A lower beam balance device of a super-large powder molding machine

A technology of powder molding machine and balancing device, which is applied to presses, manufacturing tools, etc., can solve the problem that the reset balancing device cannot be installed with the balancing device, and achieves the effect of solving the difficulty of debugging, easy installation and disassembly, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

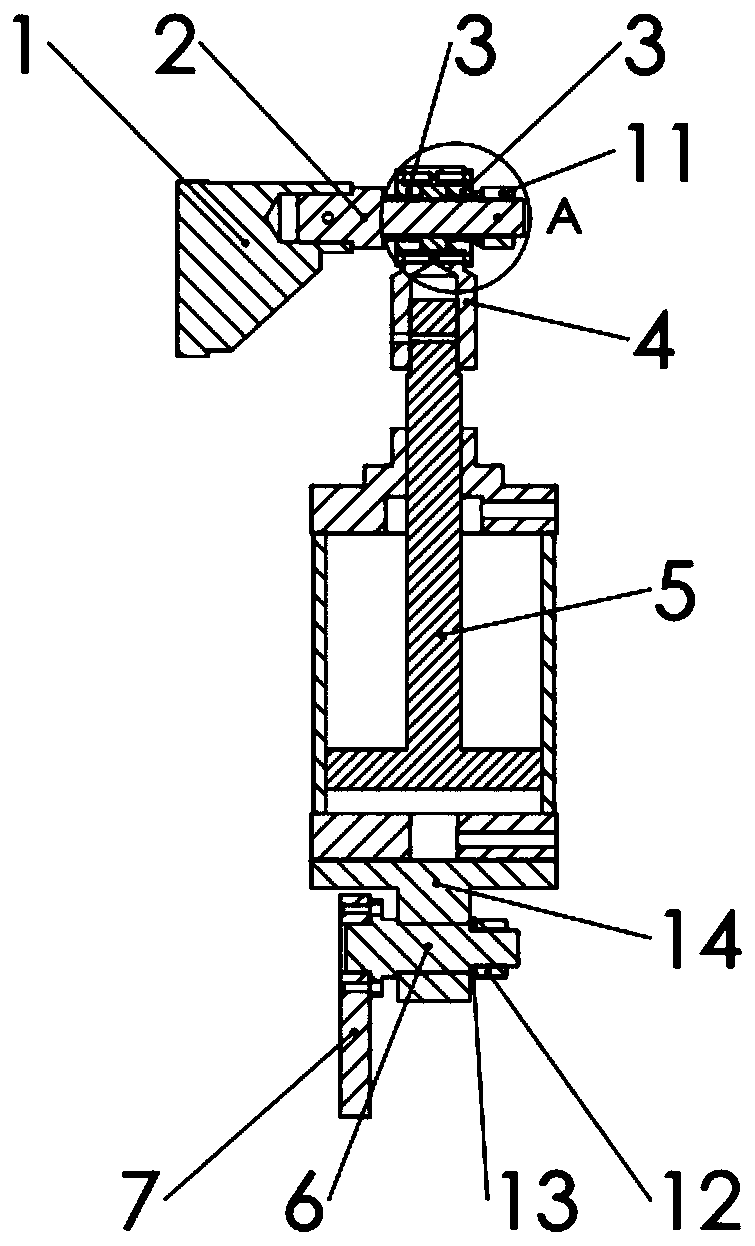

[0020] In order to illustrate the technical scheme and technical purpose of the present invention, the present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

