Steel pipe bending equipment for construction site building

A technology for construction and steel pipes, which is applied in metal processing equipment, manufacturing tools, feeding devices, etc., and can solve problems such as manual loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

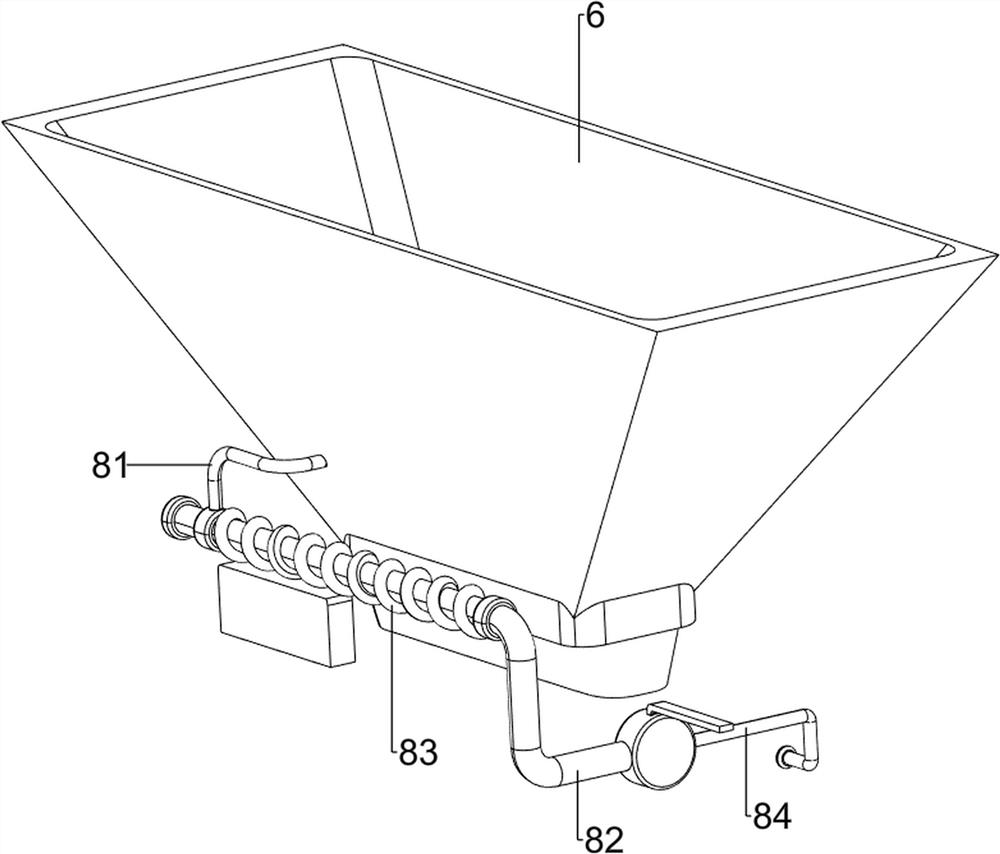

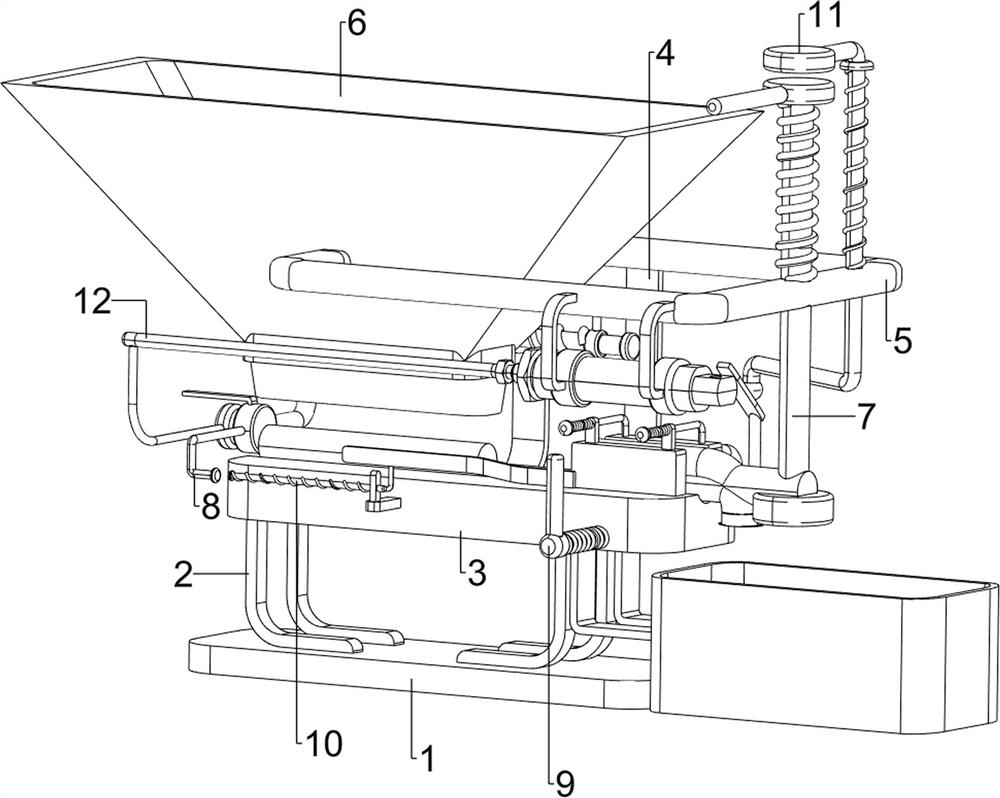

[0061] A steel pipe bending equipment for construction site construction, such as figure 1 As shown, it includes a first support plate 1, a first support frame 2, a second support plate 3, a third support frame 4, a fixed rod 5, a discharge frame 6, a bending mechanism 7, a pushing mechanism 8 and a clamping mechanism. Mechanism 9, two first support frames 2 are symmetrically arranged on the left and right sides of the first support plate 1, and the second support plates 3 are connected between the tops of the four first support frames 2, and the left and right sides of the second support plate 3 rear Both sides are provided with a third support frame 4, a fixed rod 5 is arranged between the front parts of the two third support frames 4, the left part of the fixed rod 5 is connected with a discharge frame 6, and the right side of the fixed rod 5 is provided with a bending mechanism 7 , The left side of the rear part of the discharge frame 6 is provided with a pushing mechanism...

Embodiment 2

[0064] On the basis of Example 1, such as Figure 2-4 As shown, the pushing mechanism 8 includes a fourth support frame 81, a pusher 82, a second spring 83 and a first round bar 84, and the right side of the discharge frame 6 rear portion is provided with a fourth support frame 81, and the fourth The support frame 81 is slide-typely provided with a pusher 82, the front portion of the pusher 82 is provided with a first round bar 84, and a second spring 83 is connected between the pusher 82 and the fourth support frame 81, and the second spring 83 is wound on the pusher 82.

