A right-angle hanging board processing equipment and stamping system

A technology of right-angle hanging plate and processing equipment, applied in the field of workpiece processing, can solve the problems of low work efficiency, high defective rate of finished products, and many forming processing procedures, so as to reduce investment, reduce processing and material costs, and reduce labor intensity of employees Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

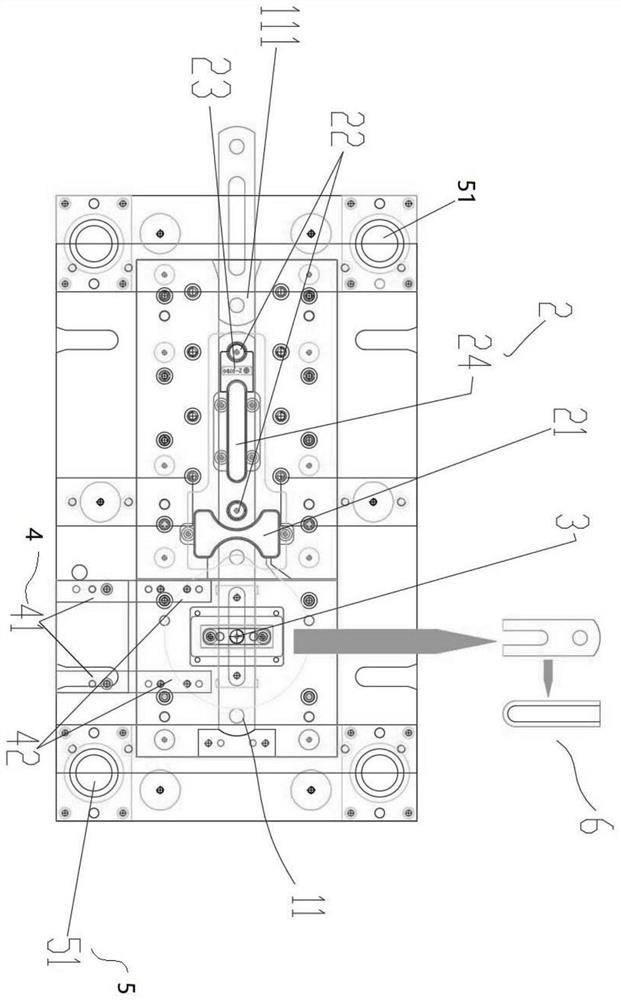

[0037] see figure 1 , figure 2 , a stamping system described in the present invention will now be described. The stamping system of this embodiment includes right-angle hanging board processing equipment, which is used for stamping and forming raw material sheets. The formed right-angle hanging board is a right-angle hanging board. plate, and transport the formed right-angle hanging plate 6 to the stamping system in the receiving chute. This stamping system improves the integration of the stamping die and improves the processing efficiency. Reduce the cumulative error caused by setting multiple punching machines to ensure the qualified rate of products.

[0038] In this example, if figure 1 and figure 2As shown, the above-mentioned right-angle hanging board processing equipment includes an upper mold body and a lower mold body, wherein the lower mold body is provided with a conveying channel 11, in order to ensure the stable conveying of the raw material sheet in the conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com