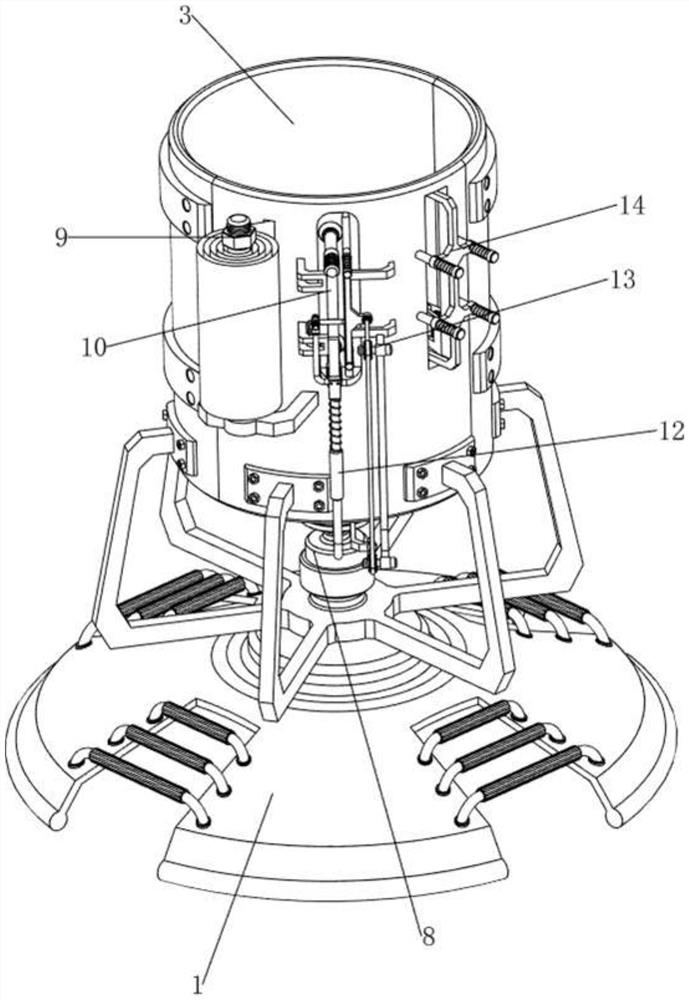

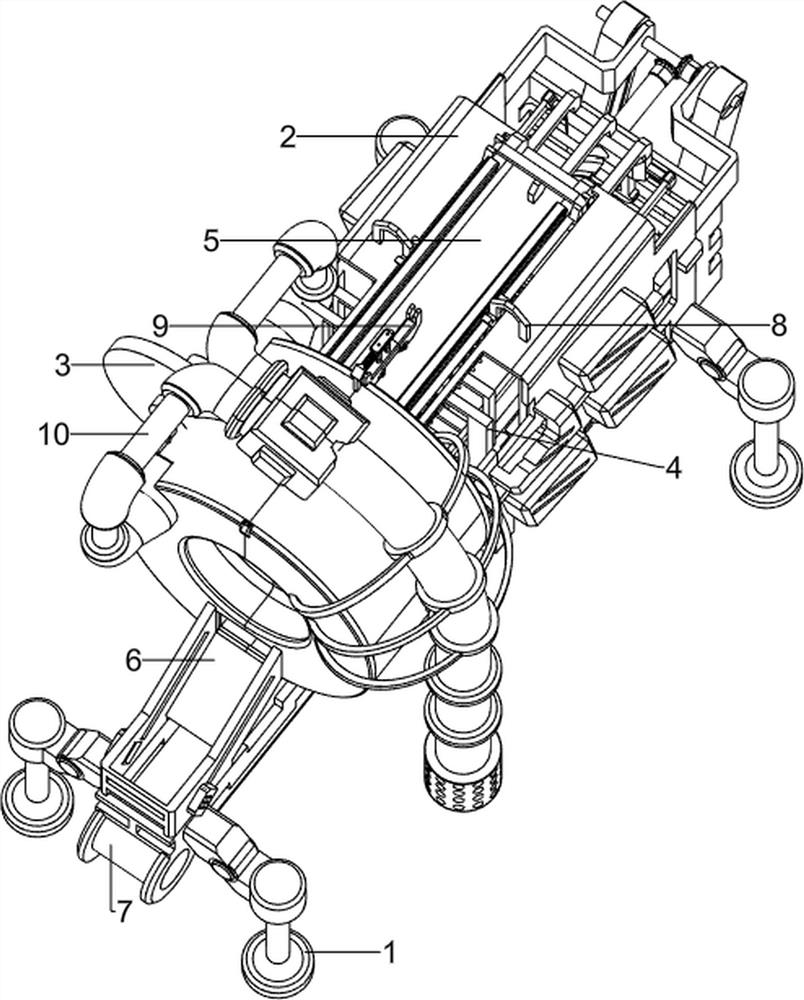

An automatic treatment device for large-volume solid waste

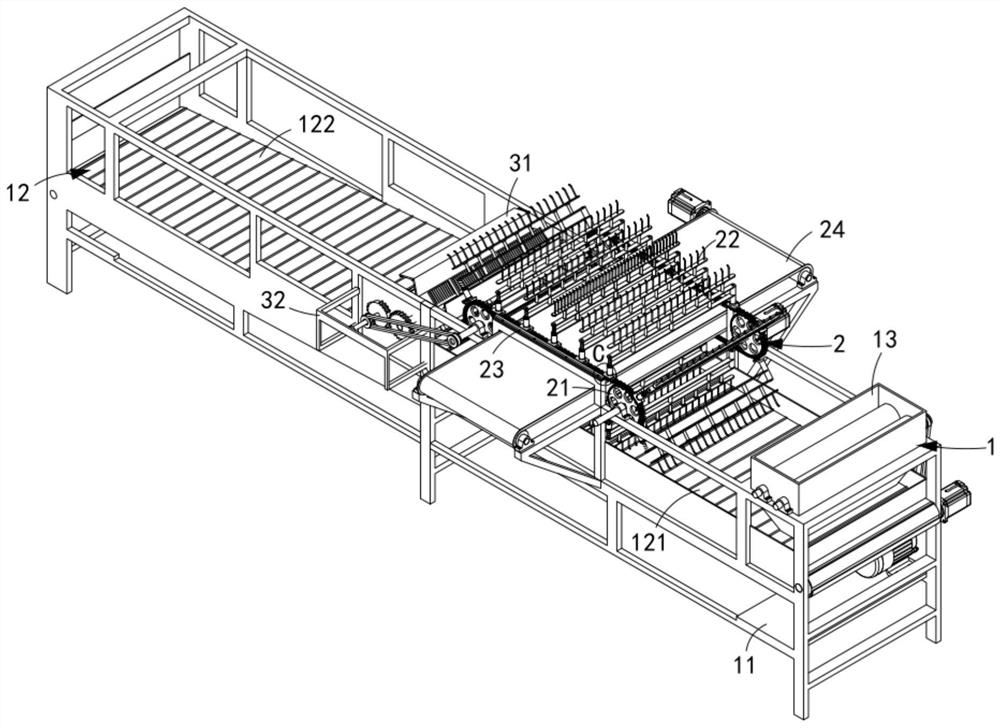

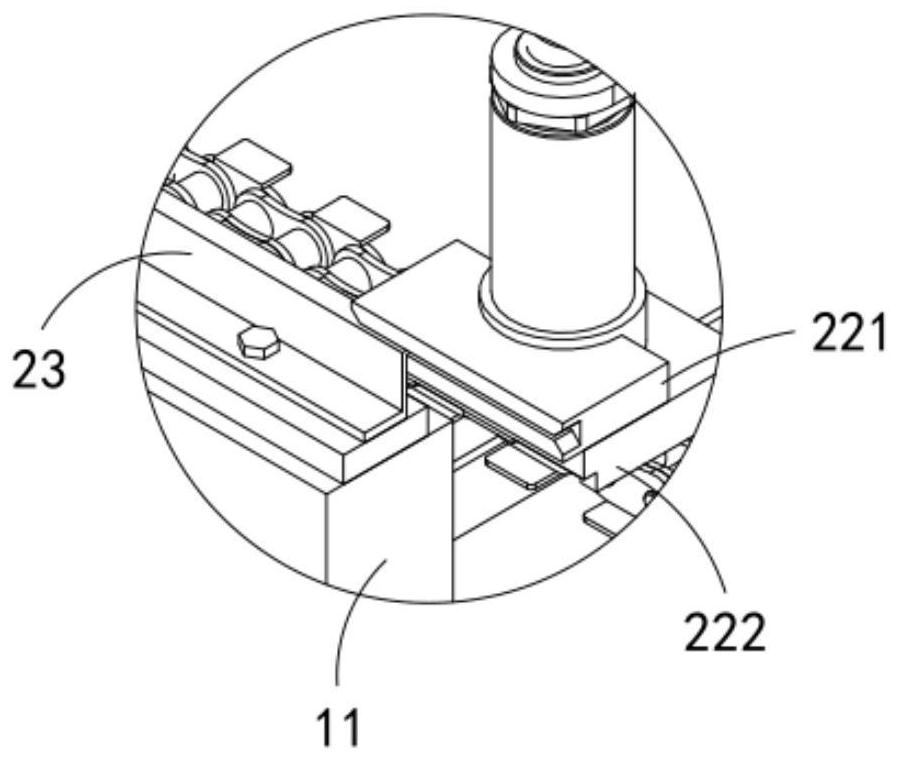

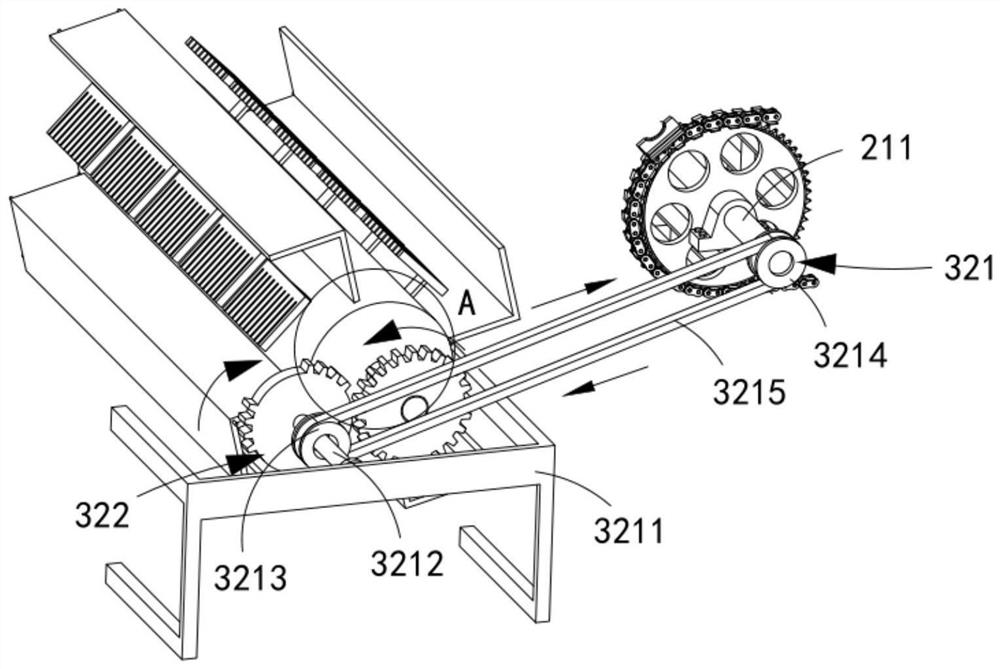

ActiveCN109465097BAvoid incomplete treatmentImprove purification efficiencyMagnetic separationGrain treatmentsEngineeringCrusher

The invention relates to an automatic treatment device for the large-size solid waste. The device includes a crushing mechanism, an impurity removal mechanism and a material return mechanism. The crushing mechanism includes a frame, a conveying assembly and a crushing assembly, the conveying assembly consists of a first conveying portion horizontally disposed and a second conveying portion obliquely disposed; the impurity removal mechanism is located behind the crushing assembly and at the tail end of the first conveying portion, and