Patents

Literature

37results about How to "Solve debugging difficulties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

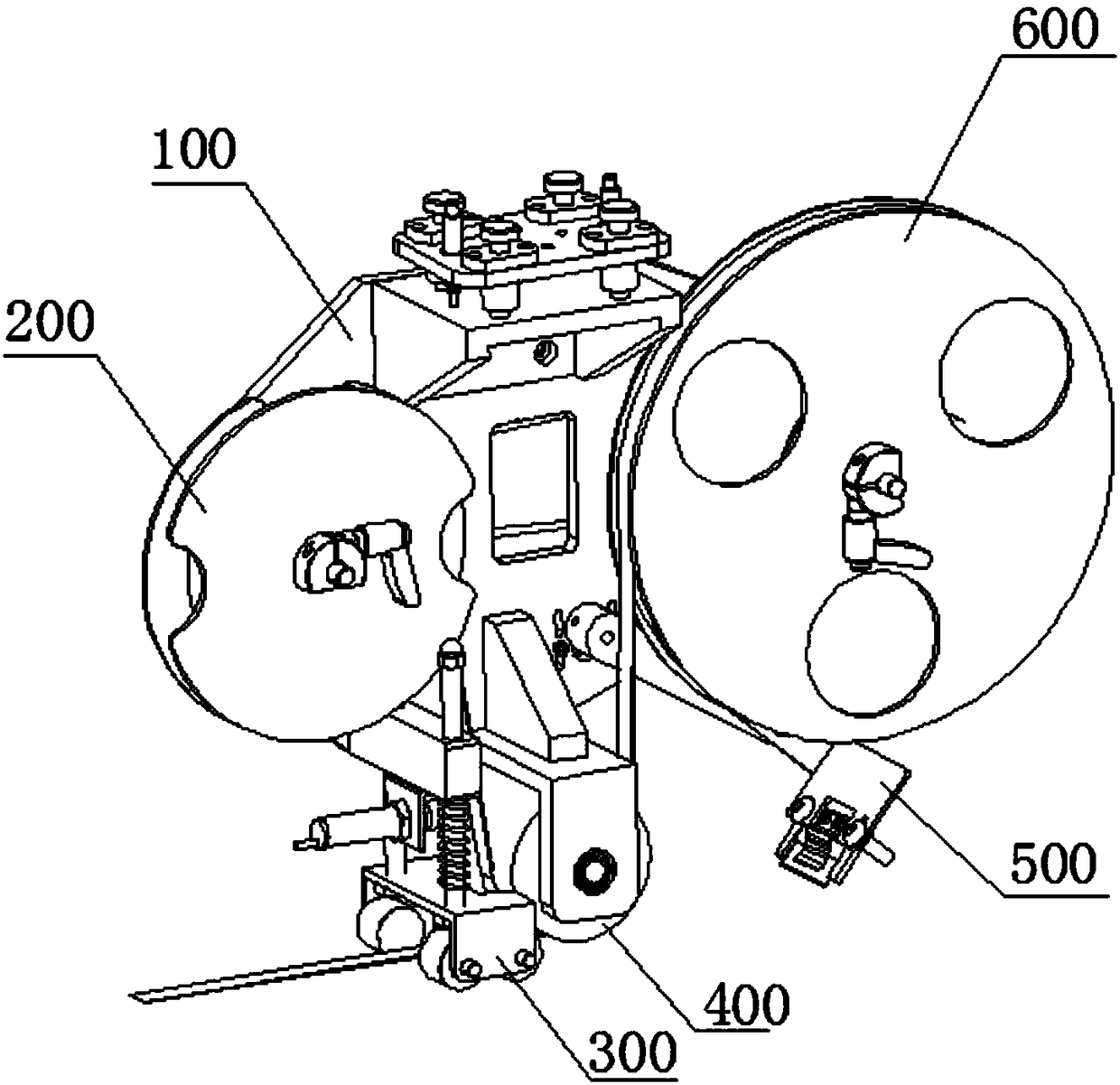

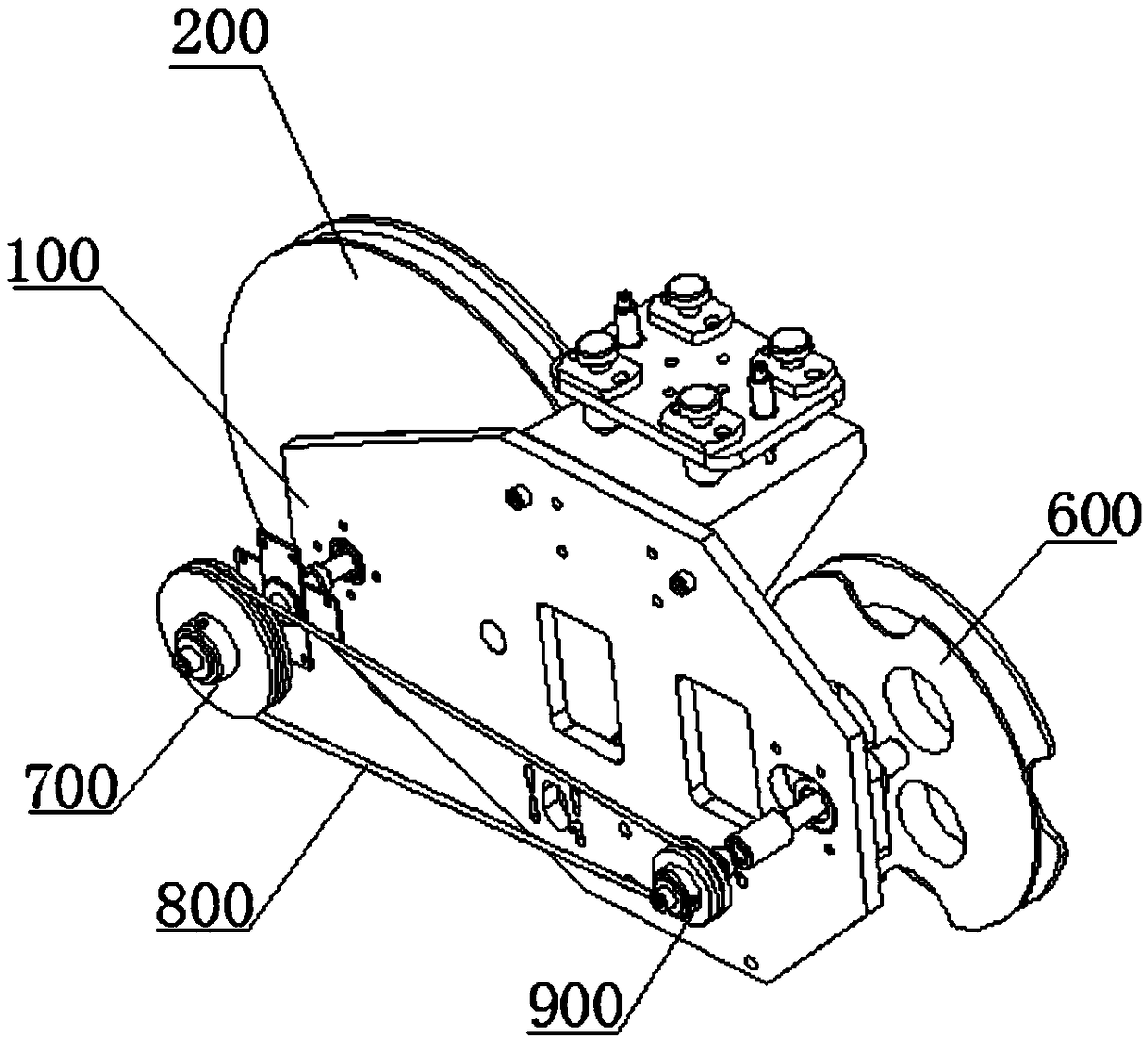

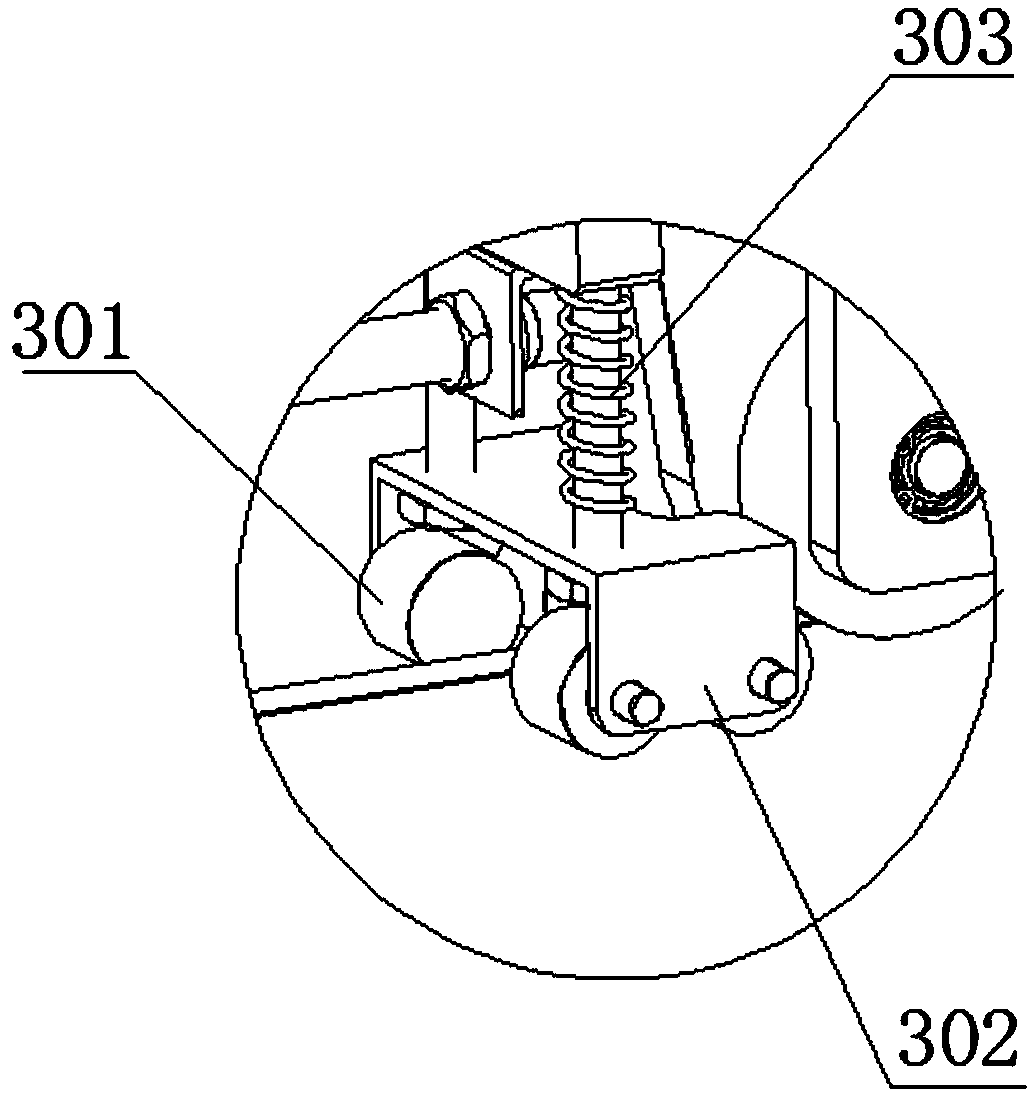

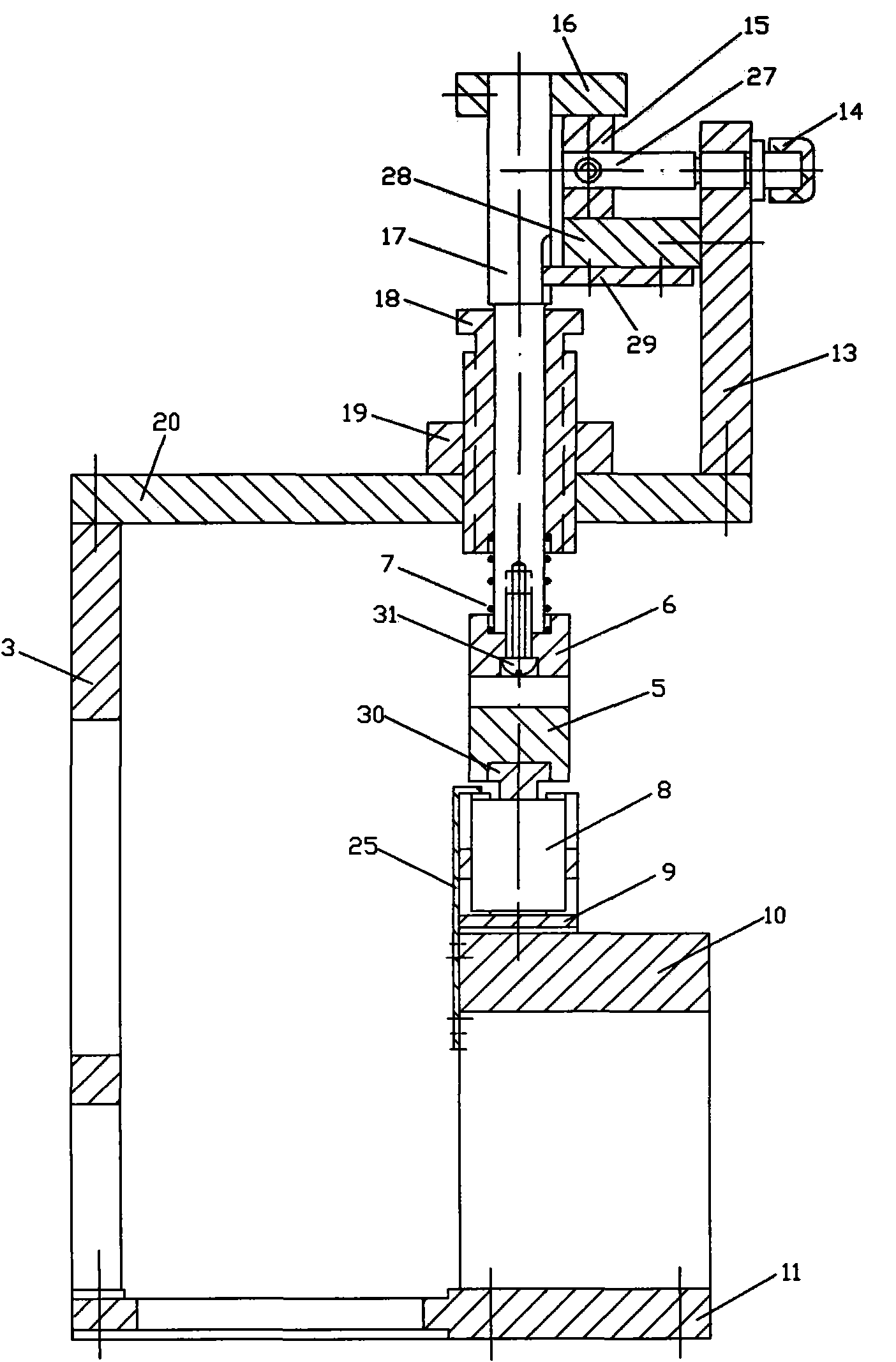

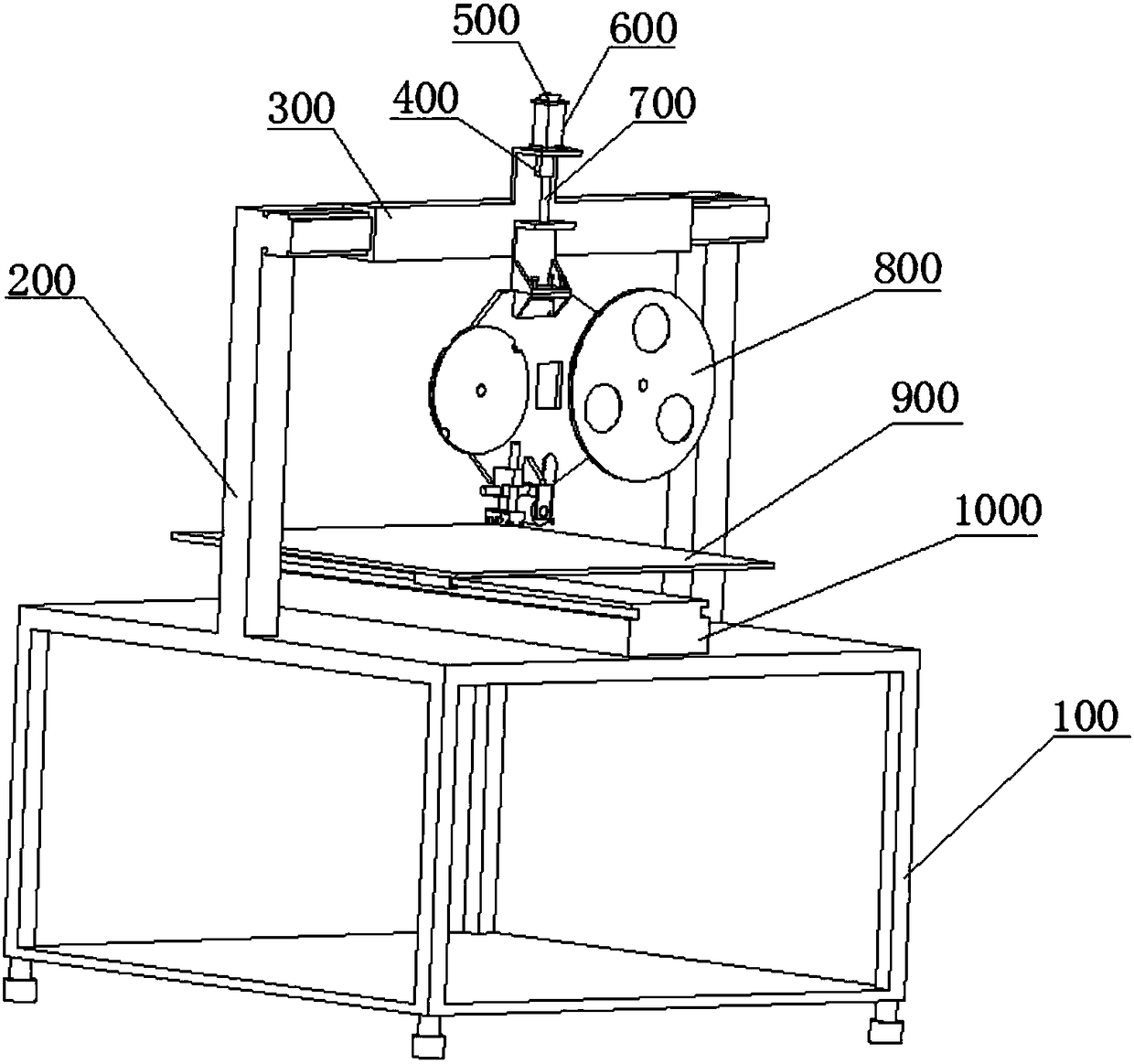

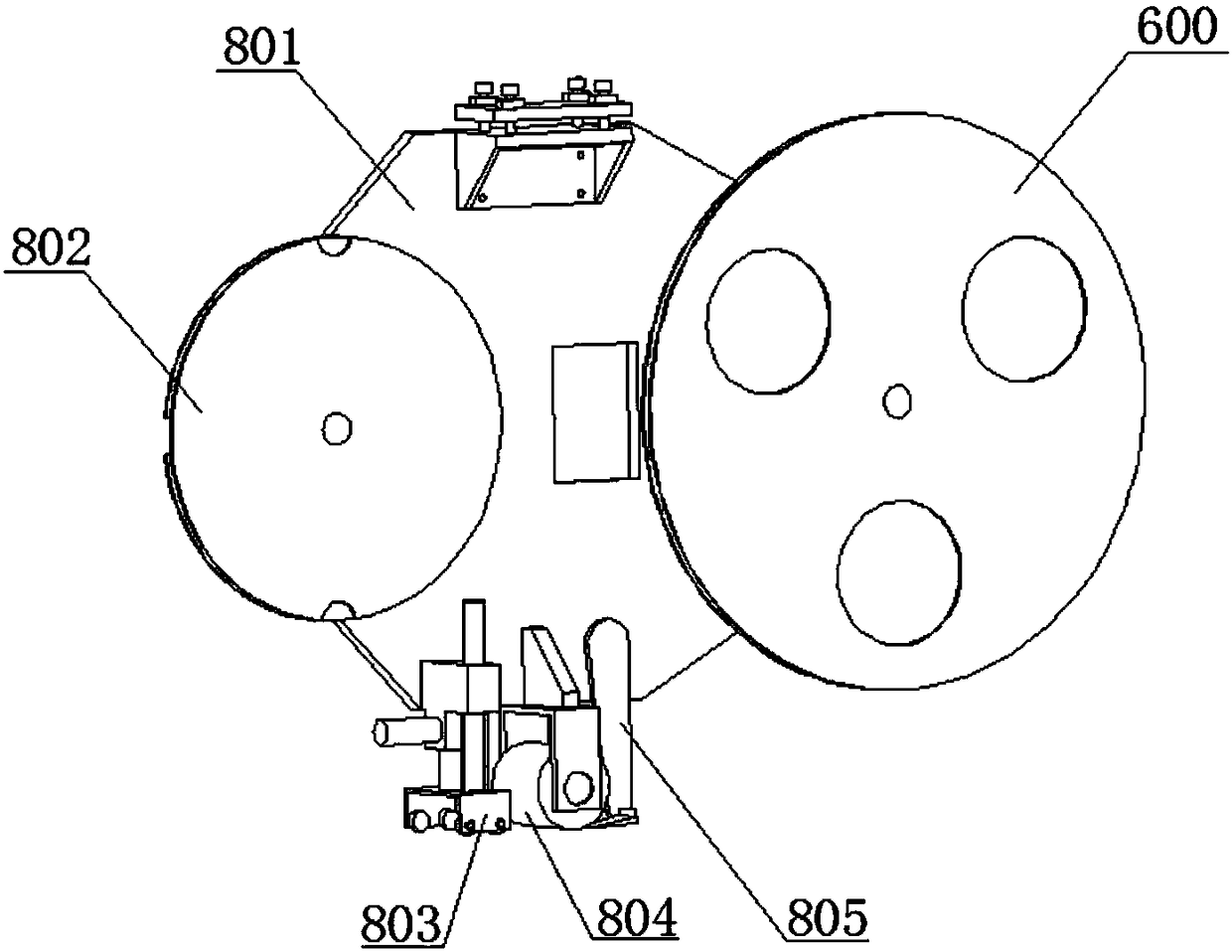

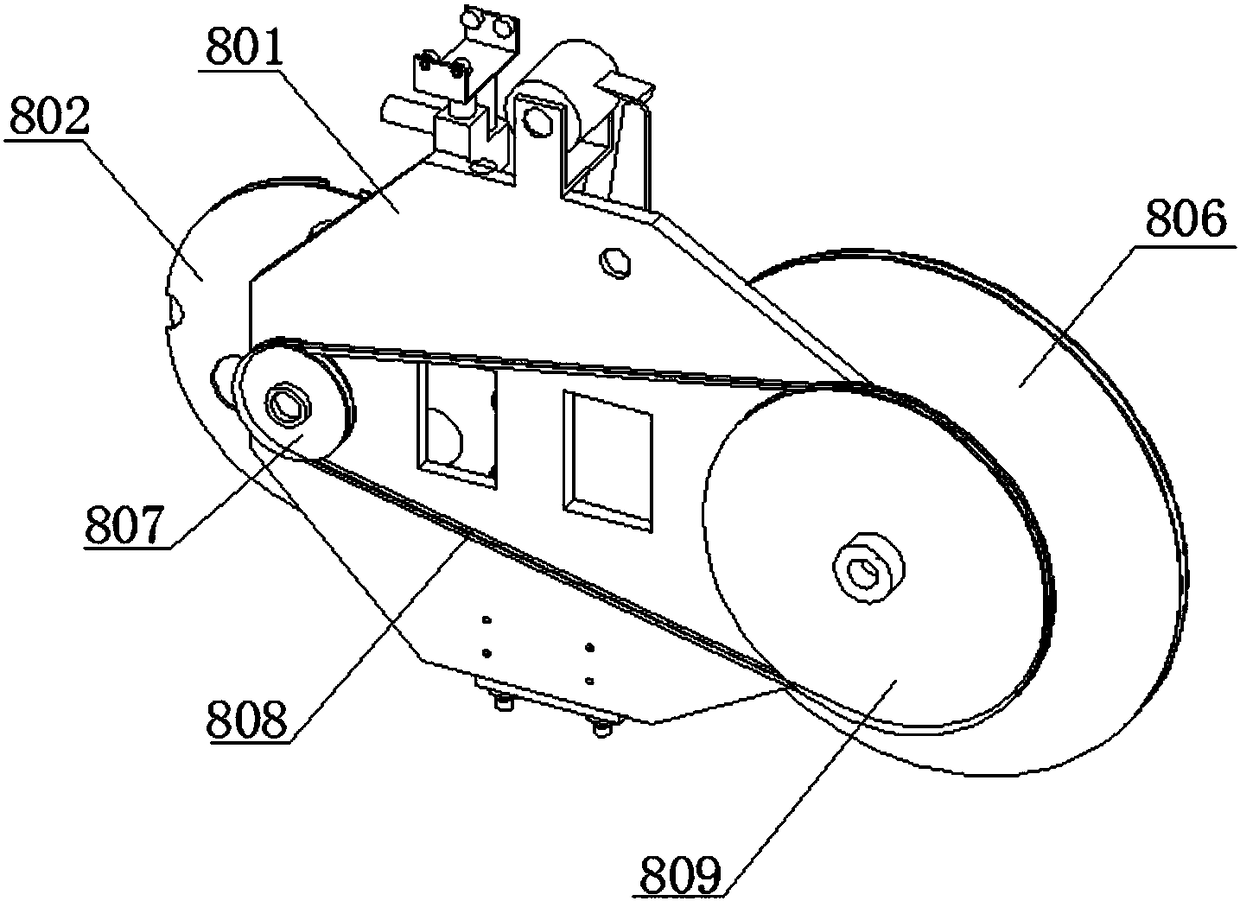

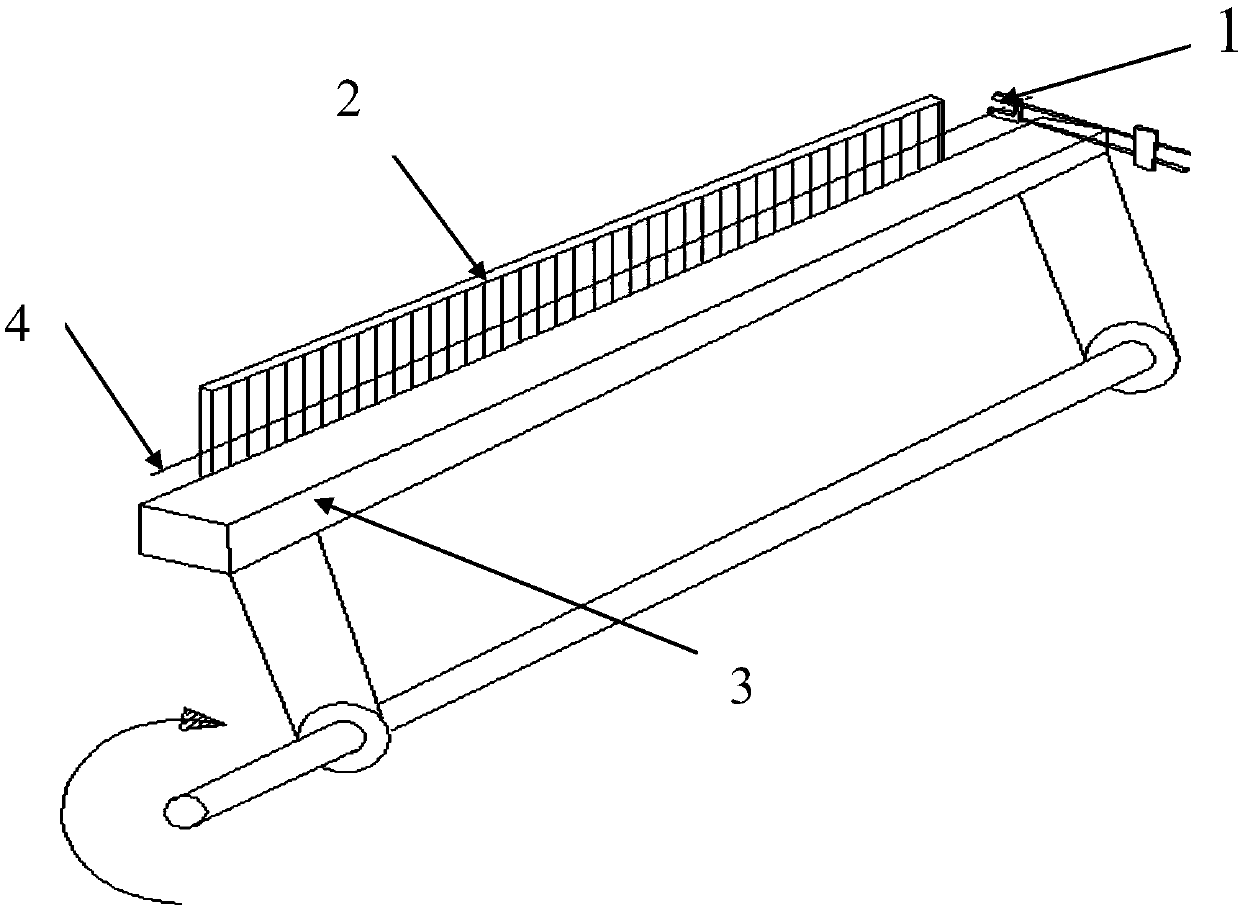

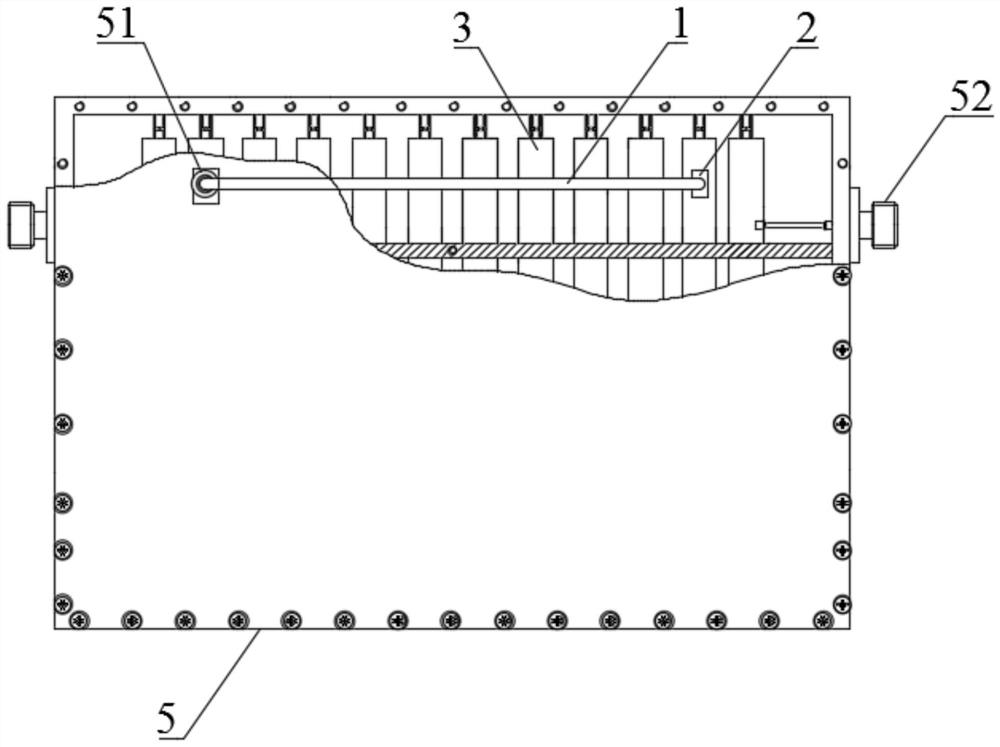

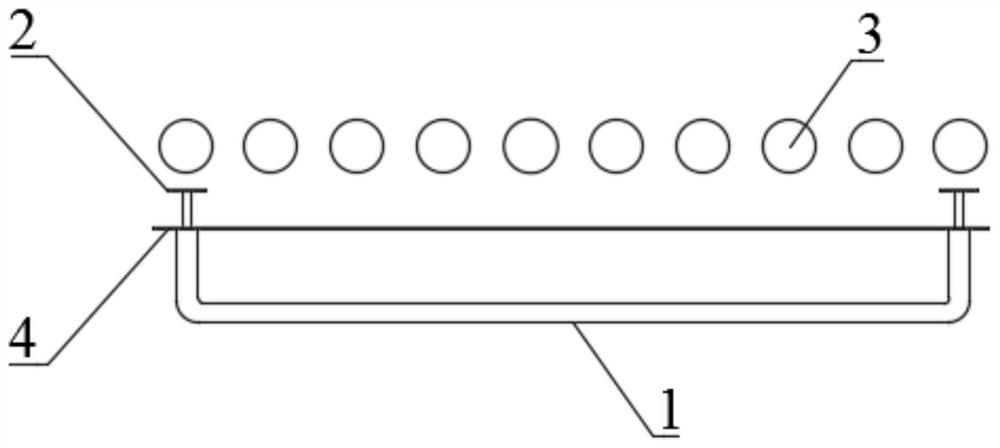

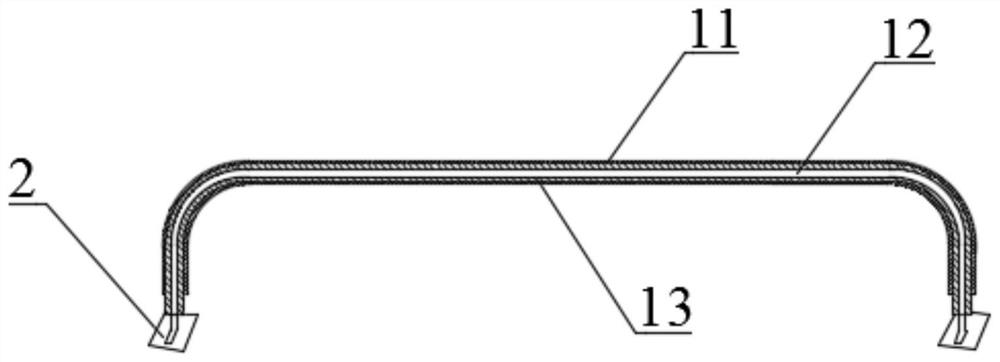

Double faced adhesive tape attaching mechanism and double faced adhesive tape attaching equipment

The invention relates to the technical field of automatic adhesive tape attaching, in particular to a double faced adhesive tape attaching mechanism and double faced adhesive tape attaching equipment.The double faced adhesive tape attaching mechanism comprises a rack. The rack is provided with an adhesive tape putting wheel for loading double faced adhesive tape, an adhesive tape pressing wheel for keeping the double faced adhesive tape to be attached to a workpiece, a storage wheel for rolling release paper and a pressure maintaining mechanism for exerting pressure on the workpiece. The adhesive tape pressing wheel presses the adhesive tape to the workpiece, the movement of the workpiece drives the adhesive tape pressing wheel to rotate, and the adhesive tape pressing wheel drives the adhesive tape putting wheel to rotate through the double faced adhesive tape; and the adhesive tape putting wheel is connected with an adhesive tape putting belt wheel, the storage wheel is connected with a storage belt wheel, the adhesive tape putting belt wheel is connected with the storage belt wheel through a conveyor belt, and the adhesive tape putting wheel drives the storage wheel to rotate through the adhesive tape putting wheel and the storage belt wheel. The double faced adhesive tape attaching equipment comprises the double faced adhesive tape attaching mechanism. By means of the double faced adhesive tape attaching mechanism and the double faced adhesive attaching equipment, the technical problems that in the prior art, debugging is difficult and the cost is high are solved.

