Novel spiral label reel pipe slitting integrated machine

An all-in-one, spiral technology, applied in the direction of winding strips, sending objects, processing thin materials, etc., can solve the problems that labeling and slitting cannot be carried out at the same time, waste of work time, slow work efficiency, etc., to achieve easy labeling. , Reasonable design, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

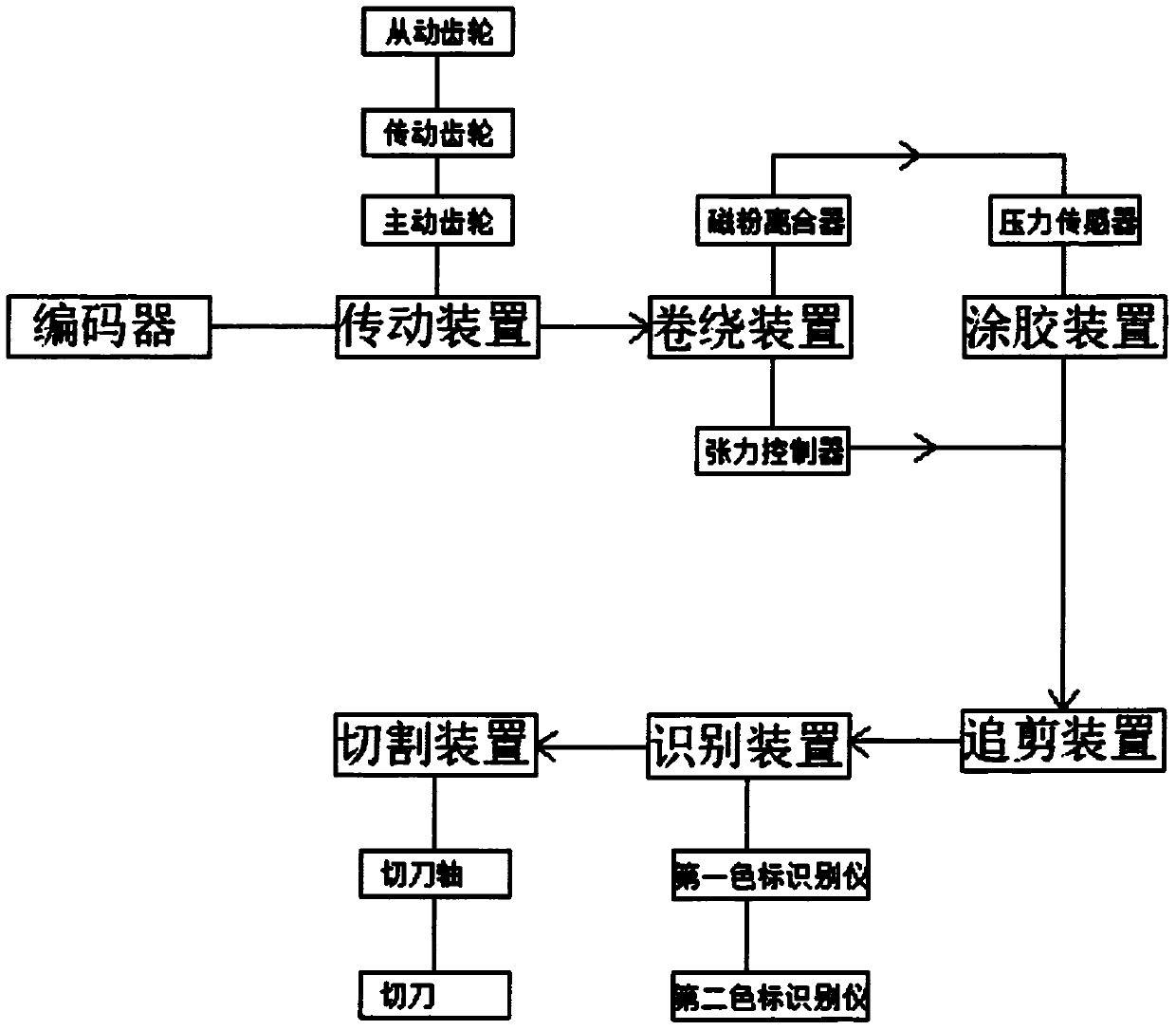

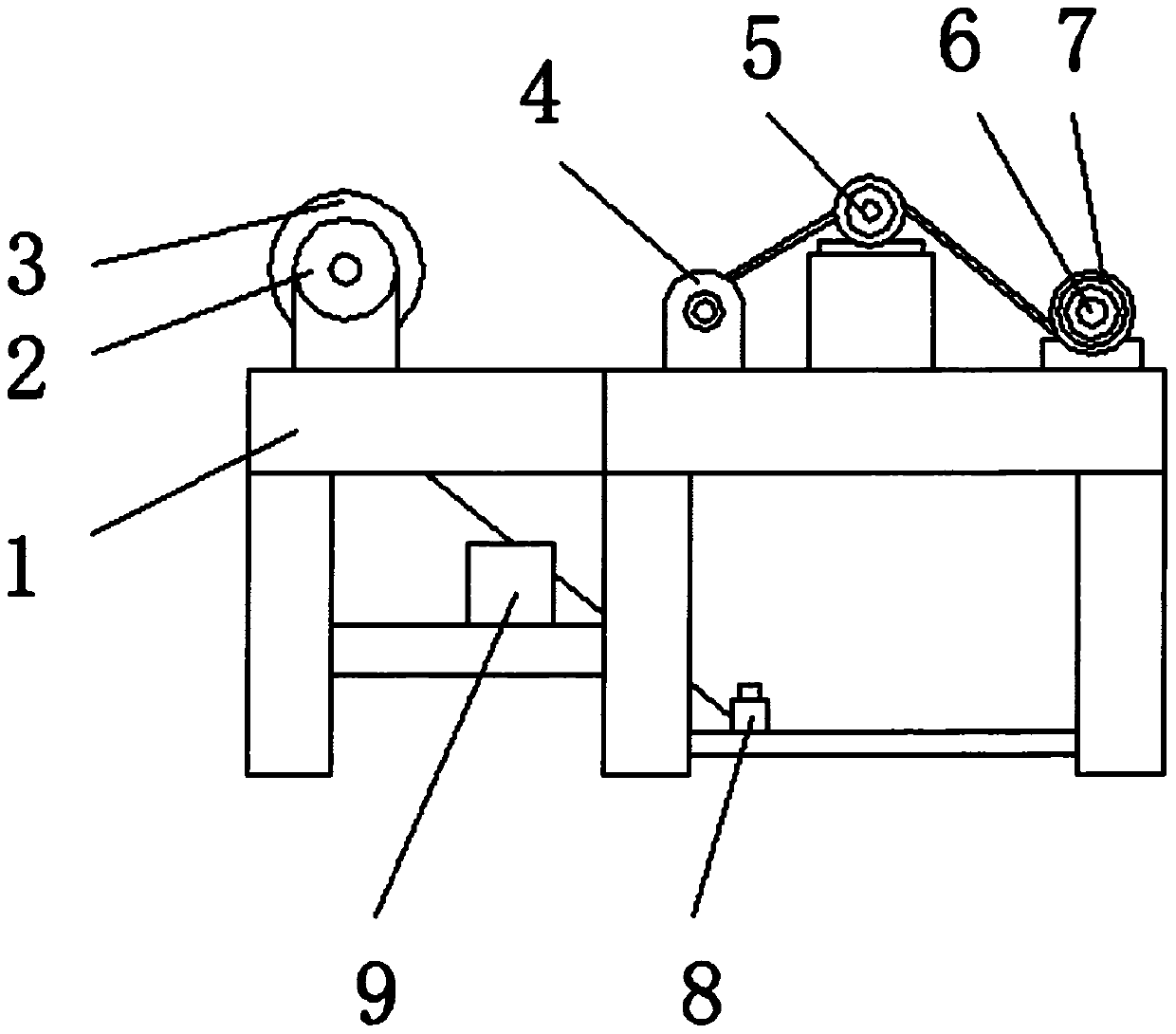

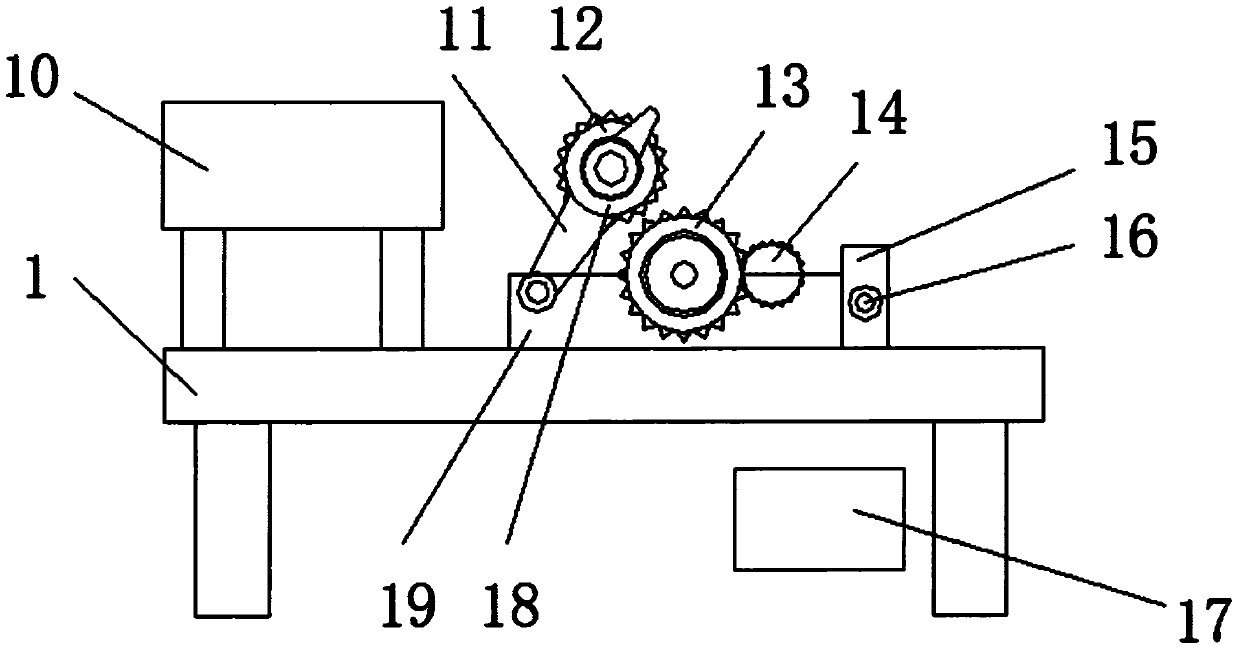

[0027]A new type of spiral label tube slitting and cutting machine, comprising a workbench 1, a magnetic powder clutch 2 is arranged on one end of the surface of the workbench 1, a paper roll 3 is sleeved on the surface of the magnetic powder clutch 2, and the magnetic powder clutch 2 One side of the encoder 4 is fixedly connected with an encoder 4, and one end of the encoder 4 is clamped with a pressure sensor 5, and one end of the pressure sensor 5 is connected to a guide roller 7 through a rotating shaft 6, and one end of the bottom end of the workbench 1 A redirection roller 8 is provided, one end of the redirection roller 8 is embedded with a