includes a driving assembly, a screening assembly, a power off assembly, and a receiving assembly; the material return mechanism is arranged at the top end of the second conveying portion and located behind the impurity removal mechanism, and includes a material return assembly rotatably arranged on the frame and a transmission assembly connected with the driving assembly and cooperating with the material return assembly for driving the material return assembly to rotate intermittently in the opposite rotational direction of the driving assembly. The automatic treatment device solves the technical problem that the large-size solid waste in the solid waste is not easy to be thoroughly treated.

Owner:南通耀江建设集团有限公司

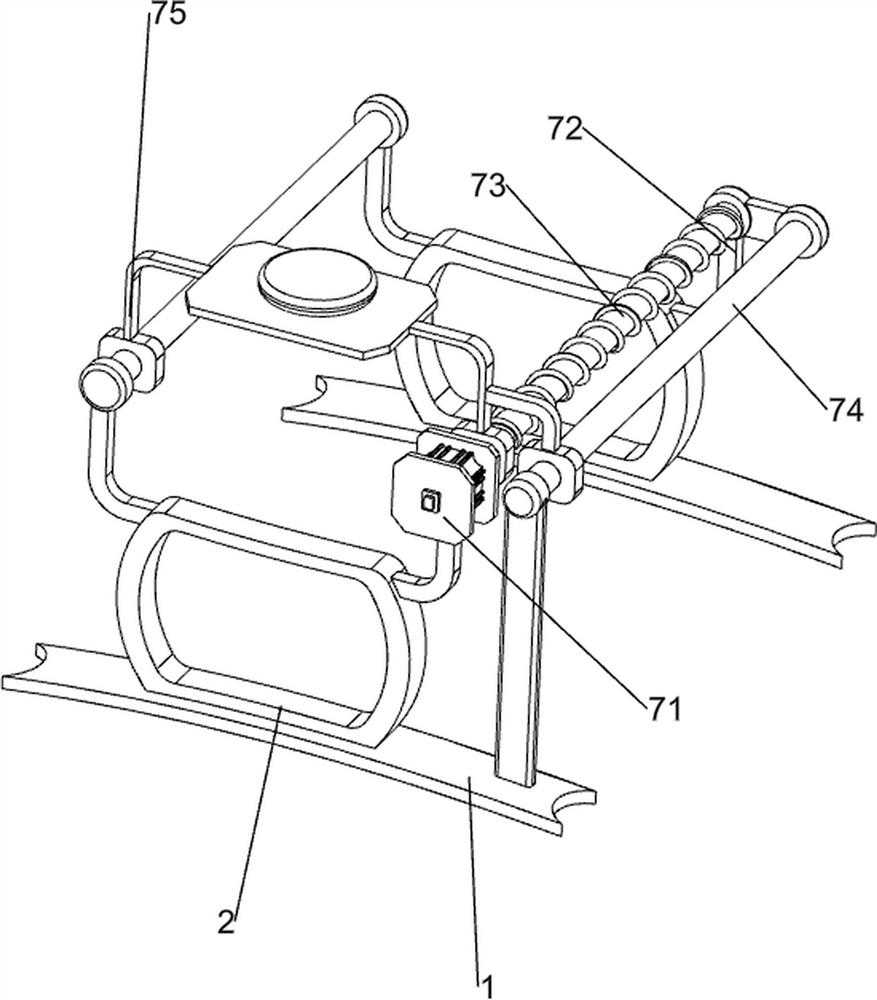

Outer wall labeling device for empty fermented bean curd can

ActiveCN113002909AEasy labelingRealize the driving effectBio-packagingLabelling short rigid containersEngineeringBiology