Owner:国机智能科技有限公司 +1

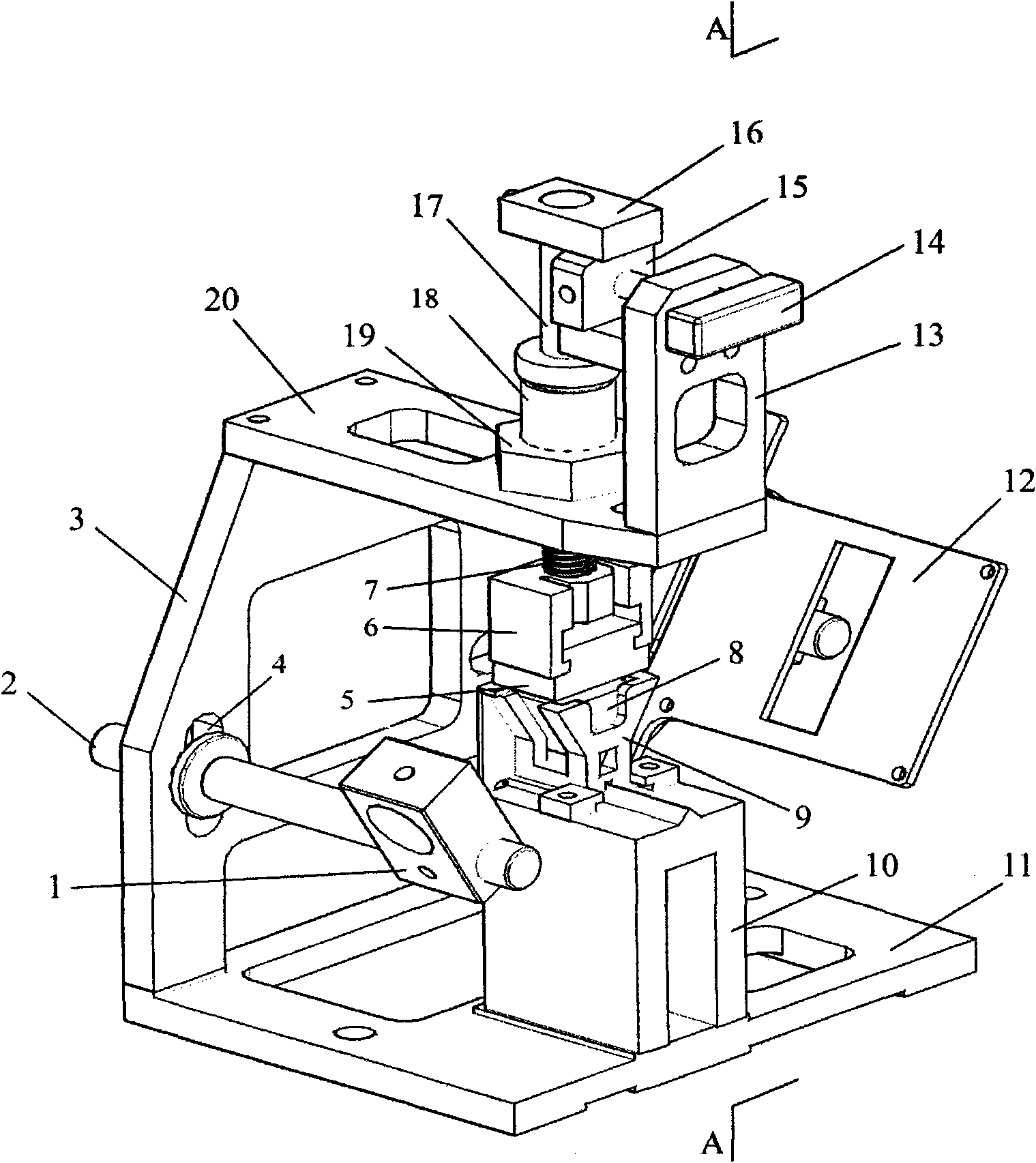

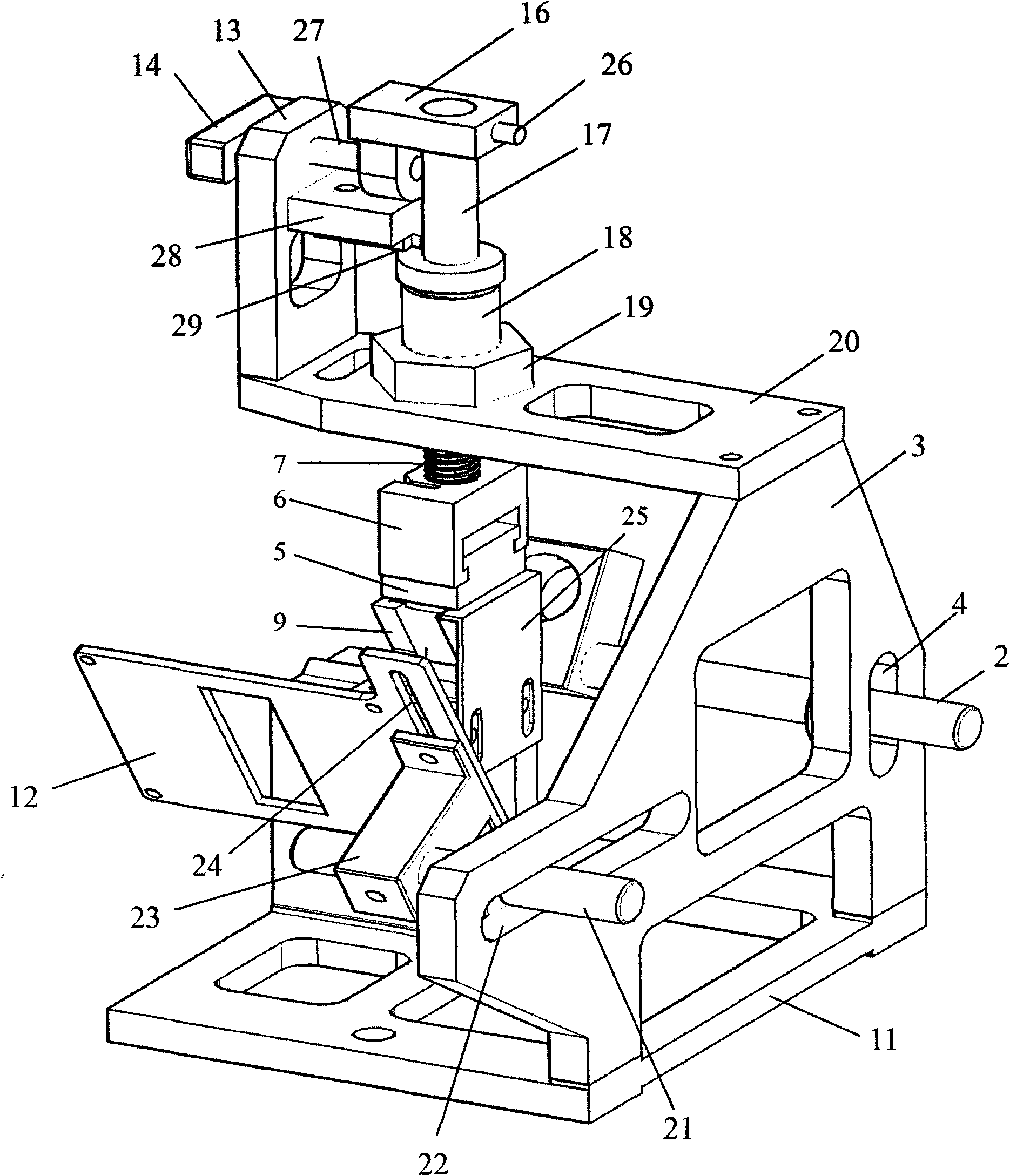

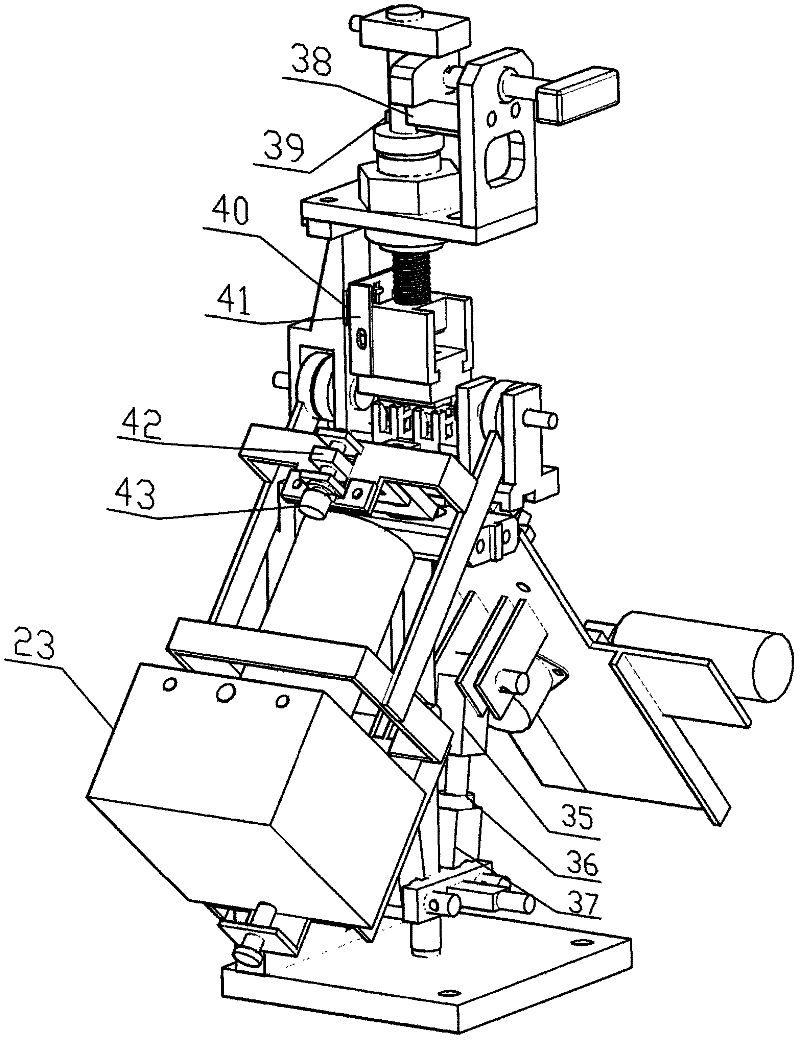

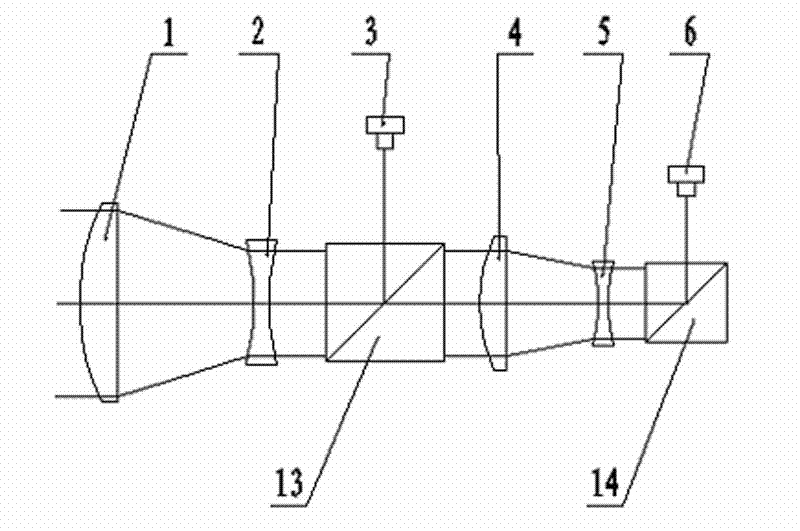

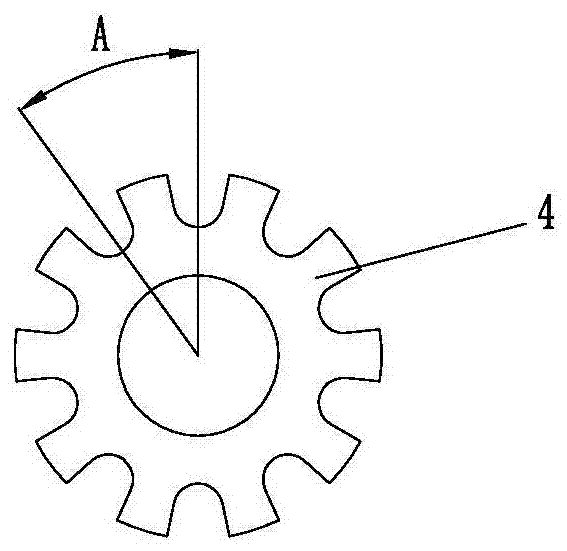

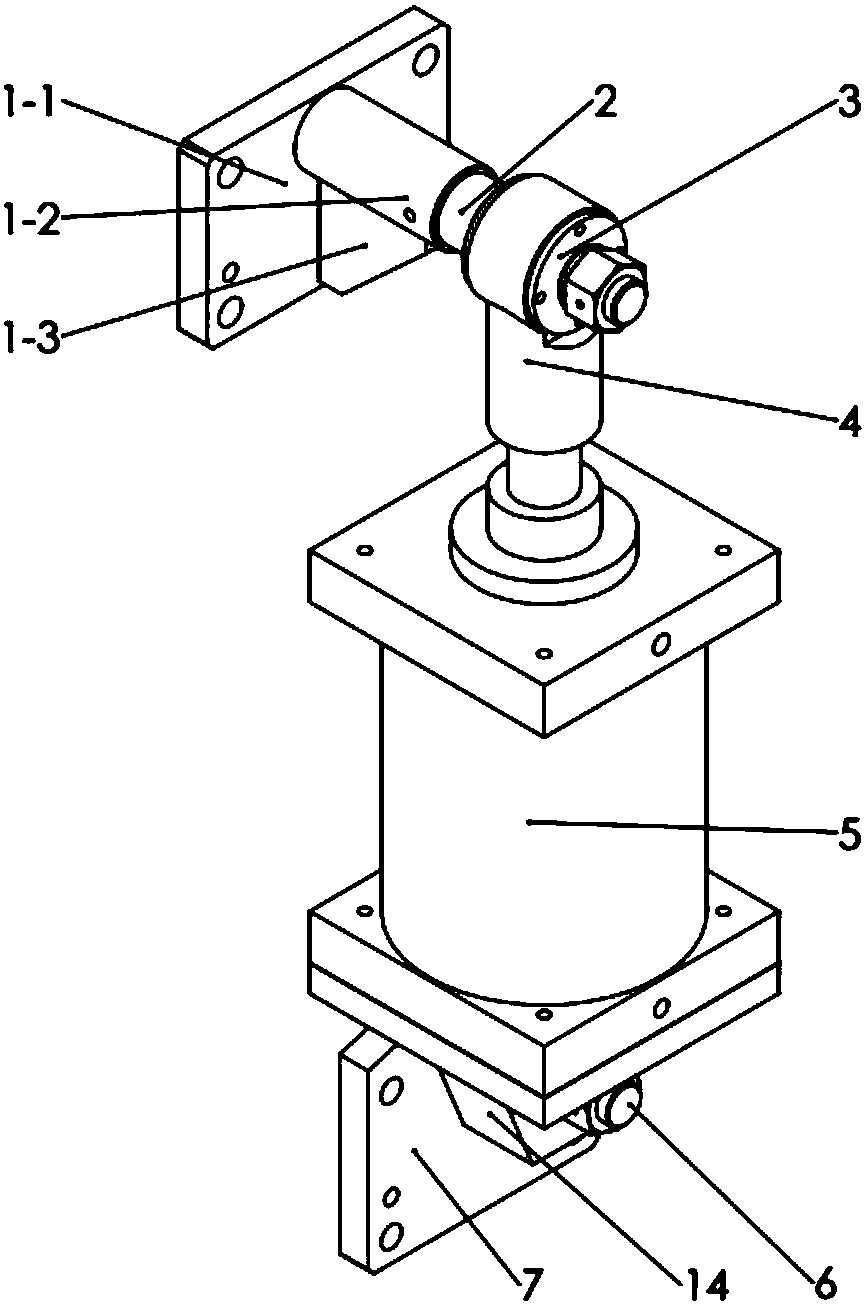

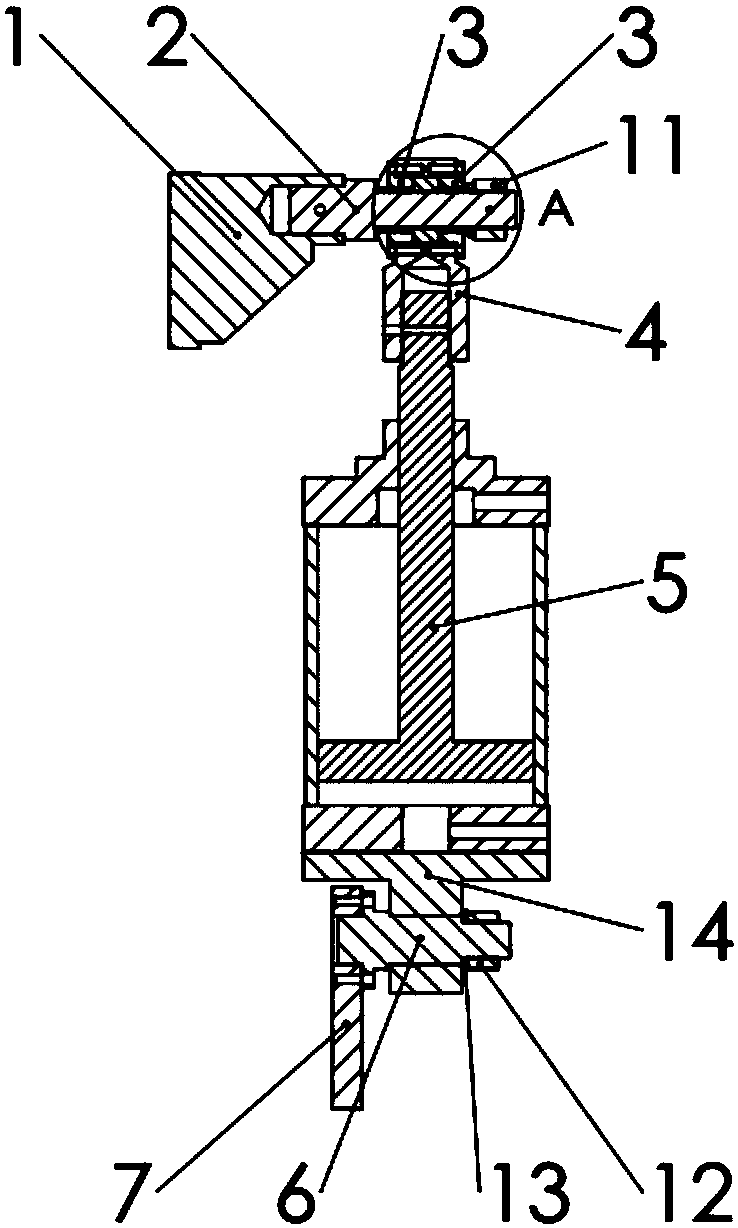

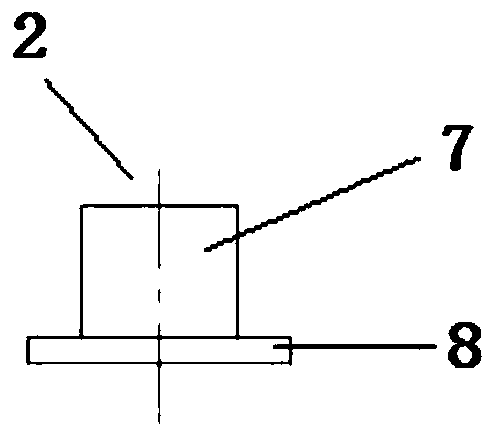

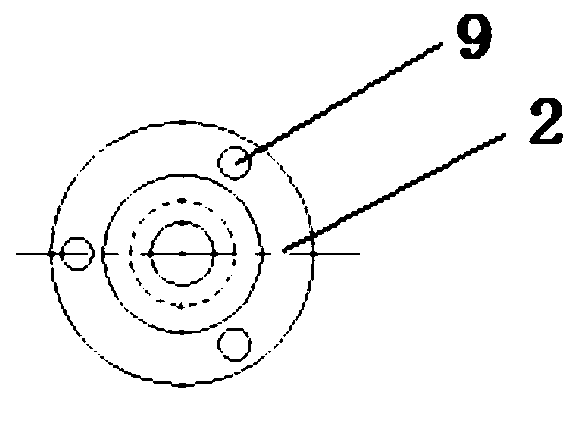

Multiple-DOF (degree of freedom) adjusting mechanism of optical surface plasma resonance biosensor

InactiveCN102095684APrecise positioningEasy to adjust pressurePhase-affecting property measurementsFlow cellRefractive index

The invention relates to a multiple-DOF (degree of freedom) adjusting mechanism of an optical SPR (surface plasma resonance) biosensor. The mechanism comprises a laser regulating unit, a biochip component, a CCD (charge coupled device) regulating unit, a support plate and a base used for mounting the support plate, wherein the laser regulating unit and the CCD regulating unit are symmetrically arranged at the two sides of the prism bracket, and certain light paths can be formed among a laser, the biochip component and a CCD by adjusting the relative position of the laser regulating unit and the CCD regulating unit. The mechanism provided by the invention has the advantages that the structural design is delicate, and the location is accurate, thus the consistency of the light paths among the laser, the biochip component and the CCD can be conveniently adjusted; the pressure between a flow cell and the biochip component can be conveniently adjusted; the flow cell can maintain to be circulated after being lifted and reset and the accurate location of the biochip component can be guaranteed; the problems that debugging is difficult and the refractive index is difficult to match as the biochip provided with a glass substrate is replaced only are solved, the analysis accuracy of the biosensor is improved, and the use cost and the maintenance cost of the optical SPR sensor are greatly reduced.

