Double faced adhesive tape attaching mechanism and double faced adhesive tape attaching equipment

A technology of double-sided adhesive and double-sided tape, which is applied in the direction of sending objects, thin material handling, transportation and packaging, etc., and can solve problems such as high cost and difficult debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

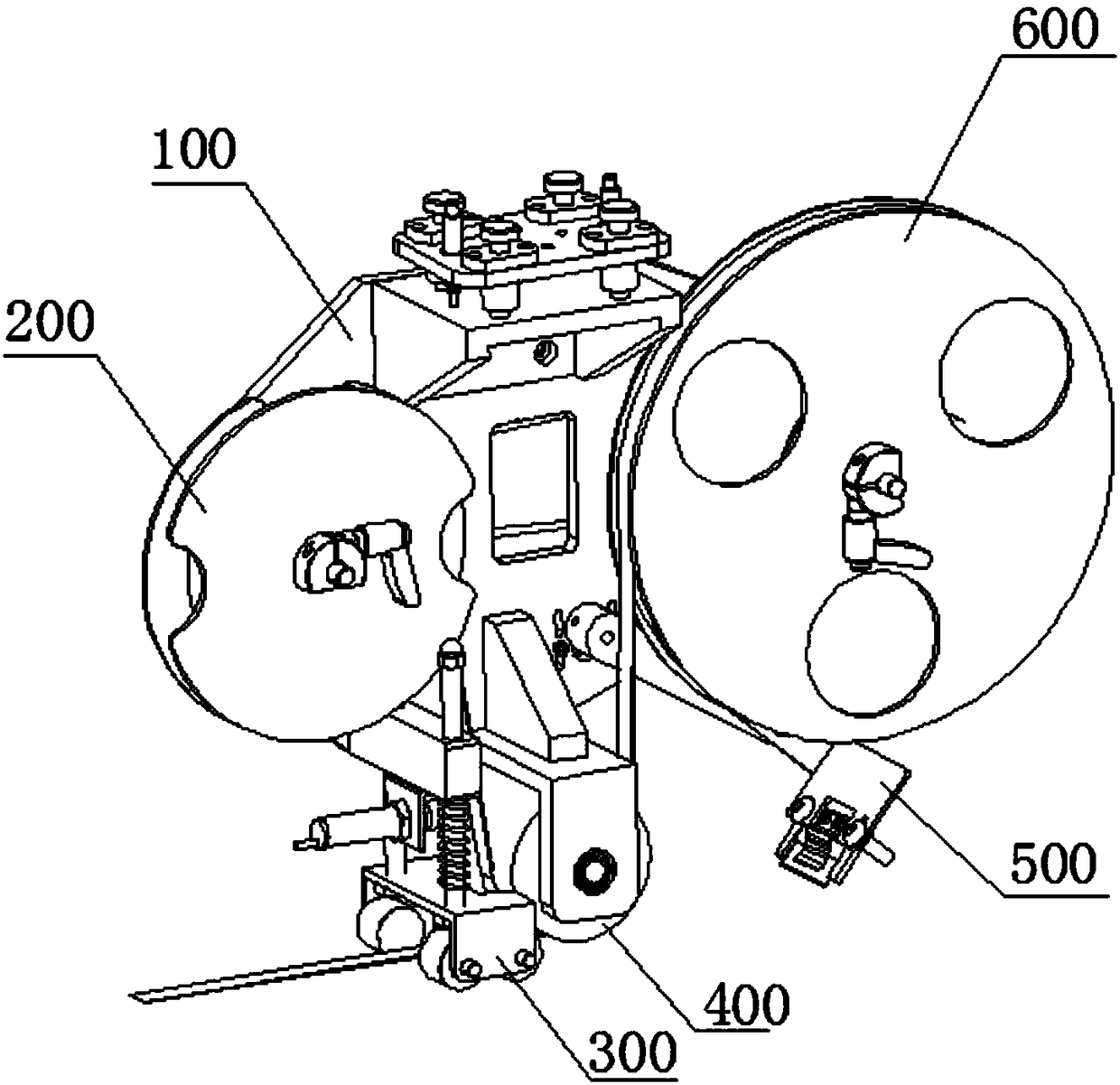

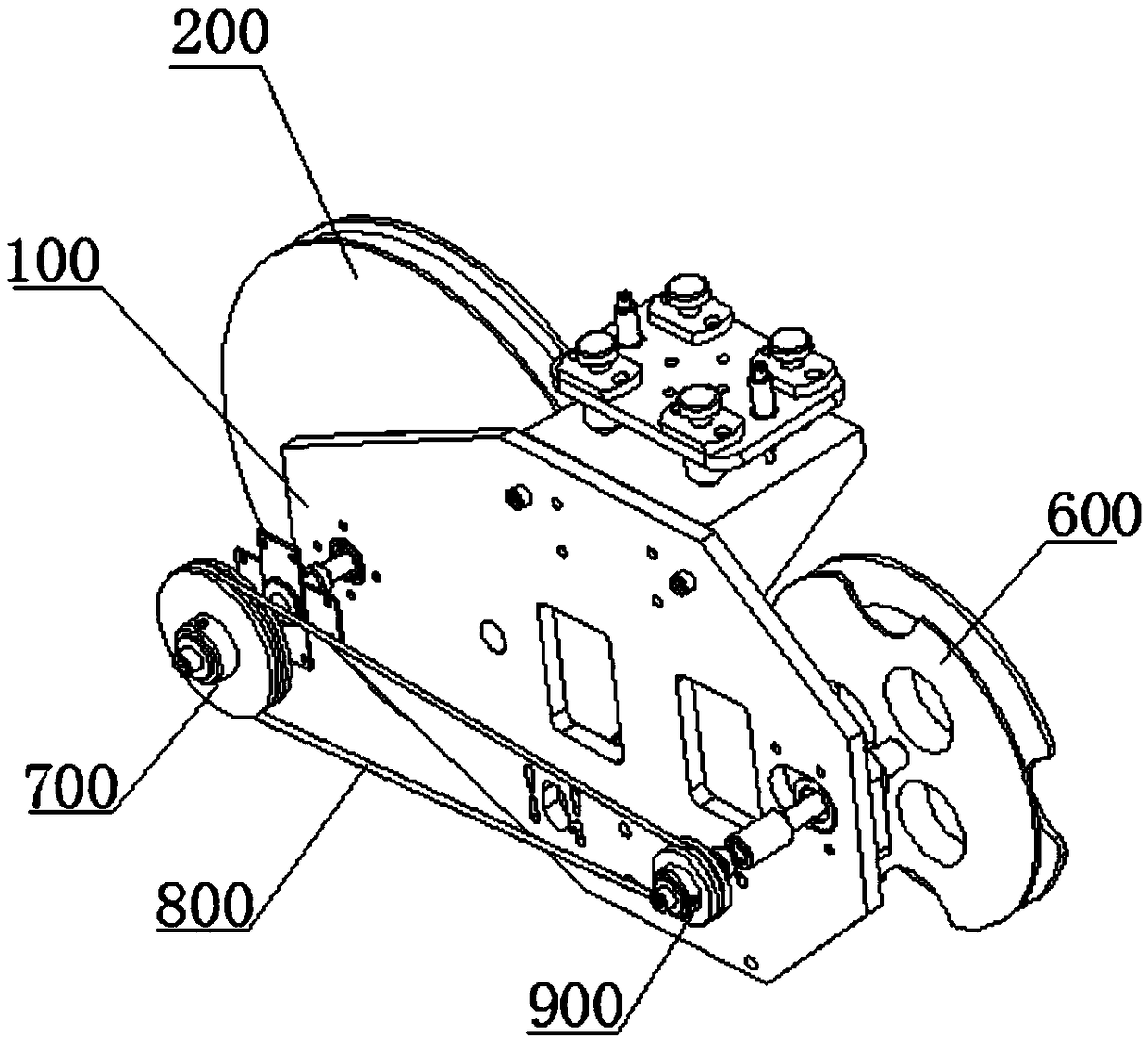

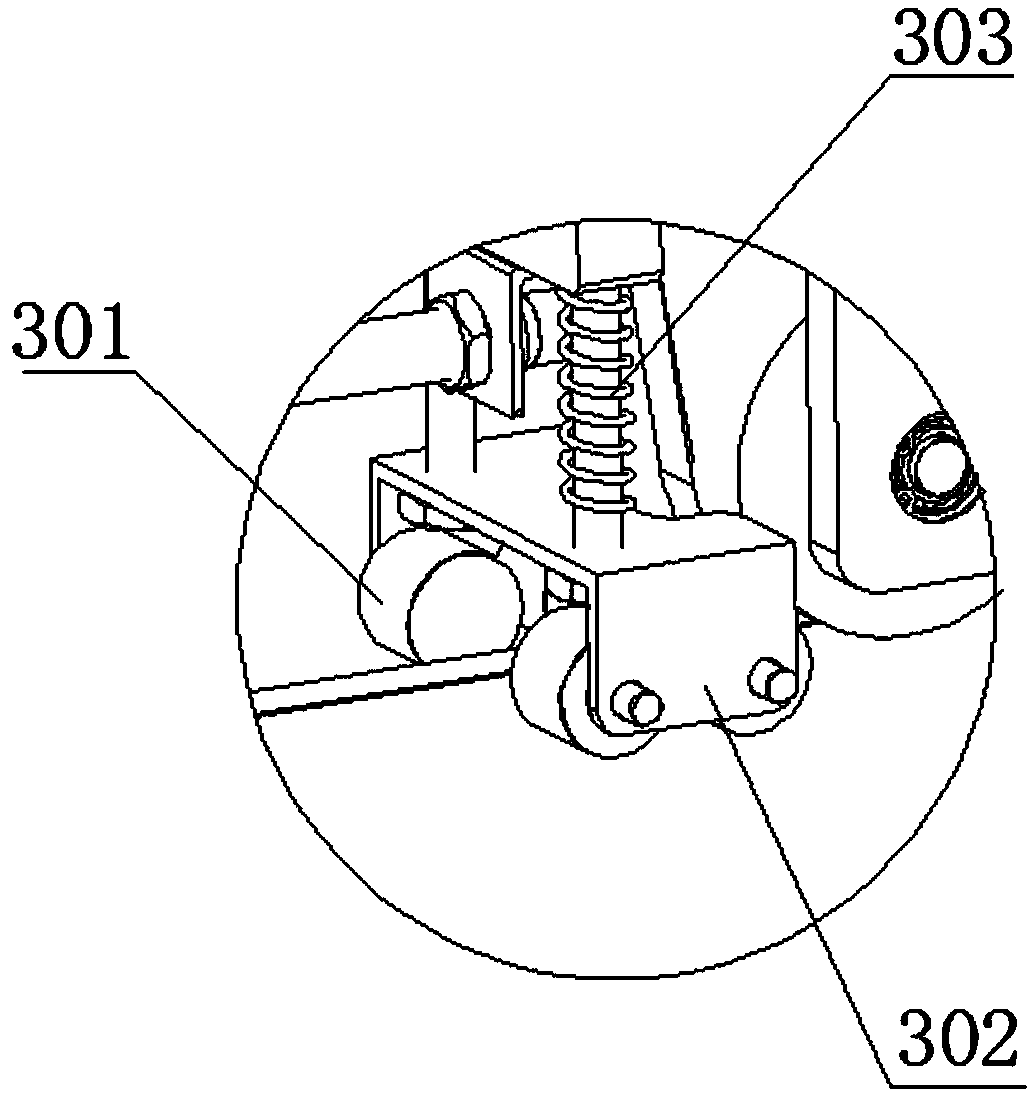

[0034] like Figure 1-3 as shown, figure 1 Structural schematic diagram of the double-sided tape sticking mechanism provided for the embodiment of the present invention Figure 1 ; figure 2 Structural schematic diagram of the double-sided tape sticking mechanism provided for the embodiment of the present