Patents

Literature

78results about How to "Easy labeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

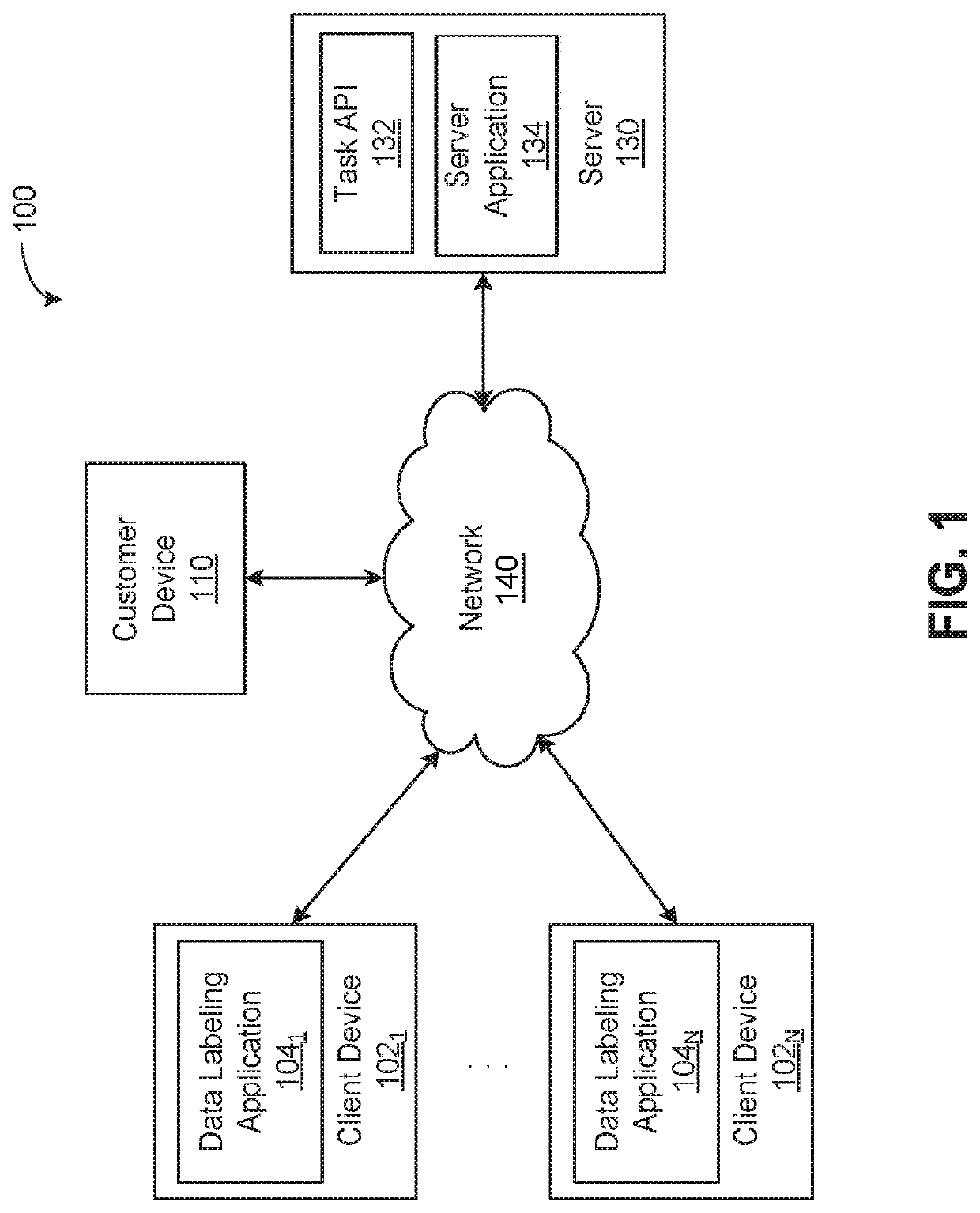

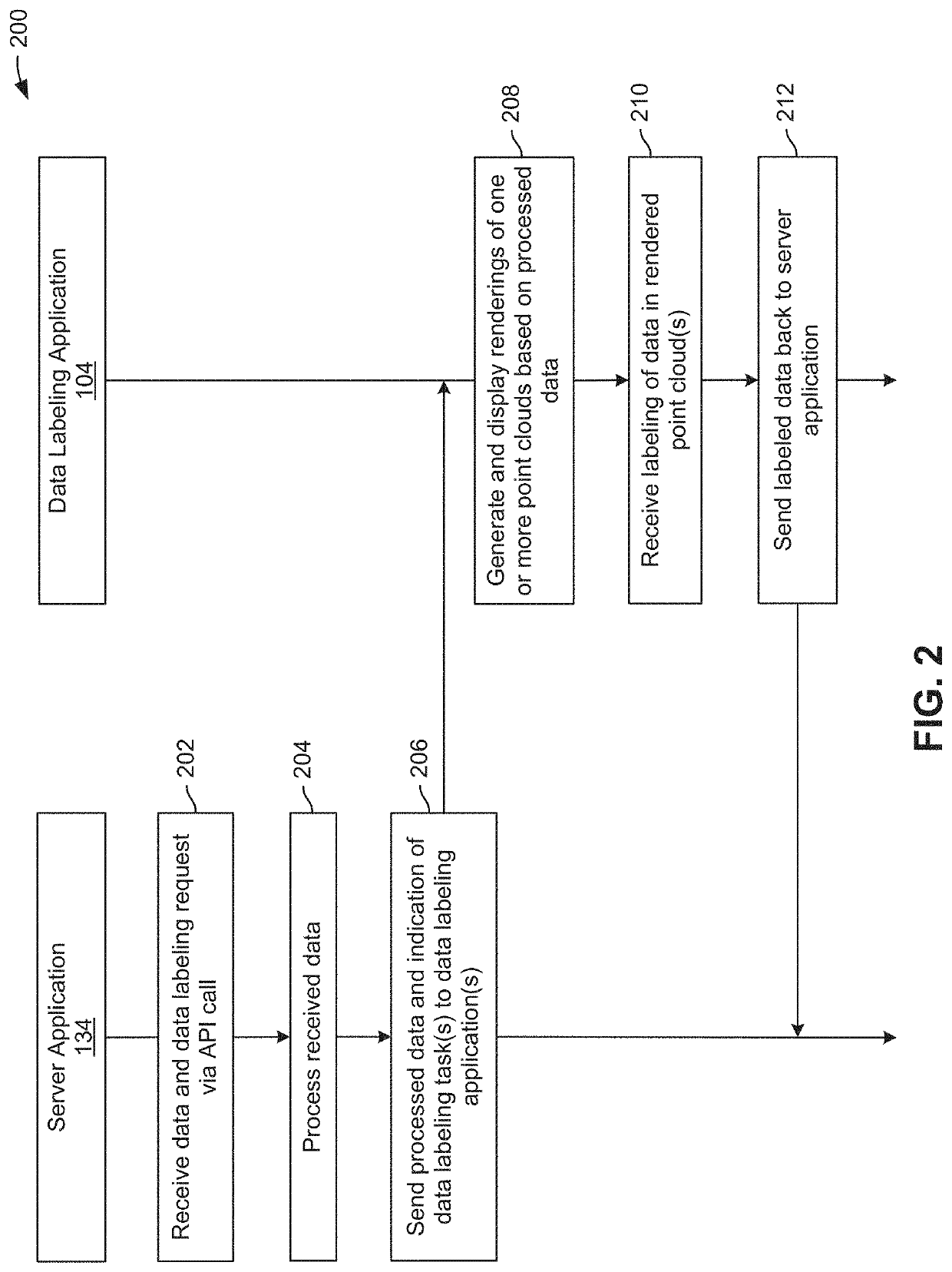

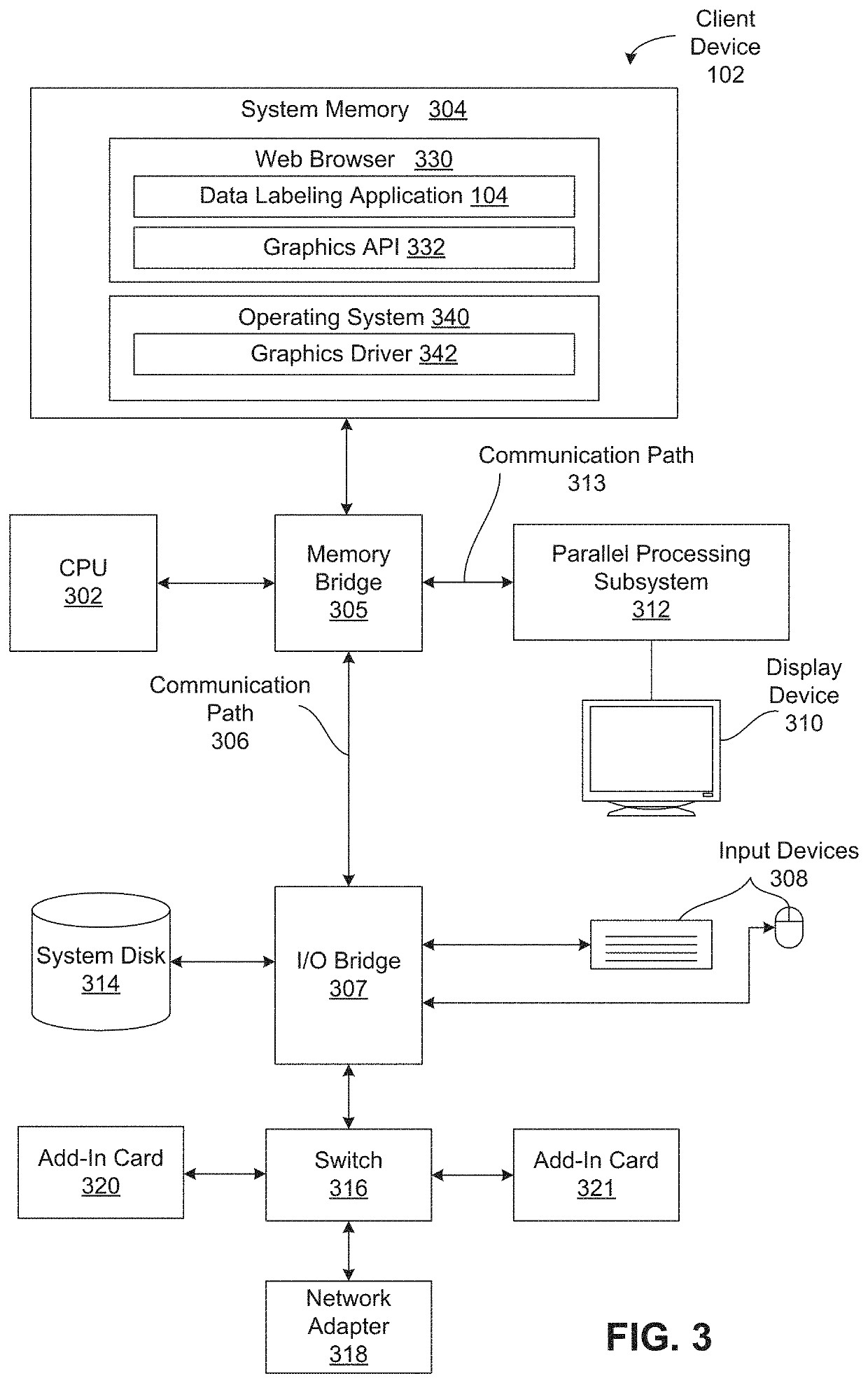

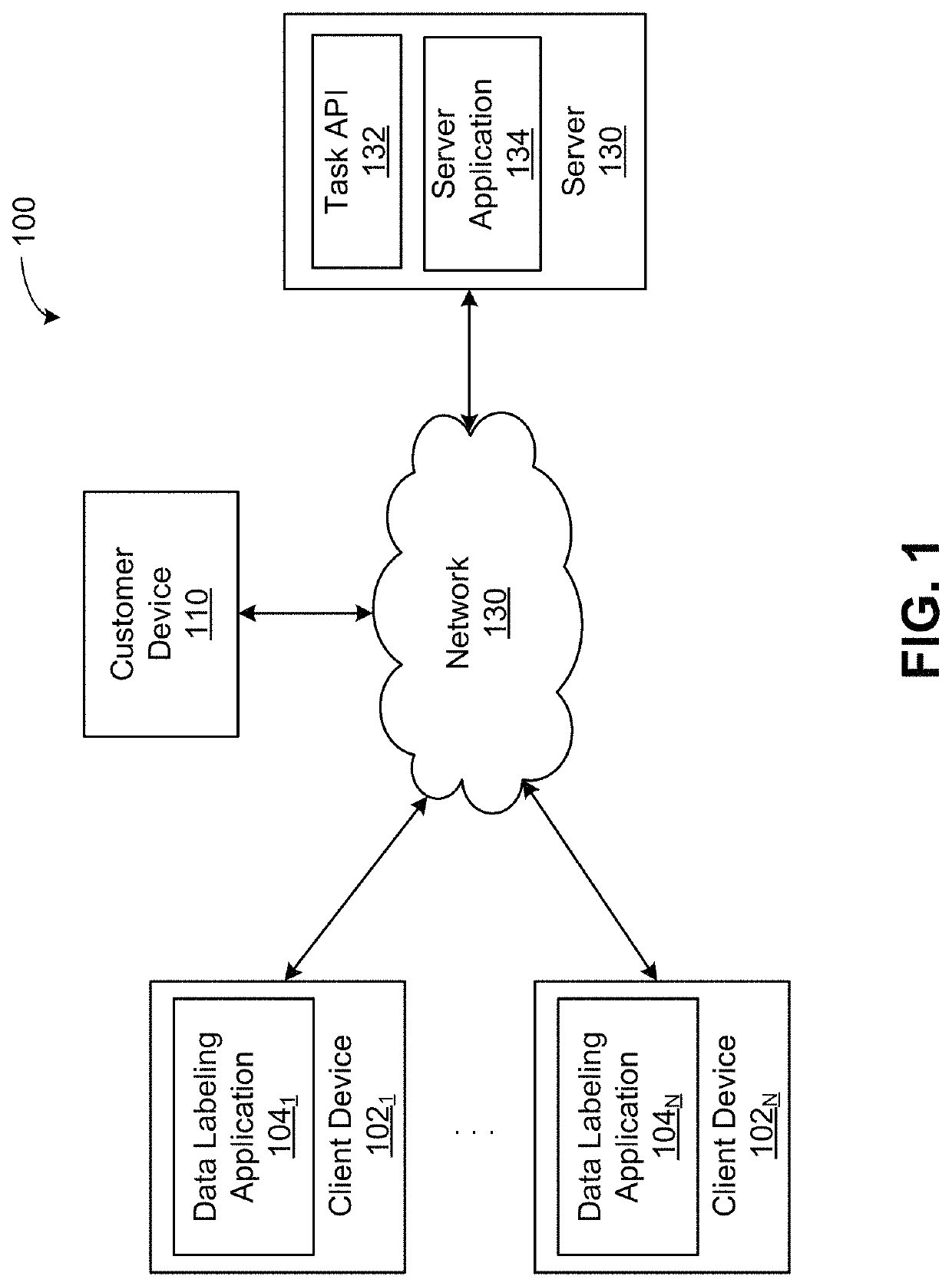

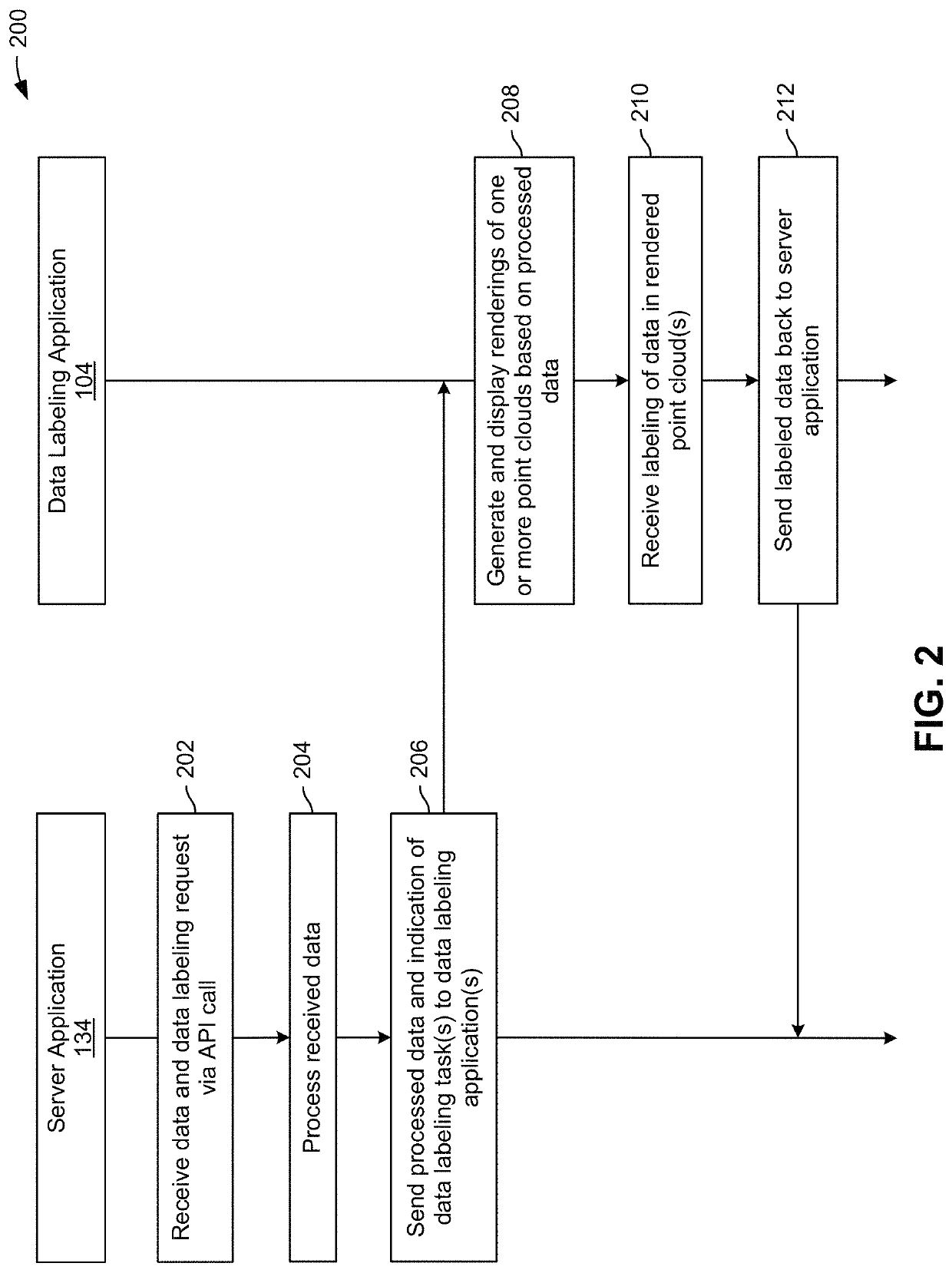

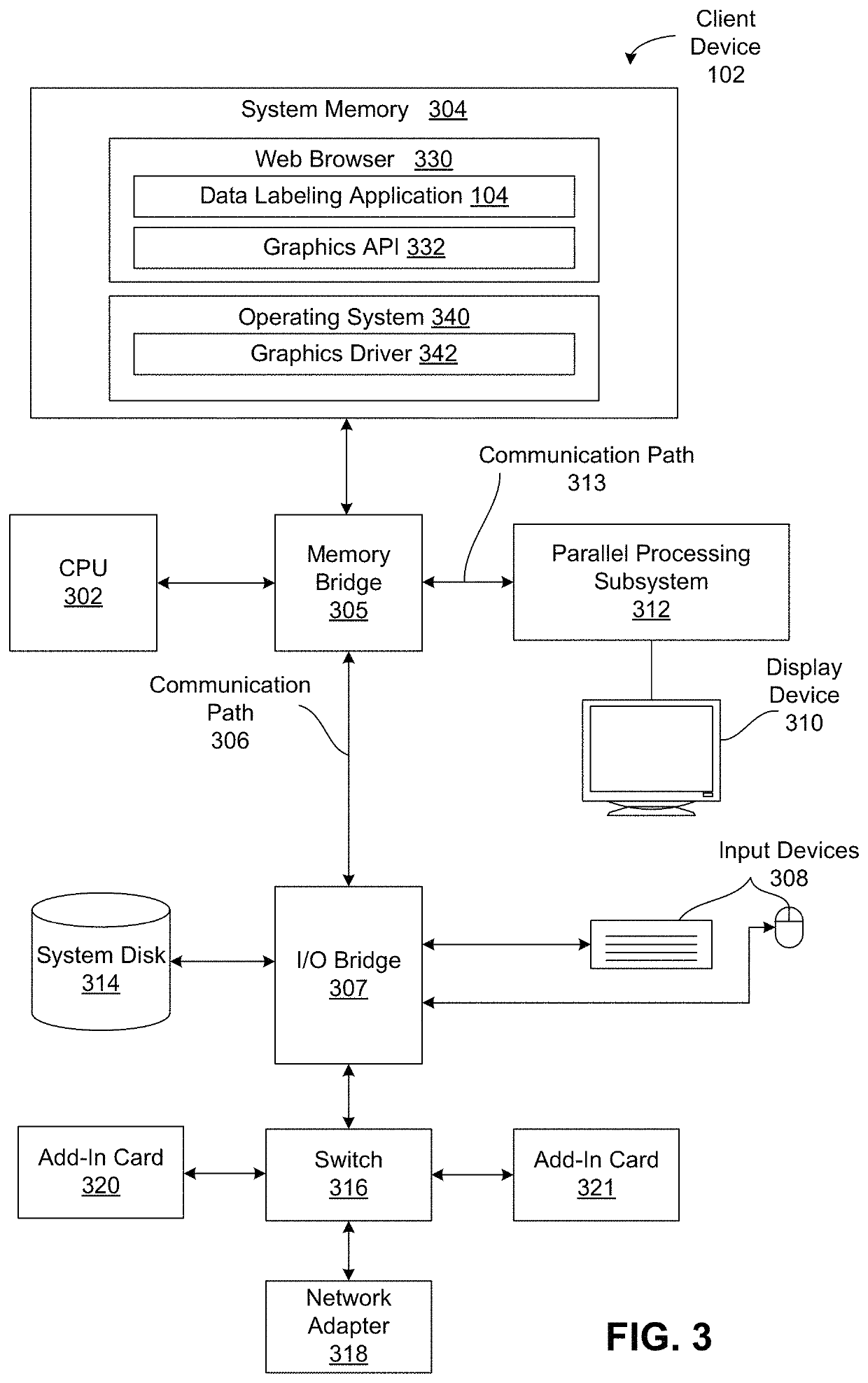

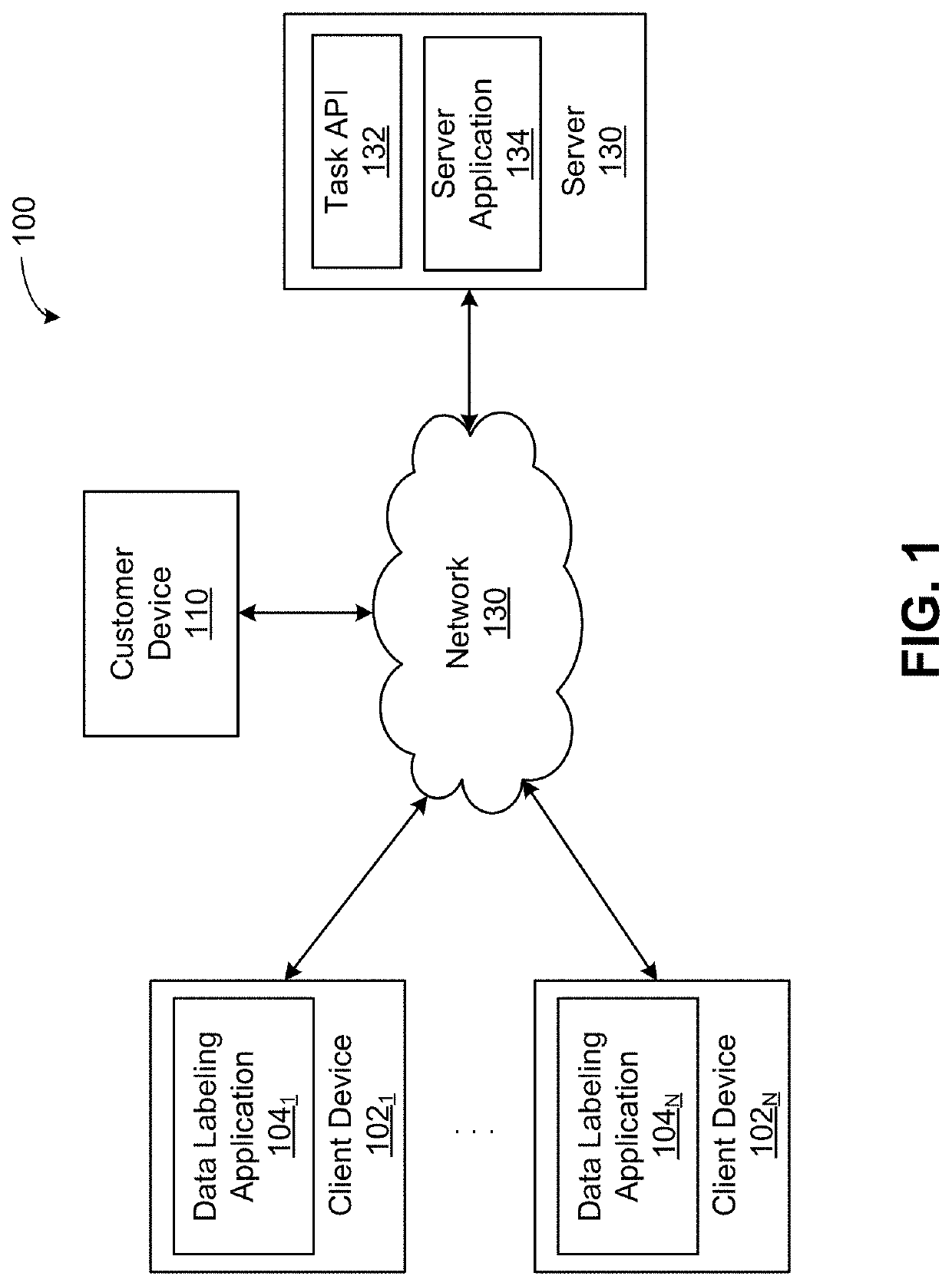

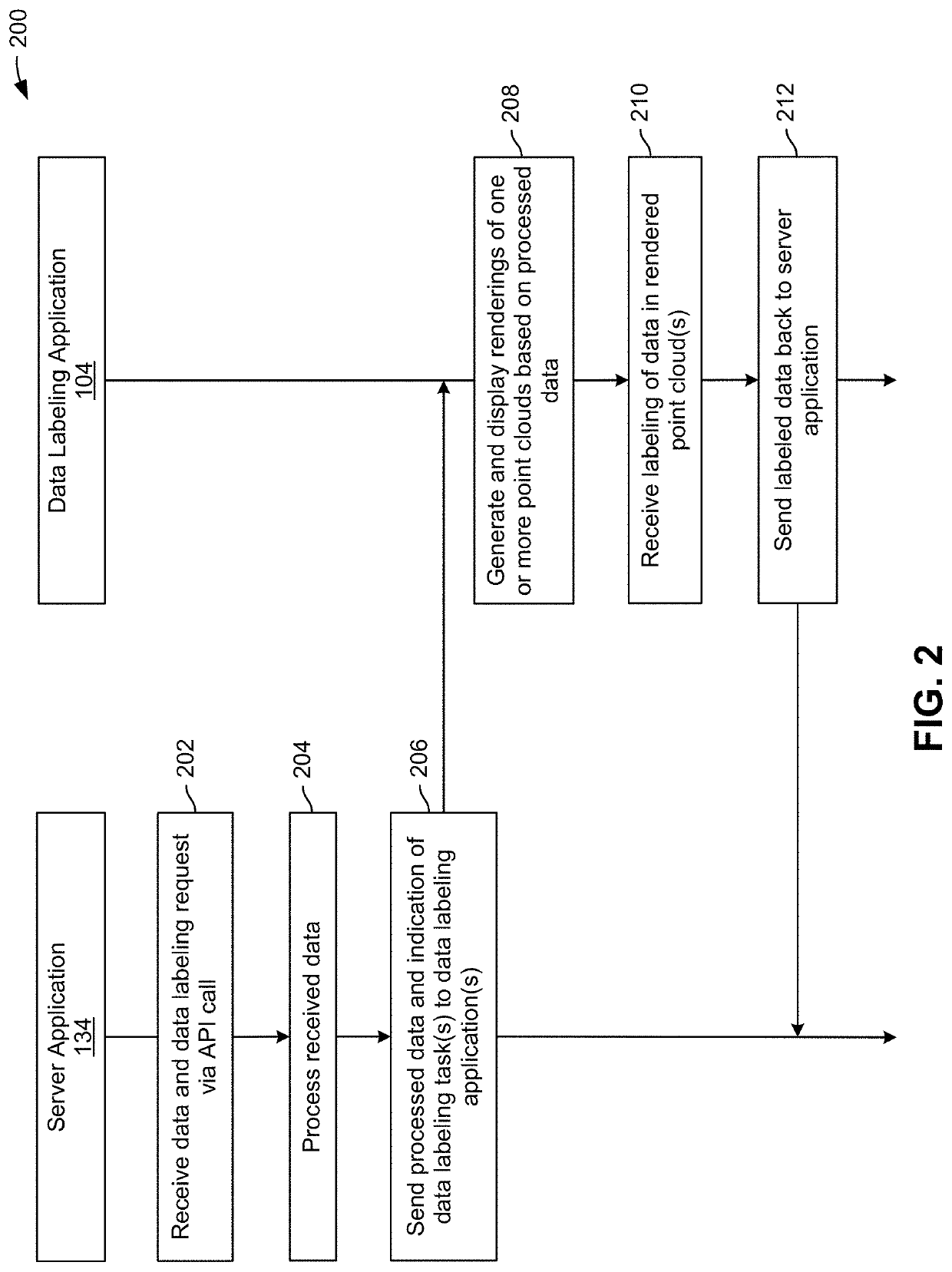

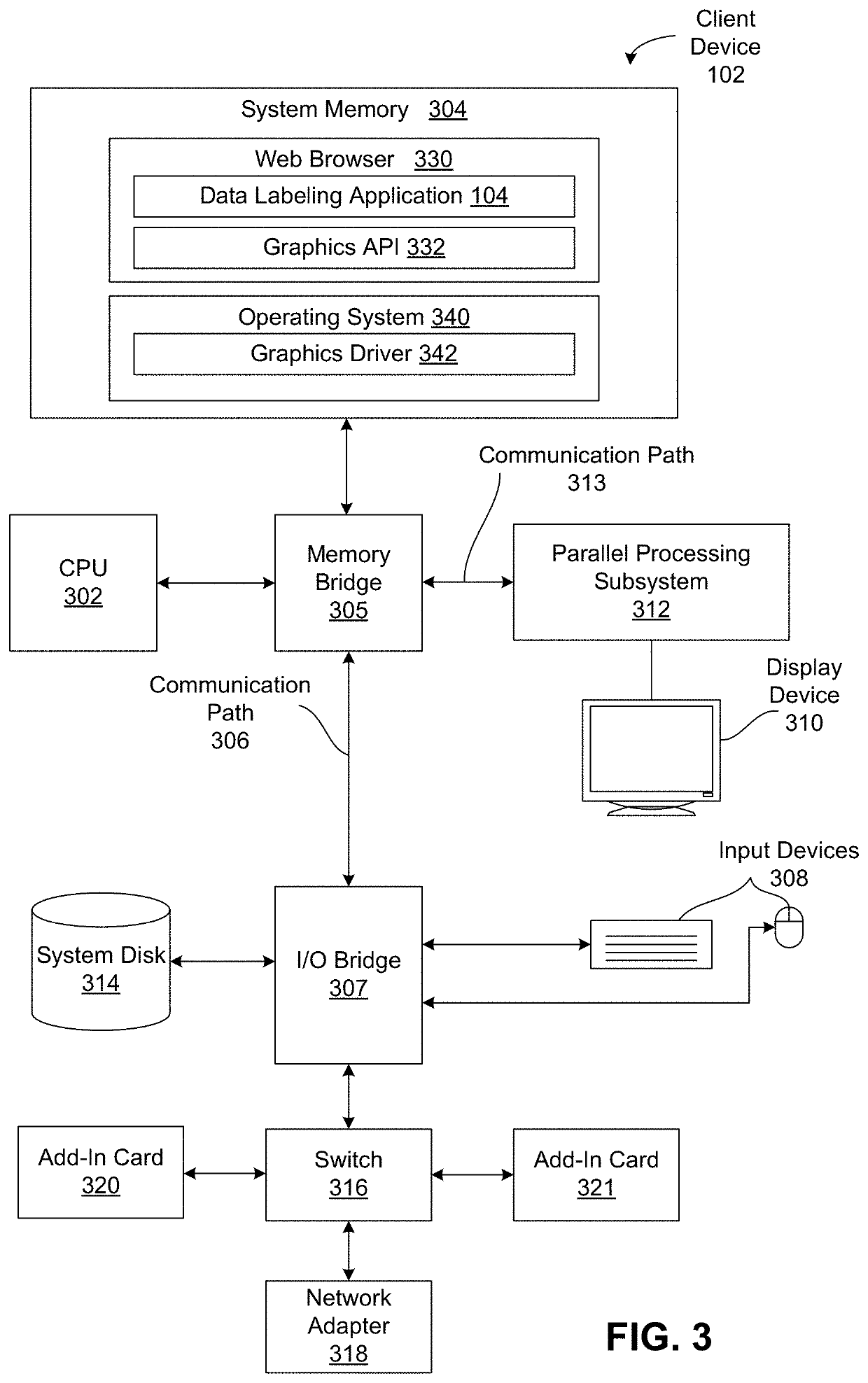

Visualization techniques for data labeling

ActiveUS20210027524A1Easy labelingImage enhancementImage analysisPoint cloudComputer graphics (images)

One embodiment provides a user interface (UI) that permits users to select how point cloud colorings determined from multiple data sources are blended together in a rendering of a point cloud. The data sources may include photographic, label, and / or LIDAR intensity data. To improve frame rates, an aggregated point cloud may be generated using a spatial hash of a large set of points and sampling of each hash bucket based on the number of points therein and a user-configurable density. Sizes of points in the point cloud may decrease proportionally to distance from a viewer, but increase based on an activation function that enlarges points greater than a threshold distance from the viewer. In addition, luminance statistics for sub-regions of photographic data and dominant colors determined from photographic data may be used to automatically determine color properties to apply to a point cloud coloring.