Owner:HENAN AGRICULTURAL UNIVERSITY

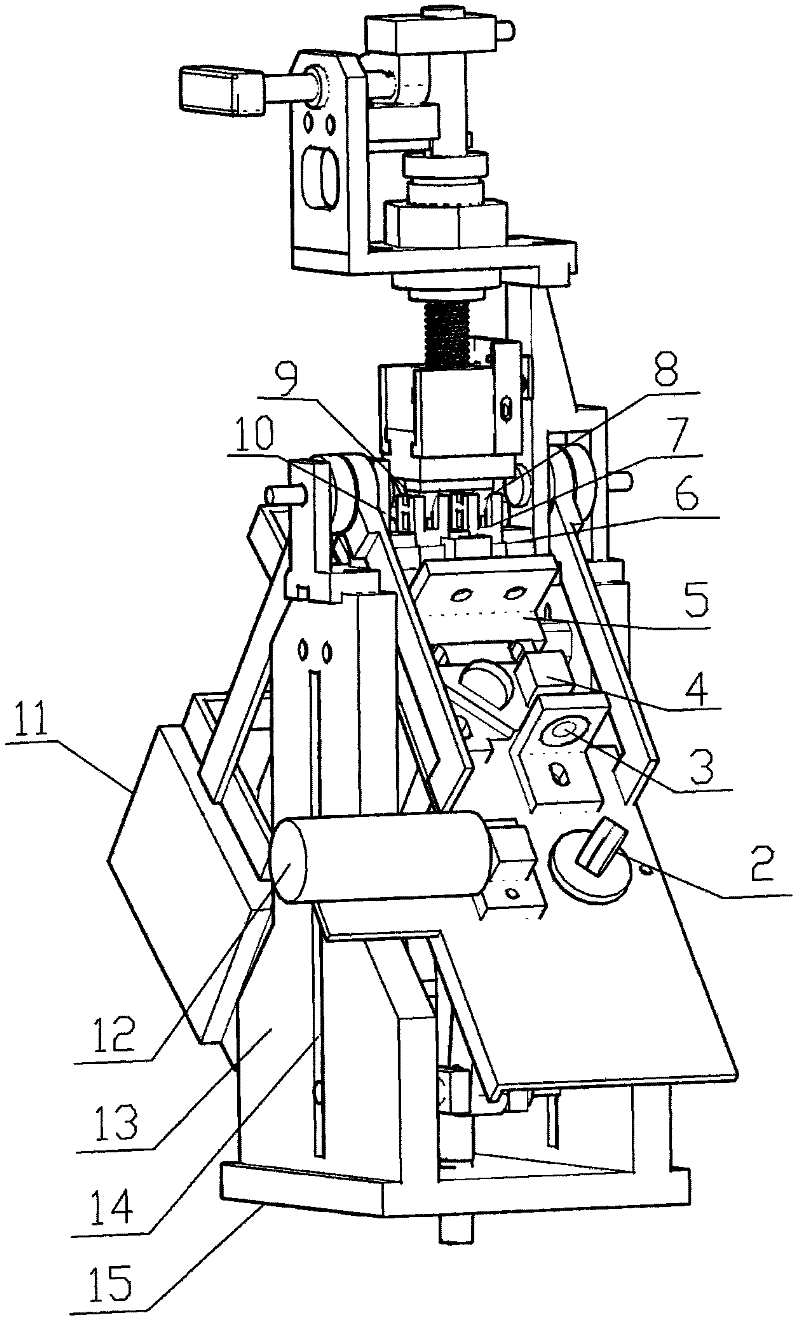

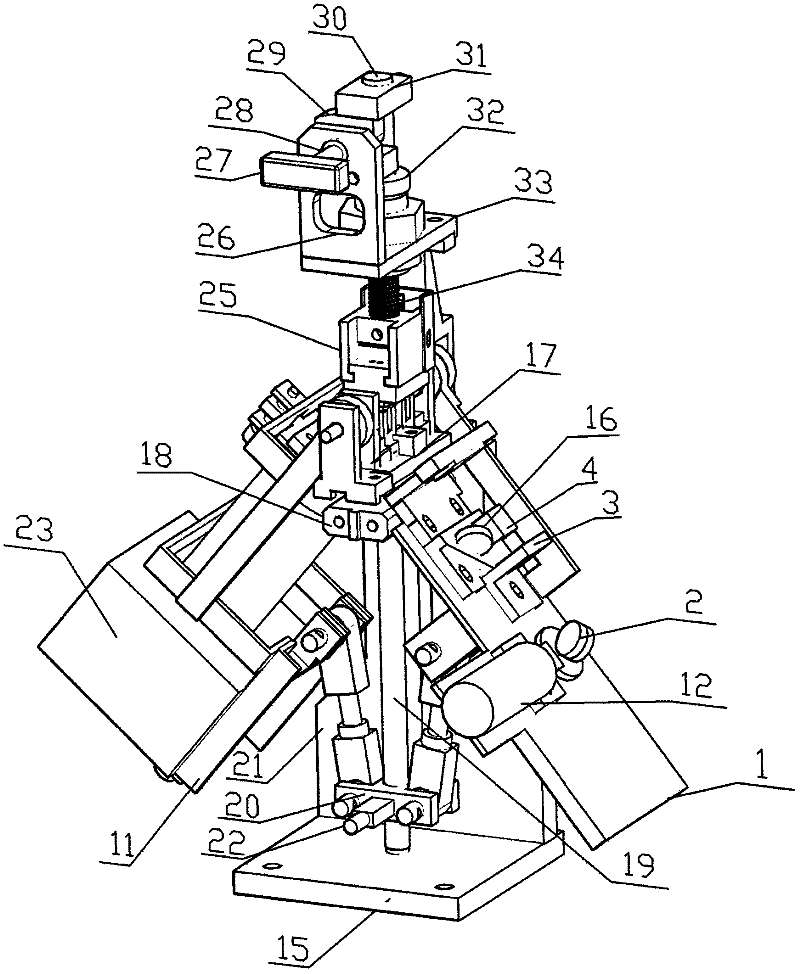

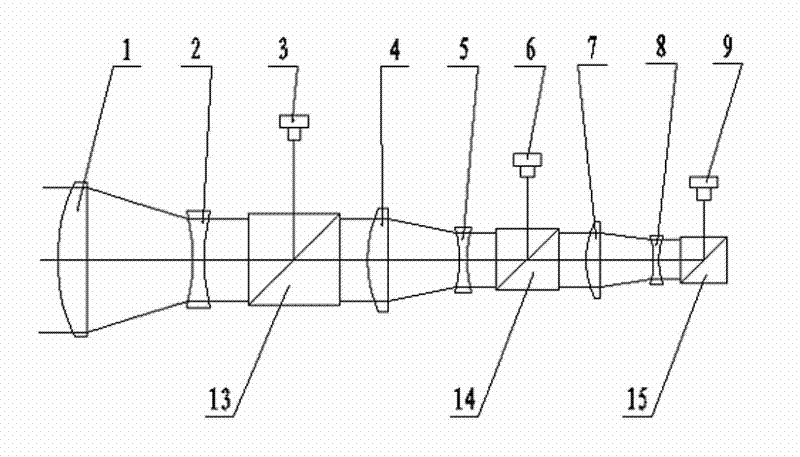

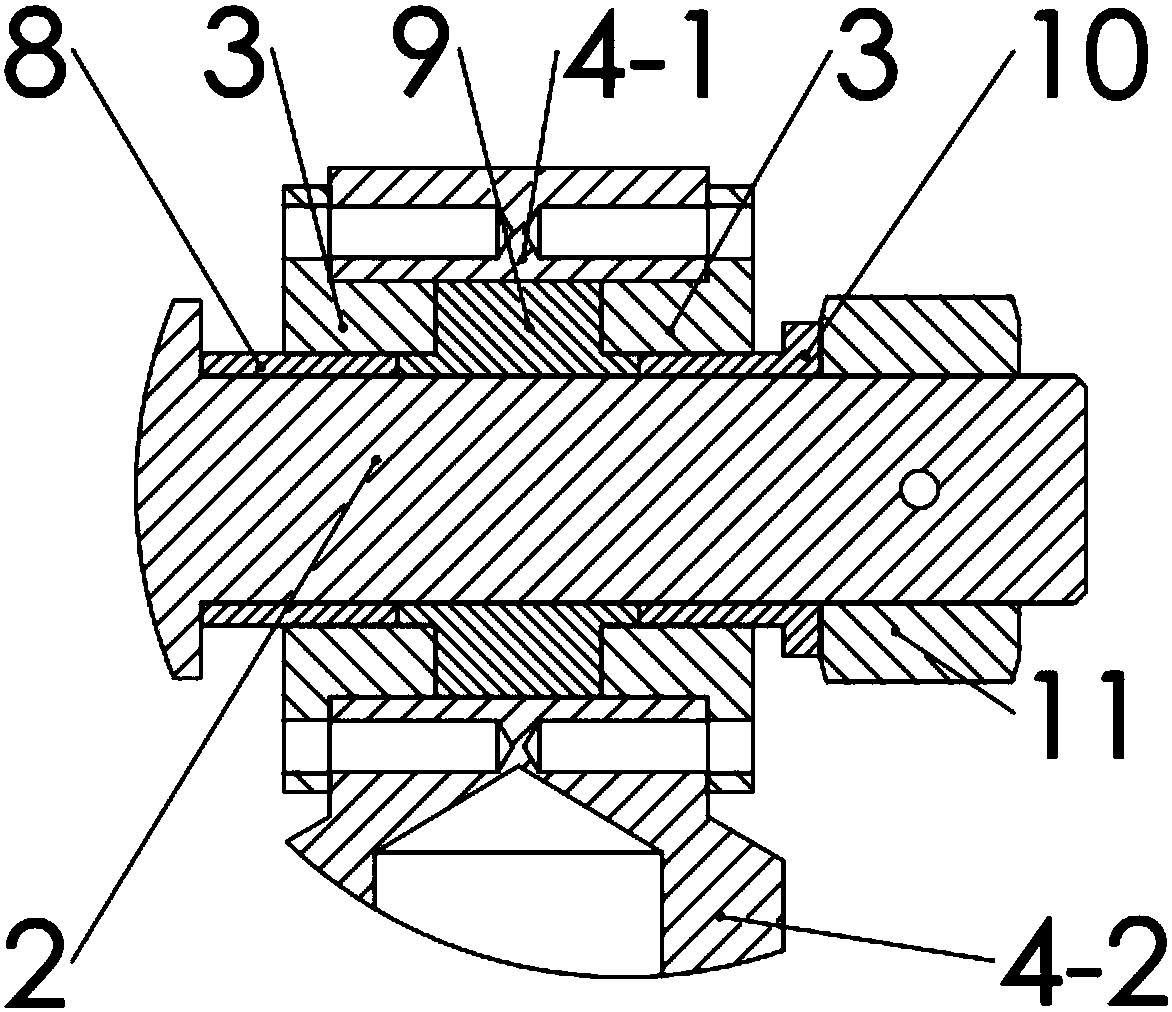

Dual-channel MDOF (multidegree of freedom) adjustment mechanism of optical surface plasma resonance biosensor

InactiveCN102410989APrecise positioningEasy to adjust pressurePhase-affecting property measurementsRefractive indexEngineering

The invention relates to a dual-channel MDOF (multidegree of freedom) adjustment mechanism of an optical surface plasma resonance biosensor. The mechanism comprises a biochip assembly regulating unit, an optical path regulating unit, an angle regulating unit and a supporting and guiding unit, wherein the optical path regulating unit comprises a laser swing frame and a charge coupled device (CCD) swing frame; the angle regulating unit comprises an elevating assembly, a rotating support arm, a transmission shaft and a driving device; driven by the driving device, the transmission shaft drives the elevating assembly to complete the elevating travel, and at the same time, drives the laser swing frame and the CCD swing frame to form an included angle within a certain range via the corresponding rotating support arm, and form two corresponding optical path detection passages among laser, a CCD image sensor and the biochip assembly. The dual-channel MDOF adjustment mechanism provided by the invention is convenient for operation and accurate in positioning and has high testing precision, and solves the problems, such as debugging difficulty and hard refractivity matching caused when only the biochip with a glass substrate is replaced, thereby increasing the analytic precision of the biosensor and also substantially reducing the using and maintaining cost of the optical surface plasma resonance (SPR) sensor.

Owner:HENAN AGRICULTURAL UNIVERSITY

Equipment and system for pasting double faced adhesive tape

PendingCN108275502ASolve efficiency problemsFix stability issuesArticle deliveryAutomationSupport plane

The invention relates to the technical field of double faced adhesive tape pasting automation, in particular to equipment and a system for pasting a double faced adhesive tape. The equipment for pasting the double faced adhesive tape comprises a working rack, wherein a supporting rack is mounted on the working rack; a first driving mechanism which drives along the X-axis direction is arranged on the working rack, a second driving mechanism which drives along the Y-axis direction is arranged on the supporting rack, and a third driving mechanism which drives along the Z-axis direction is arranged on the second driving mechanism; a positioning tool for placing a workpiece is connected above the first driving mechanism; and a pasting mechanism matched with the positioning tool in use is connected to the third driving mechanism. The system for pasting the double faced adhesive tape comprises the equipment for pasting the double faced adhesive tape. The equipment and system provided by the invention solve the technical problems that in the prior art, the manual pasting efficiency is low and the pasting quality is unstable.

Owner:国机智能科技有限公司 +1

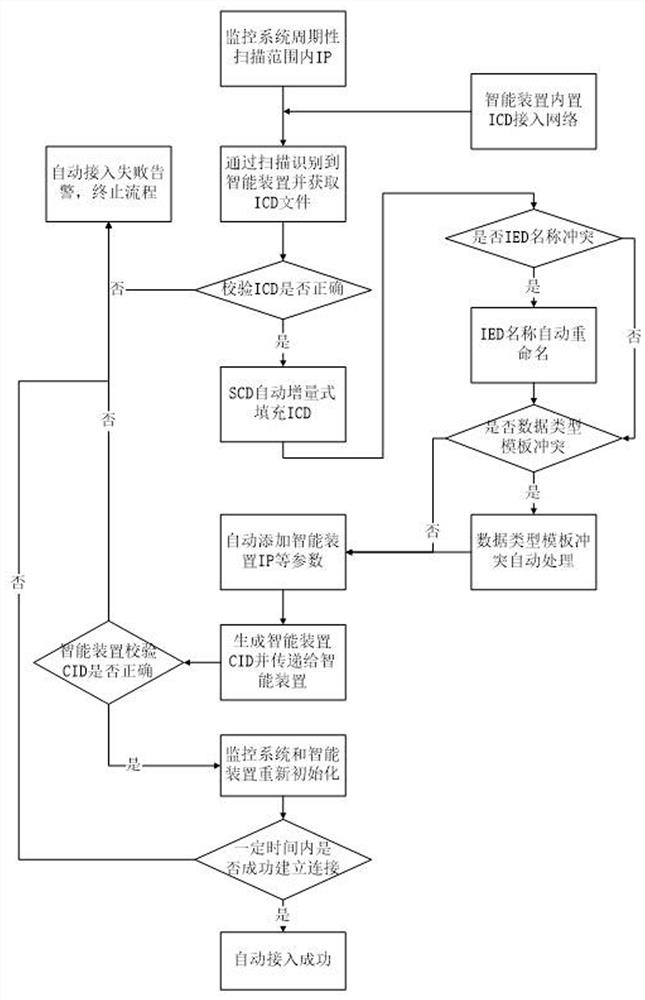

Access configuration method for realizing plug-and-play of an IEC61850 intelligent device

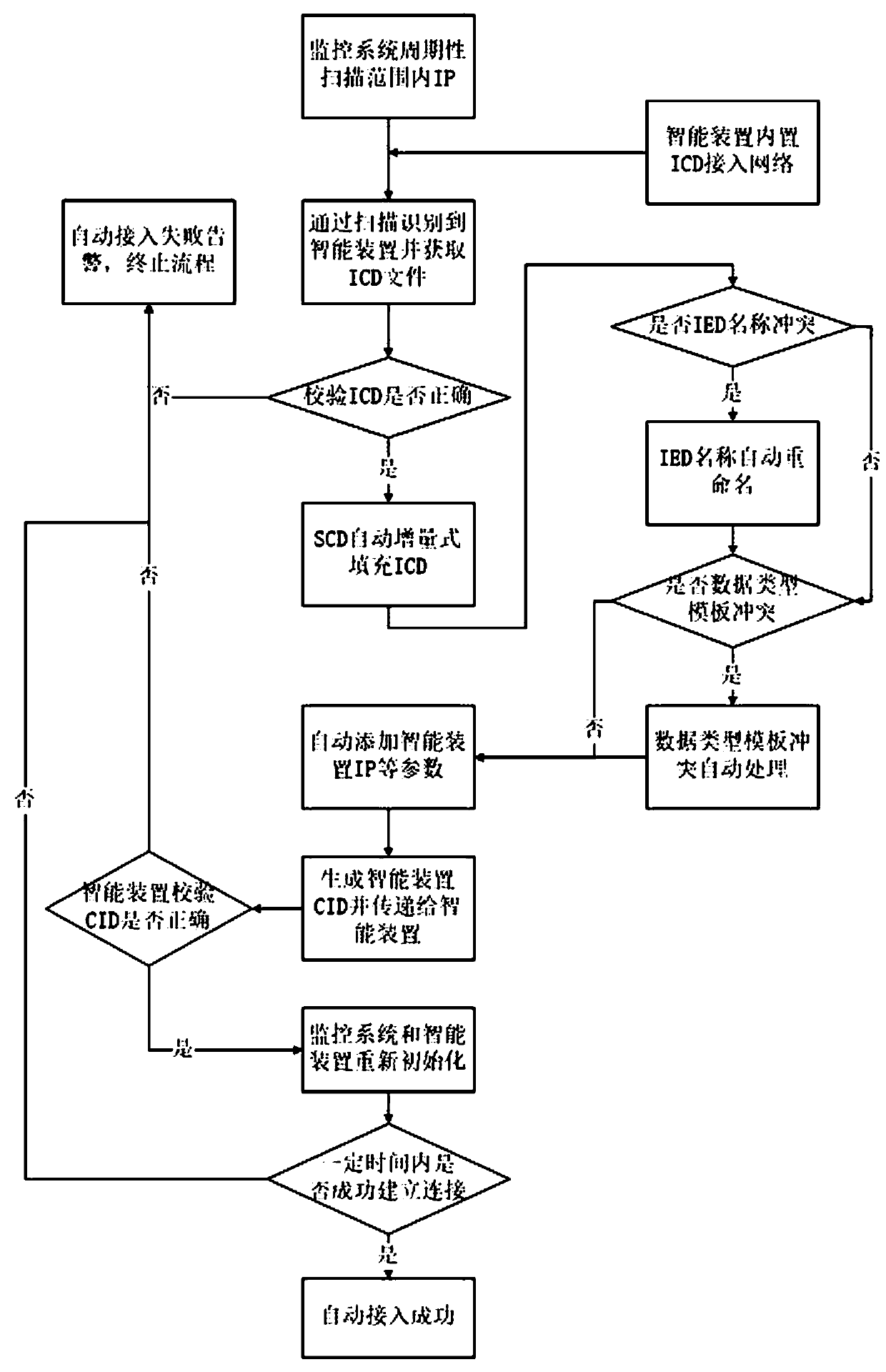

ActiveCN110896363ASolve debugging difficultiesImprove configuration efficiencyData switching networksSmart substationMonitoring system

The invention discloses an access configuration method for realizing plug-and-play of an IEC61850 intelligent device, which comprises the following steps that: (1) a monitoring system periodically scans a system network where the monitoring system is located, and when the intelligent device with a built-in ICD file is accessed to the system network, the monitoring system identifies the intelligentdevice and obtains the ICD file of the intelligent device; (2) the monitoring system performs automatic incremental configuration on the original SCD file by using the ICD file of the intelligent device to obtain a new SCD file; (3) the monitoring system uses the new SCD file to generate a CID file for the intelligent device and transmits the CID file to the corresponding intelligent device; and(4) the monitoring system and the intelligent device are reinitialized and establishes a communication connection. According to the method, plug-and-play in the true sense is achieved, the problem that the intelligent substation is difficult to reconstruct, expand, configure and debug is well solved, and the reconstruct, expand, configure and debug efficiency of the intelligent substation can be effectively improved.

Owner:DONGFANG ELECTRONICS

Generating tool of function module

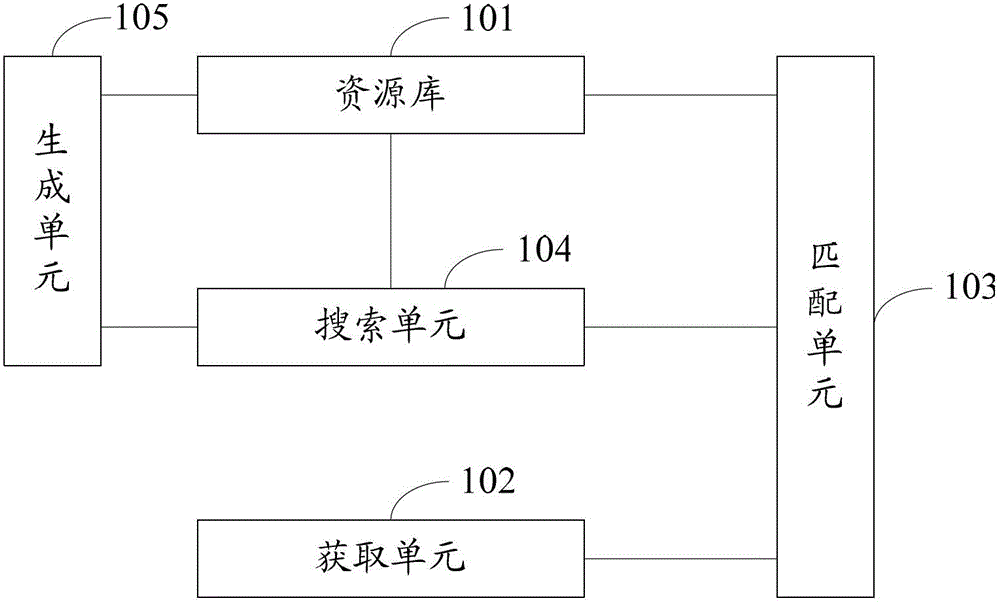

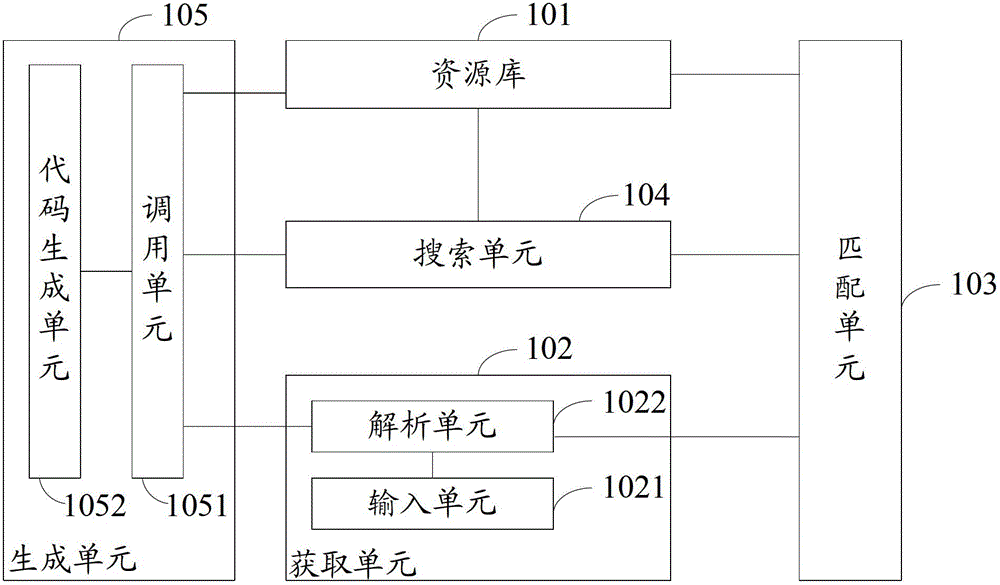

InactiveCN102750144ASimplify the development processReduce development costsSpecific program execution arrangementsComputer moduleSoftware engineering

A generating tool of a function module comprises a resource library, an acquisition unit, a matching unit, a searching unit and a generating unit, wherein the resource library is used for storing function information, a called module and called module information, the function information comprises function names and correspondingly achieved functions, the called module information comprises functions which are achieved by the called module, the acquisition unit is used for acquiring at least one piece of demanding information of the function module, the matching unit is used for acquiring the function names which are matched with the demanding information of the function module in the resource library, the searching unit is used for searching the called module information in the resource library to determine one called module to be called based on the achieved functions corresponding to the function names which are matched with the matching unit, and the generating unit is used for calling the called module which is searched by the searching unit to generate the function module. According to the generating tool of the function module, during the developing process of the function module, blocking phenomena and development cost increasing can be prevented, and conveniences are brought for developers.

