Multi-wavelength laser-integrated optical emission system

A multi-wavelength laser and emission system technology, applied in optics, optical components, instruments, etc., can solve the problems of high cost, multiple optical paths, and huge system, and achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

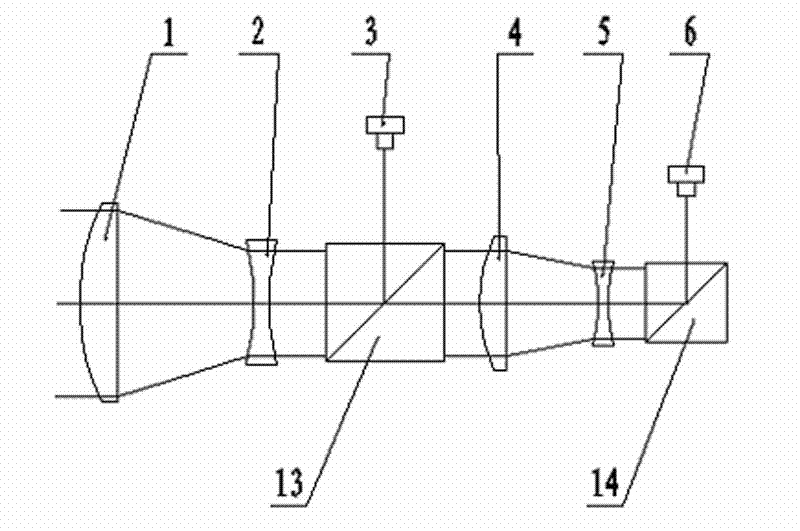

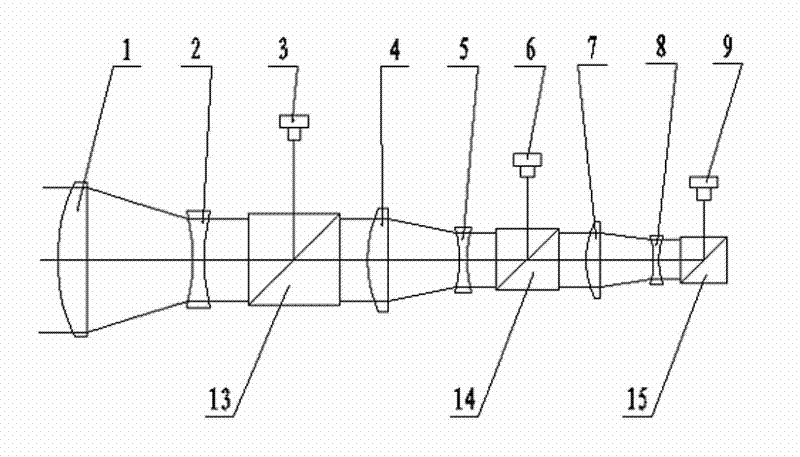

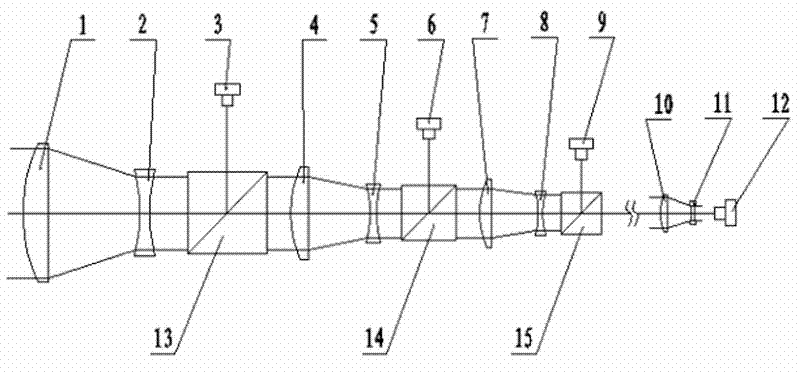

[0012] Such as figure 1 The shown two-wavelength laser fusion emission optical system is composed of a first emission system and a second emission system, and the first emission system is composed of a first emission objective lens 1, a first emission eyepiece 2, a first light-combining prism 13 and a wavelength It is composed of the first wavelength laser 3 of λ1, the glued surface of the first light-combining prism is coated with a film system that reflects the wavelength of the first wavelength laser, and the emission magnification is β1; the second emission system consists of the second emission objective lens 4, the second emission The eyepiece 5, the second light-combining prism 14 and the second-wavelength laser 6 with a wavelength of λ2 are composed, and the cemented surface of the second light-combining prism is plated with a film system reflecting the wavelength of the second-wavelength laser, and the emission magnification is β2; the first emission The system and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com