Dynamic vibration absorber with stepless adjustable frequency

A dynamic vibration absorber, stepless technology, applied in the field of dynamic vibration absorber and automotive dynamic vibration absorber, can solve the problems of changing the mass ratio of dynamic vibration absorber, poor reliability, large error, etc., to solve low precision, solve debugging difficulties, adjust convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

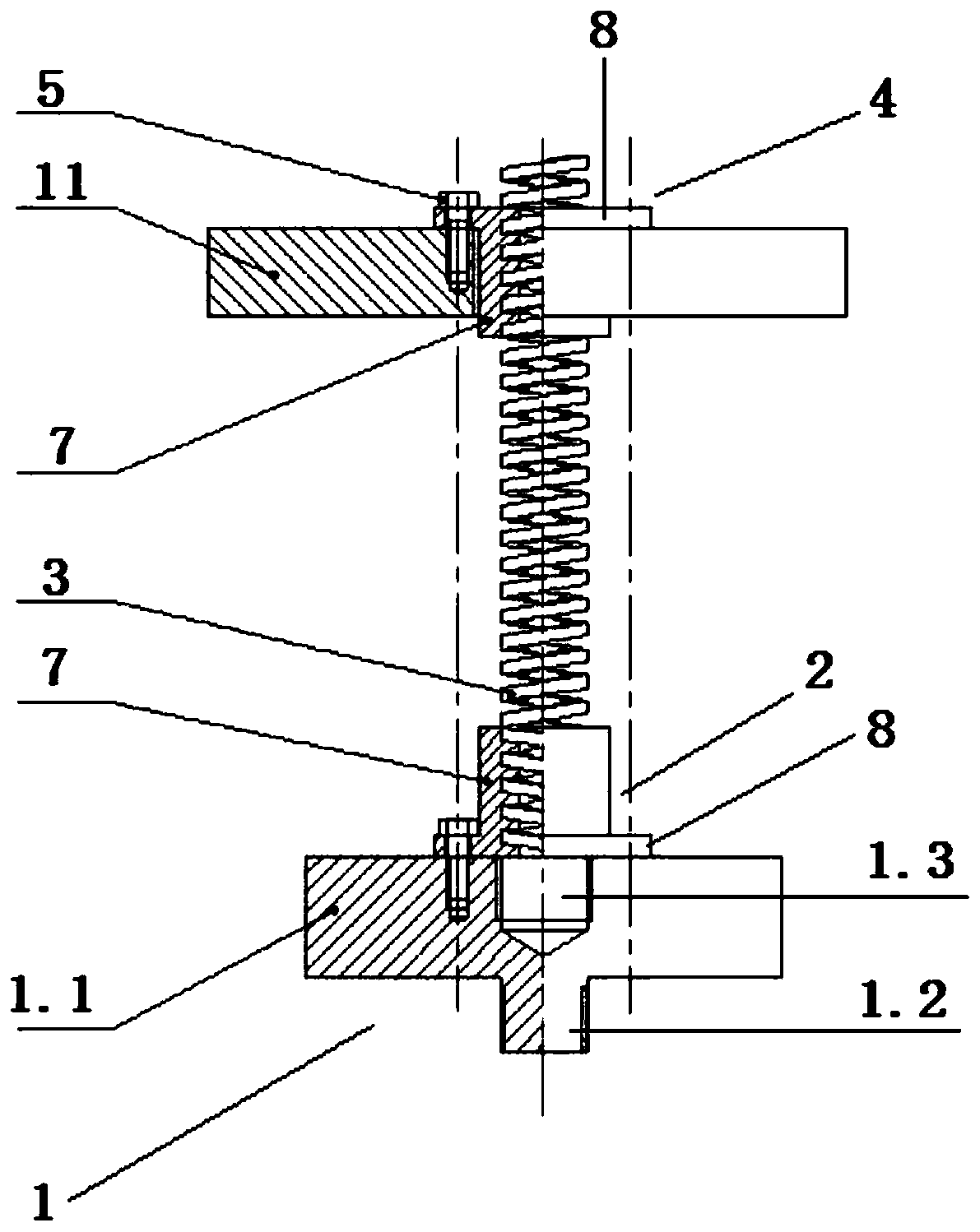

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

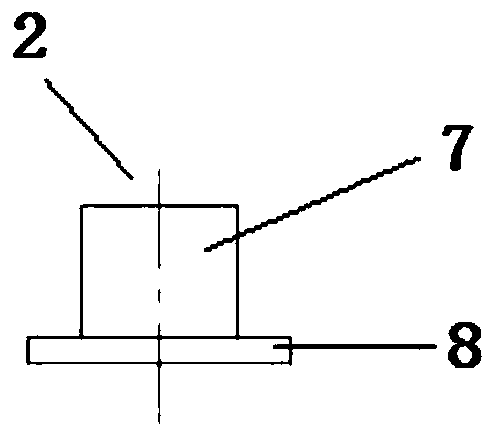

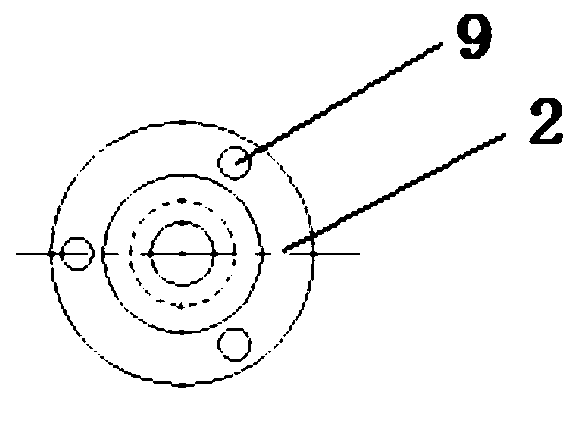

[0027] like figure 1 The dynamic vibration absorber with a steplessly adjustable frequency shown in -7 includes a mass block and a spring 3. Both ends of the spring 3 are respectively connected with an adjustment sleeve, and the adjustment sleeve includes a first adjustment sleeve 4 and a second adjustment sleeve that are oppositely arranged up and down. Sleeve 2, the structure of the two adjustment sleeves is the same, and both include a sleeve 7 and a flanging collar 8 which is coaxially fixedly connected to the peripheral surface of one end of the sleeve 7 and is an integral structure with the sleeve 7. The inner wall of the sleeve 7 A threaded groove 6 corresponding to the shape of the spring 3 and in an interference fit with the surface of the spring 3 is opened on the top, and the groove wall of the threaded groove 6 is coated wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com