The invention relates to a labeling device, in particular to an outer wall labeling device for an empty fermented bean curd can. According to the outer wall labeling device for the empty fermented bean curd can, the labor intensity of workers is lowered, operation is convenient and fast, and the applicability is good. The outer wall labeling device for the empty fermented bean curd can comprises a base, a first support, a material storage frame, a second support, a first sliding sleeve, and a material supporting frame, wherein the first support is arranged in the middle of the base, the material storage frame is arranged on the upper side of the first support, the second support is arranged on the lower side of the inner wall of the material storage frame, the first sliding sleeve is rotationally arranged on the second support, and the material supporting frame is arranged on the first sliding sleeve in a sliding mode. According to the outer wall labeling device for the empty fermented bean curd can, a second disc drives telescopic blocks to rotate, so that a first disc is driven to rotate, the material supporting frame is further driven to rotate, the material supporting frame can rotate to drive the empty fermented bean curd can to rotate, labeling of the empty fermented bean curd can is facilitated, and the driving effect is achieved.

Owner:江西永叔府食品有限公司

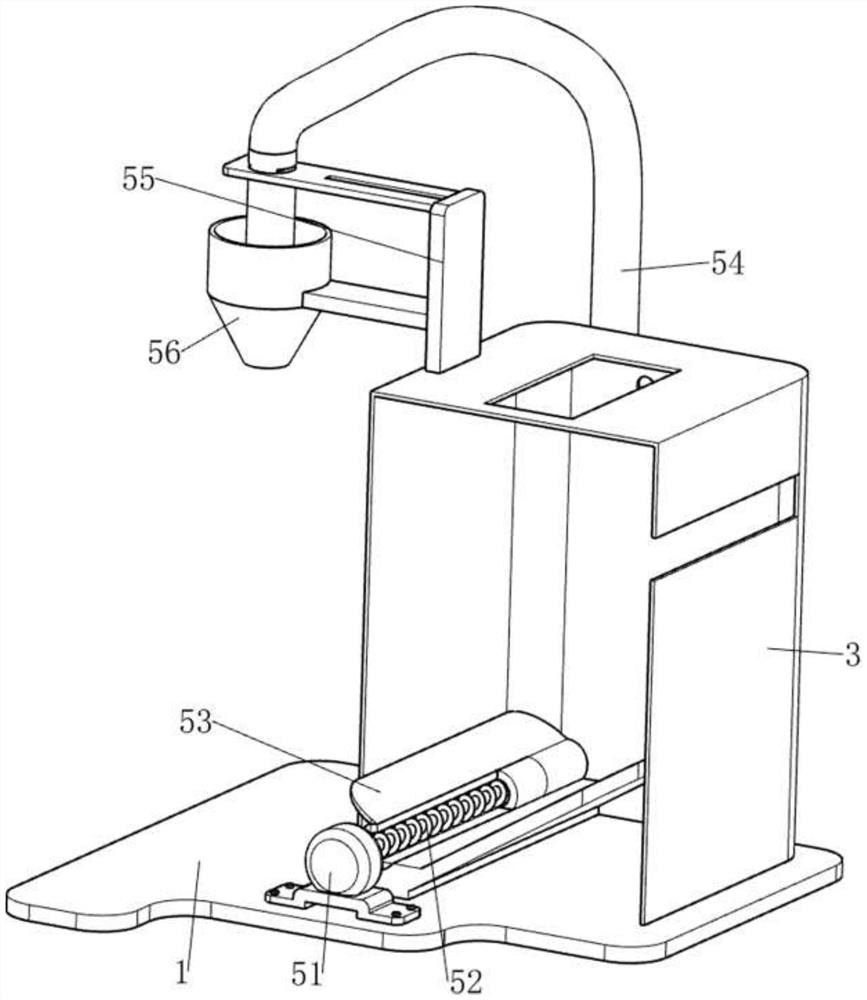

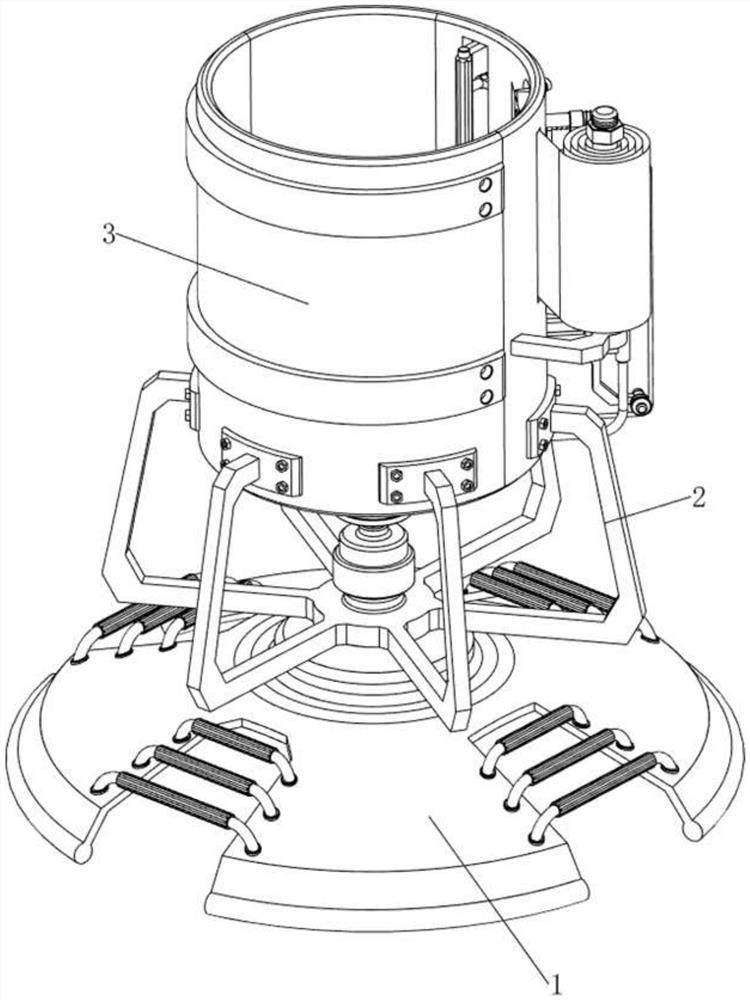

Black tea making device for food processing

ActiveCN113875835ARealize the effect of pressing downRealize the effect of pressingPre-extraction tea treatmentFood shapingMechanical engineeringBlack teas

The invention relates to a making device, in particular to a black tea making device for food processing. According to the black tea making device for food processing, the labor intensity of people is reduced, the work progress is accelerated, and the manufacturing cost is relatively low. The black tea making device for food processing comprises a supporting bottom plate, supporting blocks arranged on the two sides of the supporting bottom plate, supporting columns arranged on the two sides of the supporting bottom plate, a working barrel arranged between the upper parts of the two supporting columns, and a discharging mechanism that is arranged on the supporting bottom plate and penetrates through the working barrel. A first sliding plate block is manually pushed to move downwards, then a material receiving plate is driven to move downwards, and a first spring is compressed; and when the material receiving plate moves downwards, a black tea cake can be driven into the working barrel, hot water can soak the black tea cake, black tea is formed, and the downward pressing effect is achieved.