Owner:SCALE AI INC

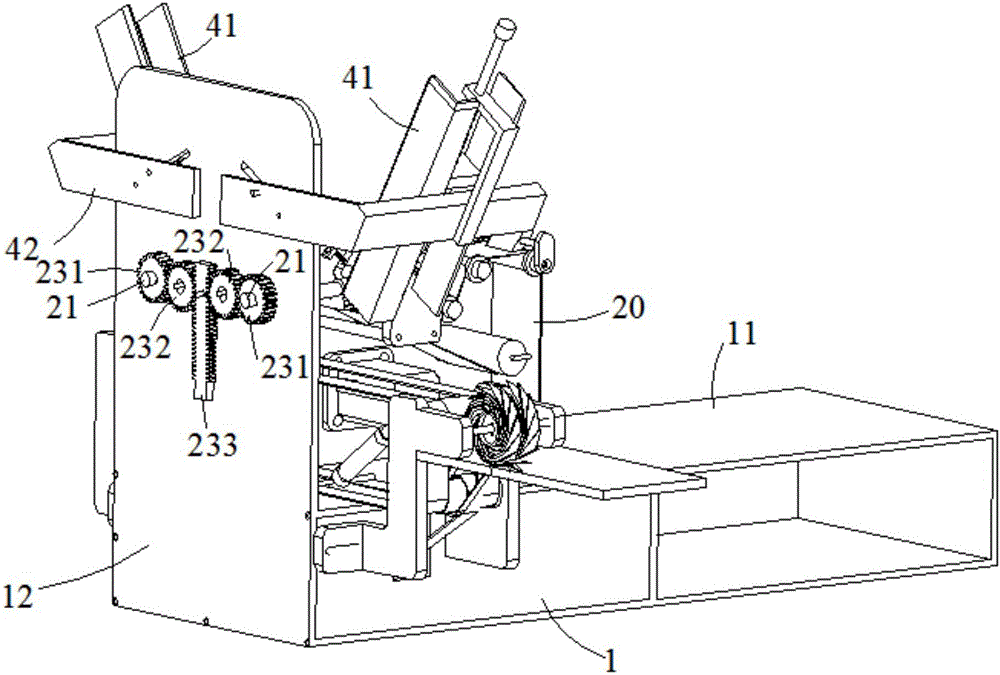

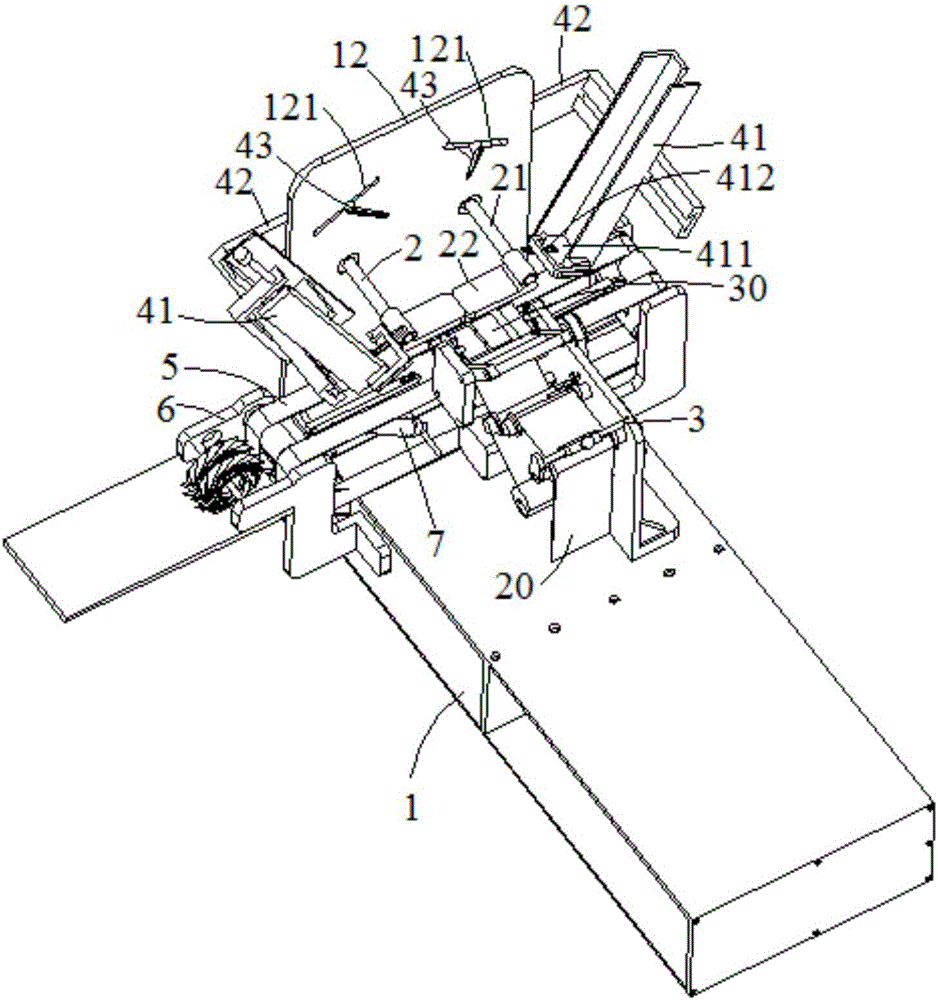

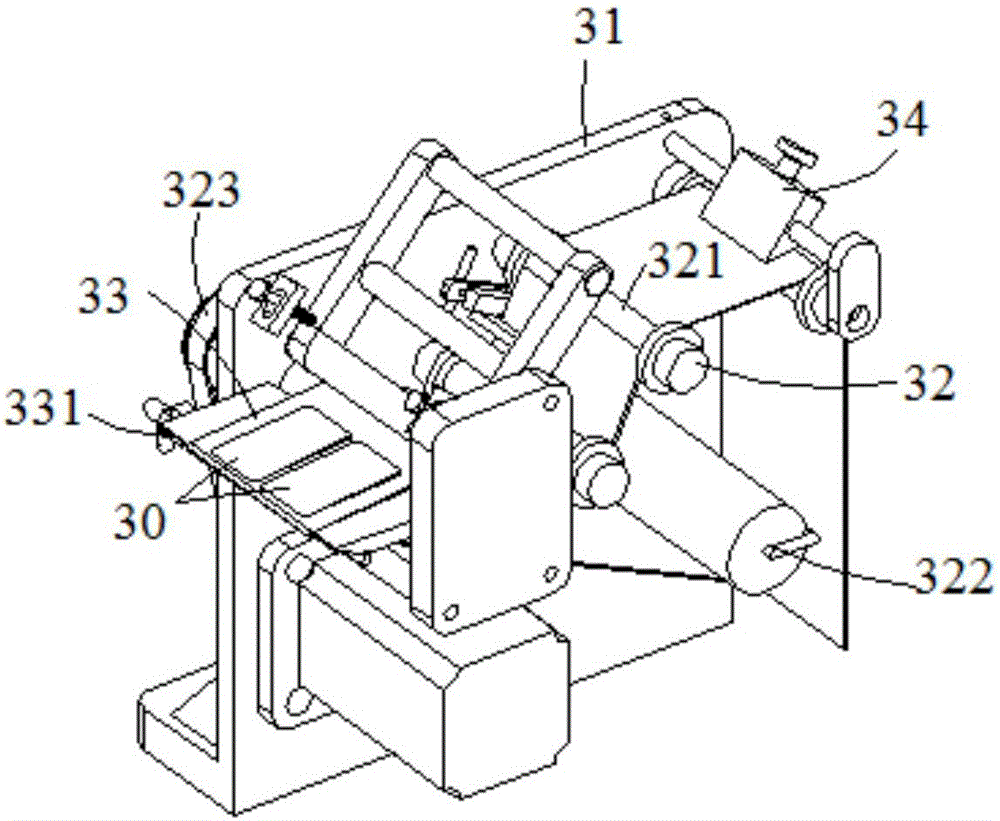

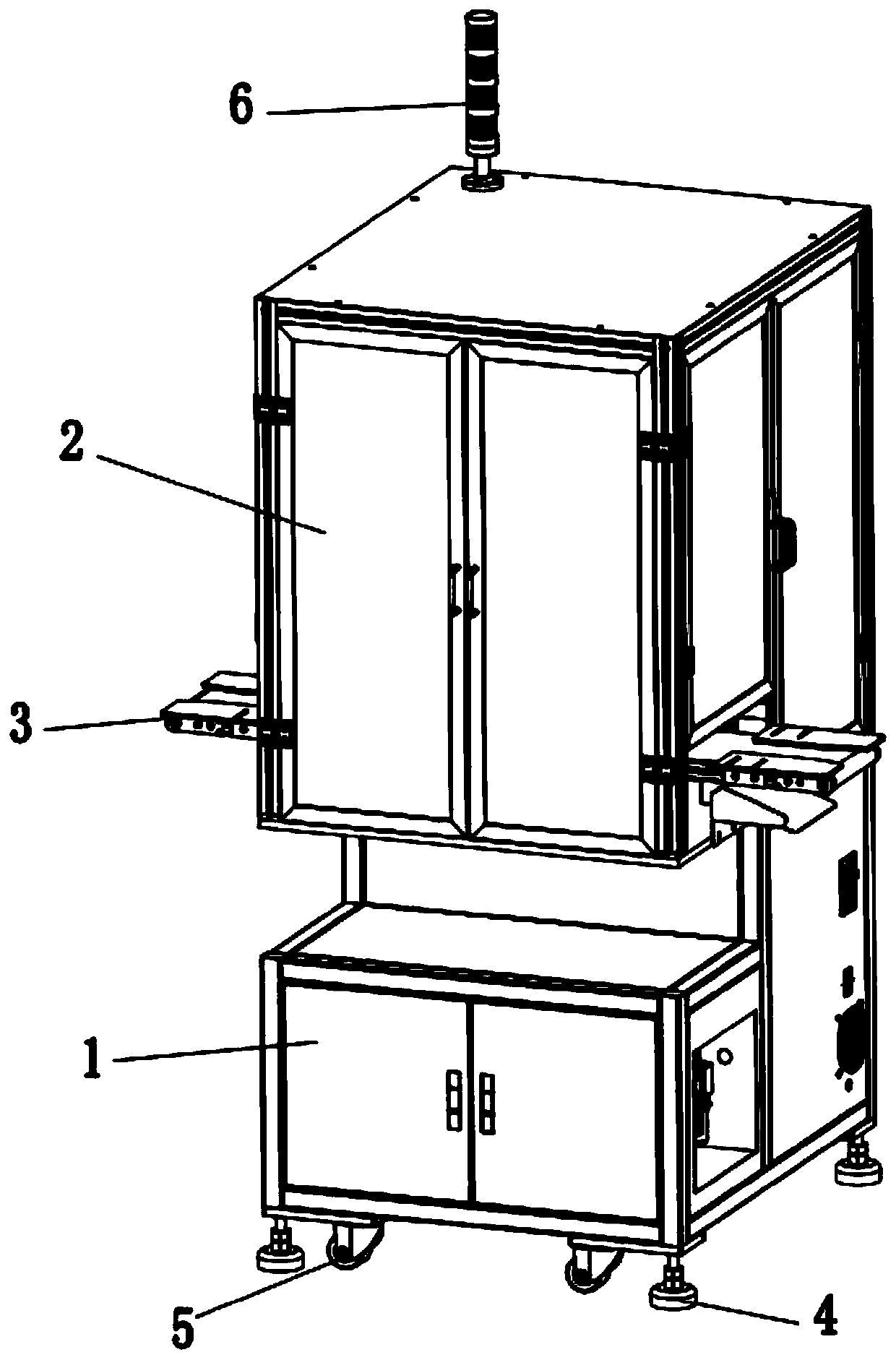

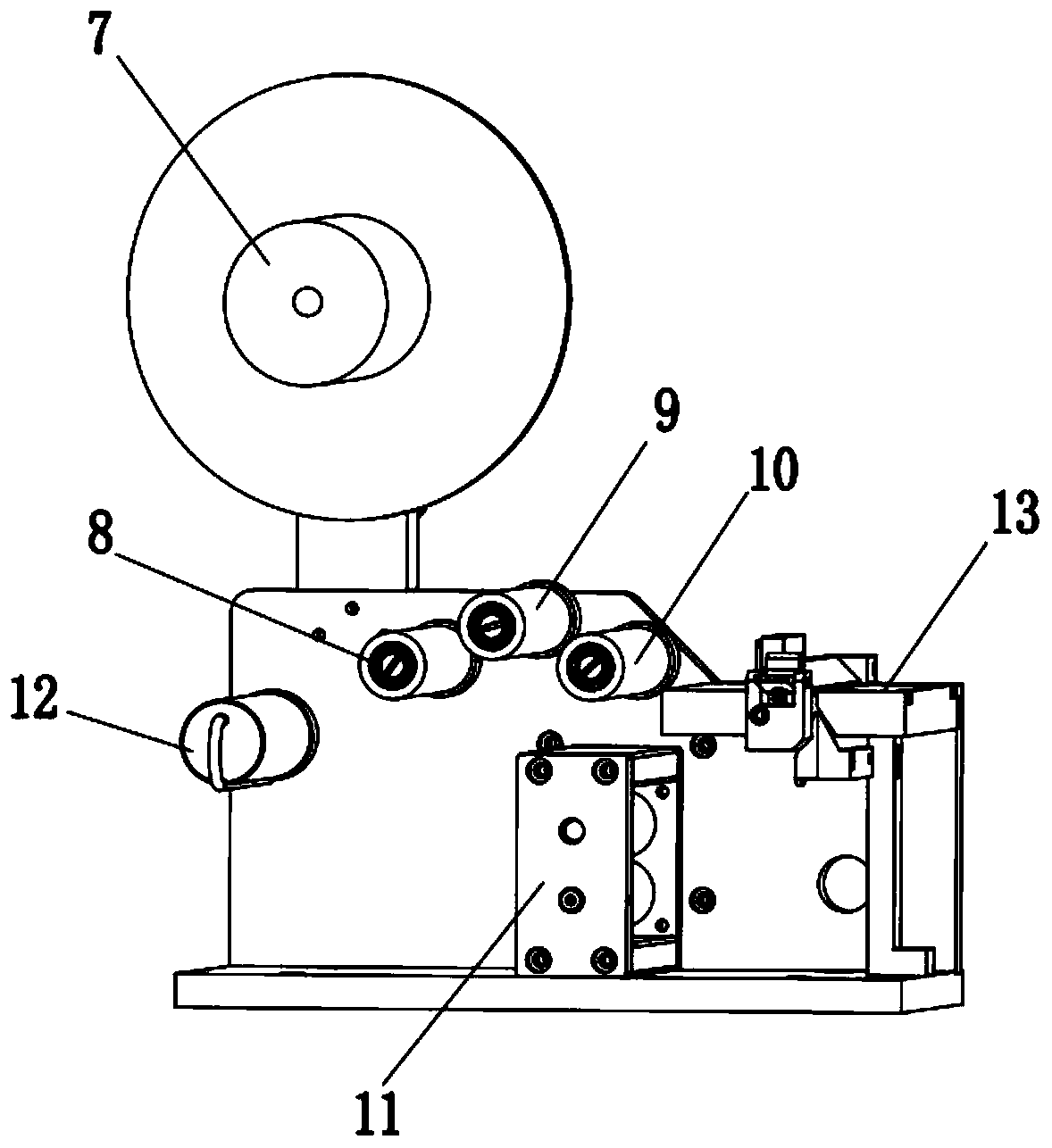

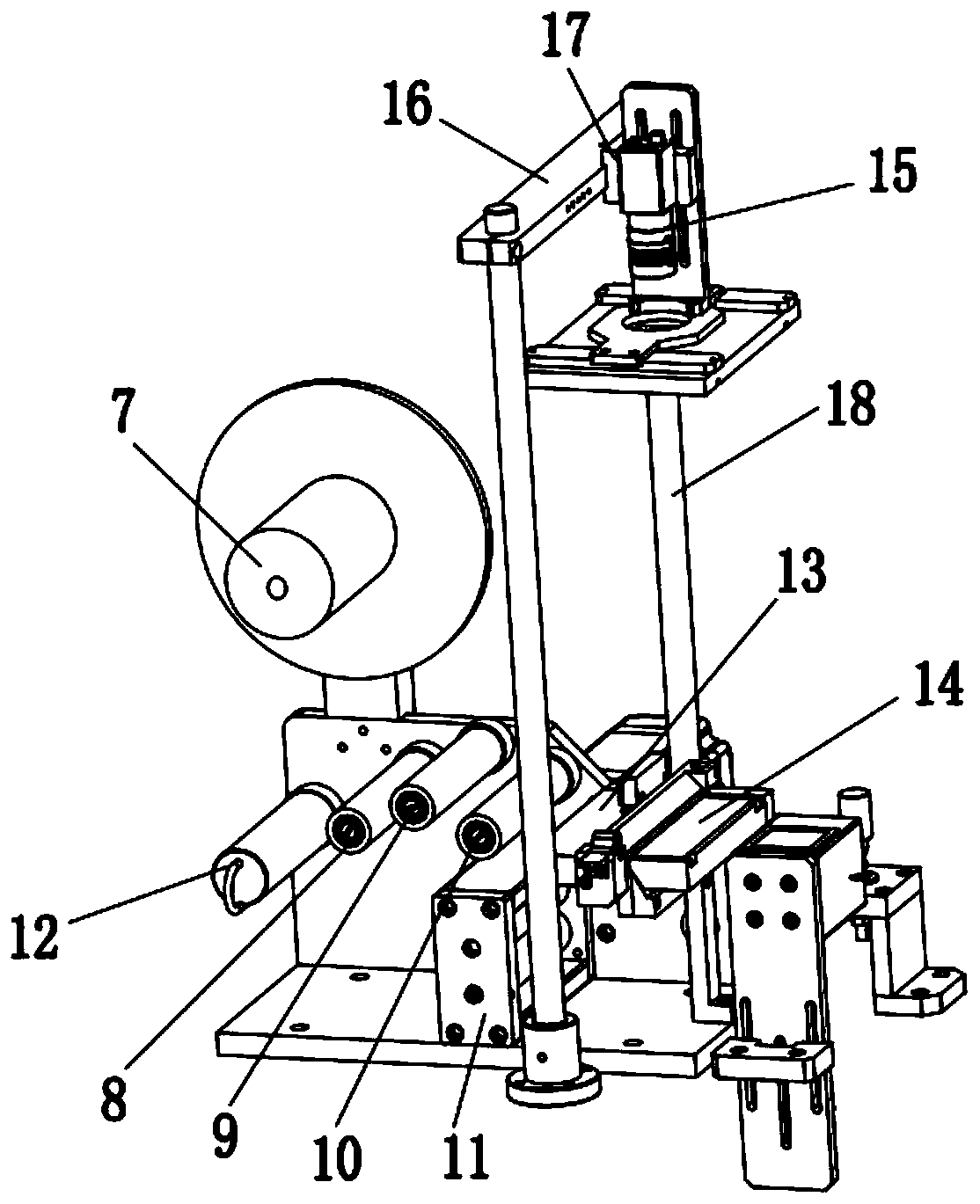

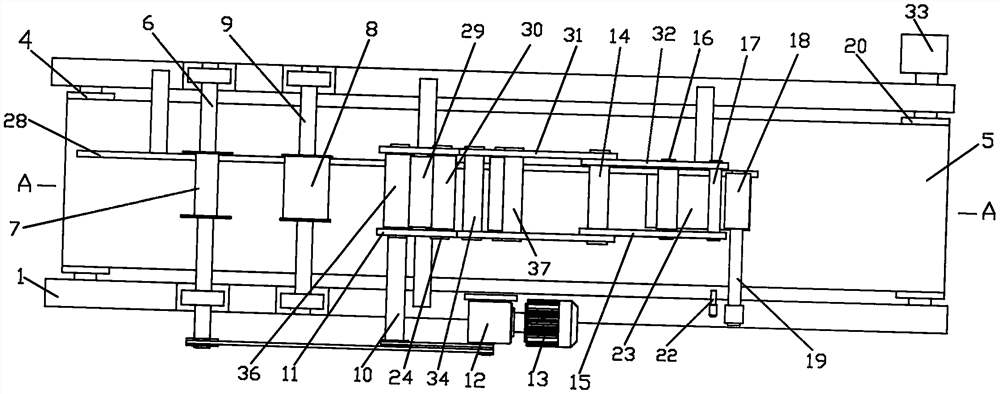

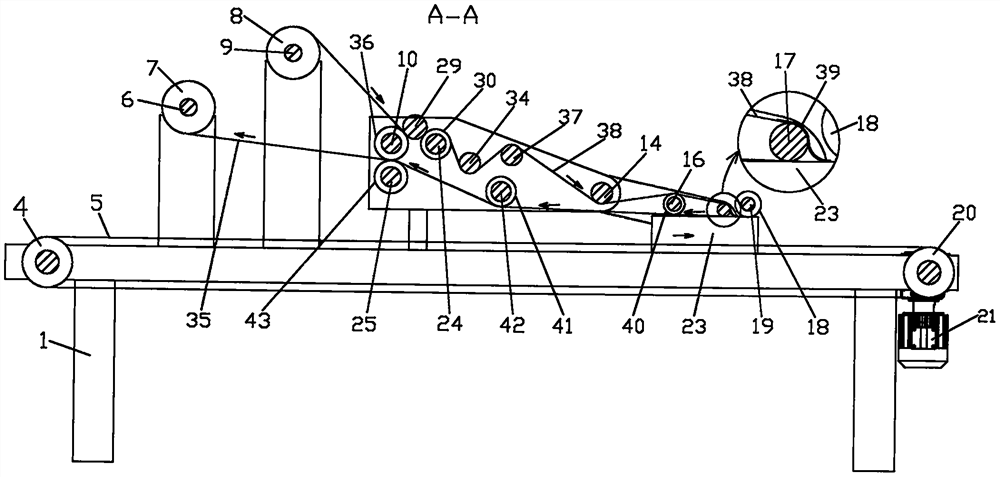

Labeling machine

InactiveCN105923226AEasy labelingAvoid missed stickersLabelling machinesPressure sensitiveLabelling machine

The invention relates to a labeling machine for pasting a pressure-sensitive adhesive paper label to an object to be labeled. The labeling machine comprises a base, a turning device arranged on the base, a transmission device located in one side of the turning device, a vacuum transmitter connected with the turning device and a card sender containing objects to be labelled. The transmission device comprises a drive device to drive the paper tape for movement and a stripping plate for stripping labels on the paper tape; the label is above the paper tape and the stripping plate; the stripping plate is provided with a stripping end; the paper tape labels is driven by the drive device to move to the stripping end of the stripping plate, until the paper tape driven by the drive device is bent and move along the stripping end, so that the labels and paper tape are gradually separated. The turning device comprises a rotating shaft, a power device for driving the rotating shaft to rotate and a turnover plate arranged on the rotating shaft and rotating with the rotating shaft; the turning plate is provided with a vacuum hole with a downward opening and a vacuum connecting hole communicated with the vacuum hole; and the vacuum connecting hole is connected to the vacuum transmitter.

Owner:KUNSHAN HEXIN PRECISE MACHINERY

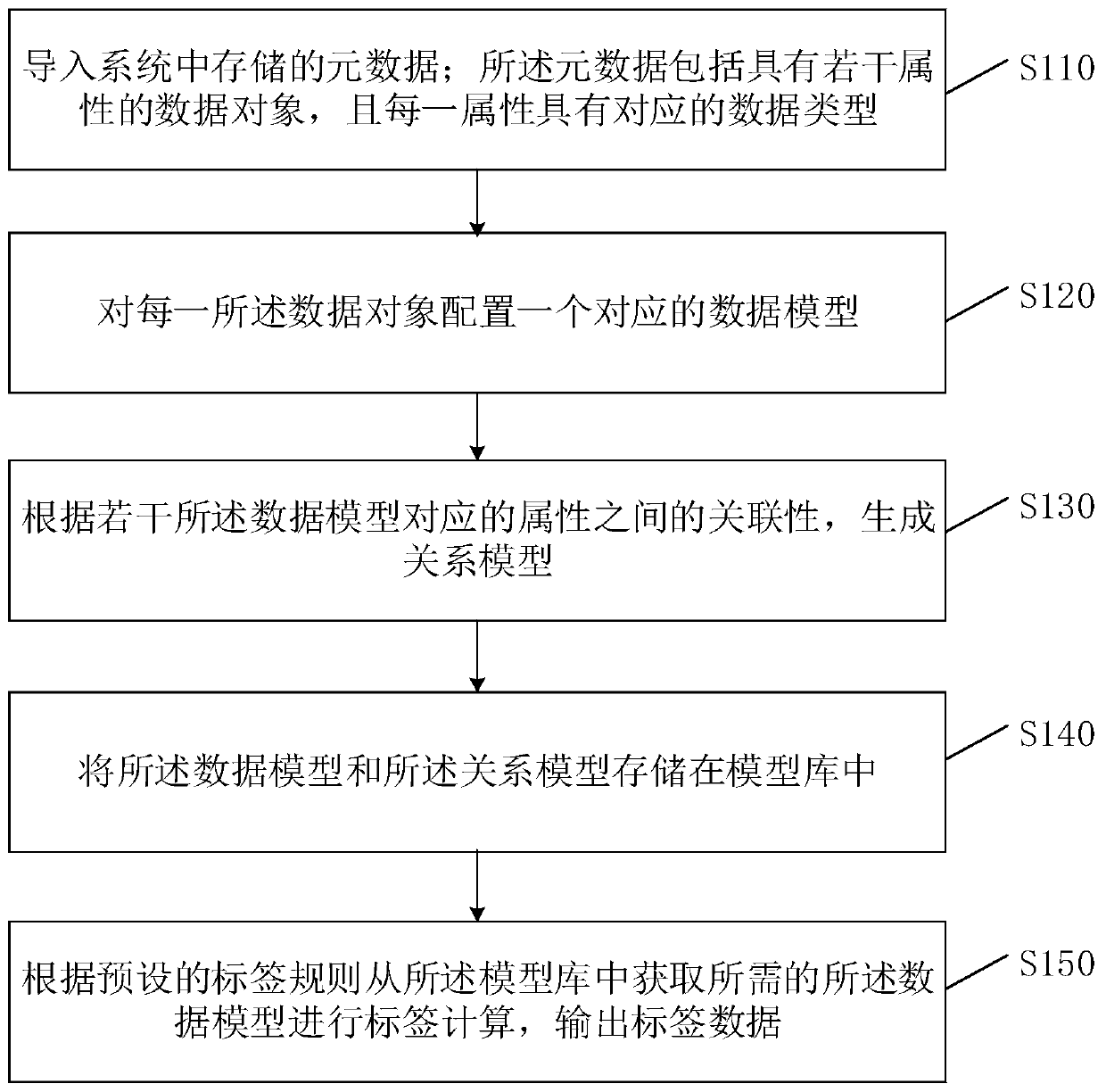

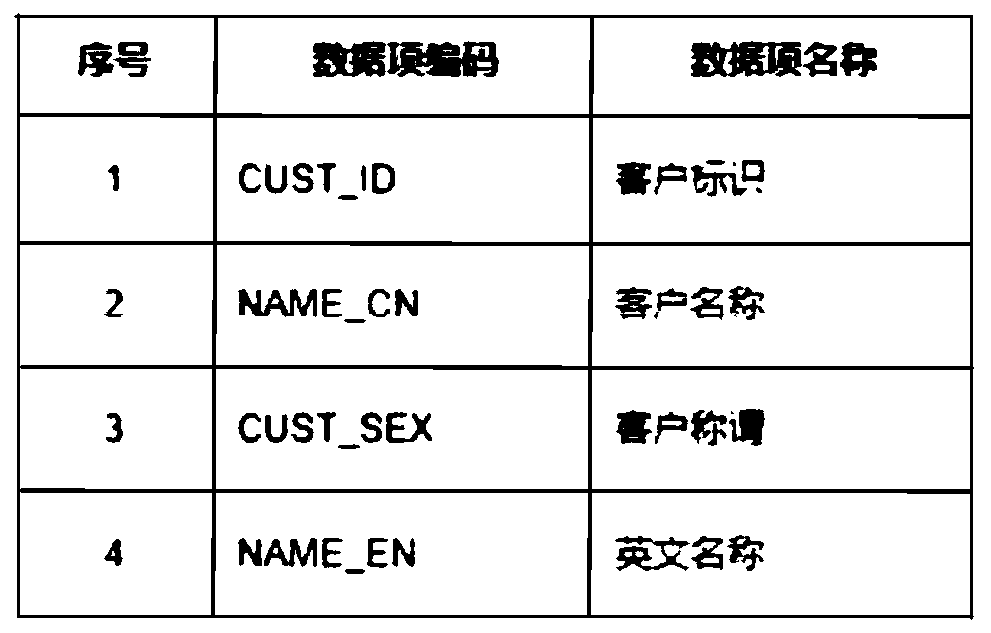

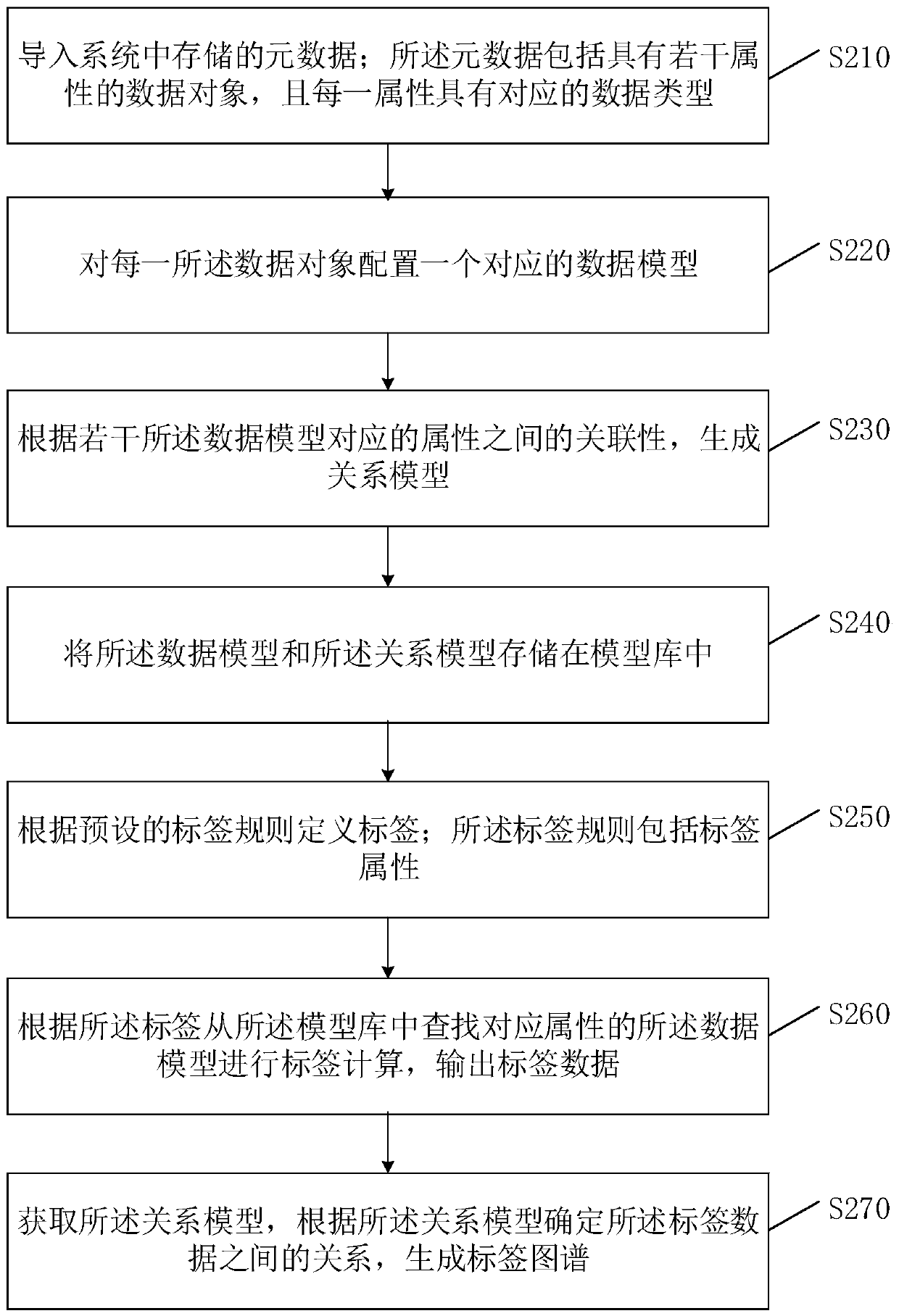

Label generation method and device, computer readable storage medium and server

ActiveCN110765101AEasy to callFlexible adjustmentRelational databasesSpecial data processing applicationsData classGeneration process

The invention belongs to the technical field of data processing, and provides a label generation method and device, a computer readable storage medium and a server. The label generation method includes the steps: importing metadata stored in the system, wherein the metadata comprises a data object with a plurality of attributes, and each attribute has a corresponding data type; configuring a corresponding data model for each data object; generating a relationship model according to the relevance among the attributes corresponding to the plurality of data models; storing the data model and therelationship model in a model library; and obtaining the required data model from the model library according to a preset label rule to perform label calculation, and outputting label data. Accordingto the embodiment of the invention, the imported system data is preprocessed to generate the data model with the corresponding attribute and the relationship model for reflecting the business relationship between the data models, so that the problem that the data script cannot be repeatedly used in the label generation process is solved.

