Economical Single Drive Shaftless Surface Winder

A single-drive, winder technology, applied in the direction of winding strips, thin material handling, transportation and packaging, etc., can solve the problems of low efficiency, and achieve the effect of simplifying the process, saving costs, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

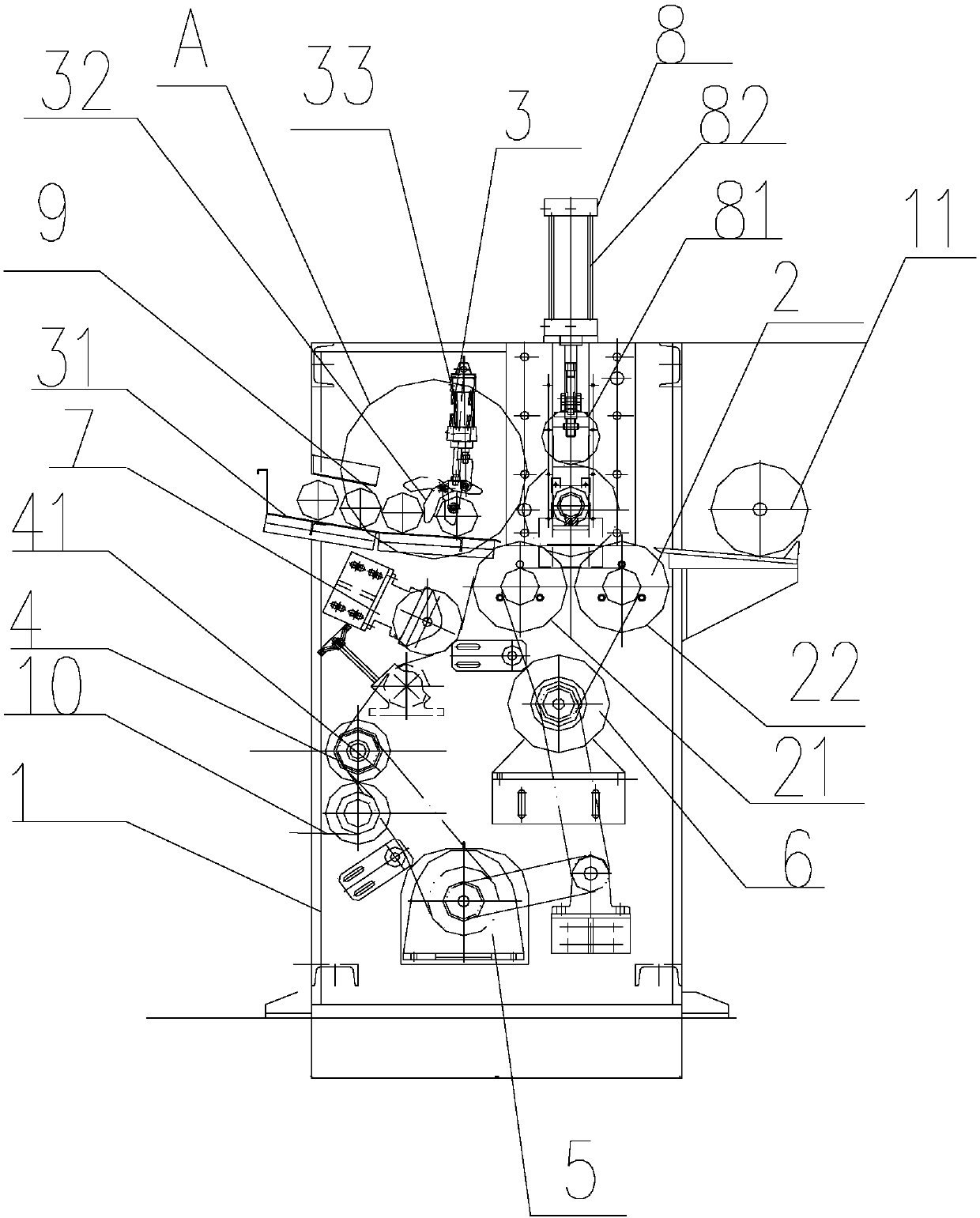

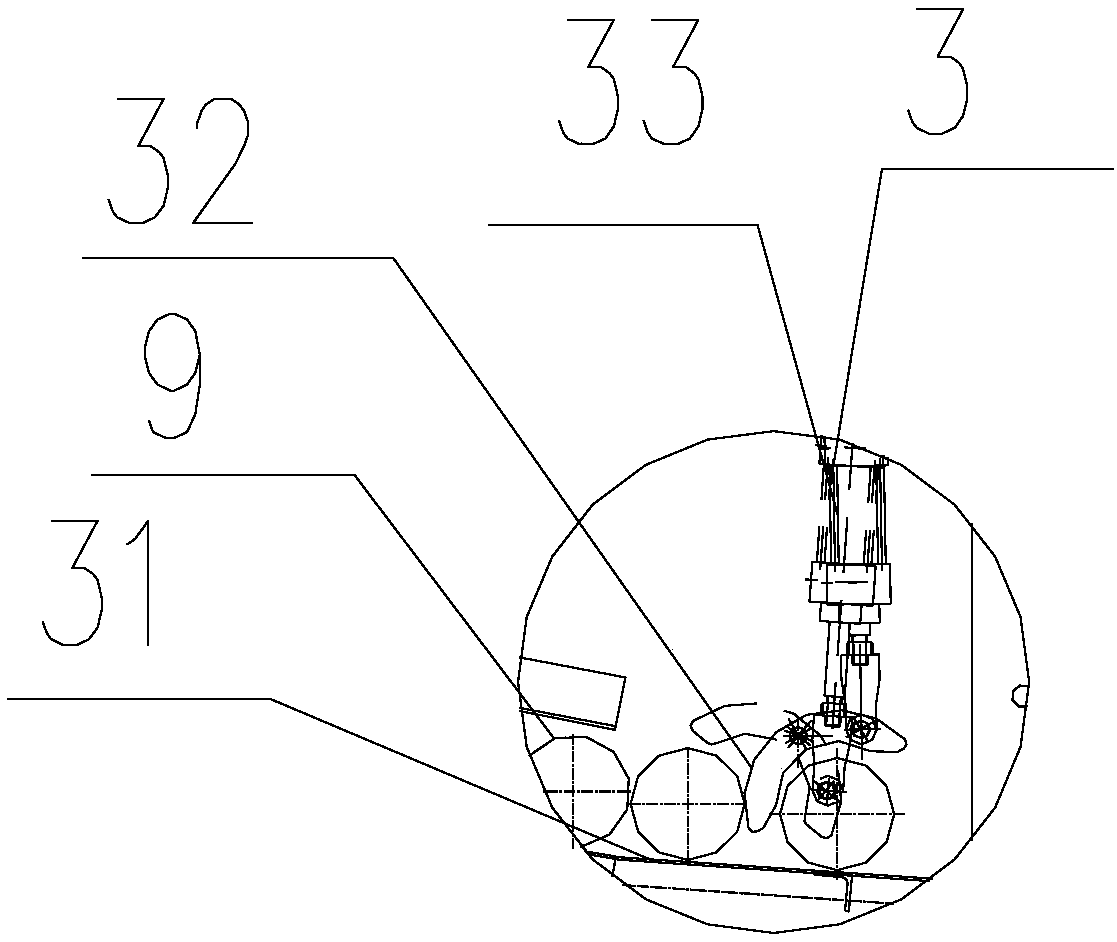

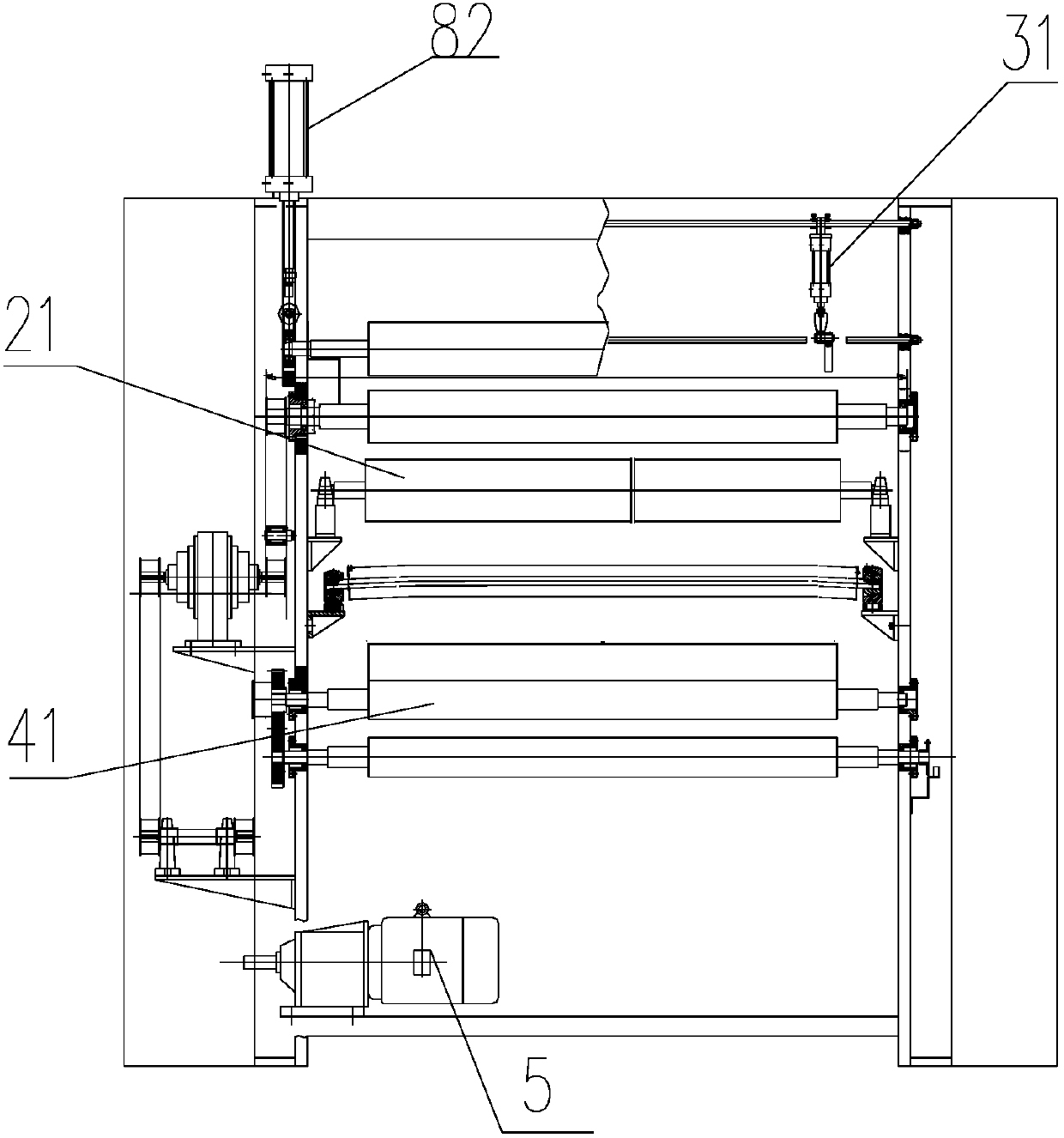

[0025] Such as Figure 1-3 , an economical single-drive shaftless surface winder, including a frame 1, which is provided with a driving roller mechanism 2 for driving the paper tube 9 to rotate for winding, and is used to send the paper tube 9 to the driving roller The paper feeding tube mechanism 3 at the mechanism 2 is used to transport the film 10 to the traction mechanism 4 at the paper tube 9, and the driving mechanism is used to provide power to the driving roller mechanism 2 and the traction mechanism 4.

[0026] The driving roller mechanism 2 includes a front rubber roller 21 and a rear rubber roller 22, and the paper tube 9 is located between the front rubber roller 21 and the rear rubber roller 22, and the gap between the front rubber roller 21 and the rear rubber roller 22 is smaller than that of the paper tube 9. diameter, the front rubber roller 21 and the rear rubber roller 22 have the same rotation direction. In this embodiment, the diameter of the rear rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com