Owner:洪江市湘佰农业发展有限公司

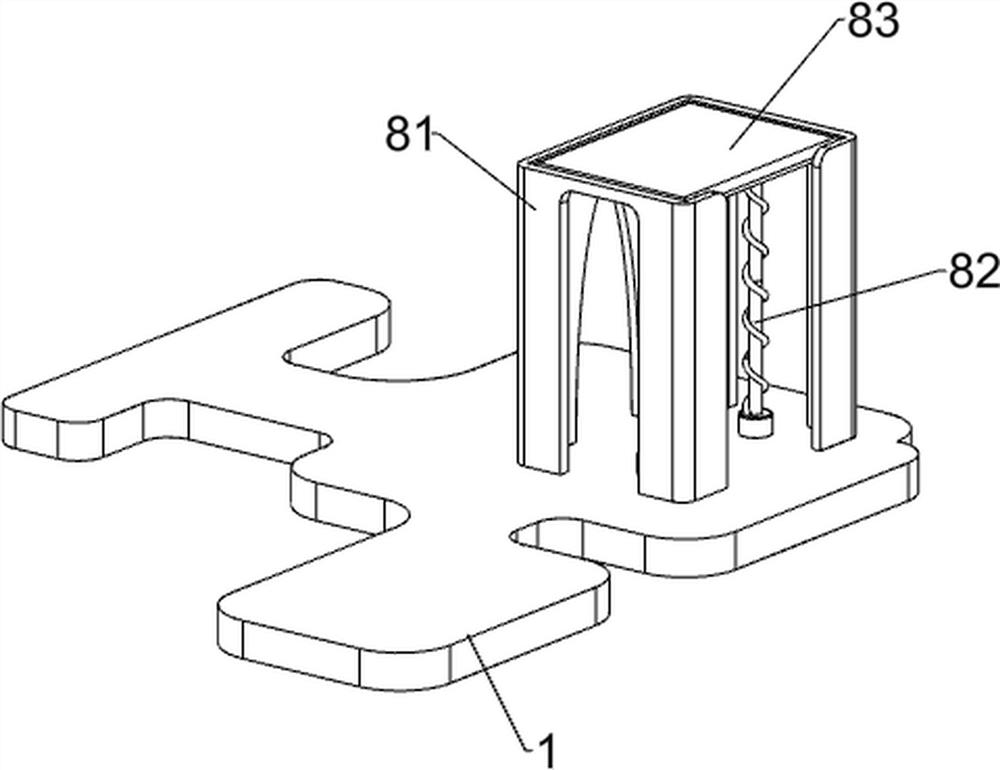

Filling equipment of injection molding machine

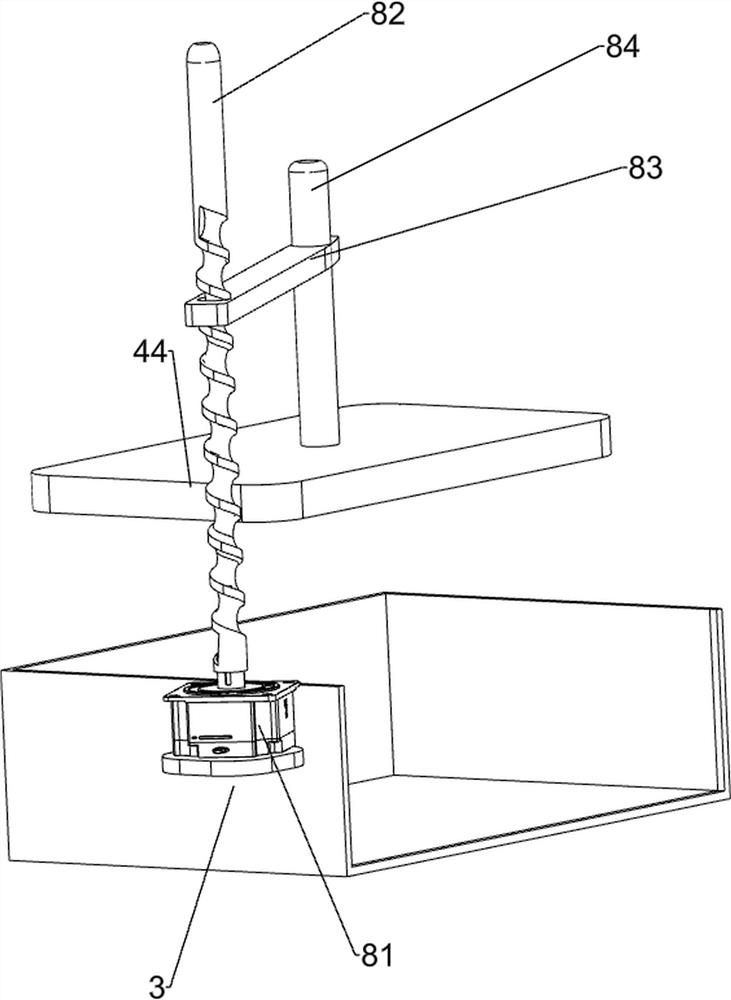

ActiveCN112848090ARealize the effect of fillerRealize the effect of automatic feedingPlastic recyclingProcess engineeringInjection molding machine

The invention relates to filling equipment, in particular to filling equipment of an injection molding machine. The filling equipment of the injection molding machine is capable of automatically feeding, relatively good in filling effect and simple to use. According to the technical scheme, the filling equipment of the injection molding machine comprises a bottom plate, a melting device arranged on the bottom plate, a storage bin arranged on the bottom plate, a filling component arranged between the bottom plate and the melting device, and an automatic feeding component arranged between the storage bin and the bottom plate. Through the arrangement of the filling component, the filling component operates to push plastic into the melting device for melting, and the plastic is pushed into the injection molding machine, so that the filling effect is achieved; and through the arrangement of the automatic feeding component, the automatic feeding component operates to push the plastic in the storage bin into the filling component manual intermittent filling is not needed, and the automatic feeding effect is achieved.