Owner:天云软件技术有限公司

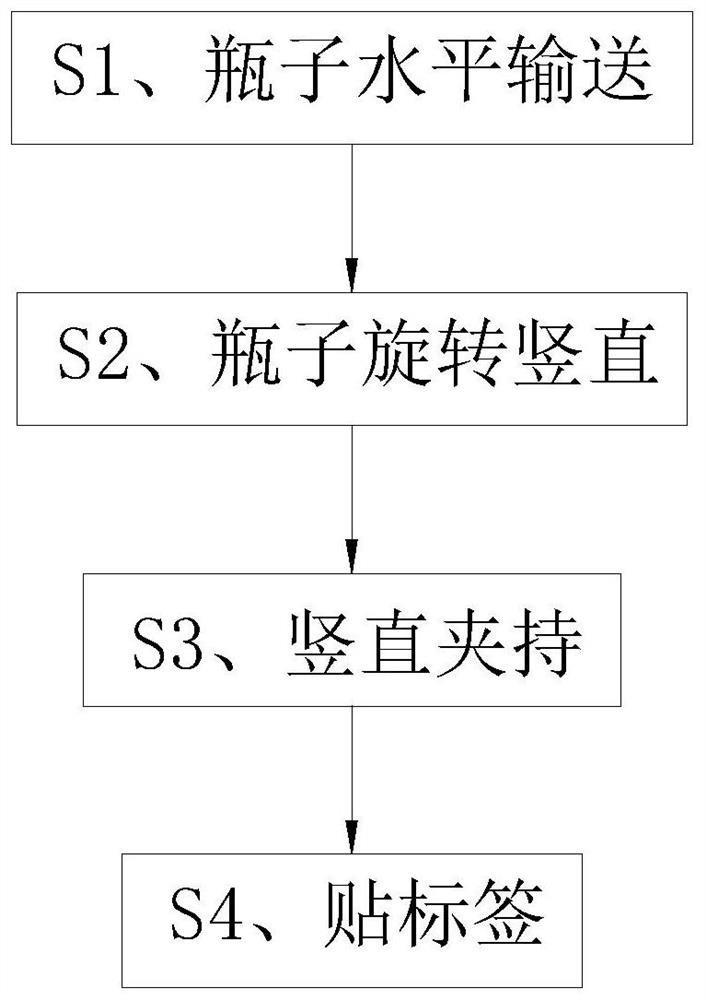

Automatic labeling method

ActiveCN112158431AEasy labelingLabelling machinesLabelling short rigid containersMotor driveAir pump

The invention discloses an automatic labeling method, and particularly relates to an automatic labeling device which can guide a bottle to move by adjusting the width of the automatic labeling device,and the moving position can be limited, so that the bottle can be aligned to be inserted into a lantern ring, a port of the bottle can be inserted into the lantern ring, and the bottle opening is connected with a pressure sensor on an abutting plate. A signal is output to an air pump and inflation is conducted on an air bag. The bottle is clamped after the air bag expands. A sliding block slidesalong a sliding plate and is used for driving the bottle to move to the position over a conveying belt, the motor drives the bottle to rotate by 90 degrees, the bottle falls on the conveying belt after the air bag loosens the bottle, the bottle rotates to the vertical position, subsequent labeling is facilitated, and the bottle moves to a position between rollers. the bottle passes through a relaytrigger rod between a front plate and a right plate, the front plate and the right plate are driven to synchronously slide inwards along a clamping plate, a label tape abuts against one of the rollers, a winding drum rotates to drive the label tape to move, labels on the label tape are abutted by the rollers and attached to the bottle body, and thus labeling is completed.

Owner:佛山市盈之泰标签材料有限公司

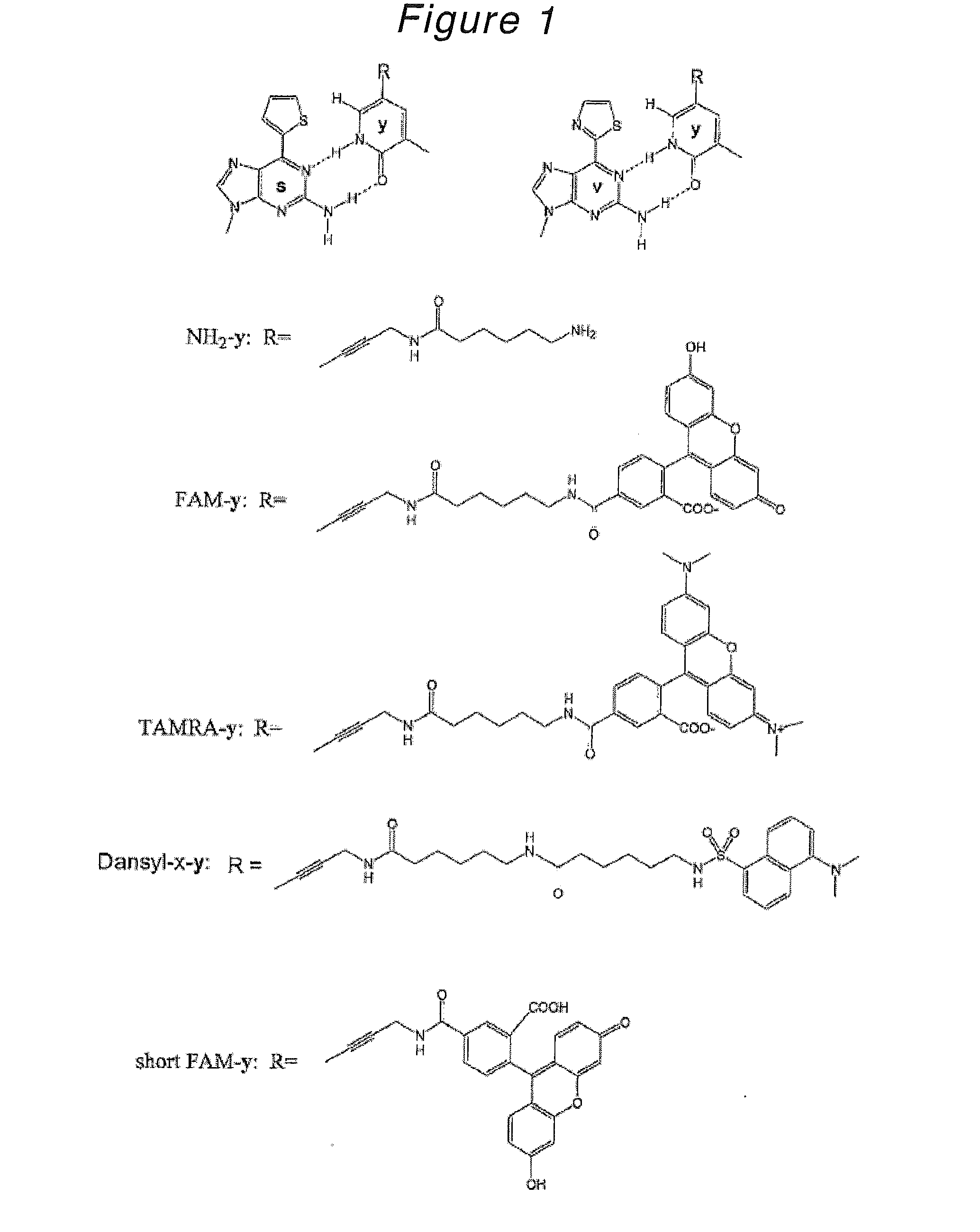

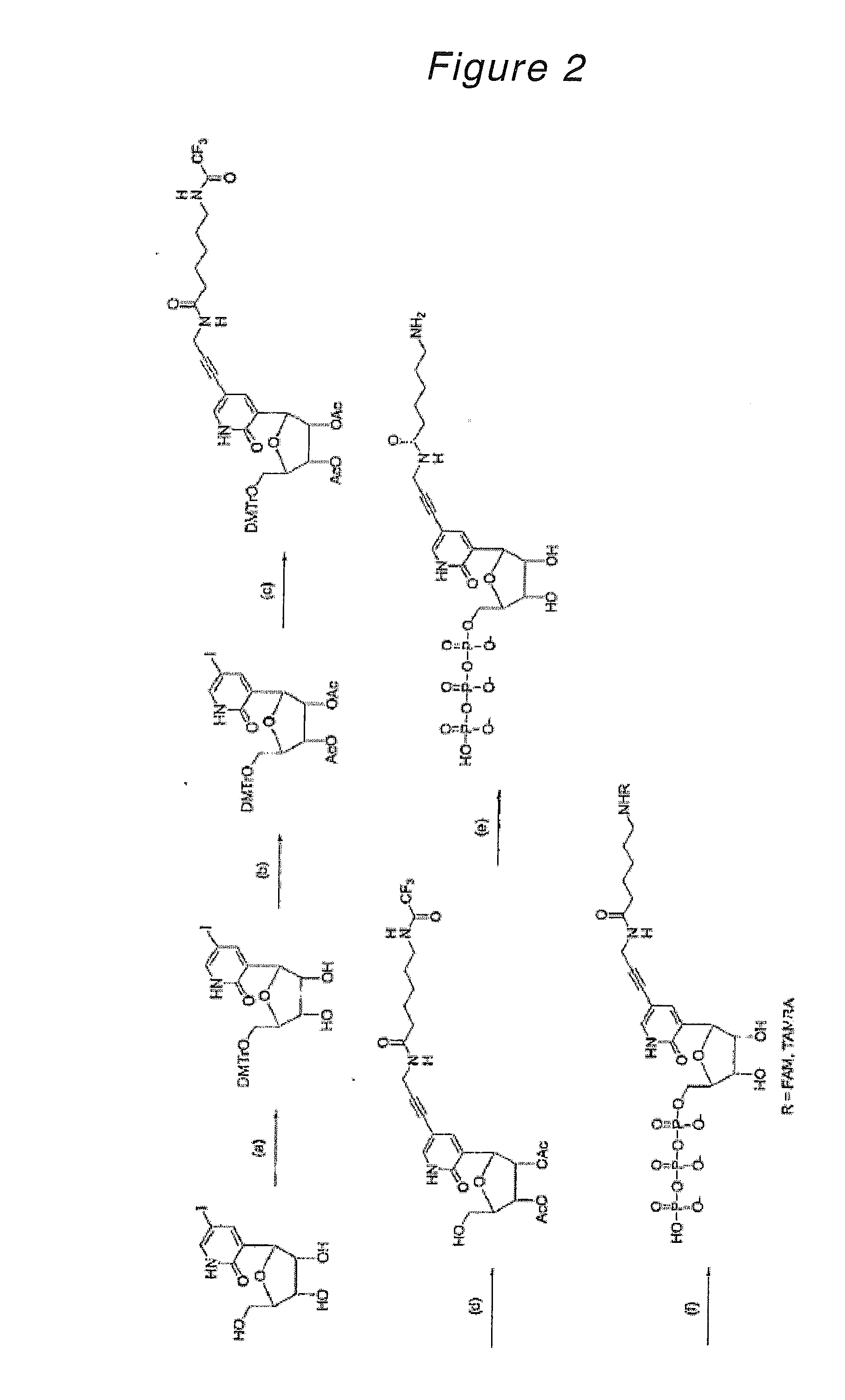

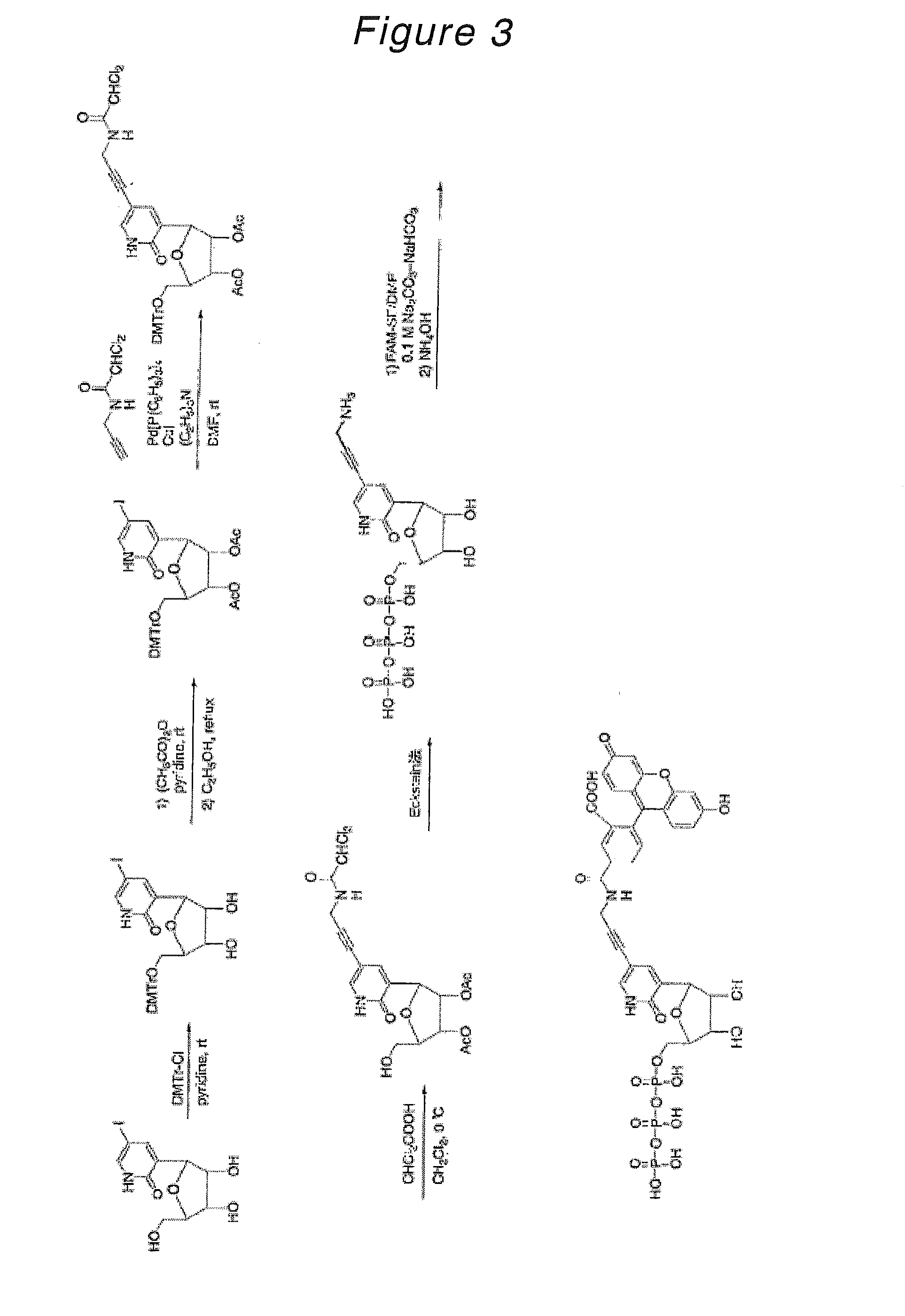

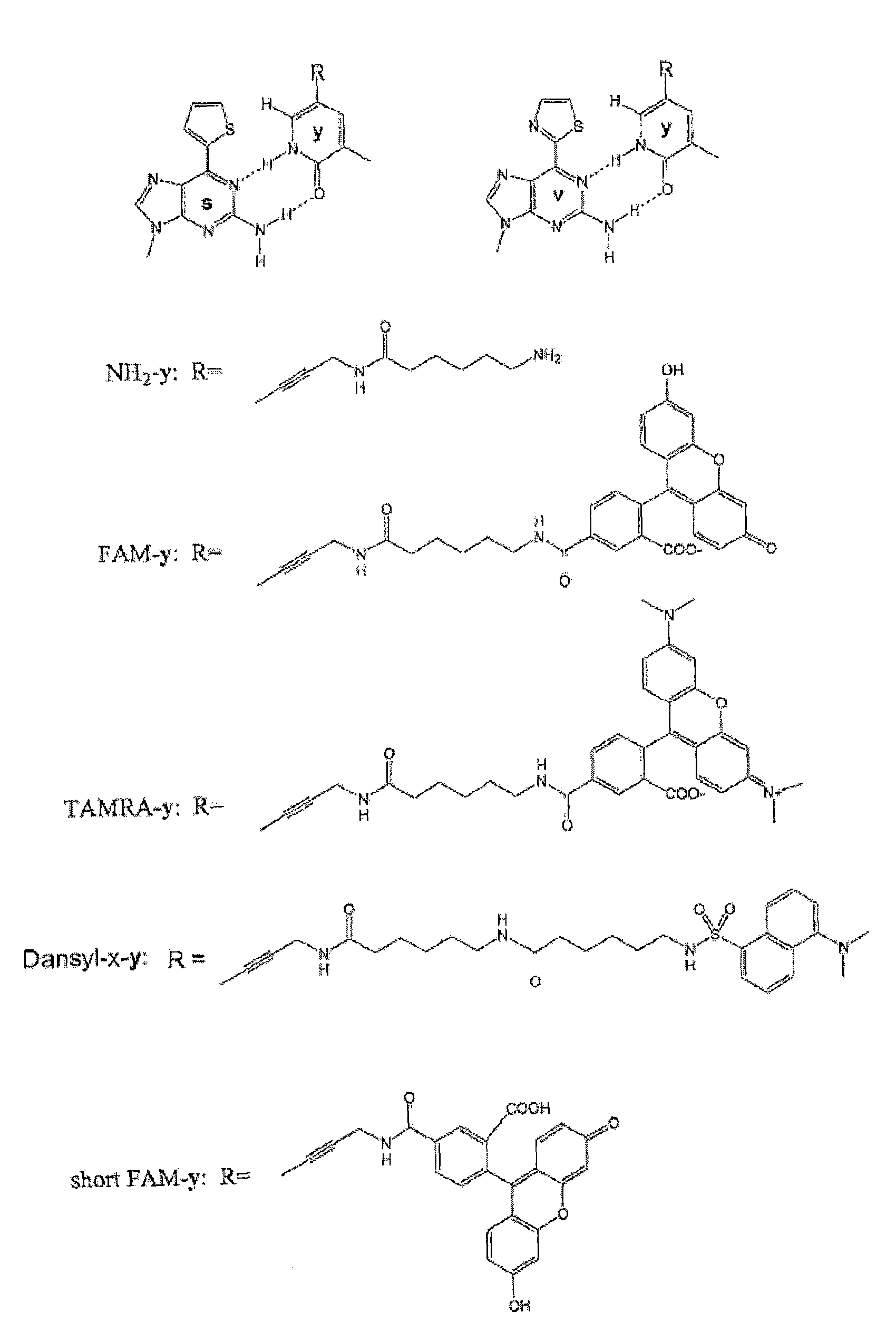

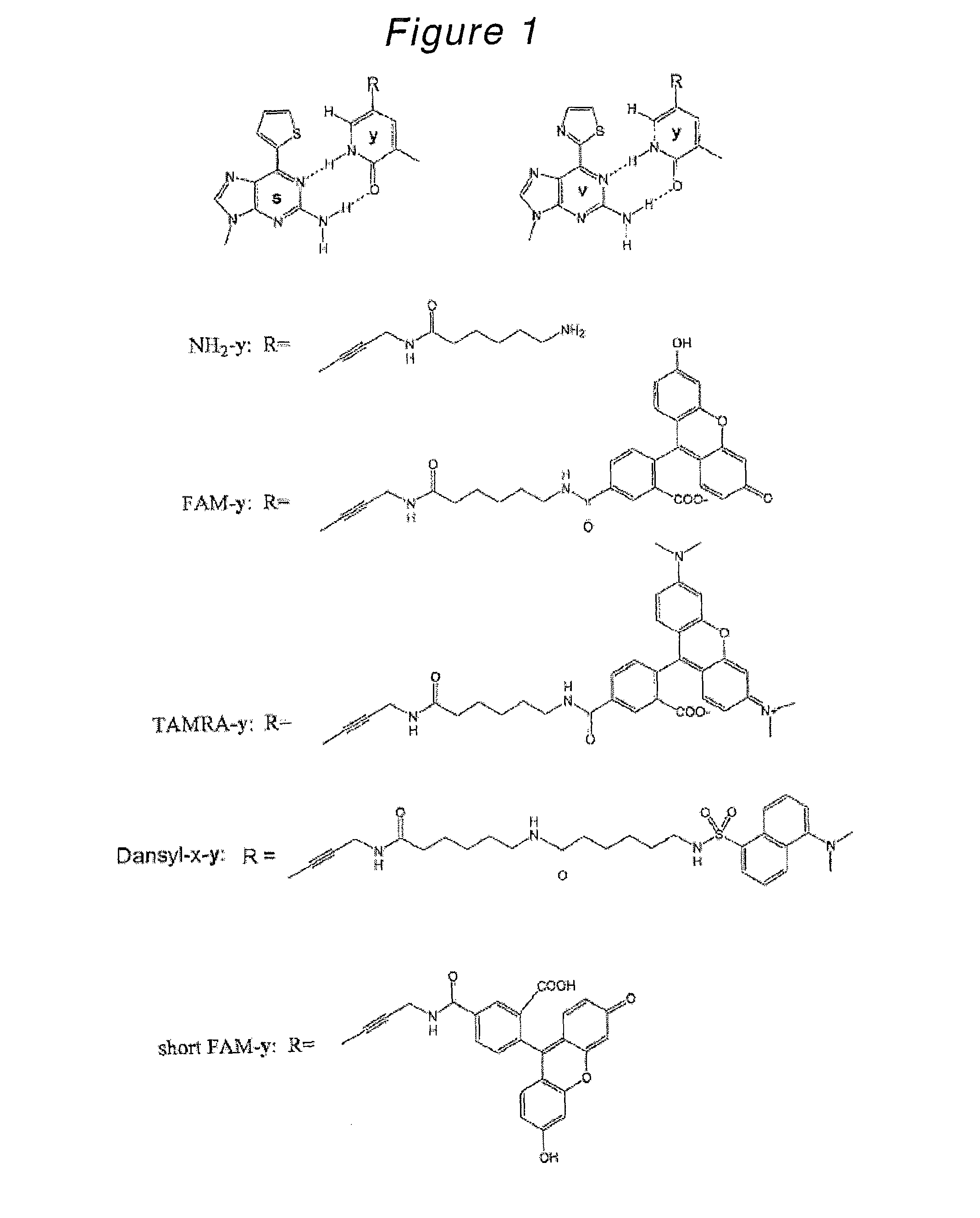

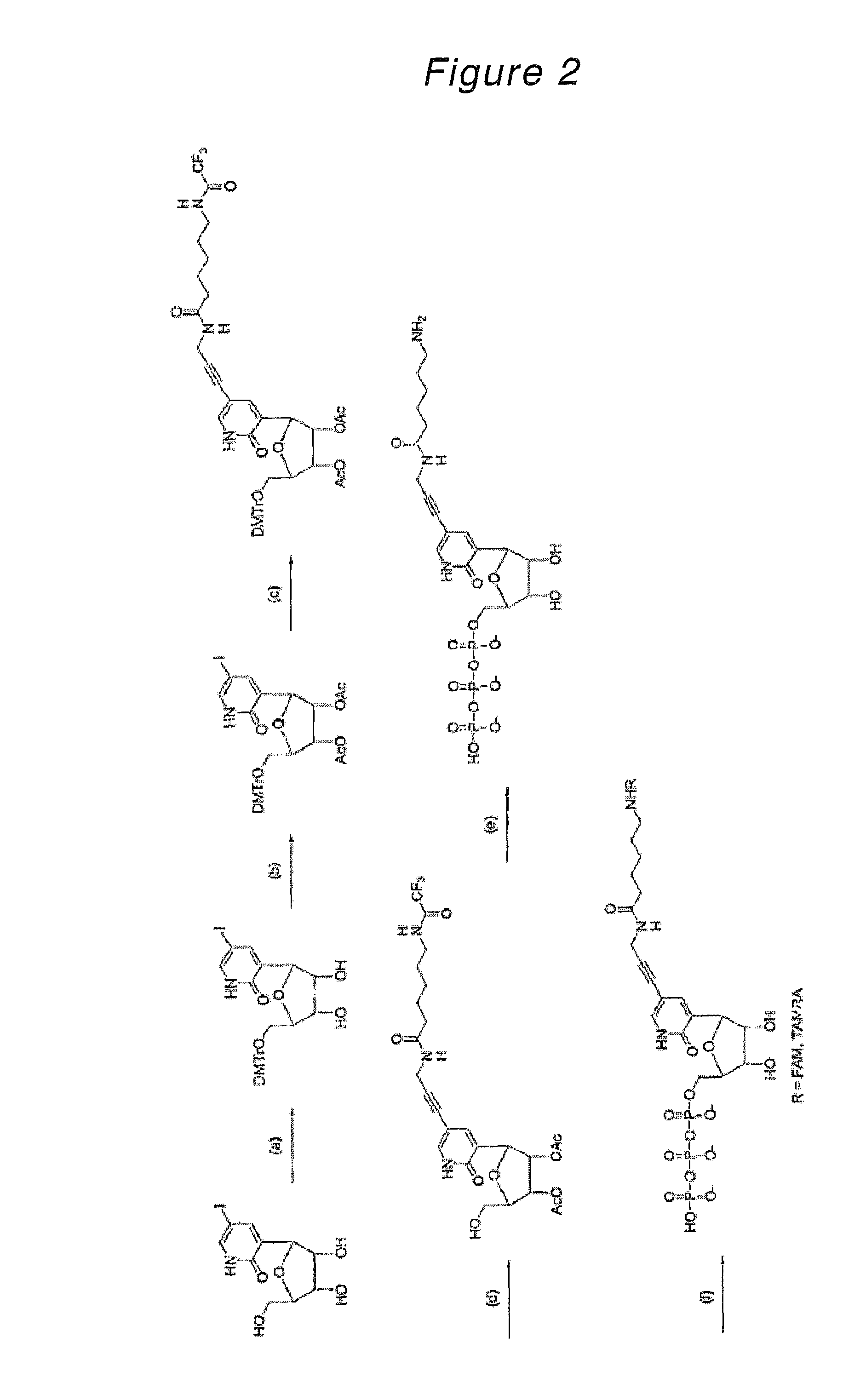

Novel Nucleoside or Nucleotide Derivative and Use Thereof

InactiveUS20090275017A1Improve efficiencyEasy labelingSugar derivativesAntibioticsNucleotidePerylene derivatives

The object of the present invention is to provide a nucleoside or nucleotide having a 5-substituted-2-oxo(1H)pyridin-3-yl group as a base, as well as a method using the same.In one embodiment, the nucleoside or nucleotide of the present invention has a fluorescent dye selected from the group consisting of 5-FAM, 6-FAM, 5-TAMRA, 6-TAMRA, DANSYL, 5-HEX, 6-HEX, 5-TET, 6-TET, 5-ROX and 6-ROX or a quencher dye selected from the group consisting of DABCYL, BHQ1 and BHQ2, which is attached either directly or through a linker to the 5-position of the above base.

