Manufacturing method of high coupling degree and high frequency circuit board

A high-frequency circuit board and manufacturing method technology, which is applied in the direction of printed circuit manufacturing, printed circuit, and chemical/electrolytic method to remove conductive materials, etc., can solve the problem of not having high frequency, thinning and stable frequency characteristics , to achieve the effect of improving production efficiency and product quality, and solving debugging difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

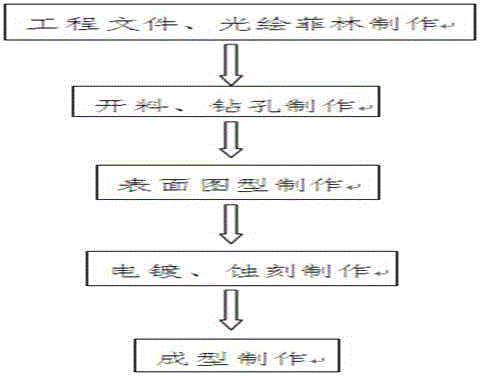

[0016] Such as figure 1 As shown, a method for making a high-coupling high-frequency circuit board includes the following steps: Step 1 uses a high-precision laser photoplotter with a resolution of 20240dpi to make a black negative film; uses a 200-fold magnifying glass to check the negative film, and uses a 5KW The exposure machine copies the diazo film. Step 2 Before drilling, treat the pre-cut board with a 500-mesh nylon brush before wrapping the board. Drilling is 2-4 pieces of drilling. The diameter of the pin hole drilled on the short side of the composite board is 3.2mm. The CNC drilling machine uses a 45-degree drill, and the number of holes drilled by the drill is less than 1,000 holes. After drilling, use sandpaper of more than 2,000 mesh to treat the burrs and burrs on the surface of the composite board. Step 3 Use an 800-mesh roller brushing machine to grind the surface of the composite board; before the composite board is aligned, first pre-align the production f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com