[0065] When the steel pipe in the discharge frame 6 falls on the second support plate 3, people manually push the pusher 82 to the right to drive the steel pipe to move to the right, the second spring 83 is compressed, and the first round bar 84 moves to the right Push the steel pipe into the clamping mechanism 9 to realize the effect of pushing the material, and then people let go, and the second spring 8...

Embodiment 3

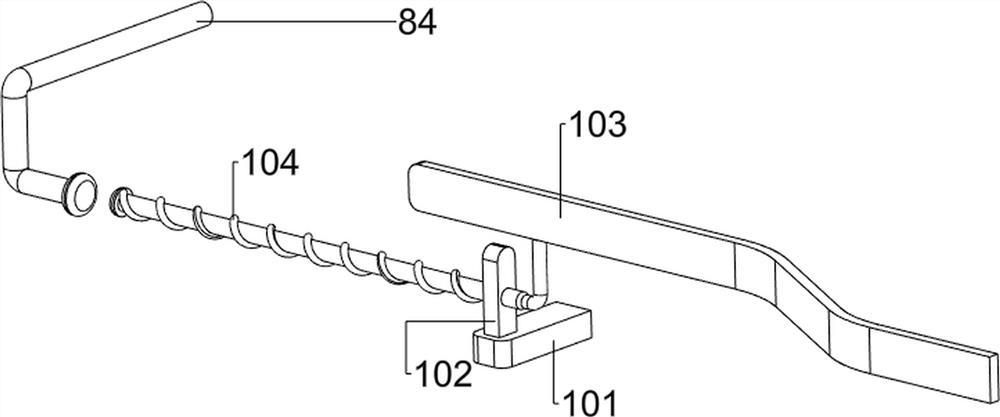

[0071] On the basis of Example 2, such as Figure 5-7 As shown, it also includes a clamping auxiliary mechanism 11. The bending auxiliary mechanism 10 includes a second fixed block 101, a third fixed block 102, a long plate 103 and a fifth spring 104. The front part of the second support plate 3 is provided with a first Two fixed blocks 101, the second fixed block 101 top front side is provided with the 3rd fixed block 102, the sliding type is provided with long plate 103 on the 3rd fixed block 102, the first round bar 84 and the second hand lever 96 are all connected with The long plate 103 cooperates, and a fifth spring 104 is connected between the long plate 103 and the third fixing block 102 , and the fifth spring 104 is wound on the long plate 103 .

[0072] When the first round bar 84 moves to the right and touches the long plate 103, the first round bar 84 drives the long plate 103 to move to the right, the fifth spring 104 is compressed, and the long plate 103 moves to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com