Owner:RIKEN

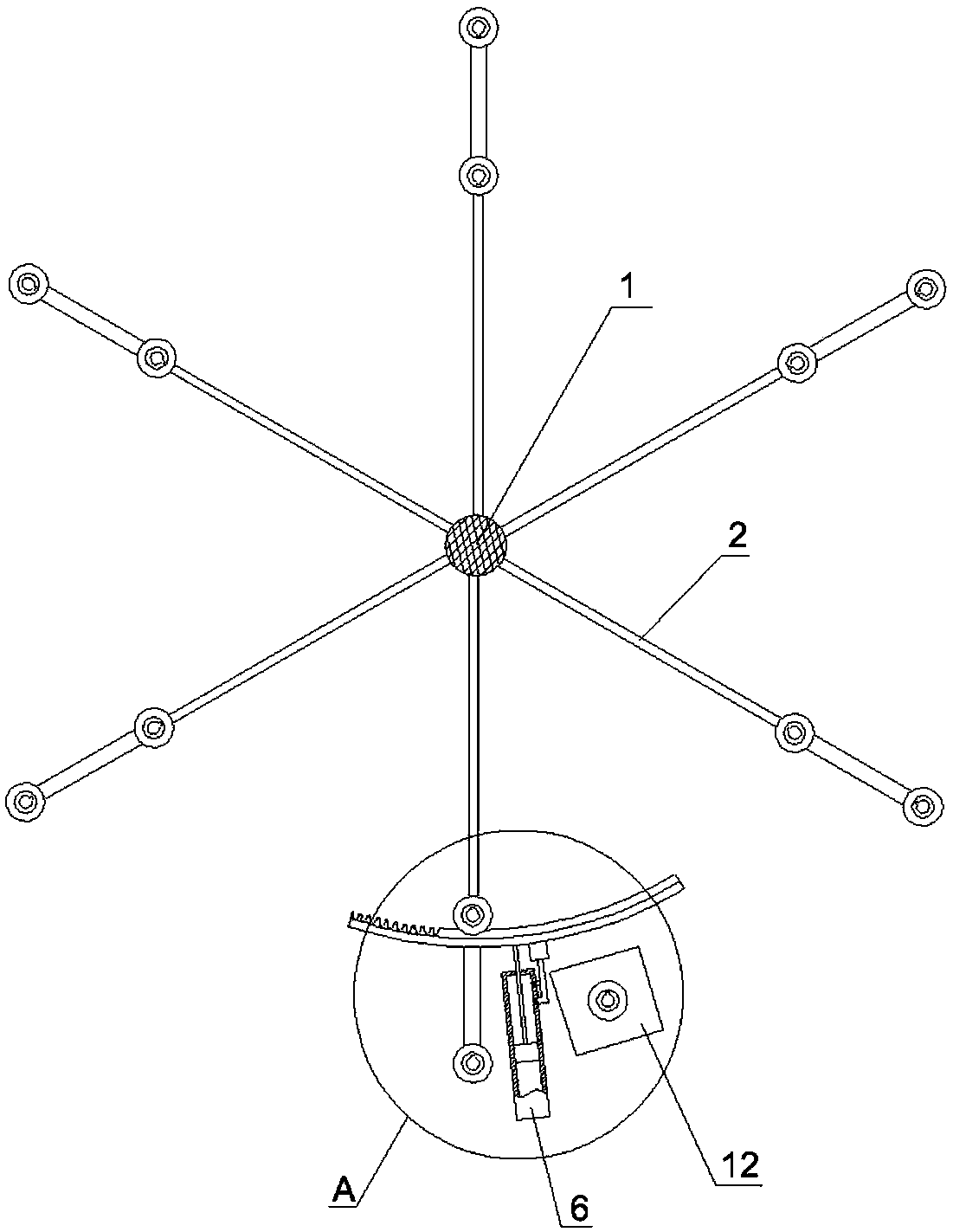

Labeling machine used for advertisement printing

The invention belongs to the field of advertisement printing, and specifically discloses a labeling machine used for advertisement printing. The labeling machine comprises a rack, wherein a labeling machine body and a transmitting mechanism are arranged on the rack; the transmitting mechanism comprises an arc-shaped rack and a drive shaft; an elastic part is connected between the arc-shaped rack and the rack; the side wall of the arc-shaped rack is fixedly connected with an arc-shaped plate; a gas cavity and a gasbag which communicate with each other are connected on the arc-shaped plate; a plurality of connecting rods are fixedly connected on the outer edge of the drive shaft; rotary shafts are rotatably connected on the connecting rods; gears which can be engaged with the arc-shaped racksleeve the rotary shafts; the gears are fixedly connected with a placing disc for placing products; a torsion spring is further connected between the rotary shaft and each connecting rod; the pressure rollers sleeve the rotary shafts; the pressure rollers are tangential to the arc-shaped plate; a piston cavity is further fixedly connected on the rack; a piston is in sliding connection in the piston cavity; the piston is fixedly connected with a piston rod; and the piston rod is fixedly connected with the arc-shaped rack. The labeling machine can solve the problem that product rotating operation is troublesome when an existing labeling machine labels.

Owner:重庆新锐科技服务有限公司

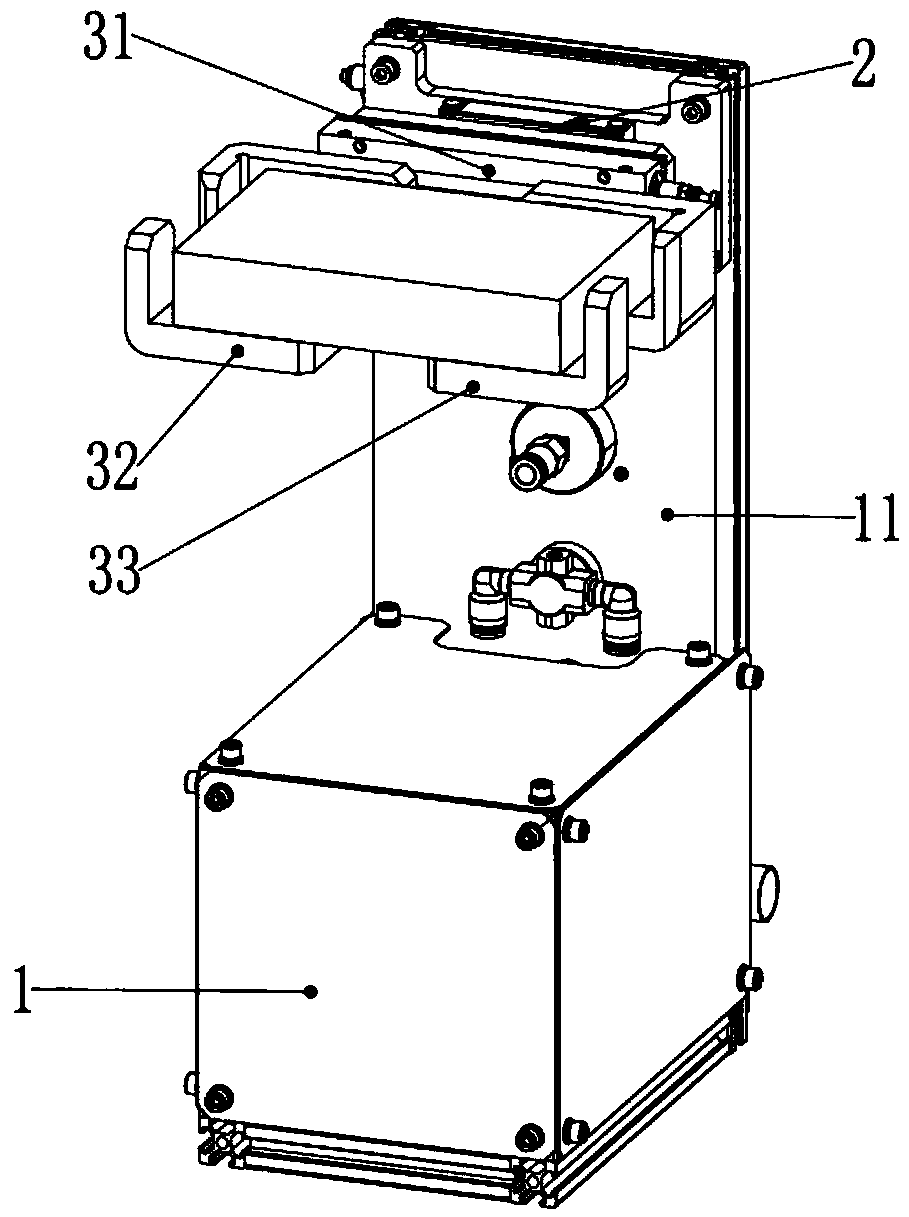

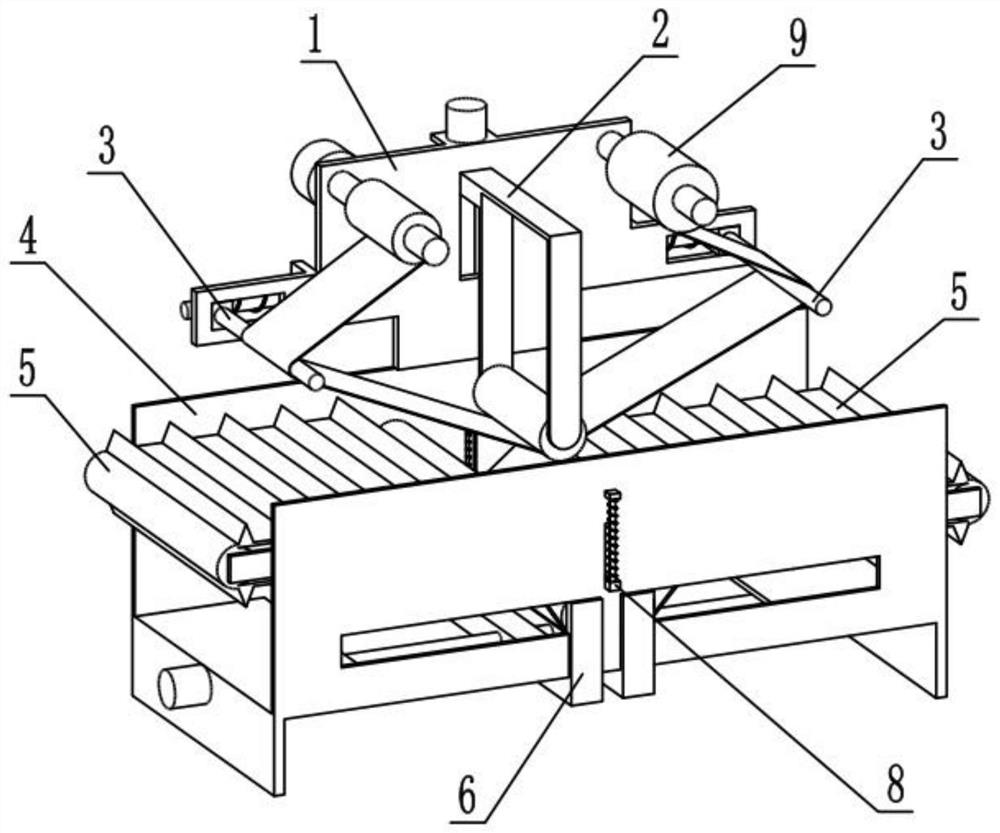

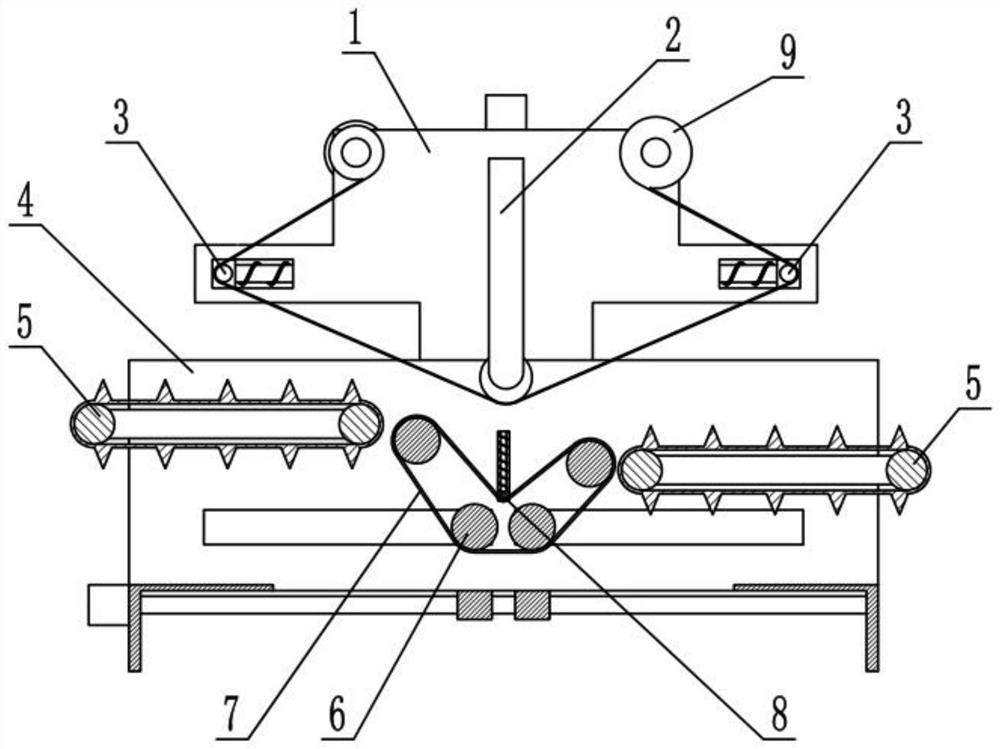

Color box position shifting machine

PendingCN109606879AMeet the labeling needs of different positionsFast labelingLabelling flat rigid surfacesLabelling machinesEngineeringMechanical engineering

The invention discloses a color box position shifting machine. The color box position shifting machine comprises a base, a turnover device and a clamping device; any side of the base is provided witha back plate extending upwardly, the turnover device is mounted on the plate surface of the back plate, the clamping device is connected with the turnover device, and the turnover device is used for rotating the clamping device; the clamping device comprises a clamping seat, a first clamping member and a second clamping member, the first clamping member and the second clamping member realize positioning and clamping of a color box through relative sliding, and the first clamping member and the second clamping member are both provided with labeling notches; and the clamping device further includes a driving device, and the driving device is used for driving sliding of the first clamping member and the second clamping member on the clamping seat. According to the color box position shiftingmachine, shifting of the color box at different angles can be realized, the labeling requirements of different positions are met, the labeling speed is improved, and the production efficiency of products is improved.

Owner:FOSHAN KINGPENG ROBOT TECH CO LTD

Animal ear tag capable of performing photoluminescence

InactiveCN102690510AExplore Activity HabitsEasy labelingAnimal husbandryPhotoluminescenceIrradiation

The invention relates to an animal ear tag capable of performing photoluminescence. The animal ear tag can still emit light continuously after exciting light stops irradiation, does not consume electric energy, can store the absorbed natural light, takes on bright and differentiable visible light, has a lighting function and can mark animals at night conveniently. The animal ear tag has the characteristics of storing light by using sunlight or lamplight and emitting light at night or in dark places. Marks such as characters or patterns and the like on the ear tag can be discriminated without other light sources. The ear tag has advanced, novel and convenient design and high functionality.

Owner:刘庆

Beverage bottle side face labeling device and labeling method

InactiveCN110577002AEasy to useSimple structureLabelling machinesLabelling short rigid containersEngineeringBottle

The invention provides a beverage bottle side face labeling device and a labeling method. The beverage bottle side face labeling device comprises a workbench. A groove wheel rotating mechanism is fixedly connected with right the middle of the upper side of the workbench. A feed port is formed right in the front side of the groove wheel rotating mechanism. A labeling mechanism is installed at the right end of the groove wheel rotating mechanism. A label pressing mechanism is installed at the rear end of the groove wheel rotating mechanism. A discharge mechanical hand and a discharge conveying belt are installed at the left end of the groove wheel rotating mechanism. A V-shaped supporting block is installed on each groove wheel of the groove wheel rotating mechanism. The discharge mechanicalhand is installed on the upper side of the rear end of the discharge conveying belt. A feed port of the discharge conveying belt is located on the left side of the left side groove wheel of the groove wheel rotating mechanism. The beverage bottle side face labeling device is convenient to use and simple in structure and is a labeling device for labeling beverage bottle bodies; and the beverage bottle side face labeling device can ensure the height consistency of labels attached to the bottle bodies in use, is high in efficiency and can have a certain protection effect on the bottle bodies inthe label pressing process.

