Integrated two-stage anaerobic ammonium oxidation coupled denitrification denitrification and carbon removal device and its control operation method

A combination of anaerobic ammonium oxidation and anaerobic ammonium oxidation technology, applied in the direction of anaerobic digestion treatment, chemical instruments and methods, water treatment parameter control, etc., can solve the problems of low volume load, sludge loss, unstable operation, etc. , to achieve the effect of low infrastructure cost, stable operation and enhanced affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

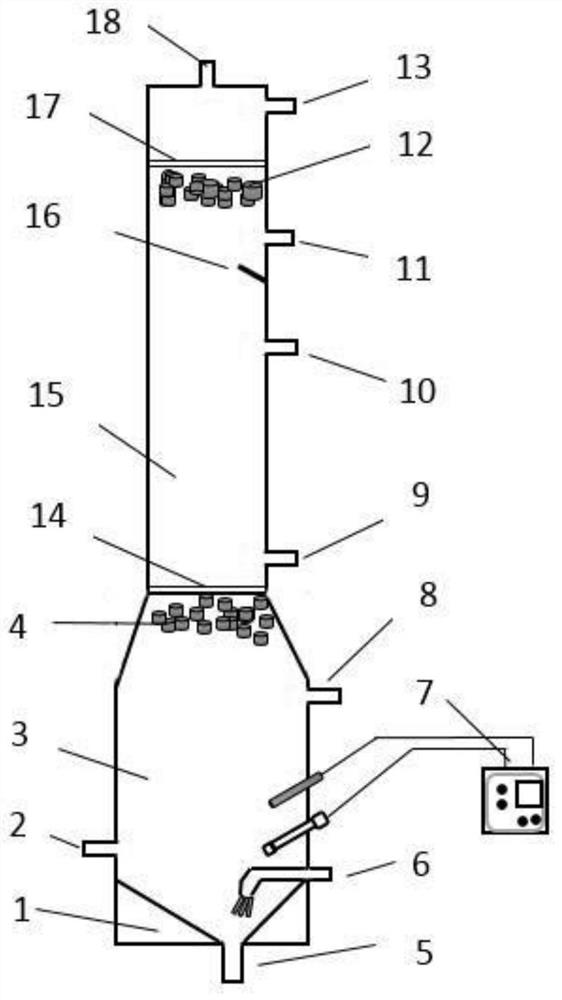

[0031] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0032]The integrated two-stage anammox coupled denitrification denitrification and carbon removal device of the present invention includes an anammox coupled denitrification reaction chamber 3 and anammox reaction chamber 15 composed of anammox coupled denitrification denitrification Nitrogen removal carbon barrel 1; the bottom of the anammox coupled denitrification reaction chamber 3 is provided with an anammox coupled denitrification reaction chamber return port 5 and a sludge discharge port 2, and an anammox coupled denitrification reaction chamber 3 is provided with a lower packing layer 4 on the top, and the measuring wall of the anammox coupled denitrification reaction chamber 3 is provided with a measuring instrument 7 for measuring pH and DO and a water distributor 6, and the upper part of the anammox coupled denitrification reaction chamber 3 A low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com