Owner:HUAYA MICROELECTRONICS (SHANGHAI) INC

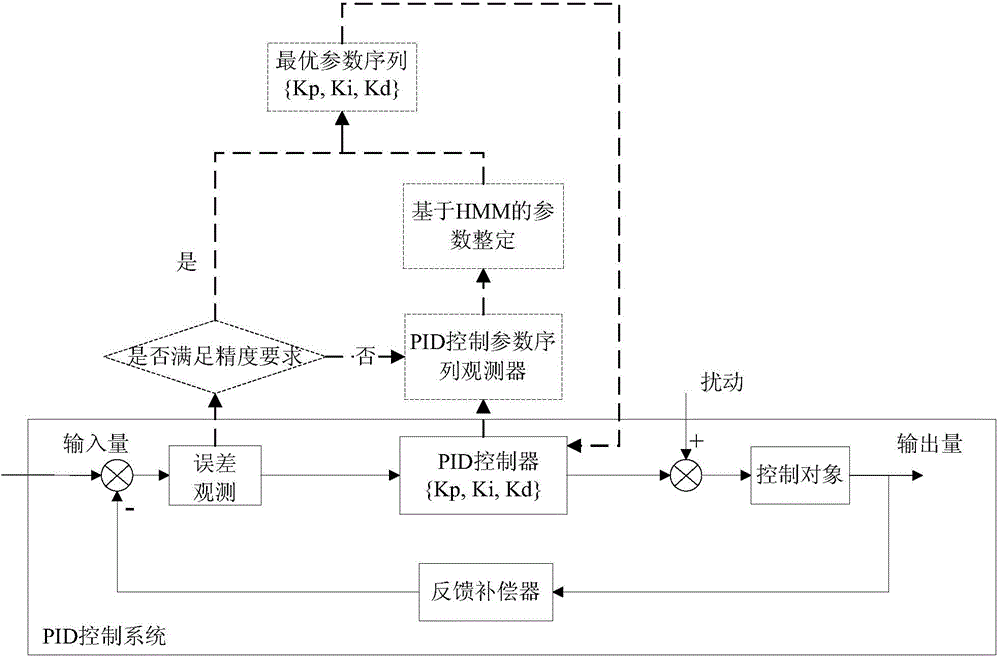

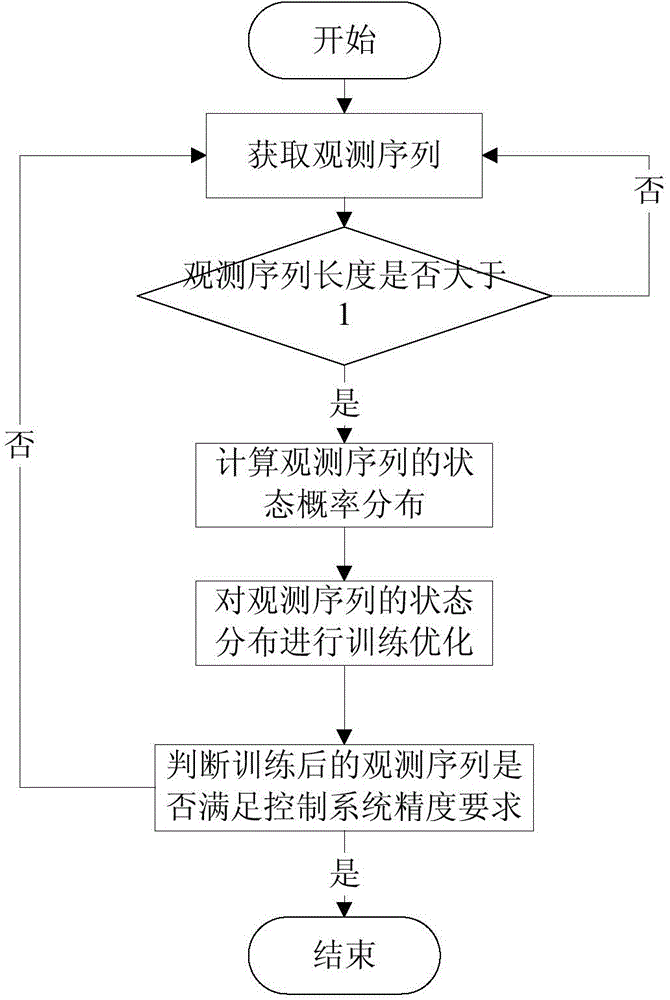

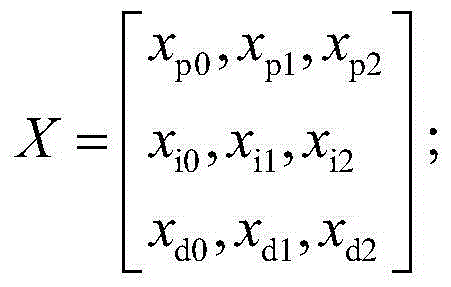

PID control parameter off-line tuning method based on hidden Markov model

ActiveCN104317193ASolve debugging difficultiesRealize deterministic computingAdaptive controlHide markov modelAlgorithm

The invention relates to a PID control parameter off-line tuning method based on a hidden Markov model. The method comprises the steps of acquiring a PID control parameter observation sequence, judging whether the length of the acquired observation sequence is greater than 1, calculating the initial state probability distribution of the observation sequence, carrying out hidden Markov model training with use of the obtained probability distribution to obtain the state probability of the observation sequence after training, sending the trained control parameter observation sequence to a PID control system for verification, and judging whether the set of control parameters meets the precision requirement of the PID control system. By adopting the method of the invention, deterministic calculation of a PID control parameter sequence vector is realized, an offline PID control parameter optimization adjustment method is proposed, and the difficulty in parameter debugging caused by the randomness of parameter determination is avoided.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

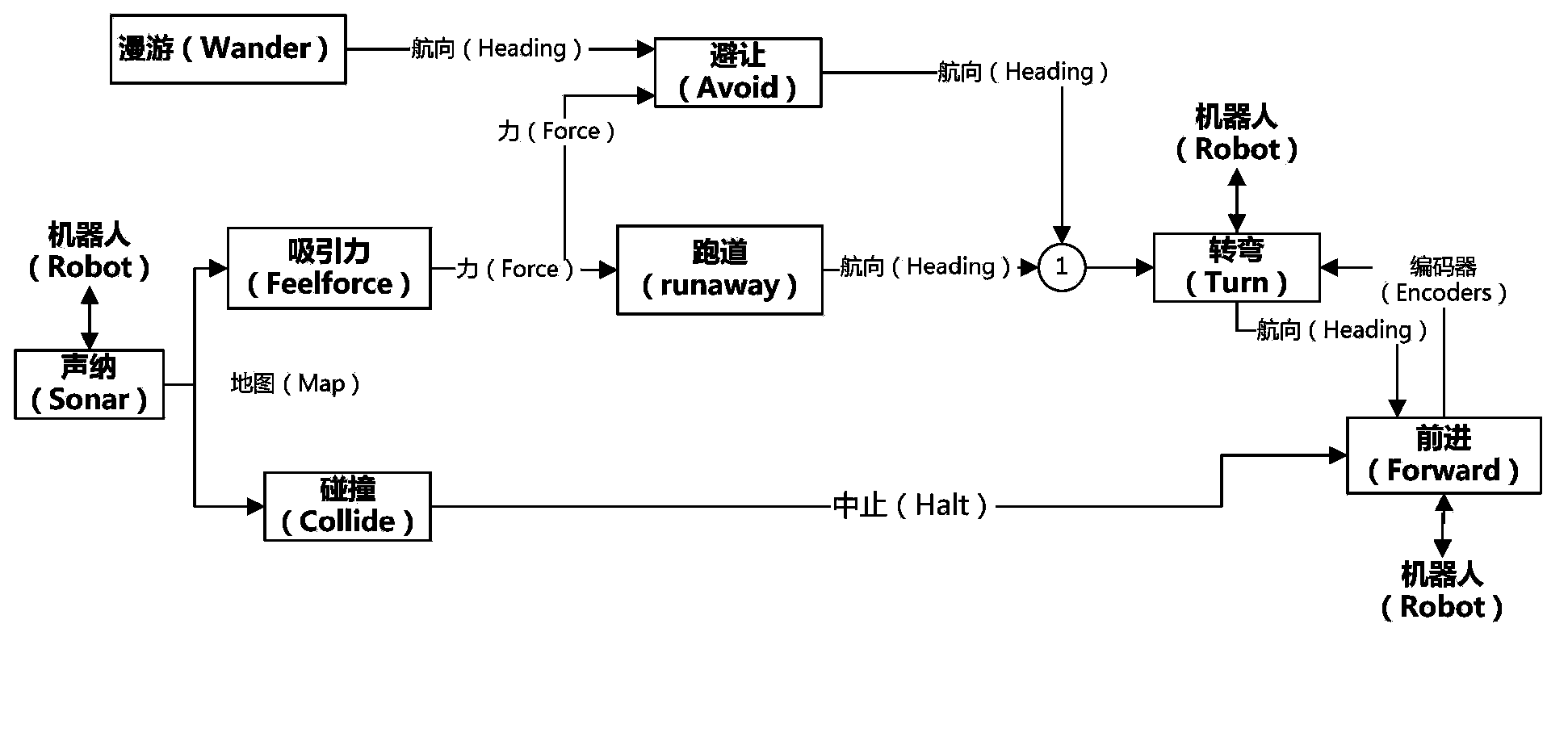

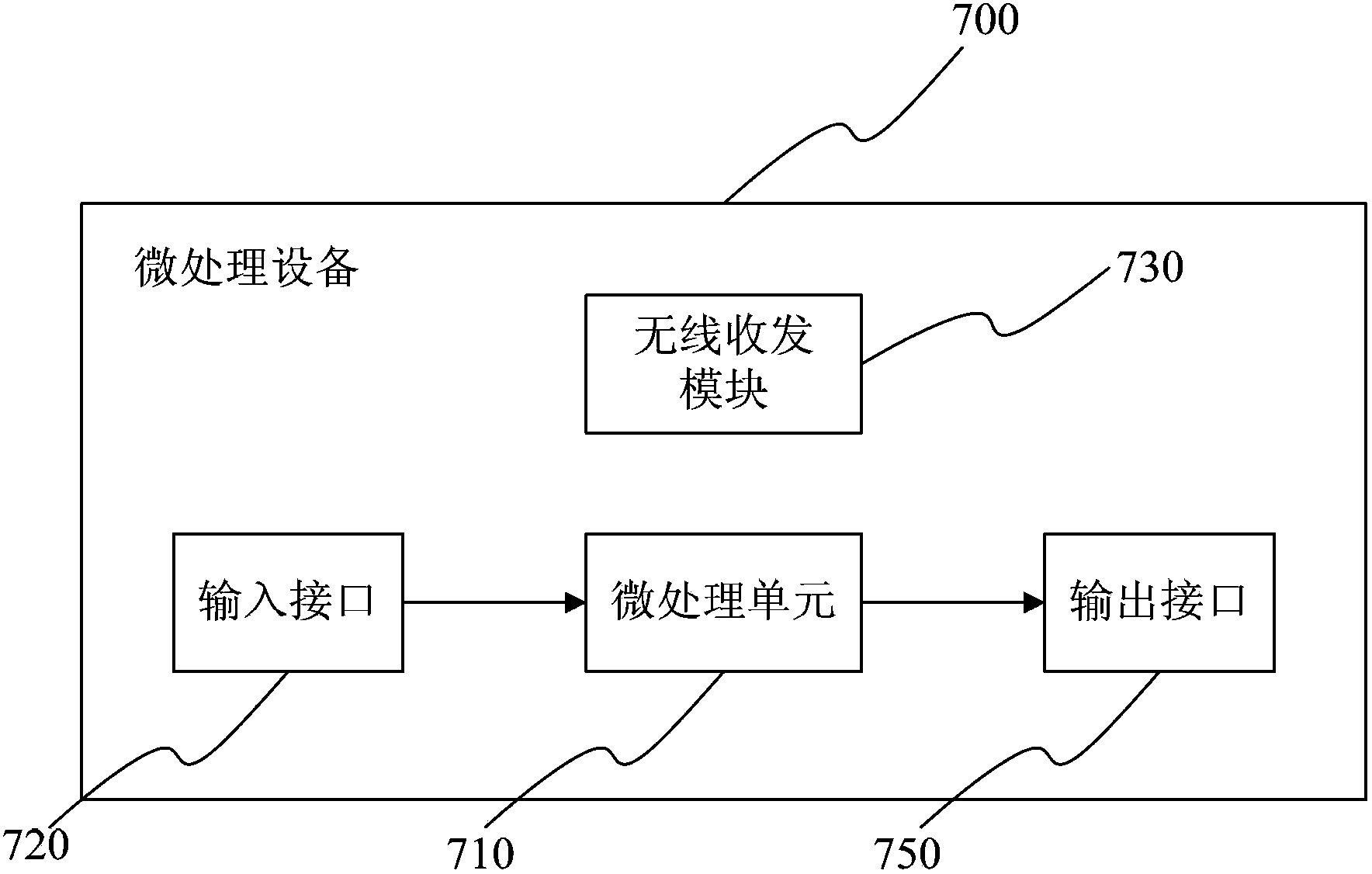

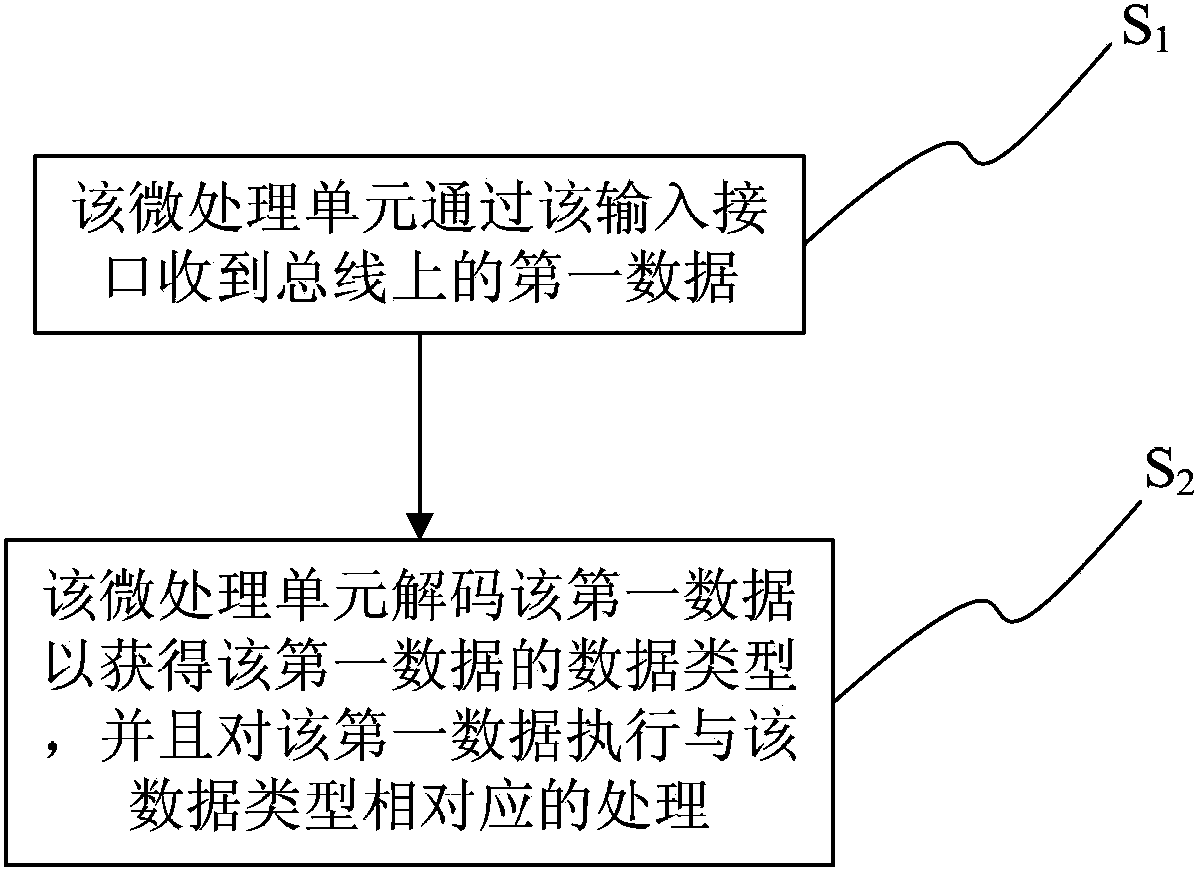

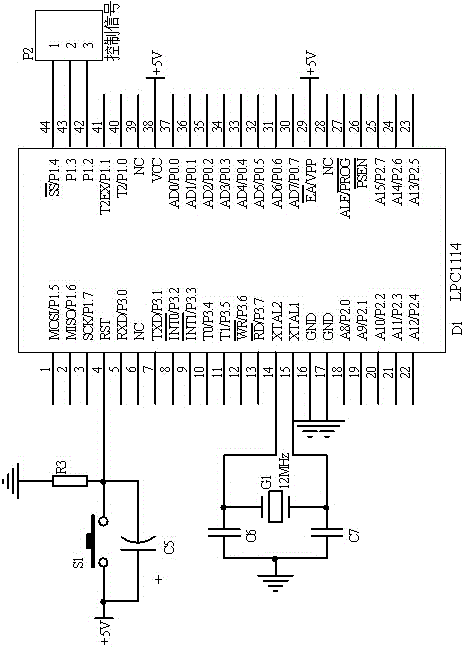

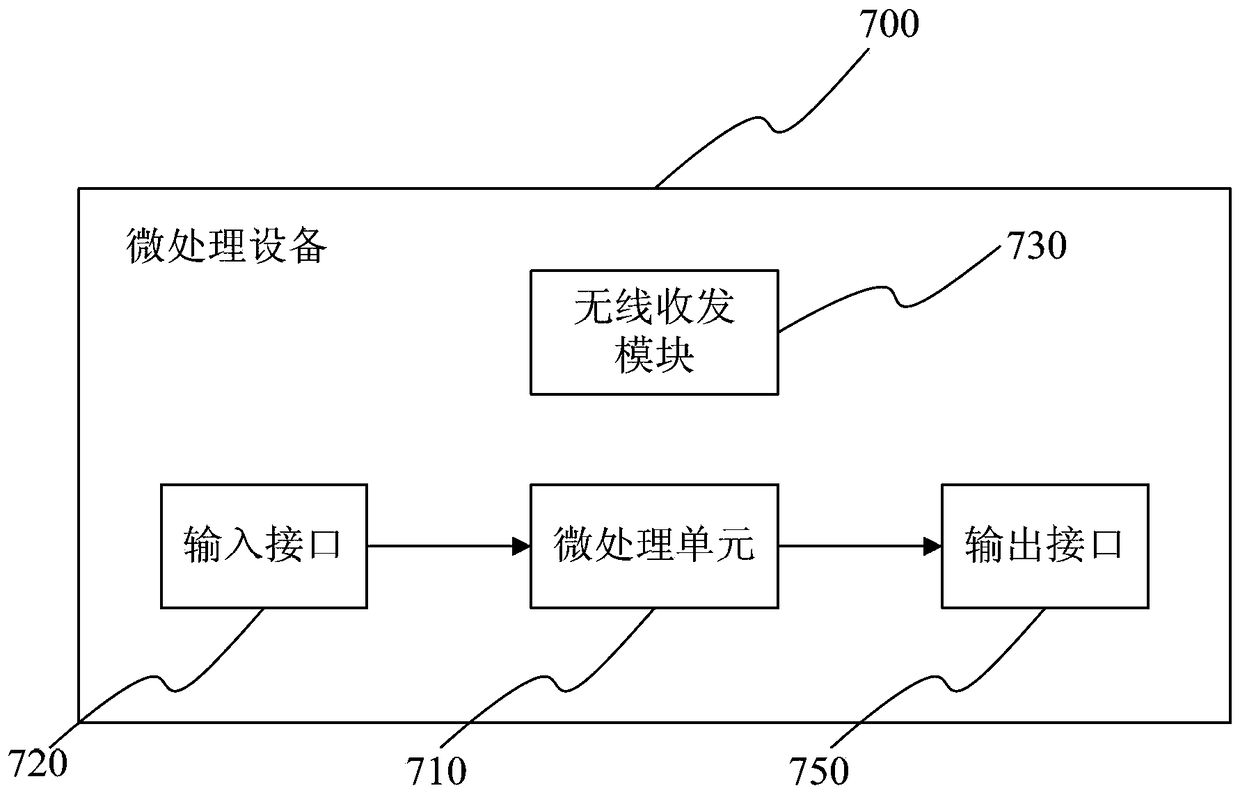

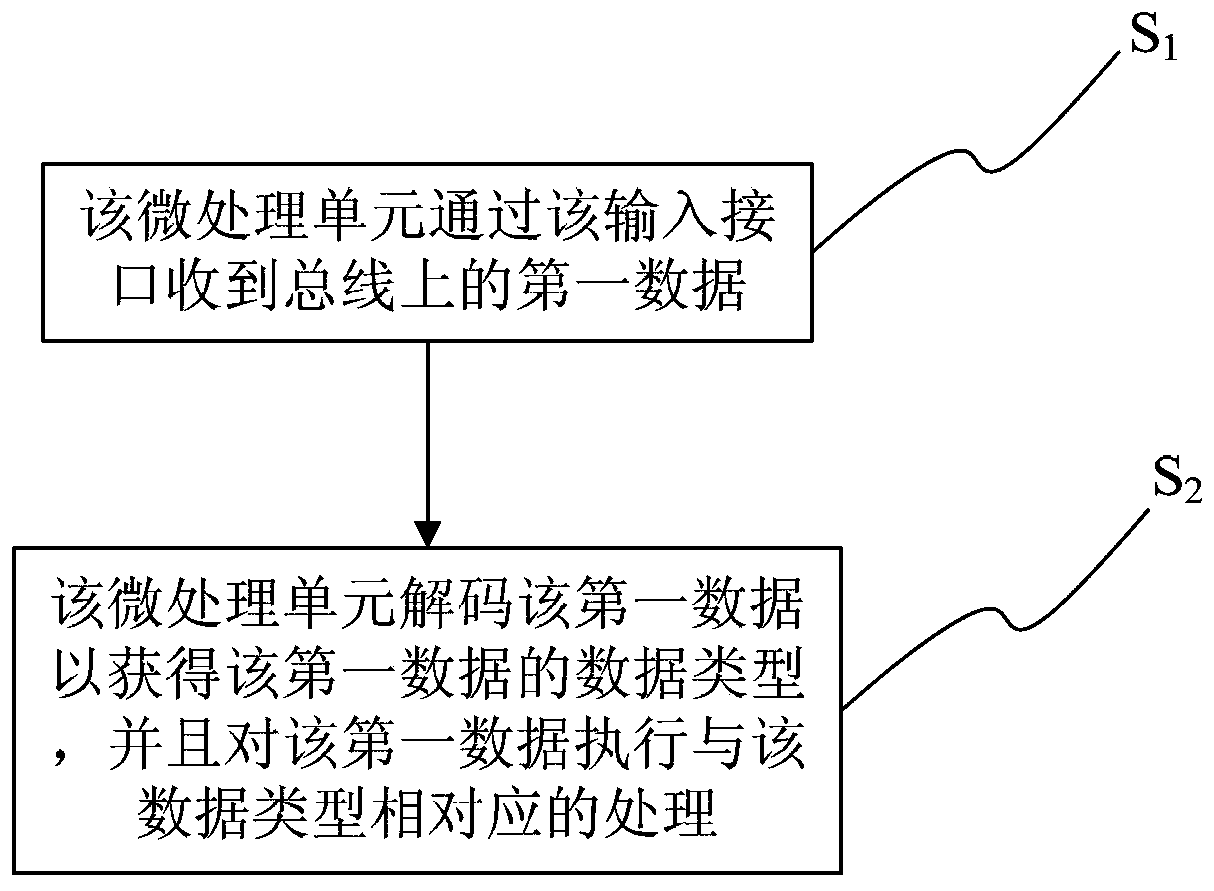

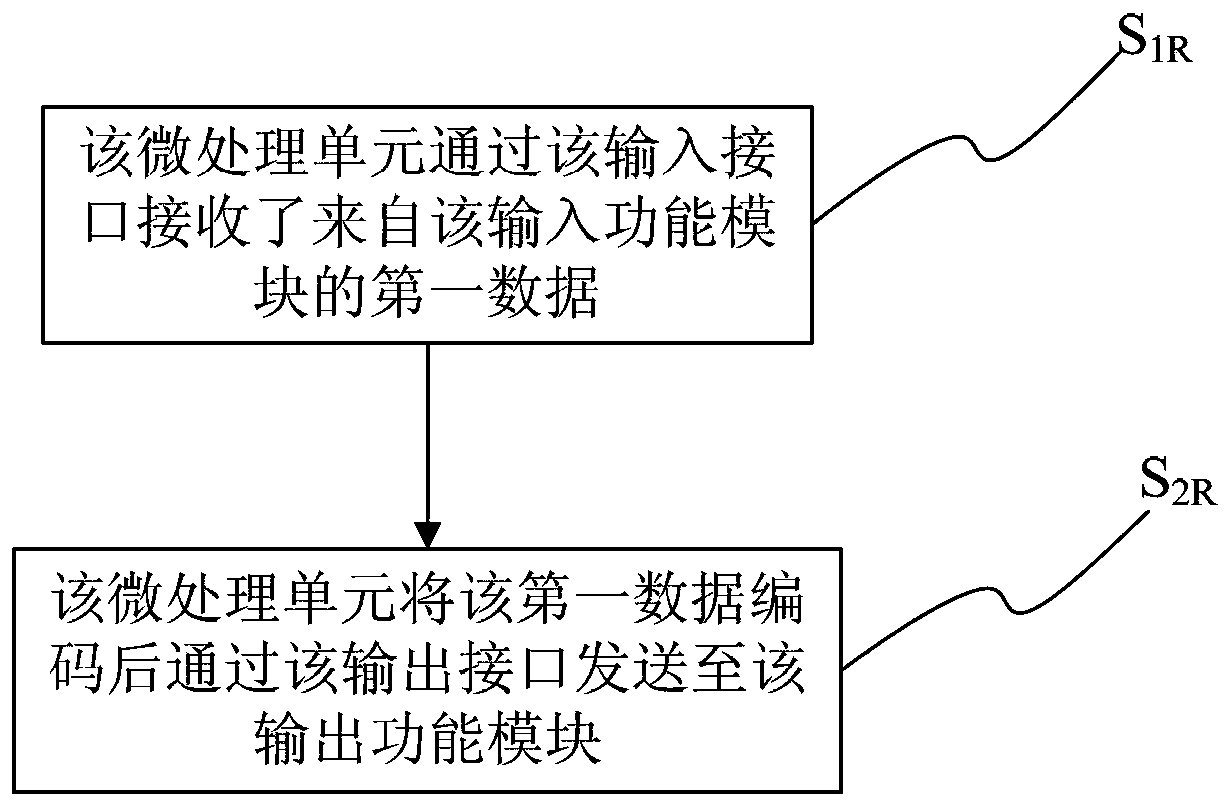

Micro-processing device, on-line debugging system and method

InactiveCN103902412ASolve debugging difficultiesRestore communication message informationDetecting faulty computer hardwareBehavior-based roboticsData information

The invention discloses a micro-processing device, an on-line debugging system and method. The on-line debugging method includes the first step that a micro-processing unit receives first data on a bus through an input interface; the second step that the micro-processing unit decodes the first data to obtain the data type of the first data and carries out corresponding processing on the data type of the first data or the micro-processing unit receives the first data from an input functional module through the input interface; the third step that the micro-processing unit codes the first data and sends the first data to an output functional module through an output interface. According to the on-line debugging method, the problem that a behavior-based robot is difficult to debug is solved, data information of a behavior-based robot system in the running process is collected and local functional modules are debugged, so reasons for problems can be conveniently analyzed and the problems can reappear conveniently.