Owner:李媛媛

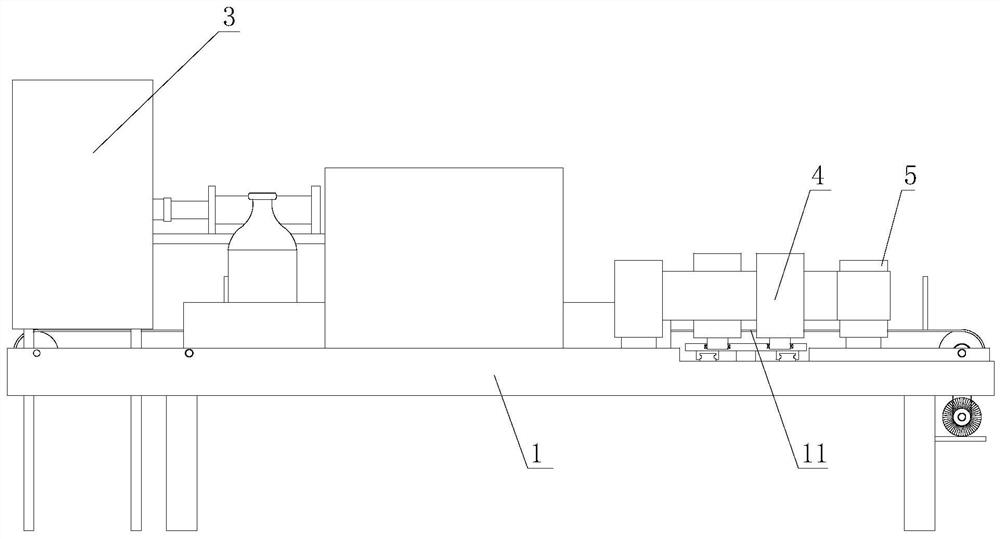

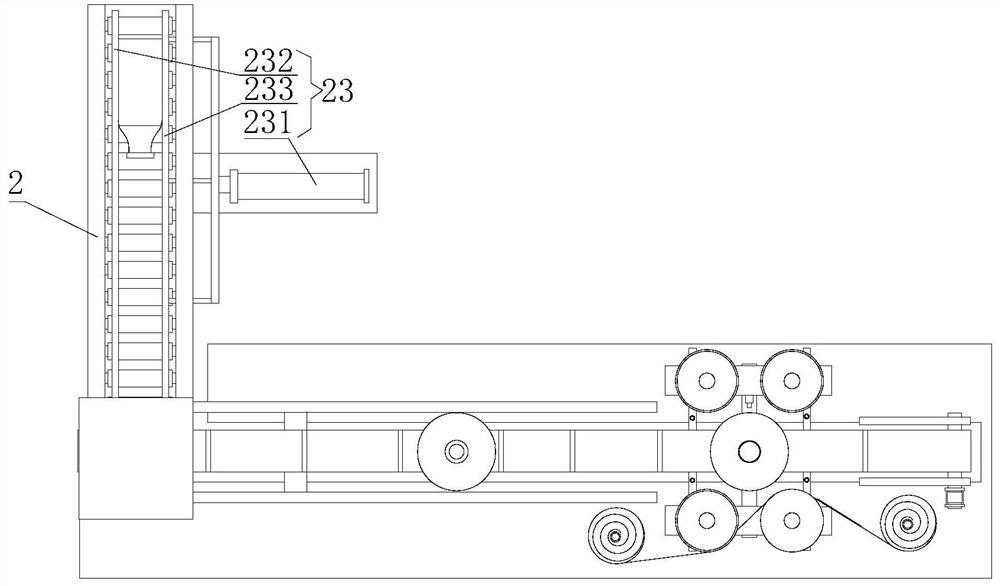

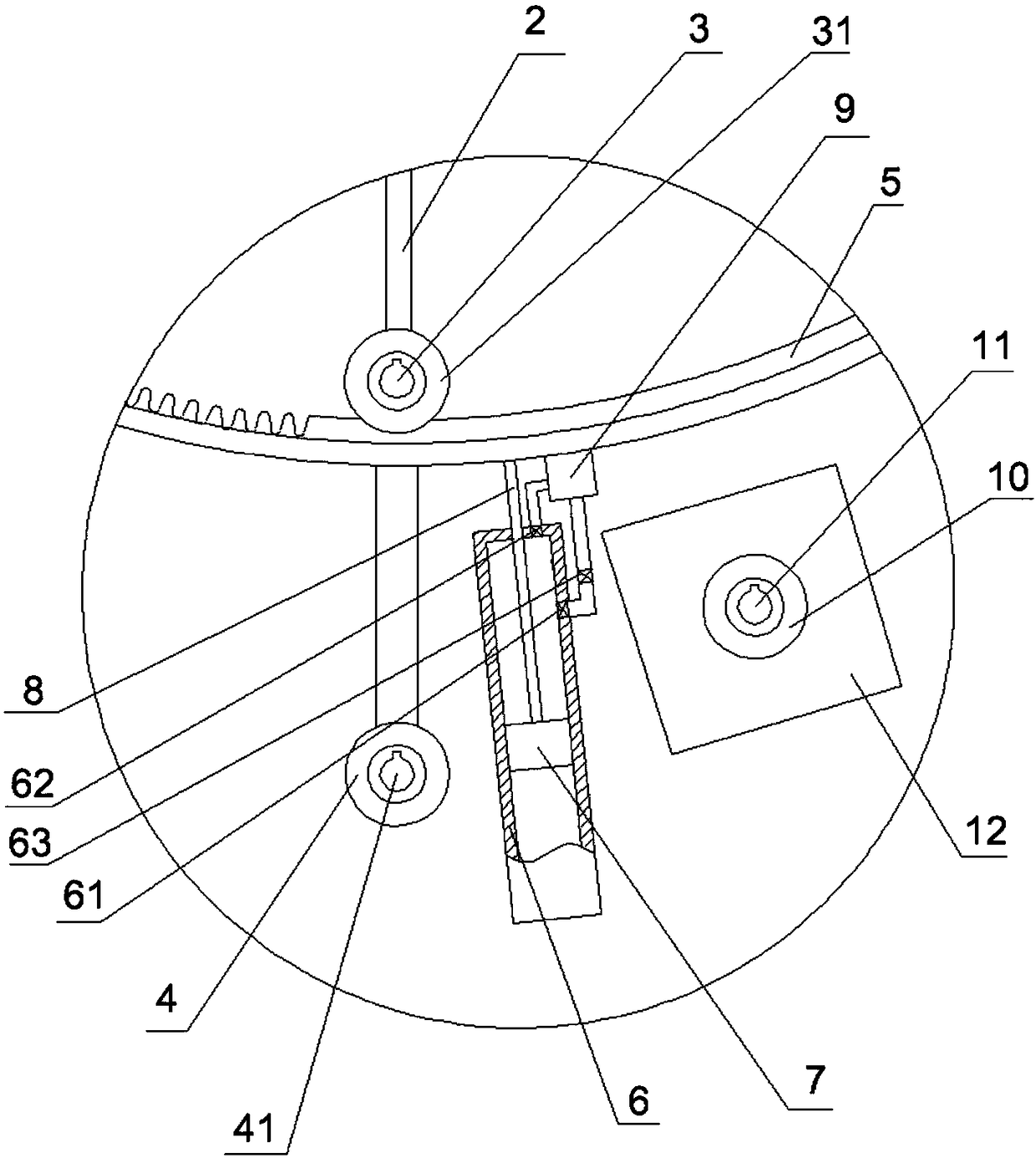

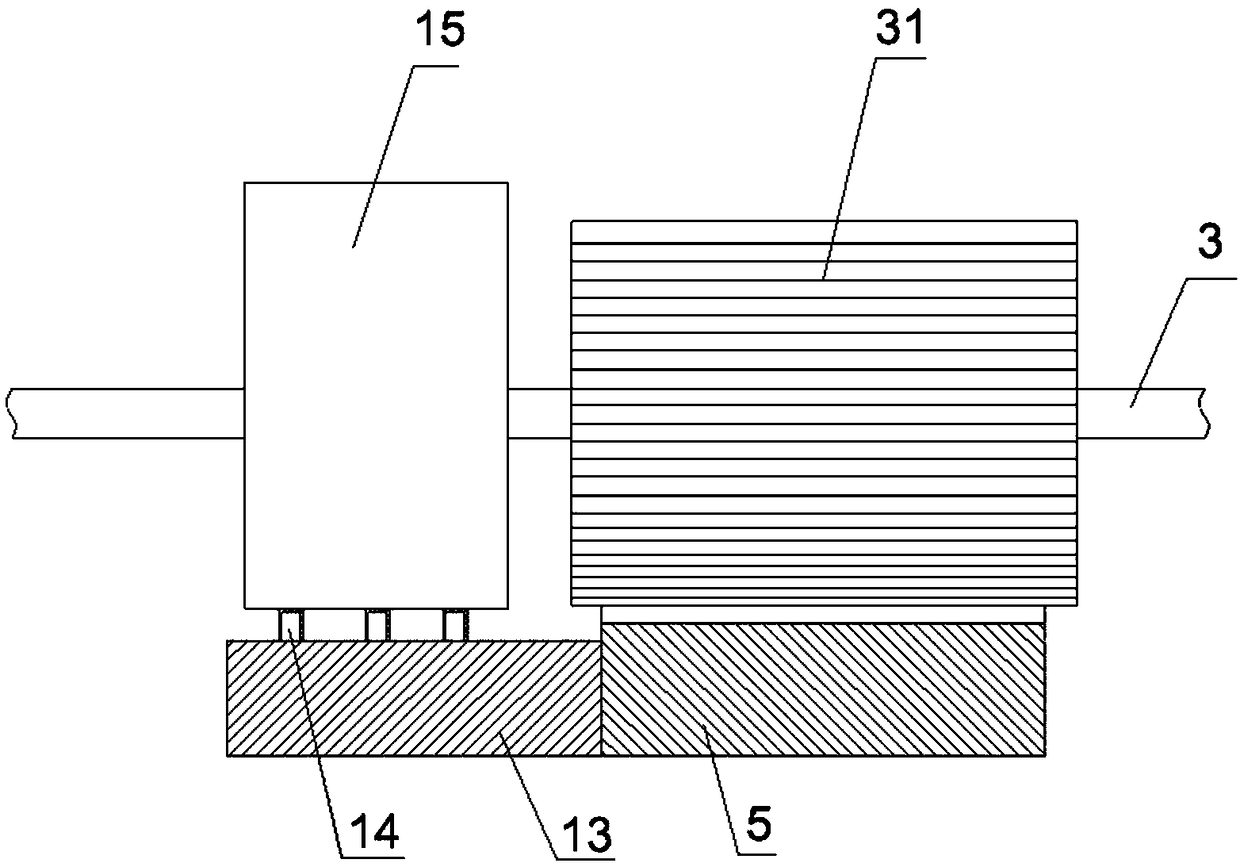

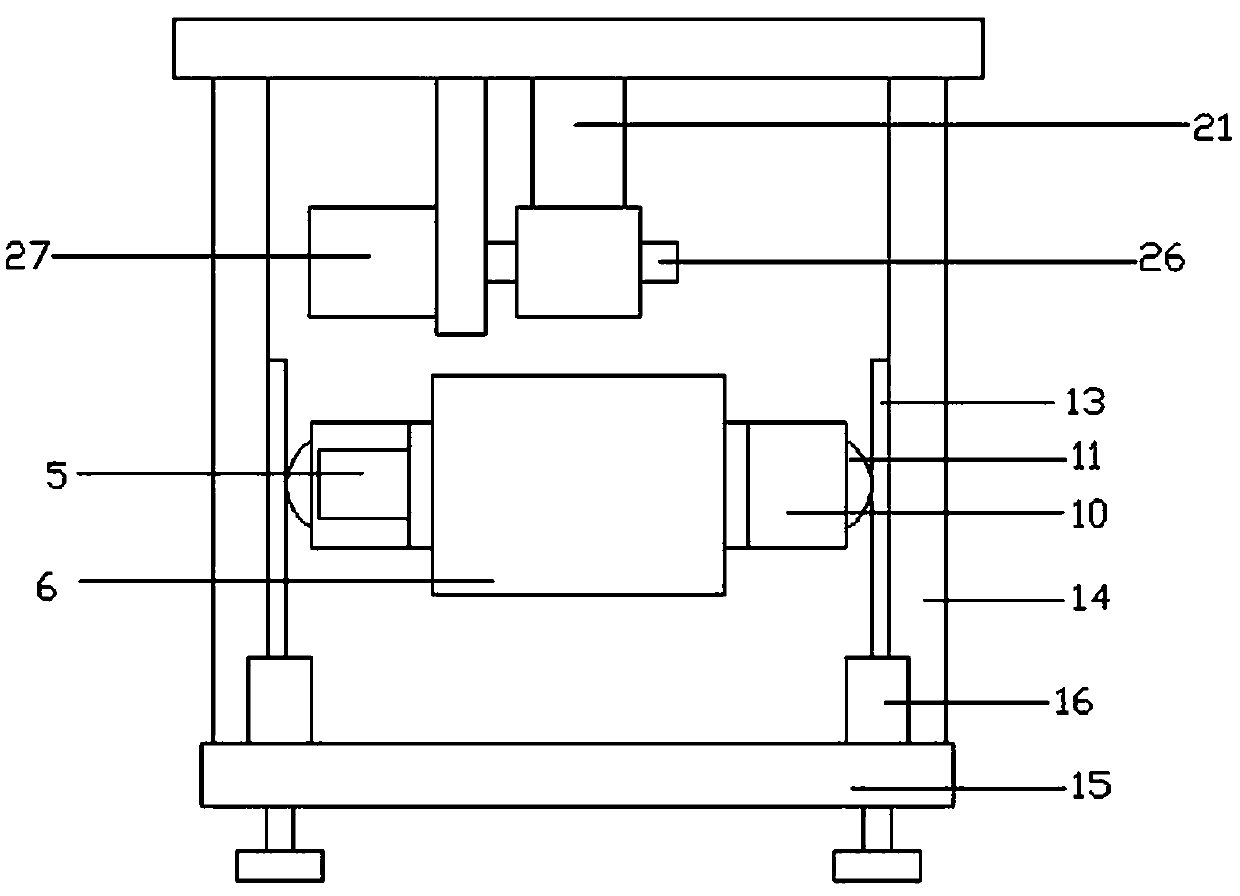

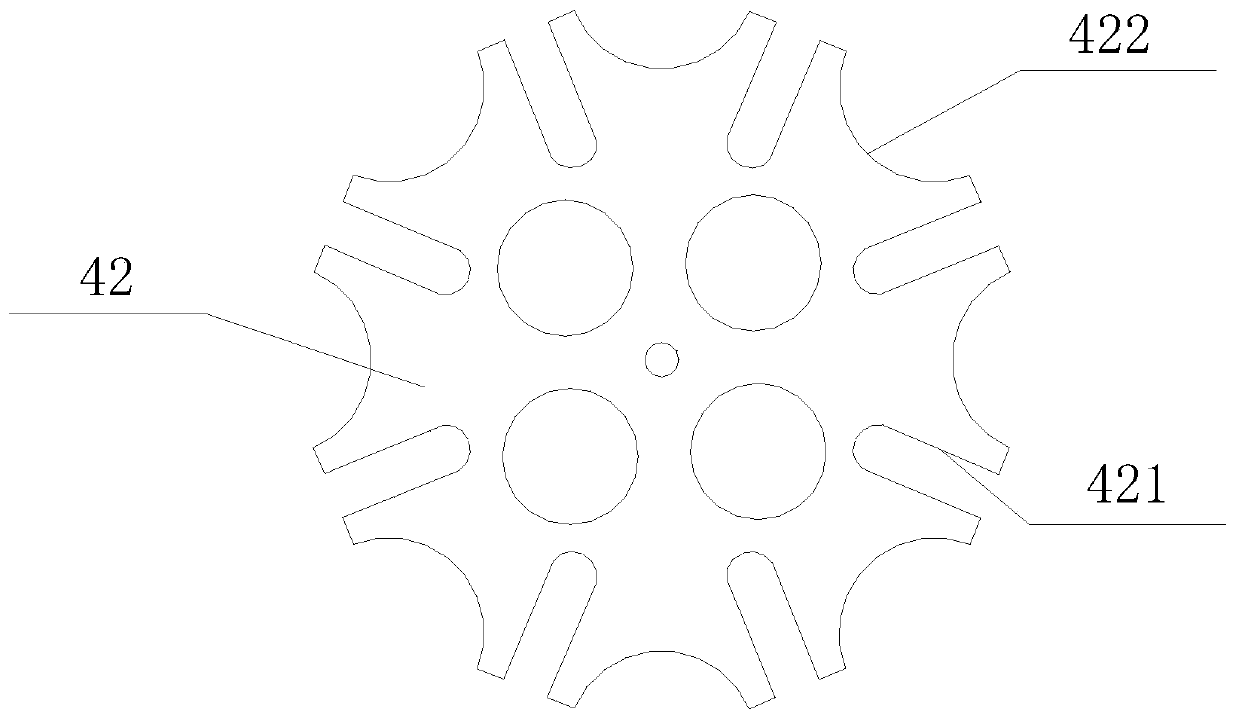

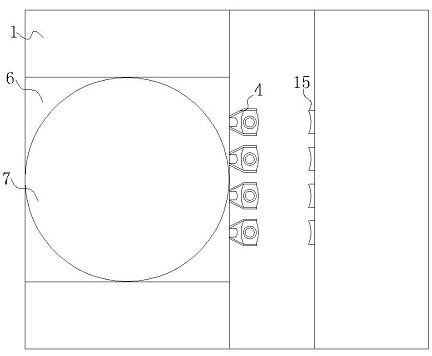

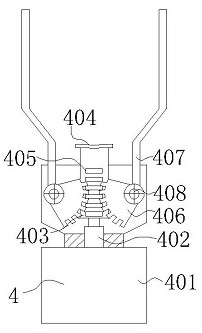

High-speed bottle arrangement device

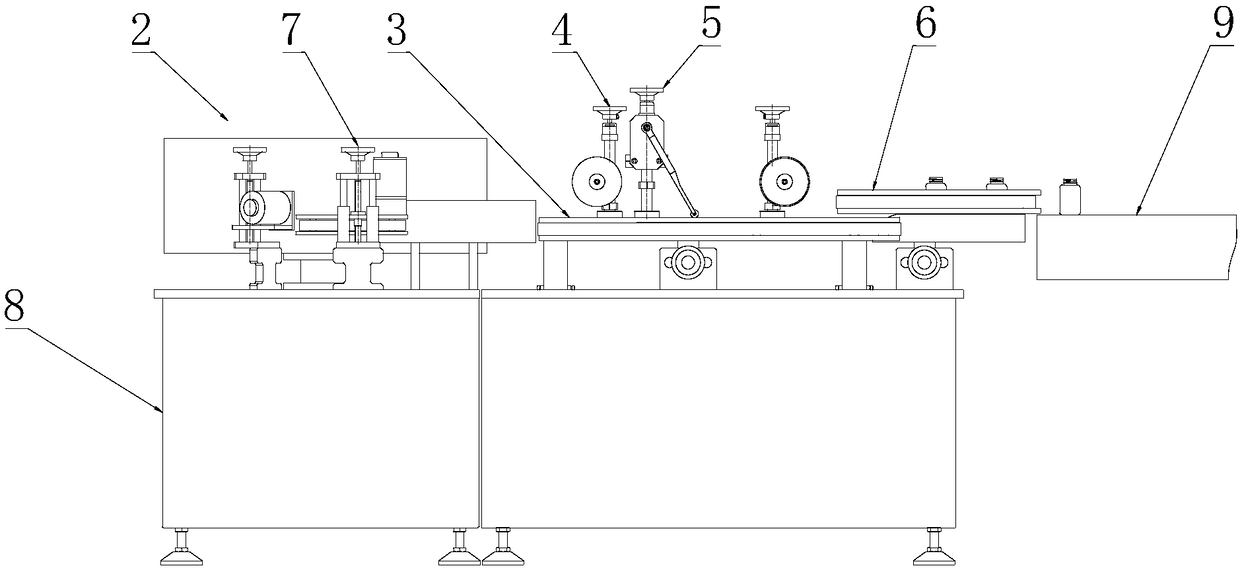

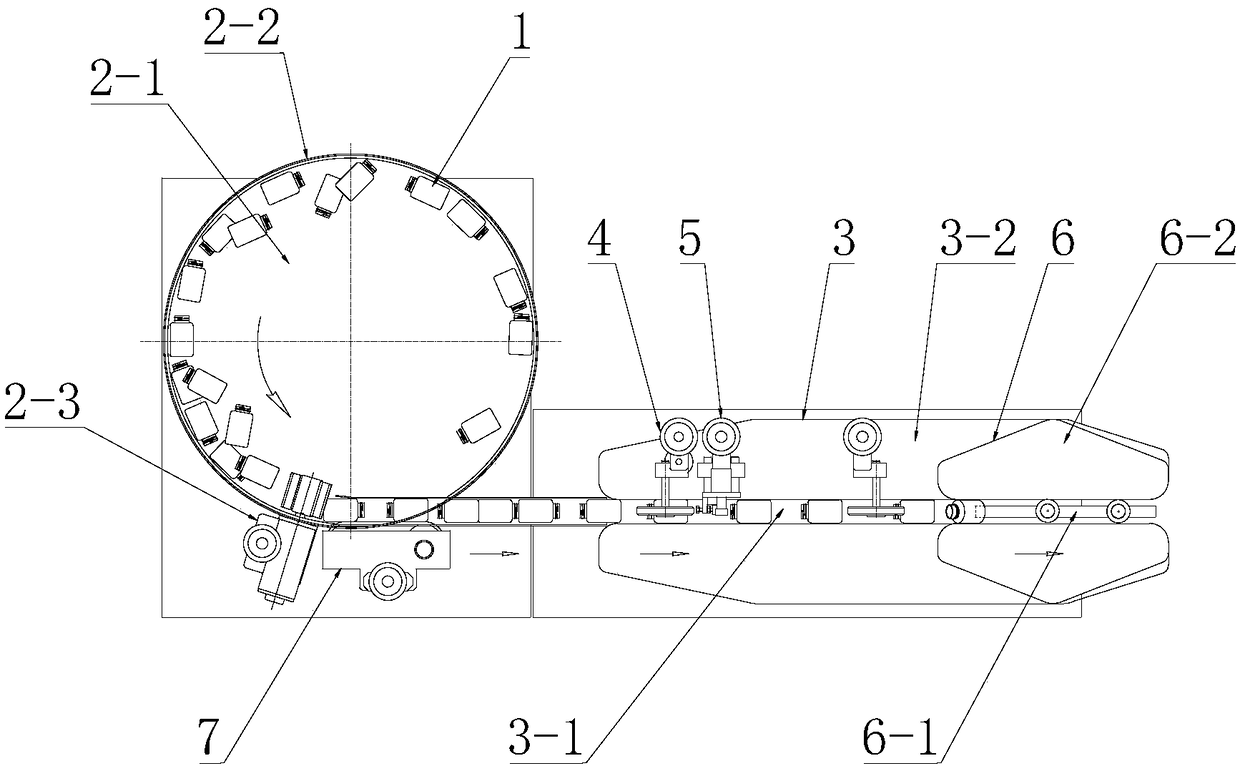

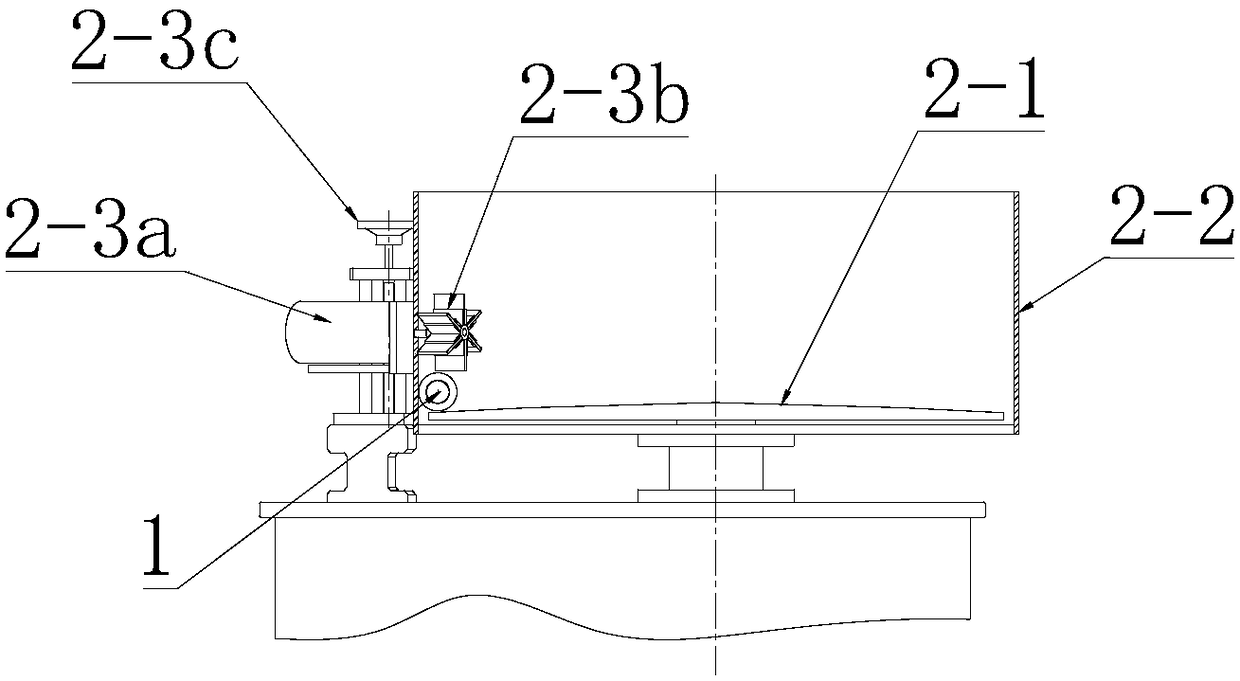

ActiveCN108609372AFor subsequent fillingEasy labelingPlastic recyclingConveyor partsOutput deviceEngineering

The invention discloses a high-speed bottle arrangement device. The high-speed bottle arrangement device comprises a bottle output device (2), a bottle conveying device (3), a bottle pressing mechanism, a direction adjustment device (5) and a bottle overturning device (6), wherein the bottle output device (2) is used for arranging bottles (1) and outputting the bottles (1) one by one; the bottle conveying device (3) is arranged at the bottle output end of the bottle output device (2) and used for conveying the bottles (1); the bottle pressing mechanism is arranged at one side of the bottle conveying device (3), comprises at least two bottle pressing devices (4) arranged in the bottle conveying direction of the bottle conveying device (3), and is used for pressing the bottles (1) and enabling the bottles (1) to be in a lying state; the direction adjustment device (5) is arranged at one side of the bottle conveying device (3) and located between the two bottle pressing devices (4), and is used for adjusting the orientation of facing the downstream part of a bottle conveying direction, of the bottle openings of the bottles (1), to the orientation of facing the upstream part of the bottle conveying direction; and the bottle overturning device (6) is arranged at the outlet end of the bottle conveying device (3), and used for adjusting the bottle openings of the bottles (1) to be upward. The bottle arrangement device provided by the invention is capable of outputting the bottles one by one and adjusting the bottle openings to be upward, and high in efficiency, and the manual investment is reduced.

Owner:南通恒力包装科技股份有限公司

Rapid labeling device for wear-resistant basketball sock processing

PendingCN110155444AImprove work efficiencyEasy labelingLabelling deformable materialsSupporting framesWear resistantAgricultural engineering

The invention relates to the field of wear-resistant basketball sock processing, in particular to a rapid labeling device for wear-resistant basketball sock processing. The rapid labeling device comprises a mounting plate; the left end and the right end of the mounting plate are provided with first grooves respectively; a conveying roller is connected to the interior of each first groove through afirst connecting shaft; a conveyor belt is connected to the outer sides of the conveying rollers at the left end and the right end; the front side and the rear side of the mounting plate are providedwith up-down adjusting devices respectively; the outer side of a rack on each up-down adjusting device is connected with a supporting column; the lower side of each supporting column is fixedly provided with a bottom plate; a supporting plate is fixedly connected to the upper side of each supporting column; the middle part of the lower side of each supporting plate is provided with a hydraulic telescopic rod; and the lower side of the hydraulic telescopic rod is fixedly provided with a push plate. By adopting the rapid labeling device provided by the invention, rapid labeling treatment of a wear-resistant basketball sock can be effectively and conveniently performed, so that the working efficiency of equipment is improved, and use of people is facilitated.

Owner:湖南莎丽袜业股份有限公司

Automatic packaging device for colored crepe paper

InactiveCN111377283AEasy to carryAdjustable tightnessPaper article packagingFolding thin materialsCrêpe paperIndustrial engineering

The invention belongs to the technical field of crepe paper packaging, and provides an automatic packaging device for colored crepe paper. The automatic packaging device for the colored crepe paper comprises a bearing frame, an adjusting roller, a paper pressing roller, a labeling device and a folding device; the labeling device comprises an eccentric member, a driven member, a rotating plate anda circulating moving device; the folding device comprises a paper bearing device, a drawing device, an edge folding device, a compacting device and a discharging device; and the discharging device comprises a moving rail and a clamping device located on moving rail, the clamping device comprises an upper clamping plate and a lower clamping plate, wherein the upper clamping plate and the lower clamping plate are connected through a shaft, and an air cylinder is arranged on at the end part of the lower clamping plate. The cutting, edge-folding and discharging compacting of the crepe paper can beeffectively achieved, the working efficiency is improved, and the labor cost is reduced.

Owner:青州偶园纸品有限公司

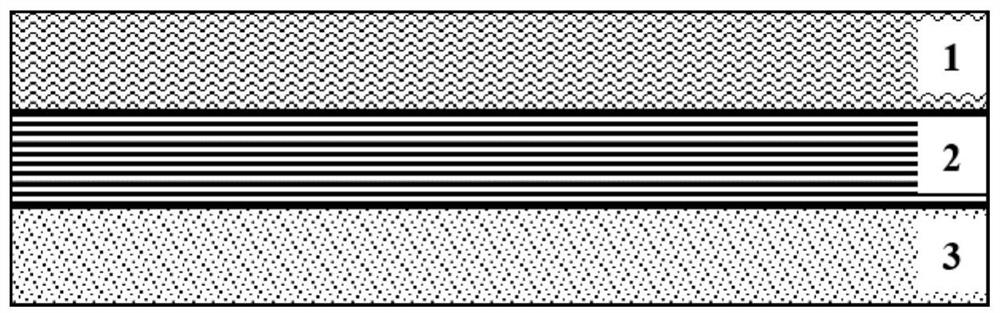

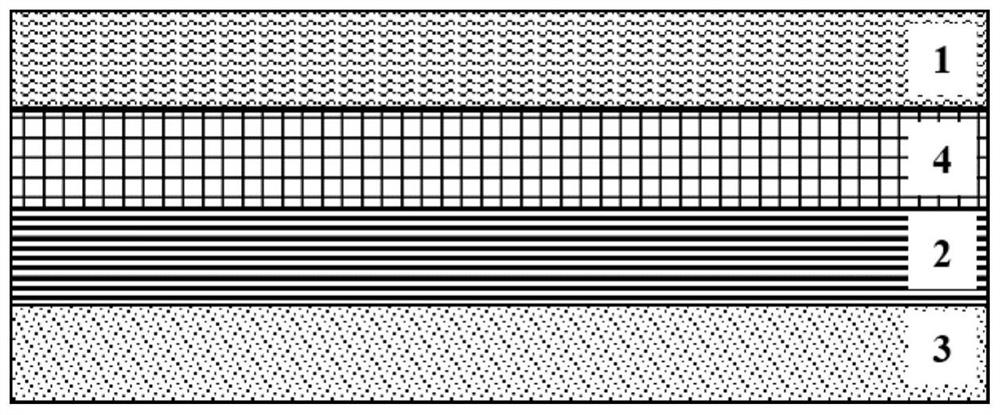

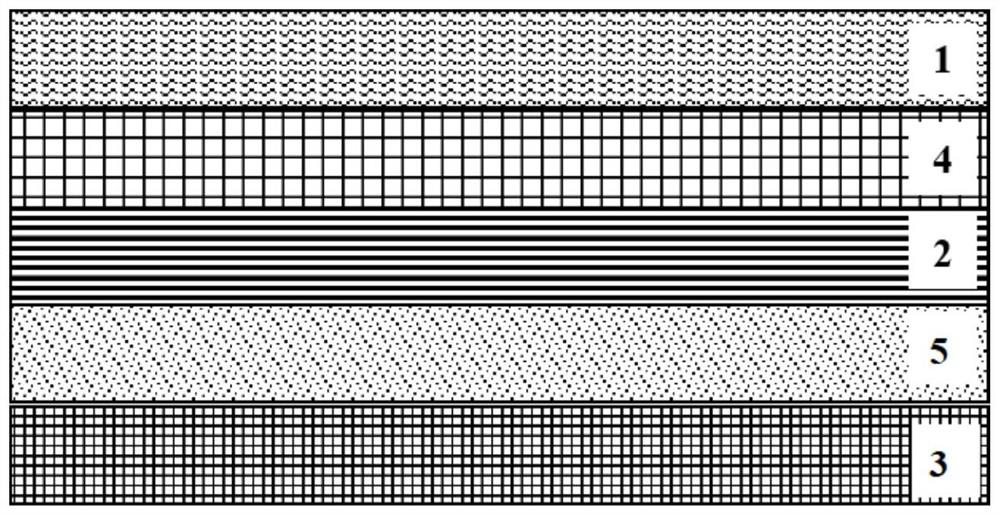

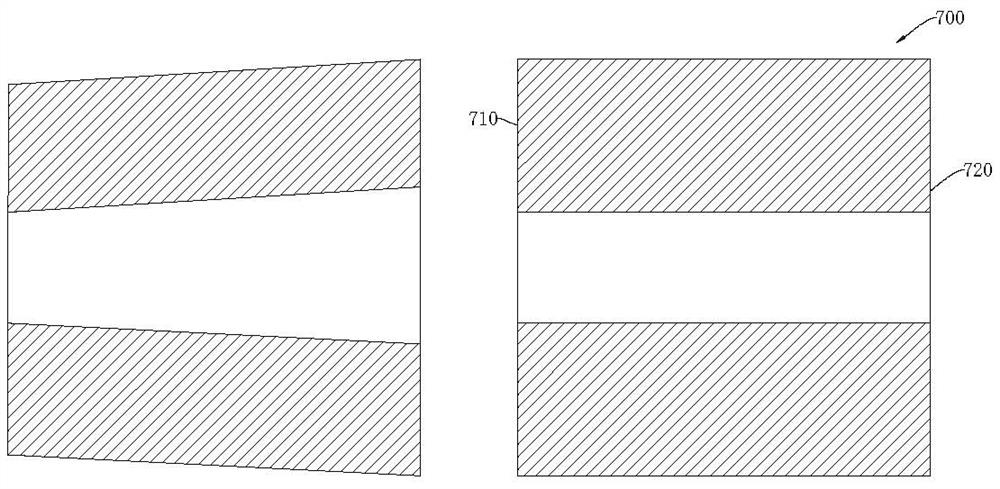

Moisture-resistant double-drawing polypropylene pearl label base film and preparation method thereof

ActiveCN114148065AEasy to castGood orientationStampsSynthetic resin layered productsPolymer scienceFilm base

The invention relates to a moisture-resistant double-drawing polypropylene pearl label base film and a preparation method thereof. The moisture-resistant double-drawing polypropylene pearl label base film is characterized by comprising a first surface layer, a core layer and a second surface layer which are arranged in sequence, the first surface layer comprises an ethylene norbornene copolymer; the core layer comprises hydrogenated petroleum resin, and the softening point Ts of the hydrogenated petroleum resin is greater than or equal to 135 DEG C. The invention also provides a preparation method of the moisture-resistant double-drawing polypropylene pearl label base film. The moisture-resistant double-drawing polypropylene pearl label base film disclosed by the invention has excellent moisture-resistant performance, does not influence the pearl effect and stiffness of a film, is beneficial to printing and labeling of a film base material, is beneficial to improving the quality of a water bottle or a bottled beverage product, and is beneficial to prolonging the shelf life of a commodity.

Owner:GUANGDONG DECRO PACKAGE FILMS +1

Mechatronic food sorting system

InactiveCN111631414AEasy to rinseEasy to cleanSortingFood treatmentAgricultural engineeringElectric machinery

The invention provides a mechatronic food sorting system. The mechatronic food sorting system comprises a sorting rack, supporting machine legs, a control panel, a protection plate, an emergency baffle, wing-shaped screws, a gear motor, a driving roller, a roller shaft, a driven roller, a hollowed-out conveying belt and a flushing type filtering, temporary storing, collecting and flow guiding boxstructure; the supporting machine legs are longitudinally connected to four corners of the bottom of the sorting rack through bolts; the control panel is connected to the upper left side between the supporting machine legs arranged at the left side through longitudinal screws; the front side and the rear side of the upper portion of the sorting rack are respectively connected with protection plates through transverse screws; and an emergency baffle is longitudinally arranged at the right side between the protection plates and is fastened and connected through the wing-shaped screws. Through arrangement of a sorting pipe, a supporting base, a guide-out barrel, a connecting base, a buffer plate, a buffer spring and an anti-damage buffer pad, buffer sorting of washed, dried and labeled food is facilitated.

Owner:SHANDONG LABOR VOCATIONAL & TECHN COLLEGE

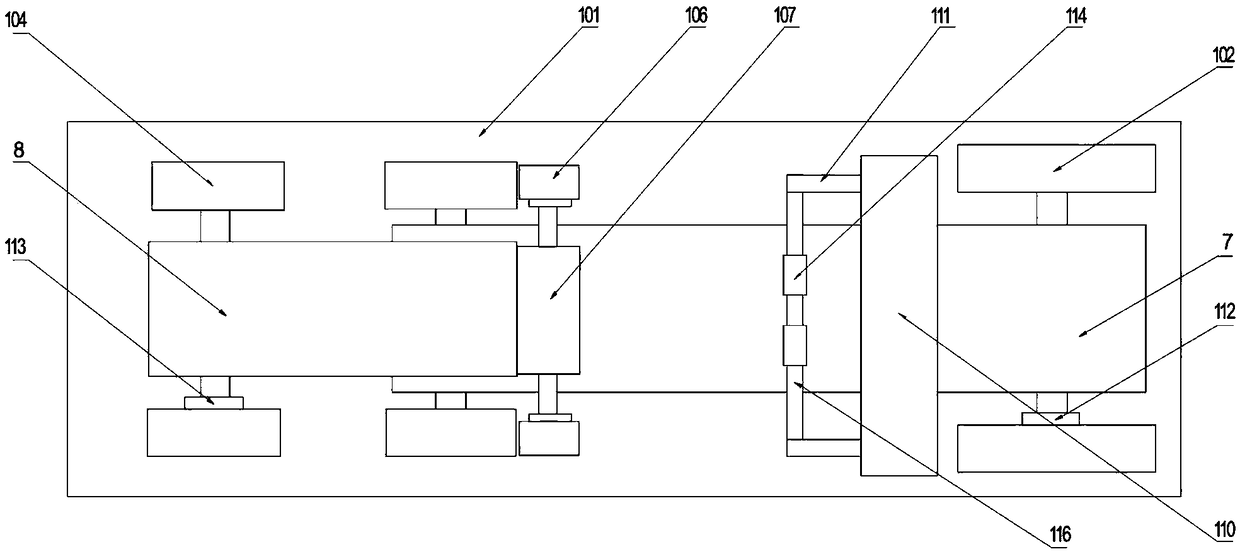

Cigarette carton two-dimensional code tagging system

PendingCN108946091AEffective shapingGood for code readingLabelling flat rigid surfacesConveyor partsCartonAssembly line

The invention discloses a cigarette carton two-dimensional code tagging system arranged on a cigarette carton sorting assembly line. A cigarette carton conveying belt comprises an upper-layer belt anda main belt. The main belt comprises a front belt segment and a rear belt segment which are each provided with a belt drive device. The upper-layer belt is converged to the main belt on the front belt segment. A cigarette carton stacking prevention device and a cigarette carton running interval control device are sequentially arranged above the front belt segment, and a cigarette carton two-dimensional code pasting machine is arranged on the rear belt segment. The cigarette carton stacking prevention device comprises a mounting shaft horizontally arranged above the front belt segment, and themounting shaft is perpendicular to the operating direction of the front belt segment and allows only one cigarette carton to pass from the lower portion. The cigarette carton running interval controldevice comprises a vertical plate capable of ascending and descending, and the vertical plate capable of ascending and descending is longitudinally arranged on the front belt segment and is perpendicular to the operating direction of the front belt segment. According to the cigarette carton two-dimensional code tagging system, cigarette cartons on a conveying belt can be effectively shaped, the cigarette posture can be adjusted, a cigarette carton running manner of a certain interval is formed, and the two-dimensional code pasting machine can carry out code pasting and code reading easily.

Owner:CHENGDU BRANCH OF SICHUAN TOBACCO CO

Multi-angle carton label pasting machine

The invention discloses a multi-angle carton label pasting machine. The multi-angle carton label pasting machine comprises a label pasting device mounted at the top of a frame, a carton, a label pasting head, an adjusting bracket, a stop mechanism, a winding and unwinding device, a printer and a conveying belt; the carton is positioned on the conveying belt; the label pasting device is provided with a rotating cavity; a first support plate and a second support plate are fixedly mounted in the rotating cavity; the same rotating shaft is fixedly mounted on the approaching sides of the first support plate and the second support plate; the rotating shaft is rotationally connected with a connecting plate; a second movable hole is formed in the inner wall of one side of the rotating cavity; andthe bottom of the connecting plate extends under the label pasting device, and is slidingly connected with the second movable hole. The multi-angle carton label pasting machine is simple in operation;and through startup of a driving motor and a rotating motor, a label pasting plate can be driven for rotation and arc displacement, so that the label pasting is convenient, the cost and the floor space are reduced, and the working efficiency is effectively improved.

Owner:长沙智能制造研究总院有限公司

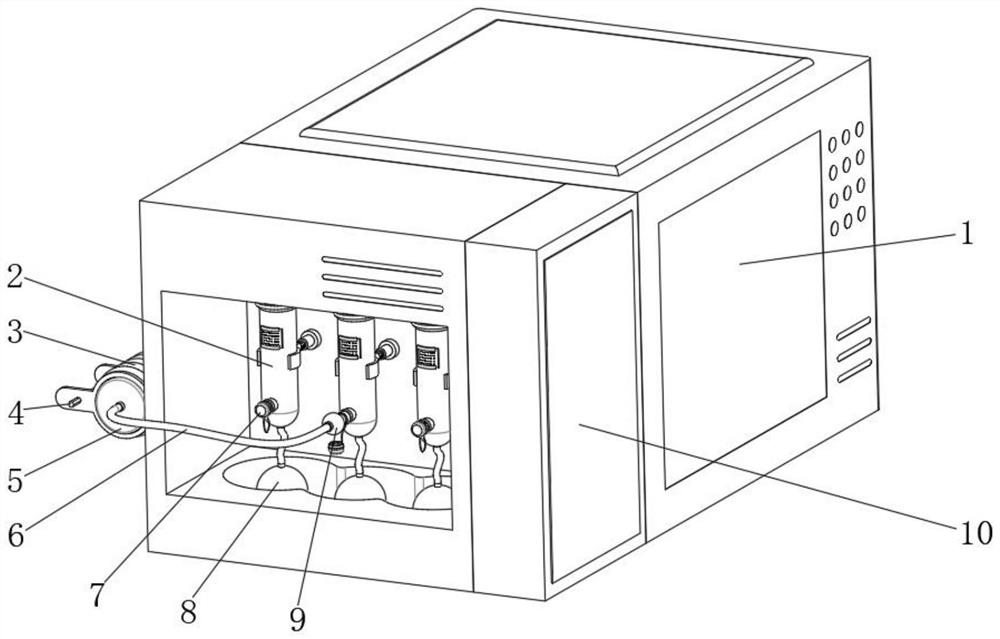

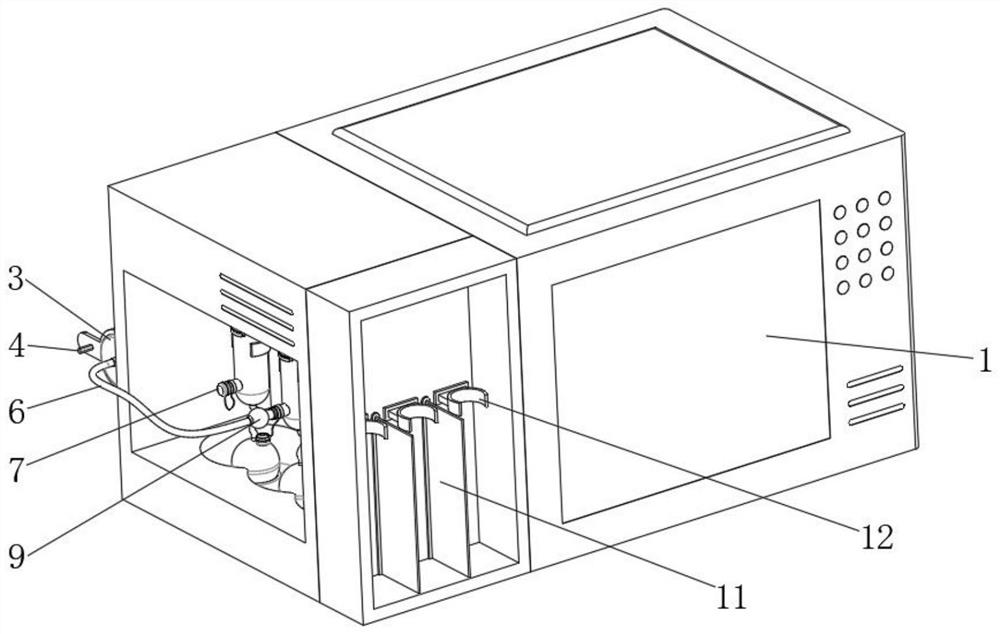

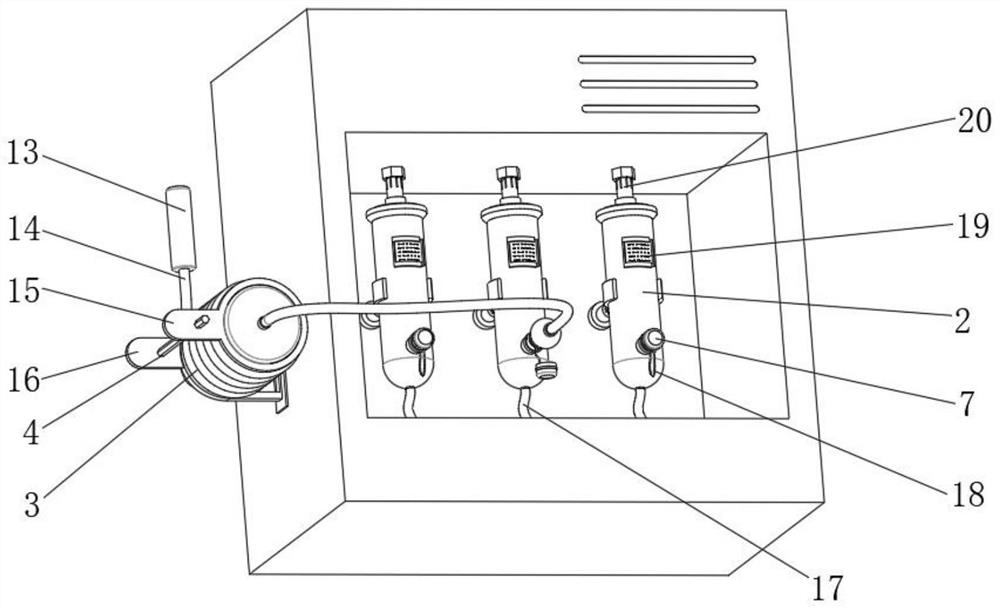

Intelligent multi-component gas collecting and analyzing device

PendingCN114705631AIncreased flexibility of useImprove reliabilityColor/spectral properties measurementsAir compressionCollection analysis

The invention discloses an intelligent multi-component gas collection and analysis device, and relates to the technical field of gas collection and analysis devices. The flexibility and reliability of acquisition and analysis are improved. The device specifically comprises an analyzer, a collection tank and an air compression assembly, analysis heads distributed at equal intervals are installed on the inner wall of one side of the analyzer, the analysis heads are detachably inserted into the top of the collection tank, the air compression assembly comprises an air compression bag, an air supply pipe and a collection pipe, and the air supply pipe and the collection pipe are arranged on the outer walls of the two ends of the air compression bag respectively. A one-way collection head is fixed at one end of the collection tube, and a support frame is fixed on the inner wall of one side of the one-way collection head. By arranging the air pressing bag, the one-way collecting head, the one-way air supply chamber and other structures, the air supply plug can be inserted into the air inlet connector of the collecting tank according to requirements, air needing to be collected is unidirectionally conveyed and extruded into the collecting tank through the one-way collecting head and the one-way air supply chamber by utilizing a mode of extruding the air pressing bag, and the use flexibility is improved.

Owner:上海伟创标准气体分析技术有限公司

Intensity data visualization

ActiveUS10937202B2Easy labelingImage enhancementWave based measurement systemsPoint cloudActivation function

Techniques for coloring a point cloud based on colors derived from LIDAR (light detection and ranging) intensity data are disclosed. In some embodiments, the coloring of the point cloud may employ an activation function that controls the colors assigned to different intensity values. Further, the activation function may be parameterized based on statistics computed for a distribution of intensities associated with a 3D scene and a user-selected sensitivity. Alternatively, a Fourier transform of the distribution of intensities or a clustering of the intensities may be used to estimate individual distributions associated with different materials, based on which the point cloud coloring may be determined from intensity data.

