An automatic treatment device for large-volume solid waste

An automatic processing and large-volume technology, which is applied in grain processing, solid separation, chemical instruments and methods, etc., can solve the problems that large-volume waste is not easy to be completely treated, and achieves simple and ingenious structure, reduced output costs, and high device utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

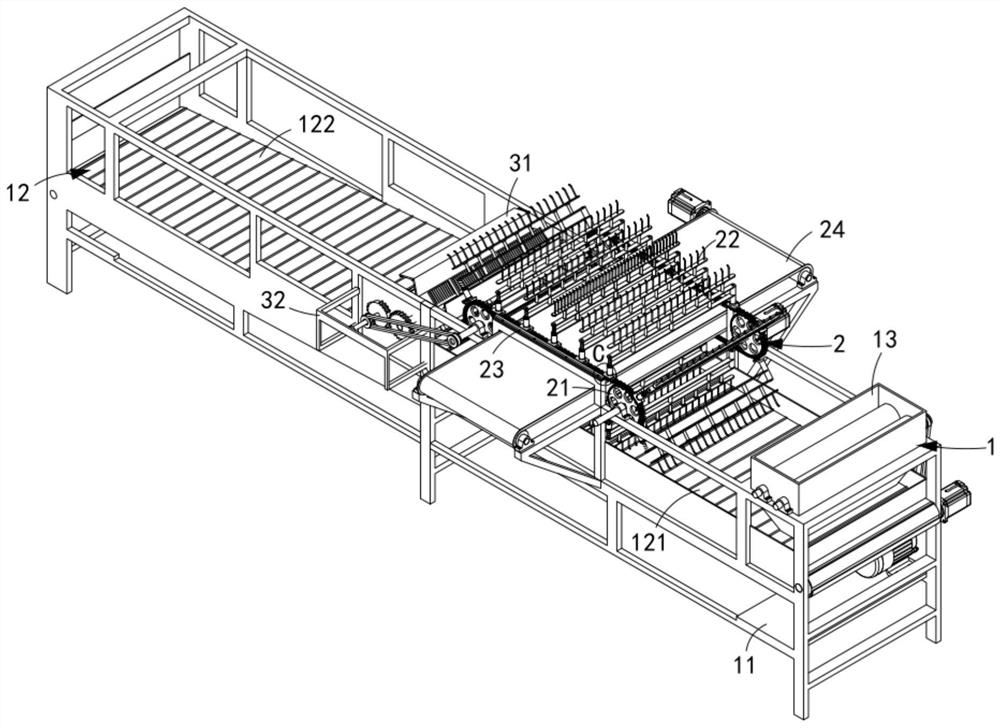

[0061] like figure 1 As shown, an automatic treatment device for large-volume solid waste, including:

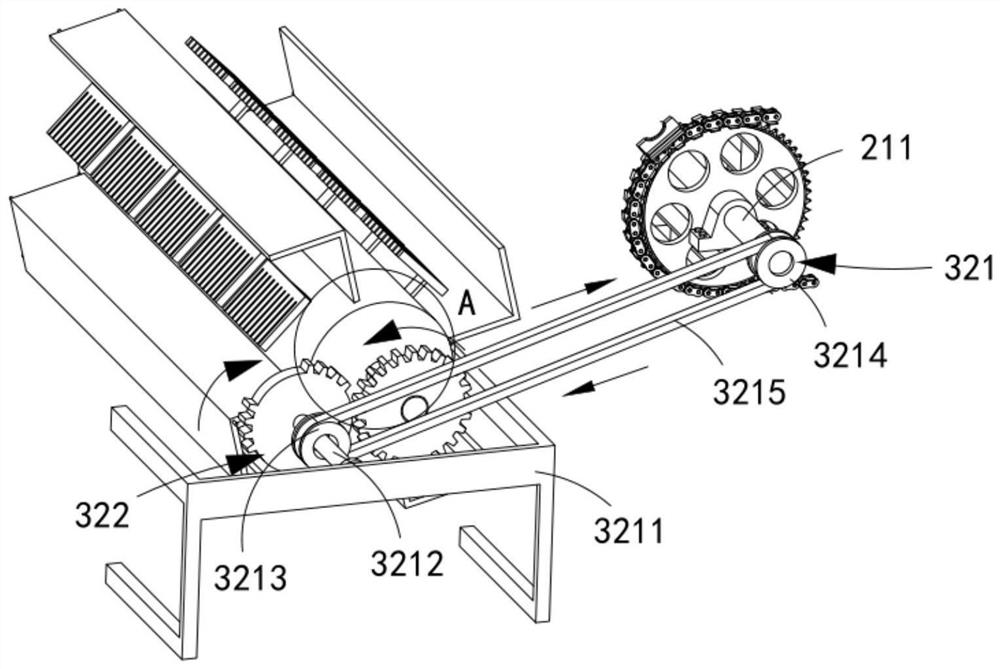

[0062] A crushing mechanism 1, the crushing mechanism 1 includes a frame 11, a transmission assembly 12 that is rotatable and arranged on the frame 11 in a gradient, and a crushing device that is installed on the frame 11 and is located at one end of the frame 11. Component 13, the transmission component 12 is composed of a first transmission part 121 arranged horizontally and a second transmission part 122 arranged obliquely;

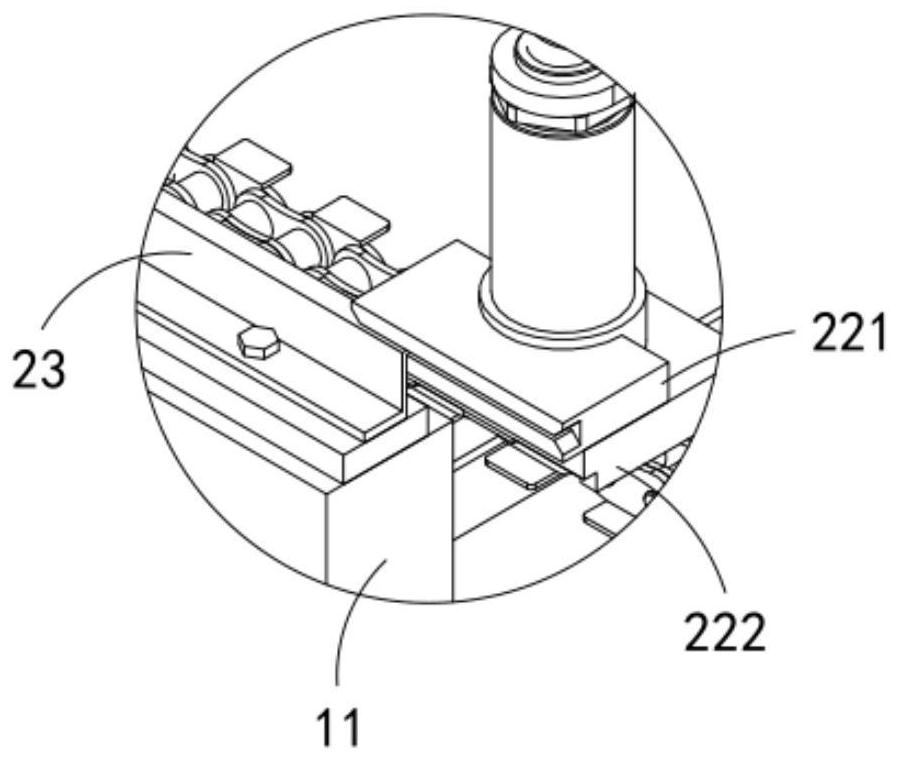

[0063] The impurity removal mechanism 2, the impurity removal mechanism 2 is located behind the crushing assembly 13 and at the tail end of the first transmission part 121, which includes a The rotating drive assembly 21, the screen assembly 22 fixedly lying on the surface of the drive assembly 21 and arranged in several groups at equal intervals, the power-off assembly arranged above the frame 11 and cooperating with the screen assembly 22 23 and ...

Embodiment 2

[0104] like Figure 8 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0105] Further, the end of the adsorption stick 223 is arranged in a hook shape.

[0106] In this embodiment, by setting the end of the adsorption rod 223 in a hook shape, the contact area between the adsorption rod 223 and the iron filings is increased, so that the iron filings are absorbed by the adsorption rod 223 to the greatest extent, and the screening of the screening assembly 22 is improved. efficiency.

[0107] work process:

[0108] Start the third motor 135, the crushing rod 134 starts to drive, solid waste enters the crushing bin 131, falls from the bottom of the bin to the transmission assembly 12 after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com