Owner:金华市艺晟工具有限公司

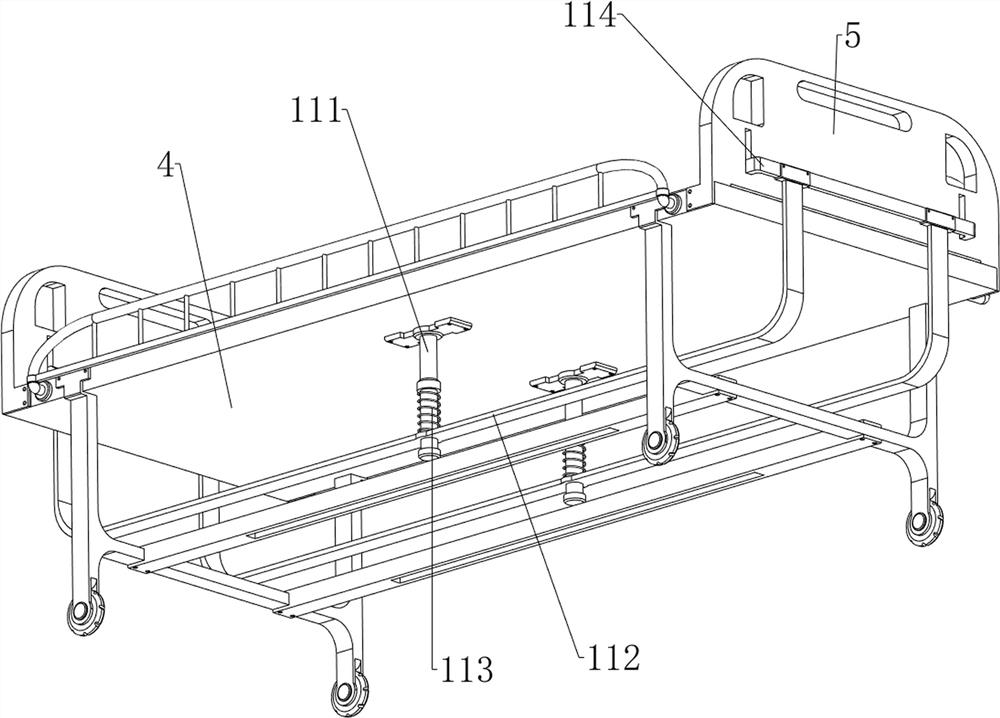

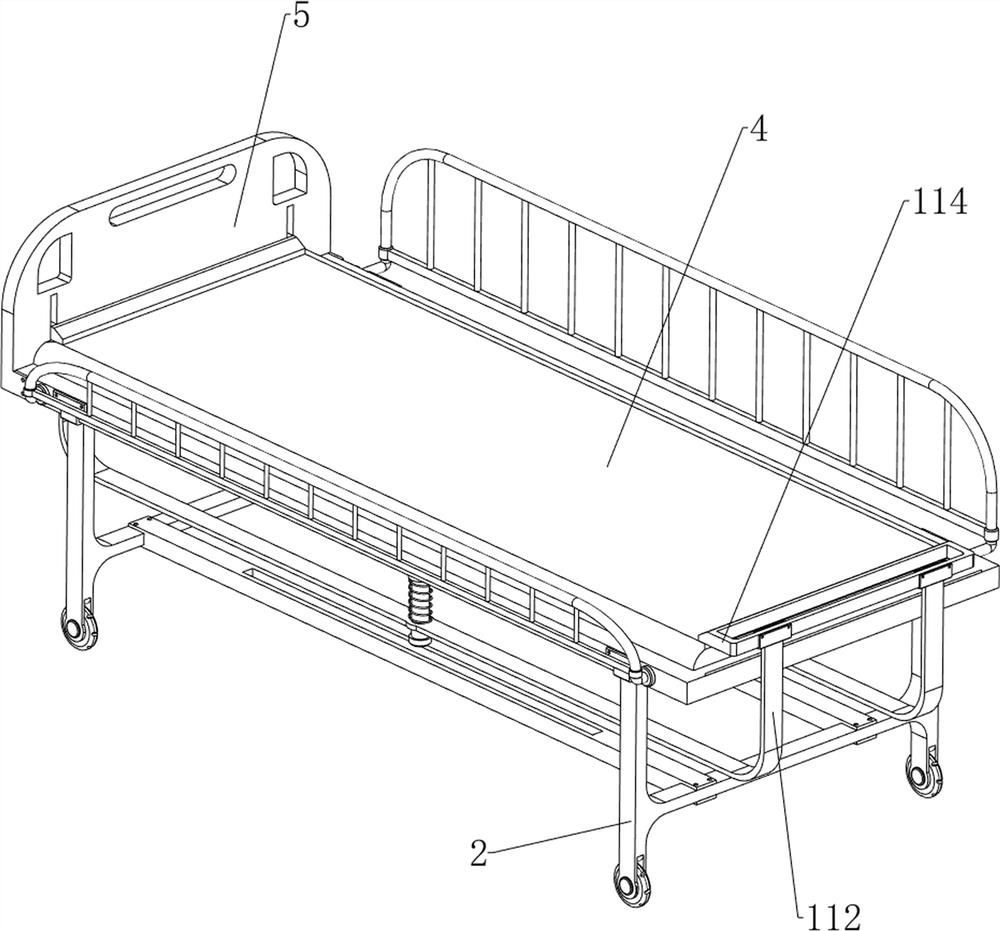

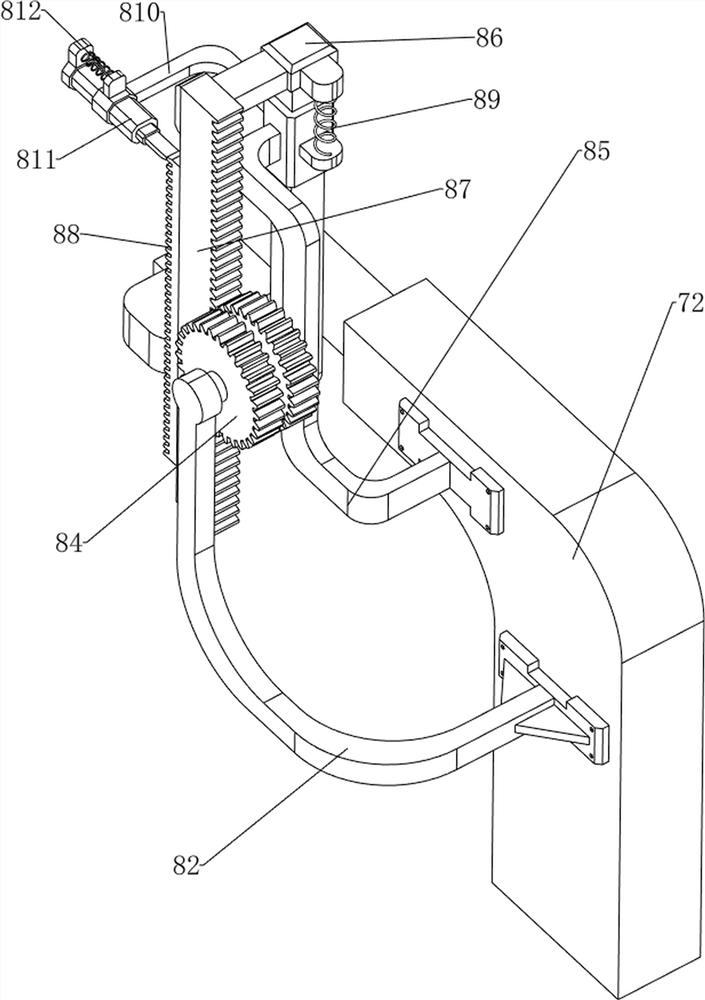

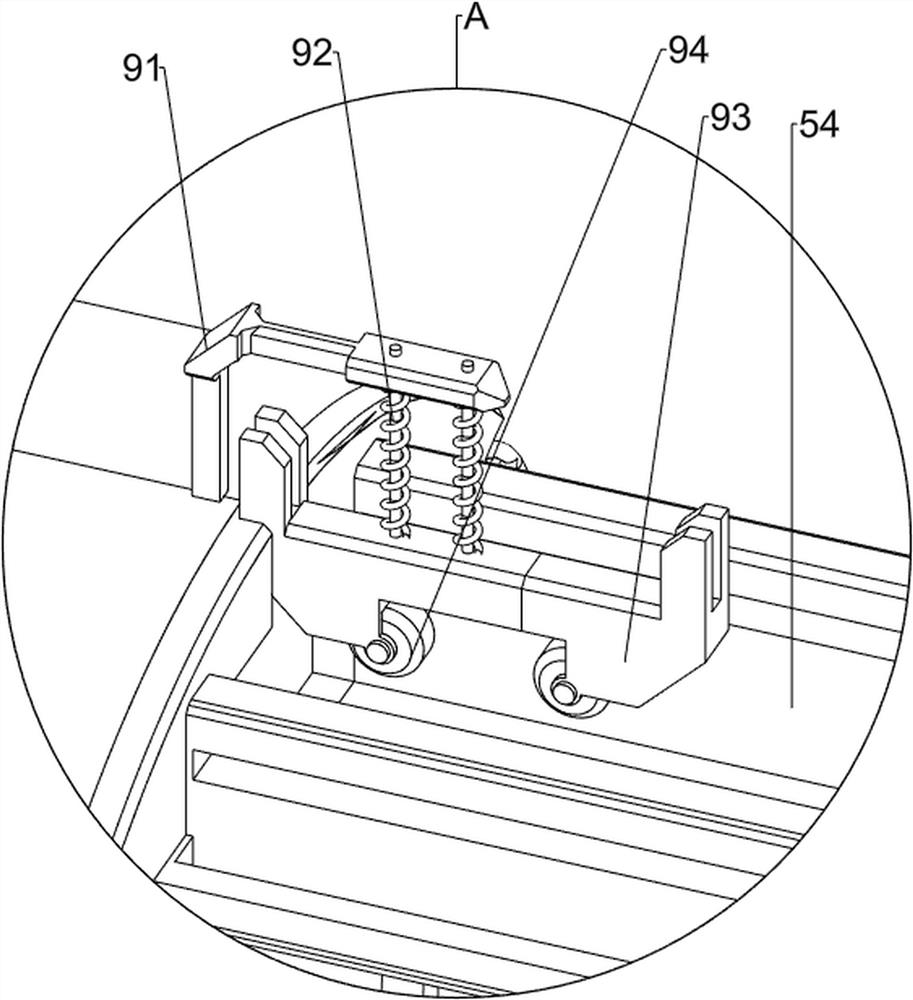

Gynecological sickbed convenient for replacing bed sheet

The invention relates to a sickbed capable of replacing a bed sheet, in particular to a gynecological sickbed convenient for replacing a bed sheet. The invention provides the gynecological sickbed convenient for replacing the bed sheet, which is convenient for medical personnel to work and simple to operate. A gynecological sickbed convenient to replace a bed sheet comprises wheels, a first support, baffles, a first frame, vertical plates, guardrails and the like, the wheels are symmetrically and rotationally arranged on the two sides of the first support, the baffles are arranged on the two sides of the first support, the first frame is arranged on the first support, the vertical plates are arranged on the two sides of the first frame, and the guardrails are arranged on the first frame. A medical worker manually pulls a rotating plate to turn forwards, a first torsion spring twists and deforms, the rotating plate can make contact with the front side of a first sliding block, then the medical worker holds up a patient and places the patient on the rotating plate, the patient can sit on the rotating plate, and the supporting effect is achieved.

Owner:曾小平

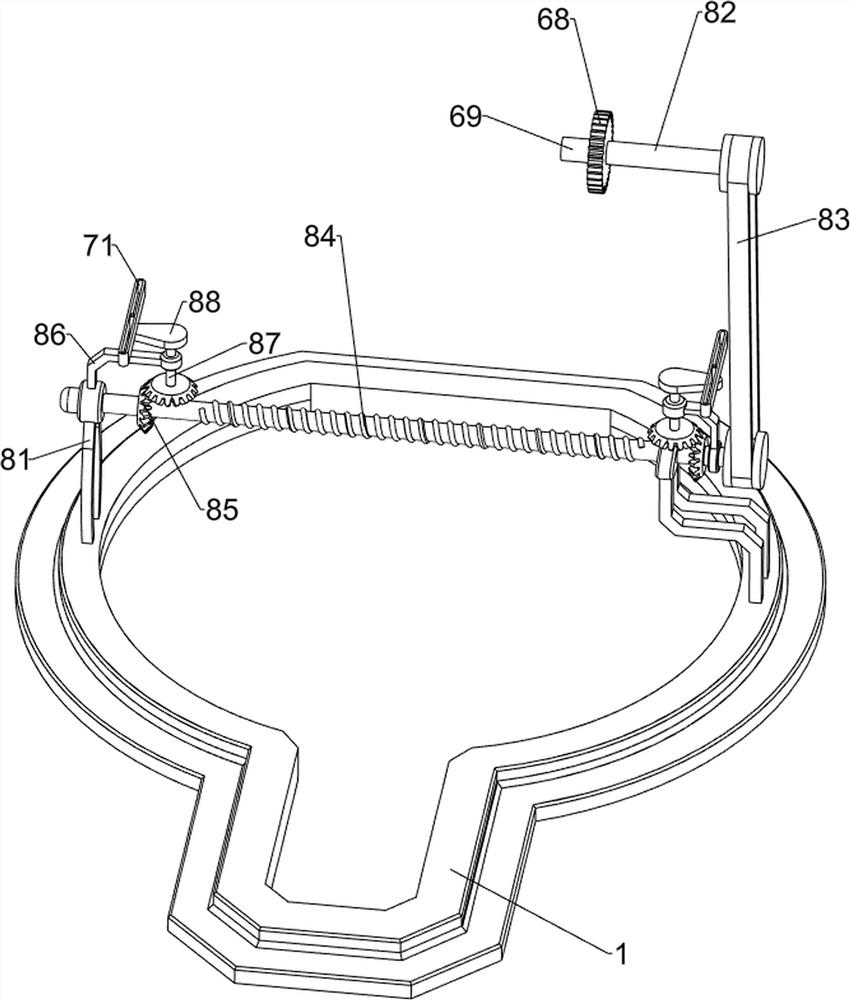

Rapid equidistant segmentation equipment for marble slabs for building

InactiveCN113967972ARealize the rotation effectNo manual push requiredWorking accessoriesStone-like material working toolsStructural engineeringMechanical engineering

The invention relates to segmentation equipment, in particular to rapid equidistant segmentation equipment for marble slabs for a building. The invention provides the rapid equidistant segmentation equipment for the marble slabs for the building, which has the advantages that the influence on a human body is relatively small, cutting and segmentation angles are uniform, and operation is simple. The rapid equidistant segmentation equipment for the marble slabs for the building comprises supporting columns, a mounting plate frame, an electric cutting knife, a rotating mechanism