Owner:SHANGHAI XPARTNER ROBOTICS

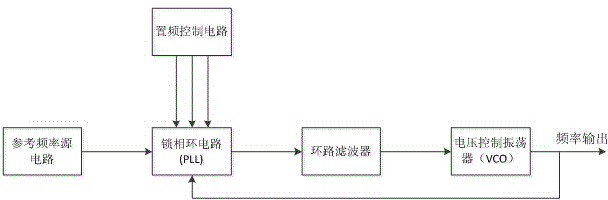

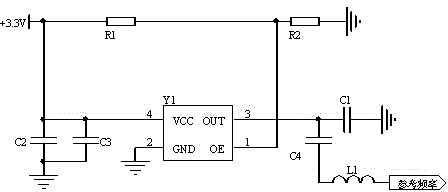

L-band frequency synthesizer circuit

InactiveCN104660257AReduce power consumptionFix stability issuesPulse automatic controlLoop filterRing circuit

The invention discloses an L-band frequency synthesizer circuit, which is used for a tacan earth station and DME equipment. According to the design, the L-band frequency synthesizer circuit comprises a phase-locked ring circuit, a loop filter, a voltage controlled oscillator, a frequency setting control circuit and a reference frequency source circuit, wherein the frequency setting control circuit and the reference frequency source circuit are respectively connected with the phase-locked ring circuit, the phase-locked ring circuit is connected with the loop filter which is connected with the voltage controlled oscillator, and the voltage controlled oscillator is connected with the phase-locked ring circuit. By adopting an improved circuit design scheme, the L-band frequency synthesizer circuit which is advanced in technology, stable in working, reliable in performance, small in volume and low in power consumption can be finally designed, so that the problems of being poor in stability, difficult to debug, poor in phase noise index of the existing circuit can be solved, and the wide working band demand of tacan and DME equipment can be met. In addition, the volume of the circuit is reduced, and the cost is lowered.

Owner:TIANJIN 764 COMM AIRMANSHIP

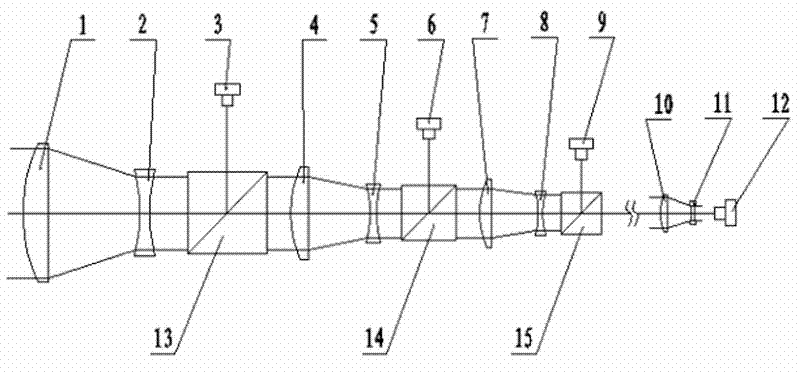

Multi-wavelength laser-integrated optical emission system

InactiveCN102520526AAchieving launch requirements for different beam spread anglesSolve multiple light pathsOptical elementsEyepieceOptical axis

The invention discloses a multi-wavelength laser-integrated optical emission system, which is provided with a first emission system and a second emission system, wherein the first emission system comprises a first emitting objective lens, a first emitting eye lens, a first coincidence prism and a first wavelength laser, and a film system for reflecting the wavelength of the first wavelength laser is plated on the cemented surface of the first coincidence prism; the second emission system comprises a second emitting objective lens, a second emitting eye lens, a second coincidence prism and a second wavelength laser, and a film system for reflecting the wavelength of the second wavelength laser is plated on the cemented surface of the second coincidence prism; the first emission system is connected in series with the second emission system, and the optical axes of the first emission system and the second emission system are superposed. The multi-wavelength laser-integrated optical emission system effectively realizes the application of single channel and multi-laser integration, thus effectively overcoming the defects of multi-laser opto-eletronic products, such as multiple light paths, multiple channels, large systems, difficult debugging, high cost and the like, and the effect is excellent.

Owner:HENAN COSTAR GRP CO LTD

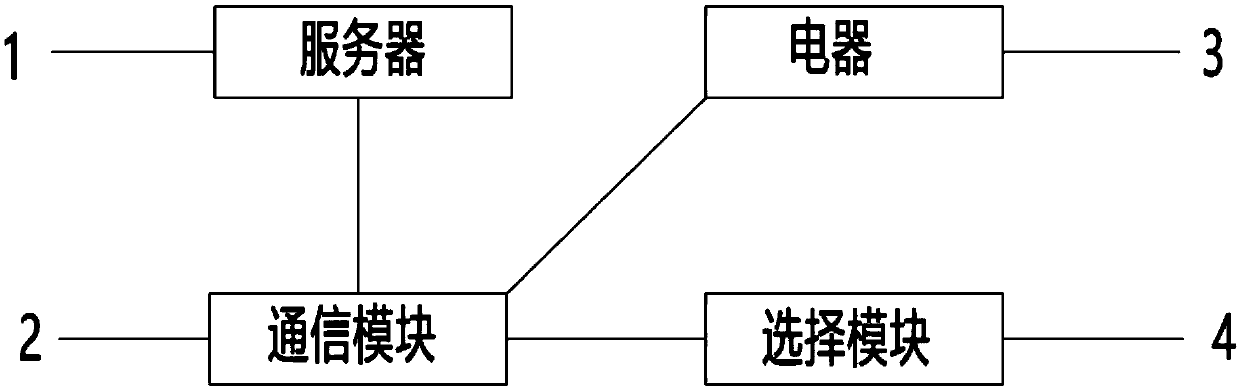

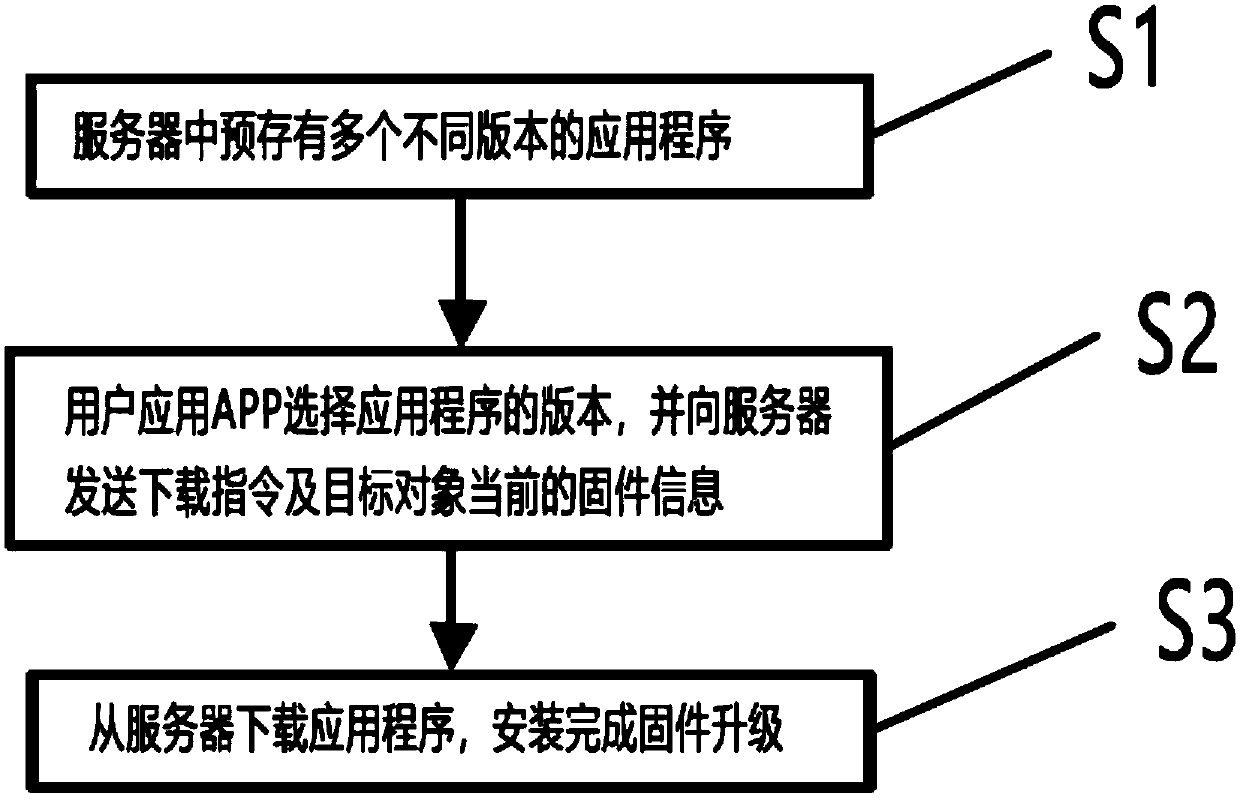

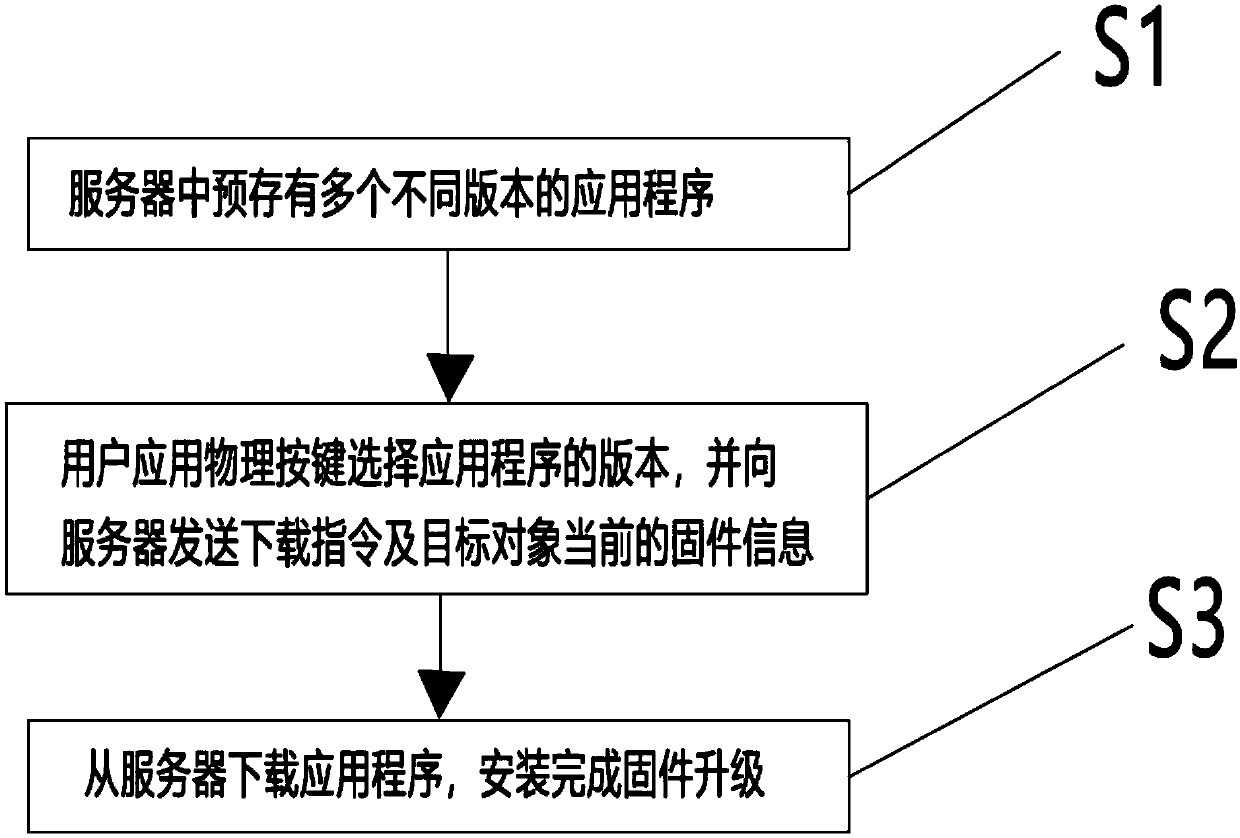

A circular remote firmware update system with open upgrade privileges and a method thereof

PendingCN109101257ASolve the difficulty of multi-party debuggingSave project debugging timeVersion controlSoftware deploymentUpgradeApplication software

The invention belongs to the technical field of communication, in particular to a circular remote firmware update system with open upgrade privileges and a method thereof. The method comprises the following steps: a plurality of application programs of different versions are pre-stored in the server; the application programs can be called remotely and the firmware is updated, so that the user canselect more upgraded versions, and the most suitable upgraded versions are selected according to the user's usage habits; the user selects the version of the application program and sends the downloadinstruction and the information of the current firmware of the target object to the server; the target object downloads the application from the server and automatically installs the application to complete the firmware update, which can realize open upgrade privileges to users, and can cycle firmware upgrade and downgrade, targeted to solve the remote firmware upgrade project debugging development encountered in the multi-debugging difficulties, thereby greatly saving the developers of the project debugging time.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

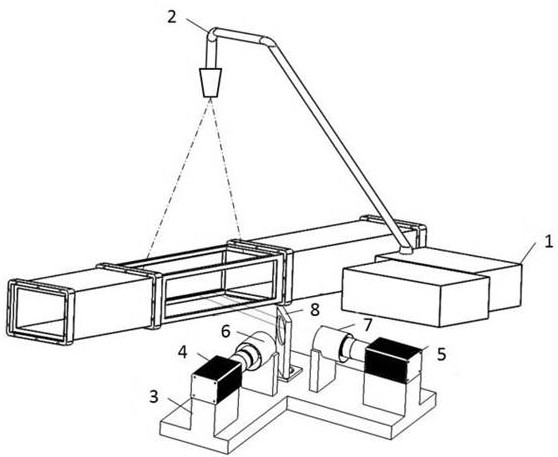

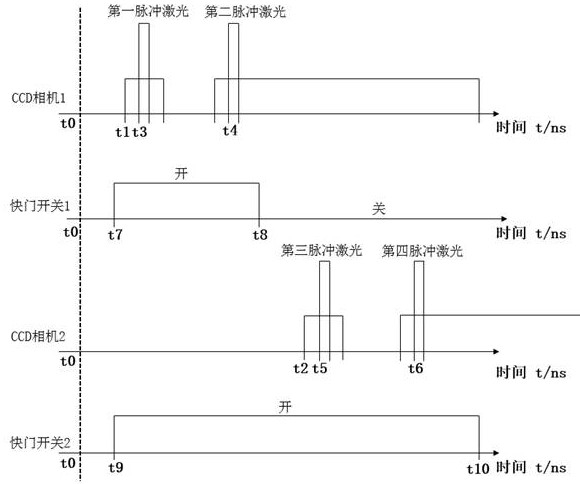

Shutter integrated device, control system and time sequence control method

ActiveCN112730875ASolve debugging difficultiesImprove efficiencyTelevision system detailsColor television detailsComputer hardwareShutter

The invention discloses a shutter integrated device, a control system and a time sequence control method. The shutter integrated device comprises an integrated device bottom plate, a first CCD camera, a second CCD camera, a first shutter switch, a second shutter switch and a light splitting device. The first CCD camera, the second CCD camera and the light splitting device are all installed on the integrated device bottom plate. The first shutter switch is arranged on the first CCD camera, and the second shutter switch is arranged on the second CCD camera; and the first shutter switch and the second shutter switch are respectively connected with the control system. According to the invention, the debugging difficulty caused by the position and state difference of the camera is avoided, the efficiency is improved, the system error is eliminated, the MHz exposure is realized, the exposure images do not interfere with each other and influence each other, and the overall precision and stability of the system are improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

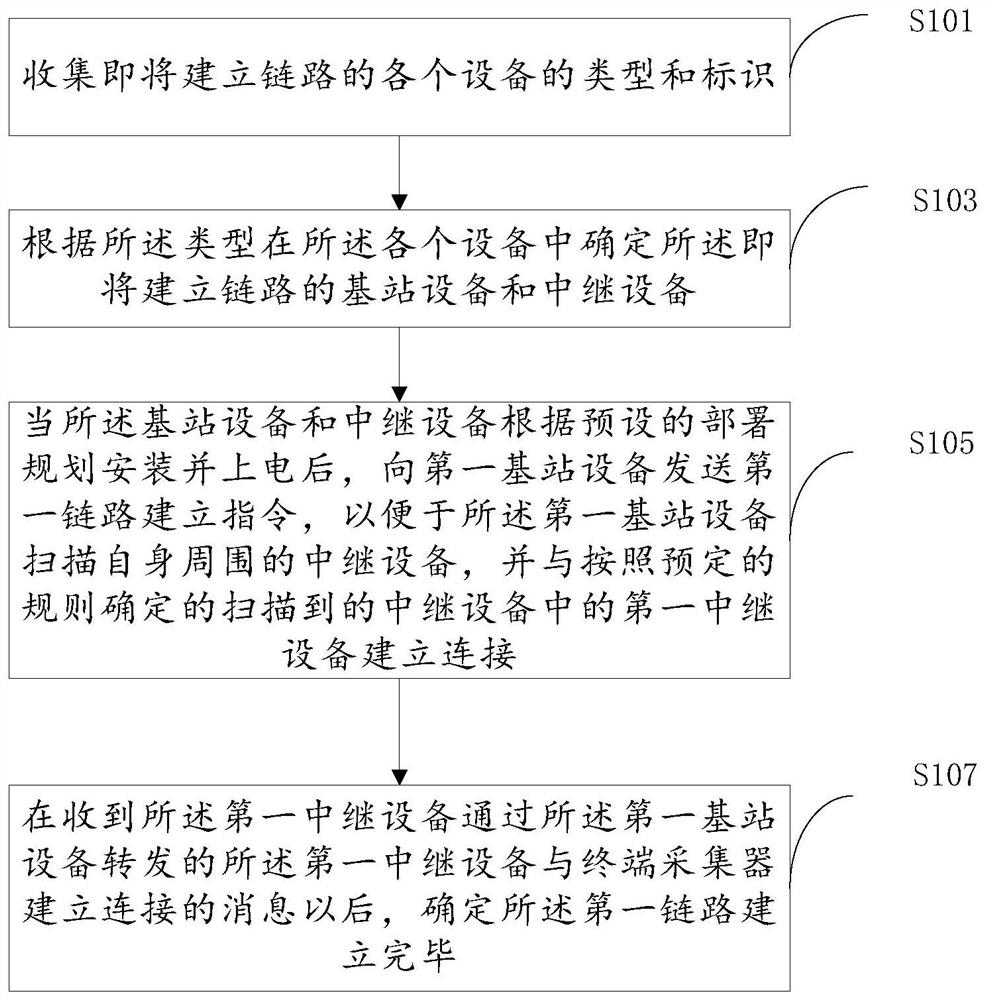

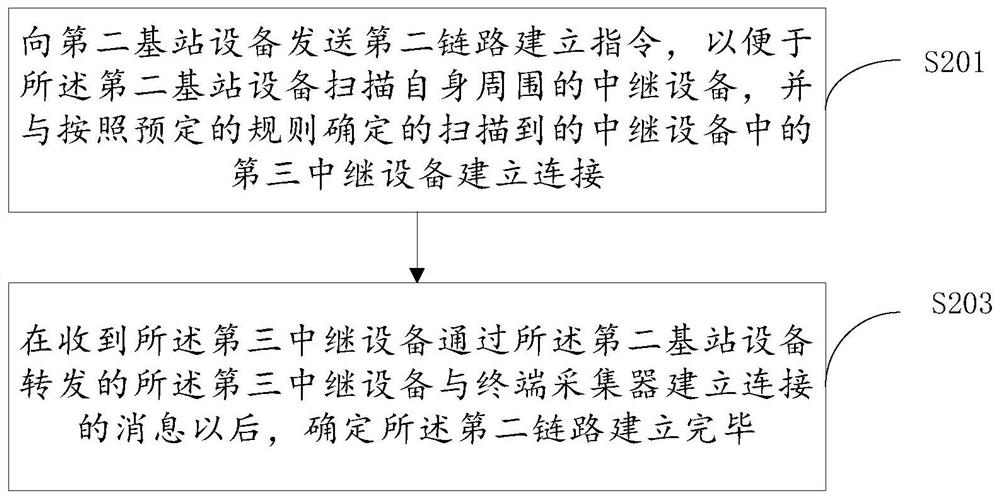

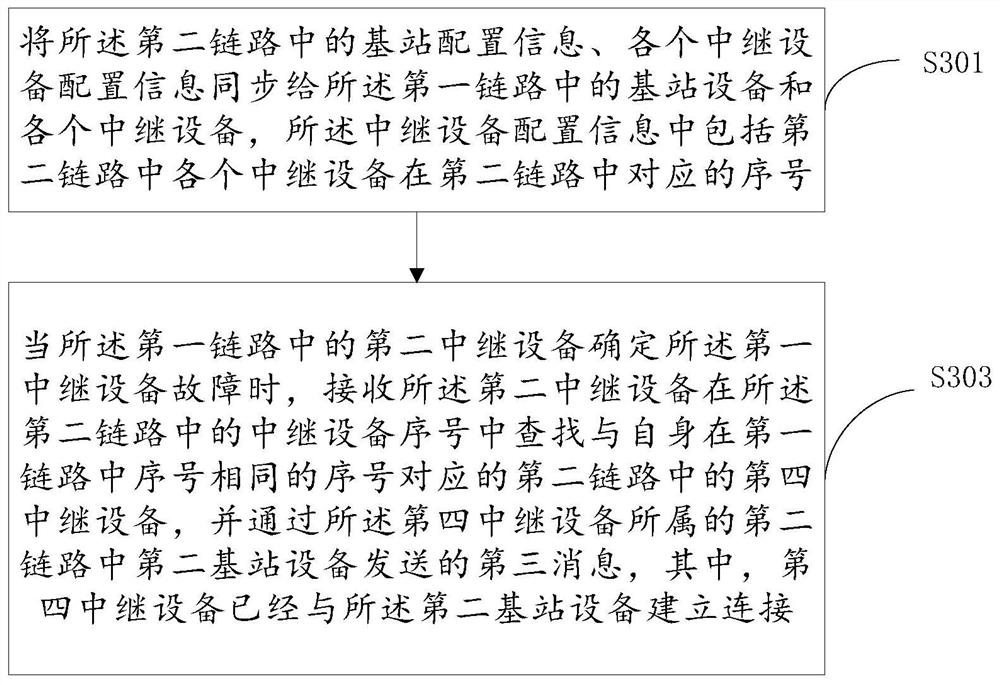

Method for establishing lora long-distance transmission link and server

ActiveCN112533299AImprove construction efficiencyIncrease the number ofSynchronisation arrangementConnection managementTrunkingEngineering

The invention provides a method and a server for establishing a lora long-distance transmission link. The method comprises the following steps of: collecting the type and identification of each pieceof equipment of which the link is about to be established; determining base station equipment and relay equipment of which the link is about to be established in the equipment according to the type; after the base station equipment and the relay equipment are installed and powered on according to a preset deployment plan, sending a first link establishment instruction to first base station equipment, so that the first base station equipment scans the relay equipment around the first base station equipment and establishes connection with the first relay equipment in the scanned relay equipmentdetermined according to a preset rule; and determining that the first link is completely established after receiving a message of establishing connection between the first relay equipment and a terminal collector forwarded by the first relay equipment through the first base station equipment. The installation cost is saved, and the reliability is improved.

Owner:RUIJIE NETWORKS CO LTD

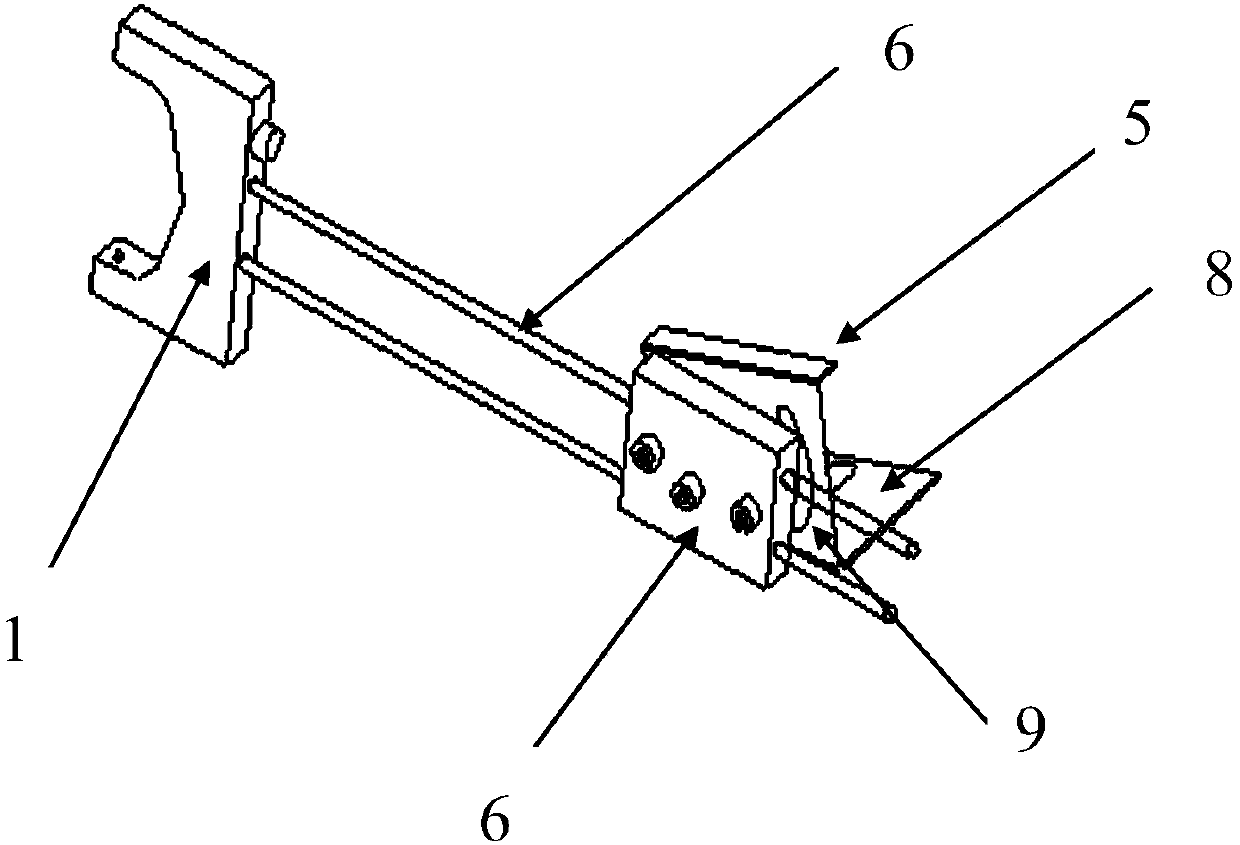

Weft breakage detection device of shuttle loom

The invention discloses a weft breakage detection device of a shuttle loom. The device comprises a weft detection fork, an adjusting support and a front-and-back adjusting rod, wherein the front-and-back adjusting rod is arranged at one end of a shuttle carrier, and the weft detection fork is arranged at the end, close to a steel buckle, of the front-and-back adjusting rod; weft penetrates throughthe weft detection fork, and an infrared receiving head and an infrared emitting head are arranged on the weft detection fork; the infrared receiving head and the infrared emitting head are electrically connected with a controller, and the adjusting support is arranged at the end, away from the steel buckle, of the weft detection fork. The device is suitable for various loom equipment, solves theproblem that the weft of the loom is broken but the loom is not stopped and accordingly defective cloth is produced, also solves a series of problems of troublesome installation, difficult debugging,complex operation, unreliable shutdown during weft detection and the like, can improve the quality and yield of woven fabric, saves manpower and materials, and effectively reduces the labor intensityof workers. A whole control device is simple and clear in structure, low in fault rate, convenient to maintain and capable of reducing the labor intensity of the workers and improving the work efficiency.