invention Figure II ; image 3 It is the front view of the double-sided adhesive sticking mechanism provided by the embodiment of the present invention.

[0035] The double-sided tape sticking mechanism that present embodiment provides, comprises frame 100, and described frame 100 is provided with the rubber unloading wheel 600 of loading double-sided tape, the pressing wheel 400 that keeps double-sided tape and workpiece laminating, winding The receiving wheel 200 of the release paper and the pressure maintaining mechanism 300 for applying pressure to the workpiece; the rubber pressing wheel presses the adhesive tape onto the workpiece, and the movement of the workpiece...

Embodiment 2

[0049] The double-sided tape sticking device provided in this embodiment includes: a double-sided tape sticking device body, the double-sided tape sticking device body includes a workbench for placing workpieces and the above-mentioned double-sided tape sticking mechanism.

[0050] The double-sided tape sticking device provided in this embodiment includes a double-sided tape sticking device body, and the double-sided tape sticking device body includes a workbench for placing workpieces and the above-mentioned double-sided tape sticking mechanism. Due to the setting of the double-sided adhesive mechanism, the double-sided adhesive equipment has all the advantages of the above-mentioned double-sided adhesive mechanism; it not only has the advantages of simple structure and low cost, but also solves the difficult debugging and high cost technology in the prior art question.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com