A continuous flow sbr sewage treatment device

A sewage treatment device and sludge tank technology, applied in biological treatment devices, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as incomplete sewage treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

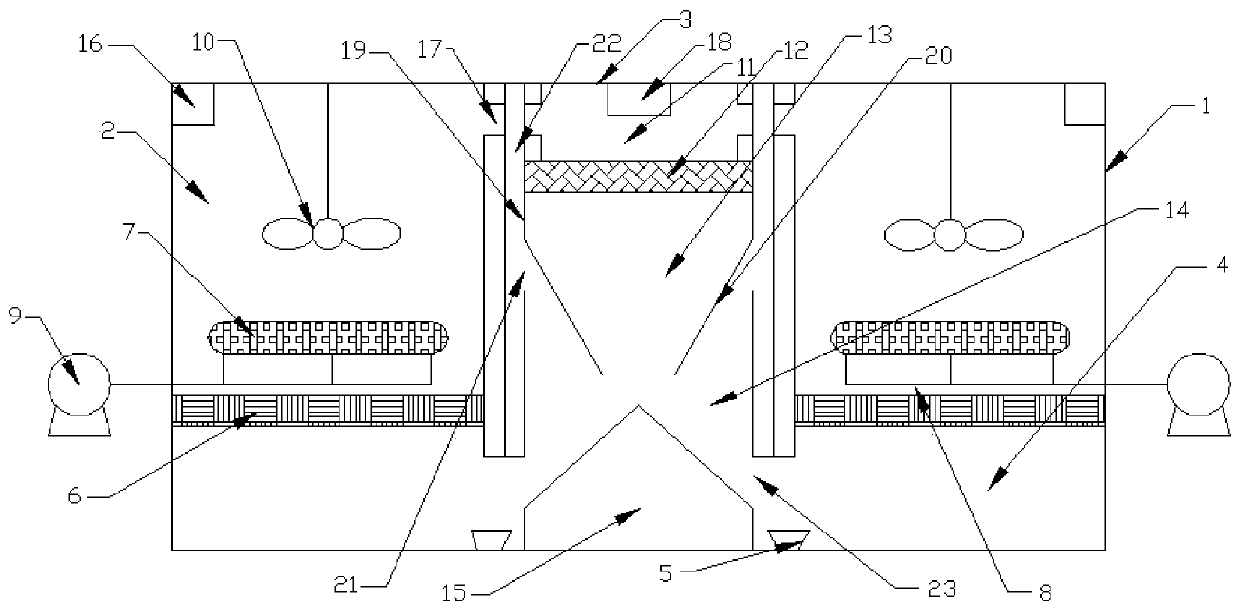

[0016] Such as figure 1 As shown, the present invention provides a kind of continuous flow SBR sewage treatment device, comprises casing 1, and the inside of casing 1 is provided with reaction pool 2 and three-phase separator 3, and the bottom of casing 1 is provided with sludge pond 4, and sewage Both sides of the sludge tank 4 are provided with sewage outlets 5, the top of the sludge tank 4 is provided with an anti-sludge floating filter 6, and the bottom of the reaction tank 2 is provided with a microporous aerator 7, and the microporous aerator One side of 7 is provided with air pipe 8, and one side of air pipe 8 is provided with blower 9, and the top of casing 1 is all provided with agitator 10, and the top of three-phase separator 3 is provided with sedimentation tank 11, and the top of sedimentation tank 11 A filter 12 is provided at the bottom, a filter zone 13 is provided on one side of the filter 12 , a solid-gas-liquid separation zone 14 is provided on one side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com