Owner:李天合

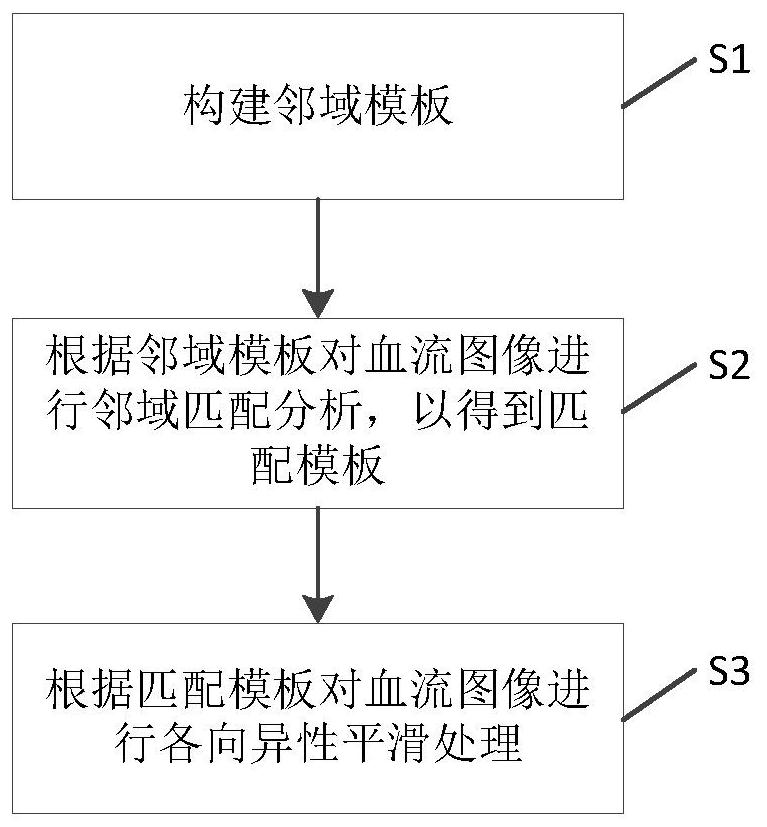

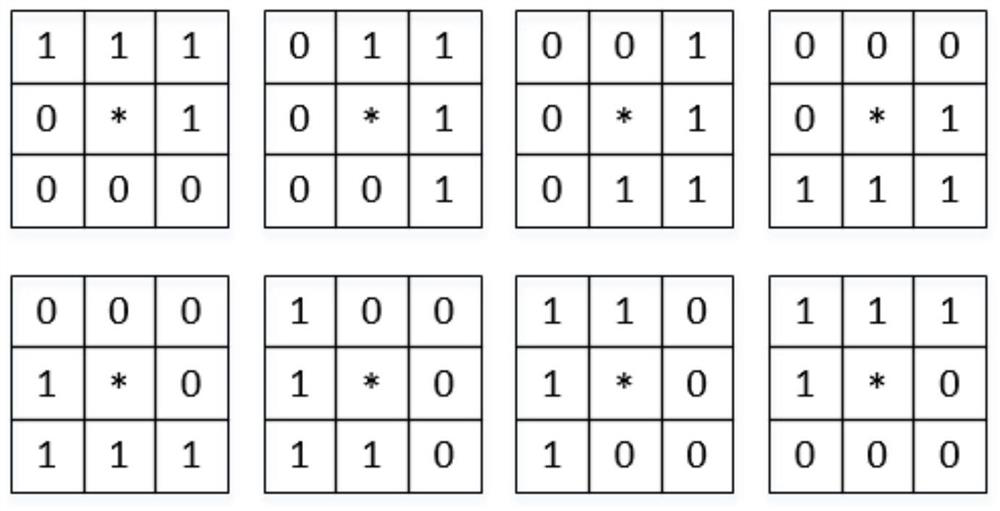

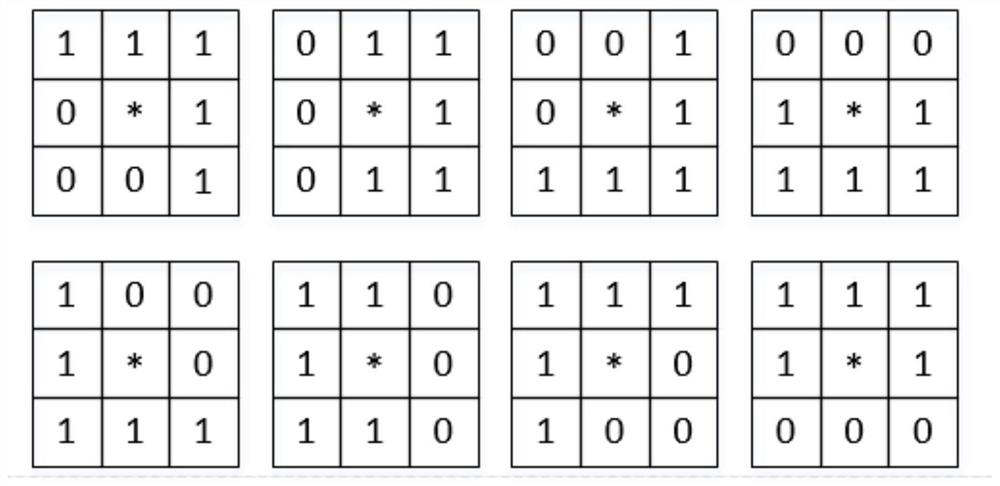

Spatial smoothing method and system for color Doppler blood flow imaging

ActiveCN113077393ASolve debugging difficultiesPracticalImage enhancementImage analysisPattern recognitionColor doppler

The invention belongs to the technical field of ultrasonic imaging, and particularly relates to a spatial smoothing method and system for color Doppler blood flow imaging, and the method comprises the following steps: S1, constructing a neighborhood template; S2, performing neighborhood matching analysis on the blood flow image according to the neighborhood template to obtain a matching template; S3, and performing anisotropic smoothing processing on the blood flow image according to the matching template; According to the method, the difficulty of parameter debugging is solved, the practicability is higher, different smoothing effects are achieved by designing different neighborhood templates, the flexibility is better, and the boundary sawteeth of the blood flow image are effectively improved.

Owner:聚融医疗科技(杭州)有限公司

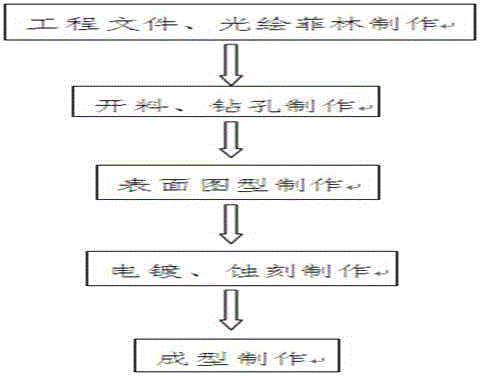

Manufacturing method of high coupling degree and high frequency circuit board

InactiveCN104582282ASolve debugging difficultiesIncrease productivityConductive material chemical/electrolytical removalSurface patternCoupling

The invention relates to a manufacturing method of a high coupling degree and high frequency circuit board. The manufacturing method comprises the following steps: step one, manufacturing project files and Plotted films; step two, cutting, pretreating a copper-clad plate, and drilling; step three, manufacturing surface patterns; step four, electroplating and etching; step five, forming. The manufacturing method has the advantages that modes of pre-grinding of the plate before drilling and pre-alignment of film production are adopted in the manufacturing process, so that the problem that antenna type high frequency plates are difficult to debug caused by the deformation of the films or the copper-clad plate is solved, and the production efficiency and product quality are greatly improved.

Owner:TAIZHOU JINDING ELECTRONICS

Coupled Resonant Filter and Its Debugging Method

ActiveCN110277615BSolve debugging difficultiesHigh out-of-band rejectionWaveguide type devicesResonator filterElectrical conductor

Owner:FUJIAN XINGHAI COMM TECH

Microprocessing device, online debugging system and method

InactiveCN103902412BSolve debugging difficultiesRestore communication message informationDetecting faulty computer hardwareBehavior-based roboticsData information

The invention discloses a micro-processing device, an on-line debugging system and method. The on-line debugging method includes the first step that a micro-processing unit receives first data on a bus through an input interface; the second step that the micro-processing unit decodes the first data to obtain the data type of the first data and carries out corresponding processing on the data type of the first data or the micro-processing unit receives the first data from an input functional module through the input interface; the third step that the micro-processing unit codes the first data and sends the first data to an output functional module through an output interface. According to the on-line debugging method, the problem that a behavior-based robot is difficult to debug is solved, data information of a behavior-based robot system in the running process is collected and local functional modules are debugged, so reasons for problems can be conveniently analyzed and the problems can reappear conveniently.

Owner:SHANGHAI XPARTNER ROBOTICS

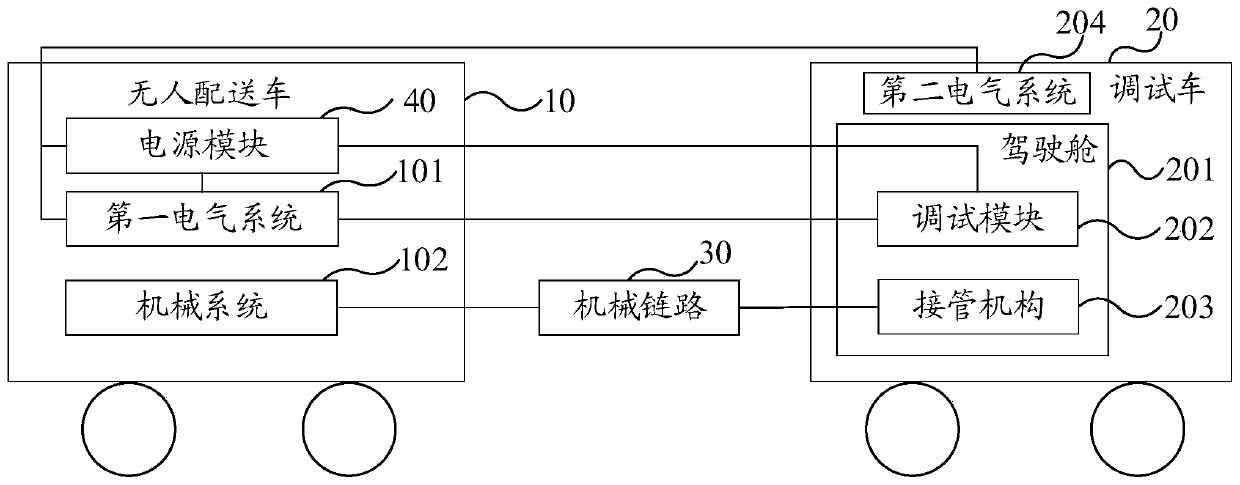

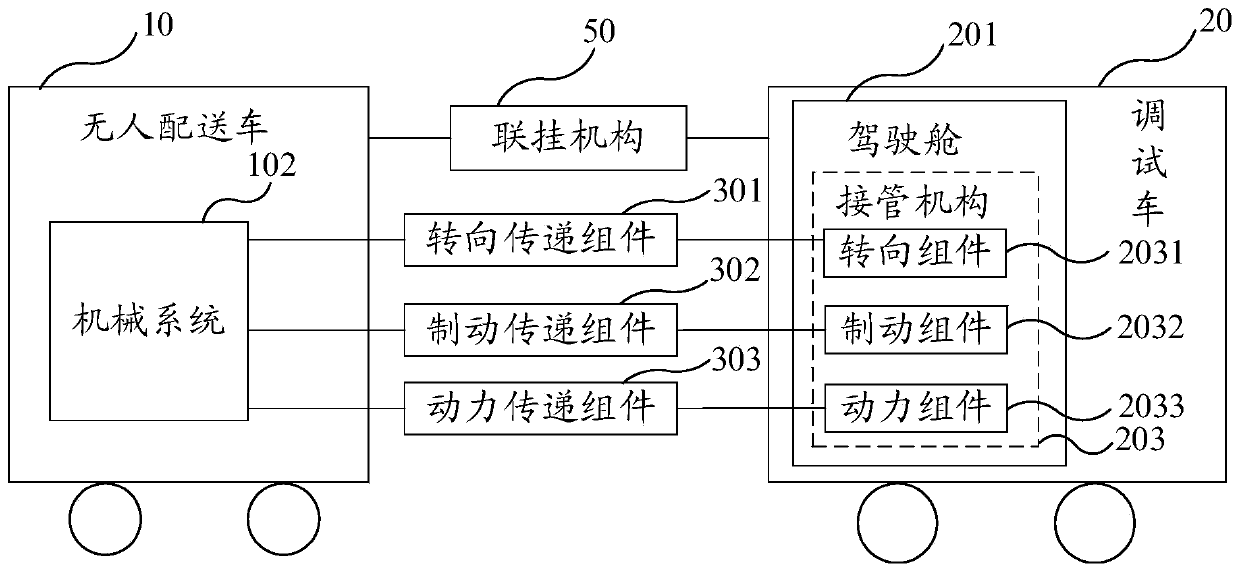

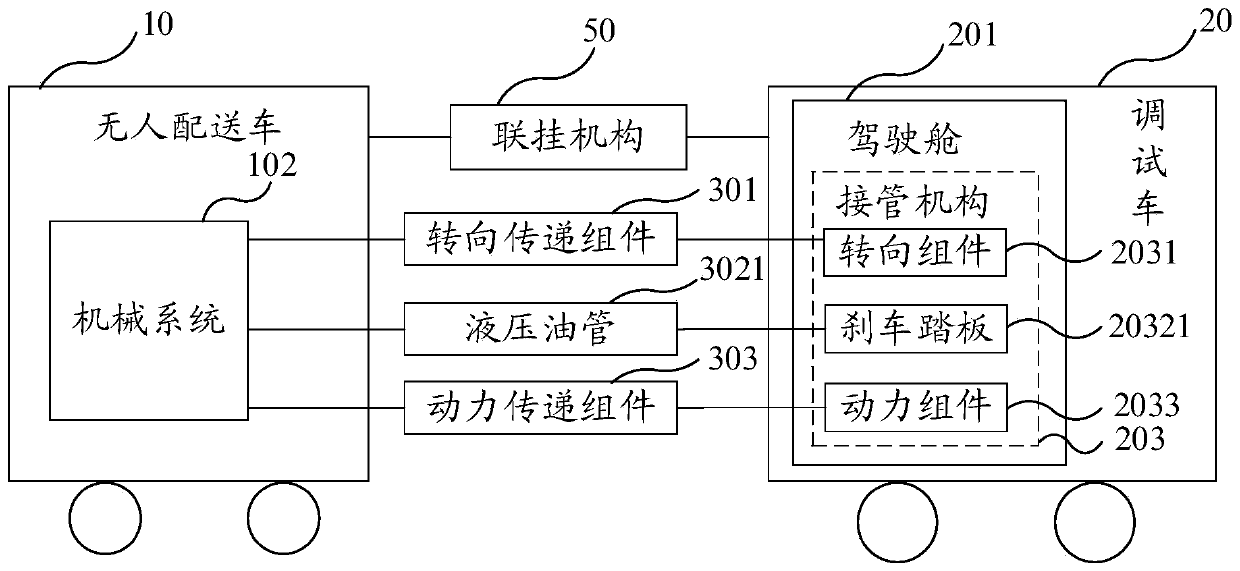

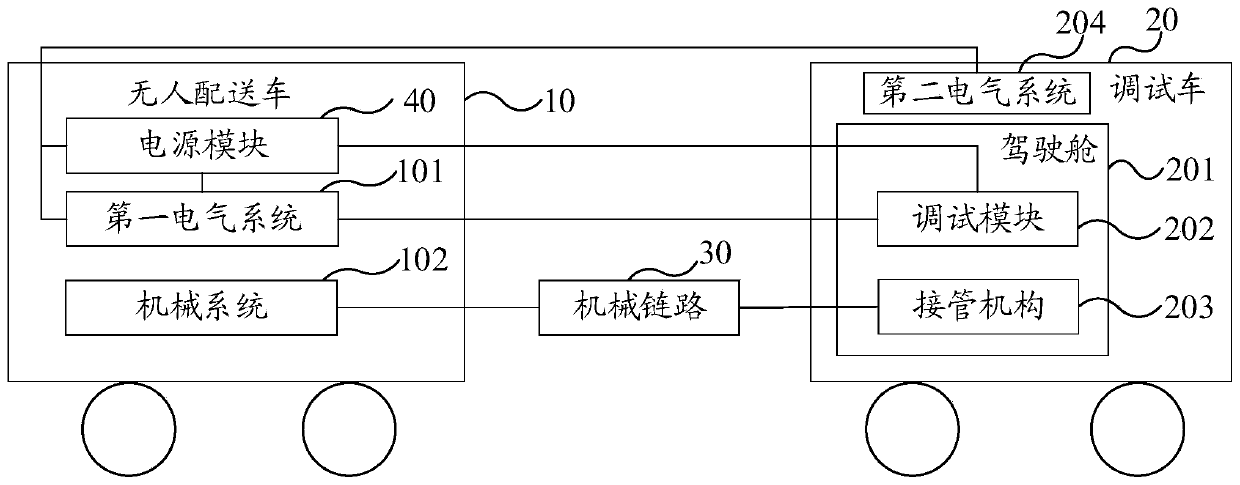

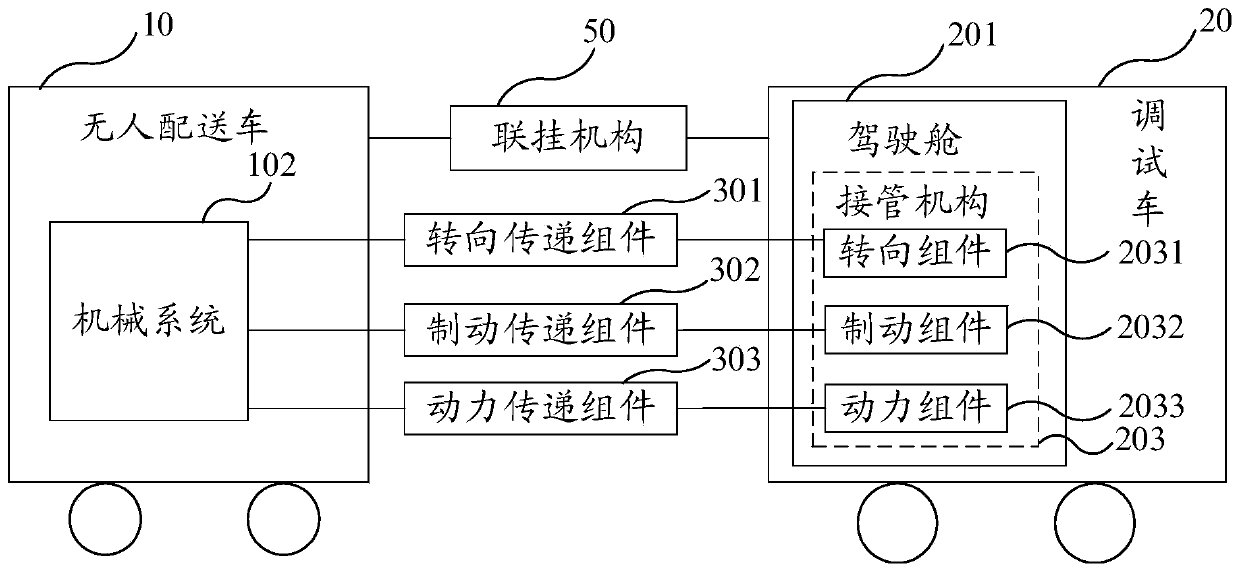

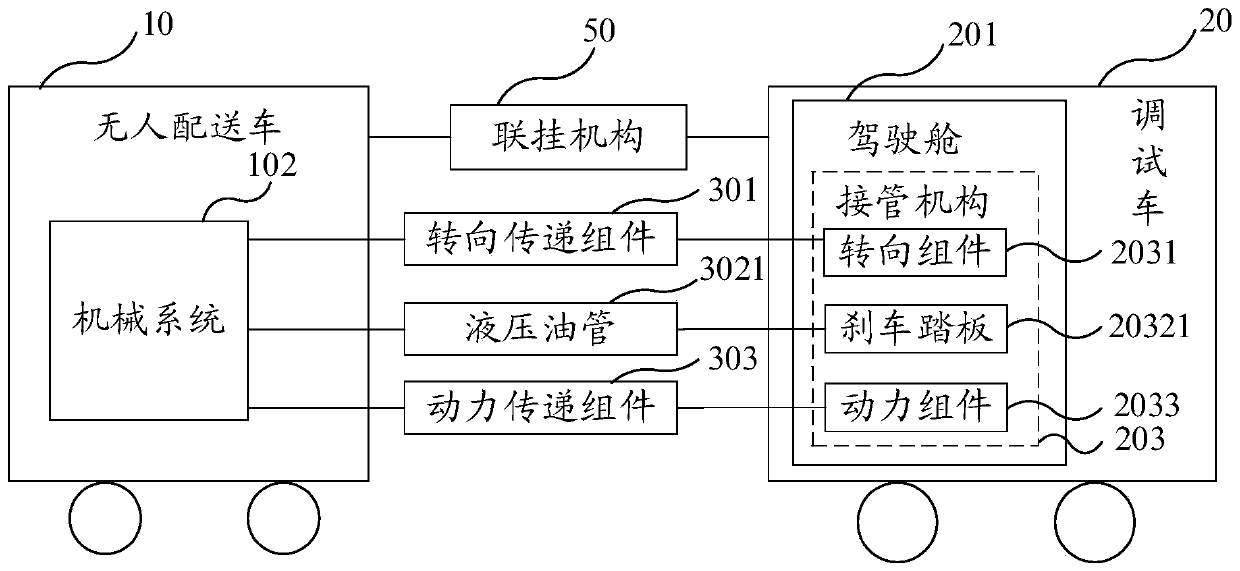

Unmanned distribution vehicle debugging system

ActiveCN110716548AImplement debuggingSolve debugging difficultiesSignalling/lighting devicesPosition/course control in two dimensionsControl engineeringReliability engineering

The invention provides an unmanned distribution vehicle debugging system, and belongs to the technical field of vehicle debugging. The unmanned distribution vehicle debugging system comprises an unmanned distribution vehicle, a debugging vehicle, a mechanical link and a power module, a cockpit is arranged on the debugging vehicle, and a debugging module and a takeover mechanism located in the cockpit are further arranged on the debugging vehicle. The debugging module is electrically connected with a first electrical system of the unmanned distribution vehicle, a second electrical system of thedebugging vehicle is electrically connected with the first electrical system, the takeover mechanism is mechanically connected with a mechanical system of the unmanned distribution vehicle through the mechanical link, and the power module is electrically connected with the debugging module, the first electrical system and the second electrical system, respectively. By means of the control of thesecond electrical system on the debugging vehicle and by means of the debugging module and the takeover mechanism arranged in the cockpit of the debugging vehicle, the unmanned distribution vehicle debugging system provided by the invention realizes the synchronous movement of the debugging vehicle and the unmanned distribution vehicle, and the debugging personnel can debug and take over the unmanned distribution vehicle in the cockpit of the debugging vehicle, so that the problem of debugging difficulty of the unmanned distribution vehicle is solved.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

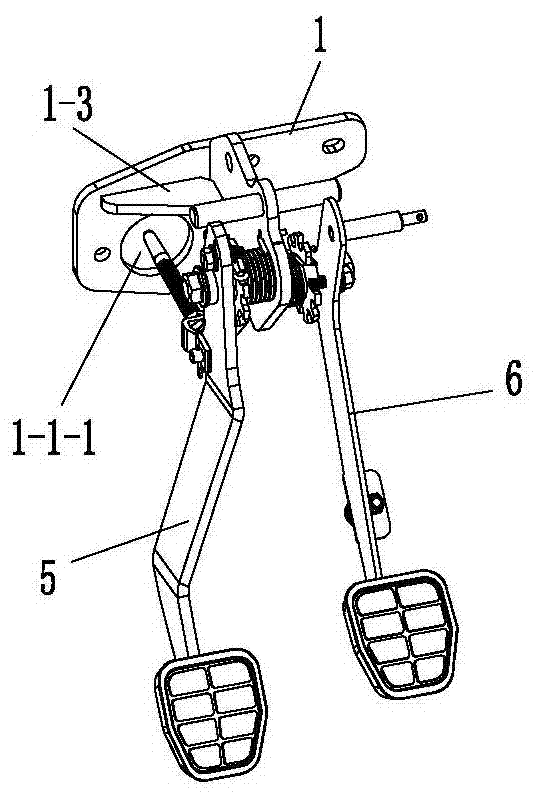

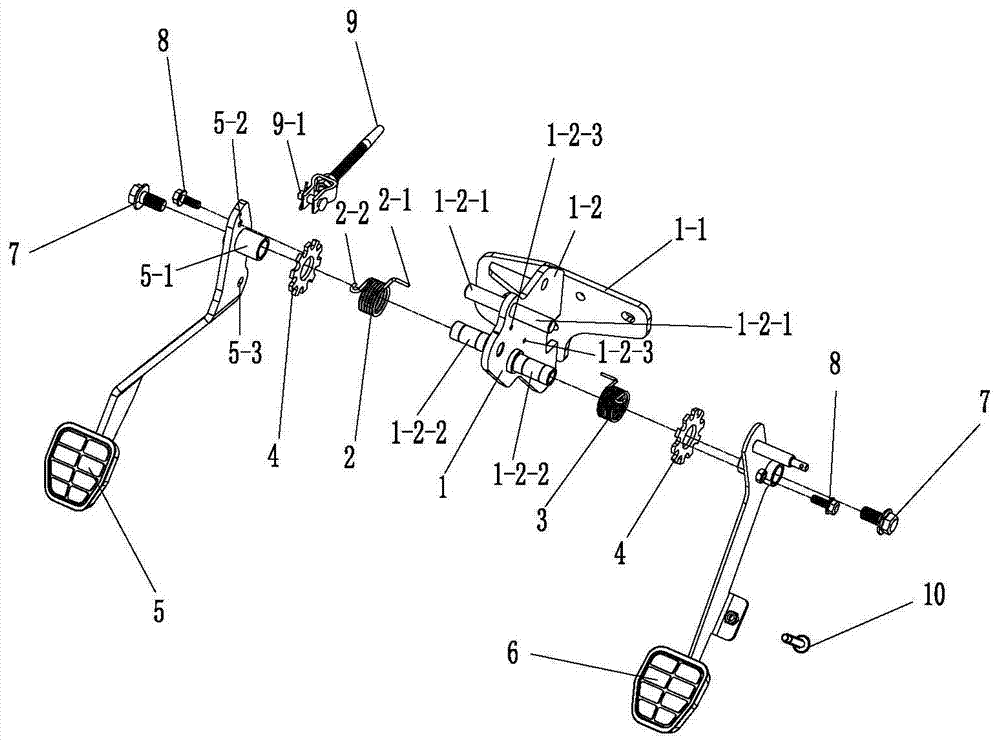

a farm cart

InactiveCN104228792BEasy to adjust the heightSimple structureFoot actuated initiationsPropulsion unit arrangementsVehicle frameTorsion spring

The invention discloses a farmland vehicle. The farmland vehicle comprises a frame and the like; a brake pedal assembly and an accelerator pedal assembly are assembled on the two sides of an accelerator brake seat in a swinging manner, wherein a pin shaft is formed in each of the two sides of the accelerator brake seat; one end of the brake pedal assembly and one end of the accelerator pedal assembly sleeve and are transversely positioned on the two pin shafts respectively; a distance is reserved among the brake pedal assembly, the accelerator pedal assembly and the accelerator brake seat; the pin shafts arranged in the distance are sleeved with torsion springs and torsion spring locking pattern baffles; one ends of the torsion springs are arranged on the accelerator brake seat and the other ends of the torsion springs are arranged on the torsion spring locking pattern baffles; the two torsion spring locking pattern baffles are arranged on the brake pedal assembly and the accelerator pedal assembly respectively. The farmland vehicle adopts a manner of integrally mounting a brake pedal and an accelerator pedal, and the brake pedal and the accelerator pedal are arranged on the two sides of the accelerator brake seat respectively and are provided with the torsion spring locking pattern baffles respectively; a brake torsion spring and an accelerator torsion spring are mounted on the corresponding pin shafts respectively and are connected with the torsion spring locking pattern baffles and the pedals; limiting devices are arranged on the brake pedal and the accelerator pedal respectively and the height of the pedals is convenient to adjust.