Owner:SCALE AI INC

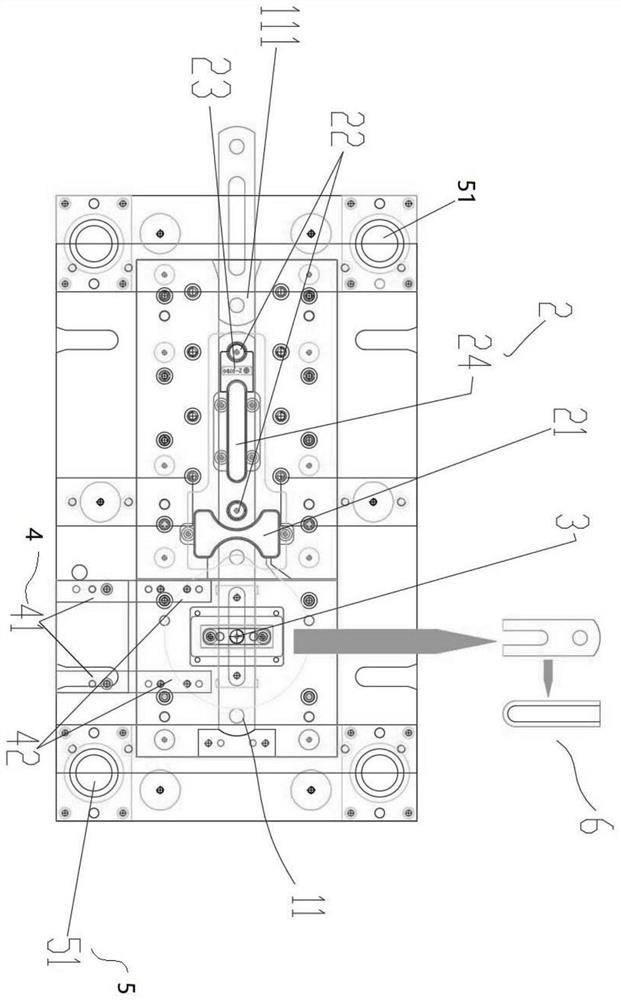

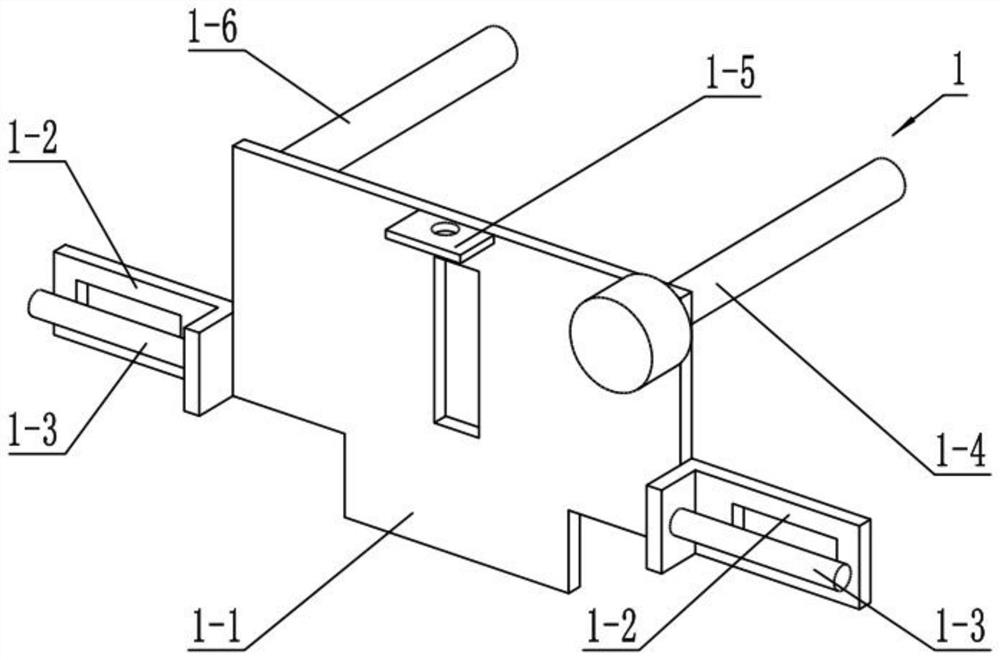

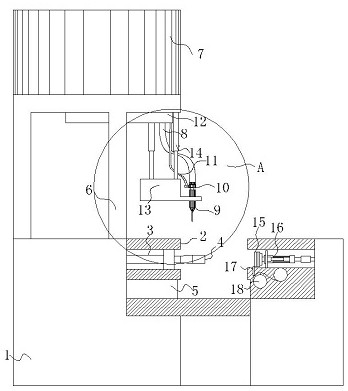

A right-angle hanging board processing equipment and stamping system

ActiveCN111515301BReduce investmentLow costShaping toolsStripping-off devicesEngineeringMechanical engineering

The invention relates to the technical field of workpiece processing, and specifically discloses a right-angle hanging plate processing equipment and a stamping system, wherein the right-angle hanging plate processing equipment includes: an upper mold body and a lower mold body, and the lower mold body is provided with a conveying channel; The first mold core group is arranged on the upper mold body and the lower mold body and is located in the middle of the conveying channel; the second mold core group is arranged on the upper mold body and the lower mold body and is located in the conveying channel The end; the pushing assembly is arranged at the end of the conveying channel, and pushes the right-angle hanging plate from the end of the conveying channel to the receiving chute. By setting the first core set, the second core set and the pushing assembly on the path of the conveying channel, when the raw material sheet moves on the conveying channel, it will be stamped and formed by the first core set and the second core set in turn into a predetermined shape. shape, and after being stamped and formed, it is pushed to the inside of the receiving chute by the pushing component, realizing the effect of automatic pushing.

Owner:YONGGU GRP

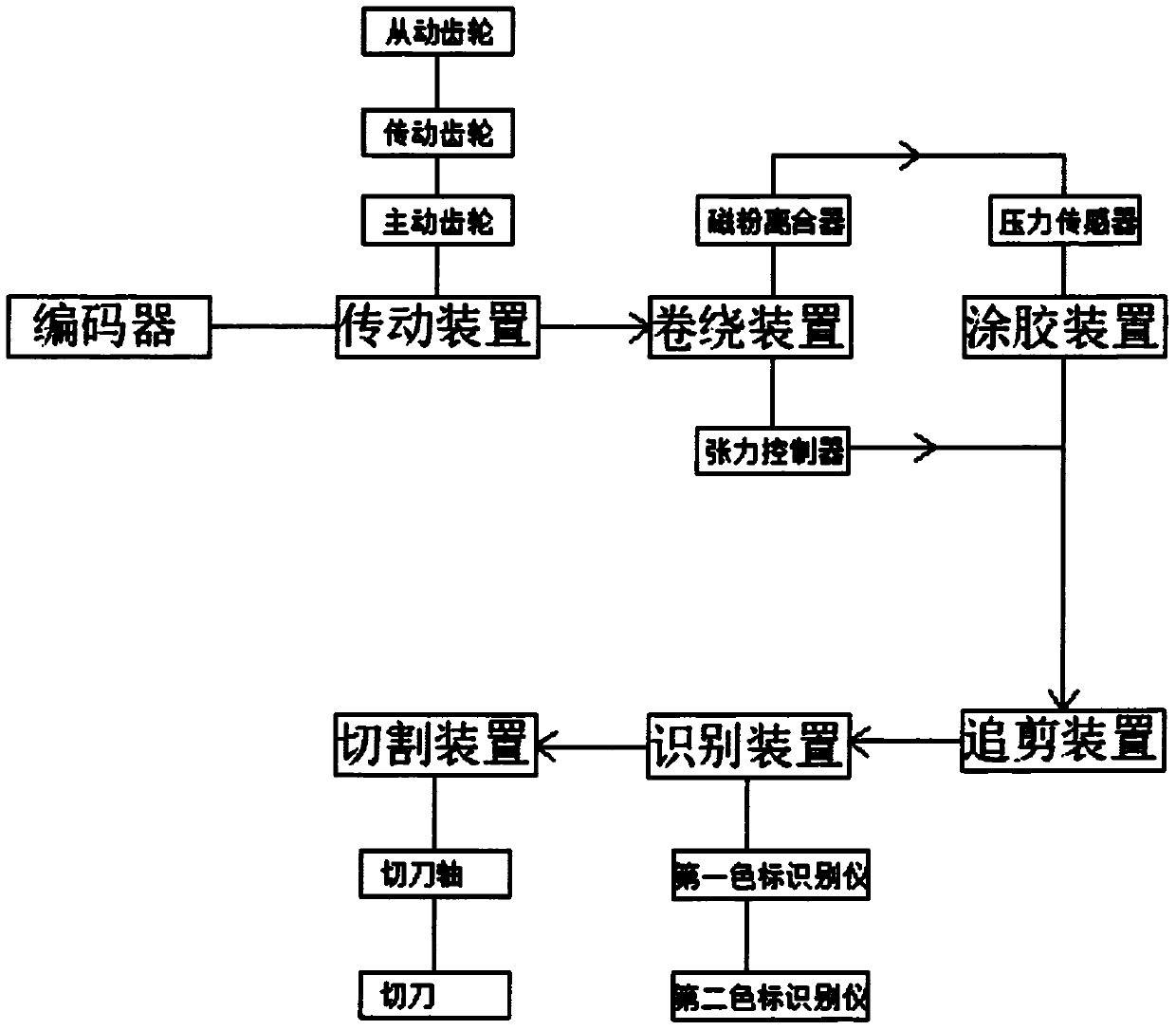

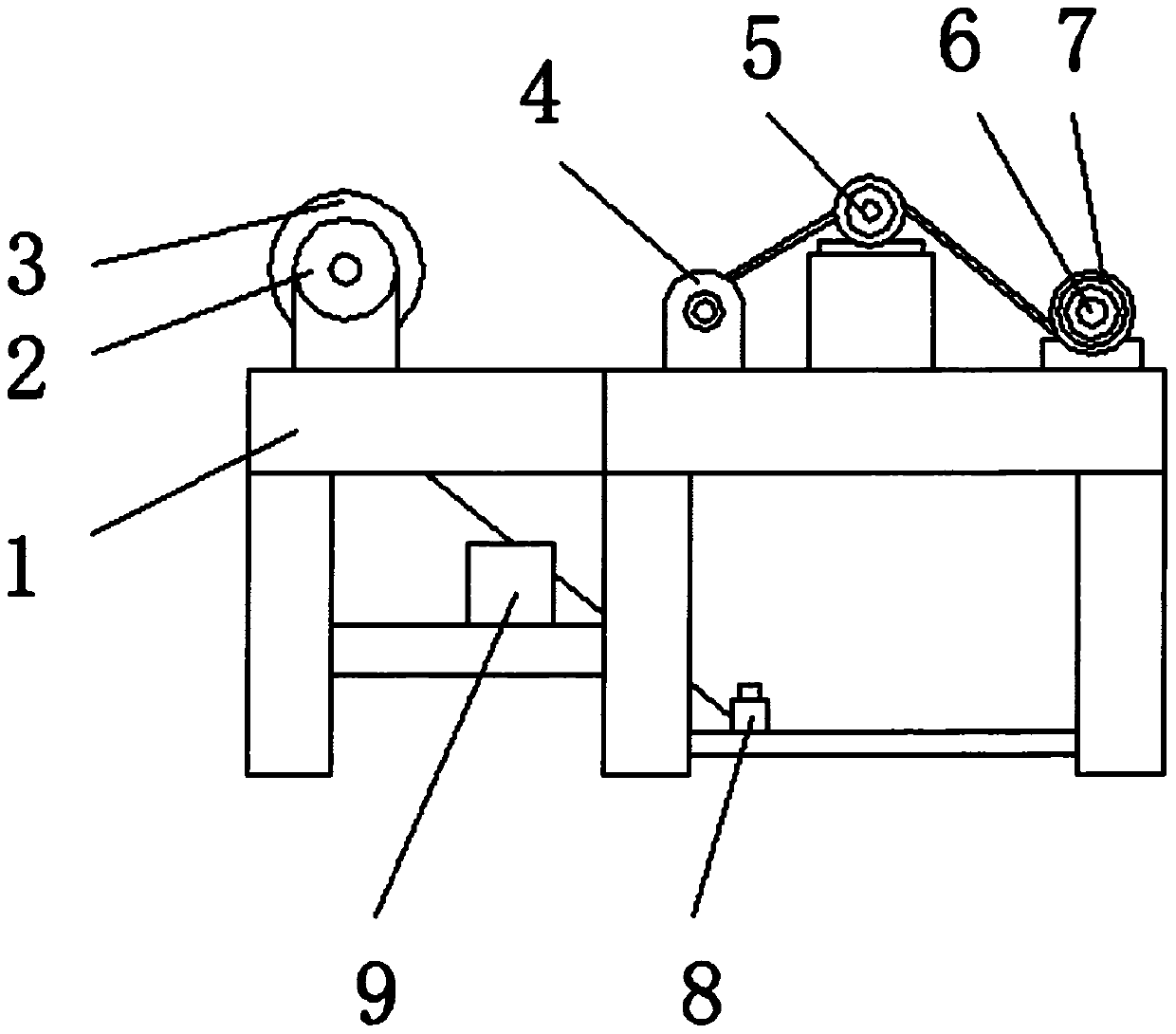

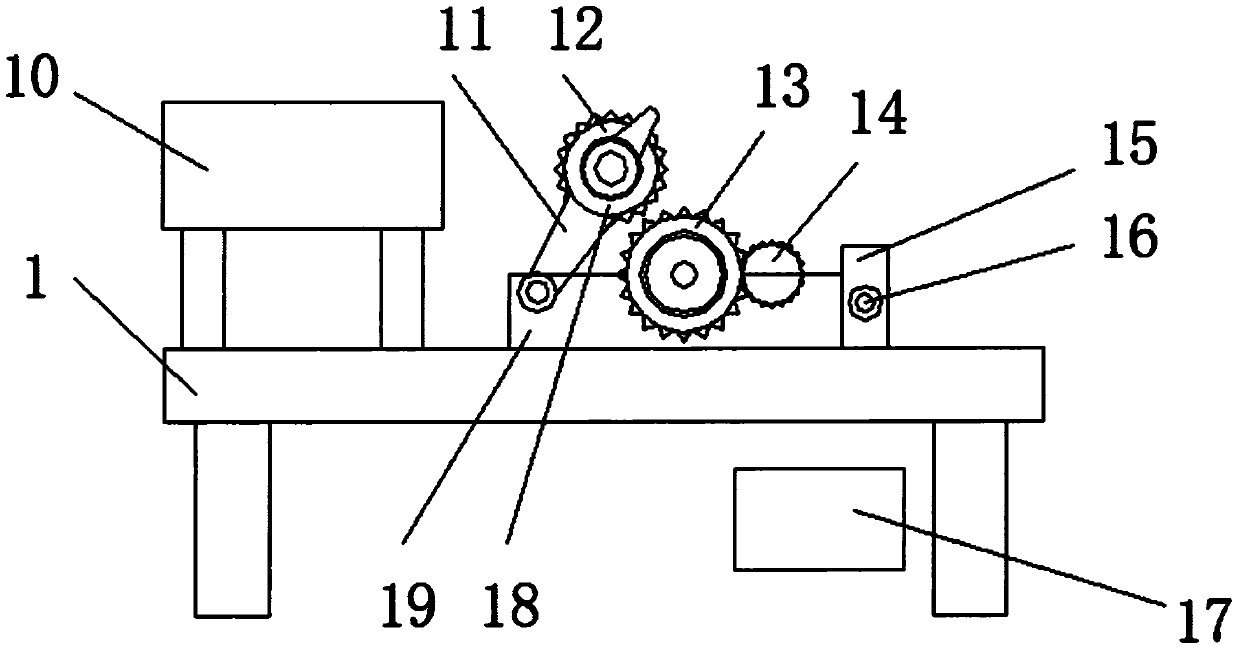

Novel spiral label reel pipe slitting integrated machine

InactiveCN109850654AConvenient double-sided glueGuaranteed tensionArticle deliveryWebs handlingColor markerPulp and paper industry

The invention discloses a novel spiral label reel pipe slitting integrated machine. The novel spiral label reel pipe slitting integrated machine comprises a workbench; a magnetic powder clutch is arranged at one end of the surface of the workbench; the surface of the magnetic powder clutch is in sleeving connection with a paper roll; one side of the magnetic powder clutch is fixedly connected withan encoder; one end of the encoder is in clamping connection with a pressure sensor; one end of the pressure sensor is rotatably connected with a guide roller through a rotating shaft; and a redirection roller is arranged at one end of the bottom end of the workbench. The novel spiral label reel pipe slitting integrated machine is reasonable in design and convenient to use; a tension controller is provided and can guarantee that the paper roll has constant tension in the pipe reeling process and prevent the paper roll from generating deviation in the transmission process, so that the precision of the reel pipe is guaranteed; a first color marker identifying instrument and a second color marker identifying instrument are provided, so that color markers on the surface of the paper roll canbe identified conveniently in the cutting process and the influence on cutting caused by disorder during cutting is avoided; and the novel spiral label reel pipe slitting integrated machine is simple,convenient and suitable for widely popularizing.