and a pushing mechanism, wherein two supporting columns are arranged on each of the two sides of the lower part of the mounting plate frame; the electric cutting knife is mounted on the upper side of the mounting plate frame; the rotating mechanism is arranged on the mounting plate frame; and the pushing mechanism is arranged between the mounting plate frame and the rotating mechanism. By using the rapid equidistant segmentation equipment disclosed by the invention, the marble slabs can be driven to rotate through rotation of a second containing rotating block and rotation of a first containing rotating block, so that the marble slabs are in contact with the electric cutting knife and can be cut and segmented through rotation of the electric cutting knife, and the rotating effect is achieved.

Owner:王卫勇

A device for labeling the outer wall of an empty fermented bean curd can

ActiveCN113002909BEasy labelingRealize the driving effectBio-packagingLabelling short rigid containersEngineeringMaterial storage

The invention relates to a labeling device, in particular to a labeling device for the outer wall of an empty fermented bean curd can. The invention provides a device for labeling the outer wall of an empty fermented bean curd can, which reduces the labor intensity of staff, has convenient operation and wide applicability. A device for labeling an outer wall of an empty fermented bean curd can, comprising: a base and a first bracket, the middle of which is provided with a first bracket; a material storage frame, the upper side of the first bracket is provided with a material storage frame; the second bracket, the material storage frame A second bracket is arranged on the lower side of the inner wall; a first sliding sleeve, a first sliding sleeve is rotatably arranged on the second bracket; a material supporting frame, a material supporting frame is slidably arranged on the first sliding sleeve. The invention drives the telescopic block to rotate through the second disc, thereby drives the first disc to rotate, and then drives the support frame to rotate, and the rotation of the support frame can drive the fermented bean curd empty can to rotate, which is convenient for labeling the bean curd empty can and realizes the driving effect. .