Owner:ZHEJIANG APPLESTONE VEHICLE

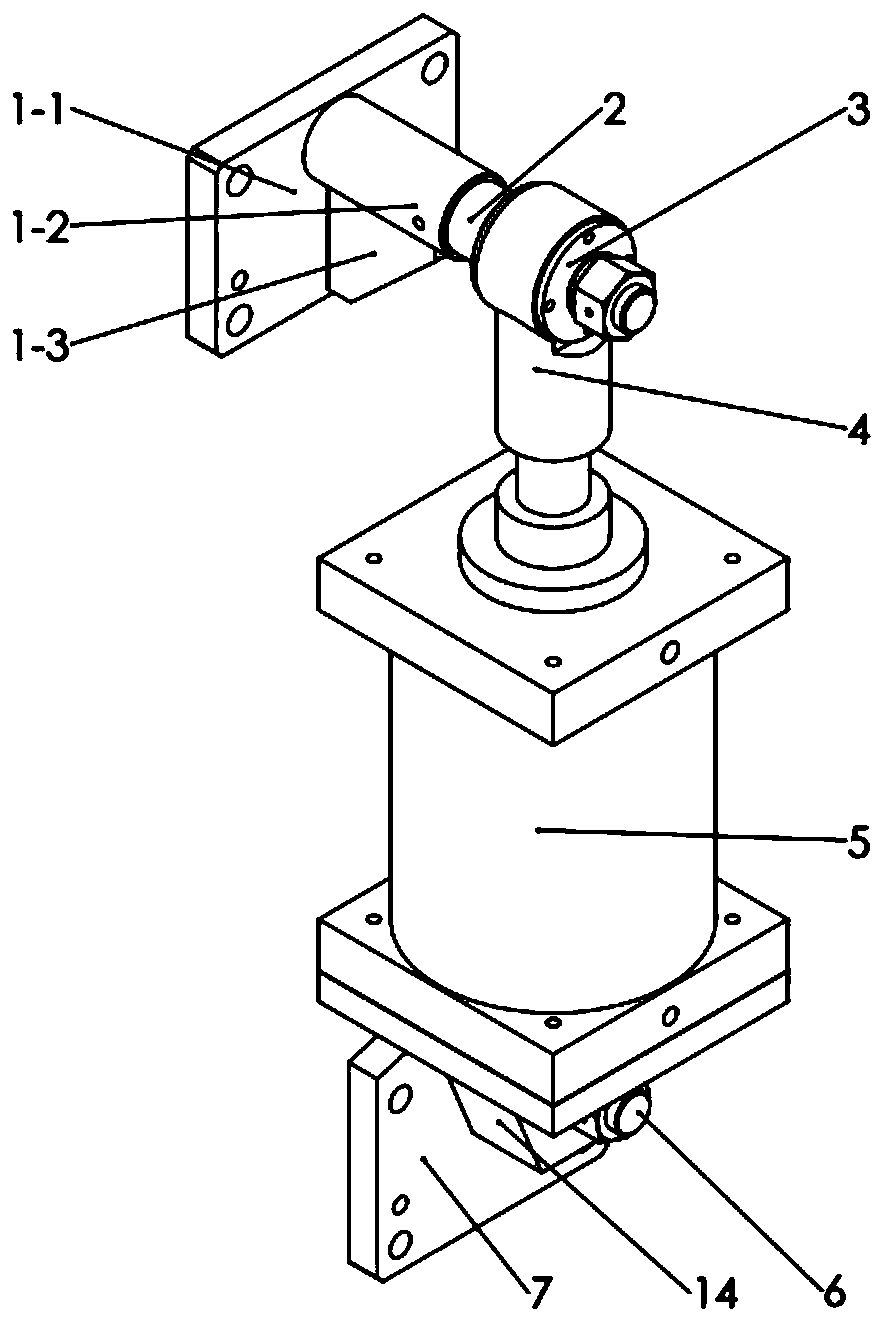

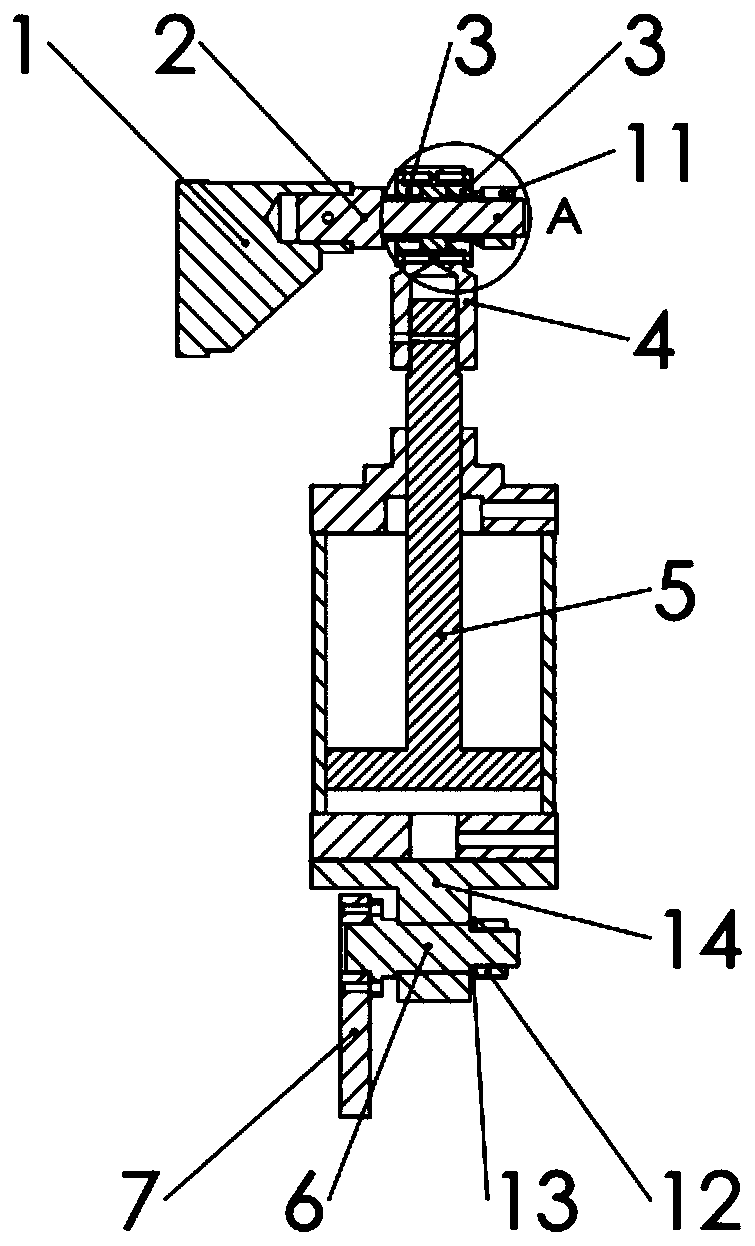

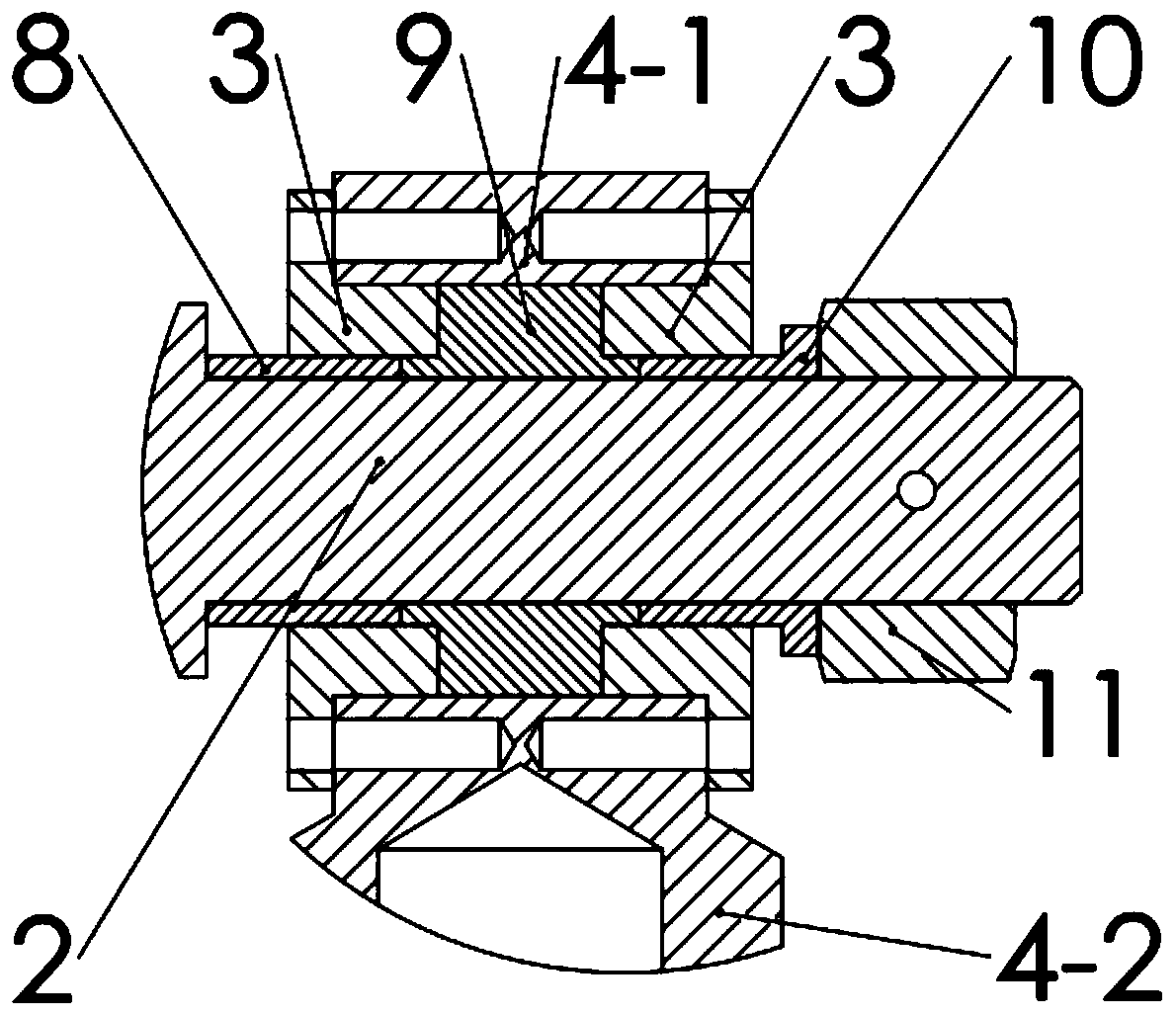

Lower cross beam balance device of ultralarge powder forming machine

ActiveCN108943823AImprove the state of stressSolve the support balance problemPressesBeam balanceScrew thread

The invention discloses a lower cross beam balance device of an ultralarge powder forming machine. The device comprises a first connecting mechanism, a second connecting mechanism, a steering connection head and an extension cylinder; the first connecting mechanism comprises a fixed bracket, a first connecting shaft, a flange end cover, a shaft sleeve, a transition shaft sleeve, a flange shaft sleeve and a first locking nut; the fixed bracket comprises a first mounting plate and a mounting base; one end of the first connecting shaft cooperates with the mounting base; the other end of the firstconnecting shaft is connected into a shaft hole of a steering head at the upper end of a connecting head, and extends out of the shaft hole; a thread is arranged at the shaft hole extension end, andis axially positioned by adopting a first locking nut; a shaft shoulder is arranged on the first connecting shaft between the mounting base and a steering head for axially positioning the first connecting shaft; and a fixed base is fixedly connected to the lower end of the extension cylinder, and is connected to a lower box base through the second connecting mechanism. When the balance device is mounted on equipment, the position can be finely adjusted by the thread depth cooperation and the extension cylinder rotation to realize flexible installation.

Owner:NANJING UNIV OF SCI & TECH +1

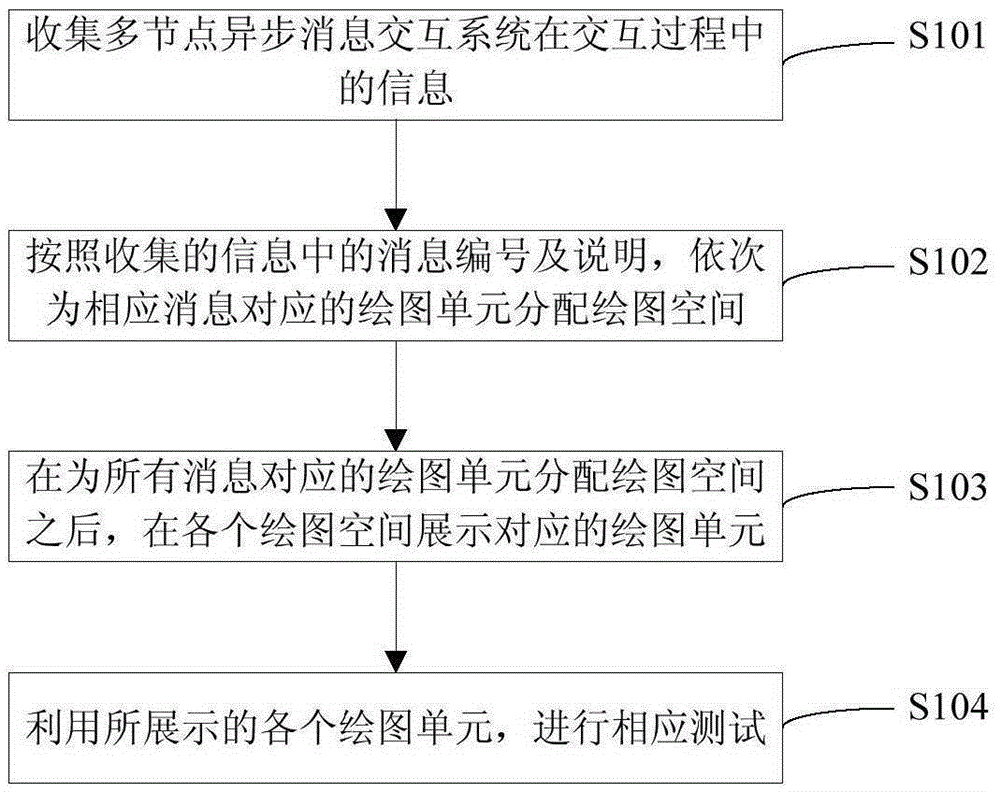

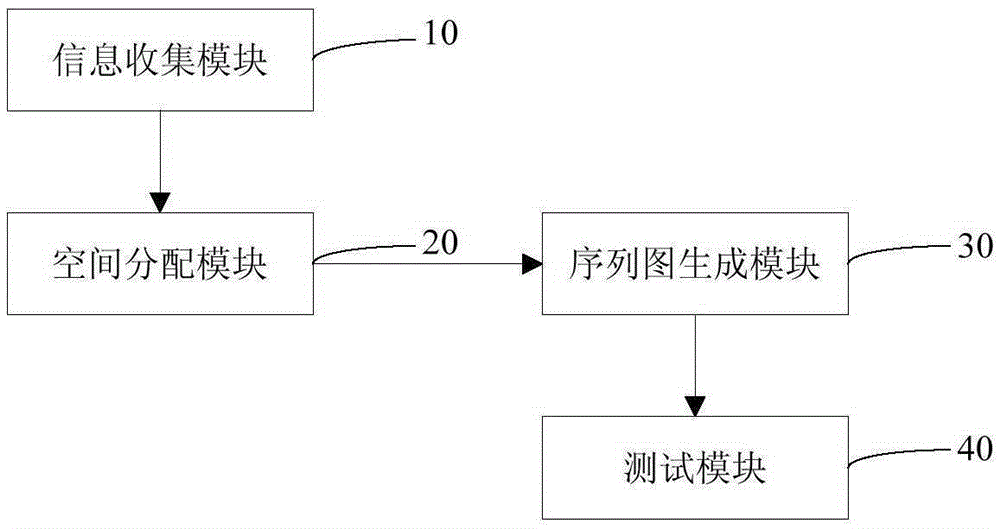

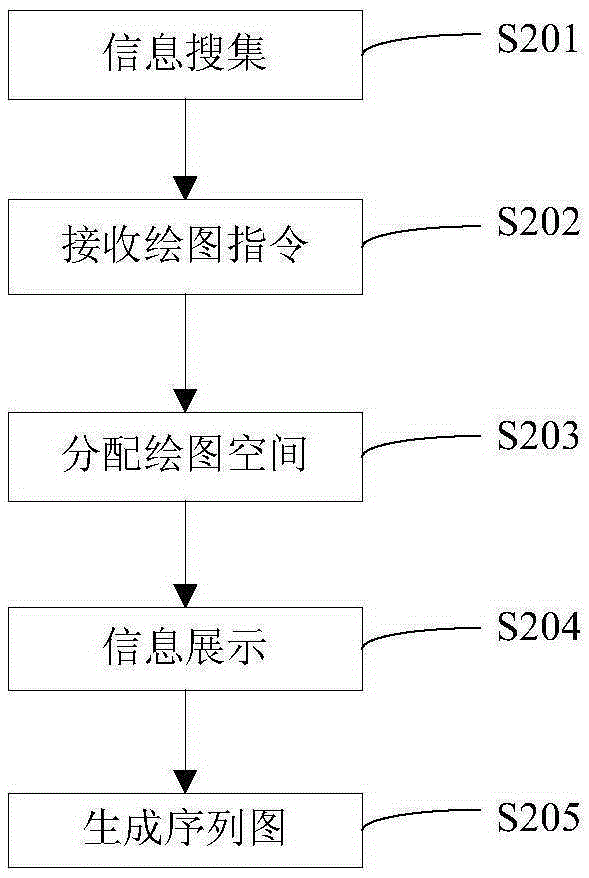

Test method and device based on automatically generated sequence diagram

InactiveCN106547685AImprove test efficiencySave human resourcesSoftware testing/debuggingTest efficiencyInteraction systems

The invention discloses a test method and device based on an automatically generated sequence diagram, and relates to the field of computer applications. The method comprises the following steps: collecting information of a multi-node asynchronous message interaction system in an interaction process; allocating drawing spaces to drawing units corresponding to corresponding messages in sequence according message serial numbers and illustrations in the collected information; after the drawing spaces are allocated to the drawing units corresponding to all messages, displaying the corresponding drawing units in the drawing spaces; and performing corresponding tests by use of the displayed drawing units. According to the test method and device provided by the invention, by means of the automatically generated sequence diagram, the interaction procedures of the messages can be displayed intuitively, thereby locating faulty nodes more conveniently and solving the problems of program debugging difficulty and problem locating difficulty in the multi-node asynchronous message interaction system, meanwhile as the sequence diagram is automatically generated, the manpower resources are saved, and the test efficiency is improved.

Owner:SHANGHAI ZTE SOFTWARE CO LTD

Unmanned delivery vehicle debugging system

ActiveCN110716548BImplement debuggingSolve debugging difficultiesSignalling/lighting devicesPosition/course control in two dimensionsDelivery vehicleControl engineering

The present disclosure provides an unmanned delivery vehicle debugging system, which belongs to the technical field of vehicle debugging. The unmanned delivery vehicle debugging system includes: an unmanned delivery vehicle, a debugging vehicle, a mechanical link and a power module. The debugging vehicle is equipped with a cockpit, and the debugging vehicle is also equipped with a debugging module and a takeover mechanism located in the cockpit. The debugging module is electrically connected to the first electrical system of the unmanned delivery vehicle, the second electrical system of the debugging vehicle is electrically connected to the first electrical system, the takeover mechanism is mechanically connected to the mechanical system of the unmanned delivery vehicle through a mechanical link, and the power modules are respectively Electrically connected to the debugging module, the first electrical system and the second electrical system. This disclosure uses the second electrical system to control the debugging vehicle and the debugging module and takeover mechanism provided in the cockpit of the debugging vehicle, so that when the debugging vehicle and the unmanned distribution vehicle move synchronously, the debugging personnel can control the driving of the debugging vehicle. The debugging and takeover of unmanned delivery vehicles in the cabin solves the problem of difficulty in debugging unmanned delivery vehicles.

Owner:BEIJING SANKUAI ONLINE TECH CO LTD

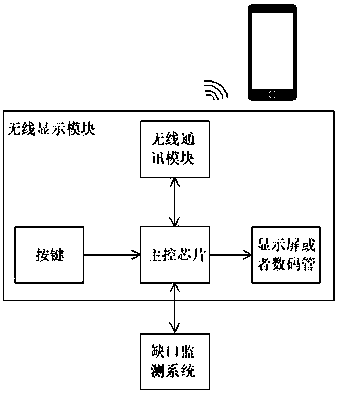

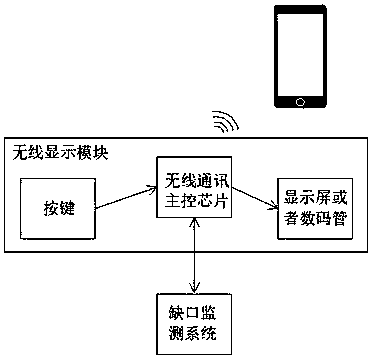

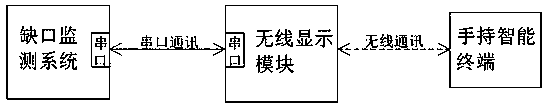

Wireless display unit and point switch gap monitoring system

PendingCN110809139AImprove work efficiencyShorten the maintenance cycleClosed circuit television systemsSubstation equipmentEmbedded systemCommunication interface

The invention discloses a wireless display unit and a point switch notch monitoring system. The wireless display unit comprises a main control module, a wireless communication module and a handheld intelligent mobile terminal. The main control module is connected with a gap image monitoring system through a communication bus serial port, and the handheld intelligent mobile terminal is connected with the main control module through the wireless communication module. And the main control module forwards the information sent to the display module by the acquisition extension set through the serial port communication interface to the handheld intelligent mobile terminal by utilizing the wireless communication module. The point switch notch monitoring system comprises the wireless display unit.According to the invention, the main control module forwards information sent to the display module by the point switch acquisition extension set through the serial port communication interface to the handheld intelligent mobile terminal by using the wireless communication module; therefore, the problem that the image sensor is difficult to debug by on-site maintenance personnel is solved, and the train running safety can be better guaranteed.