Owner:LANGFANG JUNXING YIMEI PACKAGING PROD CO LTD

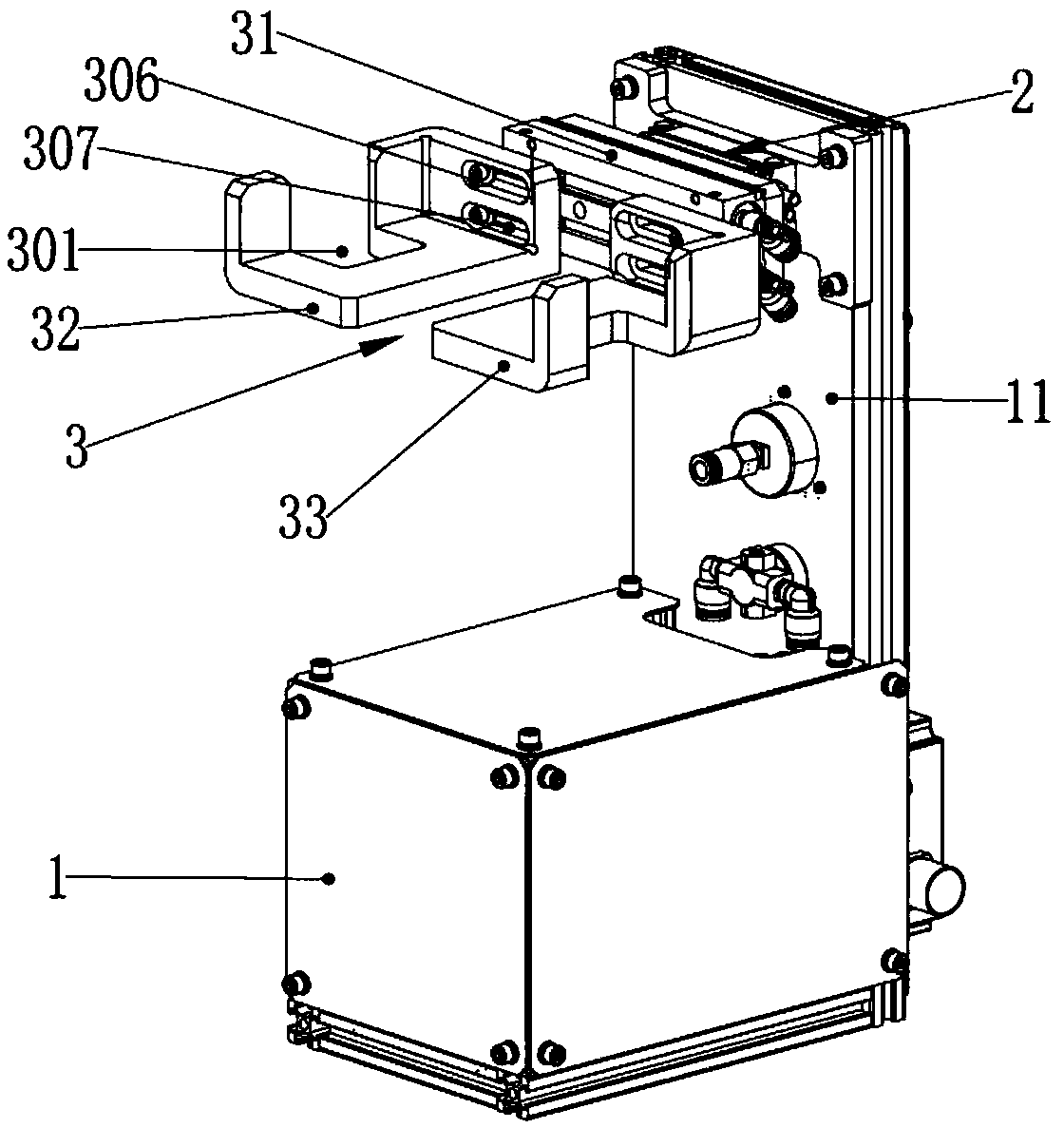

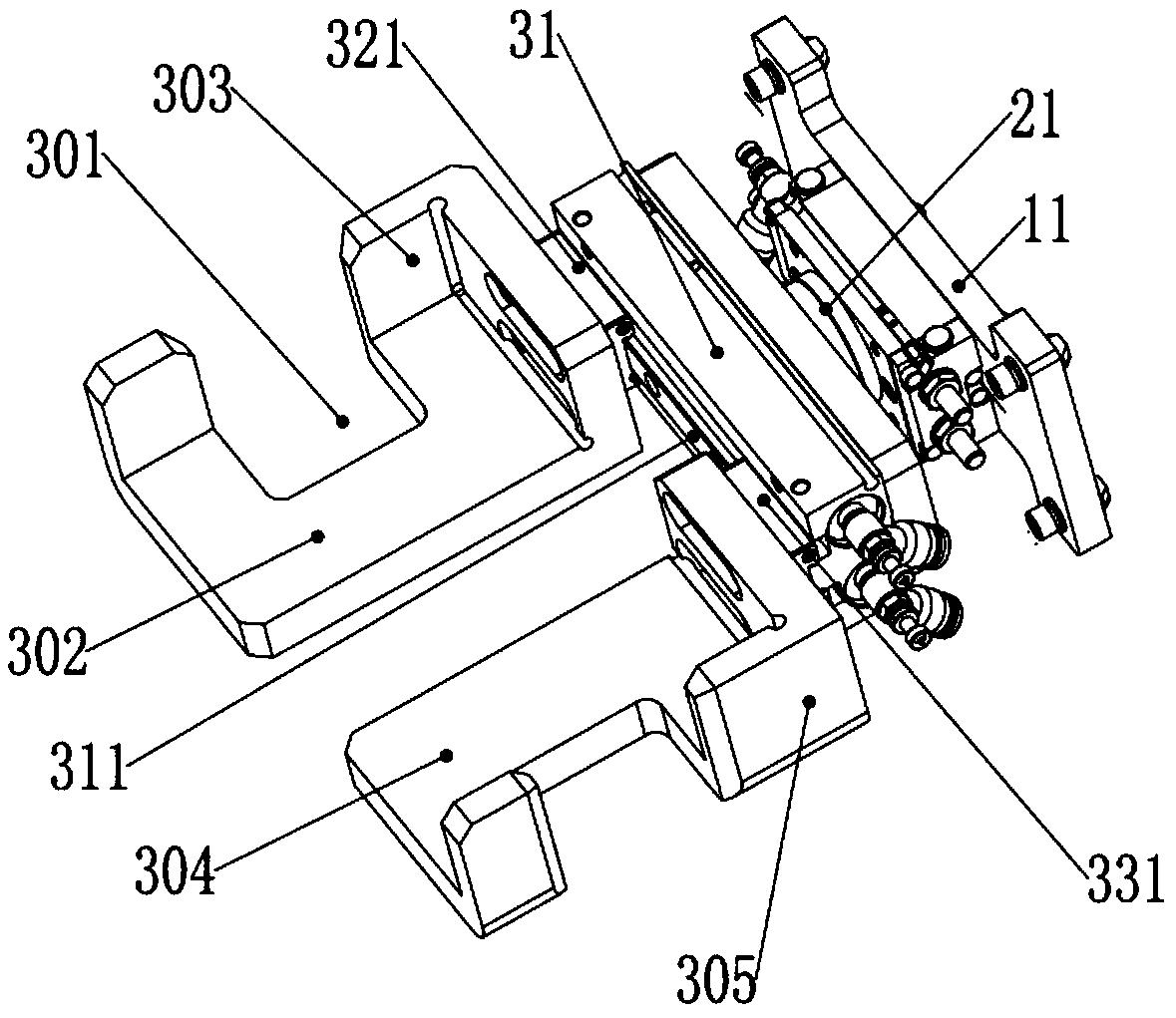

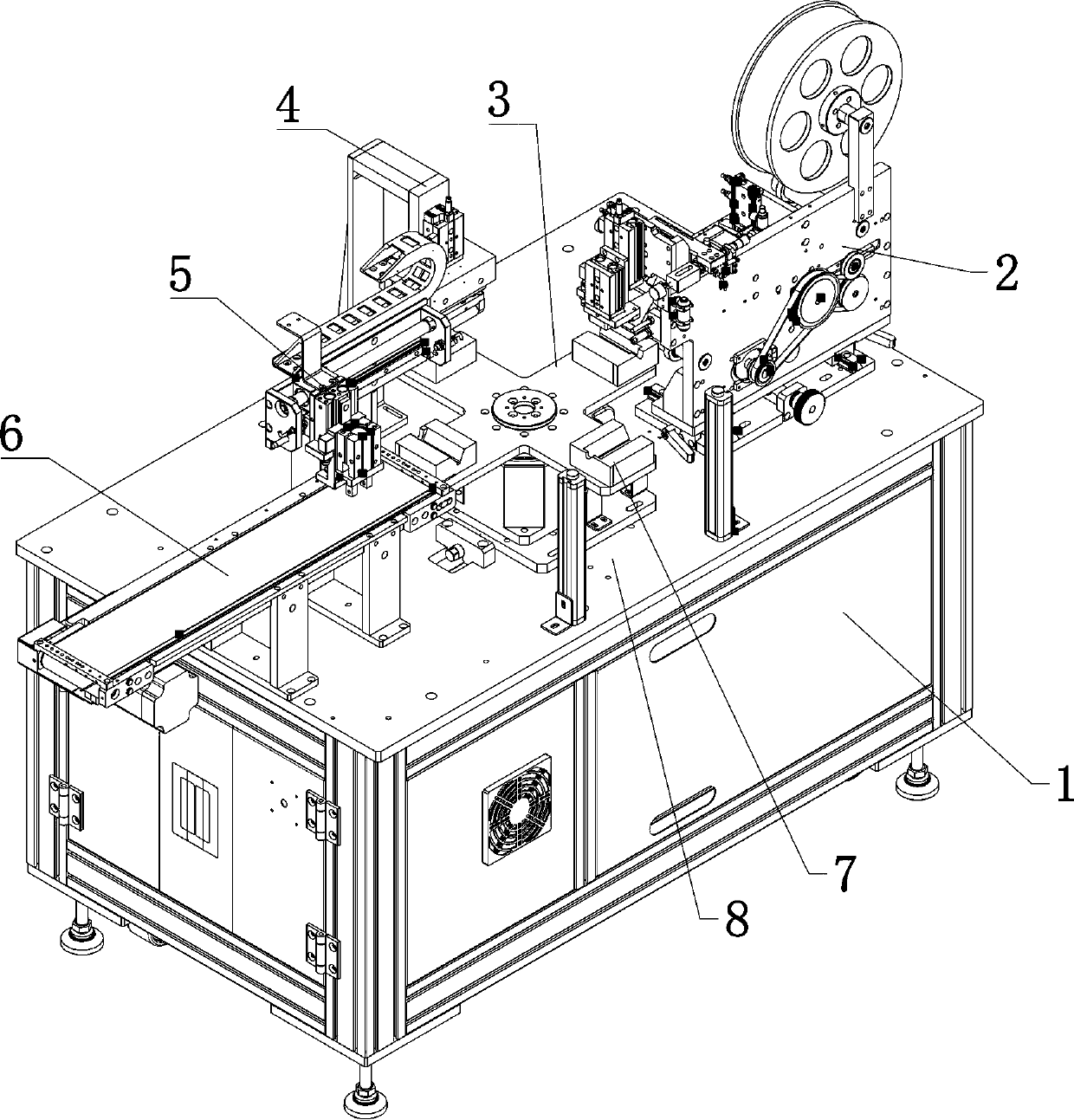

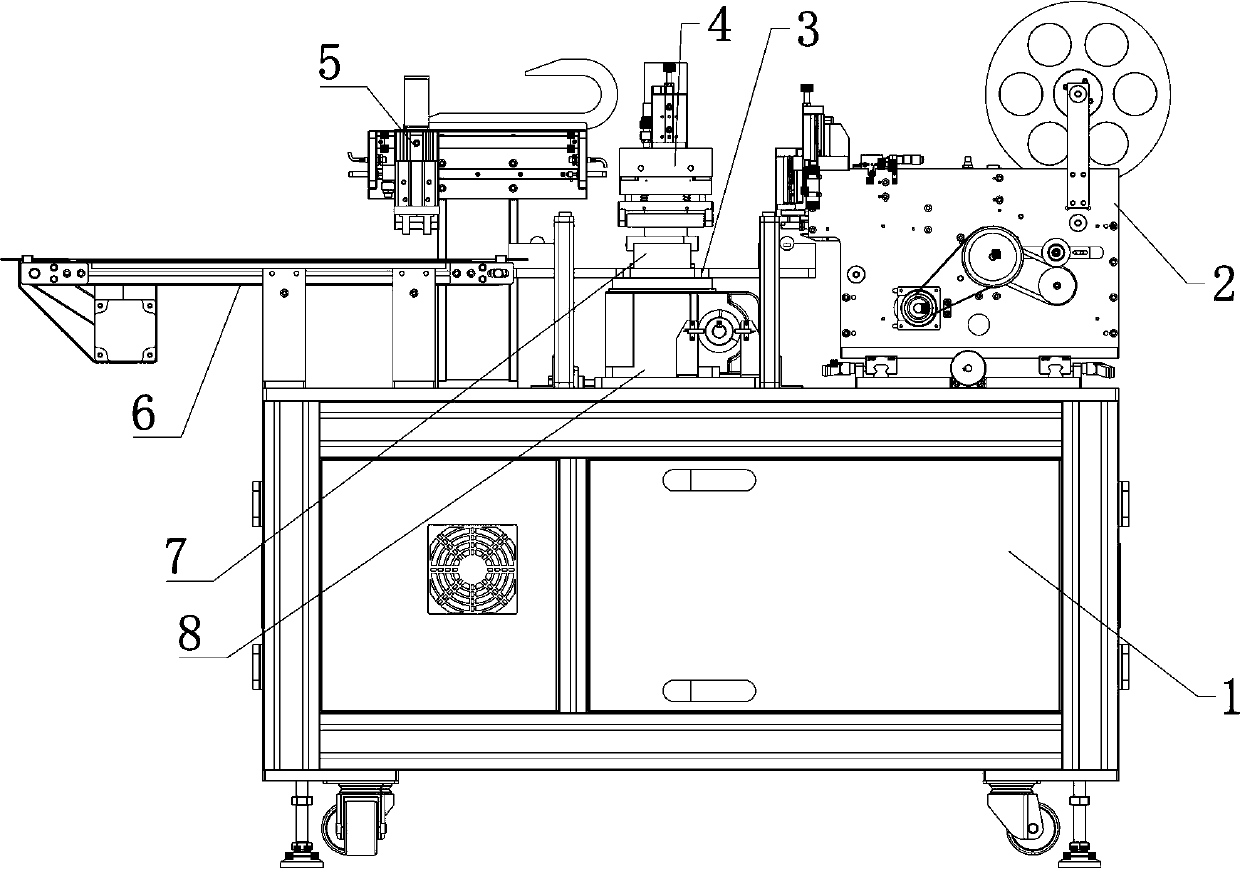

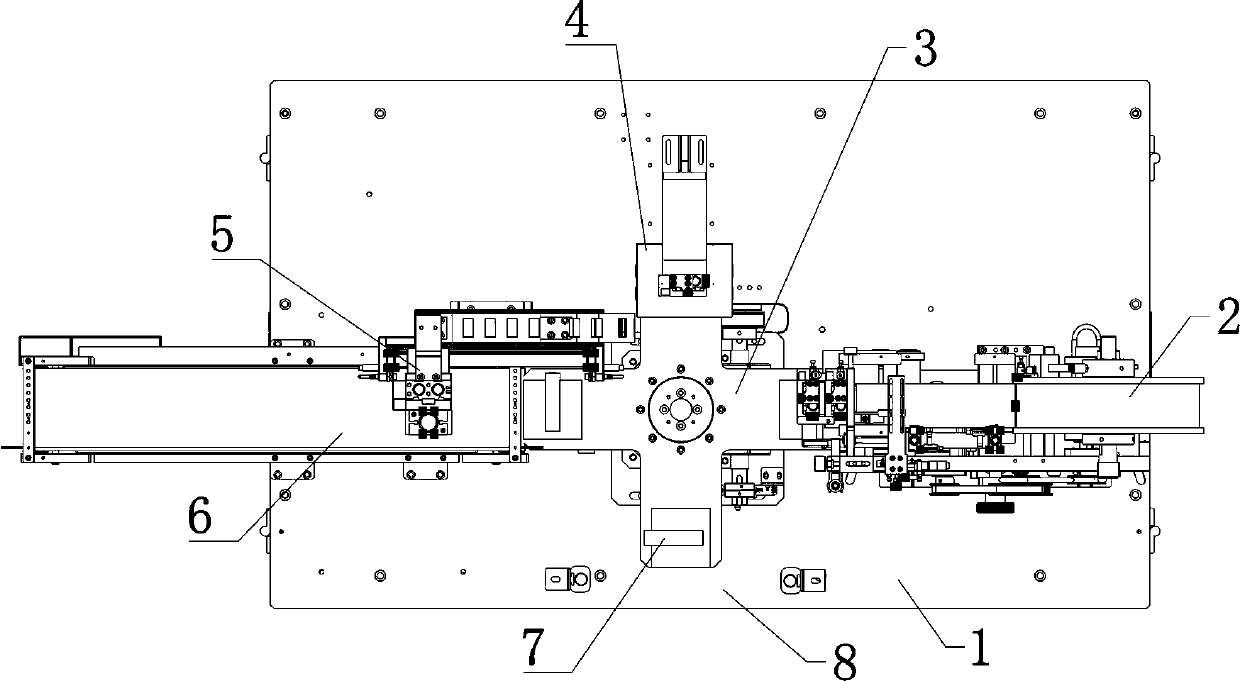

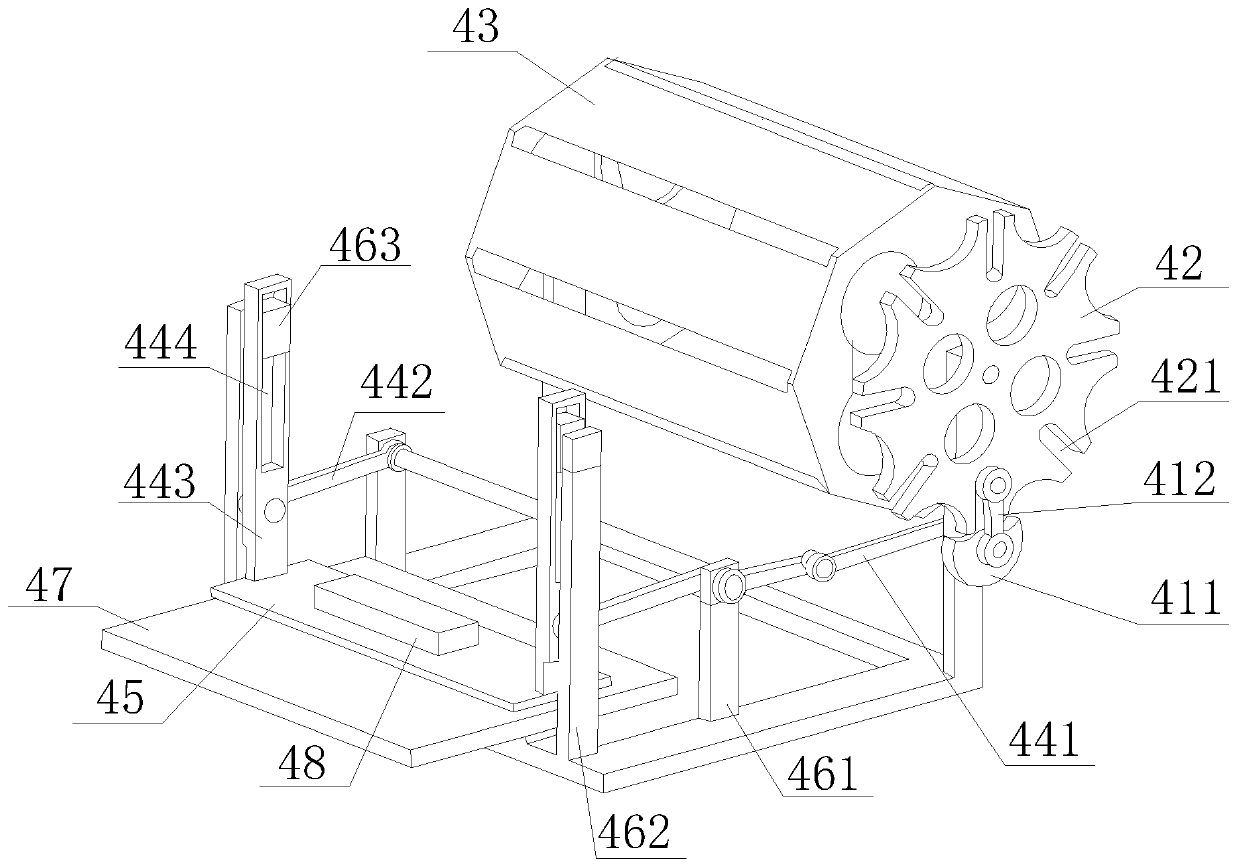

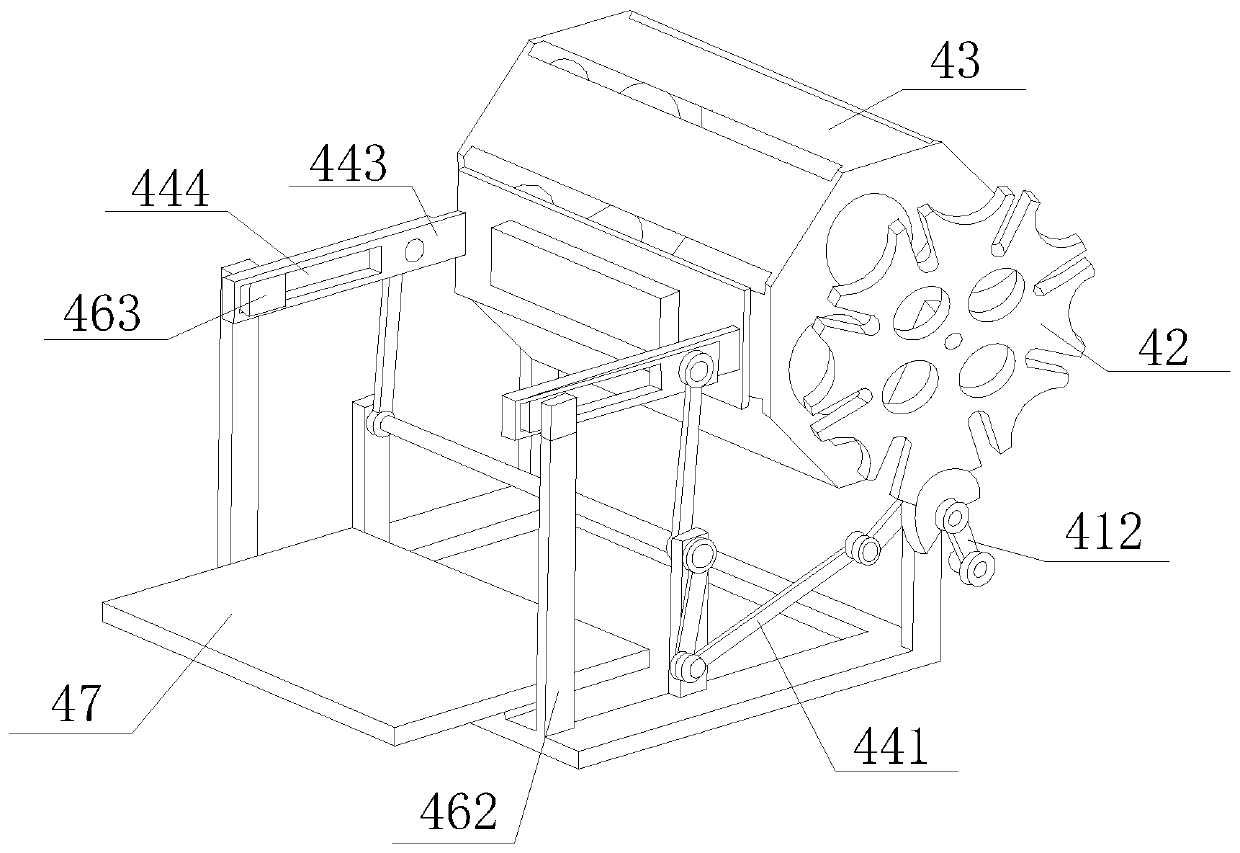

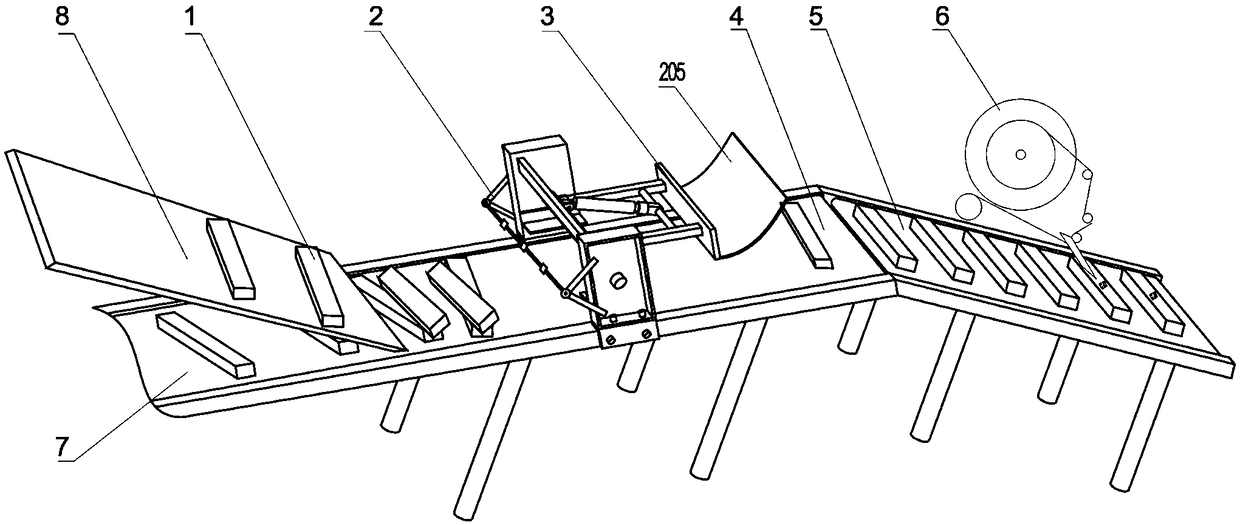

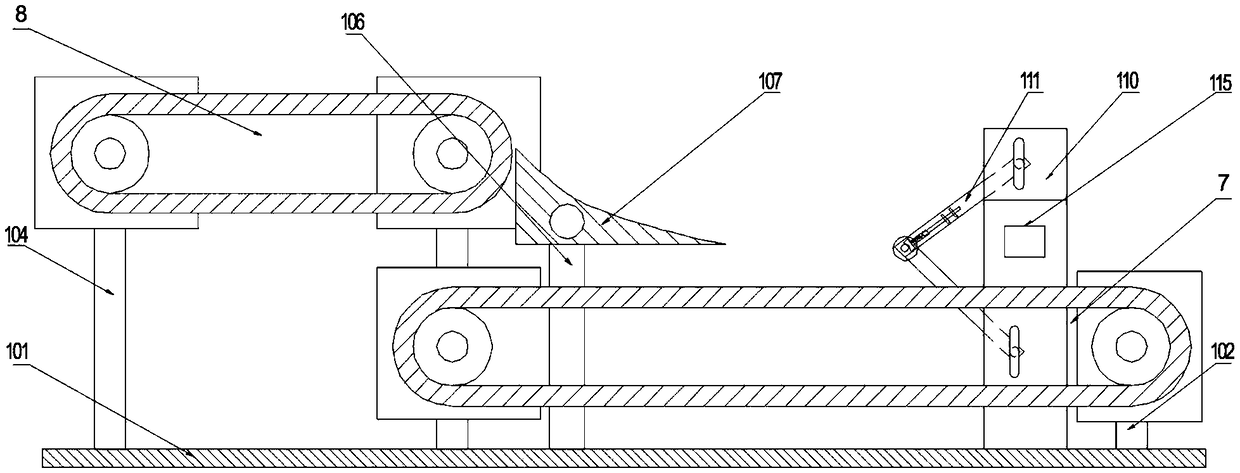

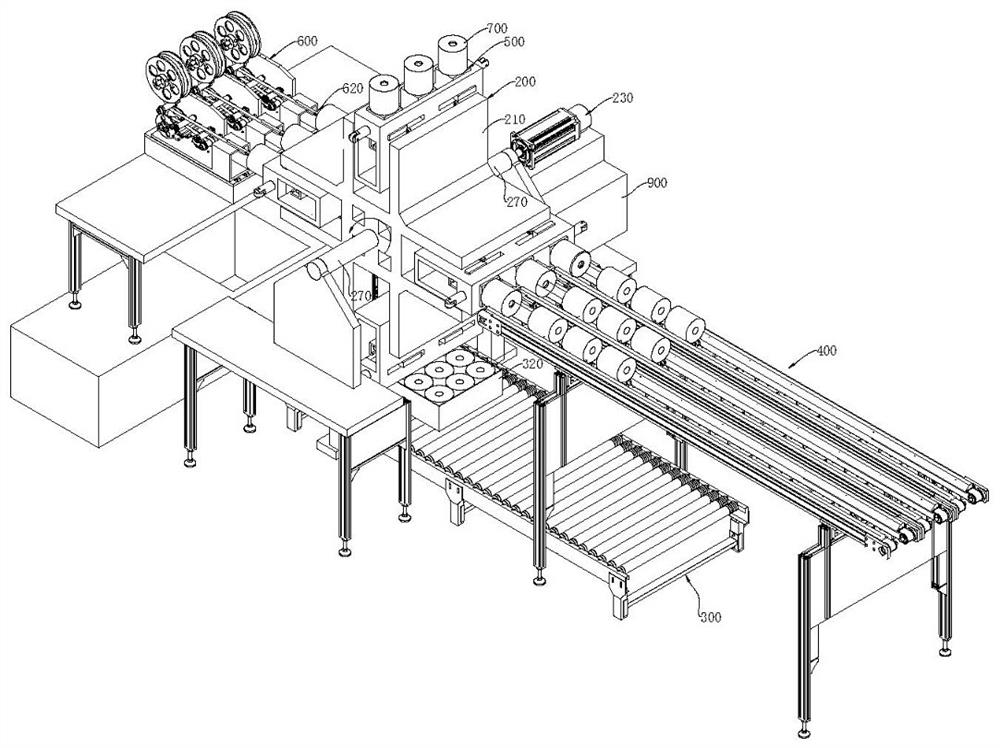

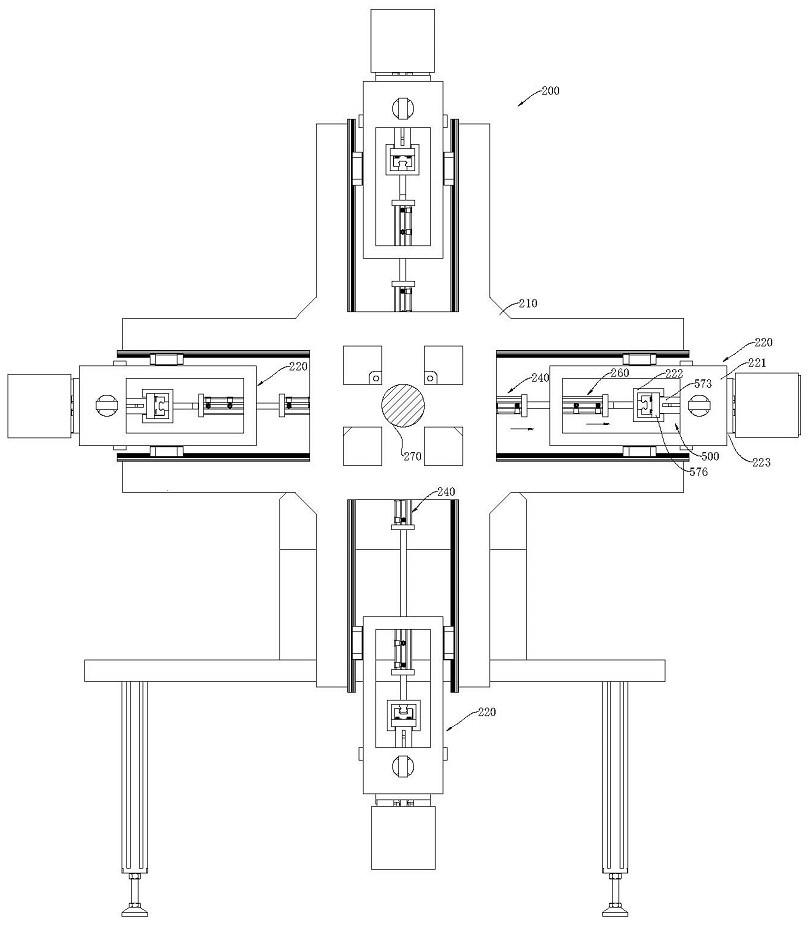

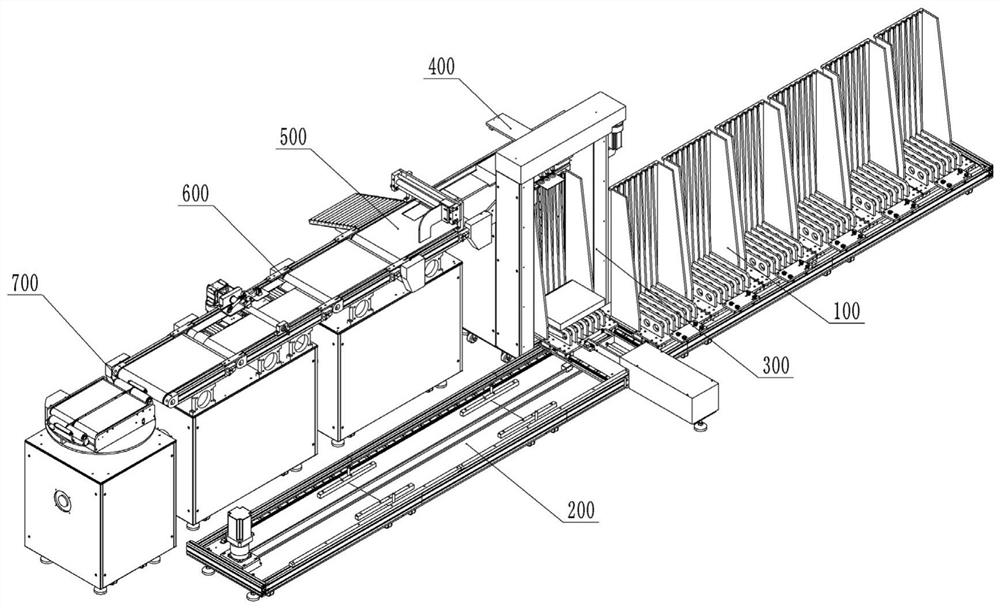

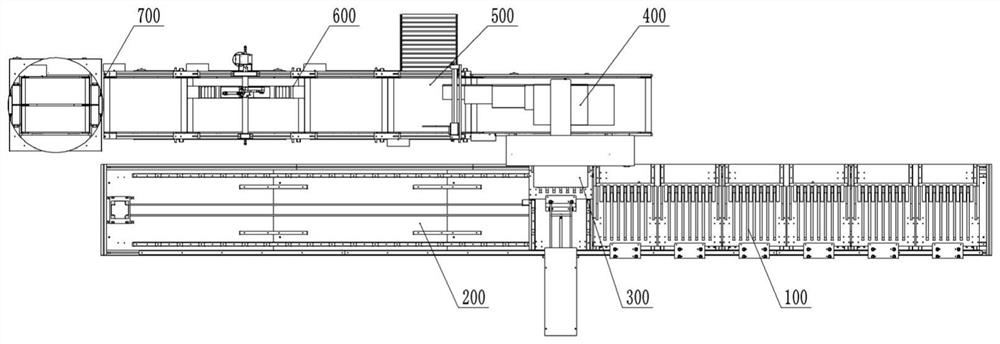

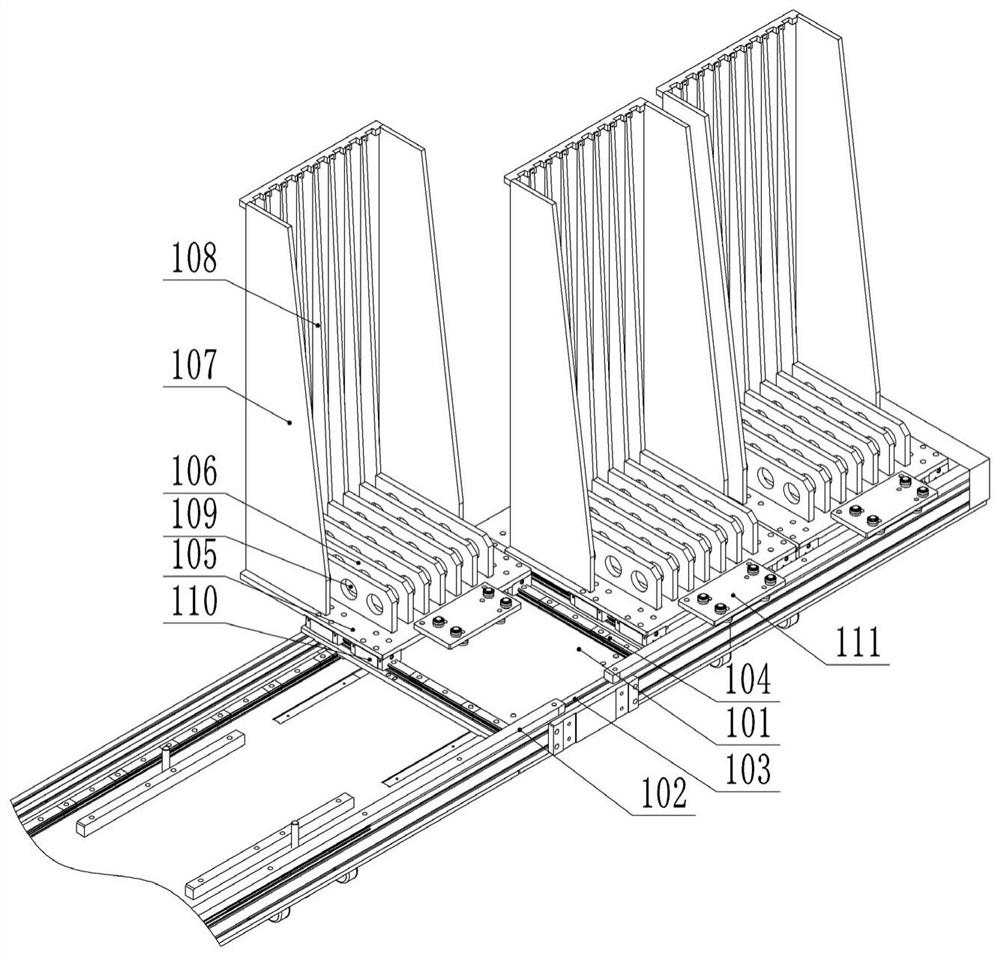

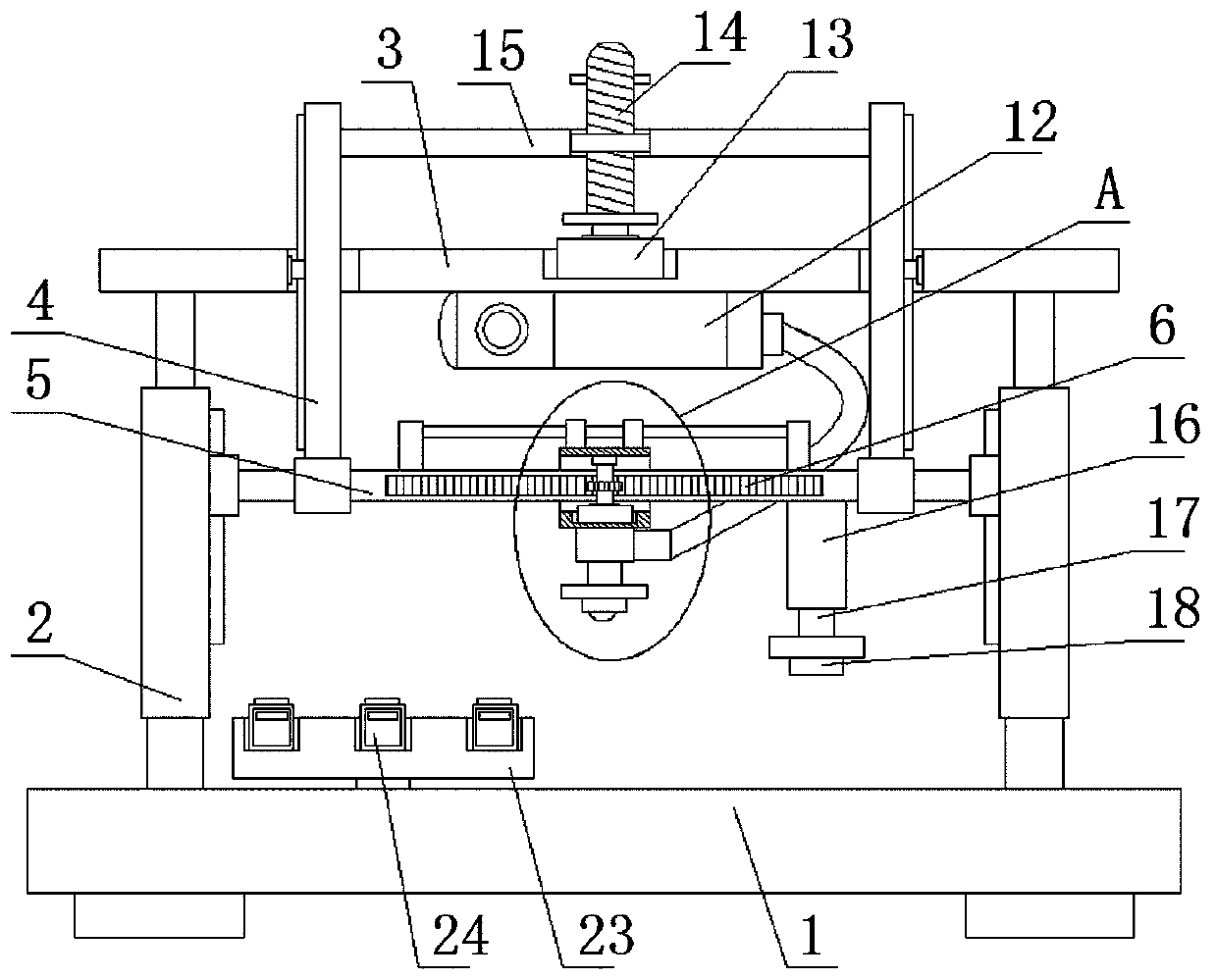

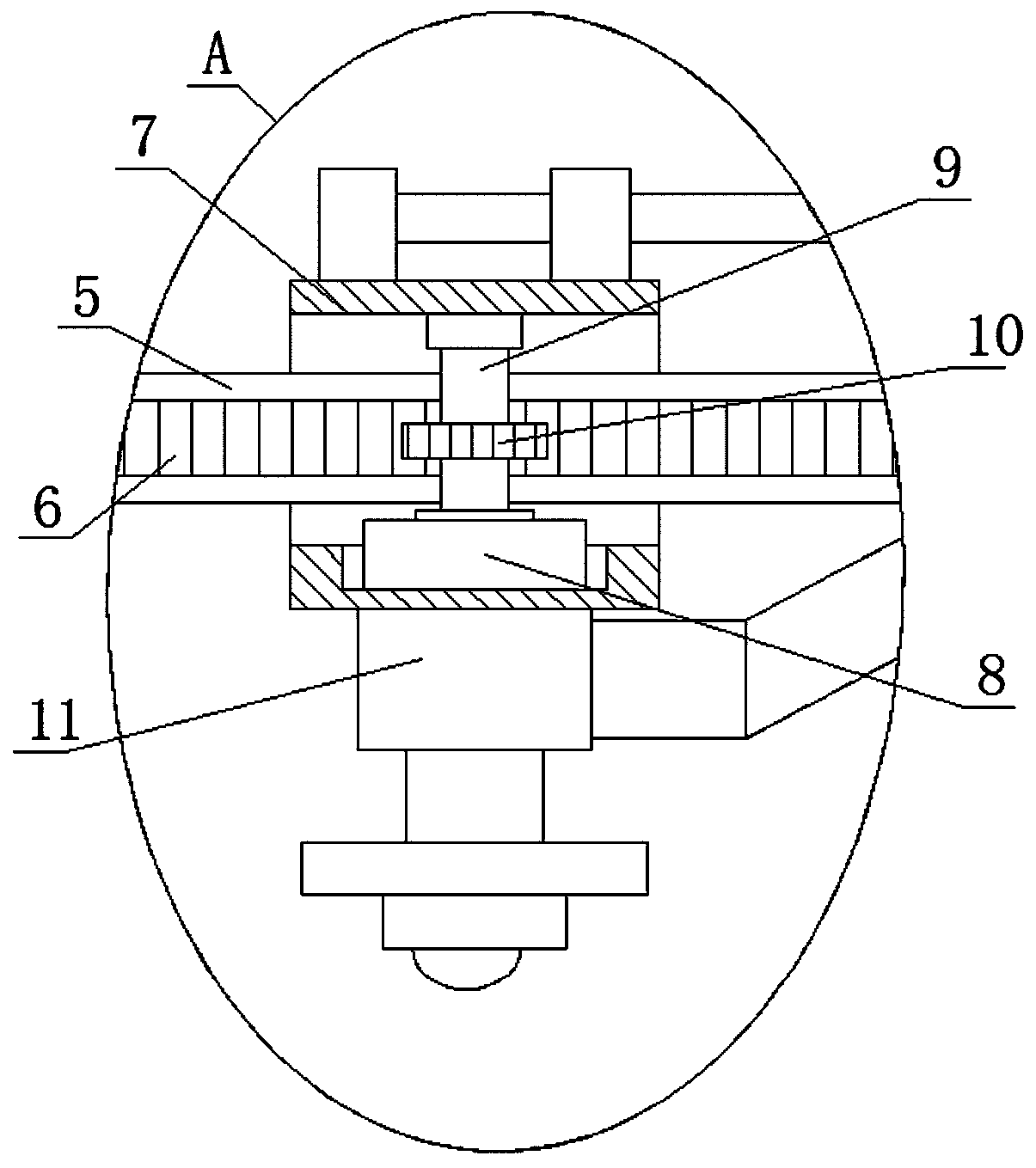

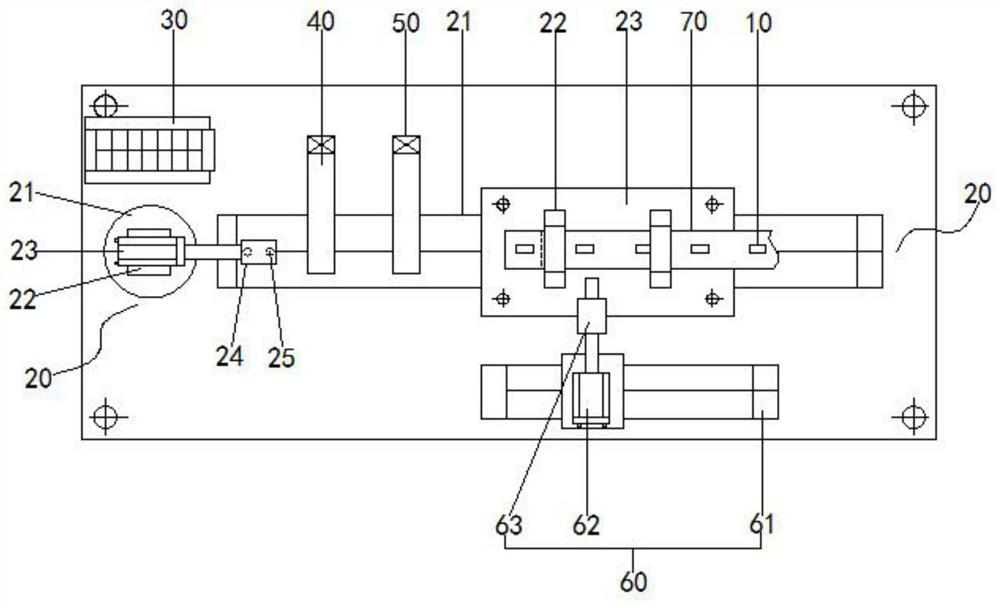

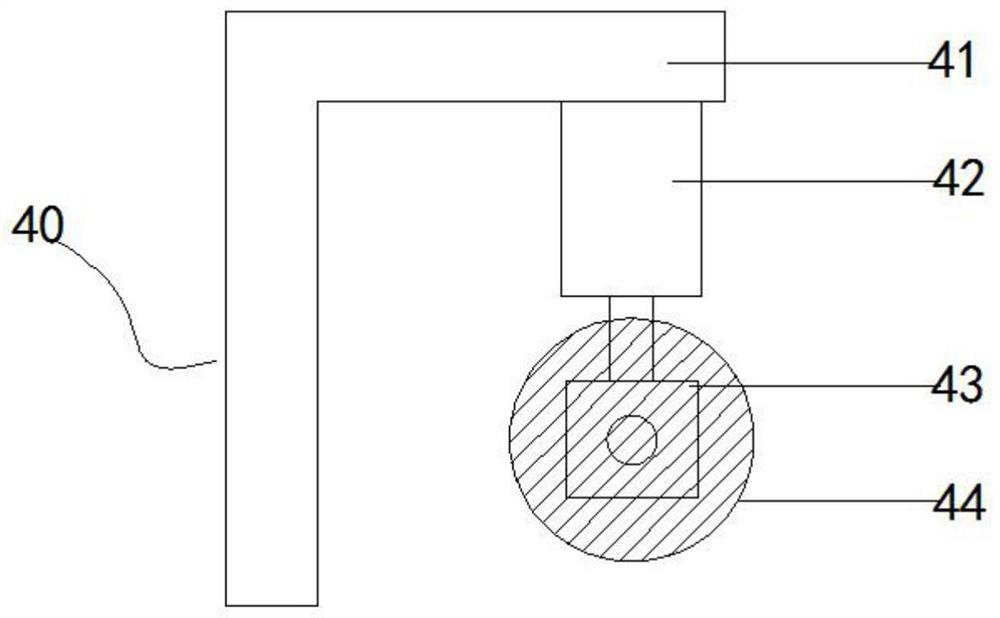

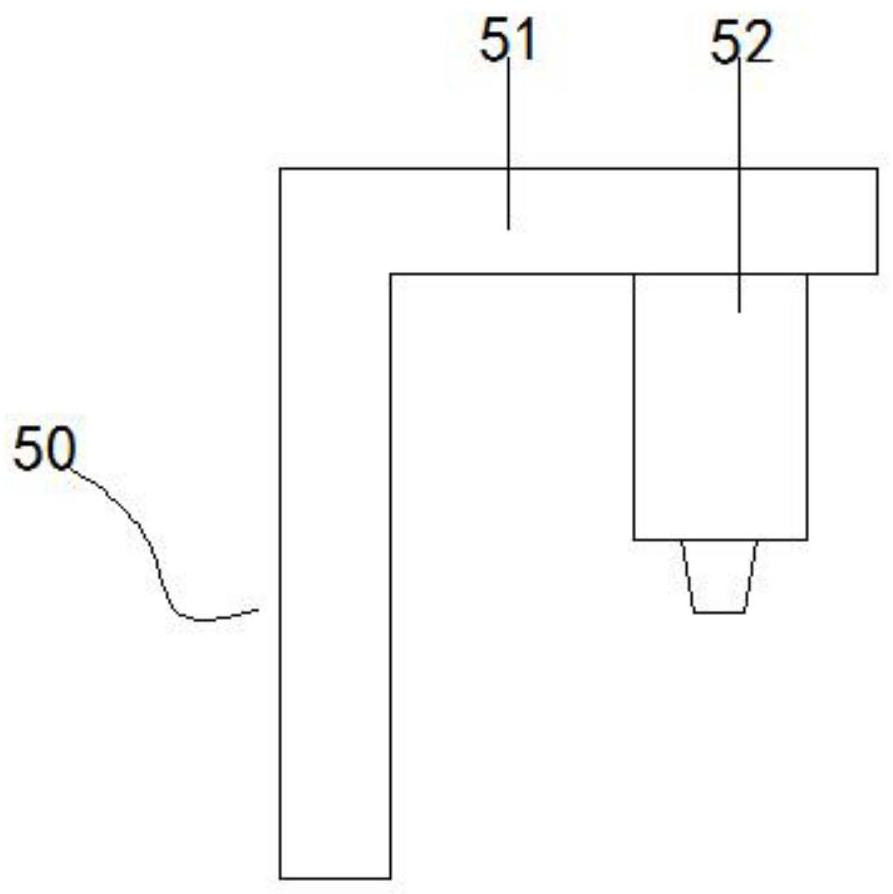

Labeling and boxing integrated equipment for inner pipes of products

InactiveCN112407495AEasy labelingConvenience needsIndividual articlesLabelling machinesMaterial transferIndustrial engineering

The invention discloses a labeling and boxing integrated equipment for inner pipes of products. According to the equipment, the products on a conveying line can be boxed, and labeling and label pressing can be completed in the boxing process. The equipment is simple and reasonable in structure, and can well meet the labeling and boxing requirements of large-batch product inner pipes. Meanwhile, the equipment can adapt to clamping of the products with inner cavities in different diameters, and can be well applied to cylindrical inner cavities and conical inner cavities. The equipment comprisesa product conveying line, a boxing device and a material transferring device used for transferring products conveyed by the product conveying line into material boxes on the boxing device; a labelingdevice is arranged on the moving path of the transferred products; a material clamping and label pressing unit is arranged on the material transferring device; a material taking part extending into inner cavities of the products to take the products is arranged on the material transferring device; the material transferring device further comprises a material transferring adjusting mechanism whichis used for adjusting the material clamping and label pressing unit to be switched among three states to box the products on the conveying line and complete labeling and label pressing in the boxing process.

Owner:合肥柱石科技有限公司

Nucleoside or nucleotide derivative and use thereof

InactiveUS7960543B2Improve efficiencyEasy labelingSugar derivativesAntibioticsCrystallographyFluorescence

The object of the present invention is to provide a nucleoside or nucleotide having a 5-substituted-2-oxo(1H)pyridin-3-yl group as a base, as well as a method using the same.In one embodiment, the nucleoside or nucleotide of the present invention has a fluorescent dye selected from the group consisting of 5-FAM, 6-FAM, 5-TAMRA, 6-TAMRA, DANSYL, 5-HEX, 6-HEX, 5-TET, 6-TET, 5-ROX and 6-ROX or a quencher dye selected from the group consisting of DABCYL, BHQ1 and BHQ2, which is attached either directly or through a linker to the 5-position of the above base.

Owner:RIKEN

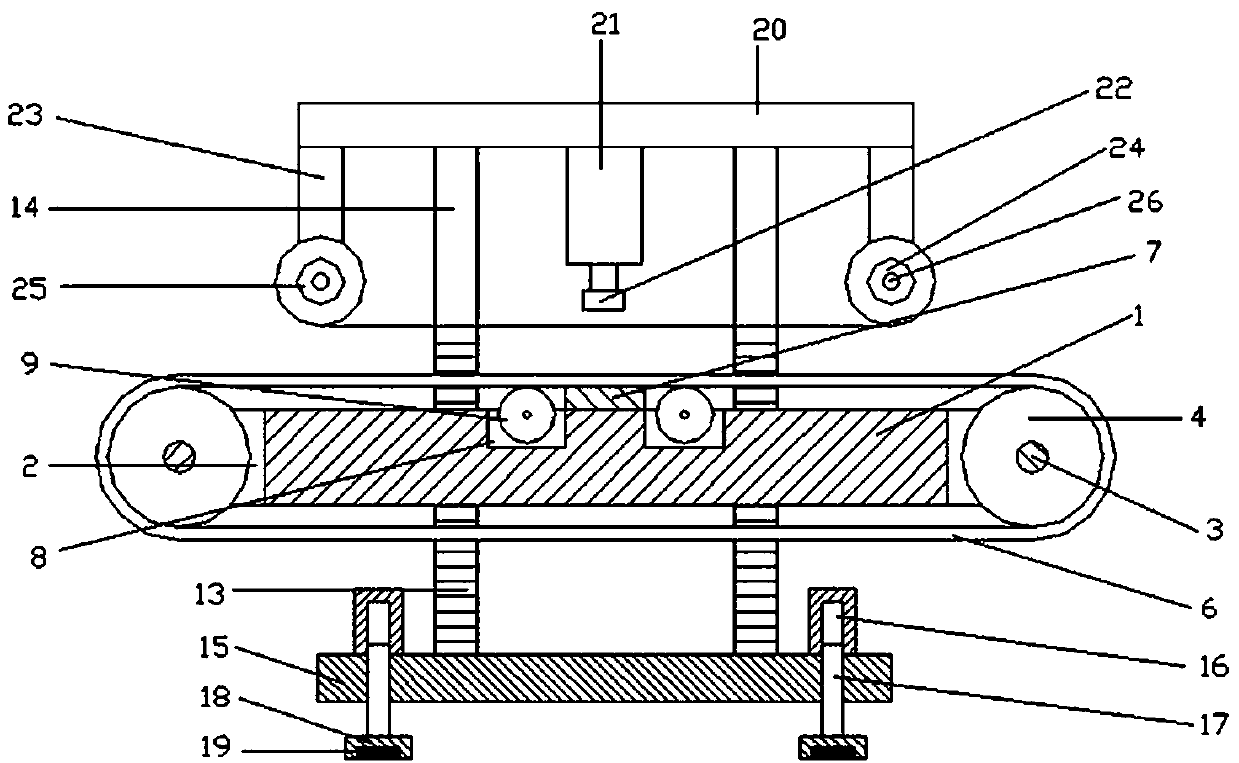

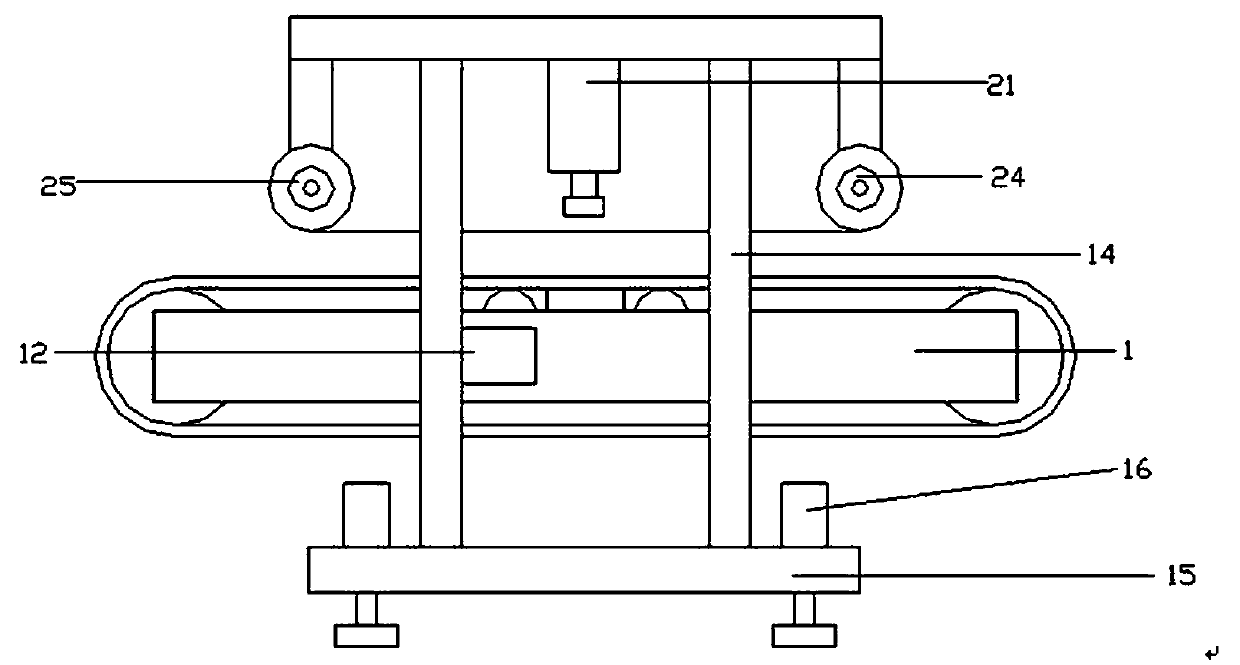

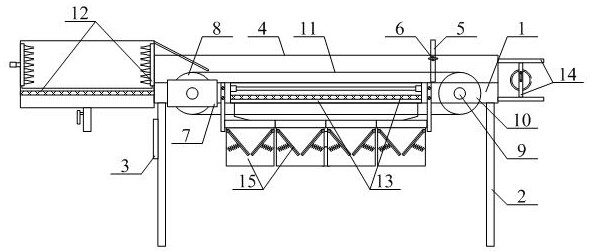

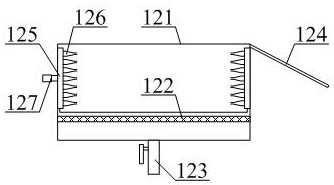

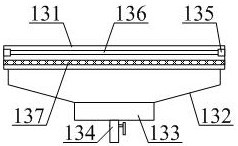

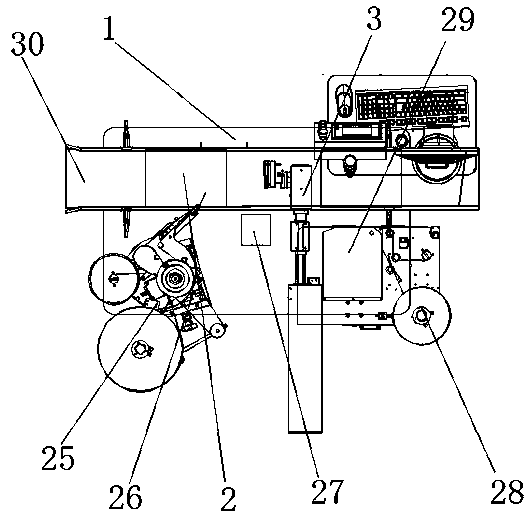

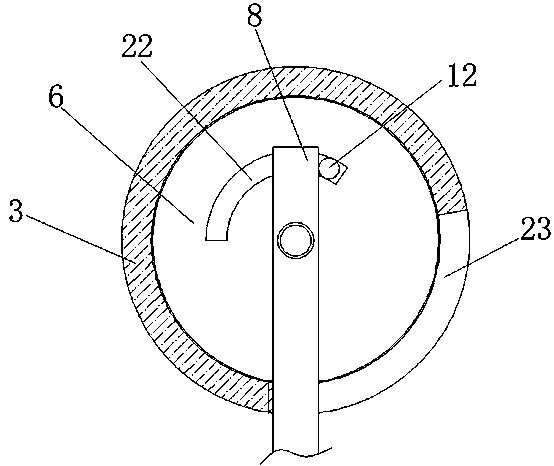

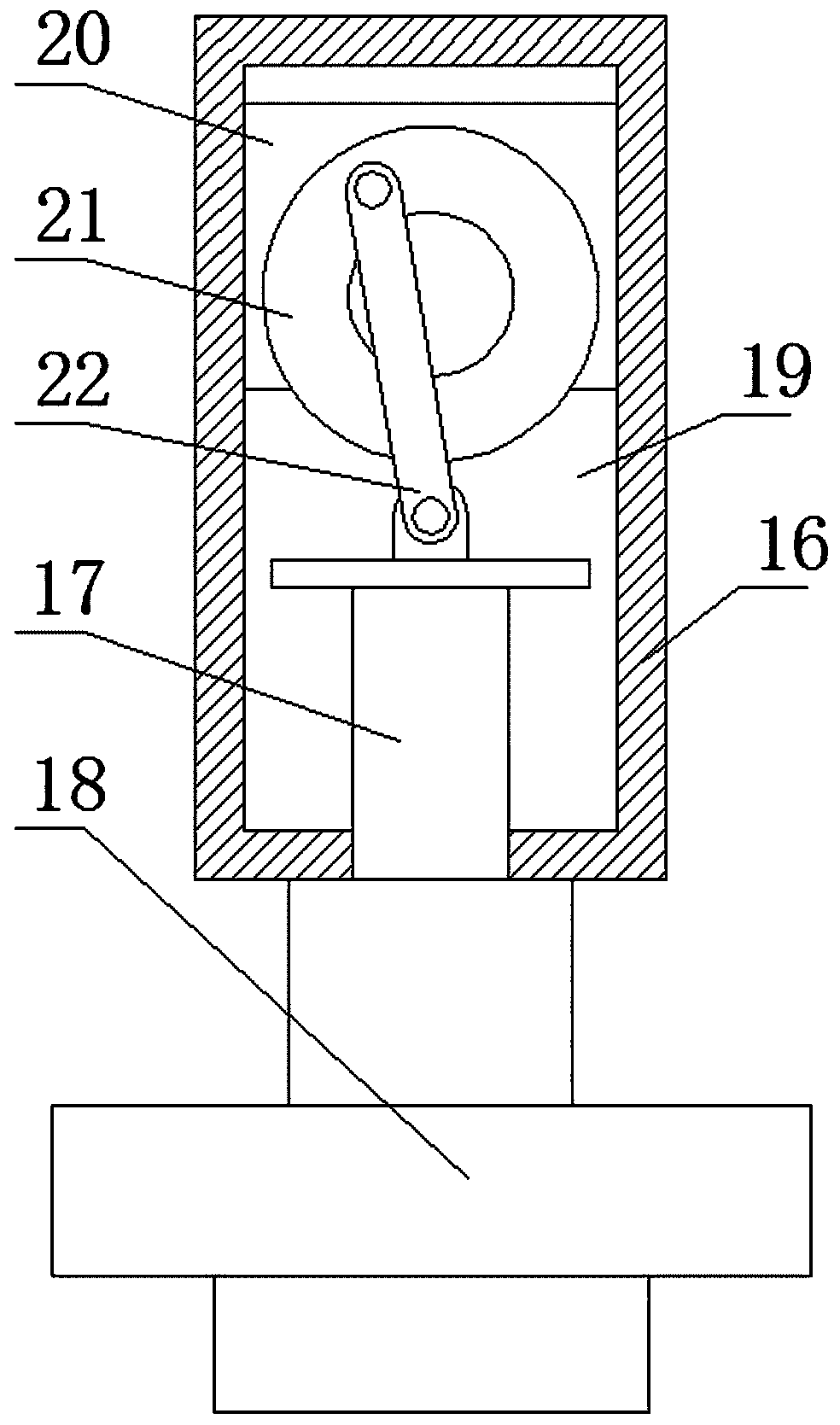

Labeling machine

InactiveCN112407505AEasy labelingImprove labeling efficiencyLabelling machinesLabelling short rigid containersLabelling machineSupport belt

The invention relates to the field of labeling, in particular to a labeling machine. The labeling machine comprises an upper mounting frame, a labeling roller mechanism, label supporting mechanisms, alower supporting frame, conveying mechanisms, a supporting belt adjusting mechanism, a labeling supporting belt, a supporting belt tensioning mechanism and a label belt. The upper mounting frame is fixedly connected to the lower supporting frame, the labeling roller mechanism is connected to the middle of the upper mounting frame, the two label supporting mechanisms are connected to the front endand the rear end of the upper mounting frame correspondingly, the two label supporting mechanisms and the labeling roller mechanism abut against the label belt, and the two conveying mechanisms are fixedly connected to the front end and the rear end of the lower supporting frame correspondingly. The supporting belt adjusting mechanism is connected to the lower end of the lower supporting frame, the supporting belt adjusting mechanism is in transmission connection with the lower supporting frame through the labeling supporting belt, the supporting belt tensioning mechanism is connected to themiddle of the lower supporting frame, and the supporting belt tensioning mechanism is located under the labeling roller mechanism. Labeling on glass bottles is facilitated, and the labeling efficiencyis high.

Owner:蔡霞

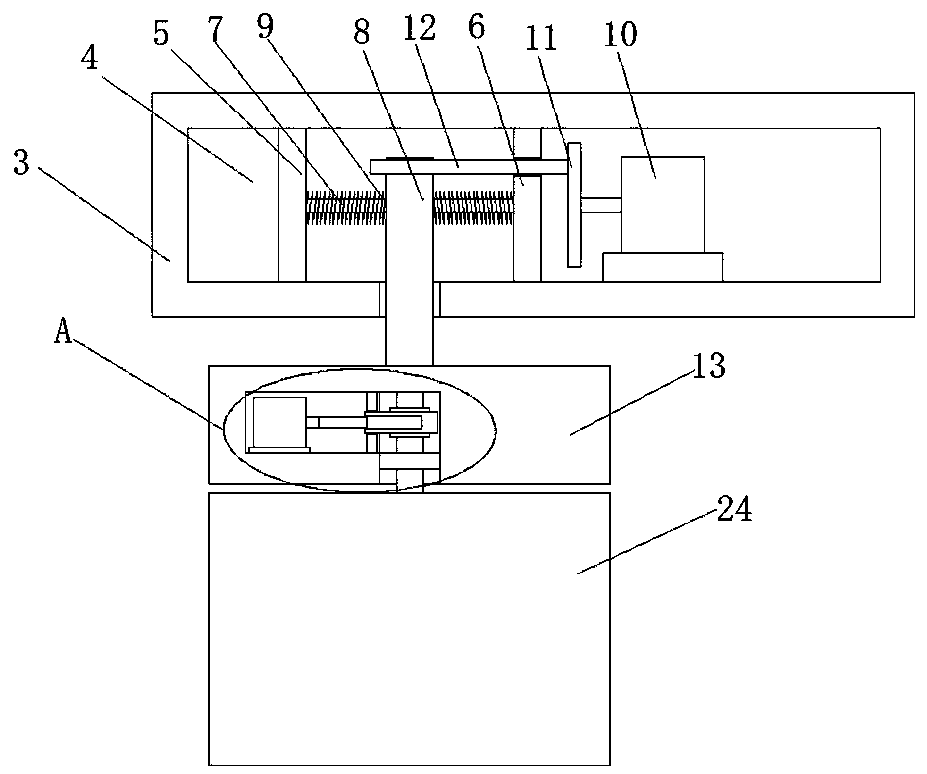

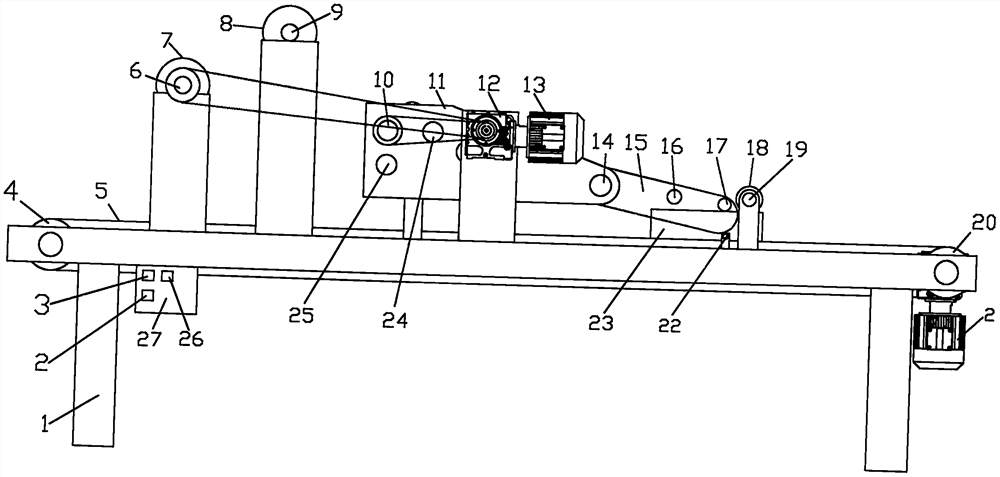

A book attitude adjustment system and method

The invention belongs to the technical field of book separation and transportation, and specifically discloses a book posture adjustment system, which includes a book sending unit, and at least one of a rejecting unit and a sorting unit. The book sending unit is the initial unit of the book posture adjustment system; The unit includes a separating device, the separating device includes a separating mechanism for transferring the books to the rejecting unit or the sorting unit; the rejecting unit includes a first conveyor belt, a rejecting mechanism capable of rejecting books from the first conveyor belt, and a recognition device for detecting books Mechanism; the finishing unit is used to adjust the position of the book. This scheme realizes the separation, abnormal elimination and sorting of books, so that the books are always transported to the labeling machine according to certain rules before labeling, which is convenient for the labeling machine to directly label the books.

Owner:广州标控科技有限公司

Intensity data visualization

Techniques for coloring a point cloud based on colors derived from LIDAR (light detection and ranging) intensity data are disclosed. In some embodiments, the coloring of the point cloud may employ an activation function that controls the colors assigned to different intensity values. Further, the activation function may be parameterized based on statistics computed for a distribution of intensities associated with a 3D scene and a user-selected sensitivity. Alternatively, a Fourier transform of the distribution of intensities or a clustering of the intensities may be used to estimate individual distributions associated with different materials, based on which the point cloud coloring may be determined from intensity data.

Owner:SCALE AI INC

Multi-station processing alcohol packaging device

InactiveCN111606288ABenefit from the improvement of production efficiencyGood gripLiquid materialLiquid bottlingTelescopic cylinderStructural engineering