tension controller 9, a glue pool 10 is provided at the top end of the middle part of the surface of the workbench 1, and a glue pool 10 is fixedly connected to the middle part of the surface of the workbench 1 Fixed block 19, one end of the fixed block 19 is rotatably connected with the driving gear 14, one end of the driving gear 14...

Embodiment 2

[0029] A new type of spiral label tube slitting and cutting machine, comprising a workbench 1, a magnetic powder clutch 2 is arranged on one end of the surface of the workbench 1, a paper roll 3 is sleeved on the surface of the magnetic powder clutch 2, and the magnetic powder clutch 2 One side of the encoder 4 is fixedly connected with an encoder 4, and one end of the encoder 4 is clamped with a pressure sensor 5, and one end of the pressure sensor 5 is connected to a guide roller 7 through a rotating shaft 6, and one end of the bottom end of the workbench 1 A redirection roller 8 is provided, one end of the redirection roller 8 is embedded with a tension controller 9, a glue pool 10 is provided at the top end of the middle part of the surface of the workbench 1, and a glue pool 10 is fixedly connected to the middle part of the surface of the workbench 1 Fixed block 19, one end of the fixed block 19 is rotatably connected with the driving gear 14, one end of the driving gear 1...

Embodiment 3

[0031] A new type of spiral label tube slitting and cutting machine, comprising a workbench 1, a magnetic powder clutch 2 is arranged on one end of the surface of the workbench 1, a paper roll 3 is sleeved on the surface of the magnetic powder clutch 2, and the magnetic powder clutch 2 One side of the encoder 4 is fixedly connected with an encoder 4, and one end of the encoder 4 is clamped with a pressure sensor 5, and one end of the pressure sensor 5 is connected to a guide roller 7 through a rotating shaft 6, and one end of the bottom end of the workbench 1 A redirection roller 8 is provided, one end of the redirection roller 8 is embedded with a tension controller 9, a glue pool 10 is provided at the top end of the middle part of the surface of the workbench 1, and a glue pool 10 is fixedly connected to the middle part of the surface of the workbench 1 Fixed block 19, one end of the fixed block 19 is rotatably connected with the driving gear 14, one end of the driving gear 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com