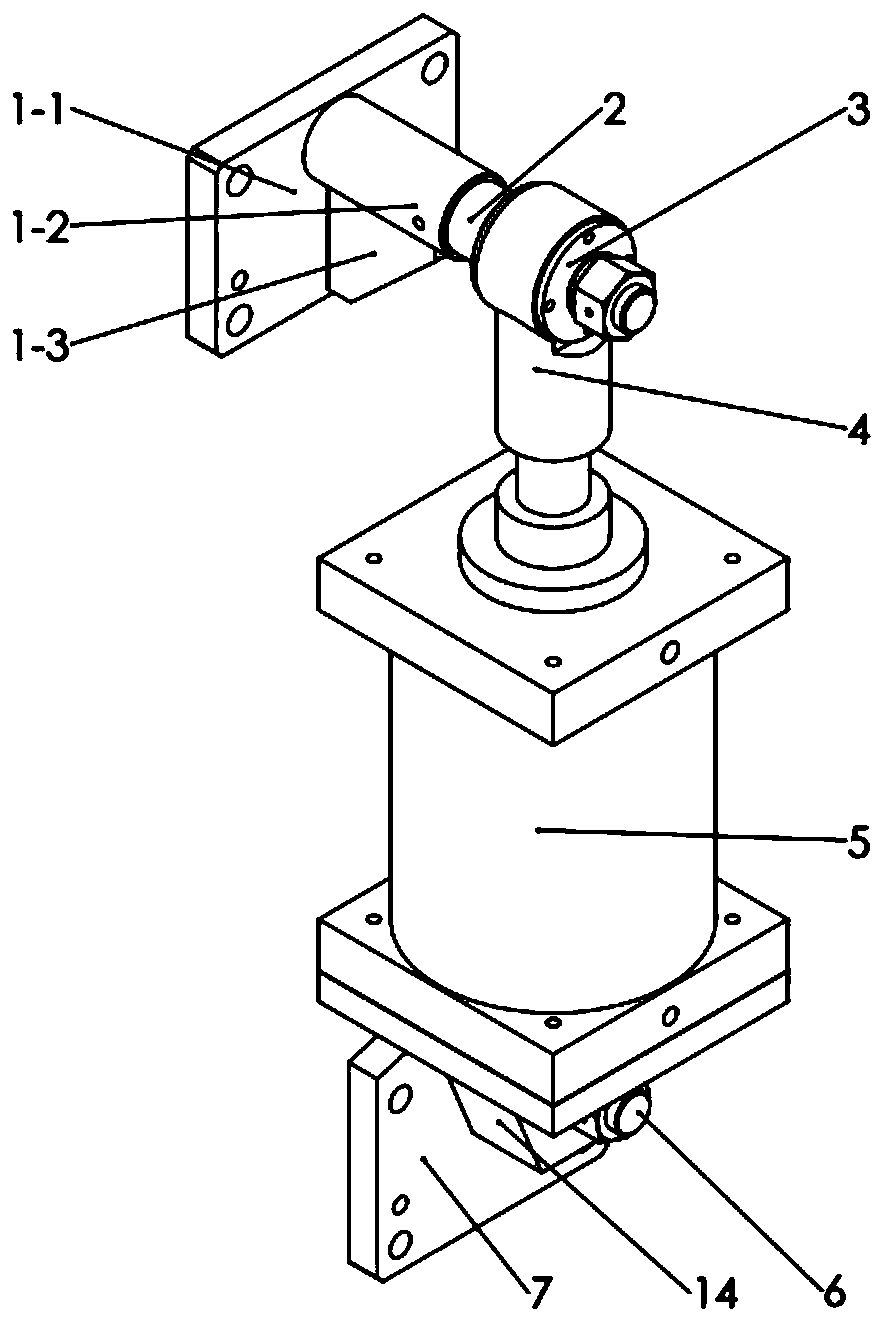

[0021] combine figure 1 , figure 2 , image 3 , a lower beam balancing device of an ultra-large powder molding machine of the present invention, comprising a first connection mechanism, a second connection mechanism, a steering joint 4, and a telescopic cylinder 5;