Owner:江西永叔府食品有限公司

An automatic packaging device for circuit breaker production

The invention relates to a packaging device, in particular to an automatic packaging device for circuit breaker production. The invention provides an automatic packaging device for circuit breaker production, which can automatically package, reduce labor, and is convenient to use. An automatic packaging device for circuit breaker production, comprising: a supporting foot and a sliding rail plate, the sliding rail plate is arranged between the upper two sides of the supporting foot; a feeding frame is provided between the upper two sides of the supporting foot; the feeding mechanism; The sliding rail plate is provided with a pushing mechanism; the moving mechanism is provided with a moving mechanism on the sliding rail plate. In the present invention, by manually pushing the first sliding rod to slide to the left, the first spring is compressed, so as to drive the slider to move to the left, so that the slider can push the circuit breaker out to achieve the effect of pushing material; After being pushed onto the packaging box, people need to push the support plate downward again, so as to drive the second sliding rod to continue to slide downward, so that the second spring continues to reset to achieve the effect of movement.

Owner:江西双宏科技电气有限公司

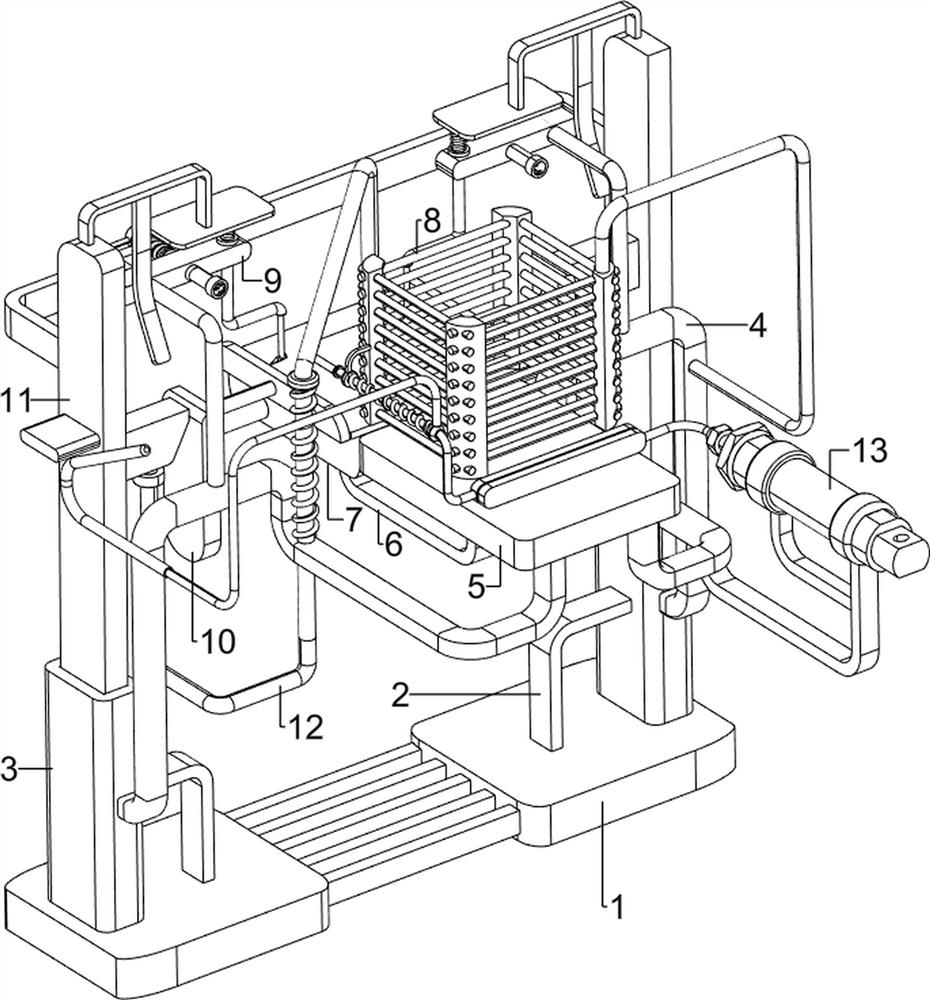

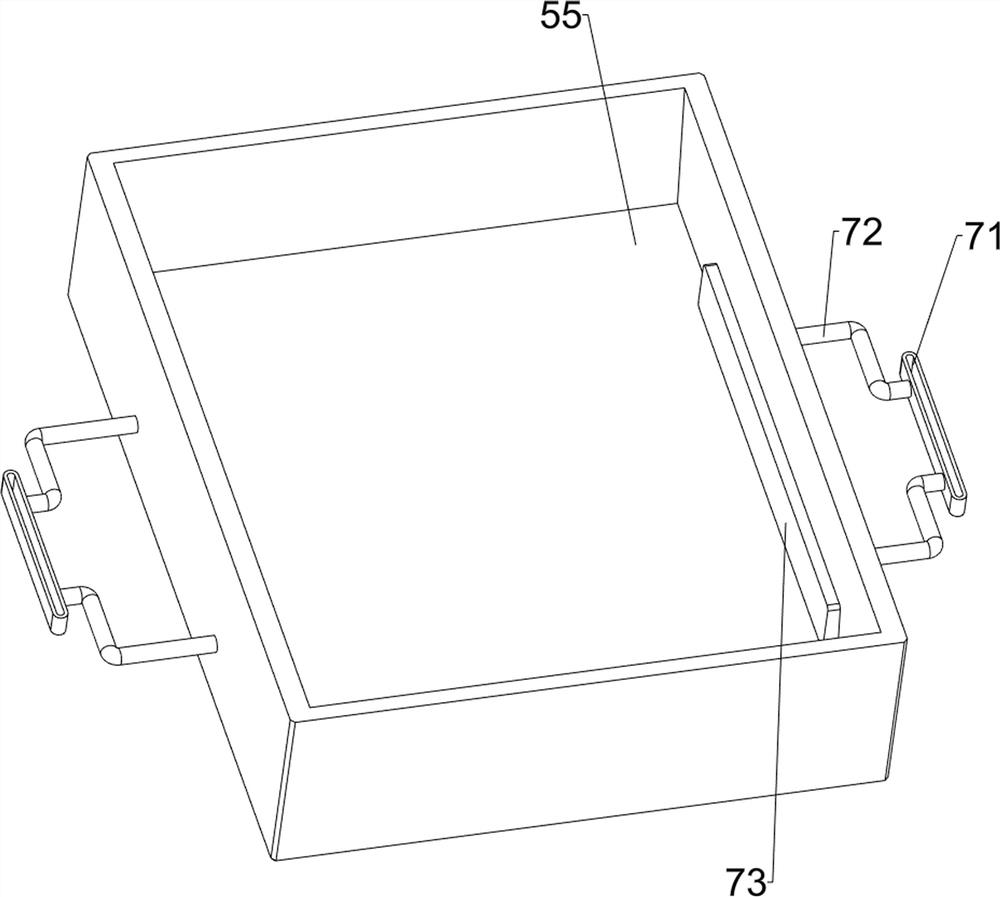

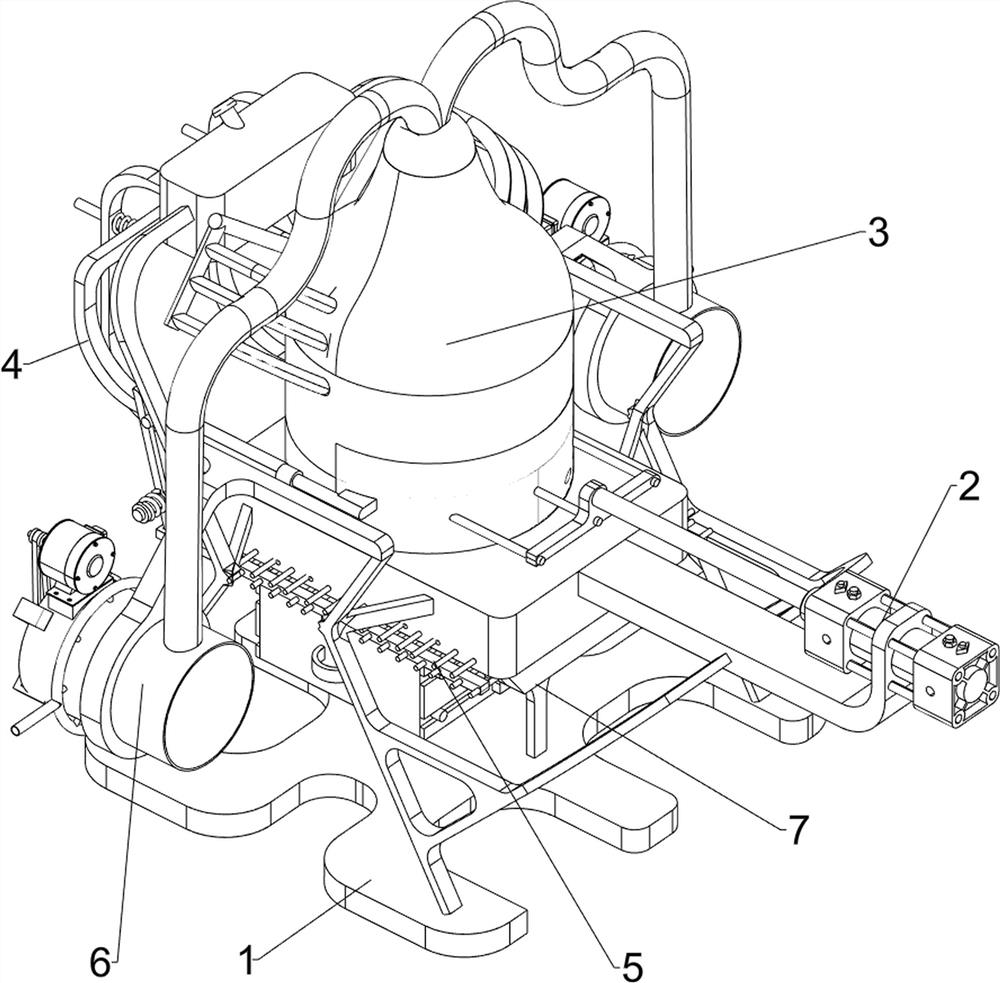

Medical waste incineration, filtration and purification equipment

PendingCN112815339ARealize the push effectTo achieve the effect of incinerationIncinerator apparatusFiltrationMedical waste

The invention relates to purification equipment, and especially relates to medical waste incineration, filtration and purification equipment. The invention provides automatic medical waste incineration, filtration and purification equipment integrating material containing, incineration and dust falling. The medical waste incineration, filtration and purification equipment comprises a material containing mechanism and an incineration mechanism, wherein the material containing mechanism is arranged at the middle part of a base frame; and the incineration