Owner:SHENZHEN MAIJIN TECH

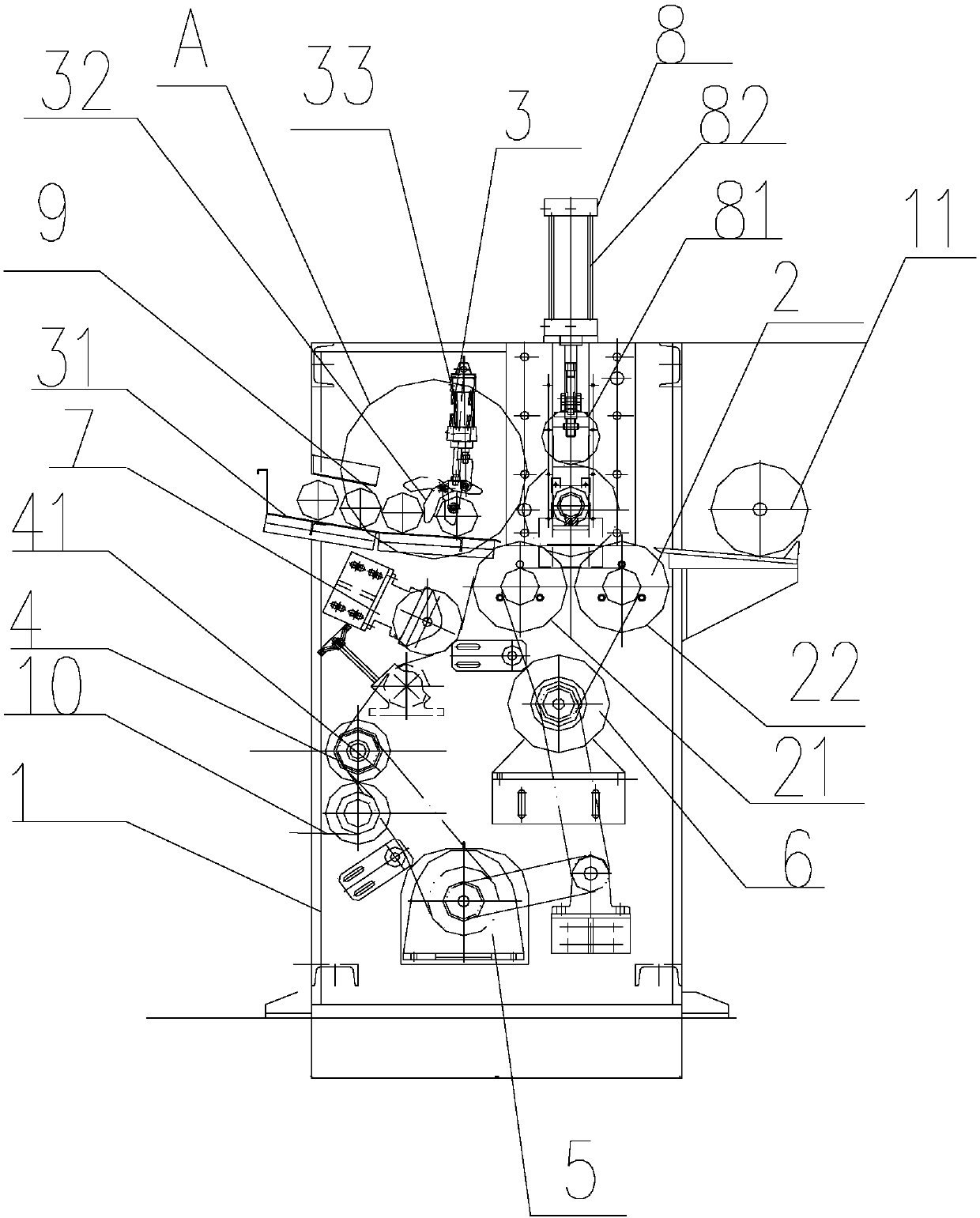

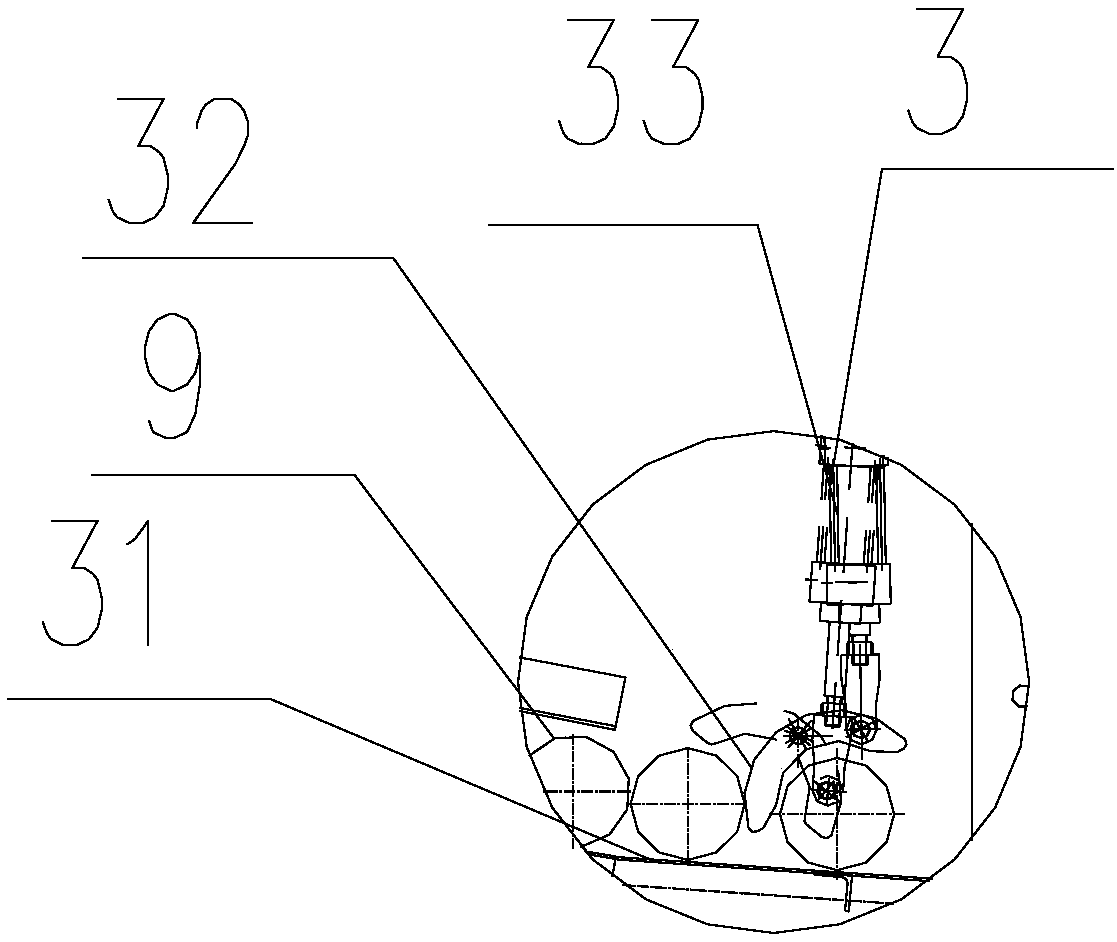

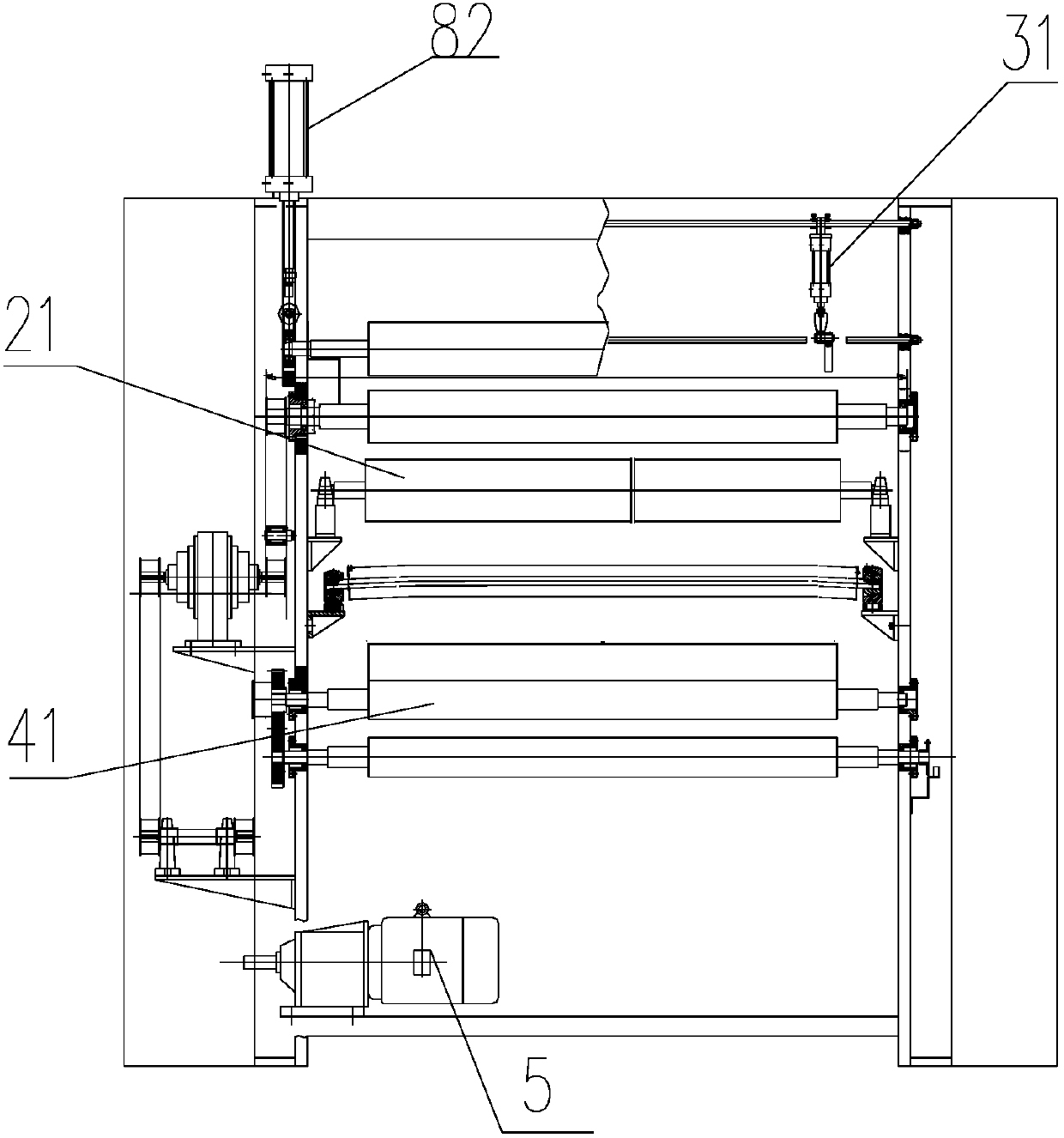

Economical Single Drive Shaftless Surface Winder

The invention relates to the technical field of glued film production, in particular to an economical single-drive shaftless surface winding machine. The economical single-drive shaftless surface winding machine comprises a frame; and the frame is provided with a driving roller mechanism for driving paper tubes to rotate for winding, a paper tube feeding mechanism for feeding the paper tubes to the driving roller mechanism, a traction mechanism for conveying films to the paper tubes and a driving mechanism for supplying power for the driving roller mechanism and the traction mechanism. The economical single-drive shaftless surface winding machine realizes direct winding of the films on the paper tubes, simplifies the procedures, and saves the cost.

Owner:CHANGZHOU INST OF NUMERICAL CONTROL TECH

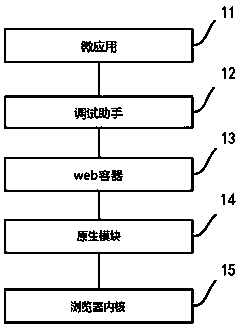

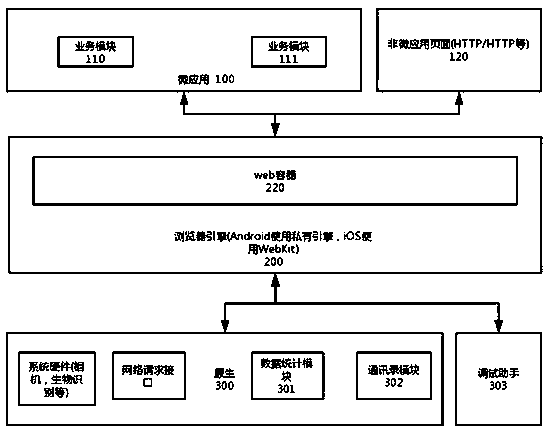

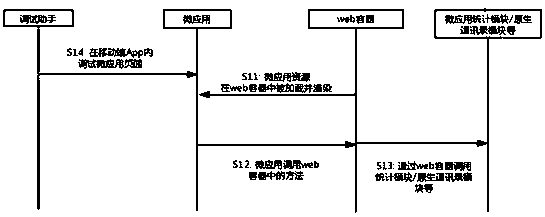

A development and testing system for micro-applications in mobile terminals

ActiveCN110659021BImprove experienceSolve debugging difficultiesSoftware testing/debuggingSoftware designSoftware engineeringWeb container

The invention discloses a development and test system for a micro-application in a mobile terminal. The development and test system comprises the micro-application, a debugging assistant, a web container, a native module and a browser kernel, the micro application is an offline resource set developed on the basis of HTML, JavaScript and CSS technologies, exists independently, and does not depend on mobile terminal App operation. The debugging assistant is used for directly debugging the micro-application / web page at the mobile terminal, positioning problems and debugging performance; the browser kernel is a rendering kernel borne by the Android end and the iOS end, the iOS end uses a webKit kernel of the system, and the Android end uses a private kernel to replace the browser kernel of thesystem; the web container is designed on the basis of a browser kernel, and micro-application loading rendering and native communication are achieved. According to the method, the problems that native heating is inconvenient to update, native webpage loading is slow, user experience is poor, and developers are difficult to debug at a mobile terminal are solved.

Owner:JIANGSU ZHUOYI INFORMATION TECH CO LTD +2

A plug-and-play access configuration method for iec61850 smart devices

ActiveCN110896363BSolve debugging difficultiesImprove configuration efficiencyTransmissionSmart substationMonitoring system

The invention discloses an access configuration method for realizing plug-and-play of IEC61850 intelligent devices. The steps are: (1) a monitoring system periodically scans the system network where it is located, and when an intelligent device with a built-in ICD file is found to be connected to the system network, The monitoring system identifies the smart device and obtains its ICD file; (2) The monitoring system uses the ICD file of the smart device to automatically incrementally configure the original SCD file to obtain a new SCD file; (3) The monitoring system uses the new SCD file to generate Aim at the CID file of the smart device and transfer the CID file to the corresponding smart device; (4) The monitoring system and the smart device are re-initialized and a communication connection is established. The method realizes plug-and-play in the true sense, better solves the problem of difficult configuration and debugging of smart substation reconstruction and expansion, and can effectively improve the configuration and commissioning efficiency of smart substation reconstruction and expansion.

Owner:DONGFANG ELECTRONICS

A lower beam balance device of a super-large powder molding machine

ActiveCN108943823BImprove the state of stressSolve the support balance problemPressesMolding machineBeam balance

The invention discloses a lower cross beam balance device of an ultralarge powder forming machine. The device comprises a first connecting mechanism, a second connecting mechanism, a steering connection head and an extension cylinder; the first connecting mechanism comprises a fixed bracket, a first connecting shaft, a flange end cover, a shaft sleeve, a transition shaft sleeve, a flange shaft sleeve and a first locking nut; the fixed bracket comprises a first mounting plate and a mounting base; one end of the first connecting shaft cooperates with the mounting base; the other end of the firstconnecting shaft is connected into a shaft hole of a steering head at the upper end of a connecting head, and extends out of the shaft hole; a thread is arranged at the shaft hole extension end, andis axially positioned by adopting a first locking nut; a shaft shoulder is arranged on the first connecting shaft between the mounting base and a steering head for axially positioning the first connecting shaft; and a fixed base is fixedly connected to the lower end of the extension cylinder, and is connected to a lower box base through the second connecting mechanism. When the balance device is mounted on equipment, the position can be finely adjusted by the thread depth cooperation and the extension cylinder rotation to realize flexible installation.

Owner:NANJING UNIV OF SCI & TECH +1

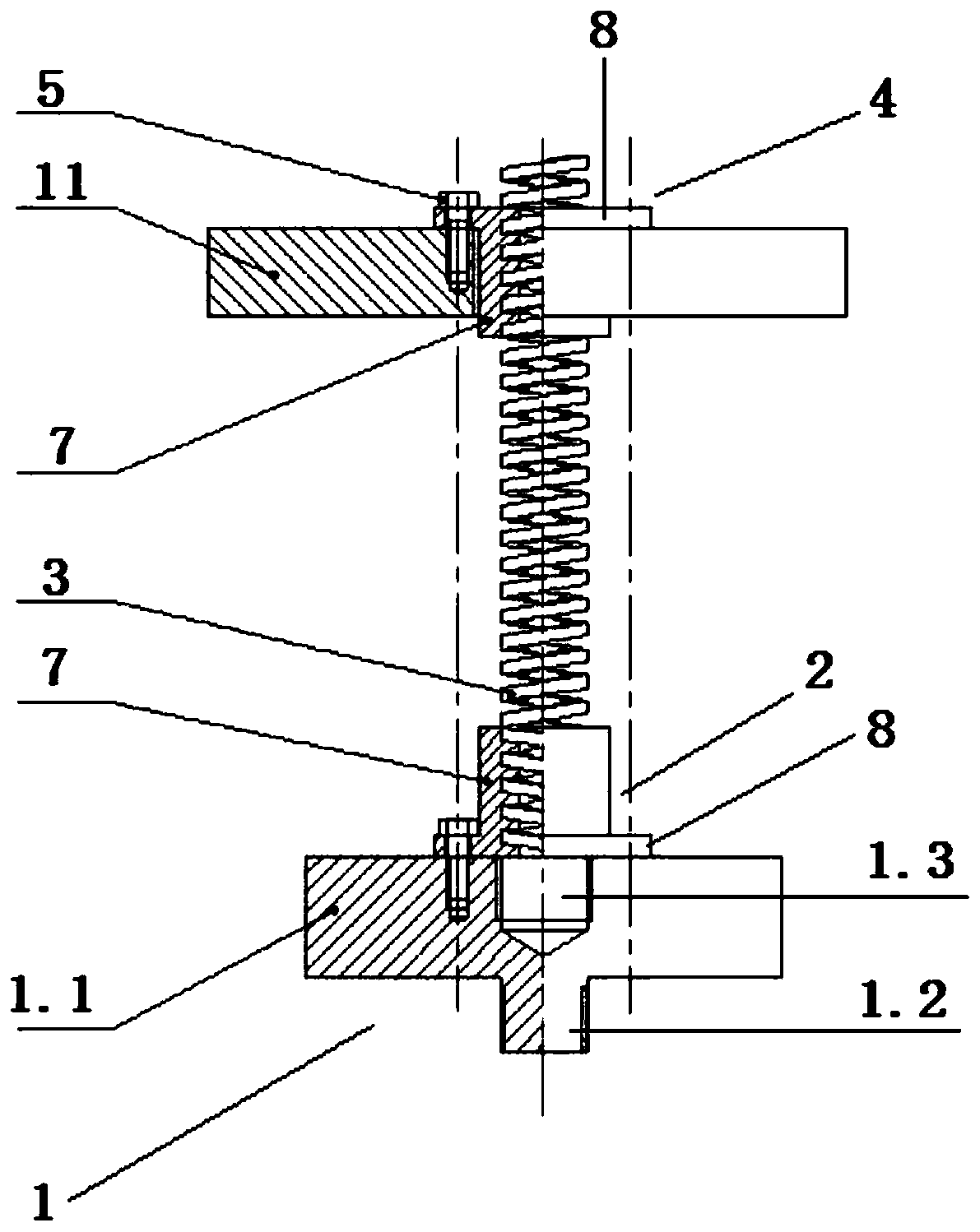

Dynamic vibration absorber with stepless adjustable frequency

ActiveCN111561535AEasy to adjustSolve debugging difficultiesShock absorbersInertia effect dampersInterference fitClassical mechanics

The invention discloses a dynamic vibration absorber with stepless adjustable frequency. The dynamic vibration absorber with stepless adjustable frequency comprises a mass block and a spring. The dynamic vibration absorber with stepless adjustable frequency is characterized in that two ends of the spring are respectively connected with adjusting sleeves, and threaded grooves corresponding to the shape of the spring and in interference fit with the surface of the spring are formed in the adjusting sleeves; the mass block comprises a plurality of mass partitioning blocks which can be coaxially fixed into a whole; and the mass partitioning blocks and the adjusting sleeves are respectively provided with a fixed structure capable of fixing the mass partitioning blocks and the adjusting sleeves.The designed dynamic vibration absorber realizes the stepless adjustment of natural frequency and covers all frequency values within a certain range. Meanwhile, whether the mass block is increased ordecreased or the spring stressed length is adjusted conveniently, and the problems of difficulty in on-site debugging and low precision are effectively solved.

Owner:DONGFENG MOTOR CORP HUBEI

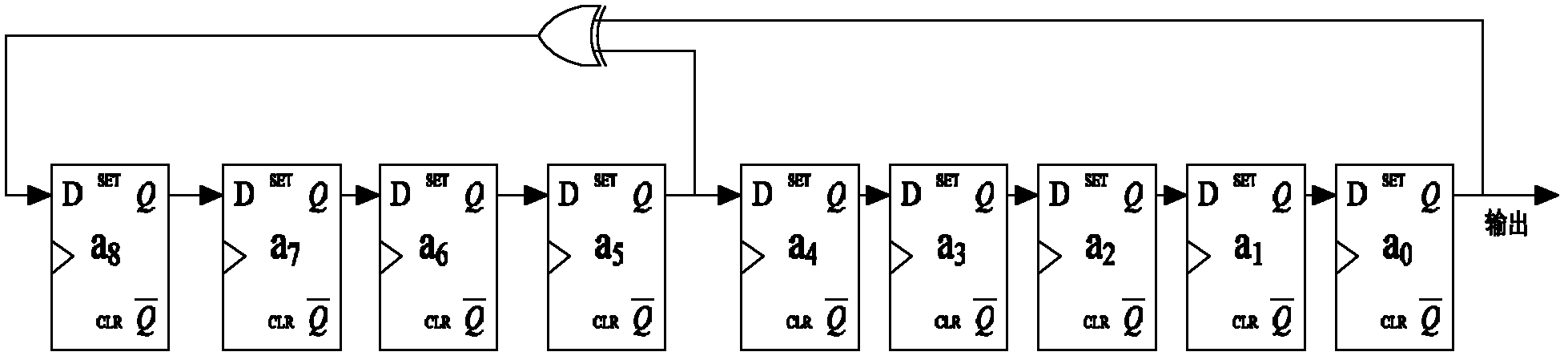

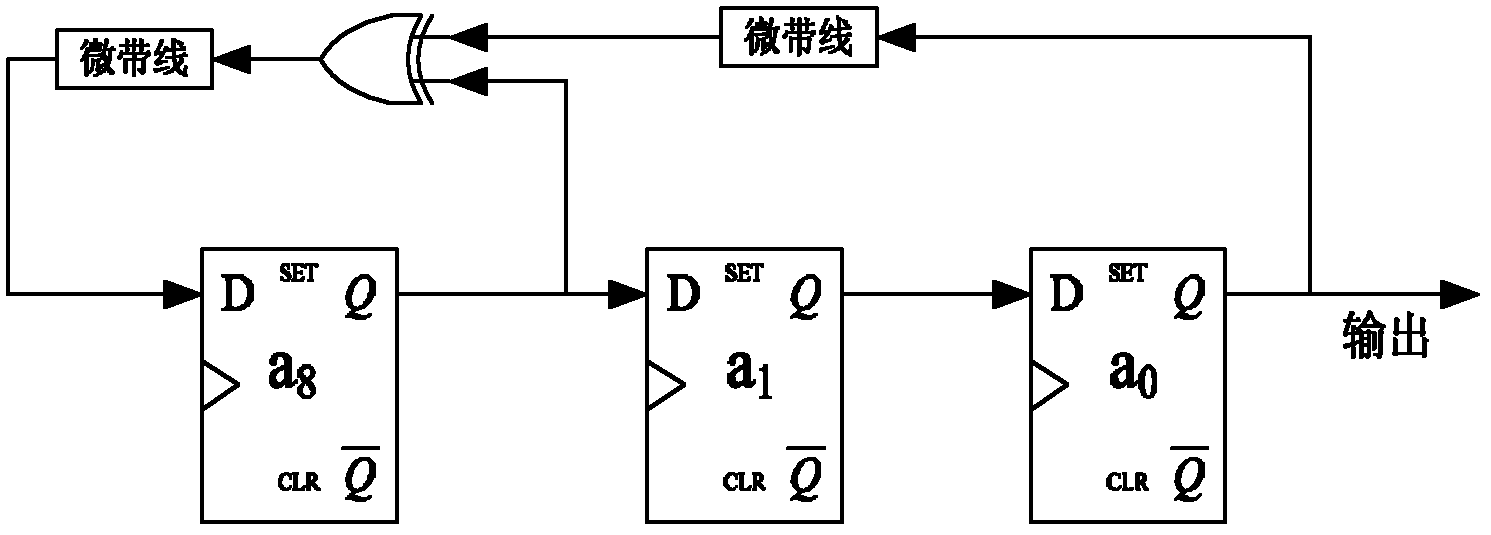

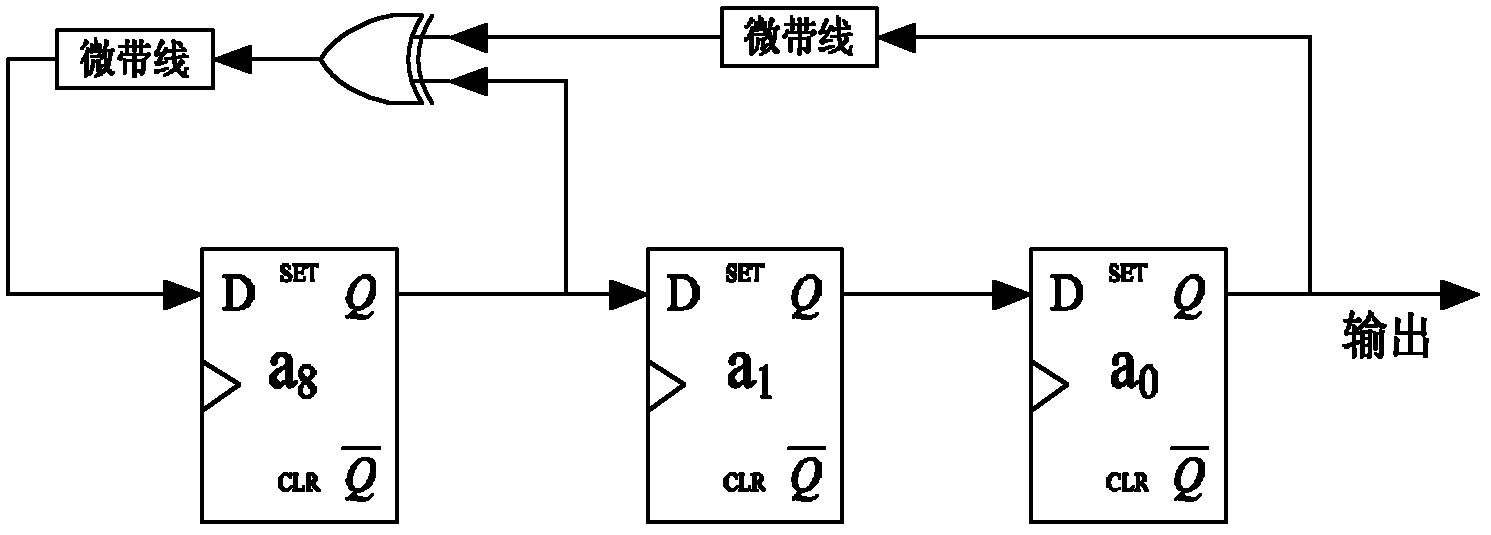

Multi-order M sequence generation circuit

The invention relates to a multi-order M sequence generation circuit, which comprises a trigger circuit and an XOR gate correspondingly connected with the trigger circuit through at least one microstrip line, wherein after the XOR gate is delayed by the microstrip line for required time, the trigger circuit outputs a required M sequence. The XOR gate is connected with the trigger circuit through at least one microstrip line; after the XOR gate is delayed by the microstrip line for required time, the trigger circuit outputs the required M sequence; the multi-order M sequence generation circuit has high frequency, namely a clock frequency of the GHz level can be realized easily, is low in cost, and the number of required devices is small, namely, the multi-order M sequence is realized by only using three D triggers and the XOR gate; the multi-order M sequence generation circuit has high reliability and high stability, can be applied to the fields of communication and radars; according to the high-frequency multi-order M sequence generation circuit constructed by the microstrip line, the problems of low storage frequency and debugging difficulty are solved; and the multi-order M sequence generation circuit can be widely applied to various high-frequency signal generation circuits.

Owner:北方通用电子集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com