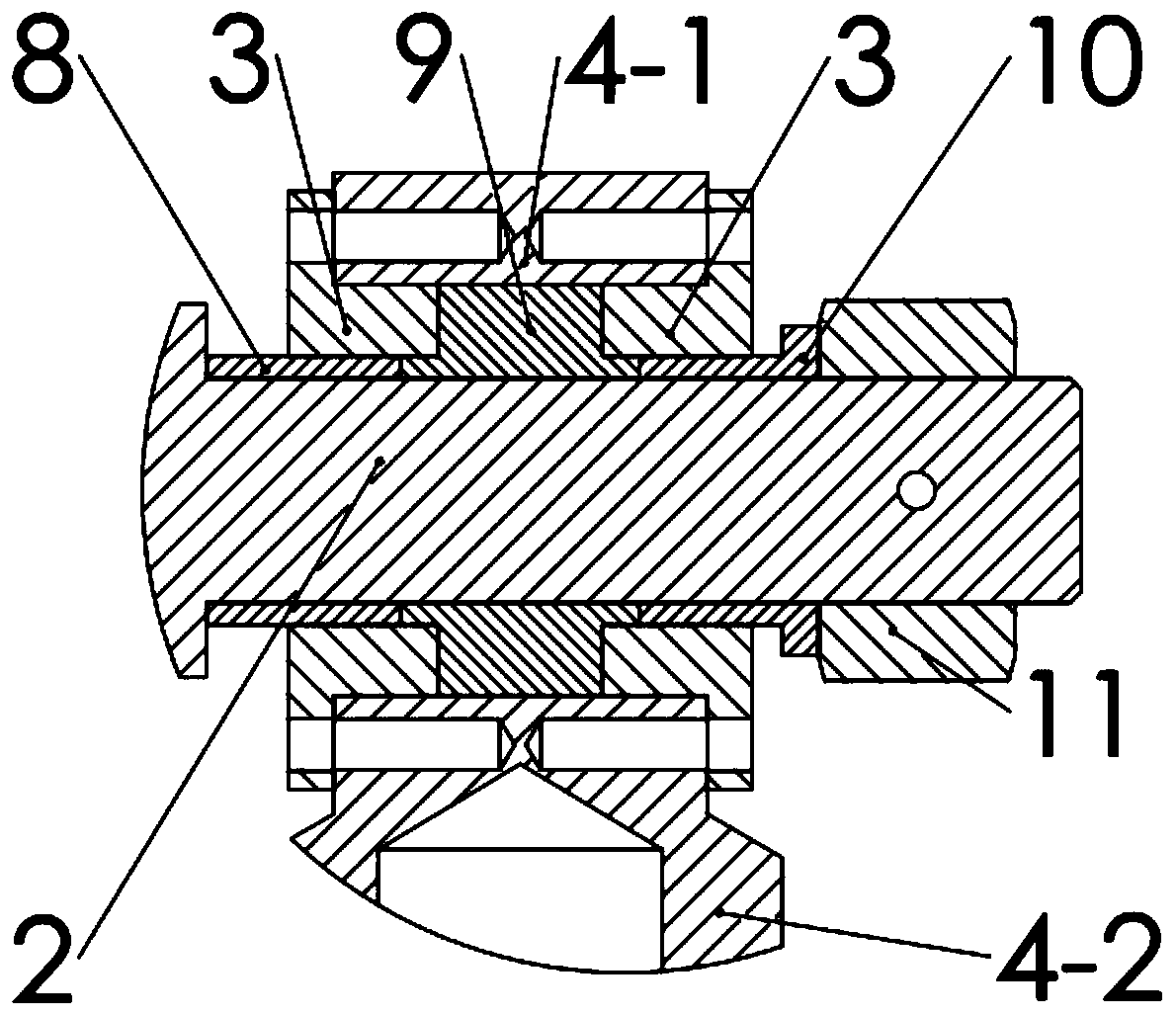

[0022] The first connecting mechanism includes a fixed support 1, a first connecting shaft 2, a flange end cover 3, a bushing 8, a transition bushing 9, a flange bushing 10, and a first locking nut 11;

[0023] The fixed support 1 includes a first mounting plate 1-1 and a mounting seat 1-2; the first mounting plate 1-1 is used to fix the first connecting mechanism with an external mechanism (such as a beam). One end of the first connecting shaft 2 is matched with the mounting seat 1-2; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com