mechanism is connected between the base frame and the material containing mechanism. According to the invention, a material containing hopper reciprocates front and back, and when the material containing hopper drives medical waste to move forwards to a position below the incineration mechanism, the incineration mechanism incinerates the medical waste; and combustible liquid enters a liquid guide pipe from a liquid storage box and then drips onto the medical waste, so that the medical waste is burnt, and the effect of burning the medical waste is realized.

Owner:黄付萍

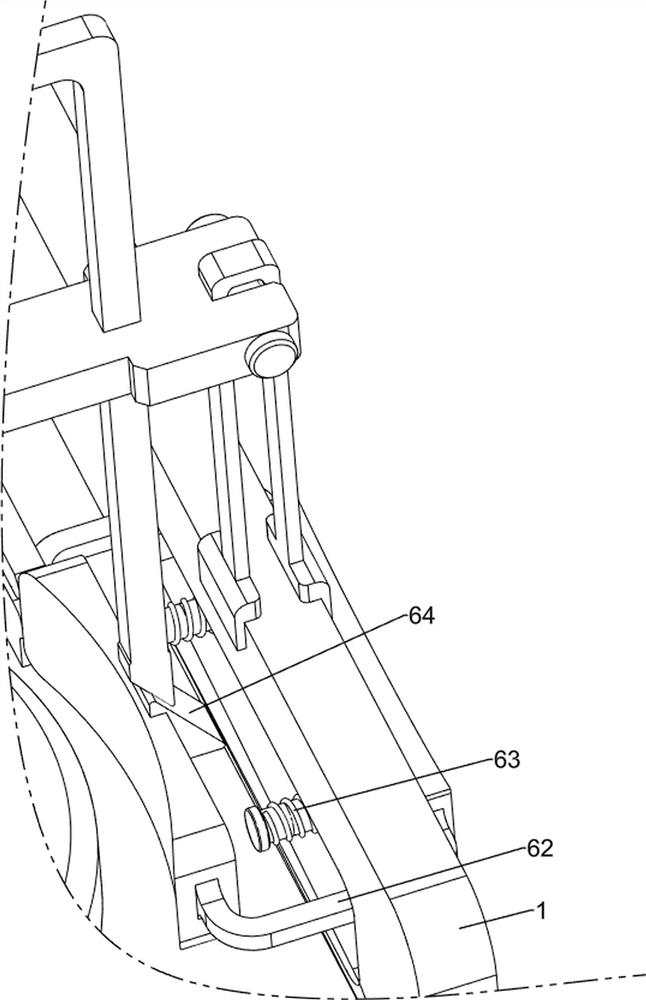

Accurate positioning and stamping device for chain production

ActiveCN112642989ARealize the effect of stamping and punchingPrecise positioningMetal chainsElectric machineryEngineering

The invention relates to an accurate positioning and stamping device, in particular to an accurate positioning stamping device for chain production. The invention provides the accurate positioning and stamping device for chain production which can prevent a chain from moving and automatically convey the chain. The accurate positioning and stamping device for chain production comprises a bottom plate, a motor, a stamping mechanism, and a clamping and positioning mechanism; a workbench is arranged on the bottom plate; the motor is mounted on the bottom plate; the stamping mechanism is arranged on the bottom plate, the stamping mechanism is connected with an output shaft on the left side of the motor; and the clamping and positioning mechanism is arranged at the top of the workbench. According to the accurate positioning and stamping device, a first rotary moving block swings up and down to drive the stamping mechanism to slide up and down, a first extension spring is adaptively stretched and reset, and the effect of stamping and punching the chain is achieved; and an elastic pushing assembly is pulled leftwards, so that a second guide sleeve slides backwards, the second guide sleeve clamps the concave position of the front wall of the chain, and therefore the chain does not deviate, and accurate positioning during punching is facilitated.

Owner:杭州钱唐链条配件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com