The invention discloses a multi-station processing alcohol packaging device. The multi-station processing alcohol packaging device includes a machine box; a workbench is arranged above the machine box; a rack is arranged on the upper left side of the machine box; a material injection box is installed above the rack; the bottom right side of the material injection box is connected with a flow guiding tube; an infusion head is connected to one end of the flow guiding tube; a stop valve is arranged on the upper left side of the infusion head; a control line is arranged on the stop valve; a labeler is arranged inside the right side of the machine box; the center line of the right side surface of the labeler is a telescopic cylinder; a label stripping block is connected below the labeler; and alabel holder is installed under the label stripping block. According to the invention, a clamping plate and the labeler are arranged on both sides of a flow guiding groove, which is convenient for fixing the position of the container and for labeling by the labeler; and meanwhile, infusion heads are arranged symmetrically and vertically above the clamping plate, which facilitates the infusion ofliquid into the container and is beneficial to the improvement of production efficiency.

Owner:DONGGUAN KAILEDI NUMERICAL CONTROL SCI & TECH CO LTD

Lithium battery intelligent welding and labeling equipment and method thereof

InactiveCN110797482AAir pressure real-time detectionEasy to operateFinal product manufactureCell component detailsSlide plateBattery cell

The invention discloses lithium battery intelligent welding and labeling equipment and a method thereof. In view of the problems that in the existing production process of the shell of the lithium battery, the material splicing part of the shell needs to be welded generally, the outer part also needs to be labeled, the two production links are separated, and thus, the lithium battery shell production time is long and the production efficiency is low, the clamping device comprises a fixing table, two symmetrically-arranged supporting rods are fixedly installed at the top of the fixing table, the same top plate is fixedly installed at the tops of the two supporting rods, a lifting assembly is arranged on the top plate, a sliding plate is fixedly installed at the bottom of the lifting assembly, and a transverse sliding assembly is arranged on the sliding plate. The structure is simple, the battery shell is welded and labeled by using a welding head and a labeling assembly, the two production procedures are combined, the production time is greatly saved, meanwhile, the production efficiency is improved, and the practicability is high.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Full-automatic labelling machine

InactiveCN110949817AEasy labelingImprove labeling efficiencyLabelling machinesControl systemEngineering

The invention discloses a full-automatic labelling machine which comprises a control chamber and a working chamber, wherein the control chamber is provided with a control system; the working chamber is provided with a label component connected with the control system, an automatic labelling component, an assembly line component and a camera shooting sensing component; the label component is used for providing a to-be-pasted label; the automatic labelling component is used for moving a label and pasting the label on a product workpiece; the assembly line component is used for moving the productworkpiece to a labelled part and moving a finished product to a placing frame; and the camera shooting sensing component is used for responding to the automatic labelling component to grab a label according to the label position and responding to the automatic labelling component to label the product workpiece according to the position of the product workpiece. The full-automatic labelling machine has the following benefits: all components work in a mutually independent and cooperated manner to finish full-automatic labelling operation of the product workpiece, the labelling efficiency is high, and excessive manual operation is not needed.

Owner:DONGGUAN ZHIHUN MACHINERY TECH CO LTD

Labeling and marking method for inner wall of tube core

ActiveCN113859695AReduce manufacturing costEasy labelingNuclear energy generationMetal working apparatusManipulatorShort distance

The invention discloses a labeling and marking method for inner wall of tube core. The labeling and marking method comprises the following steps: placing the tube core of which the upper surface is provided with avoiding holes at equal intervals on a reciprocating feeding device, and arranging a tube core traction and pulling device at the front part of one end of the reciprocating feeding device; conveying the end part of the tube core to a labeling manipulator by the reciprocating feeding device, and sucking a label from a label stripper and attaching the label to the inner wall of the end part of the tube core by the labeling manipulator; conveying the end part of the tube core to a laser marking machine by the reciprocating feeding device, and printing a pre-stored tracing bar code on a label corresponding to the inner wall of the end part of the tube core by the laser marking machine; conveying the end part of the tube core to the tube core splitting machine by the reciprocating feeding device, and splitting a small section of tube core printed with the traceability bar code by the tube core splitting machine; and pulling the core tube to move forwards at a short distance by the tube core traction and pulling device. According to the full-automatic pipe core labeling machine, the inner wall of the pipe core can be automatically labeled, the surface of the label can be automatically marked, pipe core slitting can be achieved, and the production efficiency is high.

Owner:隆扬电子(昆山)股份有限公司

Automatic labelling machine for label

The invention discloses an automatic labeling machine for a label. The automatic labeling machine comprises a rack, wherein the rack is rotatably connected to a winding roll shaft and an unwinding roll shaft and is fixedly connected to a first front side plate, a second front side plate, a pull reduction gearbox, a photoelectric switch and a flattening roll shaft, and the winding roll shaft is fixedly connected to a winding roller; the unwinding roll shaft is fixedly connected to an unwinding roller, and a label tape is wound on the unwinding roller; a pull roll shaft and a pressure roll shaftare rotatably connected between the first front side plate and the second front side plate, and a first roller shaft, a second roller shaft and first to third slide bars are fixedly connected betweenthe first front side plate and the second front side plate; the pull roll shaft is fixedly connected to a pull roller, the pressure roll shaft is fixedly connected to a pressure roller, the first roller shaft is rotatably connected to a first roller, and the second roller shaft is rotatably connected to a second roller; the pull reduction gearbox is in transmission connection with a pull motor, the winding roll shaft and the pull roll shaft respectively; the rear ends of the first front side plate and the second front side plate are rotatably and fixedly connected to a first rear side plate and a second rear side plate through a third slide bar, and the third roller shaft is in transmission connection with a third roller. The automatic labeling machine is simple in structure, low in cost,easy to operate and capable of saving time and labor.

Owner:LUOHE LIANTAI FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com